wiring CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1011 of 4284

Symptom:

REAR WIPER OUTPUT SHORT TO GROUND

When Monitored and Set Condition:

REAR WIPER OUTPUT SHORT TO GROUND

When Monitored: Ignition ON

Set Condition:

POSSIBLE CAUSES

REAR WIPER MOTOR FUNCTION

INTERMITTENT WIRING AND CONNECTORS

REAR WIPER MOTOR CONTROL CIRCUIT SHORT TO GROUND

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Ignition on, engine not running.

Turn on the Rear Wiper.

Does the Rear Wiper Function?All

Ye s®Go To 2

No®Go To 3

2 Turn the ignition on.

With the DRBIIIt, erase all BCM and FCM DTCs.

Turn the ignition off.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this

circuit.

Wiggle the wiring while checking for shorts and open circuits.

Were there any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

3 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Rear Wiper Motor harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between ground and the Rear Wiper Motor Control circuit.

Is the resistance less than 5.0 ohms?All

Ye s®Repair the Rear Wiper Motor Control Circuit for a short to

ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

982

WINDSHIELD WIPER & WASHER

Page 1013 of 4284

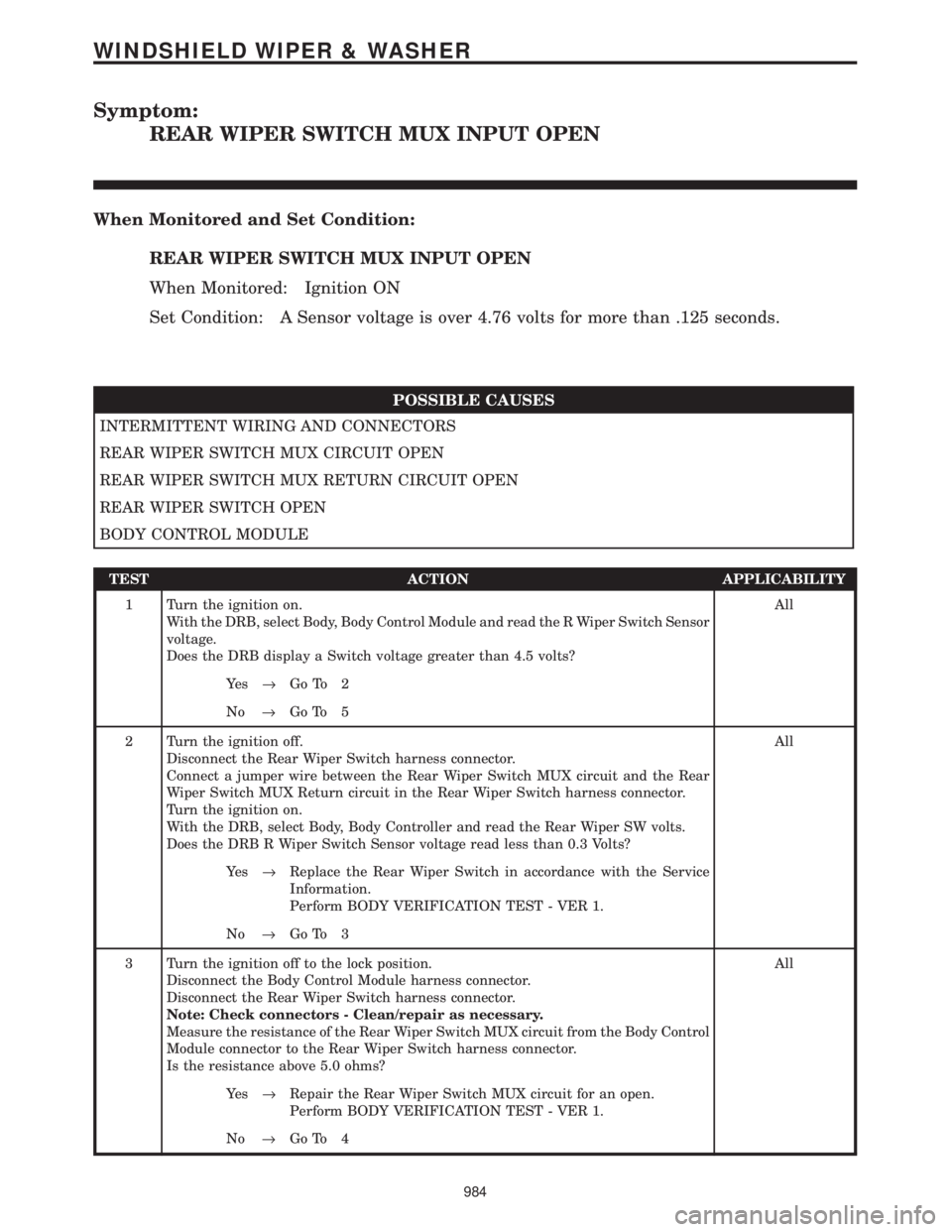

Symptom:

REAR WIPER SWITCH MUX INPUT OPEN

When Monitored and Set Condition:

REAR WIPER SWITCH MUX INPUT OPEN

When Monitored: Ignition ON

Set Condition: A Sensor voltage is over 4.76 volts for more than .125 seconds.

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

REAR WIPER SWITCH MUX CIRCUIT OPEN

REAR WIPER SWITCH MUX RETURN CIRCUIT OPEN

REAR WIPER SWITCH OPEN

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRB, select Body, Body Control Module and read the R Wiper Switch Sensor

voltage.

Does the DRB display a Switch voltage greater than 4.5 volts?All

Ye s®Go To 2

No®Go To 5

2 Turn the ignition off.

Disconnect the Rear Wiper Switch harness connector.

Connect a jumper wire between the Rear Wiper Switch MUX circuit and the Rear

Wiper Switch MUX Return circuit in the Rear Wiper Switch harness connector.

Turn the ignition on.

With the DRB, select Body, Body Controller and read the Rear Wiper SW volts.

Does the DRB R Wiper Switch Sensor voltage read less than 0.3 Volts?All

Ye s®Replace the Rear Wiper Switch in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

3 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Rear Wiper Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the Rear Wiper Switch MUX circuit from the Body Control

Module connector to the Rear Wiper Switch harness connector.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Rear Wiper Switch MUX circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

984

WINDSHIELD WIPER & WASHER

Page 1014 of 4284

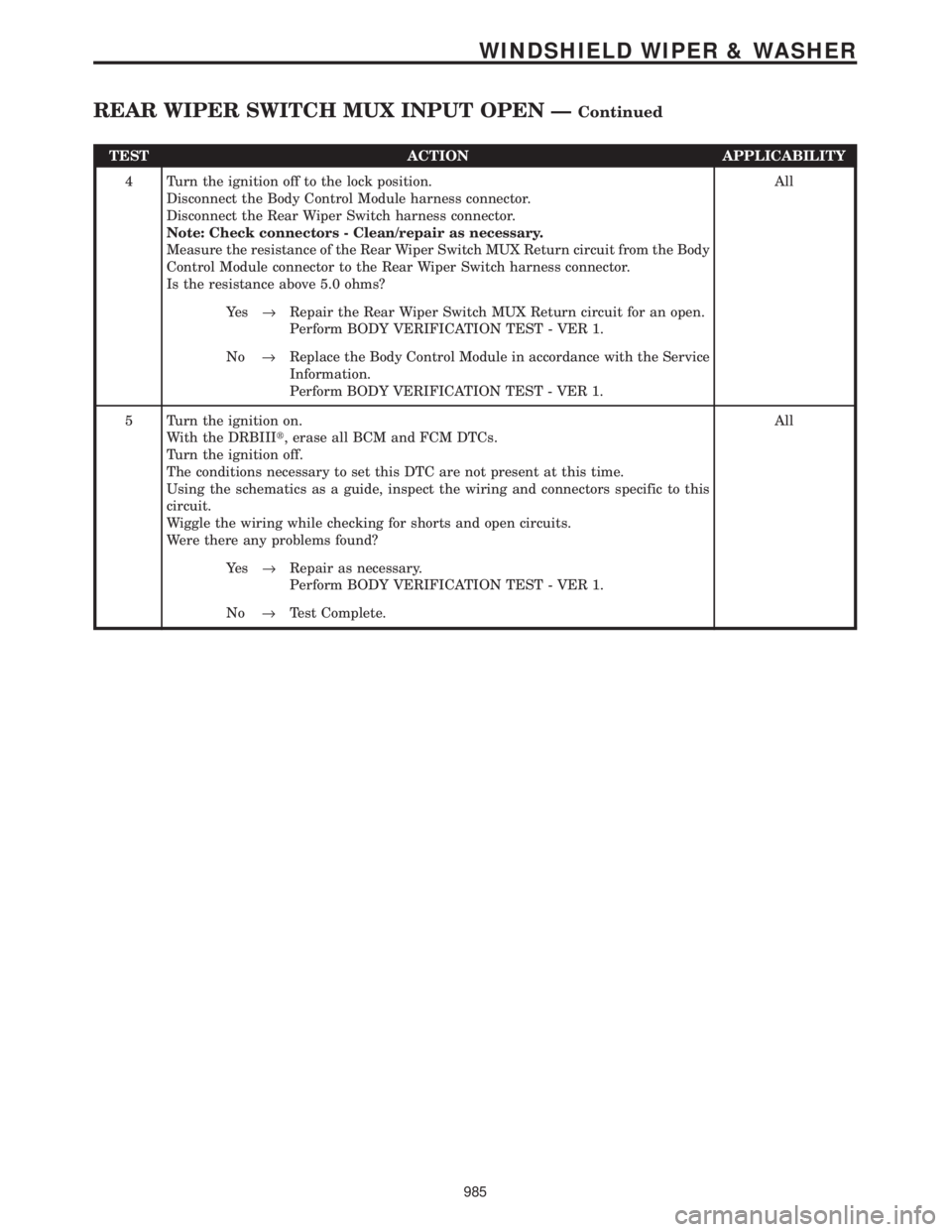

TEST ACTION APPLICABILITY

4 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Rear Wiper Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the Rear Wiper Switch MUX Return circuit from the Body

Control Module connector to the Rear Wiper Switch harness connector.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Rear Wiper Switch MUX Return circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Body Control Module in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

5 Turn the ignition on.

With the DRBIIIt, erase all BCM and FCM DTCs.

Turn the ignition off.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this

circuit.

Wiggle the wiring while checking for shorts and open circuits.

Were there any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

985

WINDSHIELD WIPER & WASHER

REAR WIPER SWITCH MUX INPUT OPEN ÐContinued

Page 1015 of 4284

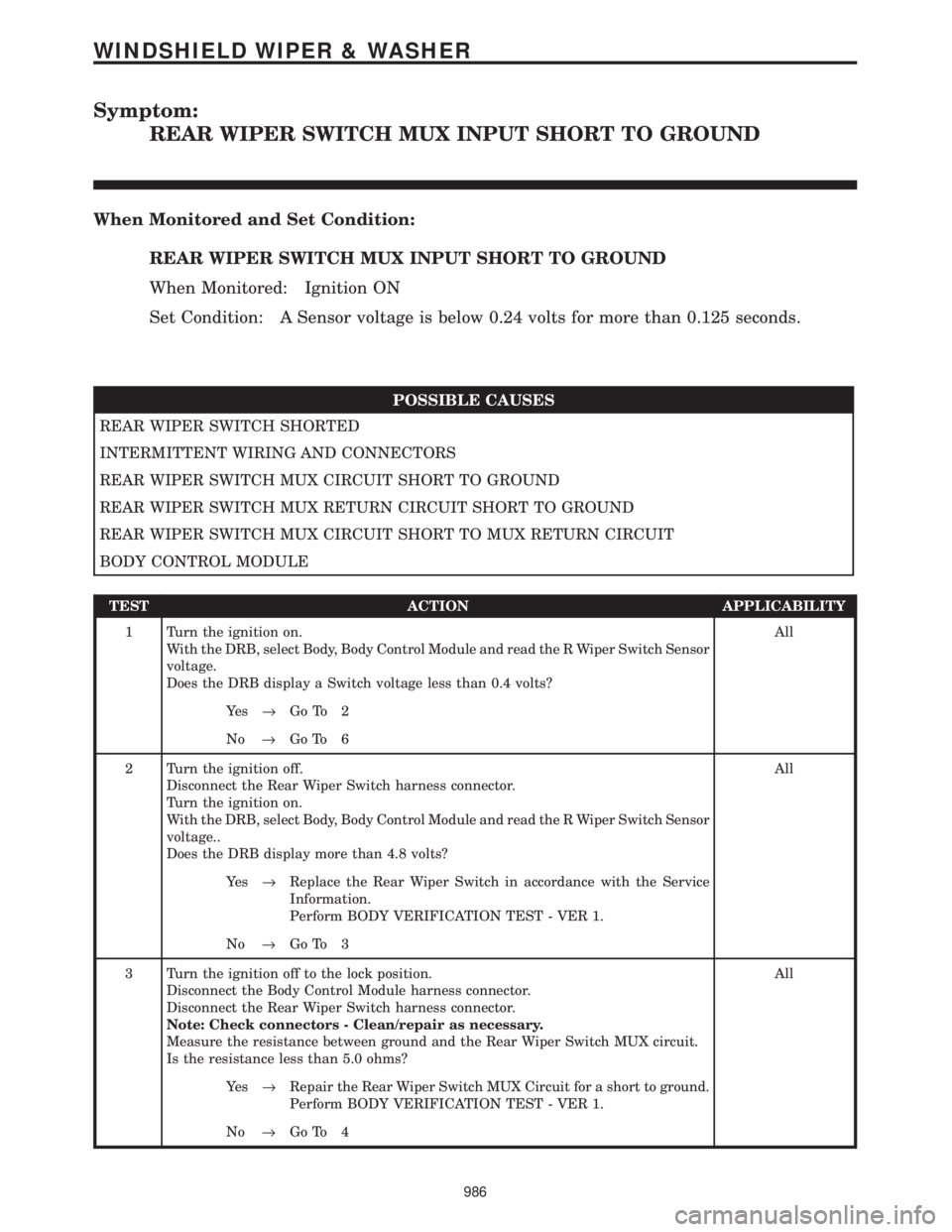

Symptom:

REAR WIPER SWITCH MUX INPUT SHORT TO GROUND

When Monitored and Set Condition:

REAR WIPER SWITCH MUX INPUT SHORT TO GROUND

When Monitored: Ignition ON

Set Condition: A Sensor voltage is below 0.24 volts for more than 0.125 seconds.

POSSIBLE CAUSES

REAR WIPER SWITCH SHORTED

INTERMITTENT WIRING AND CONNECTORS

REAR WIPER SWITCH MUX CIRCUIT SHORT TO GROUND

REAR WIPER SWITCH MUX RETURN CIRCUIT SHORT TO GROUND

REAR WIPER SWITCH MUX CIRCUIT SHORT TO MUX RETURN CIRCUIT

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRB, select Body, Body Control Module and read the R Wiper Switch Sensor

voltage.

Does the DRB display a Switch voltage less than 0.4 volts?All

Ye s®Go To 2

No®Go To 6

2 Turn the ignition off.

Disconnect the Rear Wiper Switch harness connector.

Turn the ignition on.

With the DRB, select Body, Body Control Module and read the R Wiper Switch Sensor

voltage..

Does the DRB display more than 4.8 volts?All

Ye s®Replace the Rear Wiper Switch in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

3 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Rear Wiper Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between ground and the Rear Wiper Switch MUX circuit.

Is the resistance less than 5.0 ohms?All

Ye s®Repair the Rear Wiper Switch MUX Circuit for a short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

986

WINDSHIELD WIPER & WASHER

Page 1016 of 4284

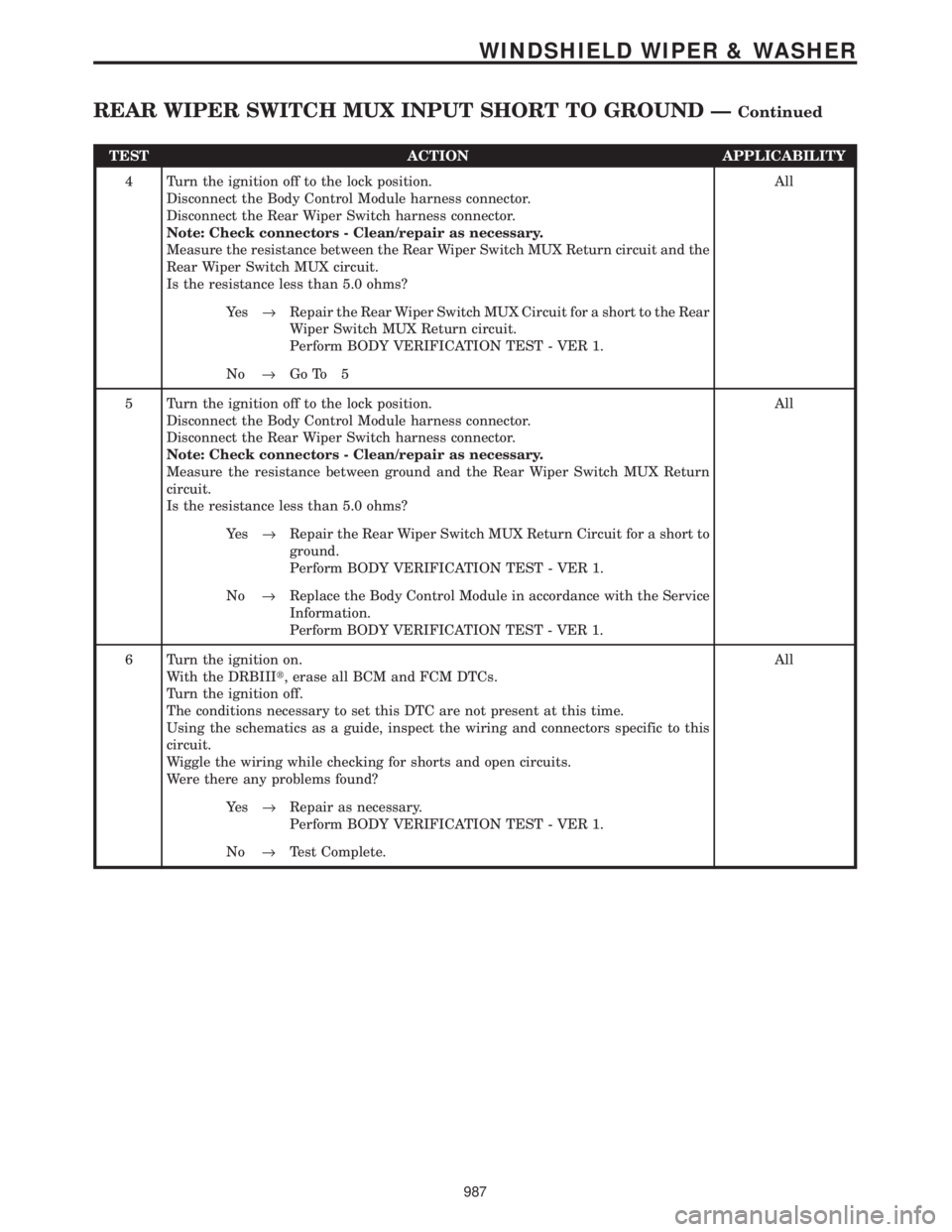

TEST ACTION APPLICABILITY

4 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Rear Wiper Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between the Rear Wiper Switch MUX Return circuit and the

Rear Wiper Switch MUX circuit.

Is the resistance less than 5.0 ohms?All

Ye s®Repair the Rear Wiper Switch MUX Circuit for a short to the Rear

Wiper Switch MUX Return circuit.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Rear Wiper Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between ground and the Rear Wiper Switch MUX Return

circuit.

Is the resistance less than 5.0 ohms?All

Ye s®Repair the Rear Wiper Switch MUX Return Circuit for a short to

ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Body Control Module in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

6 Turn the ignition on.

With the DRBIIIt, erase all BCM and FCM DTCs.

Turn the ignition off.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this

circuit.

Wiggle the wiring while checking for shorts and open circuits.

Were there any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

987

WINDSHIELD WIPER & WASHER

REAR WIPER SWITCH MUX INPUT SHORT TO GROUND ÐContinued

Page 1159 of 4284

The cycling of the build and decay valves is

similar to the ABS except that they work to control

wheel spin by applying brakes. ABS function is to

control wheel skid by releasing brakes.

Two pressure relief valves allow excess fluid vol-

ume to return to the reservoir when not used by the

build/decay cycles. These are required because the

pump supplies more volume than the traction con-

trol system requires.

If at any time the brake pedal is applied during a

traction control cycle, the brake lamp switch will

trigger the CAB to switch off the traction control.

The traction control system will be enabled at

each ignition cycle. It may be turned off by depress-

ing the Traction Control Switch. The traction con-

trol system function lamp will illuminate ªTRAC

OFFº immediately upon depressing the traction

control switch button. Only the ªTRACº portion of

the ªTRAC OFFº indicator will illuminate during a

traction control event. If the CAB calculates that

the brake temperatures are high, the traction con-

trol system will become inoperative until a time-out

period has elapsed. When in this thermal protection

mode, the traction control ªTRAC OFFº lamp will

illuminate; however, a fault will not be registered.

3.3 SYSTEM COMPONENTS

²controller antilock brake (CAB)

²vacuum booster

²master cylinder

²ABS integrated electronic control module/

hydraulic control unit (HCU), valve block assem-

bly: 8 valve solenoids (4 inlet valves, 4 outlet

valves, 2 accumulators) 1 motor, 2 pump

²ABS integrated electronic control module with

traction control same as above but has 10 valve

solenoids.

²4 wheel speed sensor/tone wheel assemblies

²ABS warning indicator

²fuses and wiring harness

²fluid reservoir

²TRAC/TRAC OFF indicator

3.3.1 ABS AND BRAKE WARNING

INDICATORS

The amber ABS warning indicator is located in

the instrument cluster. It is used to inform the

driver that the antilock function has been turned

off. The ABS warning indicator is controlled by the

CAB. The CAB controls the lamp with a command

over the PCI bus.

The ABS Warning Indicator will remain lit during

every key cycle until a circuit or component fault is

repaired and the CAB no longer detects the fault.After repair of a sensor signal fault or a pump motor

fault, the CAB must sense all four wheels at 25

km/h (15 mph) before it will extinguish the ABS and

TRAC OFF Indicators.

The Instrument Cluster will illuminate the ABS

Warning Indicator if it loses communication with

the CAB.

The red BRAKE warning indicator is also located

in the instrument cluster. It can be activated in

several ways. Application of the parking brake or a

low fluid signal from the fluid level switch located in

the master cylinder reservoir will cause the indica-

tor to come on.

3.3.2 CONTROLLER ANTILOCK BRAKE

(CAB)

The Controller Antilock Brake (CAB) is a

microprocessor-based device that monitors wheel

speeds and controls the antilock functions. The

CAB contains two microprocessors that receive

identical sensor signals and then independently

process the information. The results are then com-

pared to make sure that they agree. Otherwise, the

CAB will turn off the antilock and turn on the ABS

amber warning indicator.

The primary functions of the CAB are to:

²detect wheel locking tendencies

²control fluid pressure modulation to the brakes

during antilock stop

²monitor the system for proper operation

²manage traction control functions

²provide communication to the DRBIIItwhile in

diagnostic mode

²store diagnostic information in non-volatile memory

The CAB continuously monitors the speed of each

wheel. When a wheel locking tendency is detected,

the CAB will command the appropriate valve to

modulate brake fluid pressure in its hydraulic unit.

Brake pedal position is maintained during an an-

tilock stop by being a closed system with the use of

2 accumulators. The CAB continues to control pres-

sure in individual hydraulic circuits until a wheel

locking tendency is no longer present. The CAB

turns on the pump motor during an antilock stop.

The antilock brake system is constantly moni-

tored by the CAB for proper operation. If the CAB

detects a system malfunction, it can disable the

antilock system and turn on the ABS warning

indicator. If the antilock function is disabled, the

system will revert to standard base brake system

operation.

The CAB inputs include the following:

²diagnostic communication

²four wheel speed sensors

2

GENERAL INFORMATION

Page 1161 of 4284

the brake pedal is applied the test will be run at 40

km/h (24 mph) regardless of brake switch state. If,

during the dynamic test, the brake pedal is applied,

the driver may feel the test through brake pedal

pulsations. This is a normal condition.

If any component exhibits a trouble condition

during system initialization or dynamic check, the

CAB will illuminate the ABS warning indicator and

TRAC OFF lamp if equipped.

3.3.6 DIAGNOSTIC MODE

To enter diagnostic mode, a vehicle speed must be

below 10 km/h (6 mph) and no ABS condition

present. If vehicle speed is not below 10 km/h

(6 mph), a ªNo Responseº message could be dis-

played by the DRBIIIt. The following are charac-

teristics of diagnostic mode:

± The amber ABS warning indicator will blink

rapidly (about 1/2 second ON and 1/2 second

OFF). If a hard trouble code, such as Valve

Power Feed Failure code is present, the indi-

cator will be illuminated without blinking un-

til the trouble condition is cleared.

± Antilock operation is disabled.

± The HCU valves cannot be actuated when the

vehicle speed is above 8 km/h (5 mph). If valve

actuation is attempted above 8 km/h (5 mph), a

ªNo Responseº message will be displayed on

the DRBIIIt.

3.4 DIAGNOSTIC TROUBLE CODES

The controller antilock brake may report any of

the following diagnostic trouble codes:

CLUSTER LAMP FAILURE

VALVE POWER FEED FAILURE

BUS SYSTEM COMMUNICATION FAILURE

CAB INTERNAL FAILURE

LEFT FRONT SENSOR CIRCUIT FAILURE

LEFT FRONT WHEEL SPEED SIGNAL

FAILURE

LEFT REAR SENSOR CIRCUIT FAILURE

LEFT REAR WHEEL SPEED SIGNAL

FAILURE

PUMP CIRCUIT FAILURE

RIGHT FRONT SENSOR CIRCUIT FAILURE

RIGHT FRONT WHEEL SPEED SIGNAL

FAILURE

RIGHT REAR SENSOR CIRCUIT FAILURE

RIGHT REAR WHEEL SPEED SIGNAL

FAILURE

SYSTEM OVERVOLTAGE

SYSTEM UNDERVOLTAGE

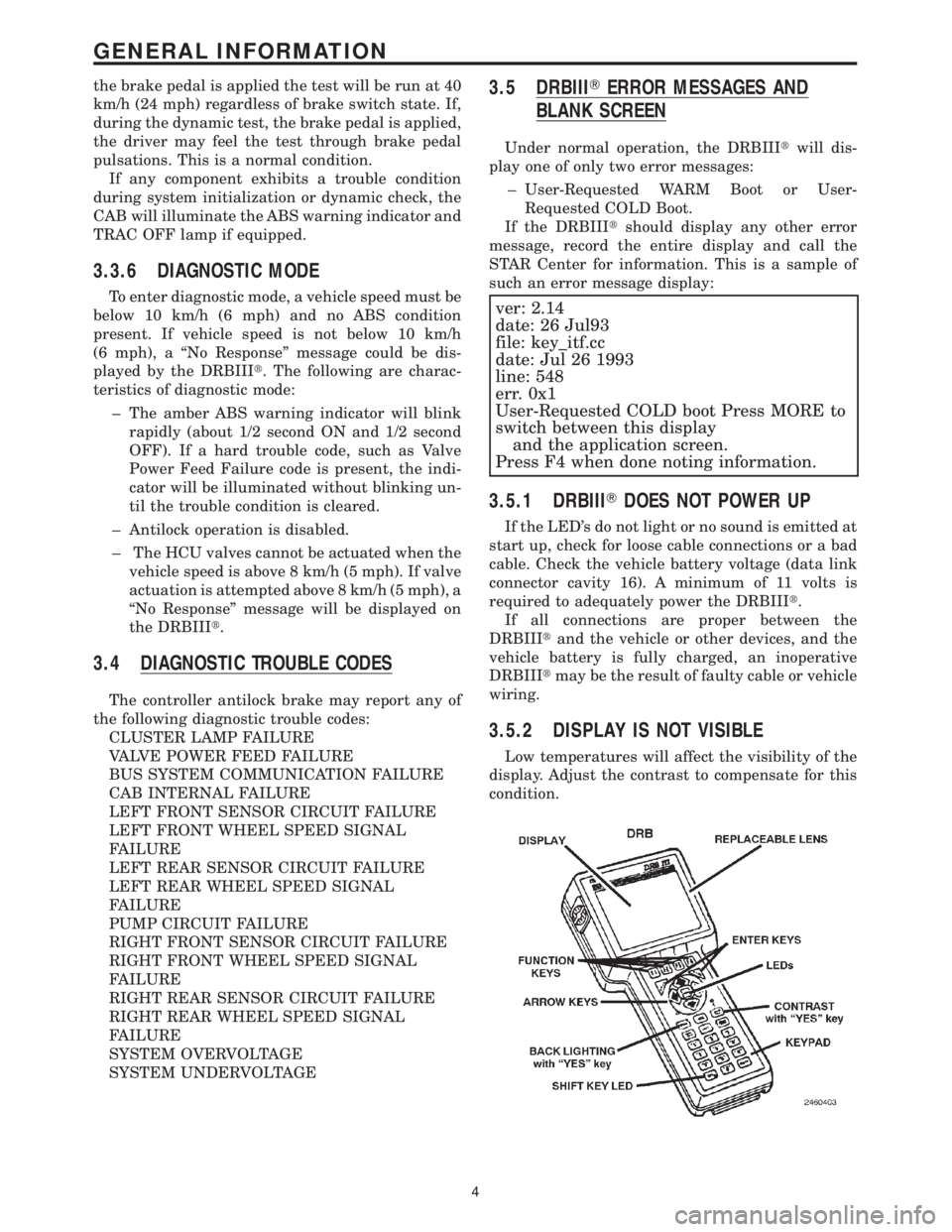

3.5 DRBIIITERROR MESSAGES AND

BLANK SCREEN

Under normal operation, the DRBIIItwill dis-

play one of only two error messages:

± User-Requested WARM Boot or User-

Requested COLD Boot.

If the DRBIIItshould display any other error

message, record the entire display and call the

STAR Center for information. This is a sample of

such an error message display:

ver: 2.14

date: 26 Jul93

file: key_itf.cc

date: Jul 26 1993

line: 548

err. 0x1

User-Requested COLD boot Press MORE to

switch between this display

and the application screen.

Press F4 when done noting information.

3.5.1 DRBIIITDOES NOT POWER UP

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage (data link

connector cavity 16). A minimum of 11 volts is

required to adequately power the DRBIIIt.

If all connections are proper between the

DRBIIItand the vehicle or other devices, and the

vehicle battery is fully charged, an inoperative

DRBIIItmay be the result of faulty cable or vehicle

wiring.

3.5.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

4

GENERAL INFORMATION

Page 1164 of 4284

6.0 GLOSSARY OF TERMS

ABSantilock brake system

CABcontroller antilock brake

CCDChrysler Collision Detection

DLCdata link connector

DRBdiagnostic read-out box

EDWelectrical distribution wiring

EMIelectro magnetic interference

HCUhydraulic control unit

ICUintegrated control unit

IFLinlet front leftIFRinlet front right

IRLinlet rear left

IRRinlet rear right

JBLKjunction block

OFLoutlet front left

OFRoutlet front right

ORLoutlet rear left

ORRoutlet rear right

PDCpower distribution center

P/Mpump motor

RFIradio frequency interference

WSSwheel speed sensor

7

GENERAL INFORMATION

Page 1173 of 4284

TEST ACTION APPLICABILITY

5 Turn the ignition off.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wire harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Refer to any Hotline letters or Technical Service Bulletins that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No®Test Complete.

16

BRAKES (CAB)

LEFT FRONT SENSOR CIRCUIT FAILURE ÐContinued

Page 1175 of 4284

TEST ACTION APPLICABILITY

3 With the DRBIIIt, read DTCs.

Did the DTC reoccur?All

Ye s®Replace the Wheel Speed Sensor in accordance with the Service

Information.

Perform ABS VERIFICATION TEST - VER 1.

No®Go To 4

4 Turn the ignition off.

Visually inspect wheel speed sensor.

Visually inspect tone wheel.

Visually inspect wiring harness.

Visually inspect brakes for locking up due to lining contamination or overheating.

Inspect all Components for defects which may cause a Signal DTC to set.

Is any Component Damaged?All

Ye s®Repair as necessary. The vehicle must be driven at 25 km/h (15

mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Test Complete.

18

BRAKES (CAB)

LEFT FRONT WHEEL SPEED SIGNAL FAILURE ÐContinued