transmission CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3800 of 4284

message the PCM will terminate engine operation,

or allow the engine to continue to operate.

3.2.7 SKIM ON-BOARD DIAGNOSTICS

The SKIM has been programmed to transmit and

monitor many different coded messages as well as

PCI Bus messages. This monitoring is called On

Board Diagnosis.

Certain criteria must be met for a diagnostic

trouble code to be entered into the SKIM memory.

The criteria may be a range of; Input voltage, PCI

Bus message, or coded messages to the SKIM. If all

of the criteria for monitoring a circuit or function

are met and a fault is sensed, a diagnostic trouble

code will be stored in the SKIM memory.

3.2.8 SKIS OPERATION

When ignition power is supplied to the SKIM, the

SKIM performs an internal self-test. After the self-

test is completed, the SKIM energizes the antenna

(this activates the transponder chip) and sends a

challenge to the transponder chip. The transponder

chip responds to the challenge by generating an

encrypted response message using the following:

Secret Key -This is an electronically stored

value (identification number) that is unique to each

SKIS. The secret key is stored in the SKIM, PCM

and all ignition key transponders.

Challenge- This is a random number that is

generated by the SKIM at each ignition key cycle.

The secret key and challenge are the two vari-

ables used in the algorithm that produces the

encrypted response message. The transponder uses

the crypto algorithm to receive, decode and respond

to the message sent by the SKIM. After responding

to the coded message, the transponder sends a

transponder I.D. message to the SKIM. The SKIM

compares the transponder I.D. to the available valid

key codes in the SKIM memory (8 key maximum at

any one time). After validating the key ignition the

SKIM sends a PCI Bus message called a Seed

Request to the engine controller then waits for a

PCM response. If the PCM does not respond, the

SKIM will send the seed request again. After three

failed attempts the SKIM will stop sending the seed

request and store a trouble code. If the PCM sends

a seed response, the SKIM sends a valid/invalid key

message to the PCM. This is an encrypted message

that is generated using the following:

VIN -Vehicle Identification Number

Seed -This is a random number that is generated

by the PCM at each ignition key cycle.

The VIN and seed are the two variables used in

the rolling code algorithm that encrypts the valid/

invalid key message. The PCM uses the rolling code

algorithm to receive, decode and respond to the

valid/invalid key message sent by the SKIM. Aftersending the valid/invalid key message the SKIM

waits 3.5 seconds for a PCM status message from

the PCM. If the PCM does not respond with a valid

key message to the SKIM, a fault is detected and a

trouble code is stored.

The SKIS incorporates a VTSS LED located on

the instrument panel upper cover. The LED re-

ceives switched ignition voltage and is hardwired to

the body control module. The LED is actuated when

the SKIM sends a PCI Bus message to the body

controller requesting the LED on. The body control-

ler then provides the ground for the LED. The

SKIM will request VTSS LED operation for the

following:

± bulb checks at ignition on

± to alert the vehicle operator to a SKIS mal-

function

± customer key programming mode

For all faults except transponder faults and VTSS

LED remains on steady. In the event of a transpon-

der fault the LED flashes at a rate of 1 Hz (once per

second). If a fault is present the LED will remain on

or flashing for the complete ignition cycle. If a fault

is stored in SKIM memory which prevents the

system from operating properly, the PCM will allow

the engine to start and run (for 2 seconds) up to six

times. After the sixth attempt, the PCM disables

the starter relay until the fault is corrected.

3.2.9 PROGRAMMING THE POWERTRAIN

CONTROL MODULE

Important Note:Before replacing the PCM for a

failed driver, control circuit or ground circuit, be

sure to check the related component/circuit integ-

rity for failures not detected due to a double fault in

the circuit. Most PCM driver/control circuit failures

are caused by internal failure to components (i.e.

12-volt pull-ups, drivers and ground sensors). These

failures are difficult to detect when a double fault

has occurred and only one DTC has set.

NOTE: IF THE PCM AND THE SKIM ARE

REPLACED AT THE SAME TIME, PROGRAM

THE VIN INTO THE PCM FIRST. ALL VEHICLE

KEYS WILL THEN NEED TO BE REPLACED

AND PROGRAMMED TO THE NEW SKIM.

The SKIS Secret Key is an I.D. code that is

unique to each SKIS. This code is programmed and

stored in the SKIM, engine controller and transpon-

der chip (ignition key). When replacing the PCM it

is necessary to program the secret key into the

PCM.

1. Turn the ignition on (transmission in park/

neutral).

2. Use the DRB and select THEFT ALARM, SKIM

then MISCELLANEOUS.

6

GENERAL INFORMATION

Page 3801 of 4284

3. Select PCM REPLACED.

4. Enter secured access mode by entering the vehi-

cle four-digit PIN.

NOTE: IF THREE ATTEMPTS ARE MADE TO

ENTER THE SECURE ACCESS MODE USING

AN INCORRECT PIN, SECURED ACCESS

MODE WILL BE LOCKED OUT FOR ONE

HOUR. TO EXIT THIS LOCKOUT MODE,

TURN THE IGNITION TO THE RUN POSITION

FOR ONE HOUR THEN ENTER THE

CORRECT PIN. (ENSURE ALL ACCESSORIES

ARE TURNED OFF. ALSO MONITOR THE

BATTERY STATE AND CONNECT A BATTERY

CHARGER IF NECESSARY).

5. Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

3.2.10 PROGRAMMING THE SENTRY KEY

IMMOBILIZER MODULE

NOTE: IF THE PCM AND THE SKIM ARE

REPLACED AT THE SAME TIME, PROGRAM

THE VIN INTO THE PCM FIRST. ALL VEHICLE

KEYS WILL THEN NEED TO BE REPLACED

AND PROGRAMMED TO THE NEW SKIM.

1. Turn the ignition on (transmission in park/

neutral).

2. Use the DRB and select THEFT ALARM, SKIM

then MISCELLANEOUS.

3. Select SKIM MODULE REPLACEMENT (GAS-

OLINE).

4. Program the vehicle four-digit PIN into the

SKIM.

5. Select COUNTRY CODE and enter the correct

country.

NOTE: BE SURE TO ENTER THE CORRECT

COUNTRY CODE. IF THE INCORRECT

COUNTRY CODE IS PROGRAMMED INTO

SKIM, THE SKIM MUST BE REPLACED.

6. Select UPDATE VIN (the SKIM will learn the

VIN from the PCM).

7. Press ENTER to transfer the VIN (the PCM will

send the VIN to the SKIM).

8. The DRB will ask if you want to transfer the

secret key. Select ENTER to transfer secret key

from the PCM. This will ensure the current

vehicle ignition keys will still operate the SKIS

system.

3.2.11 PROGRAMMING THE IGNITION

KEYS TO THE SENTRY KEY

IMMOBILIZER MODULE

1. Turn the ignition on (transmission in park/

neutral).

2. Use the DRB and select THEFT ALARM, SKIM,

then MISCELLANEOUS.

3. Select PROGRAM IGNITION KEYS.

4. Enter secured access mode by entering the vehi-

cle four-digit PIN.

NOTE: A MAXIMUM OF EIGHT KEYS CAN BE

LEARNED TO EACH SKIM AT ONE TIME.

ONCE A KEY IS LEARNED TO A SKIM IT (THE

KEY) CANNOT BE TRANSFERRED TO

ANOTHER VEHICLE.

If ignition key programming is unsuccessful, the

DRB will display one of the following messages:

Programming Not Attempted- The DRB at-

tempts to read the programmed key status and

there are no keys programmed in the SKIM mem-

ory.

Programming Key Failed -(Possible Used Key

From Wrong Vehicle) - SKIM is unable to program

key due to one of the following:

± faulty ignition key transponder

± ignition key is programmed to another vehicle.

8 Keys Already Learned, Programming Not

Done- SKIM transponder ID memory is full.

1. Obtain ignition keys to be programmed from

customer (8 keys maximum)

2. Using the DRB, erase all ignition keys by select-

ing MISCELLANEOUS and ERASE ALL CUR-

RENT IGN. KEYS

3. Program all ignition keys.

Learned Key In Ignition- Ignition key transpon-

der ID is currently programmed in SKIM memory.

3.3 DIAGNOSTIC TROUBLE CODES

Each diagnostic trouble code is diagnosed by

following a specific testing procedure. The diagnos-

tic test procedures contain step-by-step instructions

for determining the cause of trouble codes as well as

no trouble code problems. It is not necessary to

perform all of the tests in this book to diagnose an

individual code.

Always begin by reading the diagnostic trouble

codes using the DRBIIIt.

3.3.1 HARD CODE

A diagnostic trouble code that comes back within

one cycle of the ignition key is a hard code. This

means that the defect is there every time the

7

GENERAL INFORMATION

Page 3806 of 4284

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation; this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second DTC could be set, making diagnosis of the

original problem more difficult.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box) scan tool

Evaporative System Diagnostic Kit #6917

fuel filler adapter #8382

fuel pressure adapter (C-6631) or #6539

fuel pressure kit (C-4799-B) or #5069

fuel release hose (C-4799-1)

Min Air flow fitting #6714

jumper wires

ohmmeter

oscilloscope

vacuum gauge

voltmeter

12 volt test light minimum 25 ohms resistance

with probe #6801

CAUTION: A 12 VOLT TEST LIGHT SHOULD

NOT BE USED FOR THE FOLLOWING

CIRCUITS, DAMAGE TO THE POWERTRAIN

CONTROLLER WILL OCCUR.

²5 Volt Supply

²8 Volt Supply

²J1850 PCI Bus

²CCD Bus

²CKP Sensor Signal

²CMP Sensor Signal

²Vehicle Speed Sensor Signal

²O2 Sensor Signal

6.0 GLOSSARY OF TERMS

ABSanti-lock brake system

backfire,

popbackfuel ignites in either the intake or

the exhaust system

CKPcrank position sensor

CMPcamshaft position sensorcuts out,

missesa steady pulsation or the inability of

the engine to maintain a consistent

rpm

DLCdata link connector (previously

called engine diagnostic connector)

detona-

tion,

spark

knocka mild to severe ping, especially un-

der loaded engine conditions

ECTengine coolant temperature sensor

EGRexhaust gas recirculation valve

genera-

torpreviously called alternator

hard

startThe engine takes longer than usual

to start, even though it is able to

crank normally.

hesita-

tion, sag,

stumbleThere is a momentary lack of re-

sponse when the throttle is opened.

This can occur at all vehicle speeds.

If it is severe enough, the engine

may stall.

IATintake air temperature sensor

IACidle air control motor

JTECCombined engine and transmission

control module

lack of

power,

sluggishThe engine has less than expected

power, with little or no increase in

vehicle speed when the throttle is

opened.

LDPleak detection pump

MAPmanifold absolute pressure sensor

MILmalfunction indicator lamp

MTVmanifold tuning valve

O2Soxygen sensor

PCIprogrammable communication inter-

face

PCMpowertrain control module

PCVpositive crankcase ventilation

PEPperipheral expansion port

poor fuel

economyThere is significantly less fuel mile-

age than other vehicles of the same

design ad configuration

12

GENERAL INFORMATION

Page 3807 of 4284

rough,

unstable,

or er-

ratic idle

stallingThe engine runs unevenly at idle

and causes the engine to shake if it

is severe enough. The engine idle

rpm may vary (called hunting). This

condition may cause stalling if it is

severe enough.

SBECsingle board engine controller

SKIMsentry key immobilizer module

SKISsentry key immobilizer systemstart &

stallThe engine starts but immediately

dies.

surgeengine rpm fluctuation without cor-

responding change in throttle posi-

tion sensor

TPSthrottle position sensor

TRStransmission range sensor

VSSvehicle speed sensor/signal

13

GENERAL INFORMATION

Page 3826 of 4284

Symptom:

P1698-NO BUS MESSAGE FROM TRANS CONTROL MODULE

When Monitored and Set Condition:

P1698-NO BUS MESSAGE FROM TRANS CONTROL MODULE

When Monitored: Equipped with automatic transmission. The ignition on. Battery

voltage greater than 10 volts.

Set Condition: No bus messages from the TCM for 20 seconds, two trips required.

POSSIBLE CAUSES

INTERMITTENT CONDITION

COMMUNICATE WITH TCM

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, erase DTCs.

Cycle the ignition key on and off several times.

With the DRBIIIt, read DTC's.

Does the DTC reset?All

Ye s®Go To 2

No®Go To 3

2 Turn the ignition on.

With the DRBIIIt, attempt to communicate with the TCM.

Can communication be established with the TCM?All

Ye s®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Refer to the Communication Category and perform the appropri-

ate symptom related to no communication with TCM.

Perform POWERTRAIN VERIFICATION TEST VER-1.

32

COMMUNICATION

Page 3831 of 4284

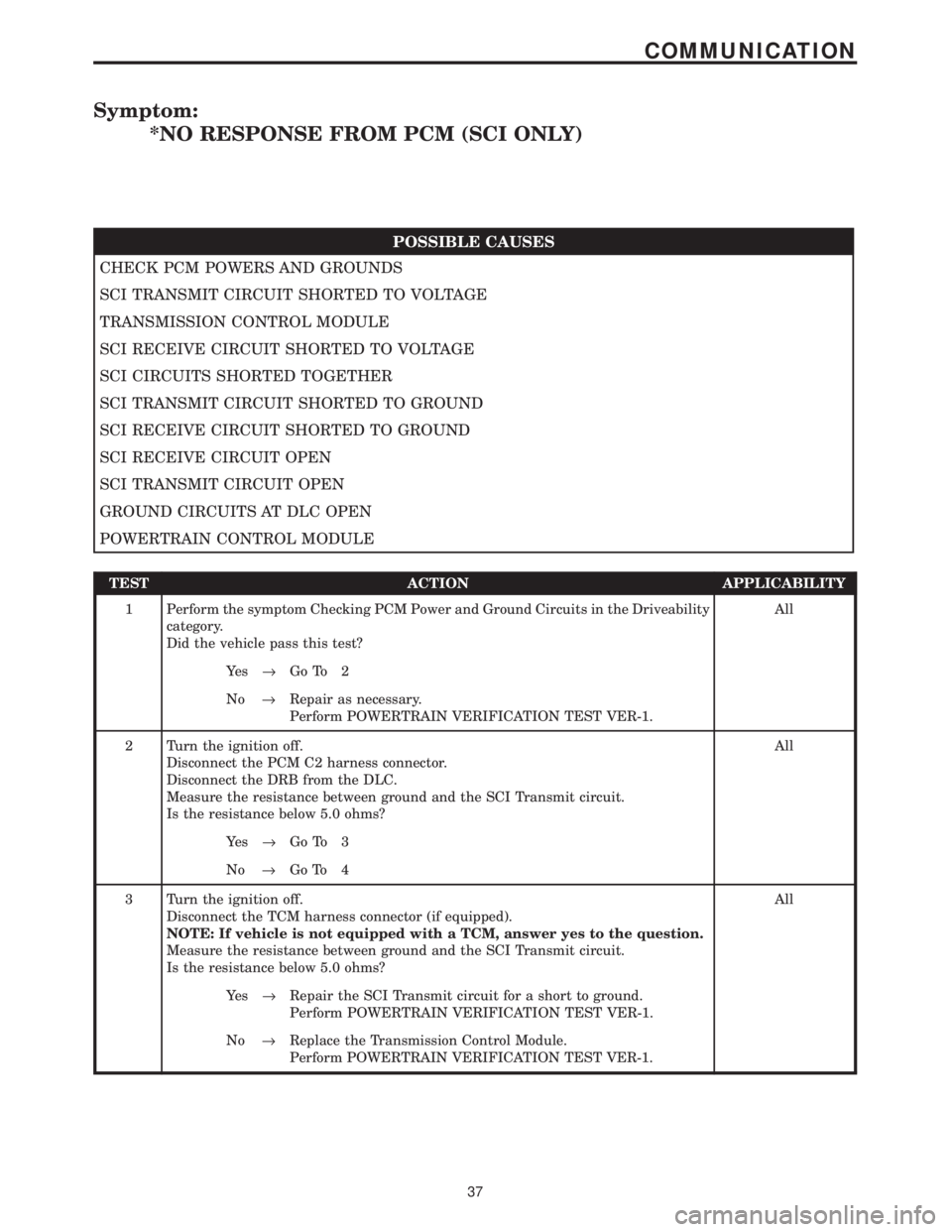

Symptom:

*NO RESPONSE FROM PCM (SCI ONLY)

POSSIBLE CAUSES

CHECK PCM POWERS AND GROUNDS

SCI TRANSMIT CIRCUIT SHORTED TO VOLTAGE

TRANSMISSION CONTROL MODULE

SCI RECEIVE CIRCUIT SHORTED TO VOLTAGE

SCI CIRCUITS SHORTED TOGETHER

SCI TRANSMIT CIRCUIT SHORTED TO GROUND

SCI RECEIVE CIRCUIT SHORTED TO GROUND

SCI RECEIVE CIRCUIT OPEN

SCI TRANSMIT CIRCUIT OPEN

GROUND CIRCUITS AT DLC OPEN

POWERTRAIN CONTROL MODULE

TEST ACTION APPLICABILITY

1 Perform the symptom Checking PCM Power and Ground Circuits in the Driveability

category.

Did the vehicle pass this test?All

Ye s®Go To 2

No®Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST VER-1.

2 Turn the ignition off.

Disconnect the PCM C2 harness connector.

Disconnect the DRB from the DLC.

Measure the resistance between ground and the SCI Transmit circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 3

No®Go To 4

3 Turn the ignition off.

Disconnect the TCM harness connector (if equipped).

NOTE: If vehicle is not equipped with a TCM, answer yes to the question.

Measure the resistance between ground and the SCI Transmit circuit.

Is the resistance below 5.0 ohms?All

Ye s®Repair the SCI Transmit circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Replace the Transmission Control Module.

Perform POWERTRAIN VERIFICATION TEST VER-1.

37

COMMUNICATION

Page 3859 of 4284

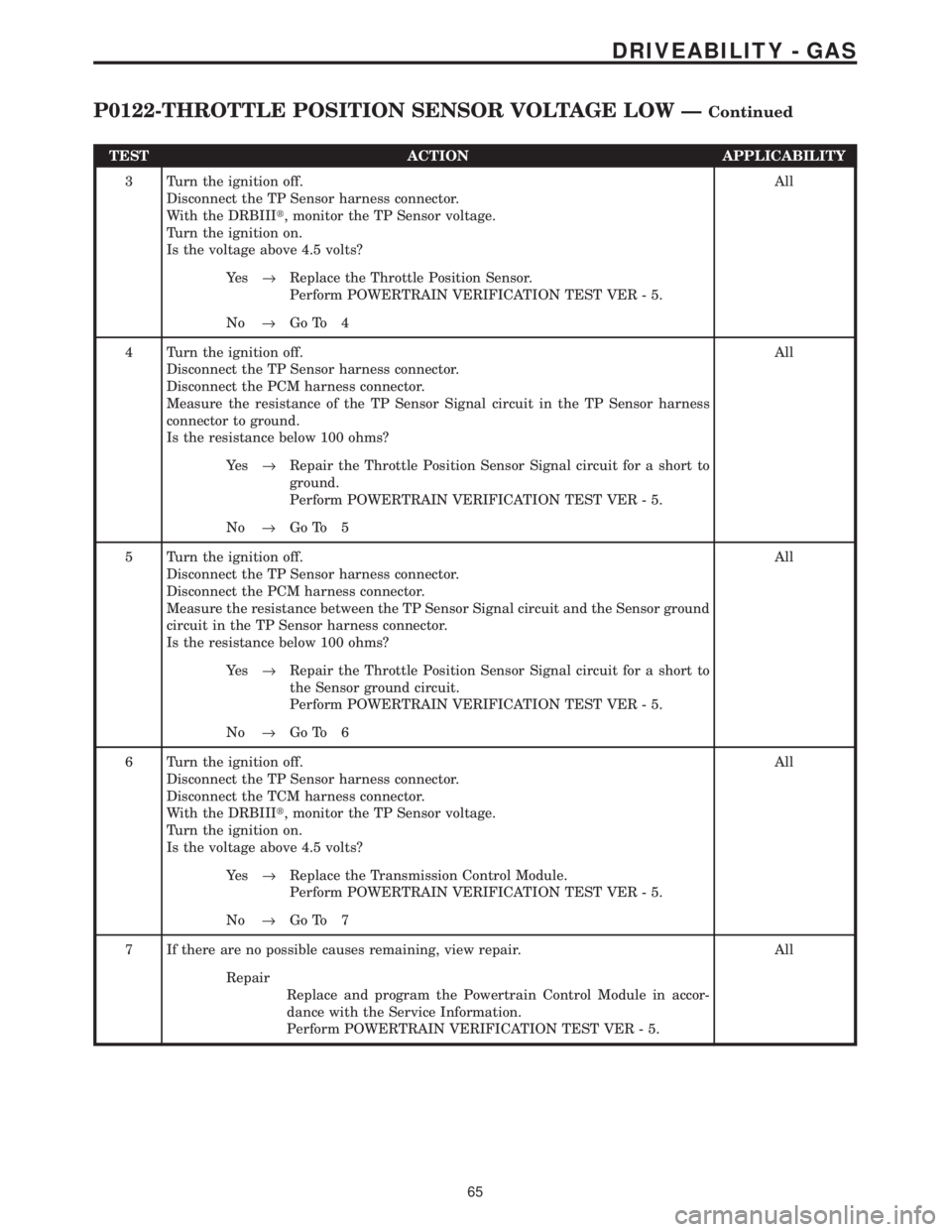

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the TP Sensor harness connector.

With the DRBIIIt, monitor the TP Sensor voltage.

Turn the ignition on.

Is the voltage above 4.5 volts?All

Ye s®Replace the Throttle Position Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 4

4 Turn the ignition off.

Disconnect the TP Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the TP Sensor Signal circuit in the TP Sensor harness

connector to ground.

Is the resistance below 100 ohms?All

Ye s®Repair the Throttle Position Sensor Signal circuit for a short to

ground.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 Turn the ignition off.

Disconnect the TP Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance between the TP Sensor Signal circuit and the Sensor ground

circuit in the TP Sensor harness connector.

Is the resistance below 100 ohms?All

Ye s®Repair the Throttle Position Sensor Signal circuit for a short to

the Sensor ground circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 6

6 Turn the ignition off.

Disconnect the TP Sensor harness connector.

Disconnect the TCM harness connector.

With the DRBIIIt, monitor the TP Sensor voltage.

Turn the ignition on.

Is the voltage above 4.5 volts?All

Ye s®Replace the Transmission Control Module.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 7

7 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

65

DRIVEABILITY - GAS

P0122-THROTTLE POSITION SENSOR VOLTAGE LOW ÐContinued

Page 3941 of 4284

Symptom:

P0500-NO VEHICLE SPEED SIGNAL (3SP AUTO AND MANUAL

TRANSMISSIONS)

When Monitored and Set Condition:

P0500-NO VEHICLE SPEED SIGNAL (3SP AUTO AND MANUAL TRANSMIS-

SIONS)

When Monitored: With the engine running, transmission not in park or neutral, brakes

not applied, and engine rpm greater than 1800.

Set Condition: This code will set if no vehicle speed signal is received from the Vehicle

Speed Sensor for more than 7.2 seconds for 2 consecutive trips.

POSSIBLE CAUSES

INTERMITTENT CONDITION

8 VOLT SUPPLY CIRCUIT OPEN

VEHICLE SPEED SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

VEHICLE SPEED SENSOR SIGNAL CIRCUIT OPEN

PCM VSS SIGNAL

SENSOR GROUND CIRCUIT OPEN

VEHICLE SPEED SENSOR

TEST ACTION APPLICABILITY

1 Raise the drive wheels off the ground.

WARNING: BE SURE TO KEEP HANDS AND FEET CLEAR OF ROTATING

WHEELS.

Start the engine.

With the DRBIIIt, monitor the Vehicle Speed Sensor

Place the transmission in any forward gear.

Allow the wheels to rotate.

Does the DRBIIItdisplay vehicle speed above 0 MPH/KMH?All

Ye s®Go To 2

No®Go To 3

147

DRIVEABILITY - GAS

Page 3944 of 4284

Symptom:

P0500-NO VEHICLE SPEED SIGNAL (4SP AUTO TRANS)

When Monitored and Set Condition:

P0500-NO VEHICLE SPEED SIGNAL (4SP AUTO TRANS)

When Monitored: With the engine running, transmission not in park or neutral, brakes

not applied, and engine rpm greater than 1800.

Set Condition: This code will set if no vehicle speed signal is received from the TCM

(transmission control module) for more than 7.2 seconds for 2 consecutive trips.

POSSIBLE CAUSES

INTERMITTENT CONDITION

VEHICLE SPEED SENSOR SIGNAL SHORTED VOLTAGE

VSS SIGNAL FROM TCM

VEHICLE SPEED SENSOR SIGNAL SHORTED TO GROUND

VEHICLE SPEED SENSOR SIGNAL OPEN

PCM VSS SIGNAL

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition off.

Disconnect the TCM harness connector.

Turn the ignition on.

Measure the voltage of the VSS Signal circuit in the TCM harness connector.

Is the voltage above 6.0 volts?All

Ye s®Repair the Vehicle Speed Sensor Signal circuit for a short to

voltage.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

150

DRIVEABILITY - GAS

Page 3945 of 4284

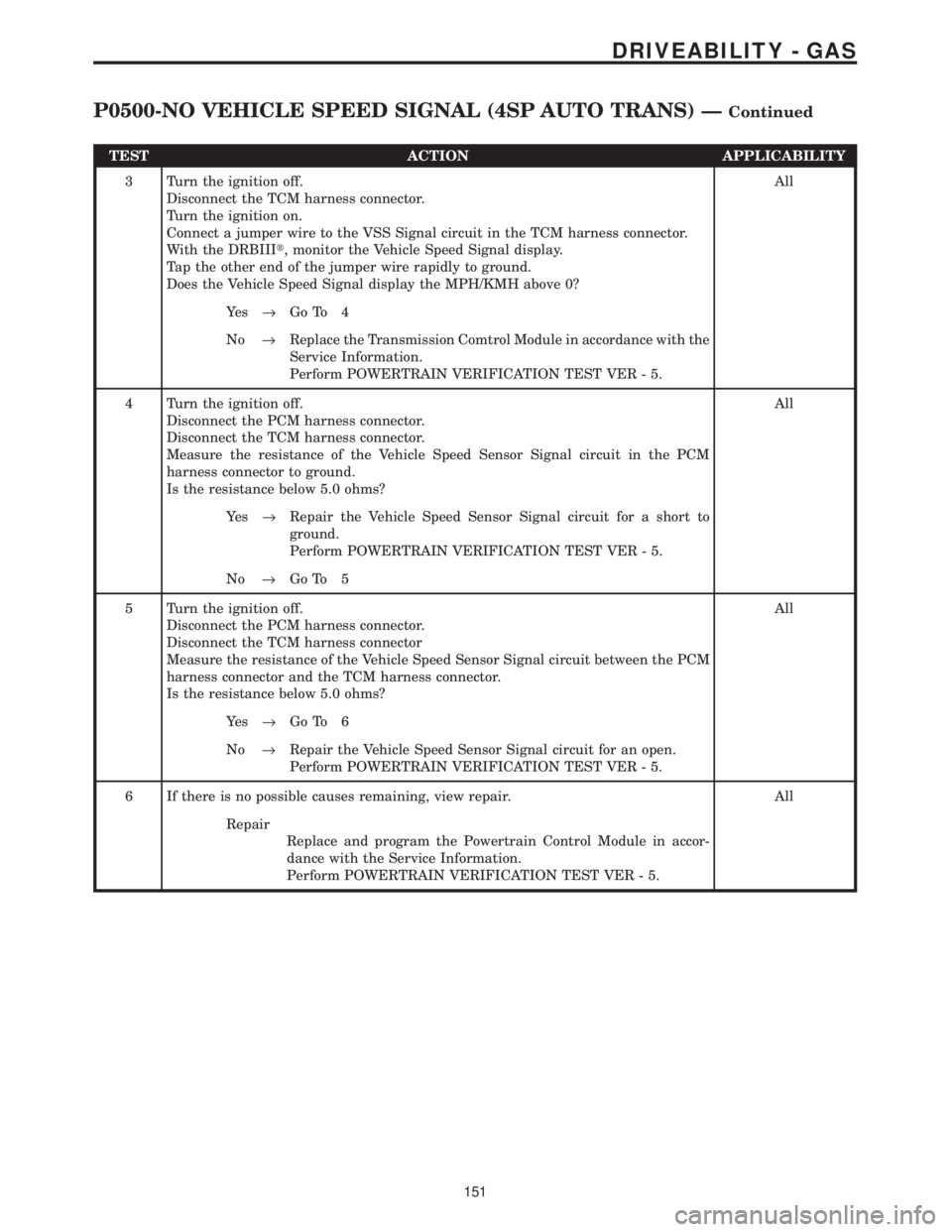

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the TCM harness connector.

Turn the ignition on.

Connect a jumper wire to the VSS Signal circuit in the TCM harness connector.

With the DRBIIIt, monitor the Vehicle Speed Signal display.

Tap the other end of the jumper wire rapidly to ground.

Does the Vehicle Speed Signal display the MPH/KMH above 0?All

Ye s®Go To 4

No®Replace the Transmission Comtrol Module in accordance with the

Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

4 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the TCM harness connector.

Measure the resistance of the Vehicle Speed Sensor Signal circuit in the PCM

harness connector to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Vehicle Speed Sensor Signal circuit for a short to

ground.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the TCM harness connector

Measure the resistance of the Vehicle Speed Sensor Signal circuit between the PCM

harness connector and the TCM harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 6

No®Repair the Vehicle Speed Sensor Signal circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

6 If there is no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

151

DRIVEABILITY - GAS

P0500-NO VEHICLE SPEED SIGNAL (4SP AUTO TRANS) ÐContinued