wheel CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2931 of 4284

CONDITION POSSIBLE CAUSES CORRECTION

3. Lack of lubrication causing binding

in front lower control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated for life type of ball joint, then

inspect ball joint for wear, replace lower

control arm as necessary. If ball joint is a

lubricated for life ball joint, replace lower

control arm ball joint.

4. Steering column coupling joints

misaligned.4. Realign steering column coupling joints.

5. Steering wheel rubbing.** 5. Adjust steering column shrouds to

eliminate rubbing condition.

6. Damaged, mis-positioned or

un-lubricated steering column

coupler to dash seal.**6. Replace, reposition, or lubricate dash

seal.

7. Binding pivot bearing in front strut

assembly.7. Replace pivot bearing in front strut

assembly.

8. Binding shaft bearing in steering

column.8. Replace the steering column.

9. Excessive friction in steering

column coupling.9. Replace steering column coupling.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

EXCESSIVE STEERING

WHEEL KICKBACK OR

TOO MUCH STEERING

WHEEL FREE PLAY.1. Air in the fluid of the power

steering system.1. Bleed air from system following the the

power steering pump initial operation

service procedure.*

2. Power steering gear loose on

cradle/crossmember.2. Inspect power steering gear mounting

bolts. Replace as necessary. Tighten to the

specified torque.

3. Steering column coupling or

intermediate shaft worn, broken or

loose.3. Replace steering column coupling or

intermediate shaft.

4. Free play in steering column. 4. Check all components of the steering

column and repair or replace as required.

5. Worn lower control arm ball joints. 5. Replace lower control arm ball joints as

required.

6. Loose steering knuckle-to-ball joint

stud pinch bolt.6. Inspect pinch bolt, replace as necessary,

and tighten to specified torque.

7. Front wheel bearing loose or

worn.7. Replace hub and bearing as necessary.

8. Loose outer tie rod end. 8. Replace outer tie rod end that has

excessive free play.

9. Loose inner tie rod. 9. Replace power steering gear.

10. Defective steering gear rotary

valve.10. Replace power steering gear.

NOTE: * Steering shudder can be expected in new

vehicles and vehicles with recent steering systemrepairs. Shudder should dissipate after the vehicle

has been driven several weeks.

RSSTEERING19-7

STEERING (Continued)

Page 2932 of 4284

NOTE: ** To evaluate this condition, it may be nec-

essary to disconnect the coupling at the base of the

steering column. Turn the steering wheel and feel or

listen for internal rubbing in steering column. To

avoid damaging the column clockspring, note the

following. Before disconnecting coupling, place

tires in the straight-ahead position and center steer-

ing wheel. Once disconnected, DO NOT rotatesteering wheel more than one revolution in either

direction and place steering wheel in original loca-

tion before reconnecting coupling. If this position is

lost, the steering column clockspring must be

recentered following the procedure found within the

procedure for steering column installation in the

steering column section.

POWER STEERING FLUID

CONDITION POSSIBLE CAUSES CORRECTION

LOW FLUID LEVEL WITH

VISIBLE LEAK.1. Loose power steering hose

fittings.1. Tighten the fitting to its specified torque.

2. Damaged or missing fitting seal,

gasket, or O-ring.2. Replace as necessary.

3. Power steering pump or power

steering gear leaking.3. Repair or replace the leaking component

as required.

AERATED FLUID. 1. Low fluid level.* 1. Fill power steering fluid reservoir to

proper level.

2. Air leak between power steering

fluid reservoir and pump.2. Inspect for proper sealing. Replace the

power steering pump (with reservoir).

3. Cracked power steering pump

housing.3. Replace the power steering pump.

RESERVOIR FLUID

OVERFLOW AND FLUID

THAT IS MILKY IN COLOR1. Water contamination. 1. Drain the power steering fluid from the

system. Flush the system with fresh clean

power steering fluid, drain, then refill to the

proper level.

NOTE: * Extremely cold temperatures may cause

power steering fluid aeration if the power steering

fluid level is low.

19 - 8 STEERINGRS

STEERING (Continued)

Page 2934 of 4284

COLUMN

TABLE OF CONTENTS

page page

COLUMN

DESCRIPTION...........................10

WARNING..............................10

DIAGNOSIS AND TESTING.................12

STEERING COLUMN....................12

REMOVAL..............................12

INSTALLATION...........................13

SPECIFICATIONS........................14

KEY/LOCK CYLINDER

DESCRIPTION...........................14OPERATION.............................14

REMOVAL..............................14

INSTALLATION...........................14

GEAR SHIFT LEVER

REMOVAL..............................15

INSTALLATION...........................15

SHROUD

REMOVAL..............................16

INSTALLATION...........................16

COLUMN

DESCRIPTION - STEERING COLUMN

The steering column has been designed to be ser-

viced as a complete assembly (Fig. 1), except for the

components listed here. They are the key cylinder,

ignition switch, lock cylinder housing, multi-function

switch, clockspring, halo lamp, speed control

switches, driver airbag, trim shrouds, steering wheel

and steering column intermediate shaft. These

replaceable components of the steering column can be

serviced without requiring removal of the steering

column from the vehicle.

SERVICE WARNINGS AND CAUTIONS

(Refer to 8 - ELECTRICAL/RESTRAINTS - WARN-

ING)

WARNING: BEFORE BEGINNING ANY SERVICE

PROCEDURES THAT INVOLVES REMOVING THE

AIR BAG. REMOVE AND ISOLATE THE NEGATIVE

(-) BATTERY CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT INACCIDENTAL DEPLOYMENT OF THE AIR BAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIR BAG COMPONENTS, HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY DESIGNED

FOR THE AIR BAG SYSTEM. THEY MUST NEVER

BE REPLACED WITH ANY SUBSTITUTES. ANYTIME

A NEW FASTENER IS NEEDED, REPLACE WITH

THE CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR FASTENERS LISTED IN

THE PARTS BOOKS.Fig. 1 STEERING COLUMN

1 - STEERING COLUMN

2 - B.T.S.I.

3 - TURN SIGNAL LEVER

4 - KEY CYLINDER

5 - SHIFT LEVER

6 - MOUNTING HOLES

7 - COUPLING

19 - 10 COLUMNRS

Page 2936 of 4284

WARNING: SAFETY GOGGLES SHOULD BE WORN

AT ALL TIMES WHEN WORKING ON STEERING

COLUMNS.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any column compo-

nent.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

DIAGNOSIS AND TESTING

For diagnosis of conditions relating to the steering

column (Refer to 19 - STEERING - DIAGNOSIS AND

TESTING) and (Refer to 19 - STEERING - DIAGNO-

SIS AND TESTING).

REMOVAL

To service the steering wheel components or the

airbag (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL). Follow all WARN-

INGS AND CAUTIONS.

(1) Make sure the front wheels of the vehicle are

in the STRAIGHT AHEAD position before beginning

the column removal procedure.

(2) Disconnect negative (ground) cable from the

battery and isolate cable from battery terminal.

(3) Remove the lower shroud (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - REMOV-

AL).

(4) Remove the traction off switch.

(5) Remove the upper shroud.

(6) Remove the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

REMOVAL).(7) Remove the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(8) Remove the parking brake handle link.

(9) Remove the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(10) Remove the airbag (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/DRIVER AIRBAG - REMOVAL).

(11) Remove the steering wheel retaining nut.

(12) Remove the vibration damper weight.

(13) Remove the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

REMOVAL). (Fig. 3)

(14) Disconnect the wiring harness connectors

from the clockspring, multi-function switch, halo

lamp, SKIM module, ignition switch and BTSI sole-

noid.

(15) Disconnect the shift cable at the lever. (Fig. 4)

1 - CLOCKSPRING WIRING

2 - STEERING WHEEL

3 - UPPER SHROUD

4 - FIXED SHROUD

5 - SCREW

6 - STEERING COLUMN MOUNTING PLATE

7 - NUT

8 - DASH PANEL STEERING COLUMN MOUNTING BRACKET

9 - STUDS 4

10 - STEERING COLUMN LOCKING PIN

11 - NUT/WASHER ASSEMBLY

12 - STEERING COLUMN ASSEMBLY

13 - LOWER SHROUD

14 - SCREWS

15 - STEERING WHEEL RETAINING NUT16 - STEERING WHEEL DAMPER

17 - CLOCKSPRING

18 - SCREW

19 - MULTI-FUNCTION SWITCH MOUNTING/HOUSING

20 - PINCH BOLT

21 - STEERING COLUMN COUPLER

22 - PINCH BOLT RETAINING PIN

23 - DASH PANEL

24 - SILENCER SHELL

25 - INTERMEDIATE SHAFT SHIELD AND SEAL

26 - INTERMEDIATE SHAFT

27 - ROLL PIN

28 - STEERING GEAR

29 - FRONT SUSPENSION CRADLE

Fig. 3 STEERING WHEEL REMOVAL

1 - STEERING WHEEL

2 - PULLER

19 - 12 COLUMNRS

COLUMN (Continued)

Page 2937 of 4284

(16) Remove the pinch side clip, then remove the

cable from the bracket on the column.

(17) Remove the pinch bolt coupling. (Fig. 5)

(18) Loosen the two lower mounting nuts.

(19) Remove the two upper mounting nuts

(20) Remove the steering column.

(21) Remove the clockspring (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/CLOCKSPRING - REMOV-

AL). (Fig. 6)

(22) Remove the mounting plate with the multi-

function switch.

(23) Remove the halo-lamp.

(24) Remove the ignition key cylinder (Refer to 19

- STEERING/COLUMN/KEY/LOCK CYLINDER -

REMOVAL).(25) Remove the BTSI.

INSTALLATION

To service the steering wheel components or the

airbag (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL). Follow all WARN-

INGS AND CAUTIONS.

(1) Make sure the front wheels of the vehicle are

still in the STRAIGHT AHEAD position before begin-

ning the column installation procedure.

(2) Install the BTSI.

(3) Install the ignition key cylinder (Refer to 19 -

STEERING/COLUMN/KEY/LOCK CYLINDER -

INSTALLATION).

(4) Install the halo-lamp.

(5) Install the mounting plate with the multi-func-

tion switch.

(6) Install the clockspring (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - INSTALLA-

TION).

(7) Install the steering column to the vehicle.

(8) Install the two upper mounting nuts

(9) Tighten the two lower mounting nuts and the

two upper mounting nuts. Tighten to 12 N´m (105 in.

lbs.).

(10) Install the coupling onto the intermediate

shaft and install the pinch bolt. Tighten the pinch

bolt to 28 N´m (250 in. lbs.).

(11) Install the cable from the bracket on the col-

umn, then install the pinch side clips.

(12) Reconnect the shift cable at the lever.

(13) Reconnect the wiring harness connectors to

the clockspring, multi-function switch, halo lamp,

SKIM module, ignition switch and BTSI solenoid.

(14) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(15) Install the vibration damper weight.

Fig. 4 SHIFT CABLE MOUNTING

1 - SHIFT CABLE MOUNT

2 - SHIFT LEVER

Fig. 5 PINCH BOLT

1 - PINCH BOLT

2 - STEERING COLUMN

Fig. 6 CLOCKSPRING

RSCOLUMN19-13

COLUMN (Continued)

Page 2938 of 4284

(16) Install the steering wheel retaining nut.

Tighten the nut to 61 N´m (45 ft. lbs.)

(17) Install the airbag (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(18) Install the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - INSTALLATION).

(19) Install the parking brake handle link.

(20) Install the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

(21) Install the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(22) Install the upper shroud (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - INSTAL-

LATION).

(23) Install the traction off switch.

(24) Install the lower shroud.

SPECIFICATIONS

COLUMN TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Steering Wheel Retaining

Nut61 45 Ð

Steering Column Mounting

Bracket Attaching Nuts12 Ð 105

Steering Column Coupling

Pinch Bolt28 Ð 250

Steering Column Airbag

Module Attaching Nuts11 Ð 100

KEY/LOCK CYLINDER

DESCRIPTION

The lock cylinder is inserted in the end of the

housing opposite the ignition switch.

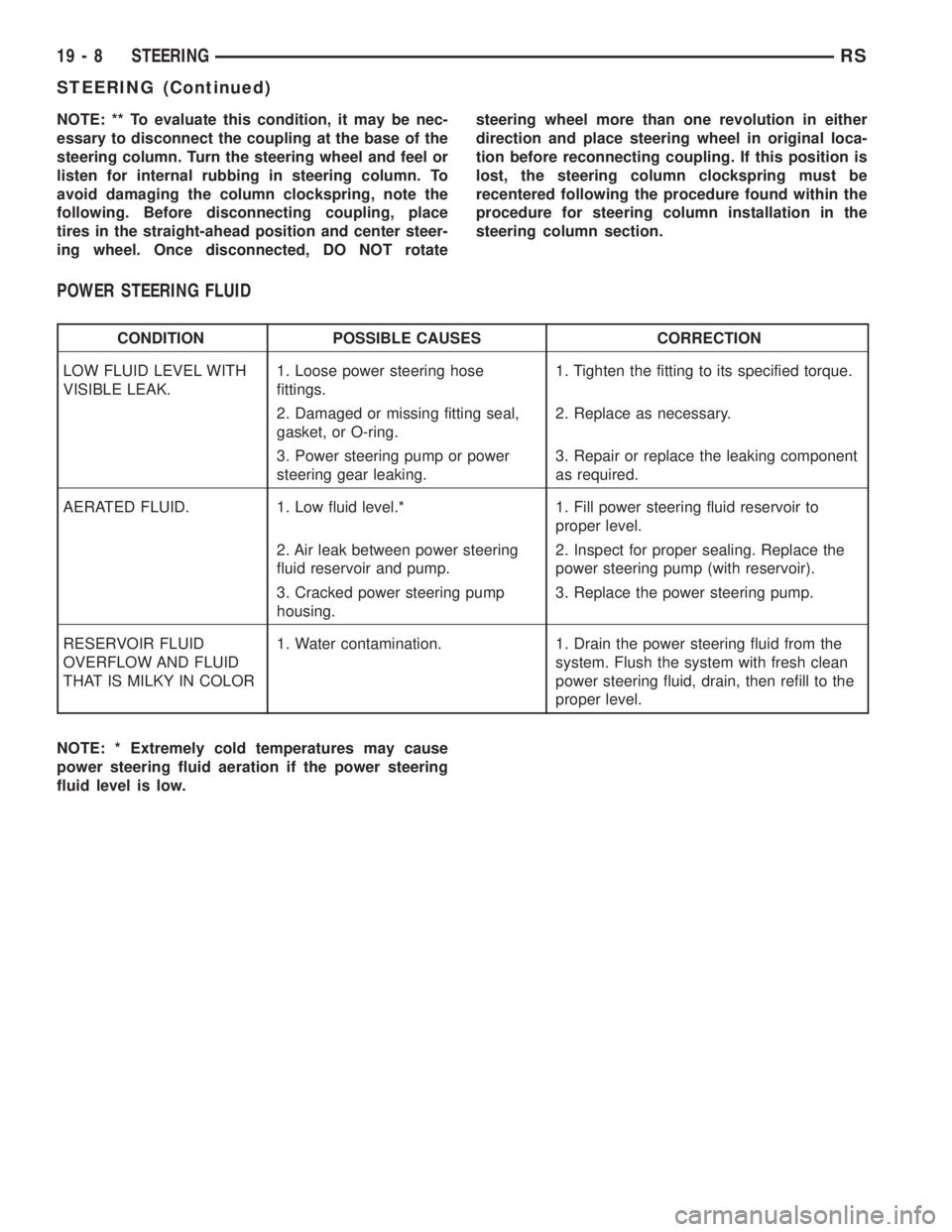

OPERATION

The ignition key rotates the cylinder to 5 different

detents (Fig. 7) :

²Accessory

²Off (lock)

²Unlock

²On/Run

²Start

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove steering column cover retaining

screws.

(3) Remove screws holding steering column

shrouds and remove lower shroud.

(4) Place key cylinder in RUN position. Depress

lock cylinder retaining tab on the bottom of the lock

housing and remove key cylinder.

INSTALLATION

(1) Install key in lock cylinder. Turn key to run

position (retaining tab on lock cylinder can be

depressed).

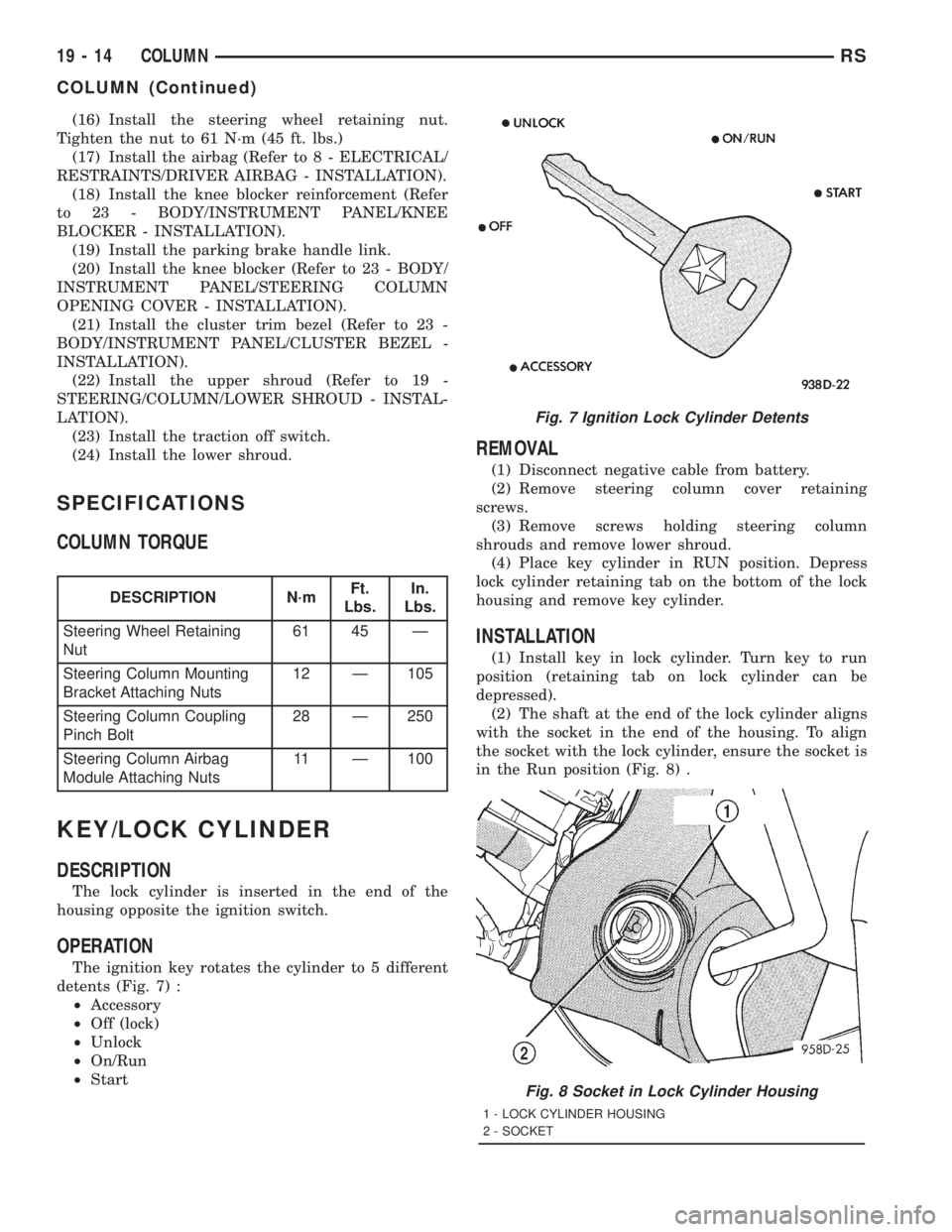

(2) The shaft at the end of the lock cylinder aligns

with the socket in the end of the housing. To align

the socket with the lock cylinder, ensure the socket is

in the Run position (Fig. 8) .

Fig. 7 Ignition Lock Cylinder Detents

Fig. 8 Socket in Lock Cylinder Housing

1 - LOCK CYLINDER HOUSING

2 - SOCKET

19 - 14 COLUMNRS

COLUMN (Continued)

Page 2941 of 4284

GEAR

TABLE OF CONTENTS

page page

GEAR

DESCRIPTION...........................17

OPERATION.............................17

CAUTION...............................18

REMOVAL..............................18INSTALLATION...........................20

SPECIAL TOOLS.........................21

OUTER TIE ROD END

REMOVAL..............................22

INSTALLATION...........................22

GEAR

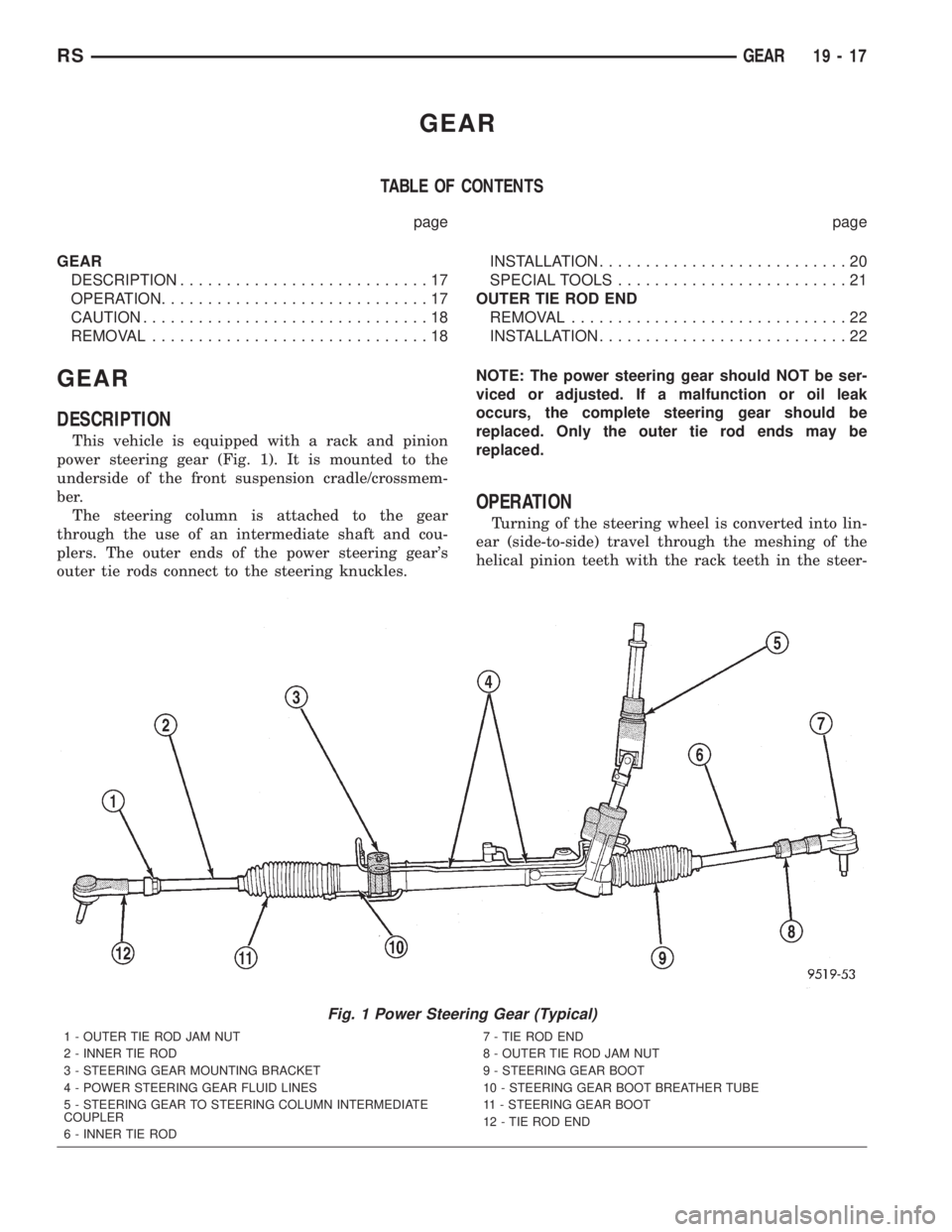

DESCRIPTION

This vehicle is equipped with a rack and pinion

power steering gear (Fig. 1). It is mounted to the

underside of the front suspension cradle/crossmem-

ber.

The steering column is attached to the gear

through the use of an intermediate shaft and cou-

plers. The outer ends of the power steering gear's

outer tie rods connect to the steering knuckles.NOTE: The power steering gear should NOT be ser-

viced or adjusted. If a malfunction or oil leak

occurs, the complete steering gear should be

replaced. Only the outer tie rod ends may be

replaced.

OPERATION

Turning of the steering wheel is converted into lin-

ear (side-to-side) travel through the meshing of the

helical pinion teeth with the rack teeth in the steer-

Fig. 1 Power Steering Gear (Typical)

1 - OUTER TIE ROD JAM NUT

2 - INNER TIE ROD

3 - STEERING GEAR MOUNTING BRACKET

4 - POWER STEERING GEAR FLUID LINES

5 - STEERING GEAR TO STEERING COLUMN INTERMEDIATE

COUPLER

6 - INNER TIE ROD7 - TIE ROD END

8 - OUTER TIE ROD JAM NUT

9 - STEERING GEAR BOOT

10 - STEERING GEAR BOOT BREATHER TUBE

11 - STEERING GEAR BOOT

12 - TIE ROD END

RSGEAR19-17

Page 2942 of 4284

ing gear. This travel pushes and pulls the tie rods to

change the direction of the vehicle's front wheels.

Power assist steering provided by the power steer-

ing pump is controlled by an open center, rotary type

control valve which directs oil from the pump to

either side of the integral rack piston upon demand.

Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As required

steering effort increases, as in a turn, the torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This move-

ment directs oil behind the integral rack piston

which, in turn, builds up hydraulic pressure and

assists in the turning effort.

Manual steering control of the vehicle can be main-

tained if power steering assist is lost. However,

under this condition, steering effort is significantly

increased.

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

REMOVAL - GEAR

CAUTION: Positioning the steering column in the

locked position will prevent the clockspring from

being accidentally over-extended when the steering

column is disconnected from the intermediate

steering coupler.

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much fluid as

possible from the power steering fluid reservoir.

(3) With the ignition key in the locked position

turn the steering wheel to the left until the steering

wheel is in the locked position.

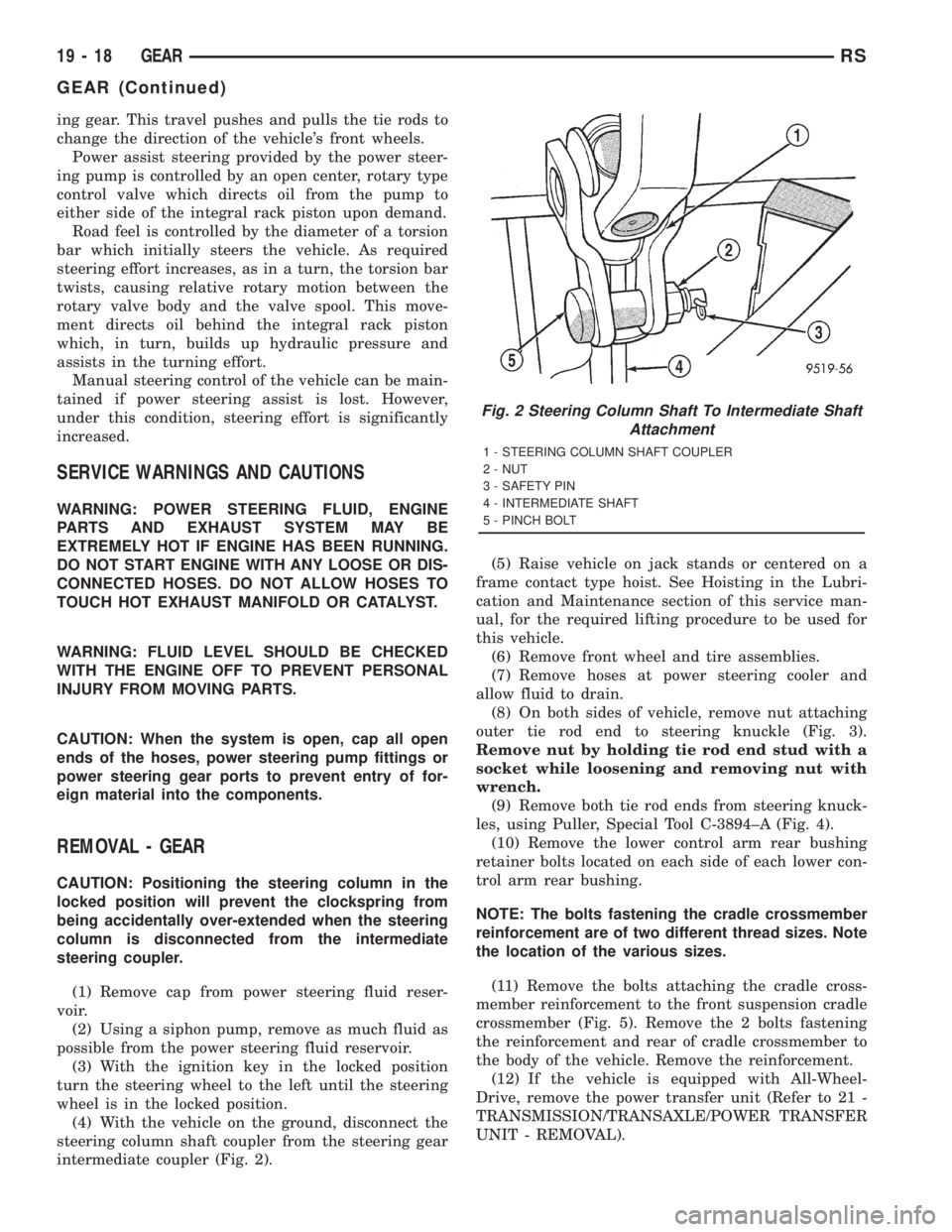

(4) With the vehicle on the ground, disconnect the

steering column shaft coupler from the steering gear

intermediate coupler (Fig. 2).(5) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this service man-

ual, for the required lifting procedure to be used for

this vehicle.

(6) Remove front wheel and tire assemblies.

(7) Remove hoses at power steering cooler and

allow fluid to drain.

(8) On both sides of vehicle, remove nut attaching

outer tie rod end to steering knuckle (Fig. 3).

Remove nut by holding tie rod end stud with a

socket while loosening and removing nut with

wrench.

(9) Remove both tie rod ends from steering knuck-

les, using Puller, Special Tool C-3894±A (Fig. 4).

(10) Remove the lower control arm rear bushing

retainer bolts located on each side of each lower con-

trol arm rear bushing.

NOTE: The bolts fastening the cradle crossmember

reinforcement are of two different thread sizes. Note

the location of the various sizes.

(11) Remove the bolts attaching the cradle cross-

member reinforcement to the front suspension cradle

crossmember (Fig. 5). Remove the 2 bolts fastening

the reinforcement and rear of cradle crossmember to

the body of the vehicle. Remove the reinforcement.

(12) If the vehicle is equipped with All-Wheel-

Drive, remove the power transfer unit (Refer to 21 -

TRANSMISSION/TRANSAXLE/POWER TRANSFER

UNIT - REMOVAL).

Fig. 2 Steering Column Shaft To Intermediate Shaft

Attachment

1 - STEERING COLUMN SHAFT COUPLER

2 - NUT

3 - SAFETY PIN

4 - INTERMEDIATE SHAFT

5 - PINCH BOLT

19 - 18 GEARRS

GEAR (Continued)

Page 2945 of 4284

(4) Install steering gear assembly on the front sus-

pension cradle. Install the 3 steering gear mounting

bolts and nuts (Fig. 7).

CAUTION: Proper torque on the steering gear to

suspension cradle mounting bolts is very impor-

tant.

(5) Tighten the 3 steering gear to suspension cra-

dle mounting bolts to a torque of 183 N´m (135 ft.

lbs.).

(6) Attach the power steering fluid pressure and

return lines (Fig. 6) to the proper fittings on the

steering gear. Tighten the power steering fluid line

tube nuts to a torque of 31 N´m (275 in. lbs.).

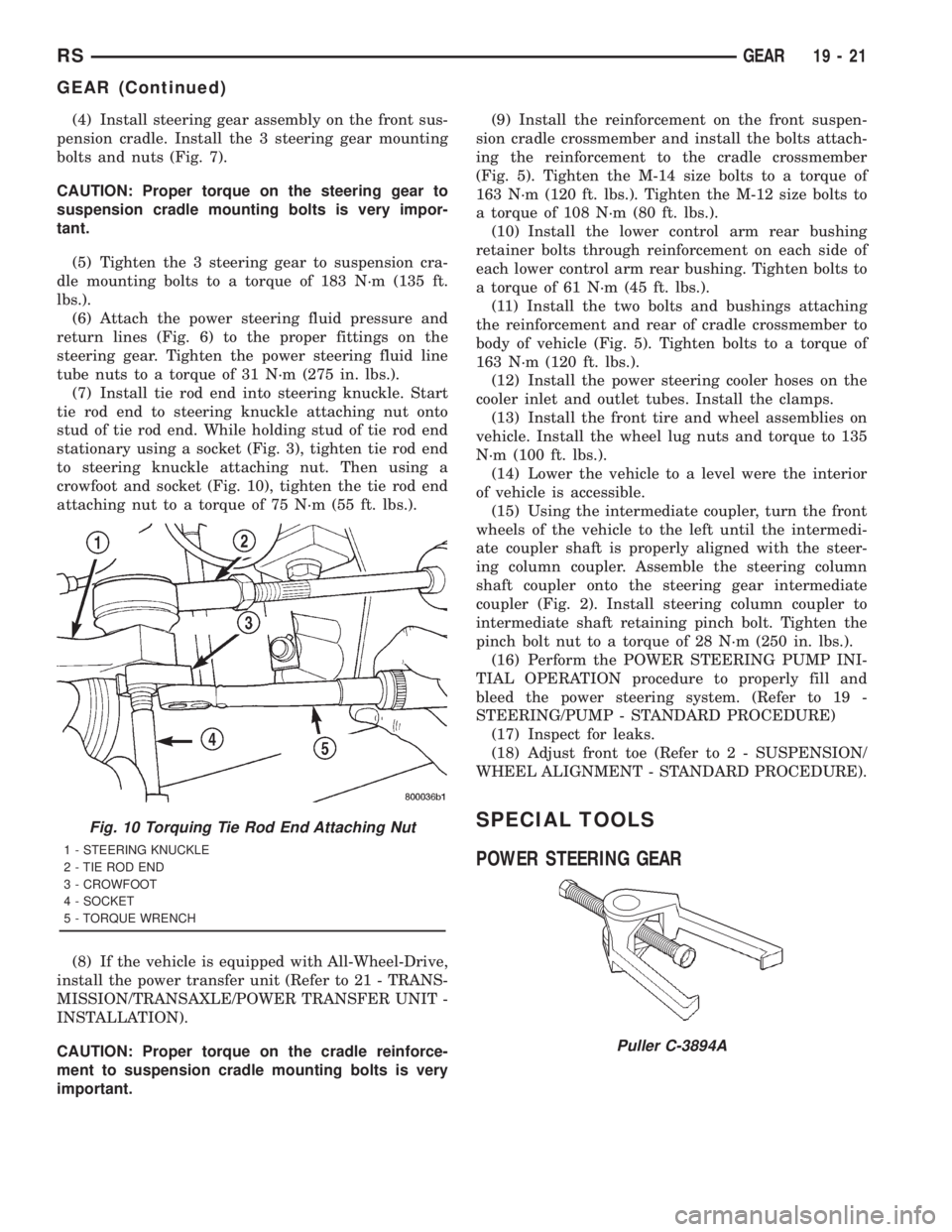

(7) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle attaching nut onto

stud of tie rod end. While holding stud of tie rod end

stationary using a socket (Fig. 3), tighten tie rod end

to steering knuckle attaching nut. Then using a

crowfoot and socket (Fig. 10), tighten the tie rod end

attaching nut to a torque of 75 N´m (55 ft. lbs.).

(8) If the vehicle is equipped with All-Wheel-Drive,

install the power transfer unit (Refer to 21 - TRANS-

MISSION/TRANSAXLE/POWER TRANSFER UNIT -

INSTALLATION).

CAUTION: Proper torque on the cradle reinforce-

ment to suspension cradle mounting bolts is very

important.(9) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 5). Tighten the M-14 size bolts to a torque of

163 N´m (120 ft. lbs.). Tighten the M-12 size bolts to

a torque of 108 N´m (80 ft. lbs.).

(10) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten bolts to

a torque of 61 N´m (45 ft. lbs.).

(11) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 5). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(12) Install the power steering cooler hoses on the

cooler inlet and outlet tubes. Install the clamps.

(13) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 135

N´m (100 ft. lbs.).

(14) Lower the vehicle to a level were the interior

of vehicle is accessible.

(15) Using the intermediate coupler, turn the front

wheels of the vehicle to the left until the intermedi-

ate coupler shaft is properly aligned with the steer-

ing column coupler. Assemble the steering column

shaft coupler onto the steering gear intermediate

coupler (Fig. 2). Install steering column coupler to

intermediate shaft retaining pinch bolt. Tighten the

pinch bolt nut to a torque of 28 N´m (250 in. lbs.).

(16) Perform the POWER STEERING PUMP INI-

TIAL OPERATION procedure to properly fill and

bleed the power steering system. (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE)

(17) Inspect for leaks.

(18) Adjust front toe (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - STANDARD PROCEDURE).

SPECIAL TOOLS

POWER STEERING GEARFig. 10 Torquing Tie Rod End Attaching Nut

1 - STEERING KNUCKLE

2 - TIE ROD END

3 - CROWFOOT

4 - SOCKET

5 - TORQUE WRENCH

Puller C-3894A

RSGEAR19-21

GEAR (Continued)

Page 2947 of 4284

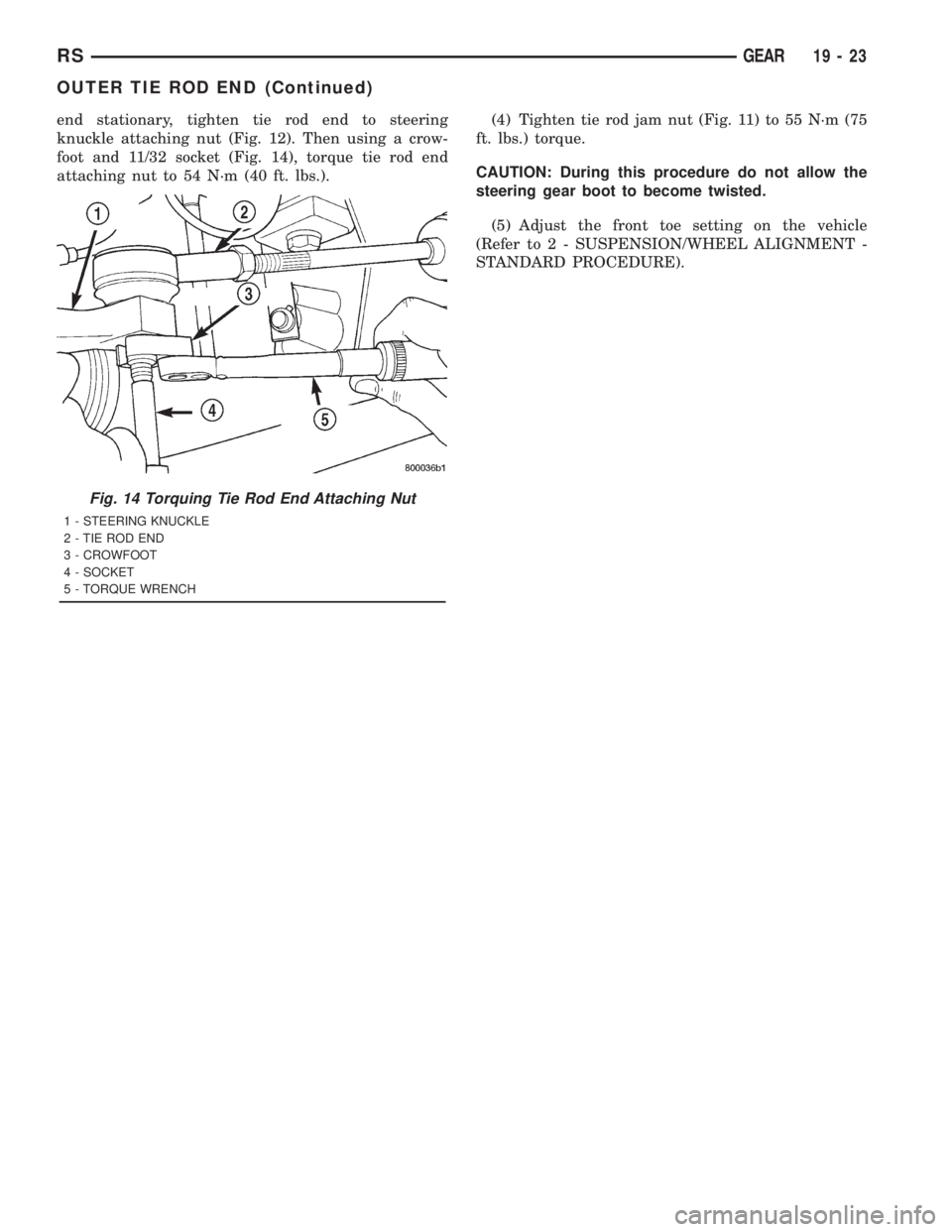

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 12). Then using a crow-

foot and 11/32 socket (Fig. 14), torque tie rod end

attaching nut to 54 N´m (40 ft. lbs.).(4) Tighten tie rod jam nut (Fig. 11) to 55 N´m (75

ft. lbs.) torque.

CAUTION: During this procedure do not allow the

steering gear boot to become twisted.

(5) Adjust the front toe setting on the vehicle

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE).

Fig. 14 Torquing Tie Rod End Attaching Nut

1 - STEERING KNUCKLE

2 - TIE ROD END

3 - CROWFOOT

4 - SOCKET

5 - TORQUE WRENCH

RSGEAR19-23

OUTER TIE ROD END (Continued)