four wheel drive CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 31 of 4284

mitted on the bus even though a module may not

require all information to perform its function. It

will only respond to messages ªaddressedº to it

through binary coding process. This method of data

transmission significantly reduces the complexity

of the wiring in the vehicle and the size of wiring

harnesses. All of the information about the func-

tioning of all the systems is organized, controlled,

and communicated by the PCI bus, which is de-

scribed in the Communication Section of this gen-

eral information.

3.1 AIRBAG SYSTEM/OCCUPANT

RESTRAINT CONTROLLER SYSTEM

The 2001 Minivan Airbag System contain the

following components: Occupant Restraint Control-

ler (ORC), Airbag Warning Indicator, Clockspring,

Driver and Passenger Airbags, Seat belt Tensioners

(SBT), Hall-effect Seat Belt Switches (SBS), Left

and Right Side Airbag Control Module (SIACM),

and Seat (mounted side) Airbags.

The Occupant Restraint Controller (ORC) is a

new type of Airbag Control Module (ACM) that

supports staged airbag deployment. Staged deploy-

ment is the ability to trigger airbag system squib

inflators all at once or individually as needed to

provide the appropriate restraint for the severity of

the impact. The ORC has four major functions: PCI

Bus communications, onboard diagnostics, impact

sensing, and component deployment. The ORC also

contains an energy-storage capacitor. This capaci-

tor stores enough electrical energy to deploy the

front airbag components for two seconds following a

battery disconnect or failure during an impact. The

ORC is secured to the floor panel transmission

tunnel below the instrument panel inside the vehi-

cle. The ORC cannot be repaired or adjusted and

must be replaced.

The ORC sends and/or receives PCI Bus mes-

sages with the Instrument Cluster (MIC), Body

Control Module (BCM), and Powertrain Control

Module (PCM). Diagnostic trouble codes will be set

if the communication with these modules is lost or

contains invalid information.

The microprocessor in the ORC monitors the

impact sensor signal and the airbag system electri-

cal circuits to determine the system readiness. The

ORC also monitors bus messages from both SIACM.

If the ORC detects a monitored system fault or

SIACM fault, it sends a message to the instrument

cluster via PCI bus to turn on the airbag warning

indicator. The ORC can set both active and stored

diagnostic trouble codes to aid in the diagnosing

system problems. See ORC/SIACM DIAGNOSTIC

TROUBLE CODES in this section.

The ORC has an internal accelerometer that

senses the rate of vehicle deceleration, which pro-vides verification of the direction and severity of an

impact. A pre-programmed decision algorithm in

the ORC microprocessor determines when the de-

celeration rate is severe enough to require airbag

system protection. The Occupant Restraint Control-

ler (ORC) also uses the driver and front passenger

seat belt switch status (buckled or unbuckled) as

inputs to determine the level of airbag deployment,

low, medium, or high as well as whether or not the

seat belt tensioners should deploy. The ORC also

uses the crash severity to determine the level of

driver and front passenger deployment, low me-

dium or high. When the programmed conditions are

met, the ORC sends an electrical signal to deploy

the appropriate airbag system components.WARNING: THE AIRBAG SYSTEM IS A

SENSITIVE, COMPLEX ELECTRO-

MECHANICAL UNIT. BEFORE ATTEMPTING

TO DIAGNOSE OR SERVICE ANY AIRBAG

SYSTEM OR RELATED STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENTS YOU MUST FIRST

DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE FURTHER SYSTEM

SERVICE. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIRBAG SYSTEM. FAILURE

TO DO THIS COULD RESULT IS ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. NEVER STRIKE OR

KICK THE AIRBAG CONTROL MODULE, AS

IT CAN DAMAGE THE IMPACT SENSOR OR

AFFECT ITS CALIBRATION. IF AN AIRBAG

CONTROL MODULE IS ACCIDENTALLY

DROPPED DURING SERVICE, THE MODULE

MUST BE SCRAPPED AND REPLACED WITH

A NEW UNIT.

The airbag warning lamp is the only point at

which the customer can observe symptoms of a

system malfunction. Whenever the ignition key is

turned to the run or start position, the MIC per-

forms a lamp check by turning the airbag warning

indicator on for 6-8 seconds. After the lamp check, if

the indicator turns on, it means that the ORC has

checked the system and found it to be free of

discernible malfunctions. If the lamp remains on,

there could be an active fault in the system or the

MIC lamp circuit may be internally shorted to

ground. If the lamp comes on and stays on for a

period longer than 6-8 seconds then goes off, there

is usually an intermittent problem in the system.

2

GENERAL INFORMATION

Page 37 of 4284

this type of system would only refer to this circuit.

A faulty speaker could not cause this DTC.

3.2.1 REMOTE RADIO CONTROLS

These radios can be controlled via remote radio

switches (optional). These switches are located on

the back side of the steering wheel. They control

mode, preset, seek up, seek down, volume up and

volume down functions.

These functions are inputs to the Body Control

Module and can be read with the DRBIIItunder

ªbody computerº. The switches are a multiplexed

signal to the BCM. The radio control MUX circuit is

a 5 volt line that is pulled to ground through

different value resistors built into the switches.

This causes a voltage drop to be seen by the BCM

and it sends a specific message to the radio on the

PCI Bus circuit. The radio then responses to the

message.

This circuit is fairly simple to troubleshoot. The

circuit must be complete from the switches in the

steering wheel to the BCM. The ground must be

complete so that the switches can cause the voltage

drop for the BCM to see. The circuit passes through

the clockspring so continuity through this devise

must be verified.

3.2.2 CD CHANGER

The new in-dash CD Changer is designed to fit

into the existing cubby bin in the center stack. This

new cartridge-less CD Changer is controlled by

your radio, and allows you to individually load up to

four discs at a time. However, due to its compact

design, the CD Changer can only carry out one

operation at a time. For example, you can not load

a new disc while playing another at the same time.

Each operation happens sequentially.

The radio unit installed with your system pro-

vides control over all features of the CD Changer

with the exception of the CD load and eject func-

tions, which are controlled by buttons located on the

front of the CD Changer. The radio also supplies the

power, ground, PCI Bus, left and right speaker

output thru a single DIN cable. All features you

would expect, such as Disc Up/Down, Track Up/

Down, Random and Scan are controlled by the

radio, which also displays all relevant CD Changer

information on the radio display.

The CD Changer contains a Load/Eject button

and an indicator light for each of the four disc

positions. The individual light indicates whether a

CD is currently loaded in that particular chamber of

the CD Changer. Pressing the individual Load/Eject

button for a particular chamber will eject a disc

currently present in that chamber. If the chamber iscurrently empty, actuating the Load/Eject button

will position that chamber to receive and load a new

disc in that chamber.

3.3 BODY CONTROL MODULE

The body control module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the module is interfaced to the

vehicle's serial bus communications network (PCI).

This network consists of the powertrain control

module (PCM), the engine control module (ECM) -

diesel only, the transmission control module (TCM),

the mechanical instrument cluster (MIC), the front

control module (FCM), the occupant restraint con-

troller (ORC), the compass/mini-trip (CMTC), the

electronic vehicle information center (EVIC), the

controller antilock brake (CAB), the HVAC control

module (ATC & MTC), the power sliding door (Left

& Right) modules (PSD), the power liftgate module

(PLG), the Audio system, the side impact airbag

control (left & right) modules (SIACM), the memory

seat/mirror module (MSMM), the RKE/thatcham

alarm module and the sentry key immobilizer mod-

ule (SKIM). The BCM is operational when battery

power is supplied to the module.

The body control module provides the following

features:

²Power Door Locks

²Automatic Door Lock

²Door Lock Inhibit

²Central Locking (with VTSS Only)

²Battery Protection

²The BCM will automatically turn off all exterior

lamps after 3 minutes and all interior lamps after

15 minutes after the ignition is turned off, if they

are not turned off by the driver.

²Chime

²Compass/Minitrip Support

²Interior Lighting (Courtesy/Reading Lamps)

²BCM Diagnostic Reporting

²Electronic Liftgate Release (with Power Door

Locks)

²Exterior Lighting

²Power Folding Mirrors

²Remote Radio Controls

²Headlamp Time Delay (with/without Autohead-

lamps)

²Automatic Headlamps (with electrochromatic

mirror)

²Illuminated Entry

²Fade to Off

8

GENERAL INFORMATION

Page 1159 of 4284

The cycling of the build and decay valves is

similar to the ABS except that they work to control

wheel spin by applying brakes. ABS function is to

control wheel skid by releasing brakes.

Two pressure relief valves allow excess fluid vol-

ume to return to the reservoir when not used by the

build/decay cycles. These are required because the

pump supplies more volume than the traction con-

trol system requires.

If at any time the brake pedal is applied during a

traction control cycle, the brake lamp switch will

trigger the CAB to switch off the traction control.

The traction control system will be enabled at

each ignition cycle. It may be turned off by depress-

ing the Traction Control Switch. The traction con-

trol system function lamp will illuminate ªTRAC

OFFº immediately upon depressing the traction

control switch button. Only the ªTRACº portion of

the ªTRAC OFFº indicator will illuminate during a

traction control event. If the CAB calculates that

the brake temperatures are high, the traction con-

trol system will become inoperative until a time-out

period has elapsed. When in this thermal protection

mode, the traction control ªTRAC OFFº lamp will

illuminate; however, a fault will not be registered.

3.3 SYSTEM COMPONENTS

²controller antilock brake (CAB)

²vacuum booster

²master cylinder

²ABS integrated electronic control module/

hydraulic control unit (HCU), valve block assem-

bly: 8 valve solenoids (4 inlet valves, 4 outlet

valves, 2 accumulators) 1 motor, 2 pump

²ABS integrated electronic control module with

traction control same as above but has 10 valve

solenoids.

²4 wheel speed sensor/tone wheel assemblies

²ABS warning indicator

²fuses and wiring harness

²fluid reservoir

²TRAC/TRAC OFF indicator

3.3.1 ABS AND BRAKE WARNING

INDICATORS

The amber ABS warning indicator is located in

the instrument cluster. It is used to inform the

driver that the antilock function has been turned

off. The ABS warning indicator is controlled by the

CAB. The CAB controls the lamp with a command

over the PCI bus.

The ABS Warning Indicator will remain lit during

every key cycle until a circuit or component fault is

repaired and the CAB no longer detects the fault.After repair of a sensor signal fault or a pump motor

fault, the CAB must sense all four wheels at 25

km/h (15 mph) before it will extinguish the ABS and

TRAC OFF Indicators.

The Instrument Cluster will illuminate the ABS

Warning Indicator if it loses communication with

the CAB.

The red BRAKE warning indicator is also located

in the instrument cluster. It can be activated in

several ways. Application of the parking brake or a

low fluid signal from the fluid level switch located in

the master cylinder reservoir will cause the indica-

tor to come on.

3.3.2 CONTROLLER ANTILOCK BRAKE

(CAB)

The Controller Antilock Brake (CAB) is a

microprocessor-based device that monitors wheel

speeds and controls the antilock functions. The

CAB contains two microprocessors that receive

identical sensor signals and then independently

process the information. The results are then com-

pared to make sure that they agree. Otherwise, the

CAB will turn off the antilock and turn on the ABS

amber warning indicator.

The primary functions of the CAB are to:

²detect wheel locking tendencies

²control fluid pressure modulation to the brakes

during antilock stop

²monitor the system for proper operation

²manage traction control functions

²provide communication to the DRBIIItwhile in

diagnostic mode

²store diagnostic information in non-volatile memory

The CAB continuously monitors the speed of each

wheel. When a wheel locking tendency is detected,

the CAB will command the appropriate valve to

modulate brake fluid pressure in its hydraulic unit.

Brake pedal position is maintained during an an-

tilock stop by being a closed system with the use of

2 accumulators. The CAB continues to control pres-

sure in individual hydraulic circuits until a wheel

locking tendency is no longer present. The CAB

turns on the pump motor during an antilock stop.

The antilock brake system is constantly moni-

tored by the CAB for proper operation. If the CAB

detects a system malfunction, it can disable the

antilock system and turn on the ABS warning

indicator. If the antilock function is disabled, the

system will revert to standard base brake system

operation.

The CAB inputs include the following:

²diagnostic communication

²four wheel speed sensors

2

GENERAL INFORMATION

Page 1160 of 4284

²three power feeds: valves, pump and microproces-

sor

²brake switch

²traction control switch

The CAB outputs include the following:

²ABS warning indicator actuation

²12 volts power to wheel speed sensors

²eight valves

²ten valves with traction control

²diagnostic communication

²PCI bus communication

²traction control lamp illumination

3.3.3 HYDRAULIC CONTROL UNIT

The hydraulic control unit (HCU) contains the

valve block assembly, two accumulators, and pump/

motor assembly. The HCU is attached to the CAB.

Valve Block Assembly:The valve block assem-

bly contains valves with four inlet valves and four

outlet valves. The inlet valves are spring-loaded in

the open position and the outlet valves are spring

loaded in the closed position. During an antilock

stop, these valves are cycled to maintain the proper

slip ratio for each wheel. If a wheel detects slip, the

inlet valve is closed to prevent and further pressure

increase. Then the outlet valve is opened to release

the pressure to the accumulators until the wheel is

no longer slipping. Once the wheel is no longer

slipping, the outlet valve is closed and the inlet

valve is opened to reapply pressure. If the wheel is

decelerating within its predetermined limits (prop-

er slip ratio), the inlet valve will close to hold the

pressure constant. On vehicles which are equipped

with a traction control system, there are two addi-

tional valves that isolate the master cylinder and

rear wheels. During a traction control event the

brakes are applied to reduce wheel slippage.

Pump Motor Assembly:The pump motor as-

sembly provides the extra amount of fluid needed

during antilock braking. The pump is supplied fluid

that is released to the accumulators when the outlet

valve is opened during an antilock stop. The pump

is also used to drain the accumulator circuits after

the antilock stop is complete. The pump is operated

by an integral electric motor. This DC-type motor is

controlled by the CAB. The CAB may turn on the

pump motor when an antilock stop is detected. The

pump continues to run during the antilock stop and

is turned off after the stop is complete. Under some

conditions, the pump motor will run to drain the

accumulators during the next drive off. The CAB

monitors the pump motor operation internally.

Accumulators:The accumulators provide tem-

porary fluid storage during an antilock stop and are

drained by the pump motor.

3.3.4 SWITCHES/SENSORS

Master Cylinder:The master cylinder is a stan-

dard tandem compensating port design for ABS and

non ABS systems. Traction control vehicles use a

dual center port master cylinder. For proper trac-

tion control operation the standard master cylinder

must not be used.

A fluid level switch is located in the master

cylinder fluid reservoir. The switch closes when a

low fluid level is detected. The fluid level switch

turns on the brake warning indicator by grounding

the indicator circuit. This switch does not disable

the ABS system.

Wheel Speed Sensors and Tone Wheels:One

active wheel speed sensor (WSS) is located at each

wheel and sends a small signal to the control

module (CAB). This signal is generated when a

toothed sensor ring (tone wheel) passes by a station-

ary wheel speed sensor. The CAB converts the

signals into digital signals for each wheel.

Because of internal circuitry, correct wheel speed

sensor function cannot be determined by a continu-

ity or resistance check through the sensor.

The front wheel speed sensor is attached to a boss

in the steering knuckle. The tone wheel is an

integral part of the front axle shaft. The rear speed

sensor is mounted though the bearing cover and the

rear tone wheel is an integral part of the rear

bearing hub. The wheel speed sensor air gap is not

adjustable. Refer to the service manual for wheel

speed sensor air gap and resistance specifications.

The four wheel speed sensors are serviced indi-

vidually. The front tone wheels are serviced as an

assembly with the outer constant velocity (C.V.)

joint housing. The rear tone wheels are serviced as

an assembly.

Correct antilock system operation is dependent

on tone wheel speed signals from the wheel speed

sensors. The vehicle's wheels and tires should all be

the same size and type to generate accurate signals.

In addition, the tires should be inflated to the

recommended pressure for optimum system opera-

tion. Variation in wheel and tire size or significant

variations in inflation pressure can produce inaccu-

rate wheel speed signals; however, the system will

continue to function when using the mini-spare.

3.3.5 SYSTEM INITIALIZATION

System initialization starts when the key is

turned to ªrunº. At this point, the CAB performs a

complete self-check of all electrical components in

the antilock systems.

Between 8-17 km/h (5-10 mph), a dynamic test is

performed. This will momentarily cycle the inlet

and outlet valves, check wheel speed sensor cir-

cuitry, and run the pump motor at 25 km/h (15

mph). The CAB will try to test the pump motor. If

3

GENERAL INFORMATION

Page 1520 of 4284

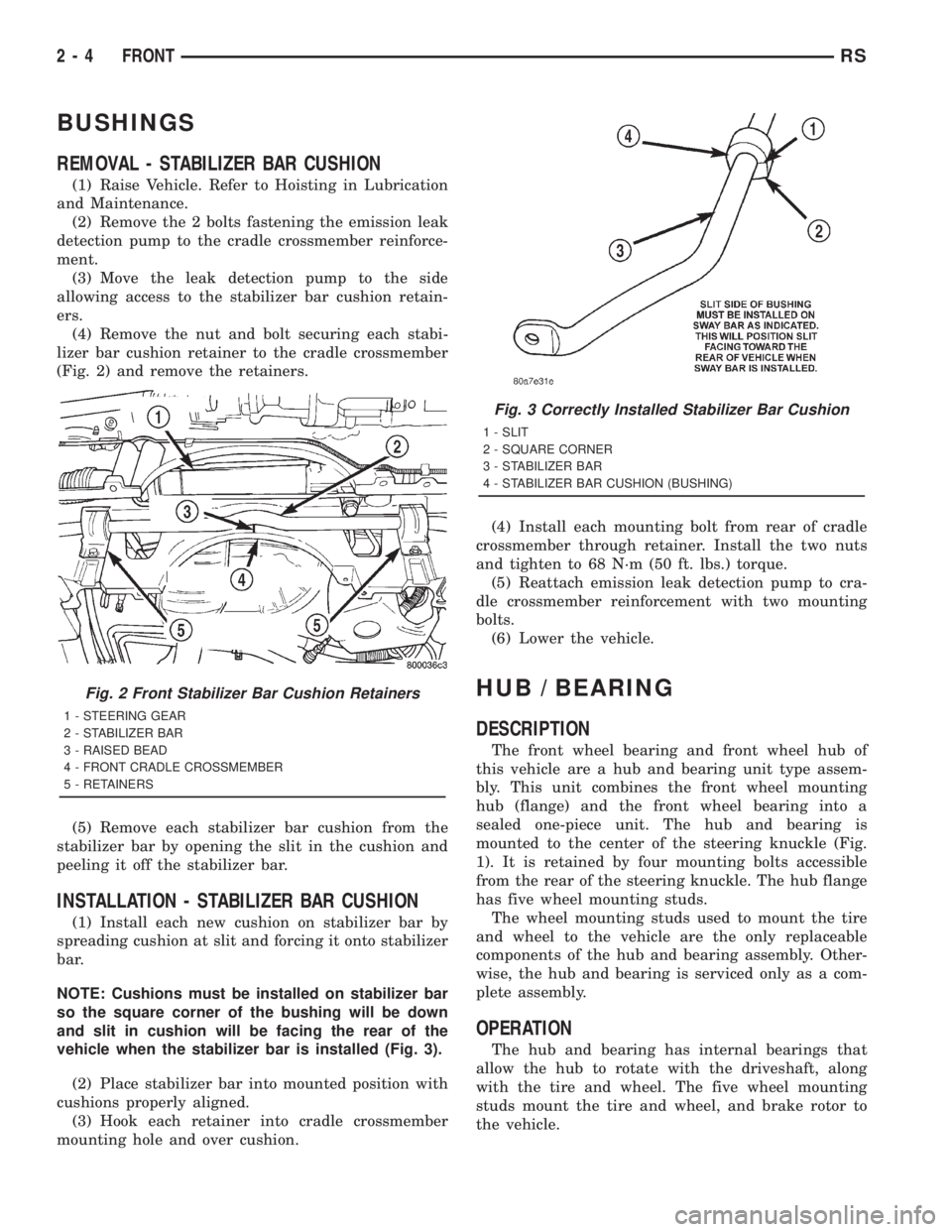

BUSHINGS

REMOVAL - STABILIZER BAR CUSHION

(1) Raise Vehicle. Refer to Hoisting in Lubrication

and Maintenance.

(2) Remove the 2 bolts fastening the emission leak

detection pump to the cradle crossmember reinforce-

ment.

(3) Move the leak detection pump to the side

allowing access to the stabilizer bar cushion retain-

ers.

(4) Remove the nut and bolt securing each stabi-

lizer bar cushion retainer to the cradle crossmember

(Fig. 2) and remove the retainers.

(5) Remove each stabilizer bar cushion from the

stabilizer bar by opening the slit in the cushion and

peeling it off the stabilizer bar.

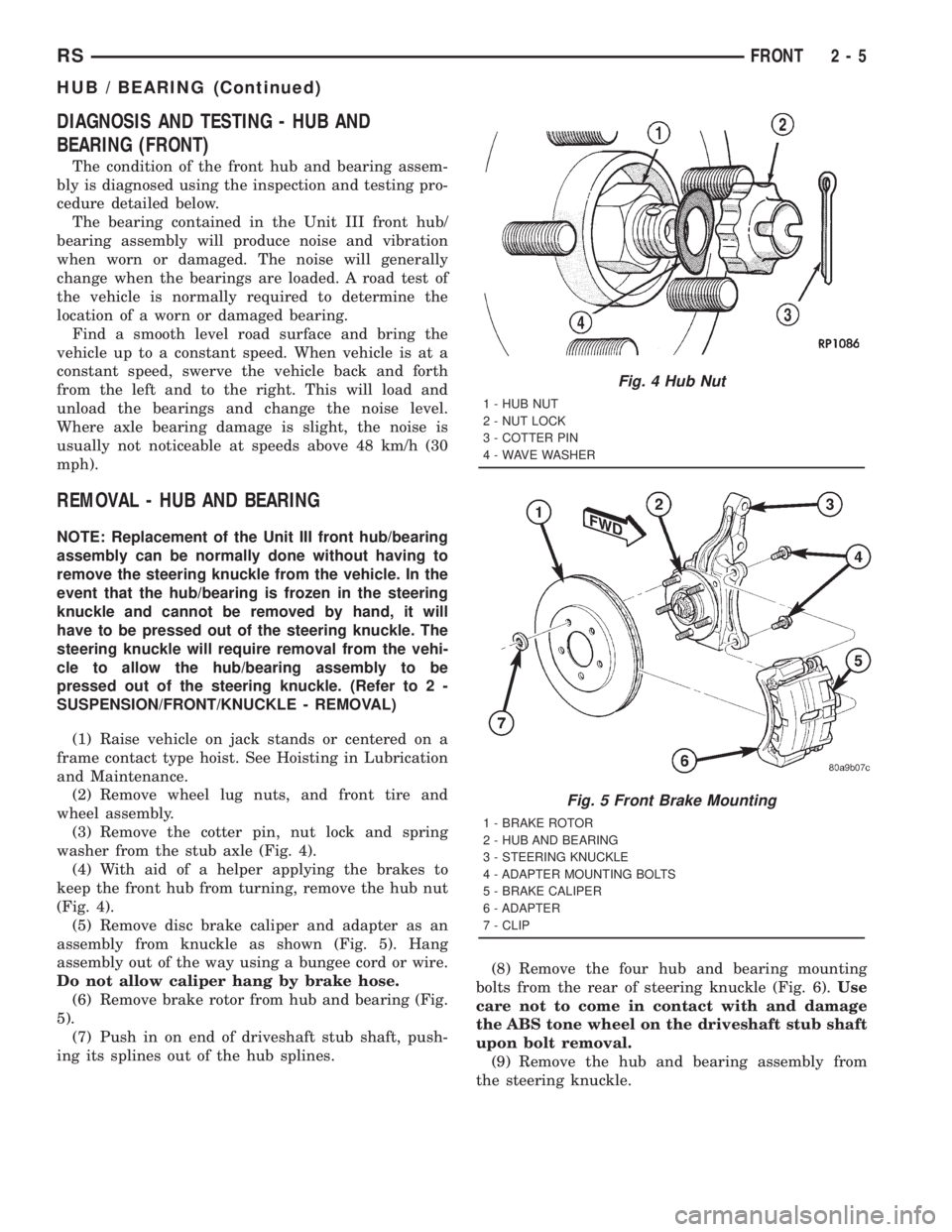

INSTALLATION - STABILIZER BAR CUSHION

(1) Install each new cushion on stabilizer bar by

spreading cushion at slit and forcing it onto stabilizer

bar.

NOTE: Cushions must be installed on stabilizer bar

so the square corner of the bushing will be down

and slit in cushion will be facing the rear of the

vehicle when the stabilizer bar is installed (Fig. 3).

(2) Place stabilizer bar into mounted position with

cushions properly aligned.

(3) Hook each retainer into cradle crossmember

mounting hole and over cushion.(4) Install each mounting bolt from rear of cradle

crossmember through retainer. Install the two nuts

and tighten to 68 N´m (50 ft. lbs.) torque.

(5) Reattach emission leak detection pump to cra-

dle crossmember reinforcement with two mounting

bolts.

(6) Lower the vehicle.

HUB / BEARING

DESCRIPTION

The front wheel bearing and front wheel hub of

this vehicle are a hub and bearing unit type assem-

bly. This unit combines the front wheel mounting

hub (flange) and the front wheel bearing into a

sealed one-piece unit. The hub and bearing is

mounted to the center of the steering knuckle (Fig.

1). It is retained by four mounting bolts accessible

from the rear of the steering knuckle. The hub flange

has five wheel mounting studs.

The wheel mounting studs used to mount the tire

and wheel to the vehicle are the only replaceable

components of the hub and bearing assembly. Other-

wise, the hub and bearing is serviced only as a com-

plete assembly.

OPERATION

The hub and bearing has internal bearings that

allow the hub to rotate with the driveshaft, along

with the tire and wheel. The five wheel mounting

studs mount the tire and wheel, and brake rotor to

the vehicle.

Fig. 2 Front Stabilizer Bar Cushion Retainers

1 - STEERING GEAR

2 - STABILIZER BAR

3 - RAISED BEAD

4 - FRONT CRADLE CROSSMEMBER

5 - RETAINERS

Fig. 3 Correctly Installed Stabilizer Bar Cushion

1 - SLIT

2 - SQUARE CORNER

3 - STABILIZER BAR

4 - STABILIZER BAR CUSHION (BUSHING)

2 - 4 FRONTRS

Page 1521 of 4284

DIAGNOSIS AND TESTING - HUB AND

BEARING (FRONT)

The condition of the front hub and bearing assem-

bly is diagnosed using the inspection and testing pro-

cedure detailed below.

The bearing contained in the Unit III front hub/

bearing assembly will produce noise and vibration

when worn or damaged. The noise will generally

change when the bearings are loaded. A road test of

the vehicle is normally required to determine the

location of a worn or damaged bearing.

Find a smooth level road surface and bring the

vehicle up to a constant speed. When vehicle is at a

constant speed, swerve the vehicle back and forth

from the left and to the right. This will load and

unload the bearings and change the noise level.

Where axle bearing damage is slight, the noise is

usually not noticeable at speeds above 48 km/h (30

mph).

REMOVAL - HUB AND BEARING

NOTE: Replacement of the Unit III front hub/bearing

assembly can be normally done without having to

remove the steering knuckle from the vehicle. In the

event that the hub/bearing is frozen in the steering

knuckle and cannot be removed by hand, it will

have to be pressed out of the steering knuckle. The

steering knuckle will require removal from the vehi-

cle to allow the hub/bearing assembly to be

pressed out of the steering knuckle. (Refer to 2 -

SUSPENSION/FRONT/KNUCKLE - REMOVAL)

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in Lubrication

and Maintenance.

(2) Remove wheel lug nuts, and front tire and

wheel assembly.

(3) Remove the cotter pin, nut lock and spring

washer from the stub axle (Fig. 4).

(4) With aid of a helper applying the brakes to

keep the front hub from turning, remove the hub nut

(Fig. 4).

(5) Remove disc brake caliper and adapter as an

assembly from knuckle as shown (Fig. 5). Hang

assembly out of the way using a bungee cord or wire.

Do not allow caliper hang by brake hose.

(6) Remove brake rotor from hub and bearing (Fig.

5).

(7) Push in on end of driveshaft stub shaft, push-

ing its splines out of the hub splines.(8) Remove the four hub and bearing mounting

bolts from the rear of steering knuckle (Fig. 6).Use

care not to come in contact with and damage

the ABS tone wheel on the driveshaft stub shaft

upon bolt removal.

(9) Remove the hub and bearing assembly from

the steering knuckle.

Fig. 4 Hub Nut

1 - HUB NUT

2 - NUT LOCK

3 - COTTER PIN

4 - WAVE WASHER

Fig. 5 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

RSFRONT2-5

HUB / BEARING (Continued)

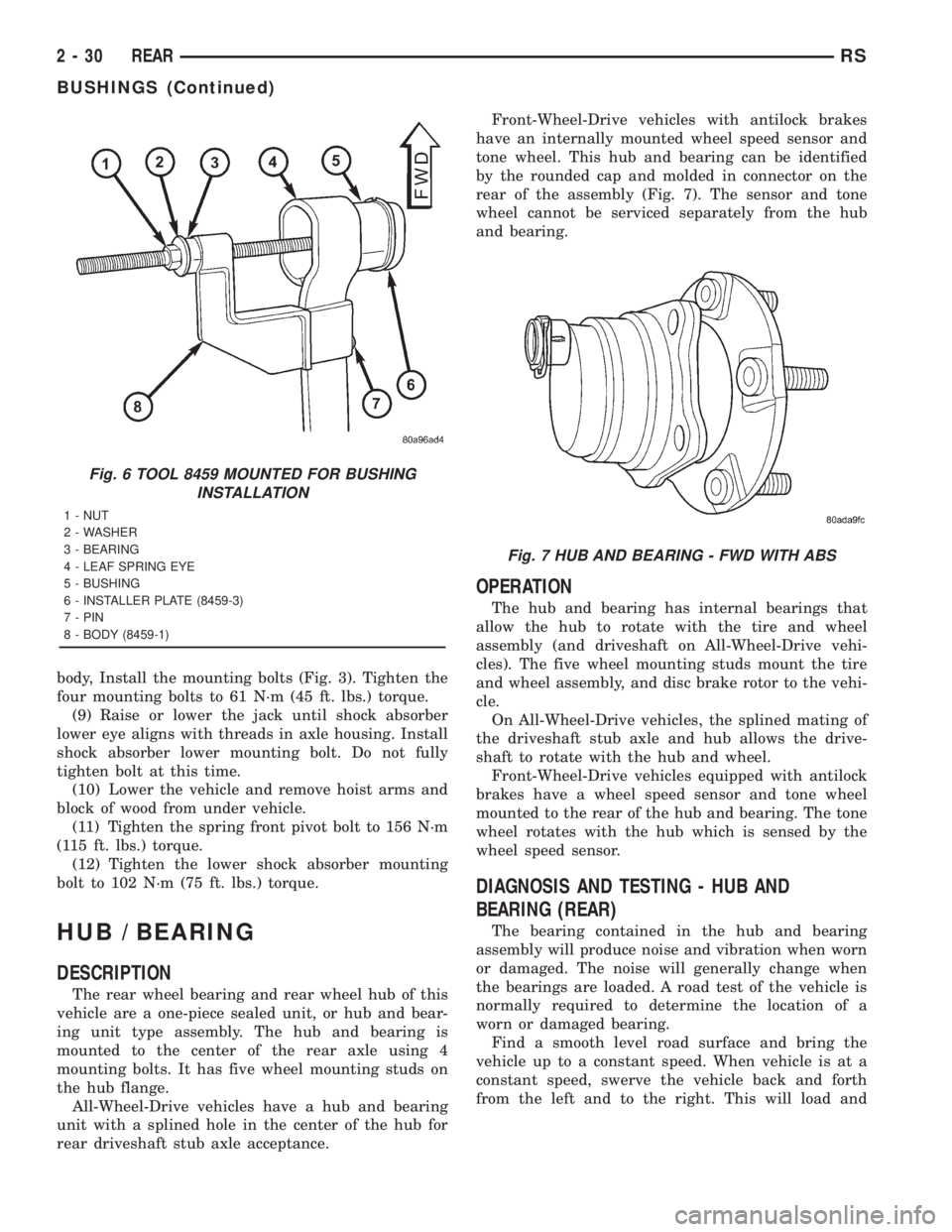

Page 1546 of 4284

body, Install the mounting bolts (Fig. 3). Tighten the

four mounting bolts to 61 N´m (45 ft. lbs.) torque.

(9) Raise or lower the jack until shock absorber

lower eye aligns with threads in axle housing. Install

shock absorber lower mounting bolt. Do not fully

tighten bolt at this time.

(10) Lower the vehicle and remove hoist arms and

block of wood from under vehicle.

(11) Tighten the spring front pivot bolt to 156 N´m

(115 ft. lbs.) torque.

(12) Tighten the lower shock absorber mounting

bolt to 102 N´m (75 ft. lbs.) torque.

HUB / BEARING

DESCRIPTION

The rear wheel bearing and rear wheel hub of this

vehicle are a one-piece sealed unit, or hub and bear-

ing unit type assembly. The hub and bearing is

mounted to the center of the rear axle using 4

mounting bolts. It has five wheel mounting studs on

the hub flange.

All-Wheel-Drive vehicles have a hub and bearing

unit with a splined hole in the center of the hub for

rear driveshaft stub axle acceptance.Front-Wheel-Drive vehicles with antilock brakes

have an internally mounted wheel speed sensor and

tone wheel. This hub and bearing can be identified

by the rounded cap and molded in connector on the

rear of the assembly (Fig. 7). The sensor and tone

wheel cannot be serviced separately from the hub

and bearing.

OPERATION

The hub and bearing has internal bearings that

allow the hub to rotate with the tire and wheel

assembly (and driveshaft on All-Wheel-Drive vehi-

cles). The five wheel mounting studs mount the tire

and wheel assembly, and disc brake rotor to the vehi-

cle.

On All-Wheel-Drive vehicles, the splined mating of

the driveshaft stub axle and hub allows the drive-

shaft to rotate with the hub and wheel.

Front-Wheel-Drive vehicles equipped with antilock

brakes have a wheel speed sensor and tone wheel

mounted to the rear of the hub and bearing. The tone

wheel rotates with the hub which is sensed by the

wheel speed sensor.

DIAGNOSIS AND TESTING - HUB AND

BEARING (REAR)

The bearing contained in the hub and bearing

assembly will produce noise and vibration when worn

or damaged. The noise will generally change when

the bearings are loaded. A road test of the vehicle is

normally required to determine the location of a

worn or damaged bearing.

Find a smooth level road surface and bring the

vehicle up to a constant speed. When vehicle is at a

constant speed, swerve the vehicle back and forth

from the left and to the right. This will load and

Fig. 6 TOOL 8459 MOUNTED FOR BUSHING

INSTALLATION

1 - NUT

2 - WASHER

3 - BEARING

4 - LEAF SPRING EYE

5 - BUSHING

6 - INSTALLER PLATE (8459-3)

7 - PIN

8 - BODY (8459-1)

Fig. 7 HUB AND BEARING - FWD WITH ABS

2 - 30 REARRS

BUSHINGS (Continued)

Page 1560 of 4284

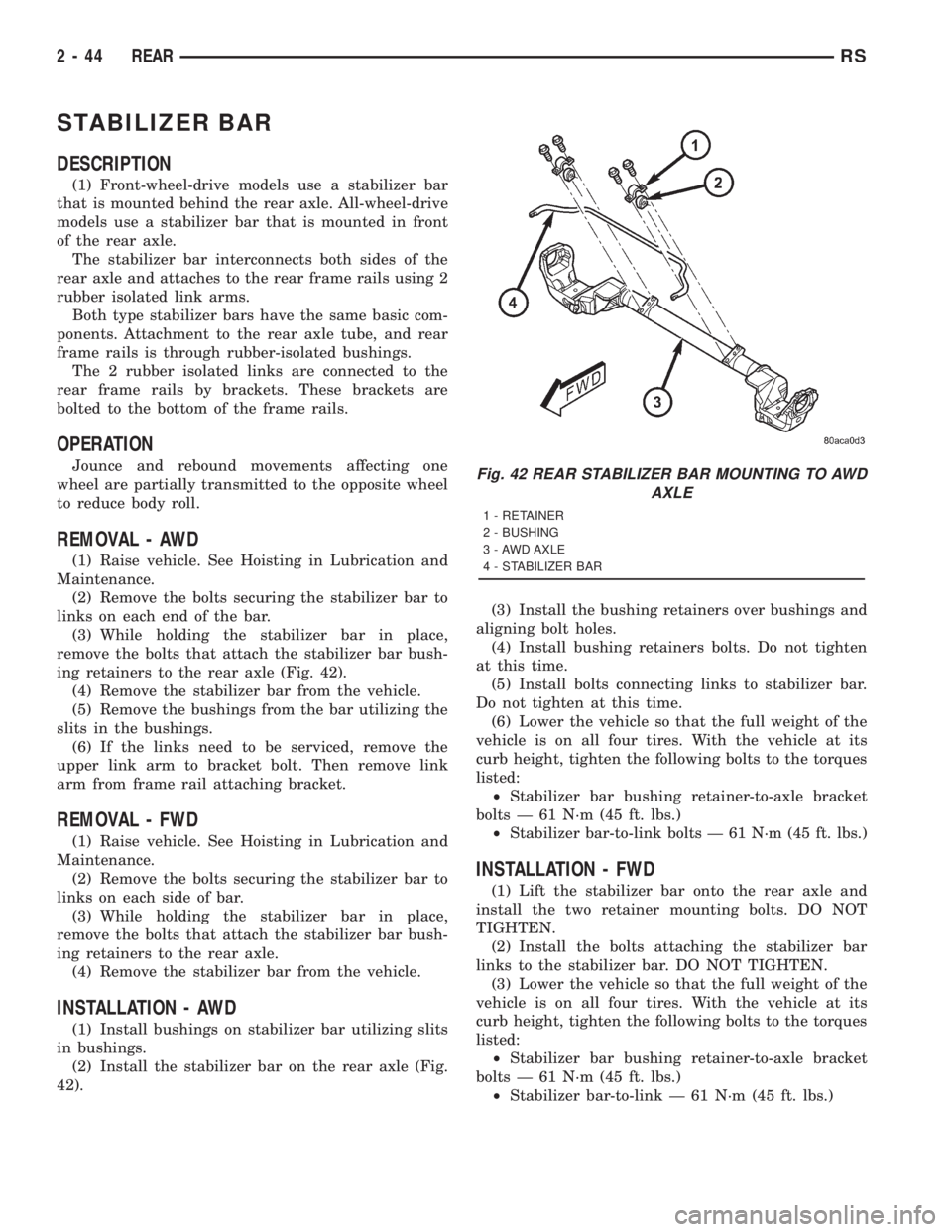

STABILIZER BAR

DESCRIPTION

(1) Front-wheel-drive models use a stabilizer bar

that is mounted behind the rear axle. All-wheel-drive

models use a stabilizer bar that is mounted in front

of the rear axle.

The stabilizer bar interconnects both sides of the

rear axle and attaches to the rear frame rails using 2

rubber isolated link arms.

Both type stabilizer bars have the same basic com-

ponents. Attachment to the rear axle tube, and rear

frame rails is through rubber-isolated bushings.

The 2 rubber isolated links are connected to the

rear frame rails by brackets. These brackets are

bolted to the bottom of the frame rails.

OPERATION

Jounce and rebound movements affecting one

wheel are partially transmitted to the opposite wheel

to reduce body roll.

REMOVAL - AWD

(1) Raise vehicle. See Hoisting in Lubrication and

Maintenance.

(2) Remove the bolts securing the stabilizer bar to

links on each end of the bar.

(3) While holding the stabilizer bar in place,

remove the bolts that attach the stabilizer bar bush-

ing retainers to the rear axle (Fig. 42).

(4) Remove the stabilizer bar from the vehicle.

(5) Remove the bushings from the bar utilizing the

slits in the bushings.

(6) If the links need to be serviced, remove the

upper link arm to bracket bolt. Then remove link

arm from frame rail attaching bracket.

REMOVAL - FWD

(1) Raise vehicle. See Hoisting in Lubrication and

Maintenance.

(2) Remove the bolts securing the stabilizer bar to

links on each side of bar.

(3) While holding the stabilizer bar in place,

remove the bolts that attach the stabilizer bar bush-

ing retainers to the rear axle.

(4) Remove the stabilizer bar from the vehicle.

INSTALLATION - AWD

(1) Install bushings on stabilizer bar utilizing slits

in bushings.

(2) Install the stabilizer bar on the rear axle (Fig.

42).(3) Install the bushing retainers over bushings and

aligning bolt holes.

(4) Install bushing retainers bolts. Do not tighten

at this time.

(5) Install bolts connecting links to stabilizer bar.

Do not tighten at this time.

(6) Lower the vehicle so that the full weight of the

vehicle is on all four tires. With the vehicle at its

curb height, tighten the following bolts to the torques

listed:

²Stabilizer bar bushing retainer-to-axle bracket

bolts Ð 61 N´m (45 ft. lbs.)

²Stabilizer bar-to-link bolts Ð 61 N´m (45 ft. lbs.)

INSTALLATION - FWD

(1) Lift the stabilizer bar onto the rear axle and

install the two retainer mounting bolts. DO NOT

TIGHTEN.

(2) Install the bolts attaching the stabilizer bar

links to the stabilizer bar. DO NOT TIGHTEN.

(3) Lower the vehicle so that the full weight of the

vehicle is on all four tires. With the vehicle at its

curb height, tighten the following bolts to the torques

listed:

²Stabilizer bar bushing retainer-to-axle bracket

bolts Ð 61 N´m (45 ft. lbs.)

²Stabilizer bar-to-link Ð 61 N´m (45 ft. lbs.)

Fig. 42 REAR STABILIZER BAR MOUNTING TO AWD

AXLE

1 - RETAINER

2 - BUSHING

3 - AWD AXLE

4 - STABILIZER BAR

2 - 44 REARRS

Page 1567 of 4284

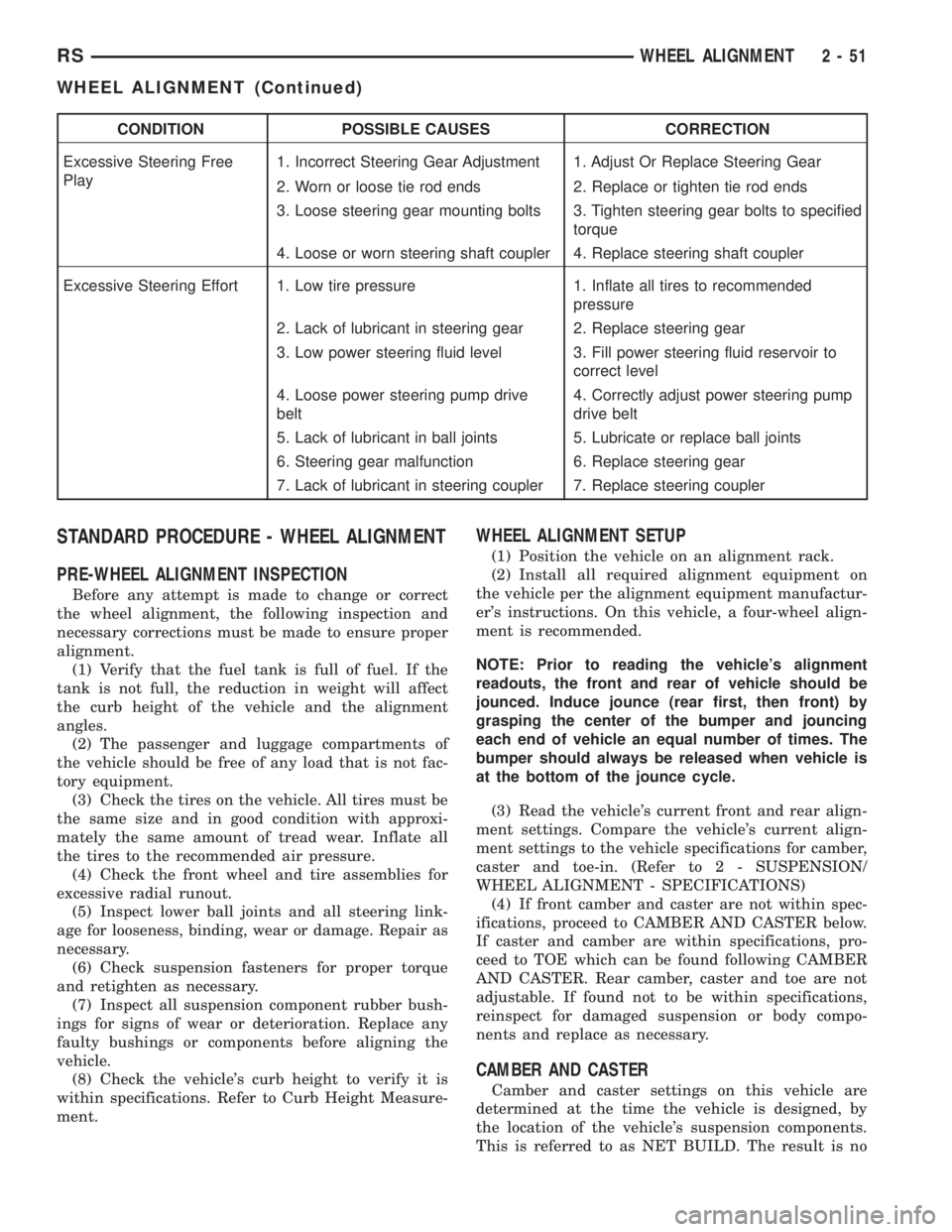

CONDITION POSSIBLE CAUSES CORRECTION

Excessive Steering Free

Play1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn or loose tie rod ends 2. Replace or tighten tie rod ends

3. Loose steering gear mounting bolts 3. Tighten steering gear bolts to specified

torque

4. Loose or worn steering shaft coupler 4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Lack of lubricant in steering gear 2. Replace steering gear

3. Low power steering fluid level 3. Fill power steering fluid reservoir to

correct level

4. Loose power steering pump drive

belt4. Correctly adjust power steering pump

drive belt

5. Lack of lubricant in ball joints 5. Lubricate or replace ball joints

6. Steering gear malfunction 6. Replace steering gear

7. Lack of lubricant in steering coupler 7. Replace steering coupler

STANDARD PROCEDURE - WHEEL ALIGNMENT

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment, the following inspection and

necessary corrections must be made to ensure proper

alignment.

(1) Verify that the fuel tank is full of fuel. If the

tank is not full, the reduction in weight will affect

the curb height of the vehicle and the alignment

angles.

(2) The passenger and luggage compartments of

the vehicle should be free of any load that is not fac-

tory equipment.

(3) Check the tires on the vehicle. All tires must be

the same size and in good condition with approxi-

mately the same amount of tread wear. Inflate all

the tires to the recommended air pressure.

(4) Check the front wheel and tire assemblies for

excessive radial runout.

(5) Inspect lower ball joints and all steering link-

age for looseness, binding, wear or damage. Repair as

necessary.

(6) Check suspension fasteners for proper torque

and retighten as necessary.

(7) Inspect all suspension component rubber bush-

ings for signs of wear or deterioration. Replace any

faulty bushings or components before aligning the

vehicle.

(8) Check the vehicle's curb height to verify it is

within specifications. Refer to Curb Height Measure-

ment.

WHEEL ALIGNMENT SETUP

(1) Position the vehicle on an alignment rack.

(2) Install all required alignment equipment on

the vehicle per the alignment equipment manufactur-

er's instructions. On this vehicle, a four-wheel align-

ment is recommended.

NOTE: Prior to reading the vehicle's alignment

readouts, the front and rear of vehicle should be

jounced. Induce jounce (rear first, then front) by

grasping the center of the bumper and jouncing

each end of vehicle an equal number of times. The

bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Read the vehicle's current front and rear align-

ment settings. Compare the vehicle's current align-

ment settings to the vehicle specifications for camber,

caster and toe-in. (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - SPECIFICATIONS)

(4) If front camber and caster are not within spec-

ifications, proceed to CAMBER AND CASTER below.

If caster and camber are within specifications, pro-

ceed to TOE which can be found following CAMBER

AND CASTER. Rear camber, caster and toe are not

adjustable. If found not to be within specifications,

reinspect for damaged suspension or body compo-

nents and replace as necessary.

CAMBER AND CASTER

Camber and caster settings on this vehicle are

determined at the time the vehicle is designed, by

the location of the vehicle's suspension components.

This is referred to as NET BUILD. The result is no

RSWHEEL ALIGNMENT2-51

WHEEL ALIGNMENT (Continued)

Page 1602 of 4284

REAR DRIVELINE MODULE

TABLE OF CONTENTS

page page

REAR DRIVELINE MODULE

DESCRIPTION...........................26

OPERATION.............................26

DIAGNOSIS AND TESTING.................27

REAR DRIVELINE MODULE NOISE.........27

REAR DRIVELINE MODULE OPERATION....29

REMOVAL..............................29

DISASSEMBLY...........................30

ASSEMBLY.............................32

INSTALLATION...........................36

SPECIFICATIONS........................37

SPECIAL TOOLS.........................37

BI-DIRECTIONAL OVERRUNNING CLUTCH

DESCRIPTION...........................37

OPERATION.............................38

DIFFERENTIAL ASSEMBLY

DESCRIPTION...........................43

OPERATION.............................43FLUID - DIFFERENTIAL ASSEMBLY

STANDARD PROCEDURE..................44

DIFFERENTIAL ASSEMBLY FLUID CHANGE . . 44

FLUID

STANDARD PROCEDURE..................44

OVERRUNNING CLUTCH HOUSING FLUID

CHANGE..............................44

VISCOUS COUPLER

DESCRIPTION...........................45

OPERATION.............................45

TORQUE ARM

REMOVAL..............................47

INSTALLATION...........................47

INPUT FLANGE SEAL

REMOVAL..............................47

INSTALLATION...........................47

OUTPUT FLANGE SEAL

REMOVAL..............................49

INSTALLATION...........................50

REAR DRIVELINE MODULE

DESCRIPTION

The rear driveline module assembly (Fig. 1) con-

sists of four main components:

²Bi-Directional Overrunning Clutch (BOC)

²Viscous Coupling

²Differential Assembly

²Torque Arm

The viscous coupling and bi-directional overrun-

ning clutch are contained within an overrunning

clutch housing, which fastens to the differential

assembly. The overrunning clutch housing and differ-

ential assembly have unique fluid sumps, each

requiring their own type and capacity of fluid. The

overrunning clutch housing requires MopartATF+4

(Automatic Transmission FluidÐType 9602) or equiv-

alent. The differential assembly requires

Driveline module service is limited to the following

components:

²Differential Assembly (serviced only as assem-

bly)

²Viscous Coupling

²Bi-Directional Overrunning Clutch (BOC)

²Overrunning Clutch Housing

²Seals (Input Flange, Output Flange, Overrun-

ning Clutch Housing O-rings)

²Input Flange/Shield²Torque Arm

²Vents

²FastenersOPERATION

The primary benefits of All Wheel Drive are:

²Superior straight line acceleration, and corner-

ing on all surfaces

²Better traction and handling under adverse con-

ditions, resulting in improved hill climbing ability

and safer driving.

The heart of the system is an inter-axle viscous

coupling. The vehicle retains predominantly front-

wheel drive characteristics, but the All Wheel Drive

capability takes effect when the front wheels start to

slip. Under normal level road, straight line driving,

100% of the torque is allocated to the front wheels.

The viscous coupling controls and distributes torque/

power to the rear wheels. The viscous coupling trans-

mits torque to the rear wheels in proportion of the

amount of the slippage at the front wheels. Thais

variable torque distribution is automatic with no

driver inputs required. The coupling is similar to a

multi-plate clutch. It consists of a series of closely

spaced discs, which are alternately connected to the

front and rear drive units. The unit is totally sealed

and partially filled with silicone fluid. There is no

3 - 26 REAR DRIVELINE MODULERS