wheel CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3272 of 4284

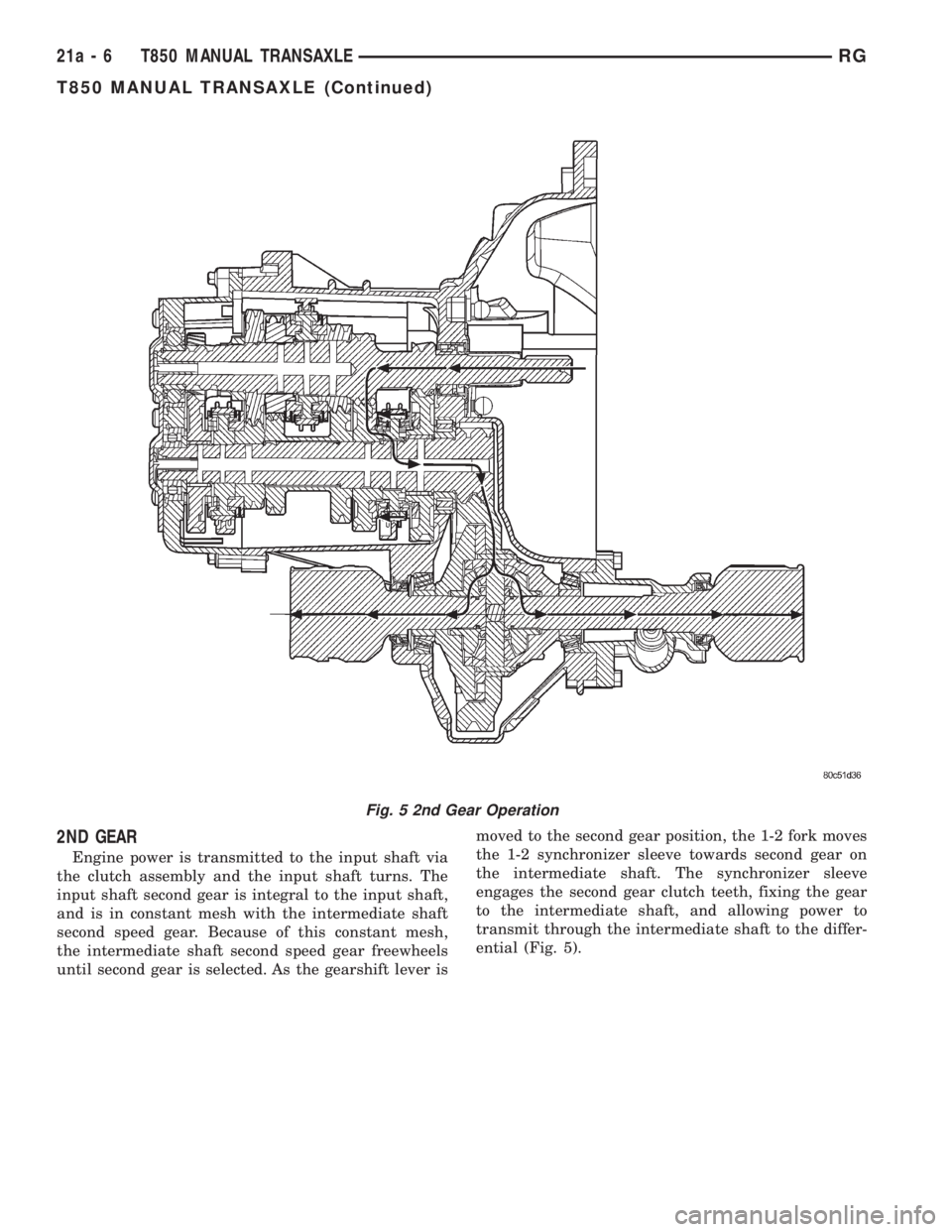

2ND GEAR

Engine power is transmitted to the input shaft via

the clutch assembly and the input shaft turns. The

input shaft second gear is integral to the input shaft,

and is in constant mesh with the intermediate shaft

second speed gear. Because of this constant mesh,

the intermediate shaft second speed gear freewheels

until second gear is selected. As the gearshift lever ismoved to the second gear position, the 1-2 fork moves

the 1-2 synchronizer sleeve towards second gear on

the intermediate shaft. The synchronizer sleeve

engages the second gear clutch teeth, fixing the gear

to the intermediate shaft, and allowing power to

transmit through the intermediate shaft to the differ-

ential (Fig. 5).

Fig. 5 2nd Gear Operation

21a - 6 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3273 of 4284

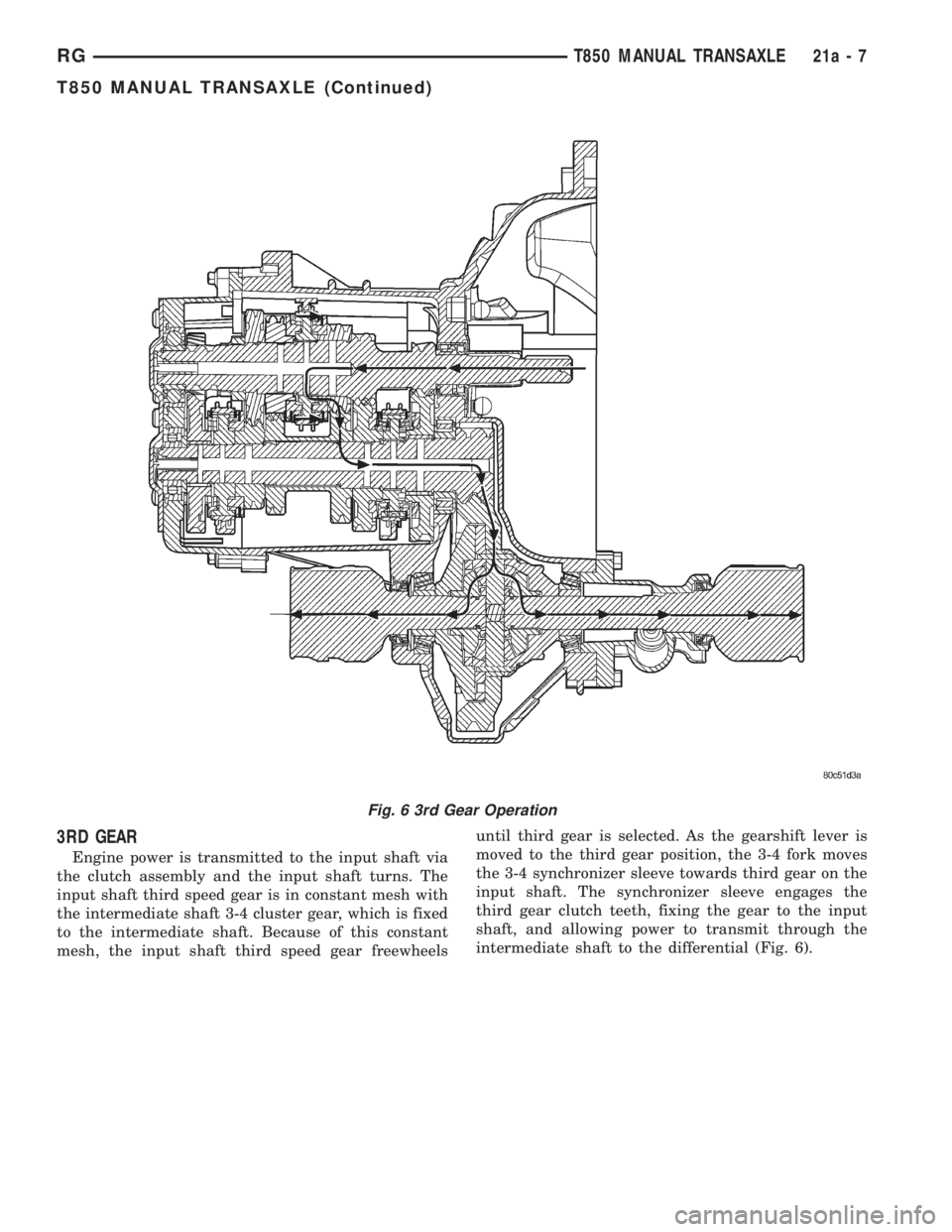

3RD GEAR

Engine power is transmitted to the input shaft via

the clutch assembly and the input shaft turns. The

input shaft third speed gear is in constant mesh with

the intermediate shaft 3-4 cluster gear, which is fixed

to the intermediate shaft. Because of this constant

mesh, the input shaft third speed gear freewheelsuntil third gear is selected. As the gearshift lever is

moved to the third gear position, the 3-4 fork moves

the 3-4 synchronizer sleeve towards third gear on the

input shaft. The synchronizer sleeve engages the

third gear clutch teeth, fixing the gear to the input

shaft, and allowing power to transmit through the

intermediate shaft to the differential (Fig. 6).

Fig. 6 3rd Gear Operation

RGT850 MANUAL TRANSAXLE21a-7

T850 MANUAL TRANSAXLE (Continued)

Page 3274 of 4284

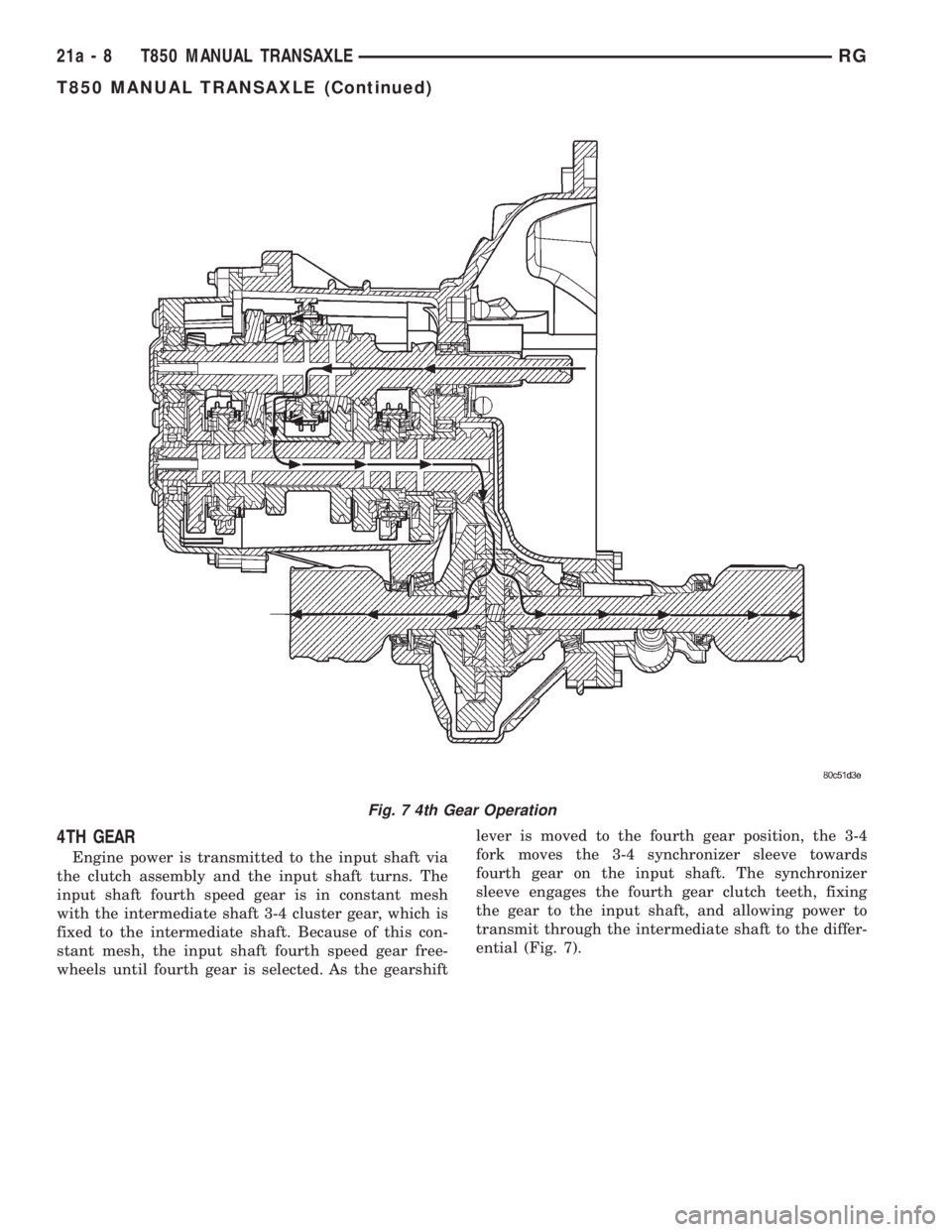

4TH GEAR

Engine power is transmitted to the input shaft via

the clutch assembly and the input shaft turns. The

input shaft fourth speed gear is in constant mesh

with the intermediate shaft 3-4 cluster gear, which is

fixed to the intermediate shaft. Because of this con-

stant mesh, the input shaft fourth speed gear free-

wheels until fourth gear is selected. As the gearshiftlever is moved to the fourth gear position, the 3-4

fork moves the 3-4 synchronizer sleeve towards

fourth gear on the input shaft. The synchronizer

sleeve engages the fourth gear clutch teeth, fixing

the gear to the input shaft, and allowing power to

transmit through the intermediate shaft to the differ-

ential (Fig. 7).

Fig. 7 4th Gear Operation

21a - 8 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3275 of 4284

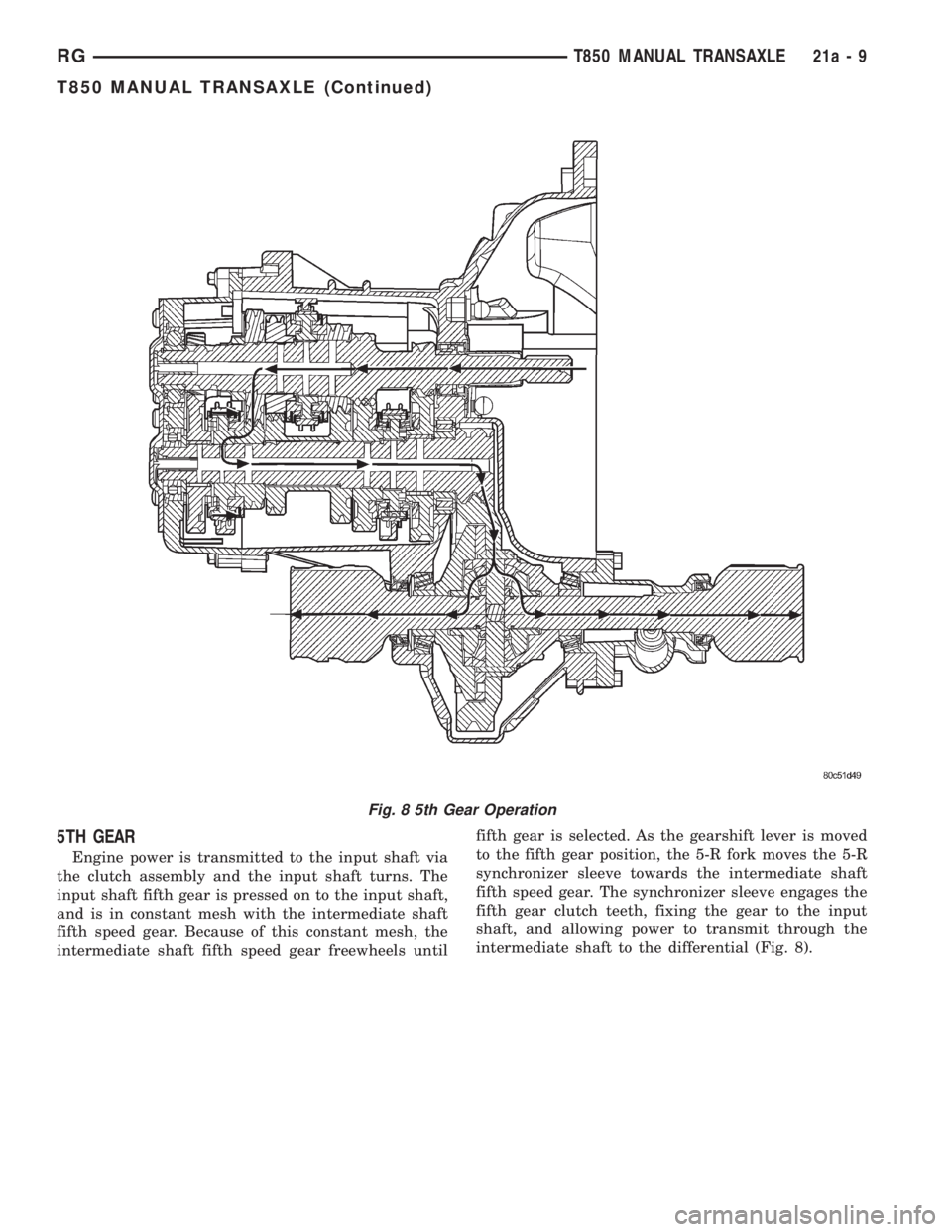

5TH GEAR

Engine power is transmitted to the input shaft via

the clutch assembly and the input shaft turns. The

input shaft fifth gear is pressed on to the input shaft,

and is in constant mesh with the intermediate shaft

fifth speed gear. Because of this constant mesh, the

intermediate shaft fifth speed gear freewheels untilfifth gear is selected. As the gearshift lever is moved

to the fifth gear position, the 5-R fork moves the 5-R

synchronizer sleeve towards the intermediate shaft

fifth speed gear. The synchronizer sleeve engages the

fifth gear clutch teeth, fixing the gear to the input

shaft, and allowing power to transmit through the

intermediate shaft to the differential (Fig. 8).

Fig. 8 5th Gear Operation

RGT850 MANUAL TRANSAXLE21a-9

T850 MANUAL TRANSAXLE (Continued)

Page 3276 of 4284

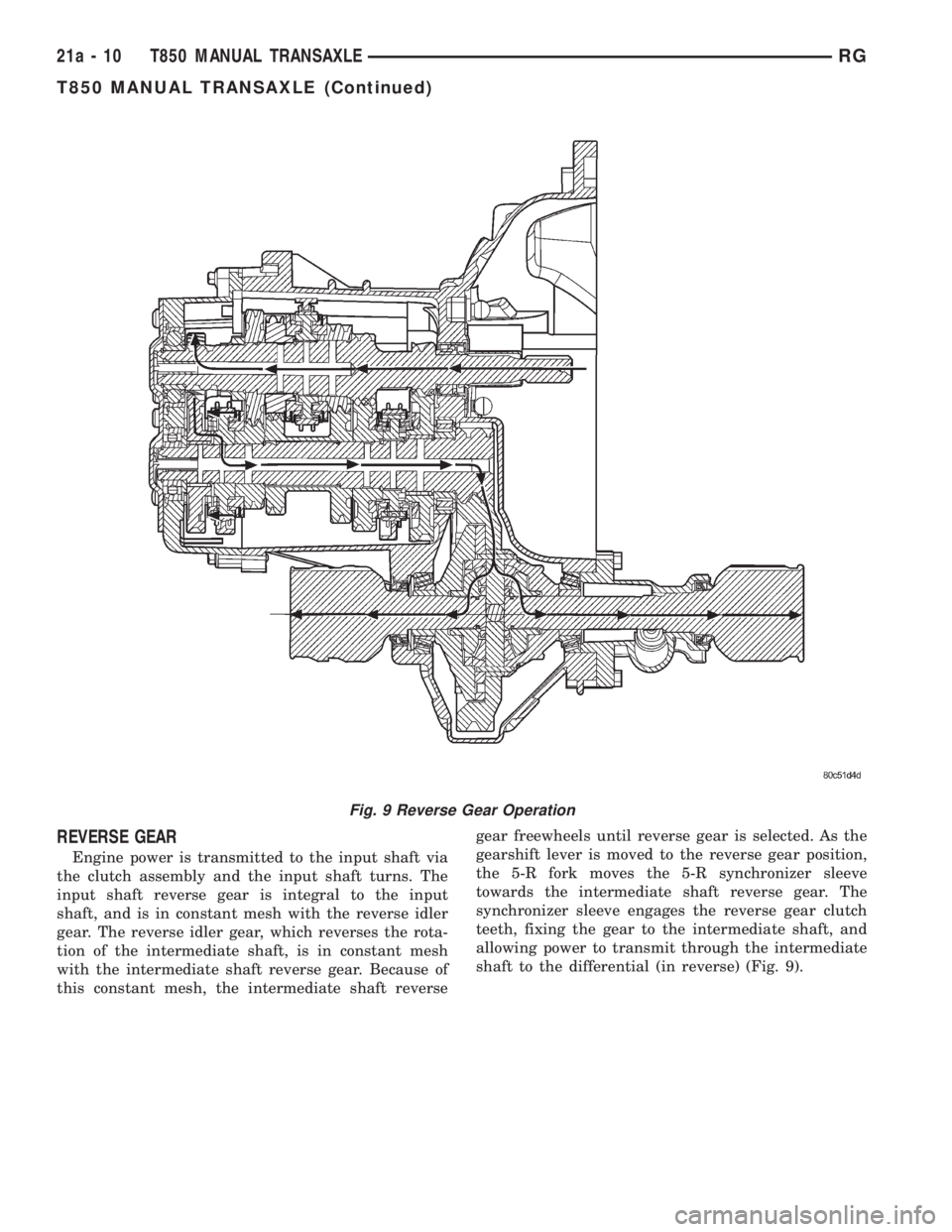

REVERSE GEAR

Engine power is transmitted to the input shaft via

the clutch assembly and the input shaft turns. The

input shaft reverse gear is integral to the input

shaft, and is in constant mesh with the reverse idler

gear. The reverse idler gear, which reverses the rota-

tion of the intermediate shaft, is in constant mesh

with the intermediate shaft reverse gear. Because of

this constant mesh, the intermediate shaft reversegear freewheels until reverse gear is selected. As the

gearshift lever is moved to the reverse gear position,

the 5-R fork moves the 5-R synchronizer sleeve

towards the intermediate shaft reverse gear. The

synchronizer sleeve engages the reverse gear clutch

teeth, fixing the gear to the intermediate shaft, and

allowing power to transmit through the intermediate

shaft to the differential (in reverse) (Fig. 9).

Fig. 9 Reverse Gear Operation

21a - 10 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3277 of 4284

DIAGNOSIS AND TESTING - COMMON

PROBLEM CAUSES

The majority of transaxle malfunctions are a result

of:

²Insufficient lubrication

²Incorrect lubricant

²Misassembled or damaged internal components

²Improper operation

HARD SHIFTING

Hard shifting may be caused by a misadjusted

crossover cable. If hard shifting is accompanied by

gear clash, synchronizer clutch and stop rings or gear

teeth may be worn or damaged.

Hard shifting may also be caused by a binding or

broken shift cover mechanism. Remove shift cover

and verify smooth operation. Replace as necessary.

Misassembled synchronizer components also cause

shifting problems. Incorrectly installed synchronizer

sleeves, keys, balls, or springs can cause shift prob-

lems.

NOISY OPERATION

Transaxle noise is most often a result of worn or

damaged components. Chipped, broken gear or syn-

chronizer teeth, and brinnelled, spalled bearings all

cause noise.

Abnormal wear and damage to the internal compo-

nents is frequently the end result of insufficient

lubricant.

SLIPS OUT OF GEAR

Transaxle disengagement may be caused by mis-

aligned or damaged shift components, or worn teeth

on the drive gears or synchronizer components. Incor-

rect assembly also causes gear disengagement. Check

for missing snap rings.

LOW LUBRICANT LEVEL

Insufficient transaxle lubricant is usually the

result of leaks, or inaccurate fluid level check or refill

method. Leakage is evident by the presence of oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill.

If air±powered lubrication equipment is used to fill

a transaxle, be sure the equipment is properly cali-

brated. Equipment out of calibration can lead to an

underfill condition.

CLUTCH PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash, and noise.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear

clash.

REMOVAL

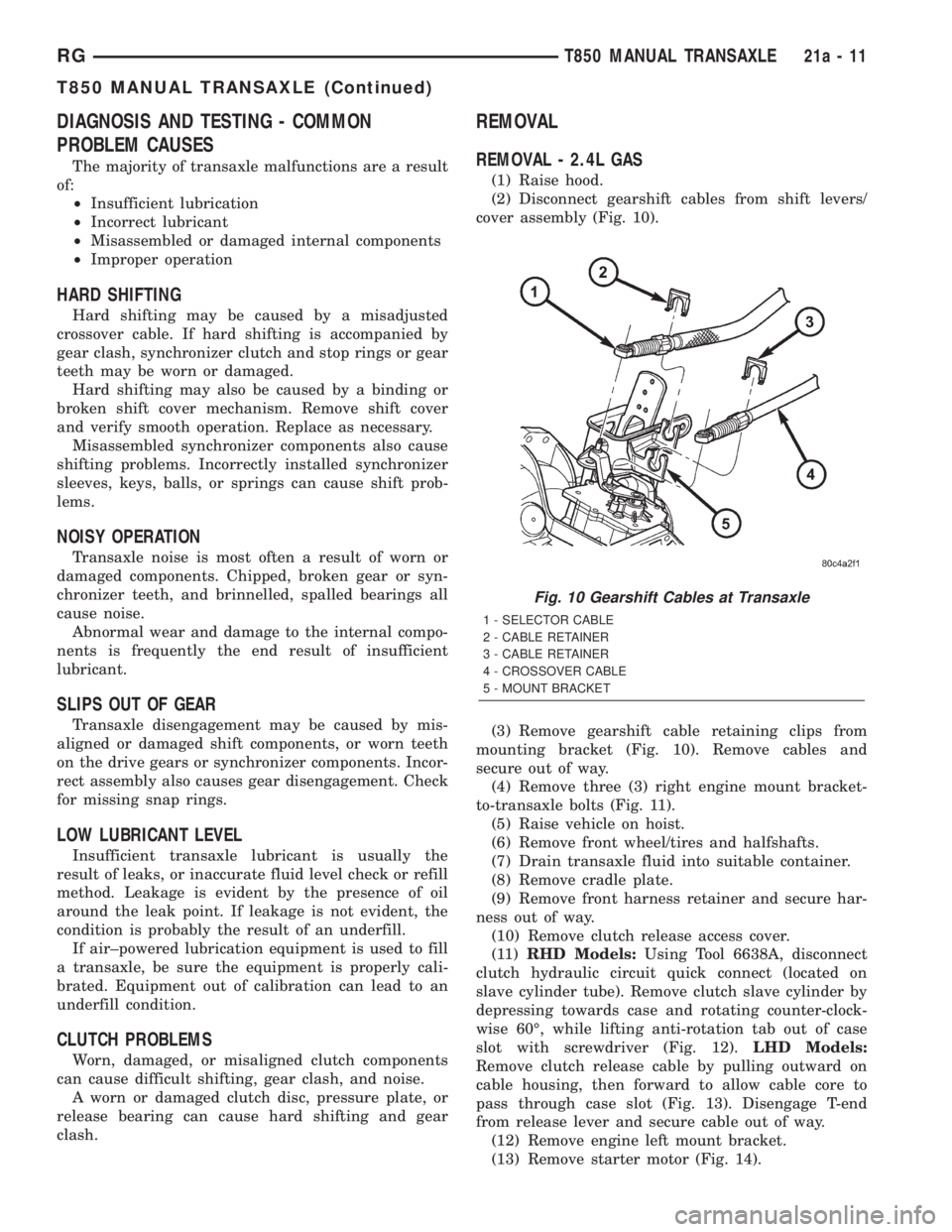

REMOVAL - 2.4L GAS

(1) Raise hood.

(2) Disconnect gearshift cables from shift levers/

cover assembly (Fig. 10).

(3) Remove gearshift cable retaining clips from

mounting bracket (Fig. 10). Remove cables and

secure out of way.

(4) Remove three (3) right engine mount bracket-

to-transaxle bolts (Fig. 11).

(5) Raise vehicle on hoist.

(6) Remove front wheel/tires and halfshafts.

(7) Drain transaxle fluid into suitable container.

(8) Remove cradle plate.

(9) Remove front harness retainer and secure har-

ness out of way.

(10) Remove clutch release access cover.

(11)RHD Models:Using Tool 6638A, disconnect

clutch hydraulic circuit quick connect (located on

slave cylinder tube). Remove clutch slave cylinder by

depressing towards case and rotating counter-clock-

wise 60É, while lifting anti-rotation tab out of case

slot with screwdriver (Fig. 12).LHD Models:

Remove clutch release cable by pulling outward on

cable housing, then forward to allow cable core to

pass through case slot (Fig. 13). Disengage T-end

from release lever and secure cable out of way.

(12) Remove engine left mount bracket.

(13) Remove starter motor (Fig. 14).

Fig. 10 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

RGT850 MANUAL TRANSAXLE21a-11

T850 MANUAL TRANSAXLE (Continued)

Page 3281 of 4284

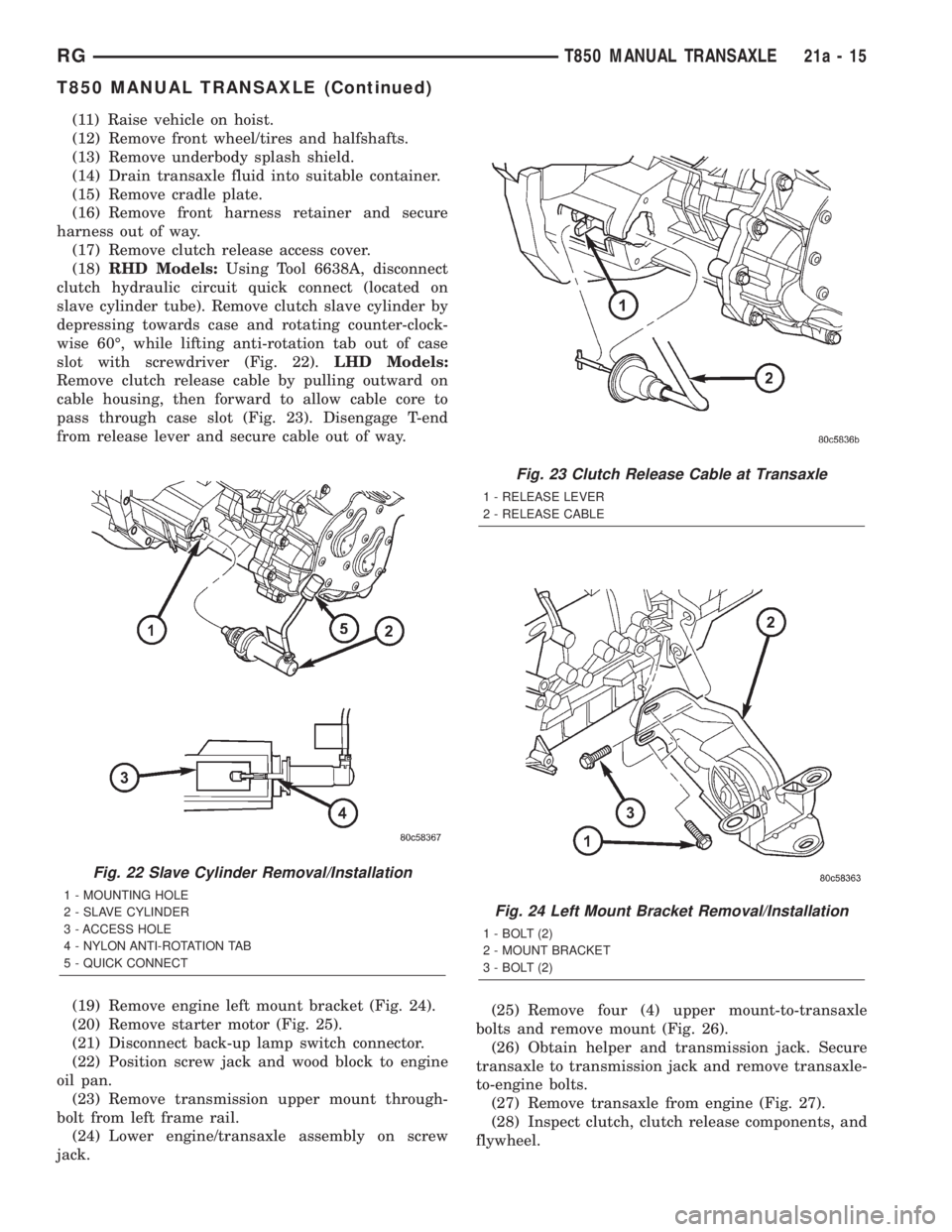

(11) Raise vehicle on hoist.

(12) Remove front wheel/tires and halfshafts.

(13) Remove underbody splash shield.

(14) Drain transaxle fluid into suitable container.

(15) Remove cradle plate.

(16) Remove front harness retainer and secure

harness out of way.

(17) Remove clutch release access cover.

(18)RHD Models:Using Tool 6638A, disconnect

clutch hydraulic circuit quick connect (located on

slave cylinder tube). Remove clutch slave cylinder by

depressing towards case and rotating counter-clock-

wise 60É, while lifting anti-rotation tab out of case

slot with screwdriver (Fig. 22).LHD Models:

Remove clutch release cable by pulling outward on

cable housing, then forward to allow cable core to

pass through case slot (Fig. 23). Disengage T-end

from release lever and secure cable out of way.

(19) Remove engine left mount bracket (Fig. 24).

(20) Remove starter motor (Fig. 25).

(21) Disconnect back-up lamp switch connector.

(22) Position screw jack and wood block to engine

oil pan.

(23) Remove transmission upper mount through-

bolt from left frame rail.

(24) Lower engine/transaxle assembly on screw

jack.(25) Remove four (4) upper mount-to-transaxle

bolts and remove mount (Fig. 26).

(26) Obtain helper and transmission jack. Secure

transaxle to transmission jack and remove transaxle-

to-engine bolts.

(27) Remove transaxle from engine (Fig. 27).

(28) Inspect clutch, clutch release components, and

flywheel.

Fig. 22 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 23 Clutch Release Cable at Transaxle

1 - RELEASE LEVER

2 - RELEASE CABLE

Fig. 24 Left Mount Bracket Removal/Installation

1 - BOLT (2)

2 - MOUNT BRACKET

3 - BOLT (2)

RGT850 MANUAL TRANSAXLE21a-15

T850 MANUAL TRANSAXLE (Continued)

Page 3298 of 4284

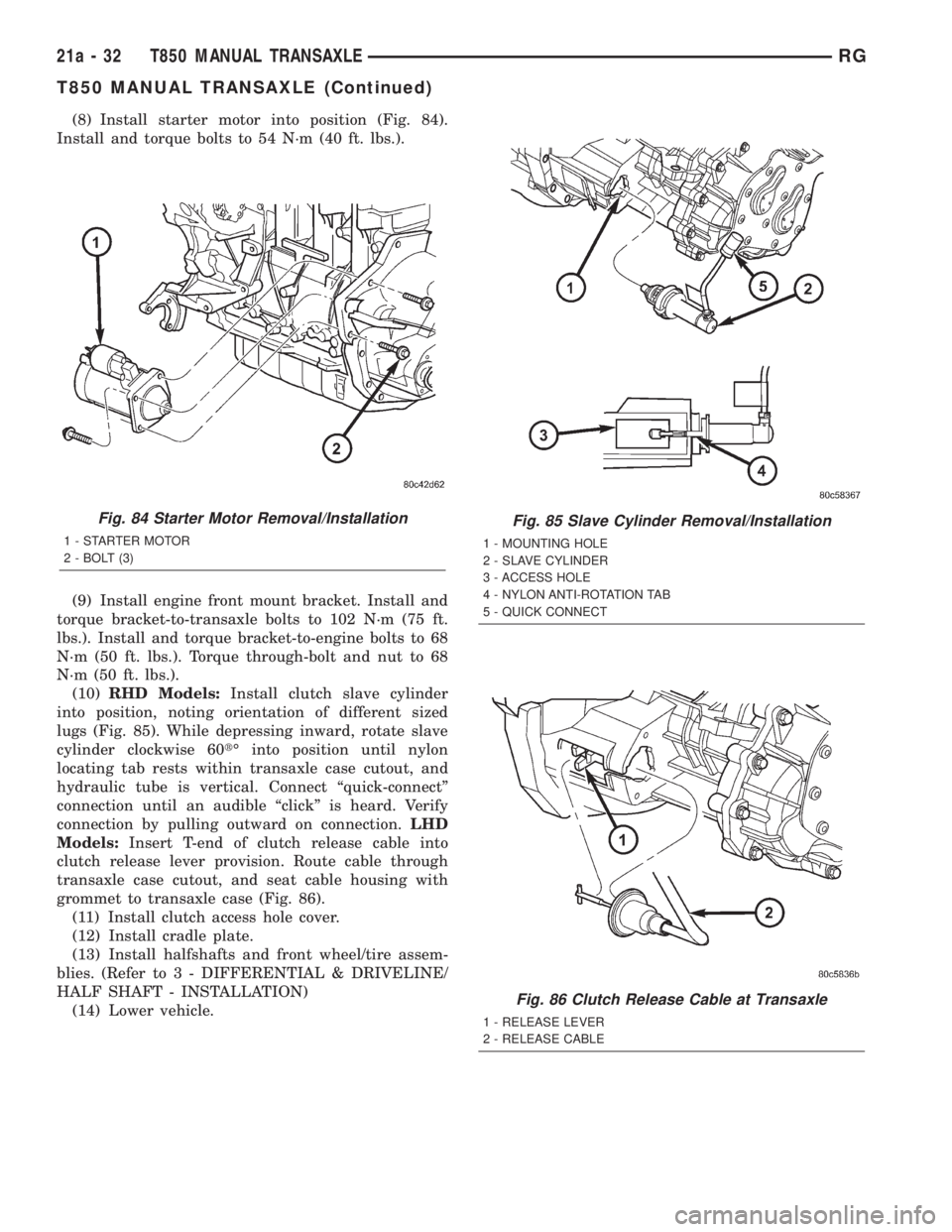

(8) Install starter motor into position (Fig. 84).

Install and torque bolts to 54 N´m (40 ft. lbs.).

(9) Install engine front mount bracket. Install and

torque bracket-to-transaxle bolts to 102 N´m (75 ft.

lbs.). Install and torque bracket-to-engine bolts to 68

N´m (50 ft. lbs.). Torque through-bolt and nut to 68

N´m (50 ft. lbs.).

(10)RHD Models:Install clutch slave cylinder

into position, noting orientation of different sized

lugs (Fig. 85). While depressing inward, rotate slave

cylinder clockwise 60tÉ into position until nylon

locating tab rests within transaxle case cutout, and

hydraulic tube is vertical. Connect ªquick-connectº

connection until an audible ªclickº is heard. Verify

connection by pulling outward on connection.LHD

Models:Insert T-end of clutch release cable into

clutch release lever provision. Route cable through

transaxle case cutout, and seat cable housing with

grommet to transaxle case (Fig. 86).

(11) Install clutch access hole cover.

(12) Install cradle plate.

(13) Install halfshafts and front wheel/tire assem-

blies. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

HALF SHAFT - INSTALLATION)

(14) Lower vehicle.

Fig. 84 Starter Motor Removal/Installation

1 - STARTER MOTOR

2 - BOLT (3)

Fig. 85 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 86 Clutch Release Cable at Transaxle

1 - RELEASE LEVER

2 - RELEASE CABLE

21a - 32 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3301 of 4284

(8) Install engine front mount bracket. Install and

torque bracket-to-transaxle bolts to 102 N´m (75 ft.

lbs.). Install and torque bracket-to-engine bolts to 68

N´m (50 ft. lbs.). Torque through-bolt and nut to 68

N´m (50 ft. lbs.).

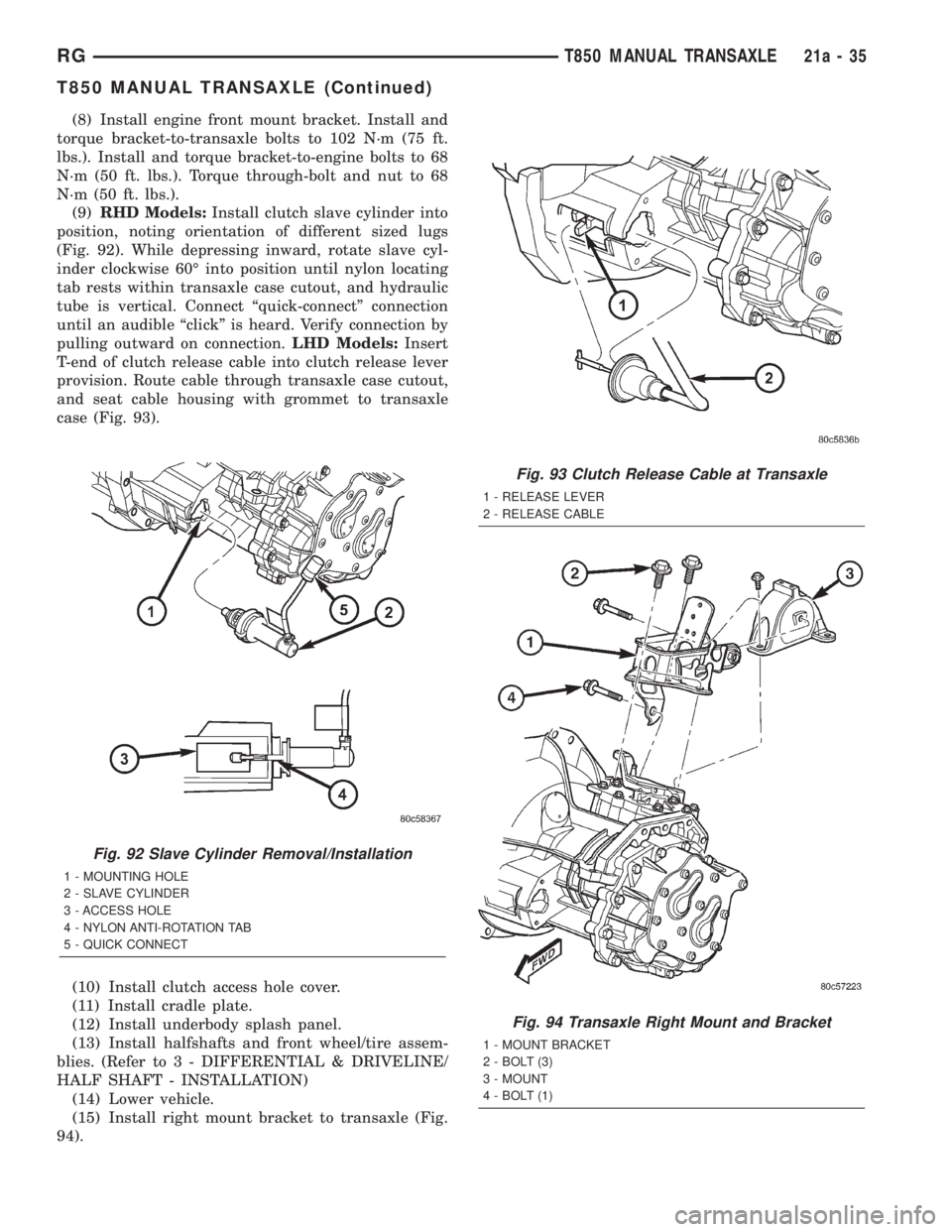

(9)RHD Models:Install clutch slave cylinder into

position, noting orientation of different sized lugs

(Fig. 92). While depressing inward, rotate slave cyl-

inder clockwise 60É into position until nylon locating

tab rests within transaxle case cutout, and hydraulic

tube is vertical. Connect ªquick-connectº connection

until an audible ªclickº is heard. Verify connection by

pulling outward on connection.LHD Models:Insert

T-end of clutch release cable into clutch release lever

provision. Route cable through transaxle case cutout,

and seat cable housing with grommet to transaxle

case (Fig. 93).

(10) Install clutch access hole cover.

(11) Install cradle plate.

(12) Install underbody splash panel.

(13) Install halfshafts and front wheel/tire assem-

blies. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

HALF SHAFT - INSTALLATION)

(14) Lower vehicle.

(15) Install right mount bracket to transaxle (Fig.

94).

Fig. 92 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 93 Clutch Release Cable at Transaxle

1 - RELEASE LEVER

2 - RELEASE CABLE

Fig. 94 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

RGT850 MANUAL TRANSAXLE21a-35

T850 MANUAL TRANSAXLE (Continued)

Page 3309 of 4284

BACK-UP LAMP SWITCH

REMOVAL

(1) Raise vehicle on hoist.

(2) Disconnect back-up lamp switch connector.

(3) Remove back-up lamp switch (Fig. 103).

INSTALLATION

(1) Install back-up lamp switch (Fig. 103) and

torque to 23 N´m (17 ft. lbs.).

(2) Connect back-up lamp switch connector.

(3) Lower vehicle.

DIFFERENTIAL

DESCRIPTION

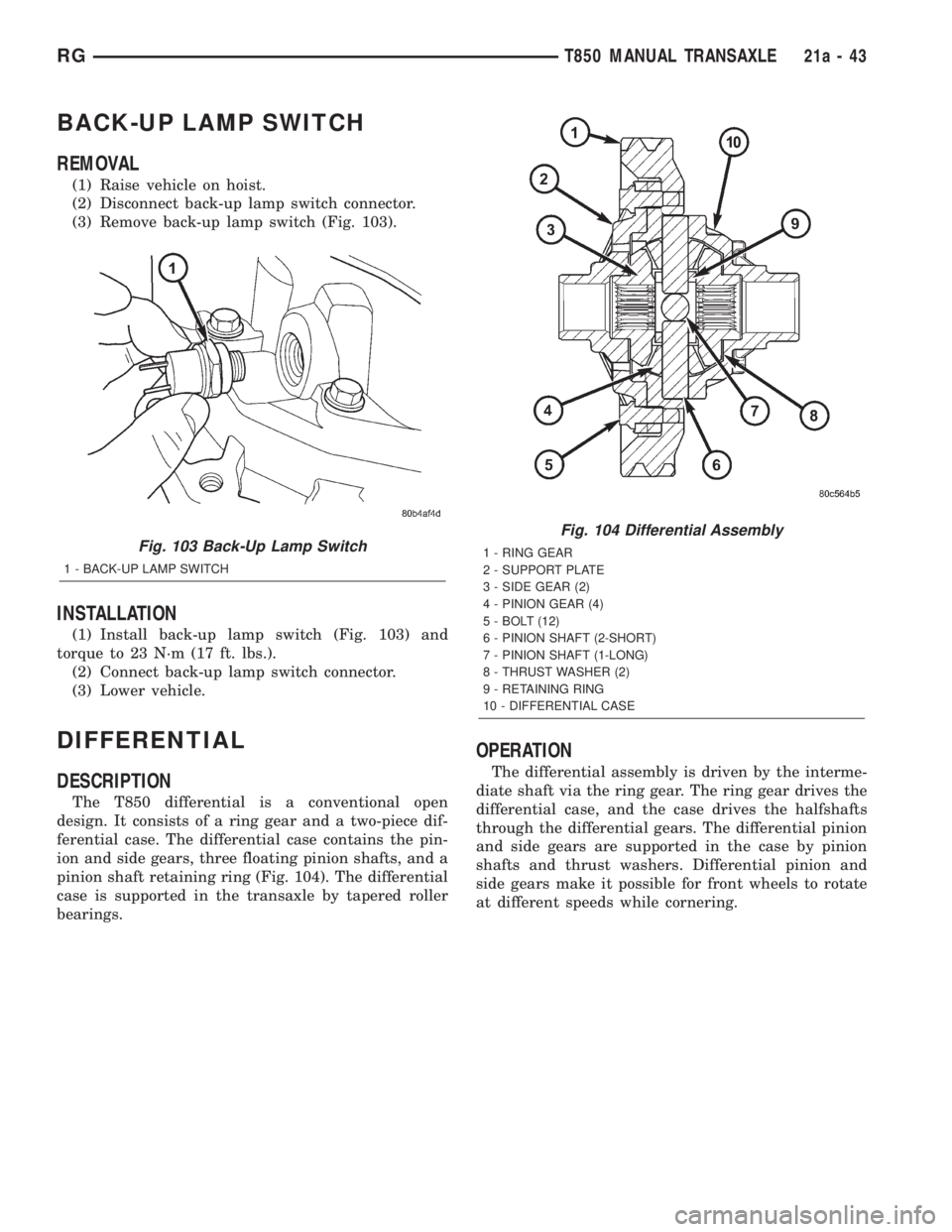

The T850 differential is a conventional open

design. It consists of a ring gear and a two-piece dif-

ferential case. The differential case contains the pin-

ion and side gears, three floating pinion shafts, and a

pinion shaft retaining ring (Fig. 104). The differential

case is supported in the transaxle by tapered roller

bearings.

OPERATION

The differential assembly is driven by the interme-

diate shaft via the ring gear. The ring gear drives the

differential case, and the case drives the halfshafts

through the differential gears. The differential pinion

and side gears are supported in the case by pinion

shafts and thrust washers. Differential pinion and

side gears make it possible for front wheels to rotate

at different speeds while cornering.

Fig. 103 Back-Up Lamp Switch

1 - BACK-UP LAMP SWITCH

Fig. 104 Differential Assembly

1 - RING GEAR

2 - SUPPORT PLATE

3 - SIDE GEAR (2)

4 - PINION GEAR (4)

5 - BOLT (12)

6 - PINION SHAFT (2-SHORT)

7 - PINION SHAFT (1-LONG)

8 - THRUST WASHER (2)

9 - RETAINING RING

10 - DIFFERENTIAL CASE

RGT850 MANUAL TRANSAXLE21a-43