transmission CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 4017 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Park/Neutral Position Switch harness connector.

Measure the resistance of the P/N Position Switch Sense circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 5

No®Repair the P/N Position Switch Sense circuit for an open.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

5 Turn the ignition off.

Disconnect the PCM harness connector.

Move the Gear selector through all gear positions, from Park to 1st and back.

While moving the gear selector through each gear, measure the resistance between

ground and the P/N Position Switch Sense circuit.

Did the resistance change from above 10.0 ohms to below 10.0 ohms?All

Ye s®Go To 6

No®Replace the Park/Neutral Position Switch.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Module in accordance with

the Service Information.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER 1..

7 At this time, the conditions required to set the DTC are not present.

NOTE: Use the Freeze Frame Data to help duplicate the conditions that set

the DTC. Pay particular attention to the DTC set conditions, such as, VSS,

MAP, ECT, and Load.

NOTE: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

NOTE: Refer to any technical service bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

No®Test Complete.

223

DRIVEABILITY - GAS

P1899-P/N SWITCH STUCK IN PARK OR IN GEAR (3SP AUTO TRANS) Ð

Continued

Page 4018 of 4284

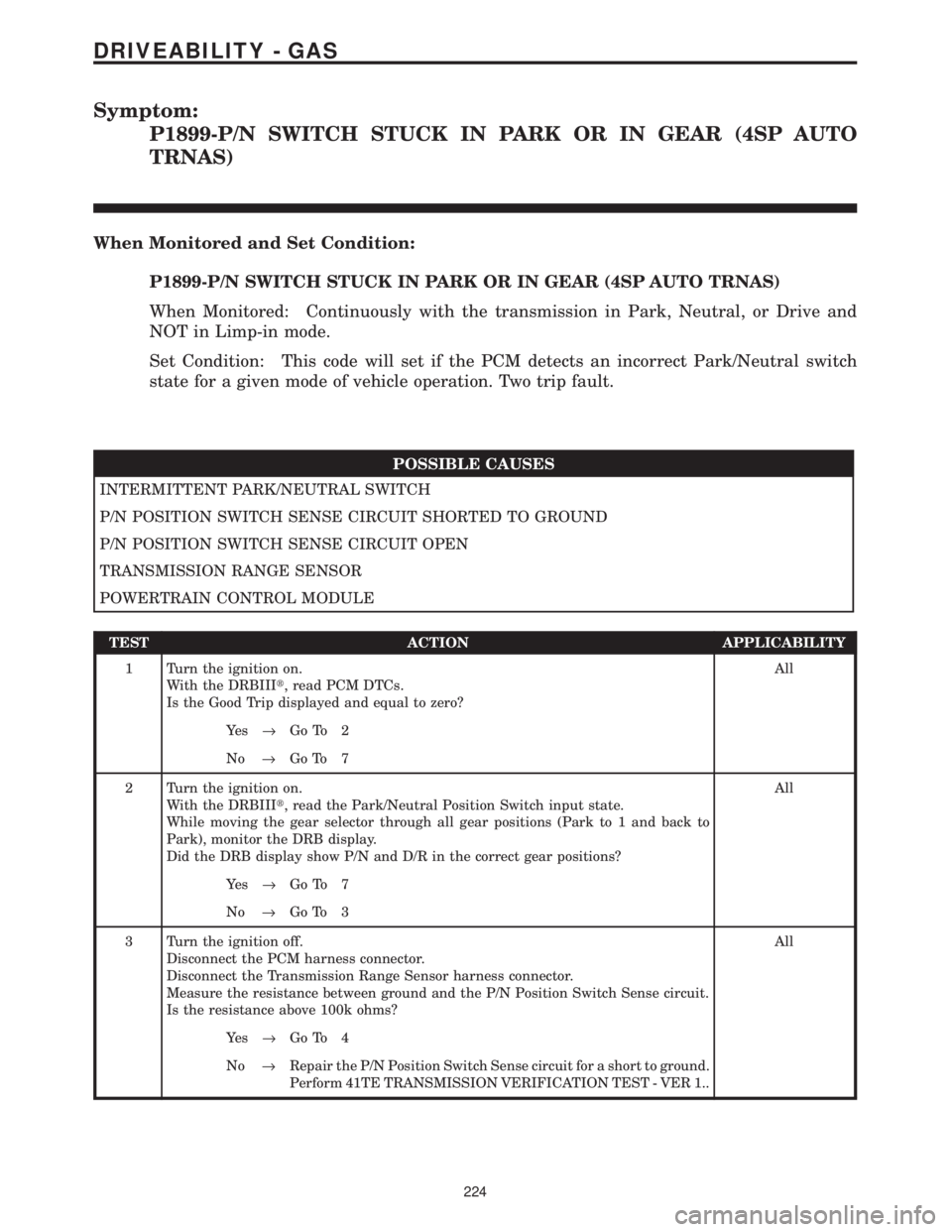

Symptom:

P1899-P/N SWITCH STUCK IN PARK OR IN GEAR (4SP AUTO

TRNAS)

When Monitored and Set Condition:

P1899-P/N SWITCH STUCK IN PARK OR IN GEAR (4SP AUTO TRNAS)

When Monitored: Continuously with the transmission in Park, Neutral, or Drive and

NOT in Limp-in mode.

Set Condition: This code will set if the PCM detects an incorrect Park/Neutral switch

state for a given mode of vehicle operation. Two trip fault.

POSSIBLE CAUSES

INTERMITTENT PARK/NEUTRAL SWITCH

P/N POSITION SWITCH SENSE CIRCUIT SHORTED TO GROUND

P/N POSITION SWITCH SENSE CIRCUIT OPEN

TRANSMISSION RANGE SENSOR

POWERTRAIN CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read PCM DTCs.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition on.

With the DRBIIIt, read the Park/Neutral Position Switch input state.

While moving the gear selector through all gear positions (Park to 1 and back to

Park), monitor the DRB display.

Did the DRB display show P/N and D/R in the correct gear positions?All

Ye s®Go To 7

No®Go To 3

3 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Transmission Range Sensor harness connector.

Measure the resistance between ground and the P/N Position Switch Sense circuit.

Is the resistance above 100k ohms?All

Ye s®Go To 4

No®Repair the P/N Position Switch Sense circuit for a short to ground.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

224

DRIVEABILITY - GAS

Page 4019 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Transmission Range Sensor harness connector.

Measure the resistance of the P/N Position Switch Sense circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 5

No®Repair the P/N Position Switch Sense circuit for an open.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

5 Turn the ignition off.

Disconnect the PCM harness connector.

Move the Gear selector through all gear positions, from Park to 1st and back.

While moving the gear selector through each gear, measure the resistance between

ground and the P/N Position Switch Sense circuit.

Did the resistance change from above 10.0 ohms to below 10.0 ohms?All

Ye s®Go To 6

No®Replace the Transmission Range Sensor.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Module in accordance with

the Service Information.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

7 At this time, the conditions required to set the DTC are not present.

NOTE: Use the Freeze Frame Data to help duplicate the conditions that set

the DTC. Pay particular attention to the DTC set conditions, such as, VSS,

MAP, ECT, and Load.

NOTE: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

NOTE: Refer to any technical service bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

No®Test Complete.

225

DRIVEABILITY - GAS

P1899-P/N SWITCH STUCK IN PARK OR IN GEAR (4SP AUTO TRNAS) Ð

Continued

Page 4052 of 4284

Symptom:

*NO CRANK CONDITION

POSSIBLE CAUSES

REPAIR MECHANICAL CONDITION

TRANSMISSION RANGE SENSOR

BATTERY CIRCUIT RESISTANCE TOO HIGH

IGNITION SWITCH OUTPUT CIRCUIT OPEN

STARTER RELAY CONTROL CIRCUIT OPEN

STARTER RELAY OUTPUT CIRCUIT OPEN

FUSED B(+) CIRCUIT OPEN

STARTER

STARTER MOTOR RELAY

STARTER RELAY

TEST ACTION APPLICABILITY

1WARNING: MAKE SURE THE BATTERY IS DISCONNECTED, THEN WAIT

TWO MINUTES BEFORE PROCEEDING.

Turn the engine over by hand to ensure the engine is not seized.

Is the engine able to turn over?All

Ye s®Go To 2

No®Repair the mechanical condition preventing the starter motor

from cranking.

Perform POWERTRAIN VERIFICATION TEST VER-1.

2 Turn the ignition off.

Disconnect the PCM harness connectors.

Move the Gear selector through all gear positions, from Park to 1st and back.

While moving the gear selector through each gear, measure the resistance between

ground and the P/N Position Switch Sense circuit.

Did the resistance change from above 10.0 ohms to below 10.0 ohms?All

Ye s®Go To 3

No®Replace the Transmission Range Sensor.

Perform POWERTRAIN VERIFICATION TEST VER-1.

3 Turn the ignition off.

Check the Battery Cables for high resistance using the service information proce-

dure.

Did either Battery Cable have a voltage drop greater than 0.2 volt?All

Ye s®Repair the Battery circuit for high resistance.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Go To 4

258

STARTING

Page 4053 of 4284

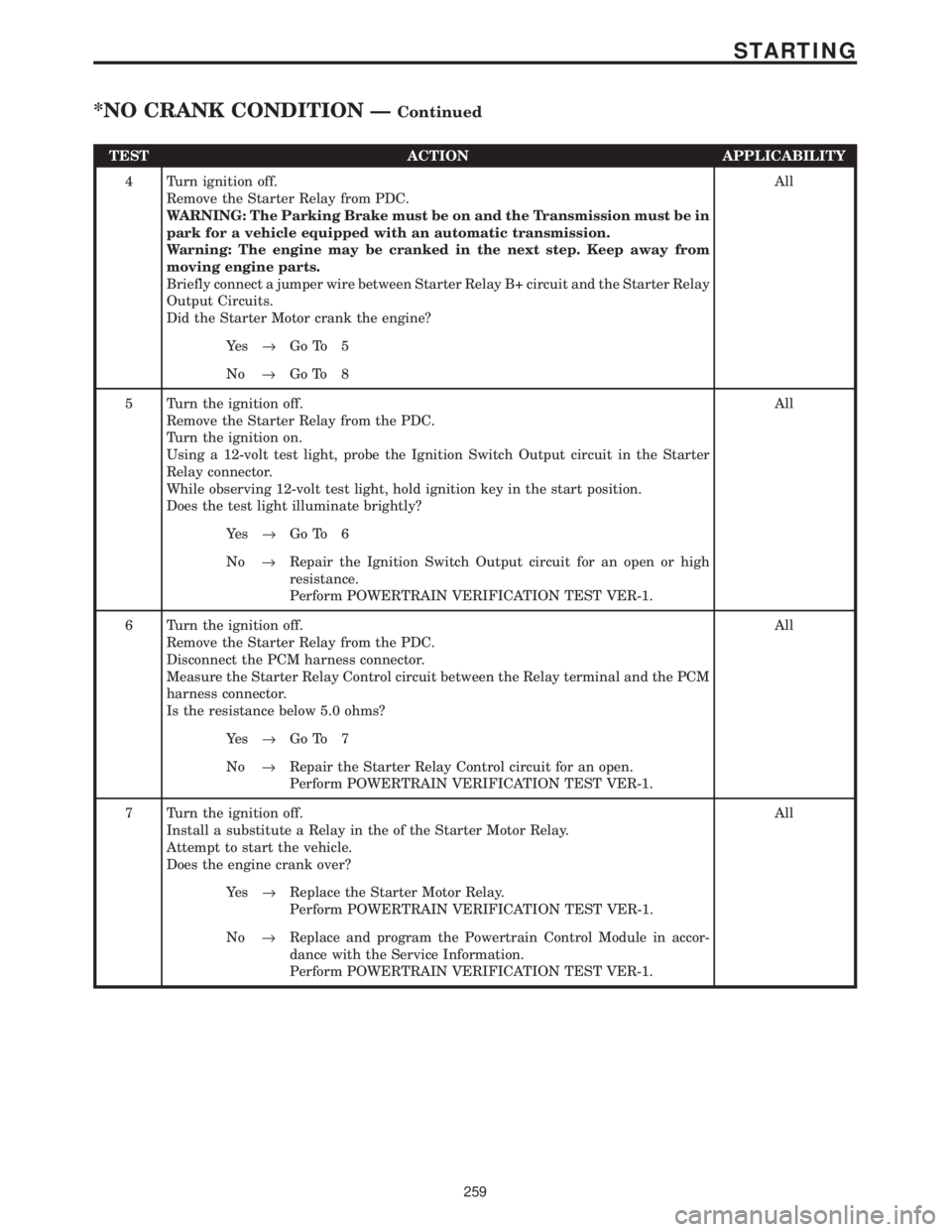

TEST ACTION APPLICABILITY

4 Turn ignition off.

Remove the Starter Relay from PDC.

WARNING: The Parking Brake must be on and the Transmission must be in

park for a vehicle equipped with an automatic transmission.

Warning: The engine may be cranked in the next step. Keep away from

moving engine parts.

Briefly connect a jumper wire between Starter Relay B+ circuit and the Starter Relay

Output Circuits.

Did the Starter Motor crank the engine?All

Ye s®Go To 5

No®Go To 8

5 Turn the ignition off.

Remove the Starter Relay from the PDC.

Turn the ignition on.

Using a 12-volt test light, probe the Ignition Switch Output circuit in the Starter

Relay connector.

While observing 12-volt test light, hold ignition key in the start position.

Does the test light illuminate brightly?All

Ye s®Go To 6

No®Repair the Ignition Switch Output circuit for an open or high

resistance.

Perform POWERTRAIN VERIFICATION TEST VER-1.

6 Turn the ignition off.

Remove the Starter Relay from the PDC.

Disconnect the PCM harness connector.

Measure the Starter Relay Control circuit between the Relay terminal and the PCM

harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 7

No®Repair the Starter Relay Control circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER-1.

7 Turn the ignition off.

Install a substitute a Relay in the of the Starter Motor Relay.

Attempt to start the vehicle.

Does the engine crank over?All

Ye s®Replace the Starter Motor Relay.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER-1.

259

STARTING

*NO CRANK CONDITION ÐContinued

Page 4066 of 4284

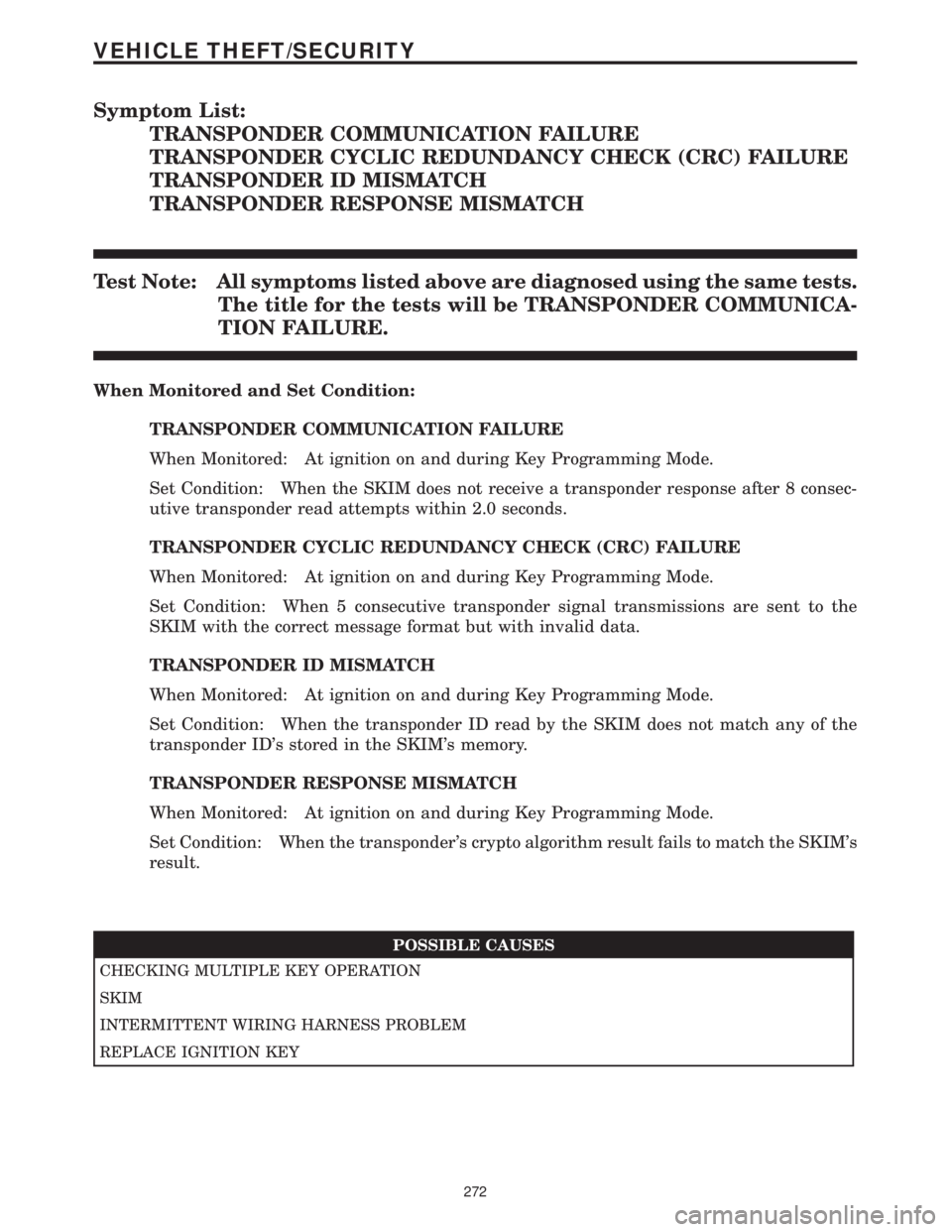

Symptom List:

TRANSPONDER COMMUNICATION FAILURE

TRANSPONDER CYCLIC REDUNDANCY CHECK (CRC) FAILURE

TRANSPONDER ID MISMATCH

TRANSPONDER RESPONSE MISMATCH

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be TRANSPONDER COMMUNICA-

TION FAILURE.

When Monitored and Set Condition:

TRANSPONDER COMMUNICATION FAILURE

When Monitored: At ignition on and during Key Programming Mode.

Set Condition: When the SKIM does not receive a transponder response after 8 consec-

utive transponder read attempts within 2.0 seconds.

TRANSPONDER CYCLIC REDUNDANCY CHECK (CRC) FAILURE

When Monitored: At ignition on and during Key Programming Mode.

Set Condition: When 5 consecutive transponder signal transmissions are sent to the

SKIM with the correct message format but with invalid data.

TRANSPONDER ID MISMATCH

When Monitored: At ignition on and during Key Programming Mode.

Set Condition: When the transponder ID read by the SKIM does not match any of the

transponder ID's stored in the SKIM's memory.

TRANSPONDER RESPONSE MISMATCH

When Monitored: At ignition on and during Key Programming Mode.

Set Condition: When the transponder's crypto algorithm result fails to match the SKIM's

result.

POSSIBLE CAUSES

CHECKING MULTIPLE KEY OPERATION

SKIM

INTERMITTENT WIRING HARNESS PROBLEM

REPLACE IGNITION KEY

272

VEHICLE THEFT/SECURITY

Page 4069 of 4284

VERIFICATION TESTS

31TH TRANSMISSION VERIFICATION TEST - VER 1. APPLICABILITY

1. Connect the DRBIIItto the Data Link Connector (DLC).

2. Reconnect any disconnected components.

3. With the DRBIIIt, erase the PCM DTC's.

4. Check the transmission fluid and adjust if necessary. Refer to the Service information for the

Fluid Fill procedure.

5. Road test the vehicle. With the DRBIIIt, monitor the engine RPM. Make 15 to 20 1-2, 2-3

upshifts. Perform these shifts from a standing start to 45 MPH with a constant throttle opening

of 20 to 25 degrees.

6. Below 25 MPH, make 5 to 8 wide open throttle kickdowns to 1st gear. Allow at least 5 seconds

each in 2nd and 3rd gear between each kickdown.

7. For a specific DTC, drive the vehicle to the Symptom's When Monitored/When Set conditions

to verify the DTC repair.

8. Check for Diagnostic Trouble Codes (DTC's) during the road test. If a DTC sets during the

road test , return to the Symptom list and follow the path.

Were any Trouble Codes set during the road test?All

Ye s®Refer to the Symptom List for appropriate diagnostic tests.

No®Repair is complete.

41TE TRANSMISSION VERIFICATION TEST - VER 1. APPLICABILITY

1. Connect the DRBIIItto the Data Link Connector (DLC).

2. Reconnect any disconnected components.

3. With the DRBIIIt, erase all Transmission DTC's, also erase the PCM DTC's.

4. With the DRBIIIt, display transmission temperature. Start and run the engine until the

transmission temperature is HOT (above 110 deg. F).

5. Check the transmission fluid and adjust if necessary. Refer to the Service information for the

Fluid Fill procedure.

6. NOTE: If the Transmission Control Module or torque converter has been replaced

or if the transmission has been repaired or replaced it is necessary to perform the

DRBIIItQuick Learn Procedure and reset the(Pinion Factor(

7. Road test the vehicle. With the DRBIIIt, monitor the engine RPM. Make 15 to 20 1-2, 2-3,

3-4 upshifts. Perform these shifts from a standing start to 45 MPH with a constant throttle

opening of 20 to 25 degrees.

8. Below 25 MPH, make 5 to 8 wide open throttle kickdowns to 1st gear. Allow at least 5 seconds

each in 2nd and 3rd gear between each kickdown.

9. For a specific DTC, drive the vehicle to the Symptom's When Monitored/When Set conditions

to verify the DTC repair.

10. Check for Diagnostic Trouble Codes (DTC's) during the road test. If a DTC sets during the

road test , return to the Symptom list and follow the path.

11. NOTE: Erase P0700 DTC in the PCM to turn the MIL light off after making

transmission repairs. This will turn the MIL off.

Were any Trouble Codes set during the road test?All

Ye s®Refer to the Symptom List for appropriate diagnostic tests.

No®Repair is complete.

275

VERIFICATION TESTS

Page 4086 of 4284

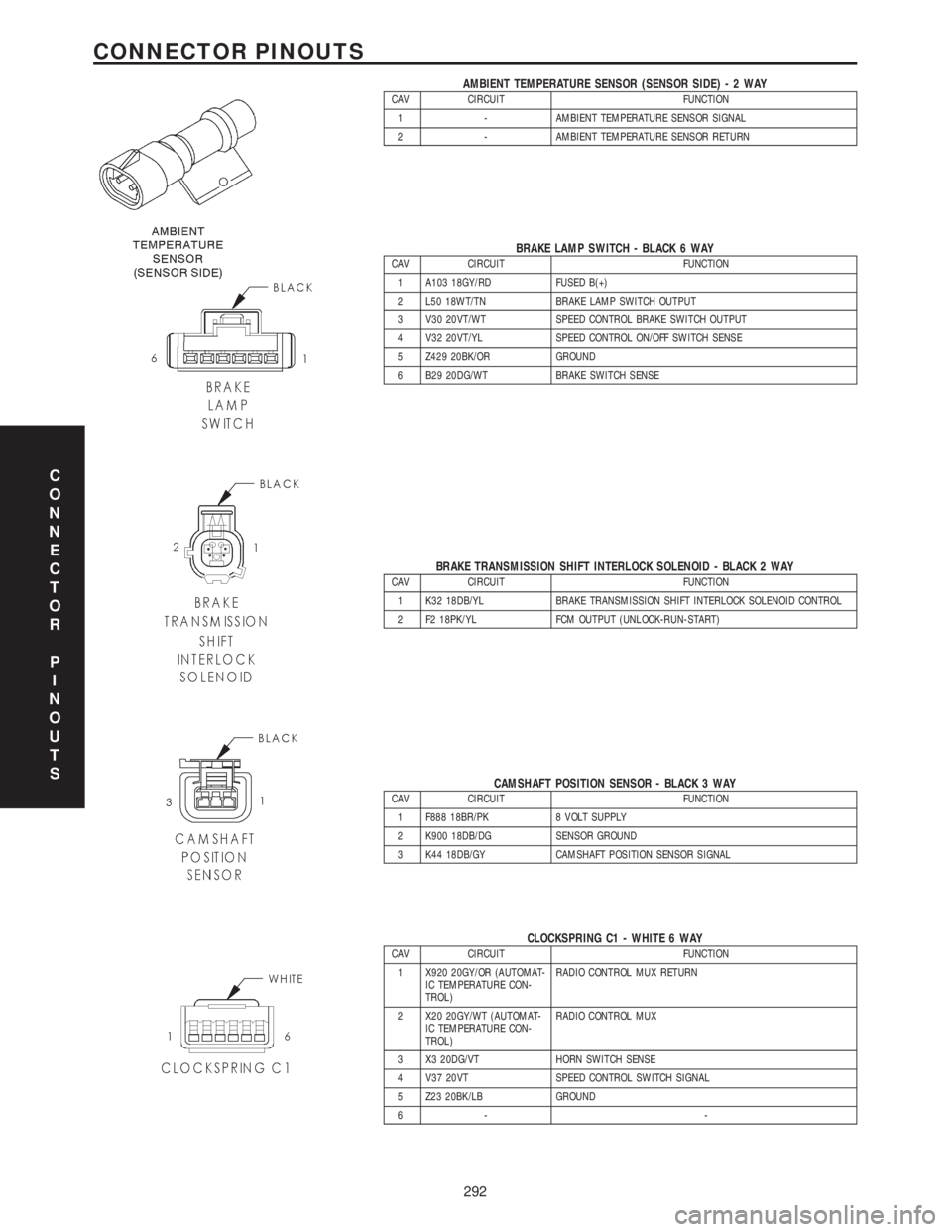

AMBIENT TEMPERATURE SENSOR (SENSOR SIDE)-2WAYCAV CIRCUIT FUNCTION

1 - AMBIENT TEMPERATURE SENSOR SIGNAL

2 - AMBIENT TEMPERATURE SENSOR RETURN

BRAKE LAMP SWITCH - BLACK 6 WAYCAV CIRCUIT FUNCTION

1 A103 18GY/RD FUSED B(+)

2 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

3 V30 20VT/WT SPEED CONTROL BRAKE SWITCH OUTPUT

4 V32 20VT/YL SPEED CONTROL ON/OFF SWITCH SENSE

5 Z429 20BK/OR GROUND

6 B29 20DG/WT BRAKE SWITCH SENSE

BRAKE TRANSMISSION SHIFT INTERLOCK SOLENOID - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 K32 18DB/YL BRAKE TRANSMISSION SHIFT INTERLOCK SOLENOID CONTROL

2 F2 18PK/YL FCM OUTPUT (UNLOCK-RUN-START)

CAMSHAFT POSITION SENSOR - BLACK 3 WAYCAV CIRCUIT FUNCTION

1 F888 18BR/PK 8 VOLT SUPPLY

2 K900 18DB/DG SENSOR GROUND

3 K44 18DB/GY CAMSHAFT POSITION SENSOR SIGNAL

CLOCKSPRING C1 - WHITE 6 WAYCAV CIRCUIT FUNCTION

1 X920 20GY/OR (AUTOMAT-

IC TEMPERATURE CON-

TROL)RADIO CONTROL MUX RETURN

2 X20 20GY/WT (AUTOMAT-

IC TEMPERATURE CON-

TROL)RADIO CONTROL MUX

3 X3 20DG/VT HORN SWITCH SENSE

4 V37 20VT SPEED CONTROL SWITCH SIGNAL

5 Z23 20BK/LB GROUND

6- -

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

292

CONNECTOR PINOUTS

Page 4094 of 4284

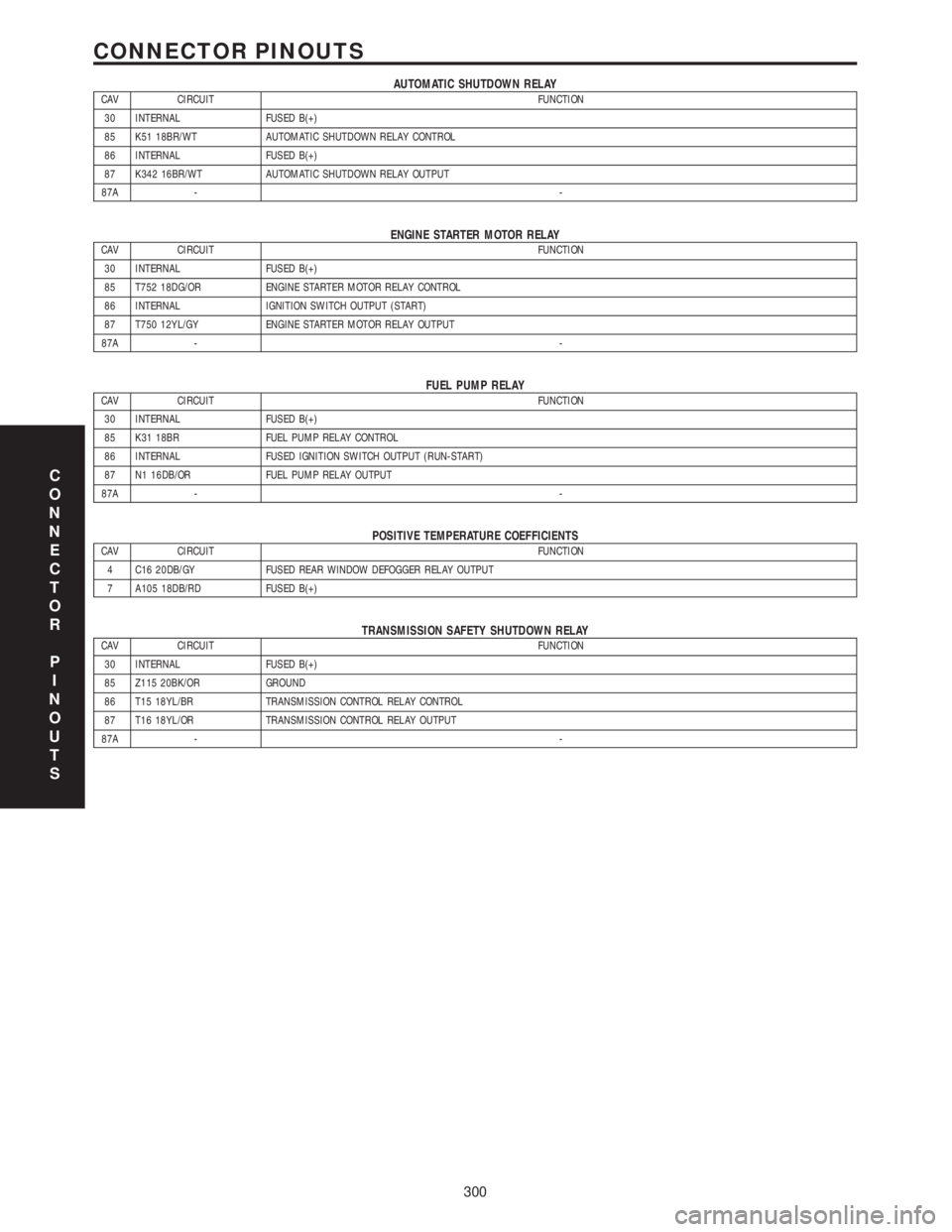

AUTOMATIC SHUTDOWN RELAYCAV CIRCUIT FUNCTION

30 INTERNAL FUSED B(+)

85 K51 18BR/WT AUTOMATIC SHUTDOWN RELAY CONTROL

86 INTERNAL FUSED B(+)

87 K342 16BR/WT AUTOMATIC SHUTDOWN RELAY OUTPUT

87A --

ENGINE STARTER MOTOR RELAYCAV CIRCUIT FUNCTION

30 INTERNAL FUSED B(+)

85 T752 18DG/OR ENGINE STARTER MOTOR RELAY CONTROL

86 INTERNAL IGNITION SWITCH OUTPUT (START)

87 T750 12YL/GY ENGINE STARTER MOTOR RELAY OUTPUT

87A --

FUEL PUMP RELAYCAV CIRCUIT FUNCTION

30 INTERNAL FUSED B(+)

85 K31 18BR FUEL PUMP RELAY CONTROL

86 INTERNAL FUSED IGNITION SWITCH OUTPUT (RUN-START)

87 N1 16DB/OR FUEL PUMP RELAY OUTPUT

87A --

POSITIVE TEMPERATURE COEFFICIENTSCAV CIRCUIT FUNCTION

4 C16 20DB/GY FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

7 A105 18DB/RD FUSED B(+)

TRANSMISSION SAFETY SHUTDOWN RELAYCAV CIRCUIT FUNCTION

30 INTERNAL FUSED B(+)

85 Z115 20BK/OR GROUND

86 T15 18YL/BR TRANSMISSION CONTROL RELAY CONTROL

87 T16 18YL/OR TRANSMISSION CONTROL RELAY OUTPUT

87A --

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

300

CONNECTOR PINOUTS

Page 4101 of 4284

TABLE OF CONTENTS

1.0 INTRODUCTION.........................................................1

1.1SYSTEM COVERAGE...............................................1

1.2SIX -STEP TROUBLESHOOTING PROCEDURE..........................1

2.0 IDENTIFICATION OF SYSTEM.............................................1

3.0 SYSTEM DESCRIPTION AND FUNCTIONAL OPERATION......................1

3.1GENERAL DESCRIPTION............................................1

3.2FUNCTIONAL OPERATION...........................................1

3.2.1AUTOSTICK FEATURE.......................................1

3.2.2TRANSMISSION OPERATION AND SHIFT SCHEDULING AT

VARIOUS OIL TEMPERATURES................................2

3.3DIAGNOSTIC TROUBLE CODES......................................3

3.3.1HARD CODE................................................3

3.3.2ONE TRIP FAILURES.........................................3

3.3.3INTERMITTENT CODE........................................3

3.3.4STARTS SINCE SET COUNTER................................3

3.3.5TROUBLE CODE ERASURE...................................4

3.3.6LIST OF DIAGNOSTIC TROUBLE CODES........................4

3.3.7DTC DESCRIPTIONS.........................................5

3.3.8QUICK LEARN.............................................16

3.3.9CLUTCH VOLUMES.........................................17

3.3.10ELECTRONIC PINION FACTOR...............................17

3.4USING THE DRBIIIT................................................18

3.5DRBIIITERROR MESSAGES........................................18

3.5.1DRBIIITDOES NOT POWER UP (BLANK SCREEN)...............18

3.5.2DISPLAY IS NOT VISIBLE....................................18

3.6TRANSMISSION SIMULATOR (MILLER TOOL # 8333) AND

FWD ADAPTER (MILLER TOOL #8333-1)..............................18

4.0 DISCLAIMERS, SAFETY, AND WARNINGS.................................18

4.1DISCLAIMERS.....................................................18

4.2.1TECHNICIAN SAFETY INFORMATION..........................19

4.2.2VEHICLE PREPARATION FOR TESTING........................19

4.2.3SERVICING SUB-ASSEMBLIES...............................19

4.2.4DRBIIITSAFETY INSTRUCTIONS.............................19

4.3WARNINGS.......................................................20

4.3.1VEHICLE DAMAGE WARNINGS...............................20

4.3.2ROAD TEST COMPLAINT VEHICLE............................20

4.3.3ELECTRONIC PINION FACTOR WARNINGS.....................20

4.3.4BULLETINS AND RECALLS...................................20

5.0 REQUIRED TOOLS AND EQUIPMENT.....................................20

6.0 GLOSSARY OF TERMS..................................................21

6.1ACRONYMS......................................................21

6.2DEFINITIONS.....................................................21

7.0 DIAGNOSTIC INFORMATION AND PROCEDURES...........................23

i