transmission CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3265 of 4284

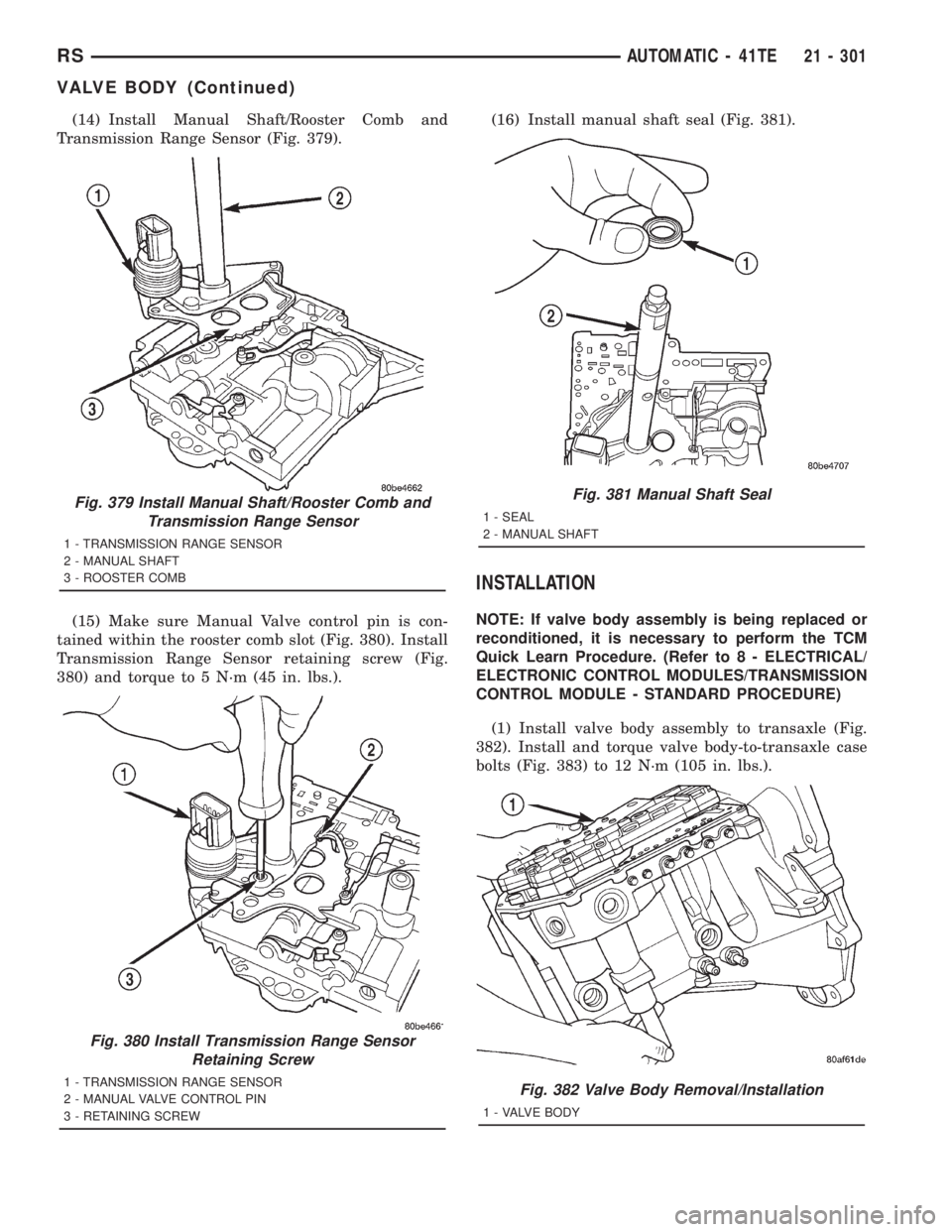

(14) Install Manual Shaft/Rooster Comb and

Transmission Range Sensor (Fig. 379).

(15) Make sure Manual Valve control pin is con-

tained within the rooster comb slot (Fig. 380). Install

Transmission Range Sensor retaining screw (Fig.

380) and torque to 5 N´m (45 in. lbs.).(16) Install manual shaft seal (Fig. 381).

INSTALLATION

NOTE: If valve body assembly is being replaced or

reconditioned, it is necessary to perform the TCM

Quick Learn Procedure. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

(1) Install valve body assembly to transaxle (Fig.

382). Install and torque valve body-to-transaxle case

bolts (Fig. 383) to 12 N´m (105 in. lbs.).

Fig. 379 Install Manual Shaft/Rooster Comb and

Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL SHAFT

3 - ROOSTER COMB

Fig. 380 Install Transmission Range Sensor

Retaining Screw

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

Fig. 381 Manual Shaft Seal

1 - SEAL

2 - MANUAL SHAFT

Fig. 382 Valve Body Removal/Installation

1 - VALVE BODY

RSAUTOMATIC - 41TE21 - 301

VALVE BODY (Continued)

Page 3266 of 4284

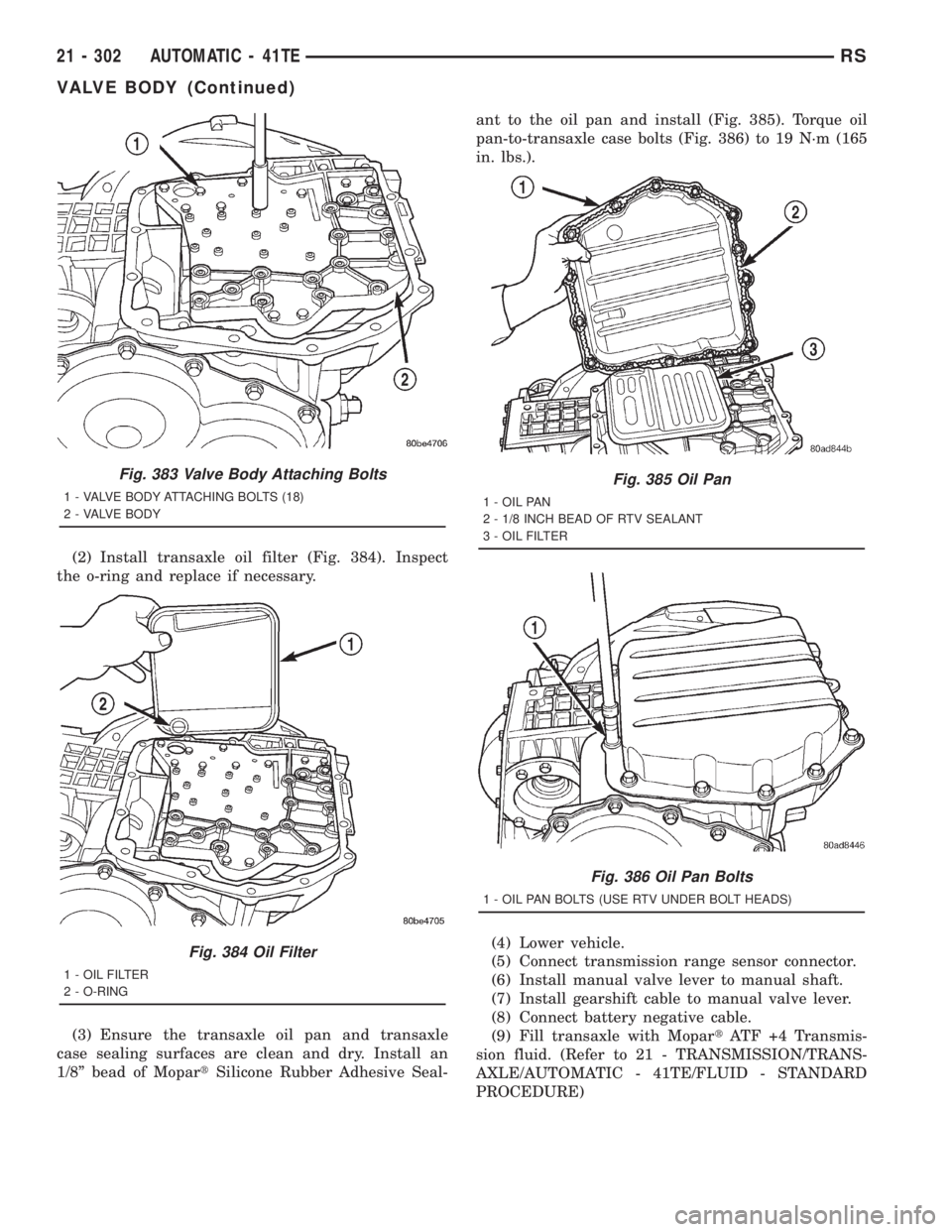

(2) Install transaxle oil filter (Fig. 384). Inspect

the o-ring and replace if necessary.

(3) Ensure the transaxle oil pan and transaxle

case sealing surfaces are clean and dry. Install an

1/8º bead of MopartSilicone Rubber Adhesive Seal-ant to the oil pan and install (Fig. 385). Torque oil

pan-to-transaxle case bolts (Fig. 386) to 19 N´m (165

in. lbs.).

(4) Lower vehicle.

(5) Connect transmission range sensor connector.

(6) Install manual valve lever to manual shaft.

(7) Install gearshift cable to manual valve lever.

(8) Connect battery negative cable.

(9) Fill transaxle with MopartATF +4 Transmis-

sion fluid. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE/FLUID - STANDARD

PROCEDURE)

Fig. 383 Valve Body Attaching Bolts

1 - VALVE BODY ATTACHING BOLTS (18)

2 - VALVE BODY

Fig. 384 Oil Filter

1 - OIL FILTER

2 - O-RING

Fig. 385 Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF RTV SEALANT

3 - OIL FILTER

Fig. 386 Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

21 - 302 AUTOMATIC - 41TERS

VALVE BODY (Continued)

Page 3278 of 4284

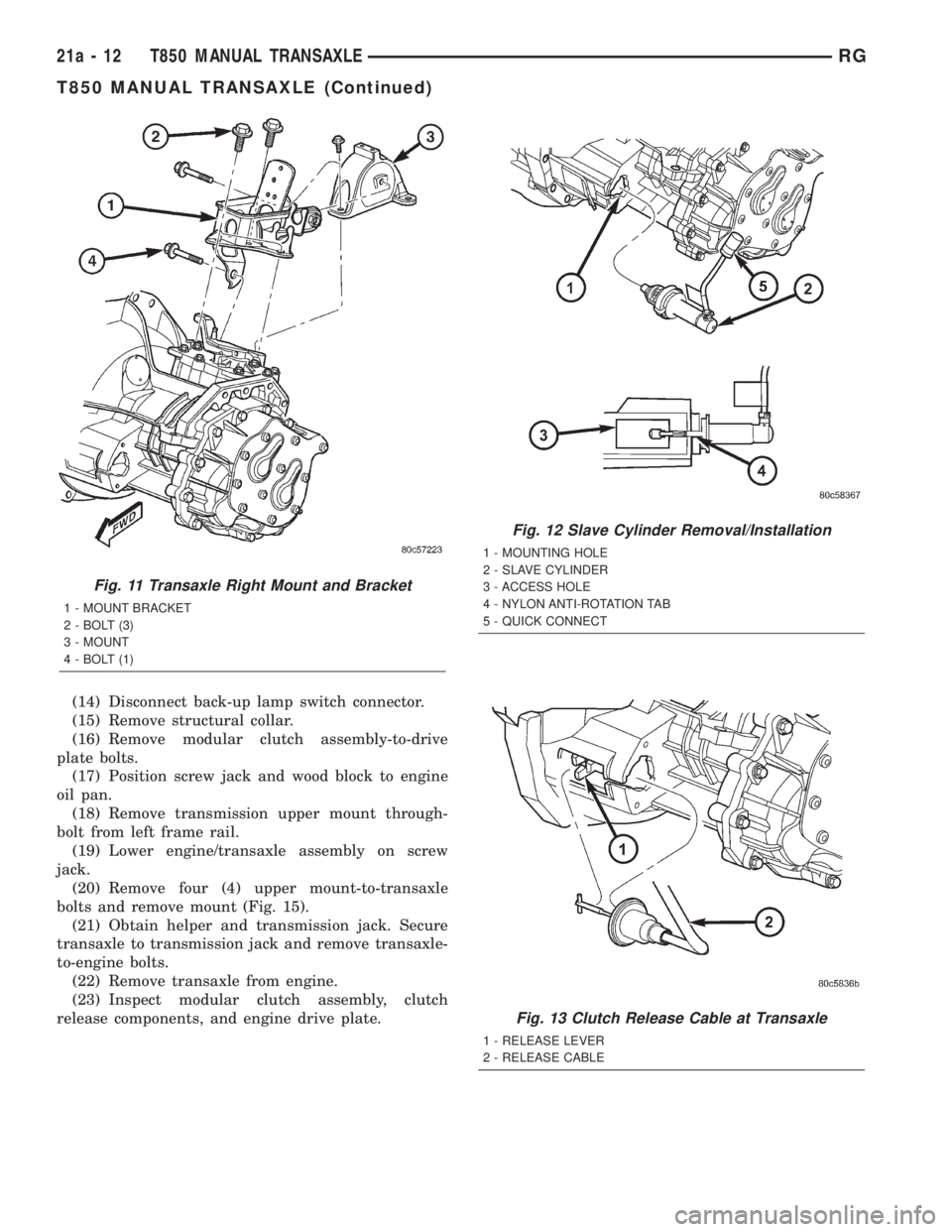

(14) Disconnect back-up lamp switch connector.

(15) Remove structural collar.

(16) Remove modular clutch assembly-to-drive

plate bolts.

(17) Position screw jack and wood block to engine

oil pan.

(18) Remove transmission upper mount through-

bolt from left frame rail.

(19) Lower engine/transaxle assembly on screw

jack.

(20) Remove four (4) upper mount-to-transaxle

bolts and remove mount (Fig. 15).

(21) Obtain helper and transmission jack. Secure

transaxle to transmission jack and remove transaxle-

to-engine bolts.

(22) Remove transaxle from engine.

(23) Inspect modular clutch assembly, clutch

release components, and engine drive plate.

Fig. 11 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

Fig. 12 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 13 Clutch Release Cable at Transaxle

1 - RELEASE LEVER

2 - RELEASE CABLE

21a - 12 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3281 of 4284

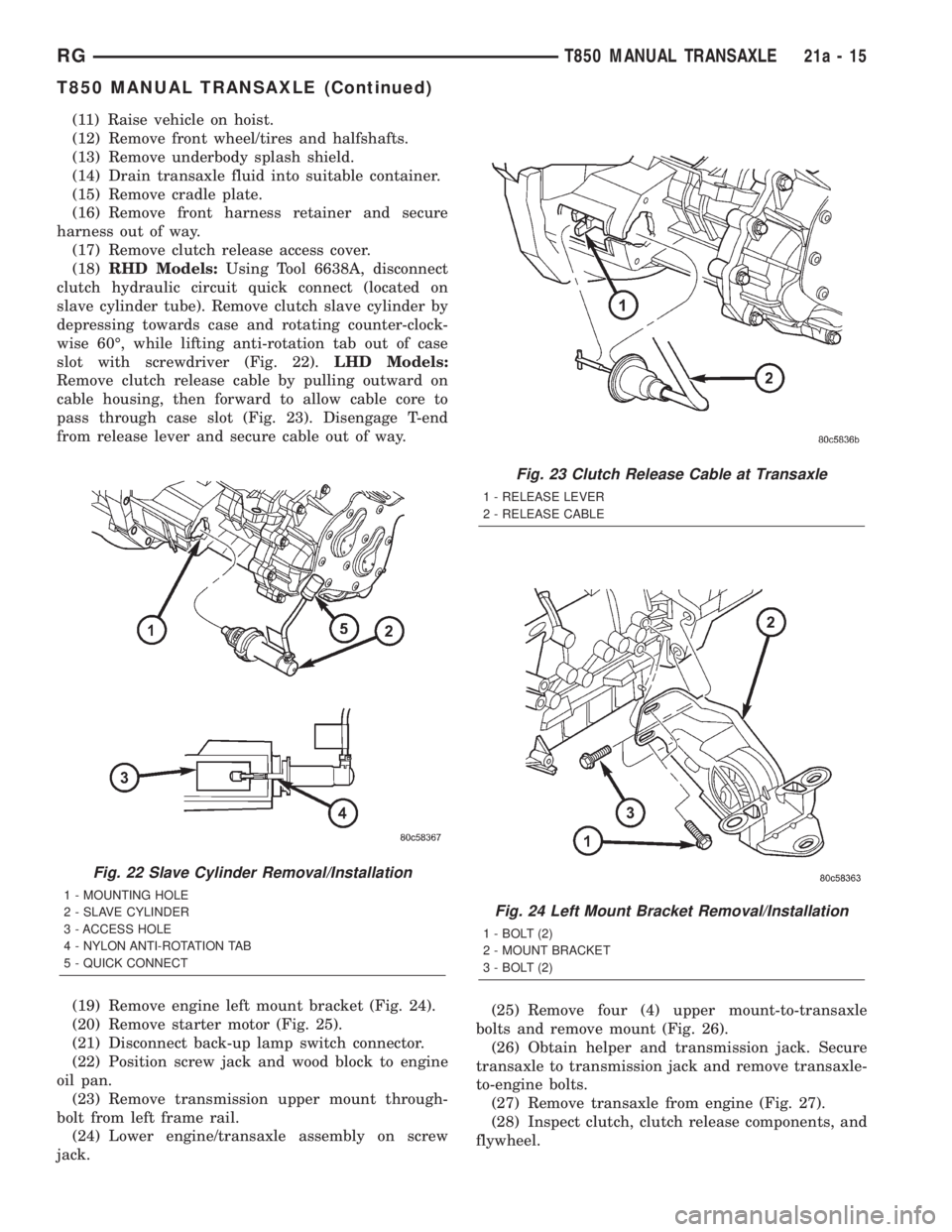

(11) Raise vehicle on hoist.

(12) Remove front wheel/tires and halfshafts.

(13) Remove underbody splash shield.

(14) Drain transaxle fluid into suitable container.

(15) Remove cradle plate.

(16) Remove front harness retainer and secure

harness out of way.

(17) Remove clutch release access cover.

(18)RHD Models:Using Tool 6638A, disconnect

clutch hydraulic circuit quick connect (located on

slave cylinder tube). Remove clutch slave cylinder by

depressing towards case and rotating counter-clock-

wise 60É, while lifting anti-rotation tab out of case

slot with screwdriver (Fig. 22).LHD Models:

Remove clutch release cable by pulling outward on

cable housing, then forward to allow cable core to

pass through case slot (Fig. 23). Disengage T-end

from release lever and secure cable out of way.

(19) Remove engine left mount bracket (Fig. 24).

(20) Remove starter motor (Fig. 25).

(21) Disconnect back-up lamp switch connector.

(22) Position screw jack and wood block to engine

oil pan.

(23) Remove transmission upper mount through-

bolt from left frame rail.

(24) Lower engine/transaxle assembly on screw

jack.(25) Remove four (4) upper mount-to-transaxle

bolts and remove mount (Fig. 26).

(26) Obtain helper and transmission jack. Secure

transaxle to transmission jack and remove transaxle-

to-engine bolts.

(27) Remove transaxle from engine (Fig. 27).

(28) Inspect clutch, clutch release components, and

flywheel.

Fig. 22 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 23 Clutch Release Cable at Transaxle

1 - RELEASE LEVER

2 - RELEASE CABLE

Fig. 24 Left Mount Bracket Removal/Installation

1 - BOLT (2)

2 - MOUNT BRACKET

3 - BOLT (2)

RGT850 MANUAL TRANSAXLE21a-15

T850 MANUAL TRANSAXLE (Continued)

Page 3286 of 4284

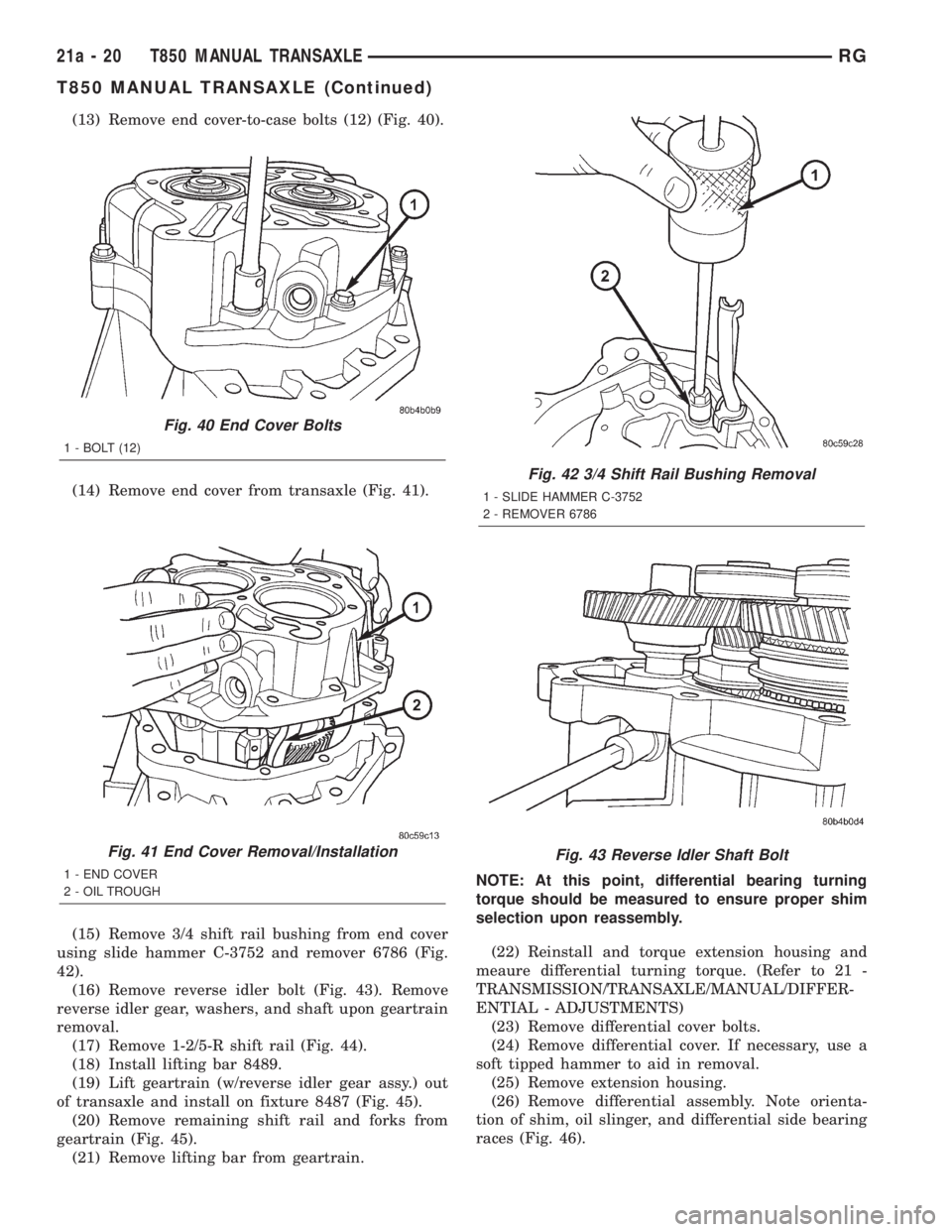

(13) Remove end cover-to-case bolts (12) (Fig. 40).

(14) Remove end cover from transaxle (Fig. 41).

(15) Remove 3/4 shift rail bushing from end cover

using slide hammer C-3752 and remover 6786 (Fig.

42).

(16) Remove reverse idler bolt (Fig. 43). Remove

reverse idler gear, washers, and shaft upon geartrain

removal.

(17) Remove 1-2/5-R shift rail (Fig. 44).

(18) Install lifting bar 8489.

(19) Lift geartrain (w/reverse idler gear assy.) out

of transaxle and install on fixture 8487 (Fig. 45).

(20) Remove remaining shift rail and forks from

geartrain (Fig. 45).

(21) Remove lifting bar from geartrain.NOTE: At this point, differential bearing turning

torque should be measured to ensure proper shim

selection upon reassembly.

(22) Reinstall and torque extension housing and

meaure differential turning torque. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL/DIFFER-

ENTIAL - ADJUSTMENTS)

(23) Remove differential cover bolts.

(24) Remove differential cover. If necessary, use a

soft tipped hammer to aid in removal.

(25) Remove extension housing.

(26) Remove differential assembly. Note orienta-

tion of shim, oil slinger, and differential side bearing

races (Fig. 46).

Fig. 40 End Cover Bolts

1 - BOLT (12)

Fig. 41 End Cover Removal/Installation

1 - END COVER

2 - OIL TROUGH

Fig. 42 3/4 Shift Rail Bushing Removal

1 - SLIDE HAMMER C-3752

2 - REMOVER 6786

Fig. 43 Reverse Idler Shaft Bolt

21a - 20 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3288 of 4284

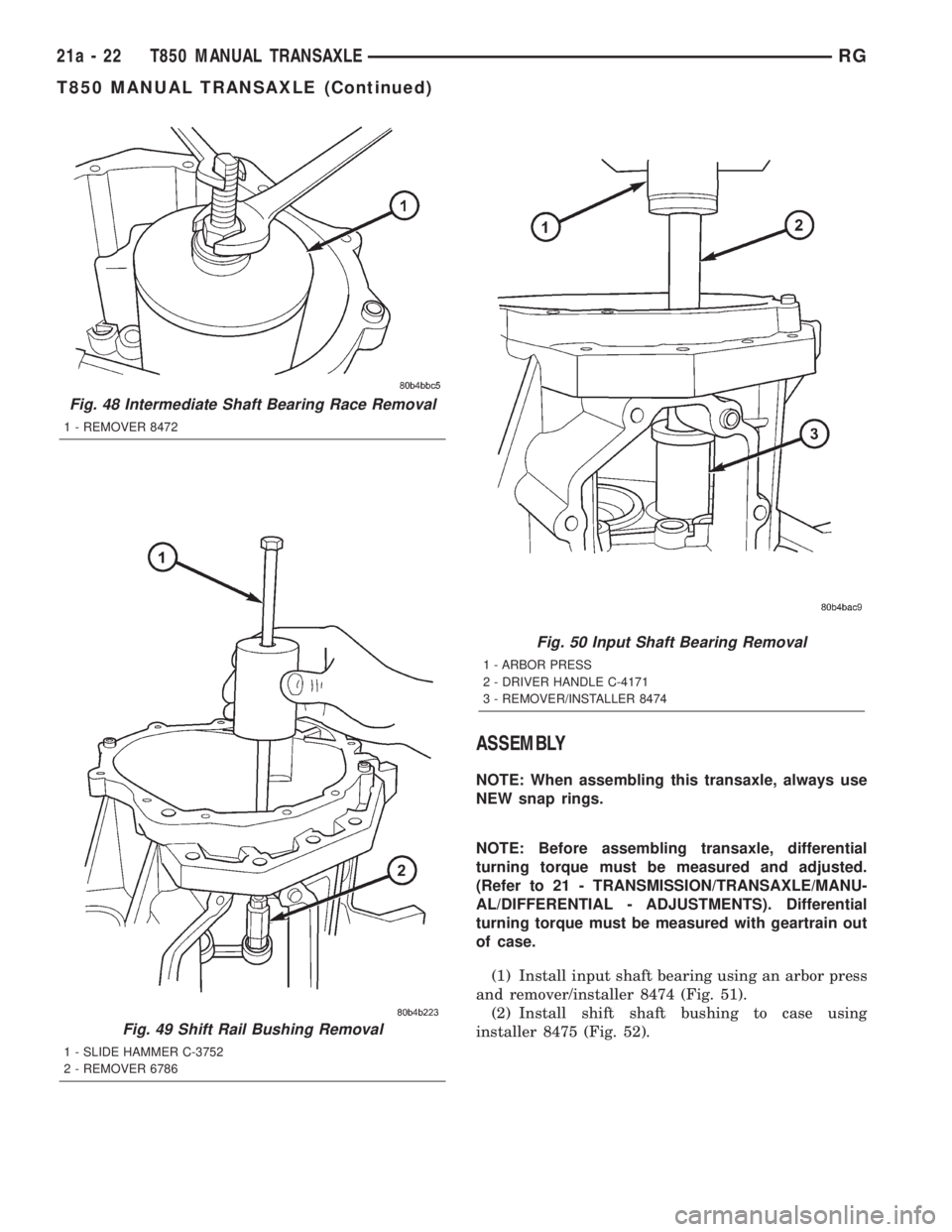

ASSEMBLY

NOTE: When assembling this transaxle, always use

NEW snap rings.

NOTE: Before assembling transaxle, differential

turning torque must be measured and adjusted.

(Refer to 21 - TRANSMISSION/TRANSAXLE/MANU-

AL/DIFFERENTIAL - ADJUSTMENTS). Differential

turning torque must be measured with geartrain out

of case.

(1) Install input shaft bearing using an arbor press

and remover/installer 8474 (Fig. 51).

(2) Install shift shaft bushing to case using

installer 8475 (Fig. 52).

Fig. 48 Intermediate Shaft Bearing Race Removal

1 - REMOVER 8472

Fig. 49 Shift Rail Bushing Removal

1 - SLIDE HAMMER C-3752

2 - REMOVER 6786

Fig. 50 Input Shaft Bearing Removal

1 - ARBOR PRESS

2 - DRIVER HANDLE C-4171

3 - REMOVER/INSTALLER 8474

21a - 22 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3289 of 4284

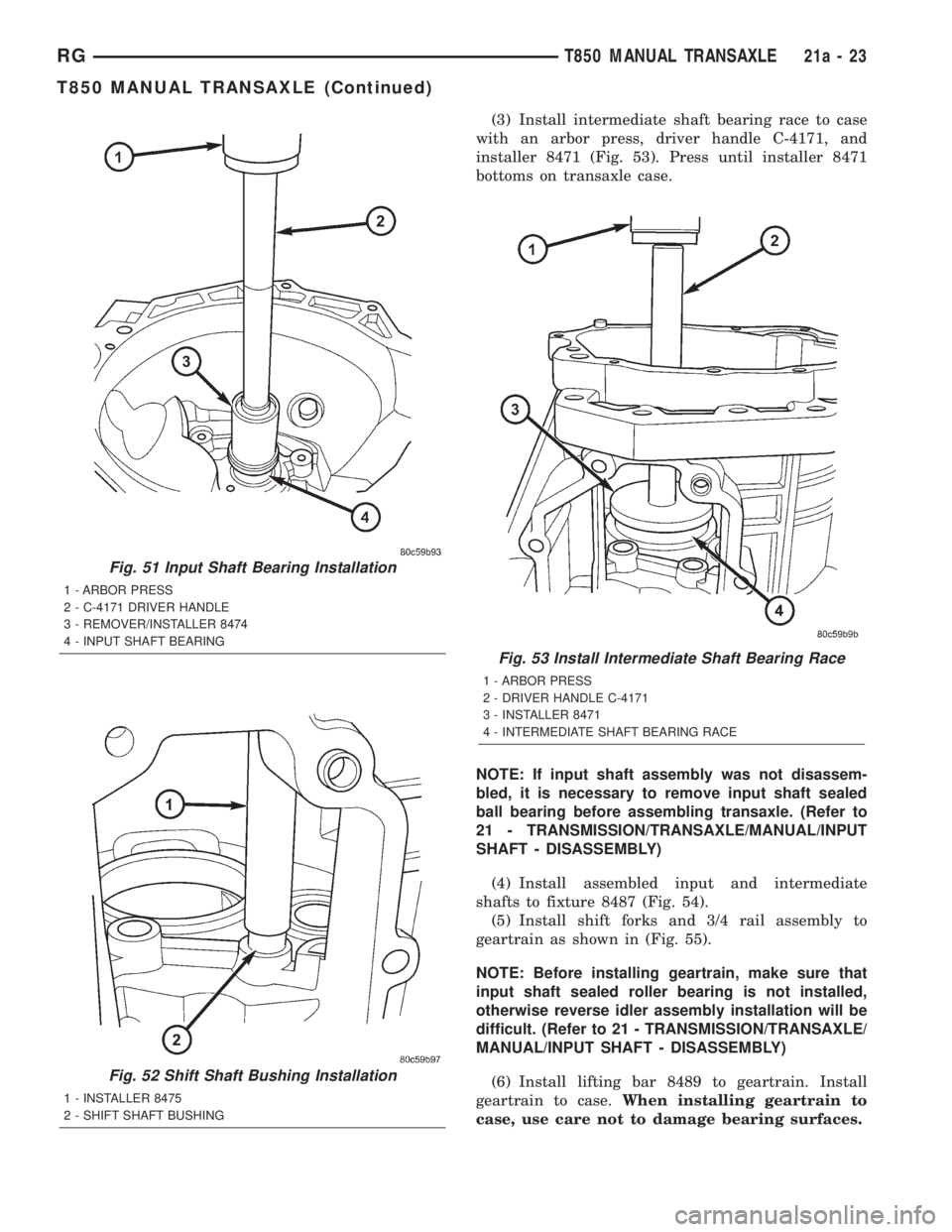

(3) Install intermediate shaft bearing race to case

with an arbor press, driver handle C-4171, and

installer 8471 (Fig. 53). Press until installer 8471

bottoms on transaxle case.

NOTE: If input shaft assembly was not disassem-

bled, it is necessary to remove input shaft sealed

ball bearing before assembling transaxle. (Refer to

21 - TRANSMISSION/TRANSAXLE/MANUAL/INPUT

SHAFT - DISASSEMBLY)

(4) Install assembled input and intermediate

shafts to fixture 8487 (Fig. 54).

(5) Install shift forks and 3/4 rail assembly to

geartrain as shown in (Fig. 55).

NOTE: Before installing geartrain, make sure that

input shaft sealed roller bearing is not installed,

otherwise reverse idler assembly installation will be

difficult. (Refer to 21 - TRANSMISSION/TRANSAXLE/

MANUAL/INPUT SHAFT - DISASSEMBLY)

(6) Install lifting bar 8489 to geartrain. Install

geartrain to case.When installing geartrain to

case, use care not to damage bearing surfaces.

Fig. 51 Input Shaft Bearing Installation

1 - ARBOR PRESS

2 - C-4171 DRIVER HANDLE

3 - REMOVER/INSTALLER 8474

4 - INPUT SHAFT BEARING

Fig. 52 Shift Shaft Bushing Installation

1 - INSTALLER 8475

2 - SHIFT SHAFT BUSHING

Fig. 53 Install Intermediate Shaft Bearing Race

1 - ARBOR PRESS

2 - DRIVER HANDLE C-4171

3 - INSTALLER 8471

4 - INTERMEDIATE SHAFT BEARING RACE

RGT850 MANUAL TRANSAXLE21a-23

T850 MANUAL TRANSAXLE (Continued)

Page 3294 of 4284

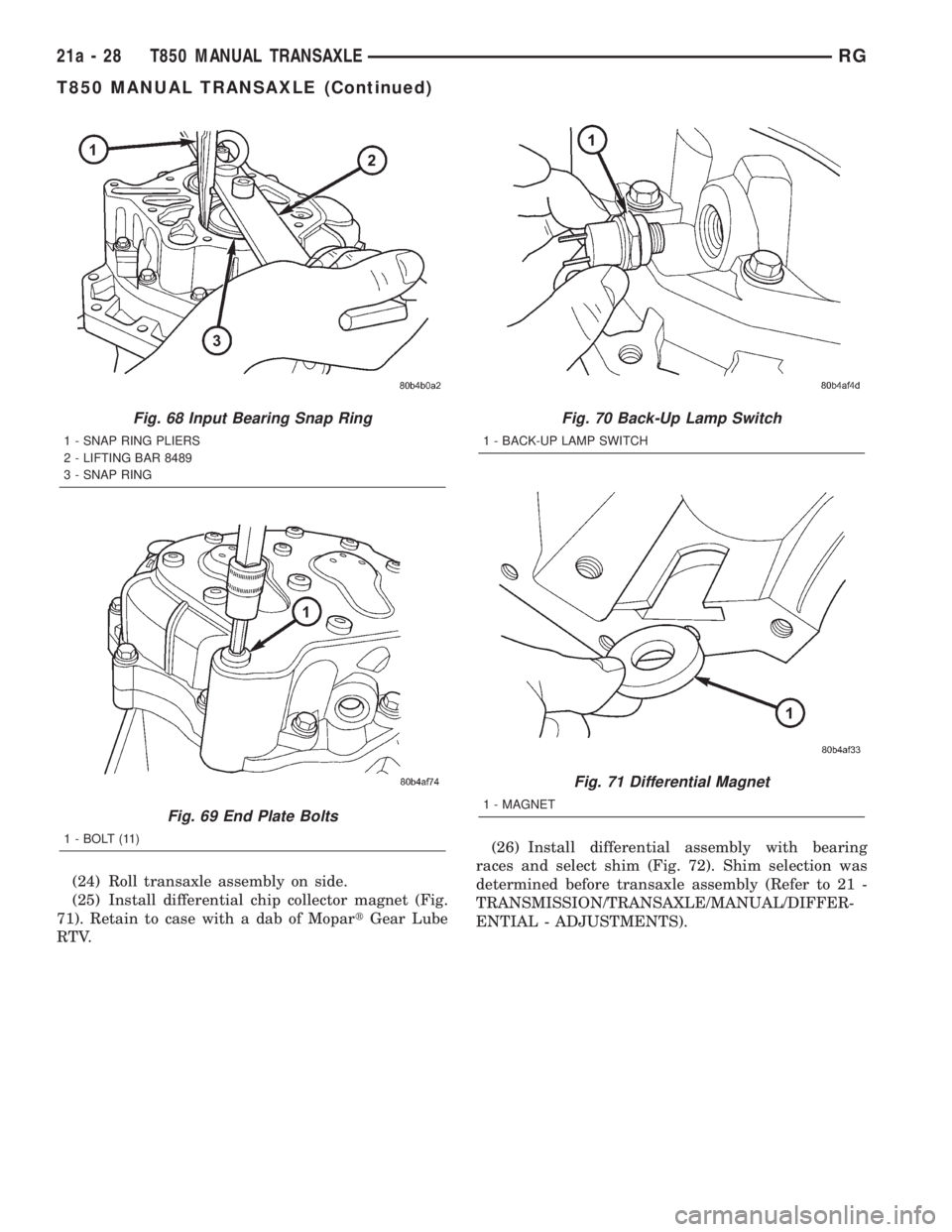

(24) Roll transaxle assembly on side.

(25) Install differential chip collector magnet (Fig.

71). Retain to case with a dab of MopartGear Lube

RTV.(26) Install differential assembly with bearing

races and select shim (Fig. 72). Shim selection was

determined before transaxle assembly (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL/DIFFER-

ENTIAL - ADJUSTMENTS).

Fig. 68 Input Bearing Snap Ring

1 - SNAP RING PLIERS

2 - LIFTING BAR 8489

3 - SNAP RING

Fig. 69 End Plate Bolts

1 - BOLT (11)

Fig. 70 Back-Up Lamp Switch

1 - BACK-UP LAMP SWITCH

Fig. 71 Differential Magnet

1 - MAGNET

21a - 28 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3303 of 4284

(21) Install battery thermal shield and clutch cable

eyelet (LHD only) (Fig. 99). Verify proper clutch cable

routing (LHD models). Cable should be routed over

guide, through eyelet, and around coolant bottle and

wiring harness.

(22) Connect battery cables.

(23) Check transaxle fluid and engine coolant lev-

els. Adjust if necessary. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL/FLUID - STANDARD

PROCEDURE)

SPECIFICATIONS

SPECIFICATIONS - T850 MANUAL TRANSAXLE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Transaxle TypeConstant-mesh, fully synchronized 5-speed with integral

differential

Lubrication MethodSplash oil collected in case passage and oil trough and

distributed to mainshafts via gravity

Fluid Type ATF+4 (Automatic Transmission FluidÐType 9602)

GEAR RATIOS

GEAR RATIO (2.4L Gas) RATIO (2.5L TD)

1st 3.65 3.46

2nd 2.07 2.05

3rd 1.39 1.37

4th 1.03 0.97

5th 0.83 0.76

Reverse 3.47 3.47

Final Drive Ratio 3.77 3.53

Overall Top Gear 3.12 2.66

Fig. 99 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

RGT850 MANUAL TRANSAXLE21a-37

T850 MANUAL TRANSAXLE (Continued)

Page 3308 of 4284

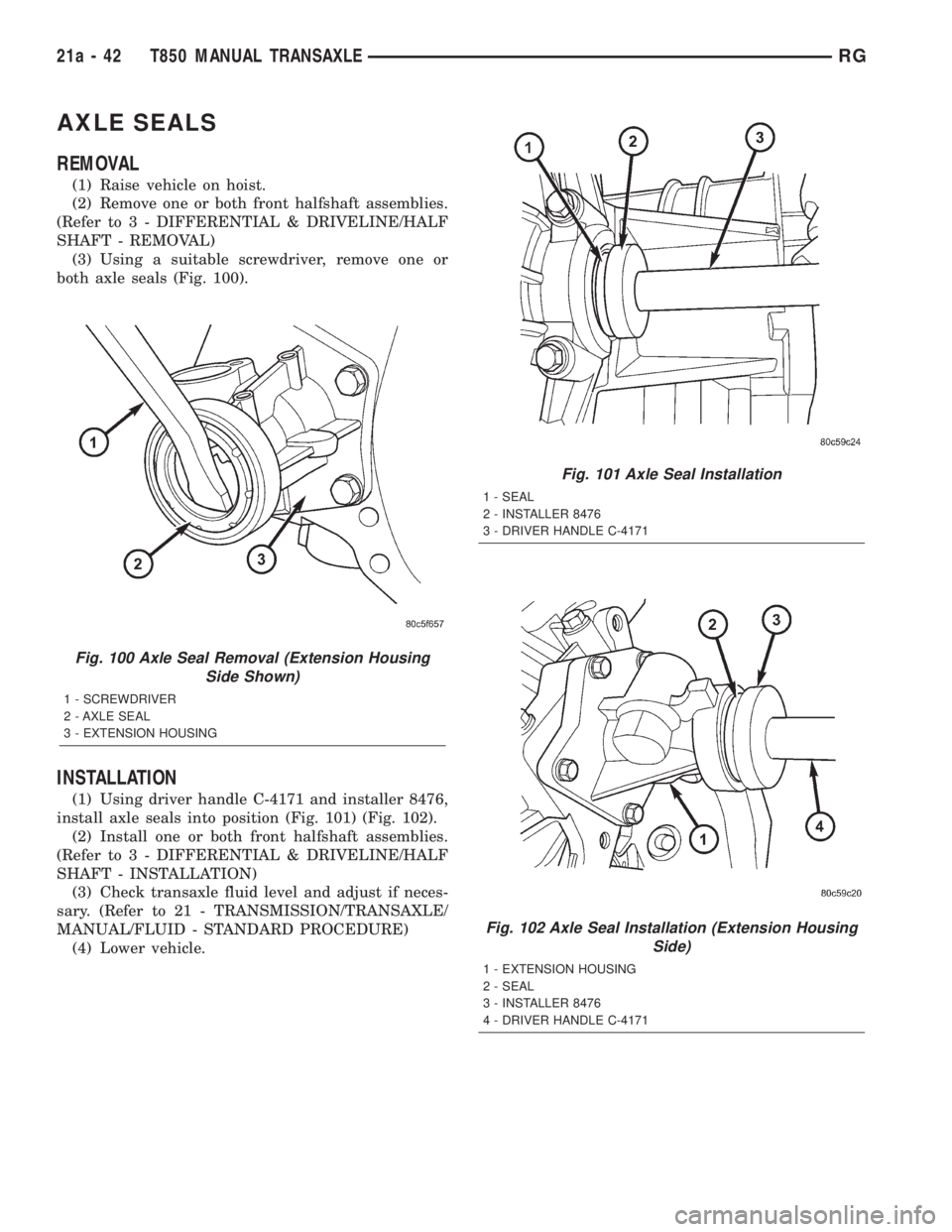

AXLE SEALS

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove one or both front halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - REMOVAL)

(3) Using a suitable screwdriver, remove one or

both axle seals (Fig. 100).

INSTALLATION

(1) Using driver handle C-4171 and installer 8476,

install axle seals into position (Fig. 101) (Fig. 102).

(2) Install one or both front halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION)

(3) Check transaxle fluid level and adjust if neces-

sary. (Refer to 21 - TRANSMISSION/TRANSAXLE/

MANUAL/FLUID - STANDARD PROCEDURE)

(4) Lower vehicle.

Fig. 100 Axle Seal Removal (Extension Housing

Side Shown)

1 - SCREWDRIVER

2 - AXLE SEAL

3 - EXTENSION HOUSING

Fig. 101 Axle Seal Installation

1 - SEAL

2 - INSTALLER 8476

3 - DRIVER HANDLE C-4171

Fig. 102 Axle Seal Installation (Extension Housing

Side)

1 - EXTENSION HOUSING

2 - SEAL

3 - INSTALLER 8476

4 - DRIVER HANDLE C-4171

21a - 42 T850 MANUAL TRANSAXLERG