CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3211 of 4284

NOTE: Only fluids of the type labeled Moparž

ATF+4 (Automatic Transmission Fluid) Type 9602

should be used. A filter change should be made at

the time of the transmission oil change. The magnet

(on the inside of the oil pan) should also be cleaned

with a clean, dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

FLUID/FILTER SERVICE (RECOMMENDED)

(1) Raise vehicle on a hoist. Refer to LUBRICA-

TION and MAINTENANCE for proper procedures.

Place a drain container with a large opening, under

transaxle oil pan.

(2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan.

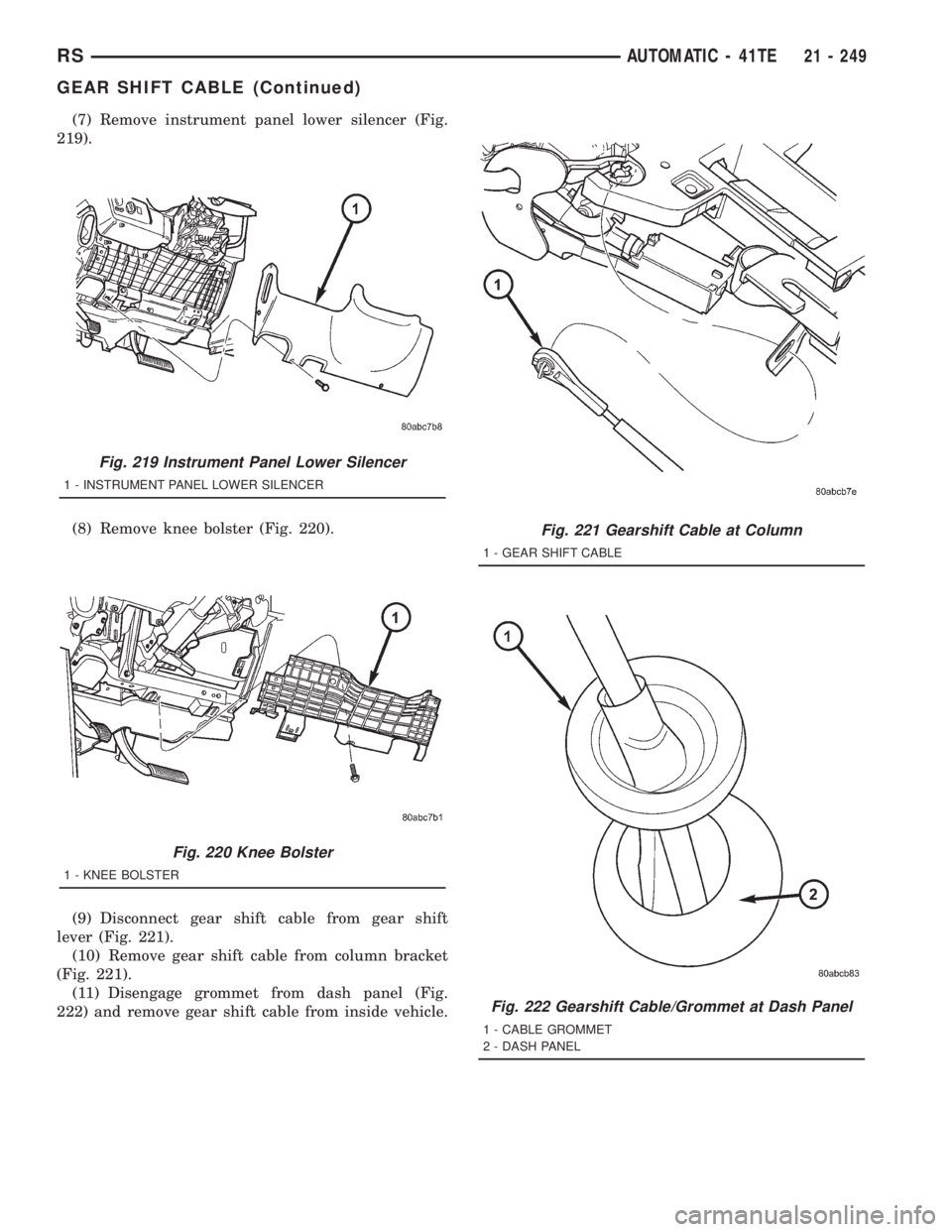

(3) Install a new filter and o-ring on bottom of the

valve body (Fig. 216).

(4) Clean the oil pan and magnet. Reinstall pan

using new Mopar Silicone Adhesive sealant. Tighten

oil pan bolts to 19 N´m (165 in. lbs.).

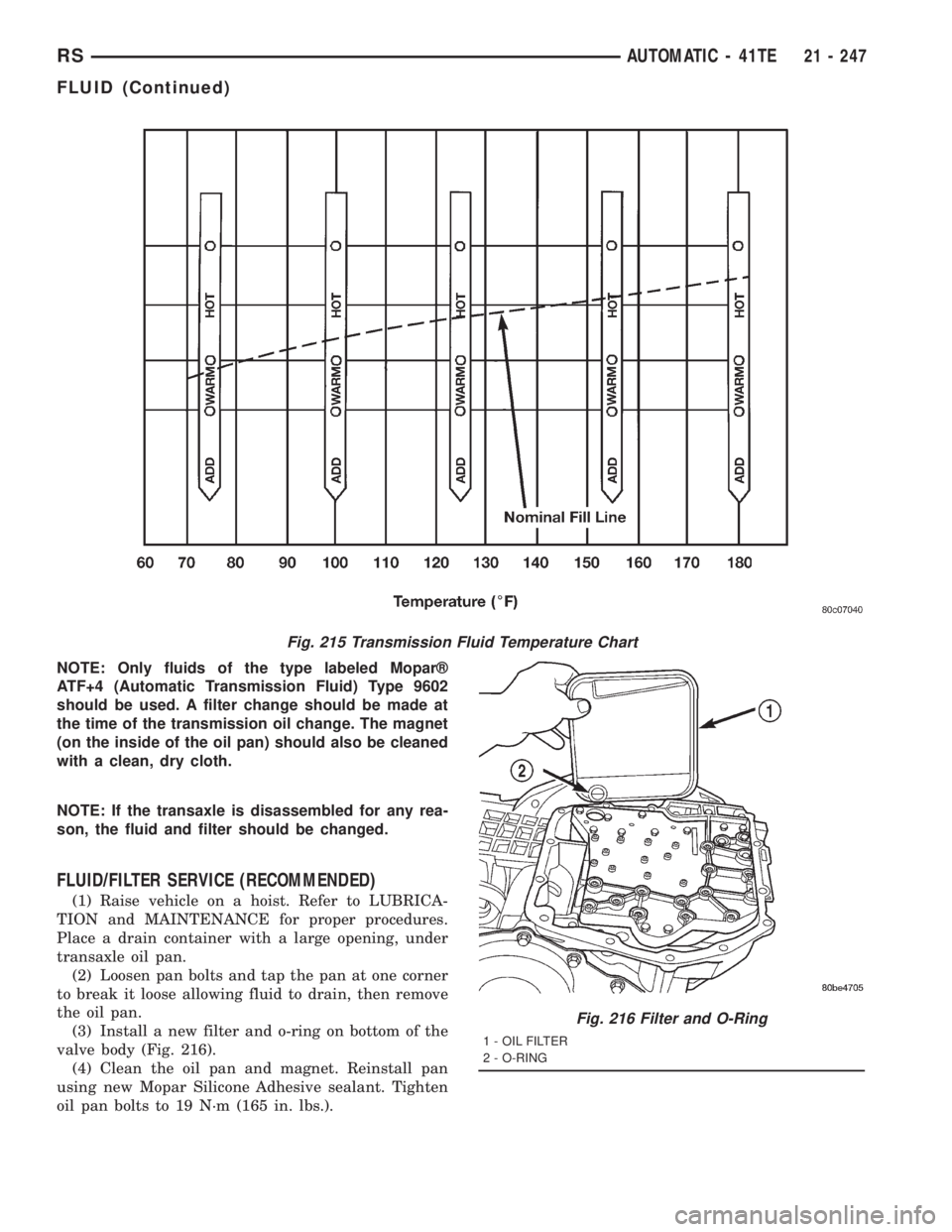

Fig. 215 Transmission Fluid Temperature Chart

Fig. 216 Filter and O-Ring

1 - OIL FILTER

2 - O-RING

RSAUTOMATIC - 41TE21 - 247

FLUID (Continued)

Page 3212 of 4284

(5) Pour four quarts of Moparž ATF+4 (Automatic

Transmission Fluid) Type 9602 through the dipstick

opening.

(6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

(7) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the lowest mark on the dip-

stick (Fig. 217).

(8) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.). Refer

to Fluid Level and Condition Check for the proper

fluid fill procedure.

(9) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

DIPSTICK TUBE FLUID SUCTION METHOD

(ALTERNATIVE)

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature.

(2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (VaculaŸ

or equivalent).

(3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

(5) Remove the suction line from the dipstick tube.

(6) Pour four quarts of Moparž ATF+4 (Automatic

Transmission Fluid) Type 9602 through the dipstick

opening.(7) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the lowest mark on the dip-

stick (Fig. 217).

(9) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.).

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 41TE/FLUID - STANDARD PROCEDURE)

(10) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

GEAR SHIFT CABLE

REMOVAL

(1) Disconnect battery cables.

(2) Remove battery shield.

(3) Remove battery.

(4) Remove speed control servo and position out of

way.

(5) Disconnect gear shift cable at manual valve

lever (Fig. 218).

(6) Disconnect gear shift cable from upper mount

bracket (Fig. 218).

Fig. 217 Transaxle Fluid Level Indicator

1 - TRANSAXLE DIPSTICK

Fig. 218 Gearshift Cable at Transaxle - Typical

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

21 - 248 AUTOMATIC - 41TERS

FLUID (Continued)

Page 3213 of 4284

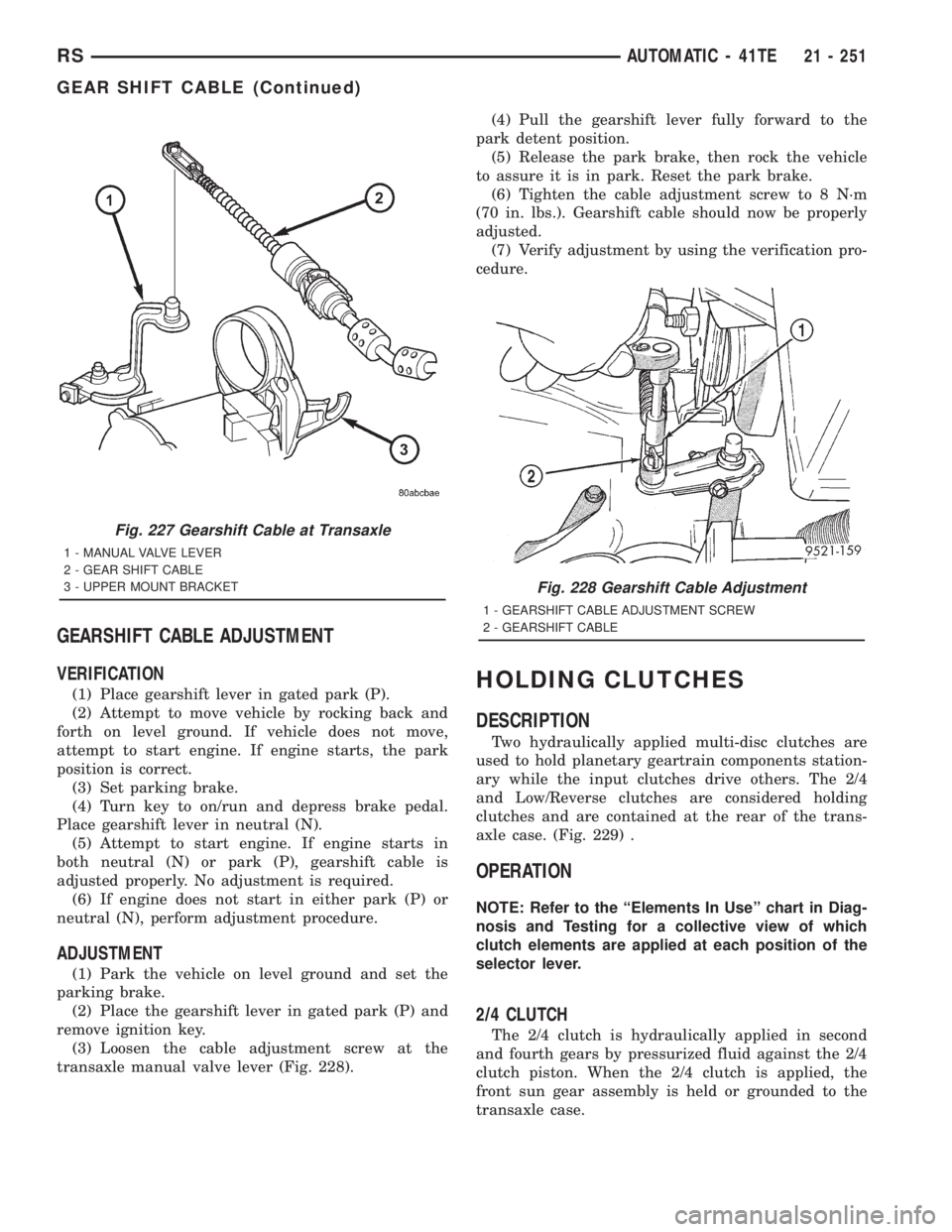

(7) Remove instrument panel lower silencer (Fig.

219).

(8) Remove knee bolster (Fig. 220).

(9) Disconnect gear shift cable from gear shift

lever (Fig. 221).

(10) Remove gear shift cable from column bracket

(Fig. 221).

(11) Disengage grommet from dash panel (Fig.

222) and remove gear shift cable from inside vehicle.

Fig. 219 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 220 Knee Bolster

1 - KNEE BOLSTER

Fig. 221 Gearshift Cable at Column

1 - GEAR SHIFT CABLE

Fig. 222 Gearshift Cable/Grommet at Dash Panel

1 - CABLE GROMMET

2 - DASH PANEL

RSAUTOMATIC - 41TE21 - 249

GEAR SHIFT CABLE (Continued)

Page 3214 of 4284

INSTALLATION

(1) Fish gear shift cable dash panel opening into

engine compartment and secure grommet (Fig. 223).

(2) Install gear shift cable through column bracket

(Fig. 224) until audible ªclickº is heard.

(3) Connect gear shift cable to gear shift lever (Fig.

224).(4) Install knee bolster (Fig. 225).

(5) Install instrument panel lower silencer (Fig.

226).

(6) Install gear shift cable to transaxle upper

mount bracket (Fig. 227). An audible ªclickº should

be heard.

(7) Connect gear shift cable end to transaxle man-

ual valve lever (Fig. 227).

(8) Adjust gearshift cable. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 41TE/GEAR

SHIFT CABLE - ADJUSTMENTS)

(9) Install speed control servo into position.

(10) Install battery.

(11) Install battery shield.

(12) Connect battery cables.

Fig. 223 Gearshift Cable/Grommet at Dash Panel

1 - CABLE GROMMET

2 - DASH PANEL

Fig. 224 Gearshift Cable at Column

1 - GEAR SHIFT CABLE

Fig. 225 Knee Bolster

1 - KNEE BOLSTER

Fig. 226 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

21 - 250 AUTOMATIC - 41TERS

GEAR SHIFT CABLE (Continued)

Page 3215 of 4284

GEARSHIFT CABLE ADJUSTMENT

VERIFICATION

(1) Place gearshift lever in gated park (P).

(2) Attempt to move vehicle by rocking back and

forth on level ground. If vehicle does not move,

attempt to start engine. If engine starts, the park

position is correct.

(3) Set parking brake.

(4) Turn key to on/run and depress brake pedal.

Place gearshift lever in neutral (N).

(5) Attempt to start engine. If engine starts in

both neutral (N) or park (P), gearshift cable is

adjusted properly. No adjustment is required.

(6) If engine does not start in either park (P) or

neutral (N), perform adjustment procedure.

ADJUSTMENT

(1) Park the vehicle on level ground and set the

parking brake.

(2) Place the gearshift lever in gated park (P) and

remove ignition key.

(3) Loosen the cable adjustment screw at the

transaxle manual valve lever (Fig. 228).(4) Pull the gearshift lever fully forward to the

park detent position.

(5) Release the park brake, then rock the vehicle

to assure it is in park. Reset the park brake.

(6) Tighten the cable adjustment screw to 8 N´m

(70 in. lbs.). Gearshift cable should now be properly

adjusted.

(7) Verify adjustment by using the verification pro-

cedure.

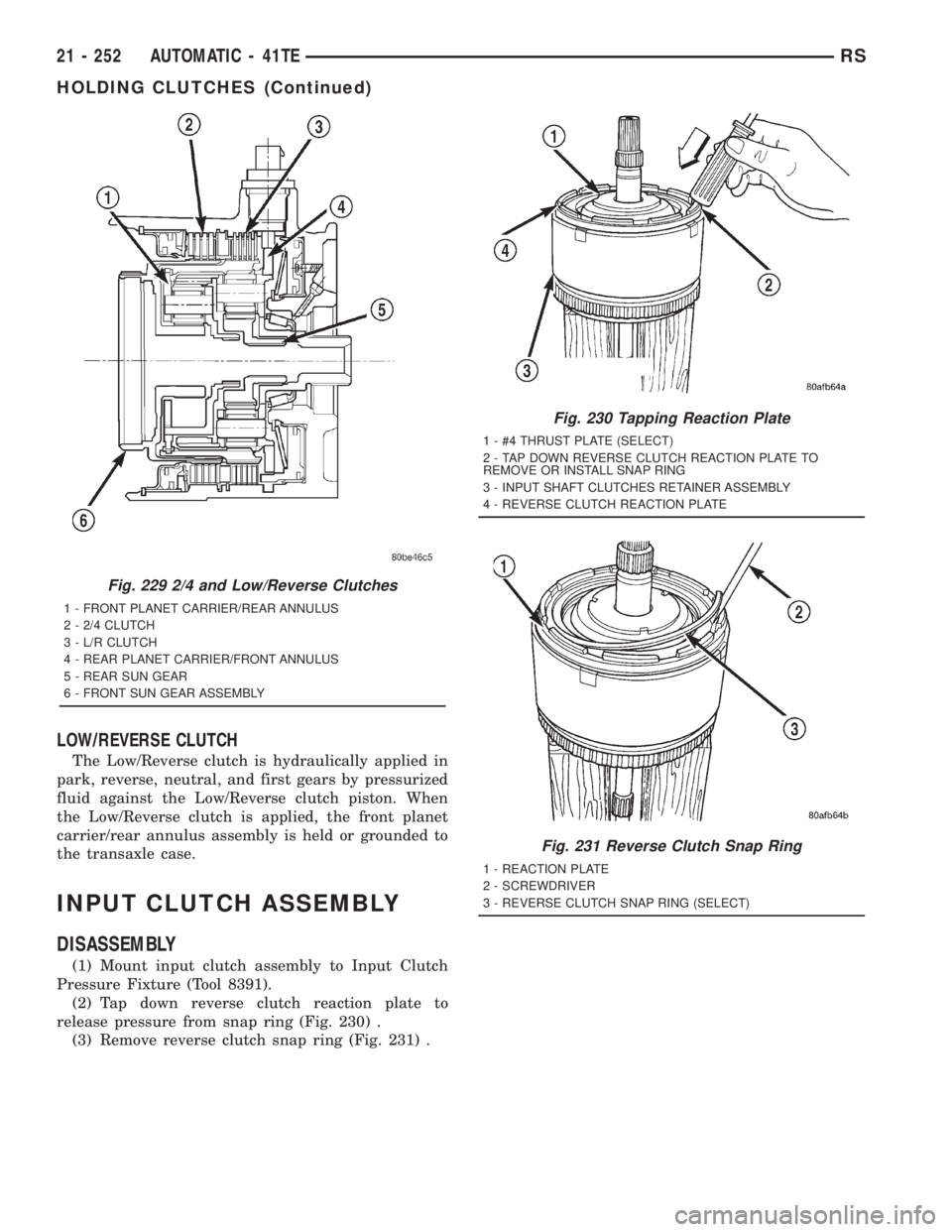

HOLDING CLUTCHES

DESCRIPTION

Two hydraulically applied multi-disc clutches are

used to hold planetary geartrain components station-

ary while the input clutches drive others. The 2/4

and Low/Reverse clutches are considered holding

clutches and are contained at the rear of the trans-

axle case. (Fig. 229) .

OPERATION

NOTE: Refer to the ªElements In Useº chart in Diag-

nosis and Testing for a collective view of which

clutch elements are applied at each position of the

selector lever.

2/4 CLUTCH

The 2/4 clutch is hydraulically applied in second

and fourth gears by pressurized fluid against the 2/4

clutch piston. When the 2/4 clutch is applied, the

front sun gear assembly is held or grounded to the

transaxle case.

Fig. 227 Gearshift Cable at Transaxle

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

Fig. 228 Gearshift Cable Adjustment

1 - GEARSHIFT CABLE ADJUSTMENT SCREW

2 - GEARSHIFT CABLE

RSAUTOMATIC - 41TE21 - 251

GEAR SHIFT CABLE (Continued)

Page 3216 of 4284

LOW/REVERSE CLUTCH

The Low/Reverse clutch is hydraulically applied in

park, reverse, neutral, and first gears by pressurized

fluid against the Low/Reverse clutch piston. When

the Low/Reverse clutch is applied, the front planet

carrier/rear annulus assembly is held or grounded to

the transaxle case.

INPUT CLUTCH ASSEMBLY

DISASSEMBLY

(1) Mount input clutch assembly to Input Clutch

Pressure Fixture (Tool 8391).

(2) Tap down reverse clutch reaction plate to

release pressure from snap ring (Fig. 230) .

(3) Remove reverse clutch snap ring (Fig. 231) .

Fig. 229 2/4 and Low/Reverse Clutches

1 - FRONT PLANET CARRIER/REAR ANNULUS

2 - 2/4 CLUTCH

3 - L/R CLUTCH

4 - REAR PLANET CARRIER/FRONT ANNULUS

5 - REAR SUN GEAR

6 - FRONT SUN GEAR ASSEMBLY

Fig. 230 Tapping Reaction Plate

1 - #4 THRUST PLATE (SELECT)

2 - TAP DOWN REVERSE CLUTCH REACTION PLATE TO

REMOVE OR INSTALL SNAP RING

3 - INPUT SHAFT CLUTCHES RETAINER ASSEMBLY

4 - REVERSE CLUTCH REACTION PLATE

Fig. 231 Reverse Clutch Snap Ring

1 - REACTION PLATE

2 - SCREWDRIVER

3 - REVERSE CLUTCH SNAP RING (SELECT)

21 - 252 AUTOMATIC - 41TERS

HOLDING CLUTCHES (Continued)

Page 3217 of 4284

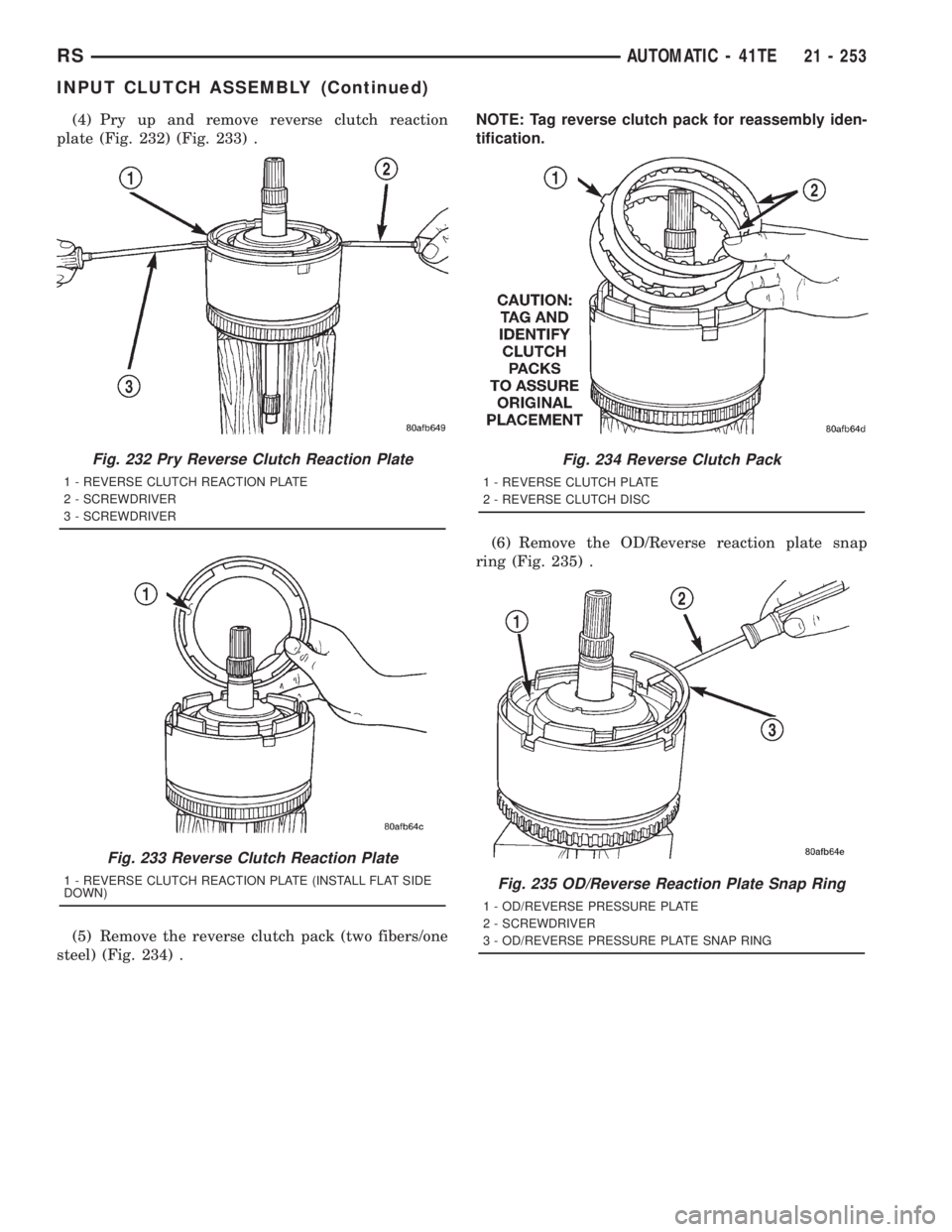

(4) Pry up and remove reverse clutch reaction

plate (Fig. 232) (Fig. 233) .

(5) Remove the reverse clutch pack (two fibers/one

steel) (Fig. 234) .NOTE: Tag reverse clutch pack for reassembly iden-

tification.

(6) Remove the OD/Reverse reaction plate snap

ring (Fig. 235) .

Fig. 232 Pry Reverse Clutch Reaction Plate

1 - REVERSE CLUTCH REACTION PLATE

2 - SCREWDRIVER

3 - SCREWDRIVER

Fig. 233 Reverse Clutch Reaction Plate

1 - REVERSE CLUTCH REACTION PLATE (INSTALL FLAT SIDE

DOWN)

Fig. 234 Reverse Clutch Pack

1 - REVERSE CLUTCH PLATE

2 - REVERSE CLUTCH DISC

Fig. 235 OD/Reverse Reaction Plate Snap Ring

1 - OD/REVERSE PRESSURE PLATE

2 - SCREWDRIVER

3 - OD/REVERSE PRESSURE PLATE SNAP RING

RSAUTOMATIC - 41TE21 - 253

INPUT CLUTCH ASSEMBLY (Continued)

Page 3218 of 4284

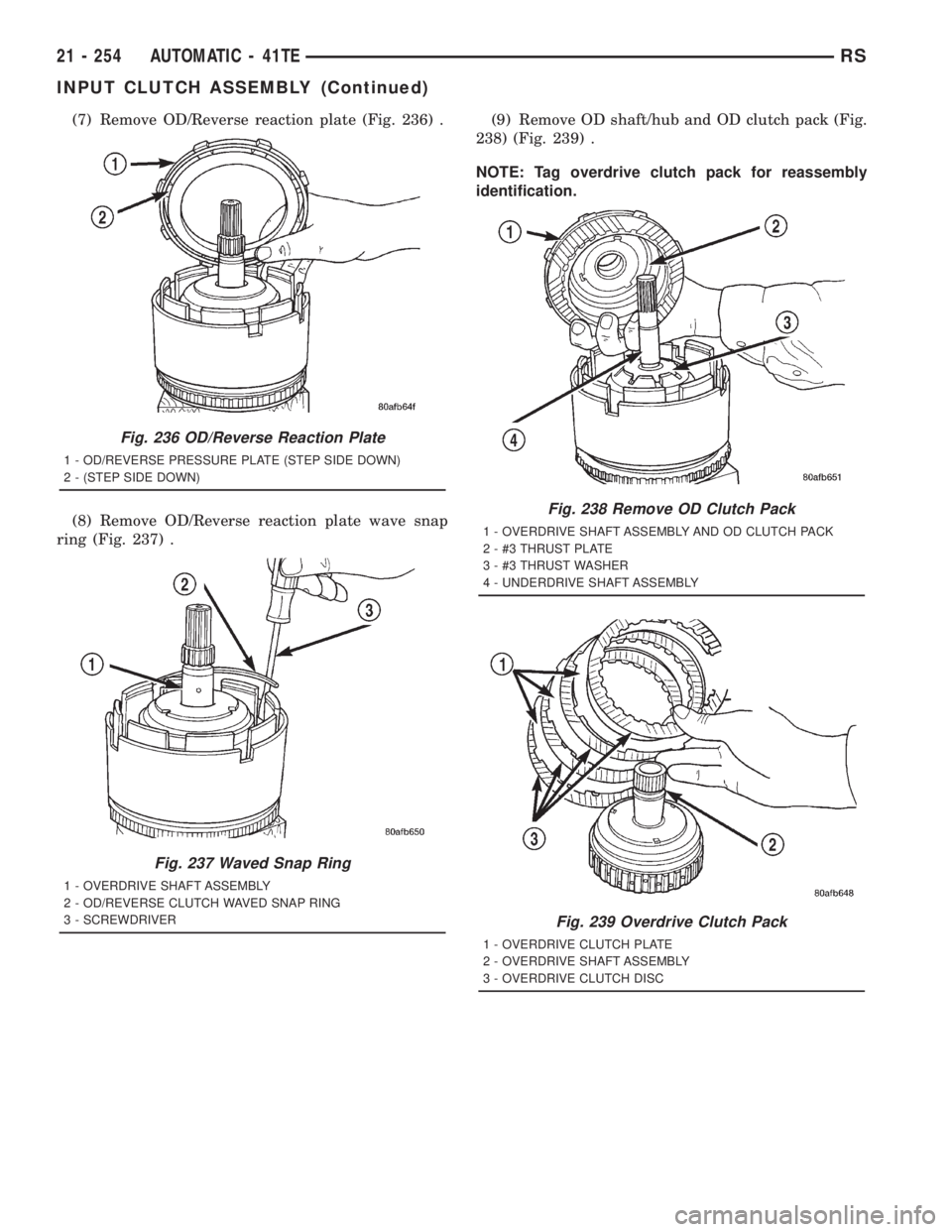

(7) Remove OD/Reverse reaction plate (Fig. 236) .

(8) Remove OD/Reverse reaction plate wave snap

ring (Fig. 237) .(9) Remove OD shaft/hub and OD clutch pack (Fig.

238) (Fig. 239) .

NOTE: Tag overdrive clutch pack for reassembly

identification.

Fig. 236 OD/Reverse Reaction Plate

1 - OD/REVERSE PRESSURE PLATE (STEP SIDE DOWN)

2 - (STEP SIDE DOWN)

Fig. 237 Waved Snap Ring

1 - OVERDRIVE SHAFT ASSEMBLY

2 - OD/REVERSE CLUTCH WAVED SNAP RING

3 - SCREWDRIVER

Fig. 238 Remove OD Clutch Pack

1 - OVERDRIVE SHAFT ASSEMBLY AND OD CLUTCH PACK

2 - #3 THRUST PLATE

3 - #3 THRUST WASHER

4 - UNDERDRIVE SHAFT ASSEMBLY

Fig. 239 Overdrive Clutch Pack

1 - OVERDRIVE CLUTCH PLATE

2 - OVERDRIVE SHAFT ASSEMBLY

3 - OVERDRIVE CLUTCH DISC

21 - 254 AUTOMATIC - 41TERS

INPUT CLUTCH ASSEMBLY (Continued)

Page 3219 of 4284

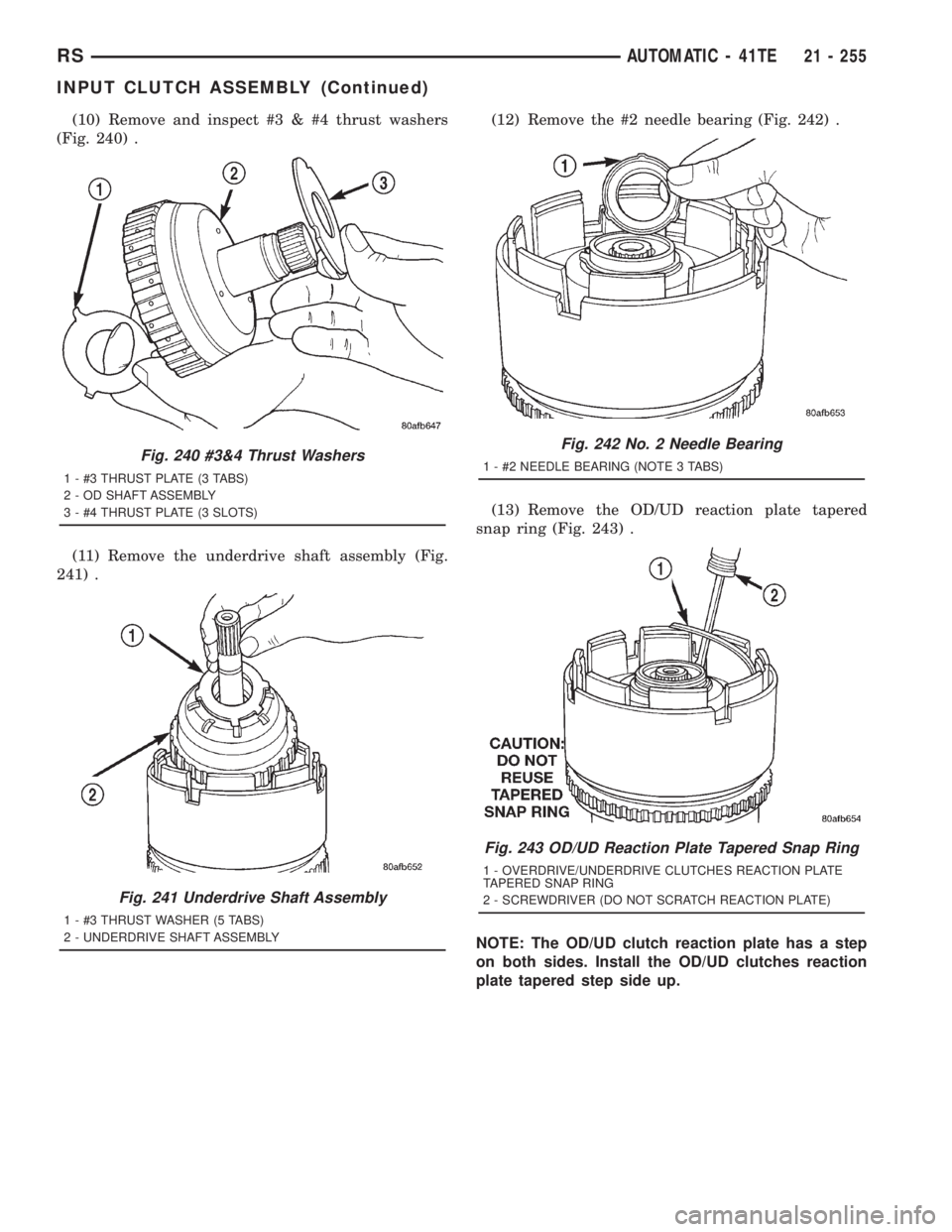

(10) Remove and inspect #3 & #4 thrust washers

(Fig. 240) .

(11) Remove the underdrive shaft assembly (Fig.

241) .(12) Remove the #2 needle bearing (Fig. 242) .

(13) Remove the OD/UD reaction plate tapered

snap ring (Fig. 243) .

NOTE: The OD/UD clutch reaction plate has a step

on both sides. Install the OD/UD clutches reaction

plate tapered step side up.

Fig. 240 #3&4 Thrust Washers

1 - #3 THRUST PLATE (3 TABS)

2 - OD SHAFT ASSEMBLY

3 - #4 THRUST PLATE (3 SLOTS)

Fig. 241 Underdrive Shaft Assembly

1 - #3 THRUST WASHER (5 TABS)

2 - UNDERDRIVE SHAFT ASSEMBLY

Fig. 242 No. 2 Needle Bearing

1 - #2 NEEDLE BEARING (NOTE 3 TABS)

Fig. 243 OD/UD Reaction Plate Tapered Snap Ring

1 - OVERDRIVE/UNDERDRIVE CLUTCHES REACTION PLATE

TAPERED SNAP RING

2 - SCREWDRIVER (DO NOT SCRATCH REACTION PLATE)

RSAUTOMATIC - 41TE21 - 255

INPUT CLUTCH ASSEMBLY (Continued)

Page 3220 of 4284

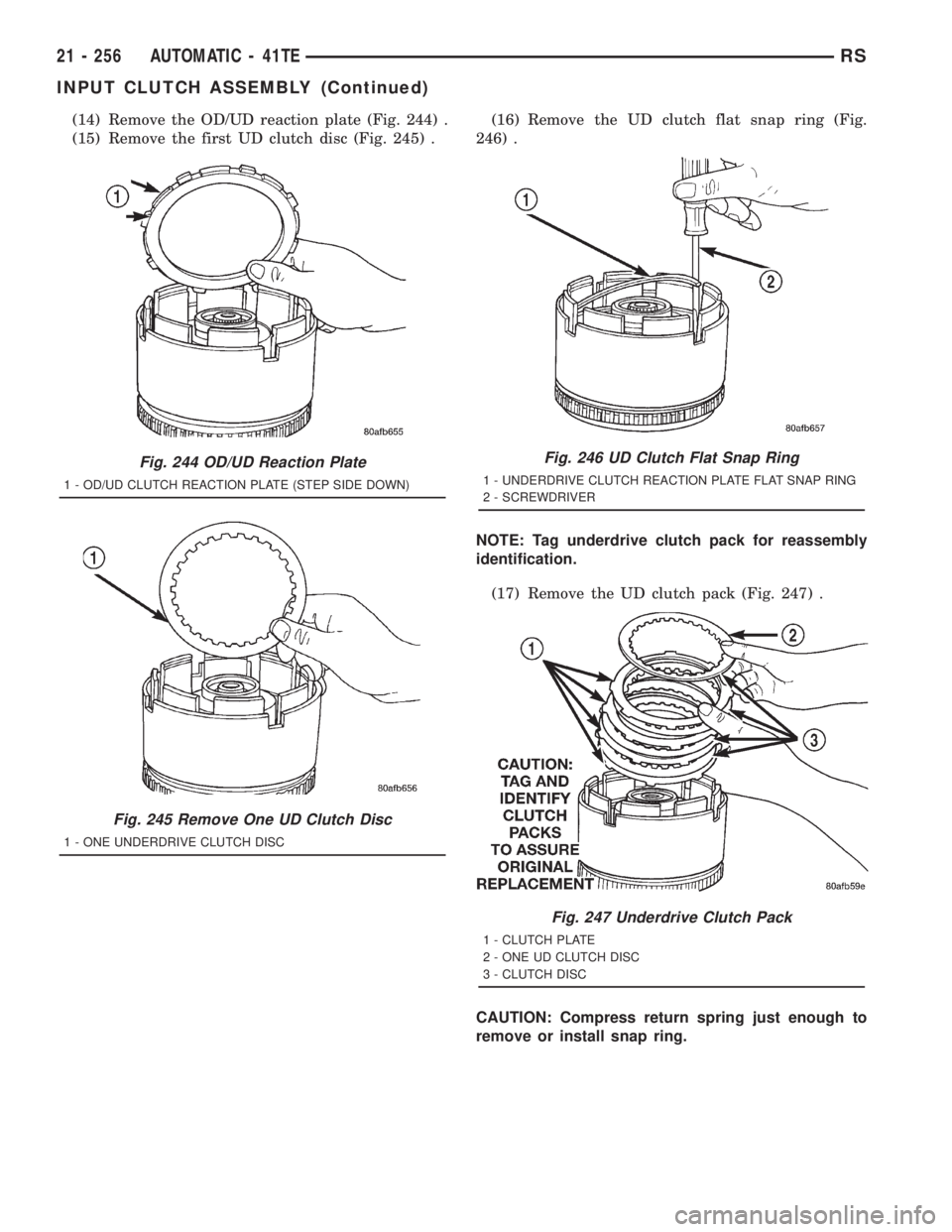

(14) Remove the OD/UD reaction plate (Fig. 244) .

(15) Remove the first UD clutch disc (Fig. 245) .(16) Remove the UD clutch flat snap ring (Fig.

246) .

NOTE: Tag underdrive clutch pack for reassembly

identification.

(17) Remove the UD clutch pack (Fig. 247) .

CAUTION: Compress return spring just enough to

remove or install snap ring.

Fig. 244 OD/UD Reaction Plate

1 - OD/UD CLUTCH REACTION PLATE (STEP SIDE DOWN)

Fig. 245 Remove One UD Clutch Disc

1 - ONE UNDERDRIVE CLUTCH DISC

Fig. 246 UD Clutch Flat Snap Ring

1 - UNDERDRIVE CLUTCH REACTION PLATE FLAT SNAP RING

2 - SCREWDRIVER

Fig. 247 Underdrive Clutch Pack

1 - CLUTCH PLATE

2 - ONE UD CLUTCH DISC

3 - CLUTCH DISC

21 - 256 AUTOMATIC - 41TERS

INPUT CLUTCH ASSEMBLY (Continued)