CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3331 of 4284

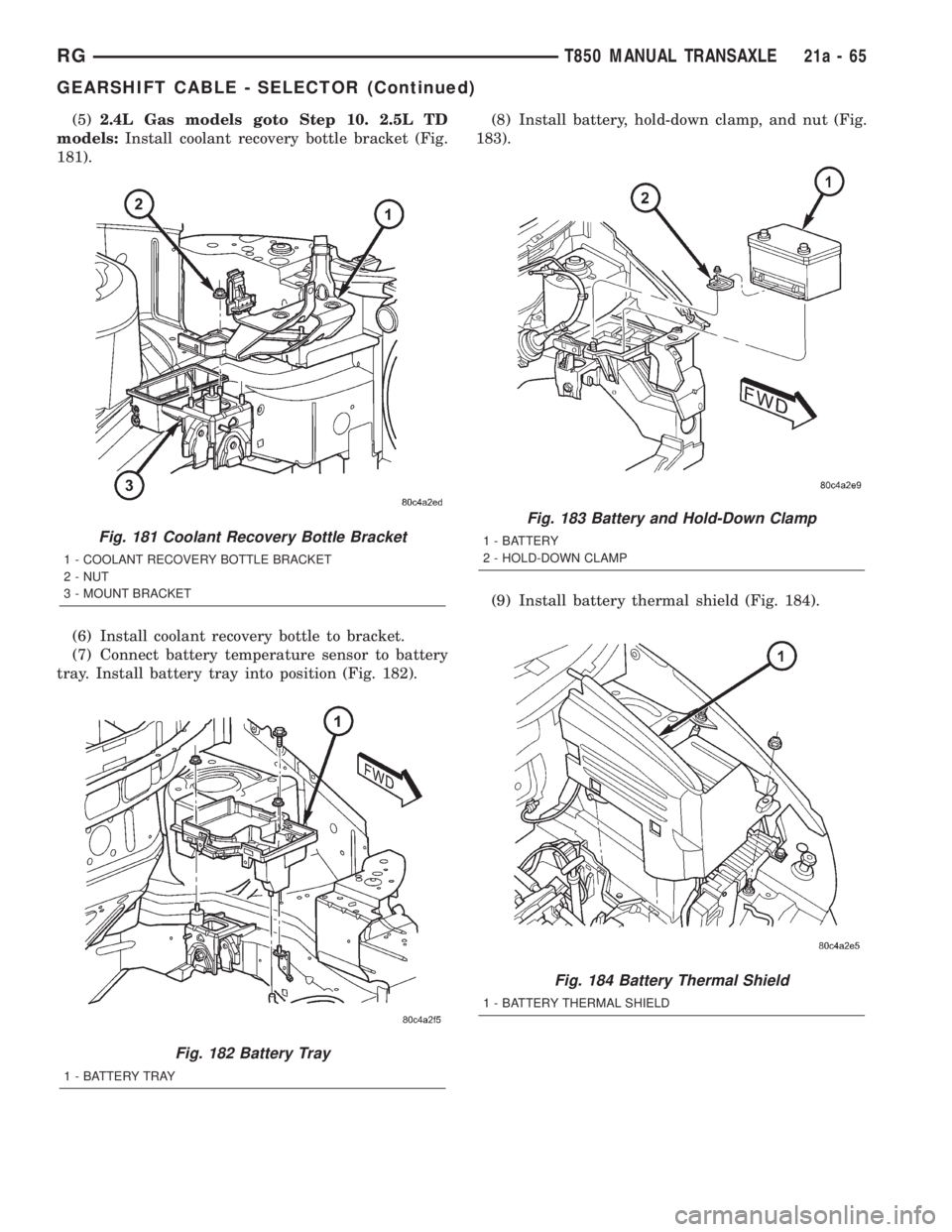

(5)2.4L Gas models goto Step 10. 2.5L TD

models:Install coolant recovery bottle bracket (Fig.

181).

(6) Install coolant recovery bottle to bracket.

(7) Connect battery temperature sensor to battery

tray. Install battery tray into position (Fig. 182).(8) Install battery, hold-down clamp, and nut (Fig.

183).

(9) Install battery thermal shield (Fig. 184).

Fig. 181 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 182 Battery Tray

1 - BATTERY TRAY

Fig. 183 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

Fig. 184 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

RGT850 MANUAL TRANSAXLE21a-65

GEARSHIFT CABLE - SELECTOR (Continued)

Page 3332 of 4284

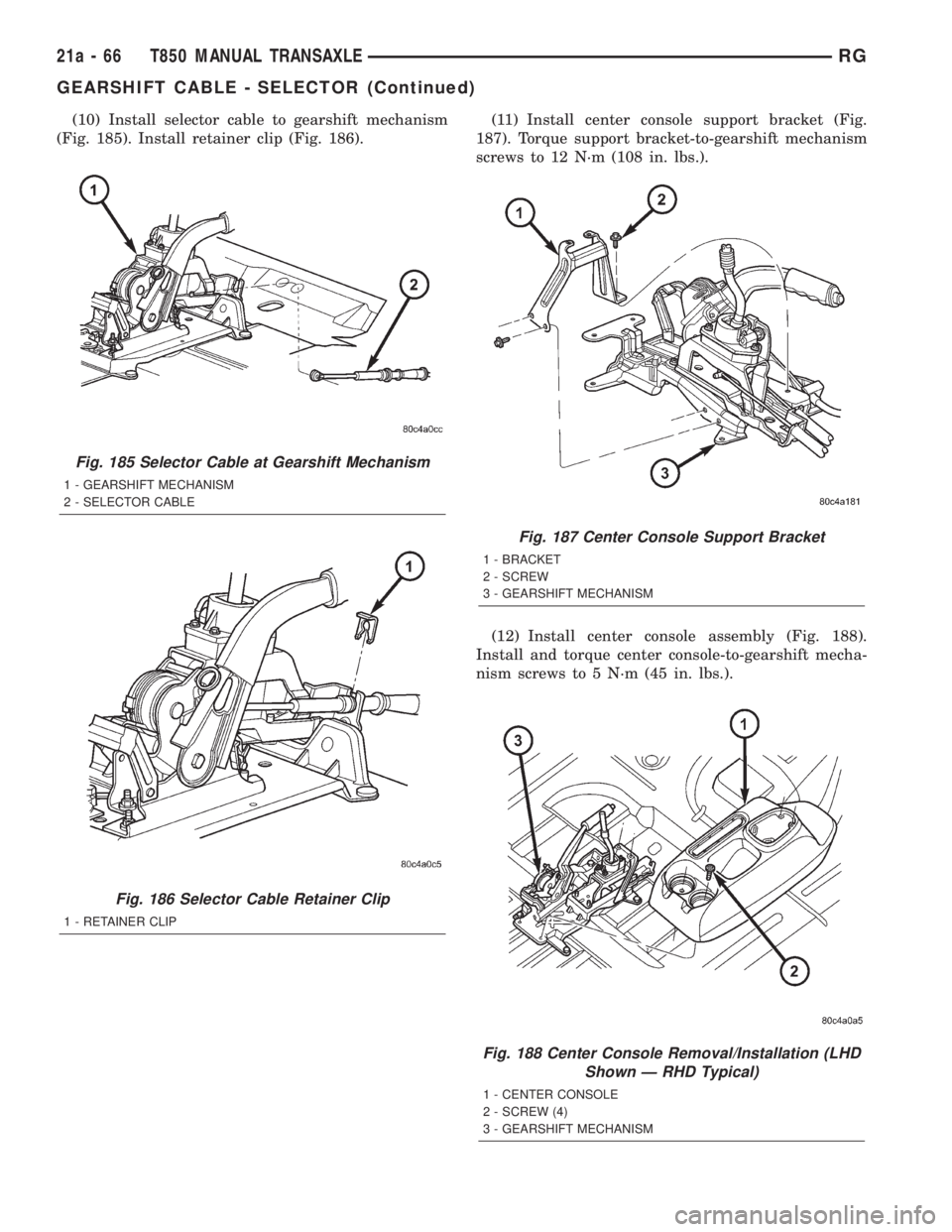

(10) Install selector cable to gearshift mechanism

(Fig. 185). Install retainer clip (Fig. 186).(11) Install center console support bracket (Fig.

187). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).

(12) Install center console assembly (Fig. 188).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

Fig. 185 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

Fig. 186 Selector Cable Retainer Clip

1 - RETAINER CLIP

Fig. 187 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 188 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

21a - 66 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - SELECTOR (Continued)

Page 3333 of 4284

(13) Install cupholder plugs (Fig. 189).

(14) Install gearshift boot to console (Fig. 190).

Secure with three (3) retainer clips.

(15) Install gearshift knob to gearshift lever (Fig.

191). Orient shift pattern ò-turn clockwise, push

down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(16) Connect battery negative cable.

GEARSHIFT KNOB

REMOVAL

(1) Separate gearshift boot from base of knob.

(2) Remove gearshift knob by pushing down and

rotating ò-turn clockwise (Fig. 192).

INSTALLATION

(1) Install gearshift knob pattern ò-turn clock-

wise, press down, and rotate ò-turn counter clock-

wise (Fig. 192).

(2) Secure gearshift boot to base of knob.

Fig. 189 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 190 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 191 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 192 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

RGT850 MANUAL TRANSAXLE21a-67

GEARSHIFT CABLE - SELECTOR (Continued)

Page 3334 of 4284

GEARSHIFT MECHANISM

REMOVAL

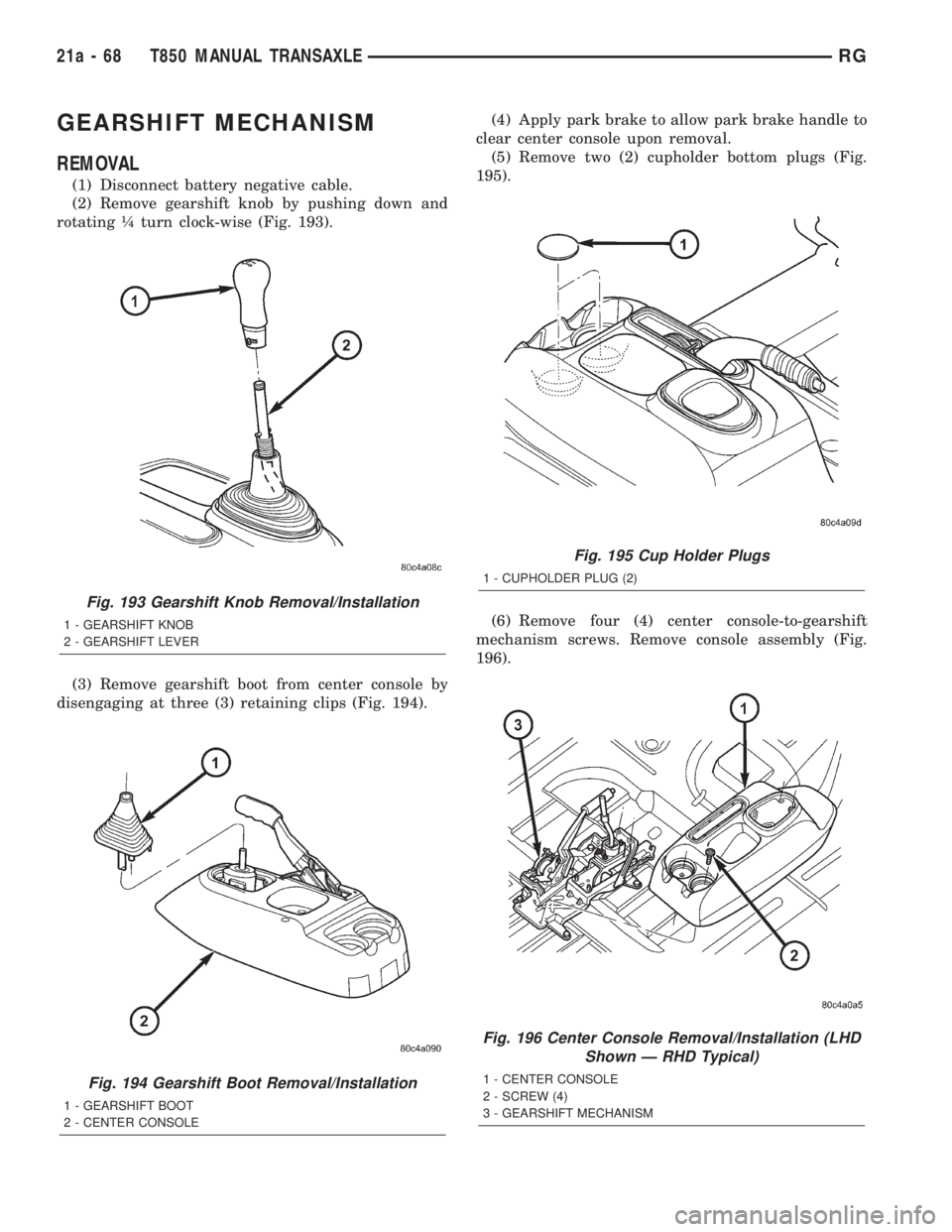

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating ò turn clock-wise (Fig. 193).

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 194).(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

195).

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

196).

Fig. 193 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 194 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 195 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 196 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

21a - 68 T850 MANUAL TRANSAXLERG

Page 3335 of 4284

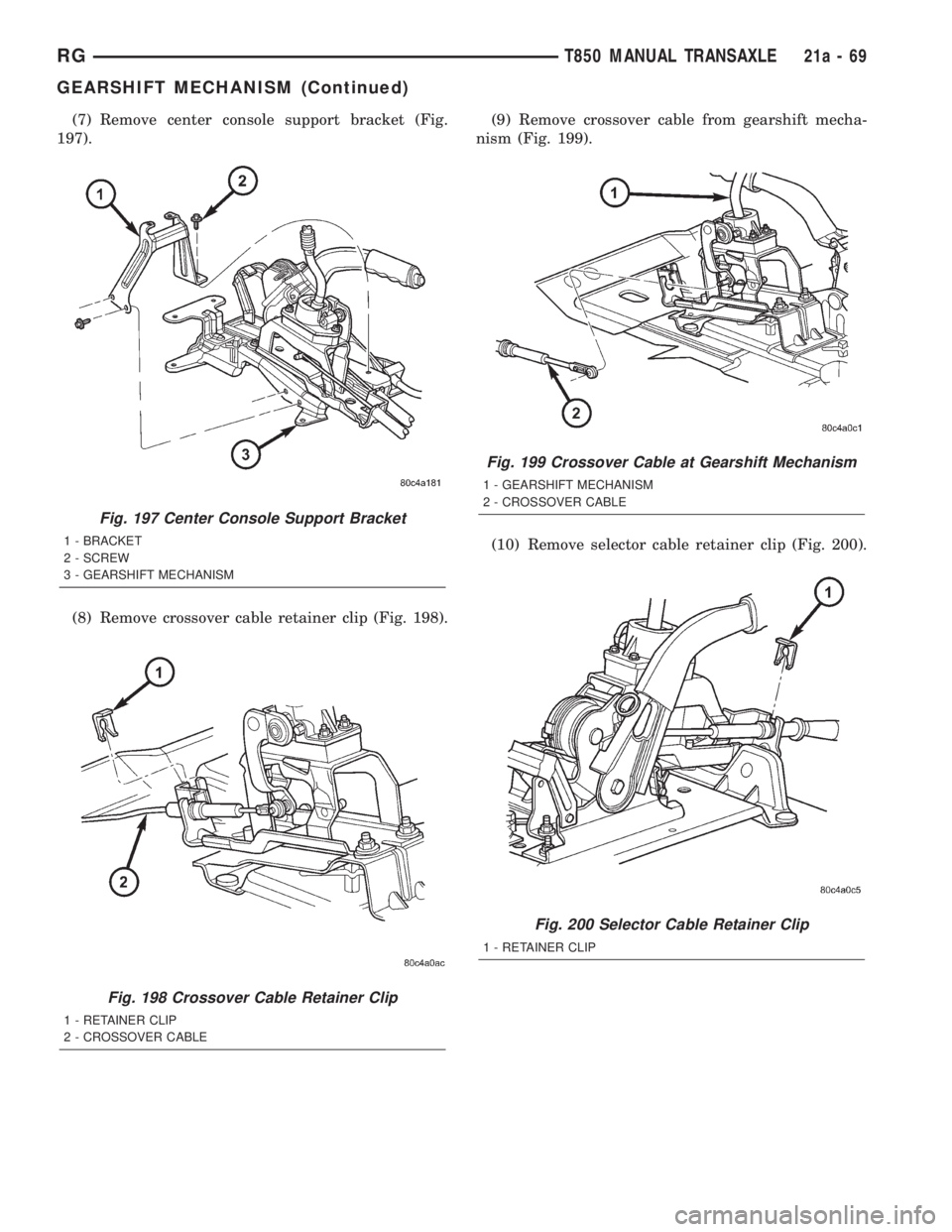

(7) Remove center console support bracket (Fig.

197).

(8) Remove crossover cable retainer clip (Fig. 198).(9) Remove crossover cable from gearshift mecha-

nism (Fig. 199).

(10) Remove selector cable retainer clip (Fig. 200).

Fig. 197 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 198 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 199 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

Fig. 200 Selector Cable Retainer Clip

1 - RETAINER CLIP

RGT850 MANUAL TRANSAXLE21a-69

GEARSHIFT MECHANISM (Continued)

Page 3336 of 4284

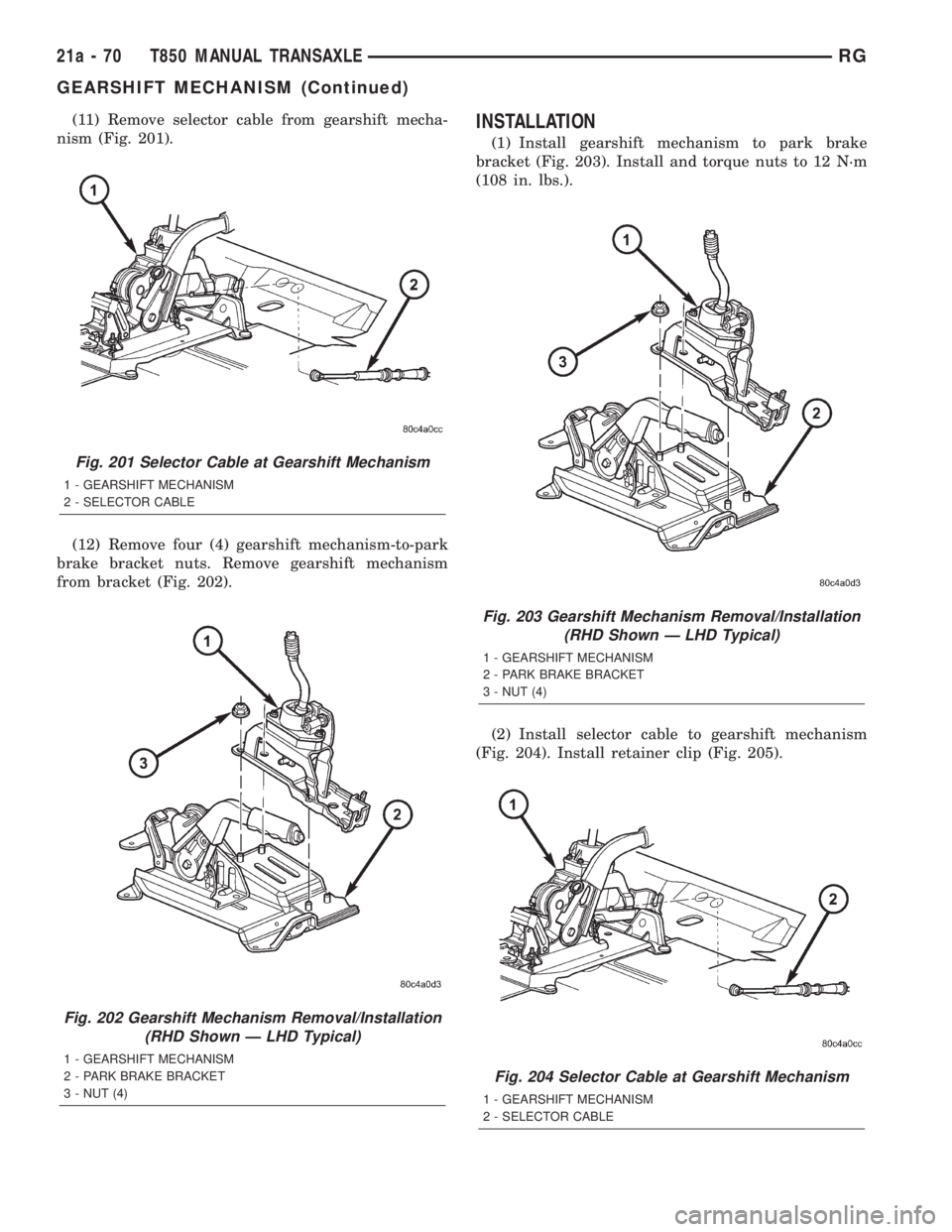

(11) Remove selector cable from gearshift mecha-

nism (Fig. 201).

(12) Remove four (4) gearshift mechanism-to-park

brake bracket nuts. Remove gearshift mechanism

from bracket (Fig. 202).INSTALLATION

(1) Install gearshift mechanism to park brake

bracket (Fig. 203). Install and torque nuts to 12 N´m

(108 in. lbs.).

(2) Install selector cable to gearshift mechanism

(Fig. 204). Install retainer clip (Fig. 205).

Fig. 201 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

Fig. 202 Gearshift Mechanism Removal/Installation

(RHD Shown Ð LHD Typical)

1 - GEARSHIFT MECHANISM

2 - PARK BRAKE BRACKET

3 - NUT (4)

Fig. 203 Gearshift Mechanism Removal/Installation

(RHD Shown Ð LHD Typical)

1 - GEARSHIFT MECHANISM

2 - PARK BRAKE BRACKET

3 - NUT (4)

Fig. 204 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

21a - 70 T850 MANUAL TRANSAXLERG

GEARSHIFT MECHANISM (Continued)

Page 3337 of 4284

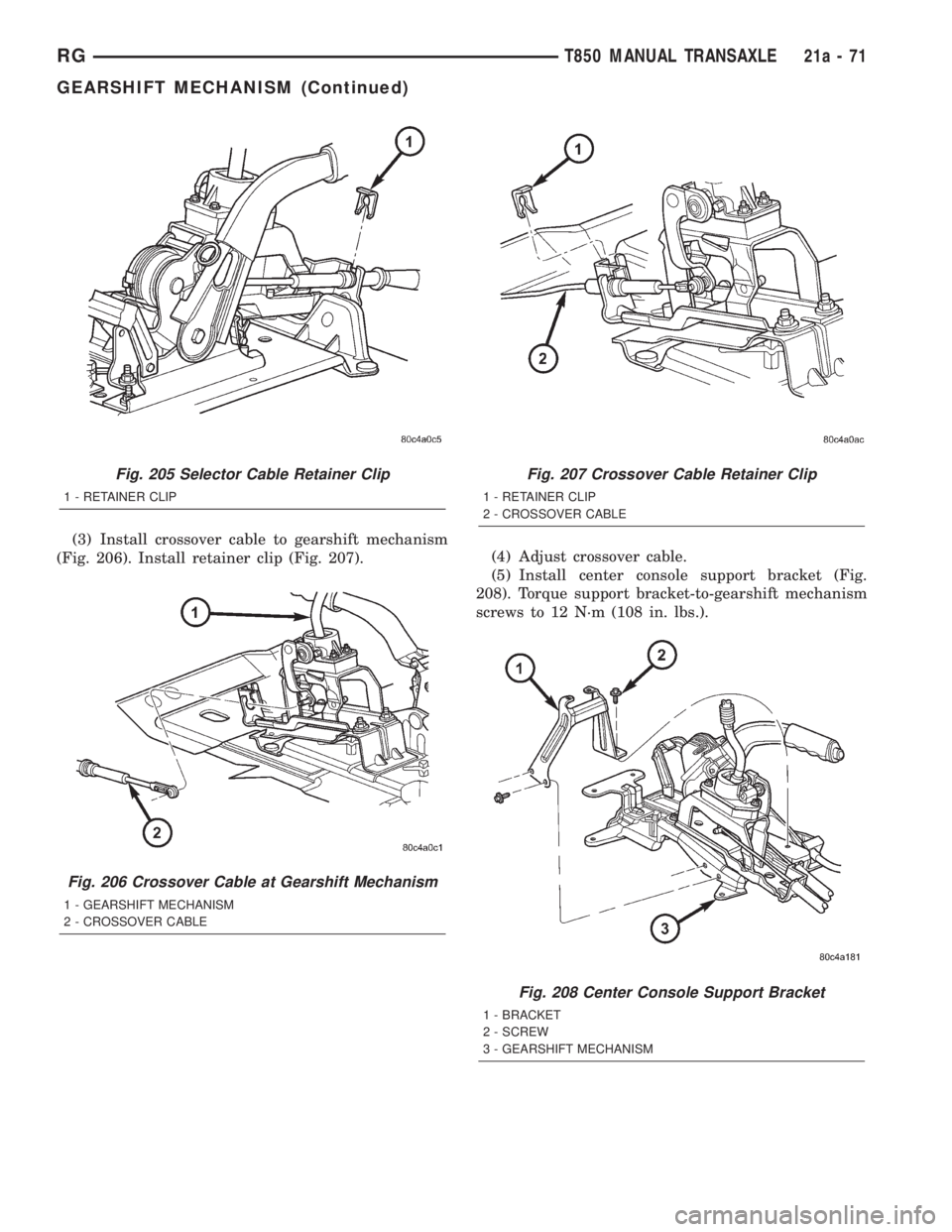

(3) Install crossover cable to gearshift mechanism

(Fig. 206). Install retainer clip (Fig. 207).(4) Adjust crossover cable.

(5) Install center console support bracket (Fig.

208). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).

Fig. 205 Selector Cable Retainer Clip

1 - RETAINER CLIP

Fig. 206 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

Fig. 207 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 208 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

RGT850 MANUAL TRANSAXLE21a-71

GEARSHIFT MECHANISM (Continued)

Page 3338 of 4284

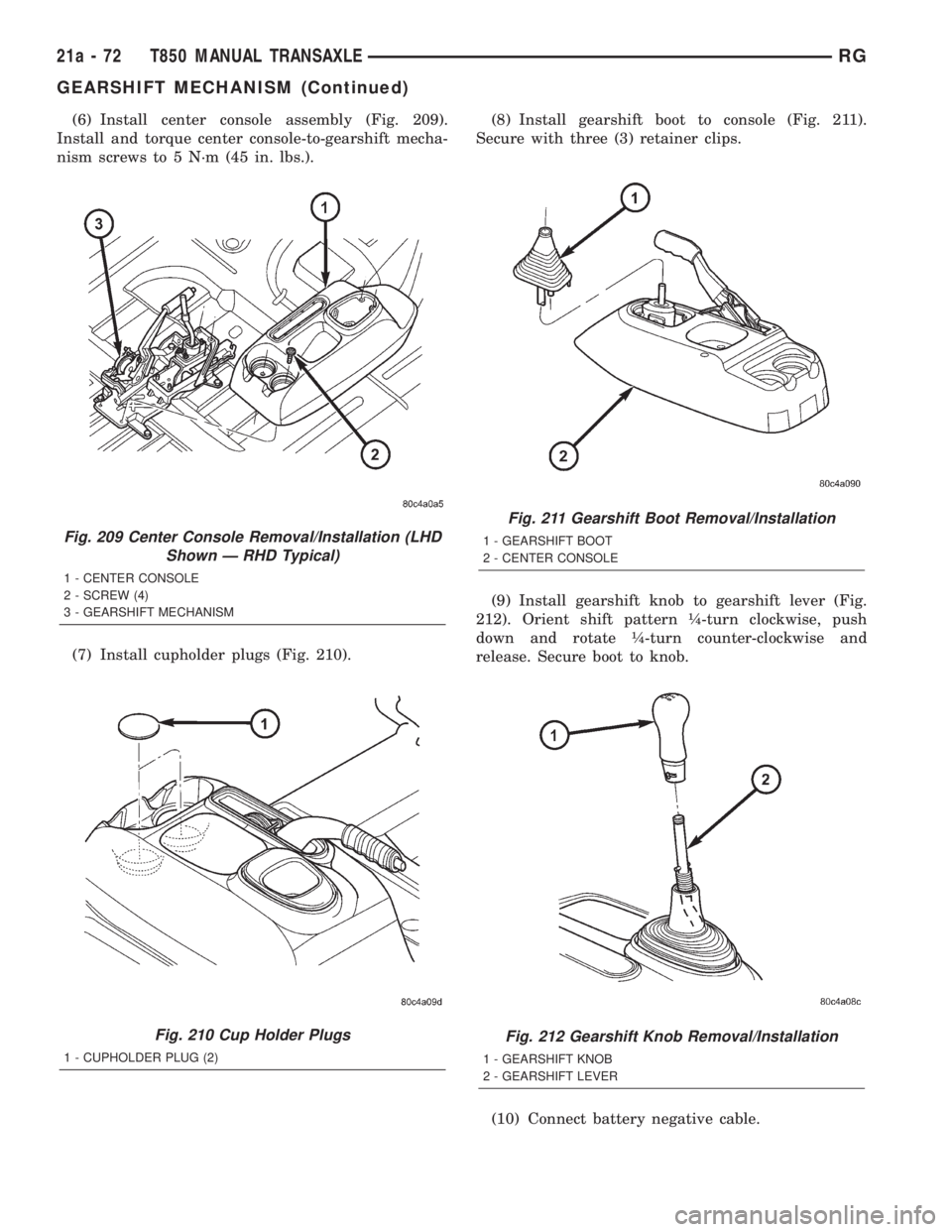

(6) Install center console assembly (Fig. 209).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(7) Install cupholder plugs (Fig. 210).(8) Install gearshift boot to console (Fig. 211).

Secure with three (3) retainer clips.

(9) Install gearshift knob to gearshift lever (Fig.

212). Orient shift pattern ò-turn clockwise, push

down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(10) Connect battery negative cable.

Fig. 209 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 210 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 211 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 212 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

21a - 72 T850 MANUAL TRANSAXLERG

GEARSHIFT MECHANISM (Continued)

Page 3339 of 4284

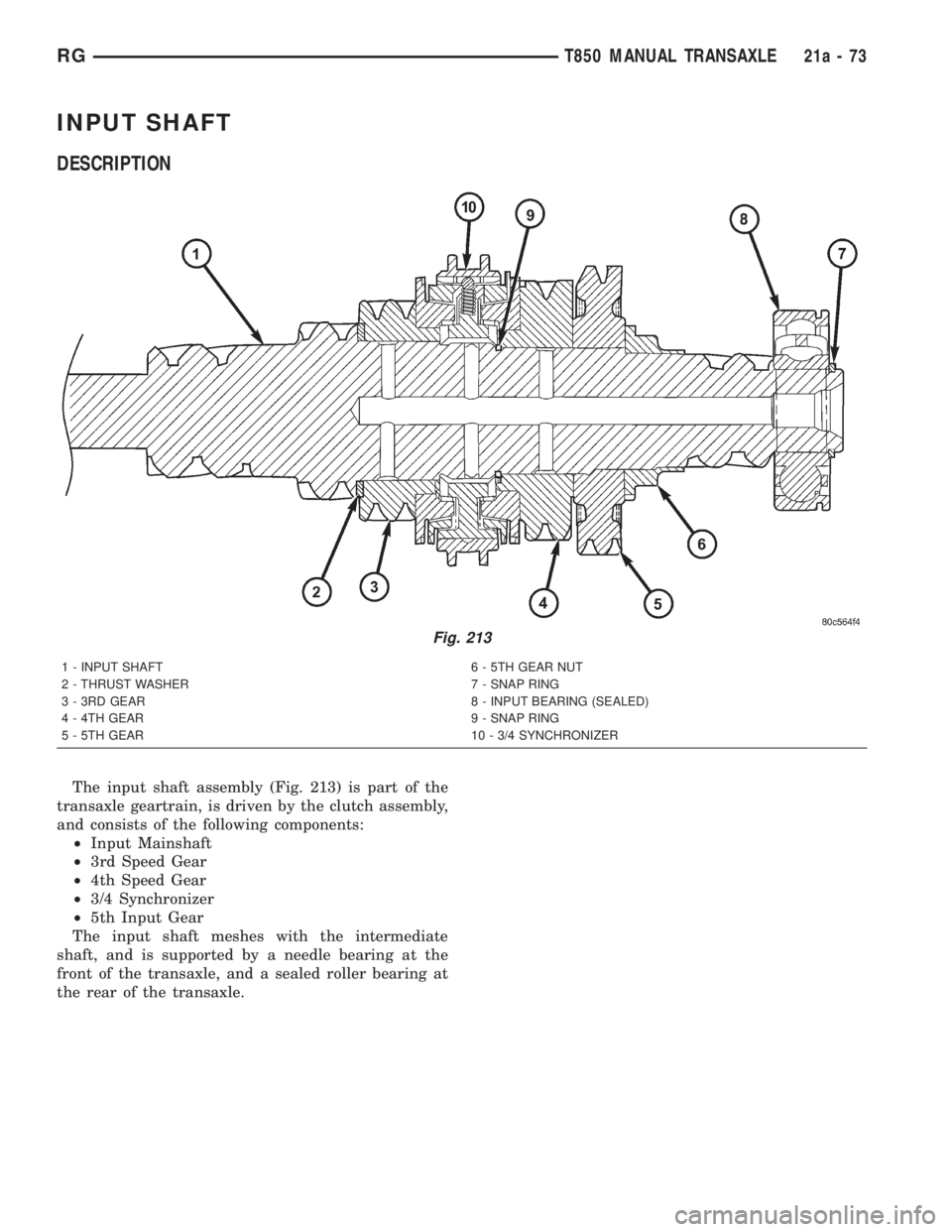

INPUT SHAFT

DESCRIPTION

The input shaft assembly (Fig. 213) is part of the

transaxle geartrain, is driven by the clutch assembly,

and consists of the following components:

²Input Mainshaft

²3rd Speed Gear

²4th Speed Gear

²3/4 Synchronizer

²5th Input Gear

The input shaft meshes with the intermediate

shaft, and is supported by a needle bearing at the

front of the transaxle, and a sealed roller bearing at

the rear of the transaxle.

1 - INPUT SHAFT 6 - 5TH GEAR NUT

2 - THRUST WASHER 7 - SNAP RING

3 - 3RD GEAR 8 - INPUT BEARING (SEALED)

4 - 4TH GEAR 9 - SNAP RING

5 - 5TH GEAR 10 - 3/4 SYNCHRONIZER

Fig. 213

RGT850 MANUAL TRANSAXLE21a-73

Page 3340 of 4284

DISASSEMBLY

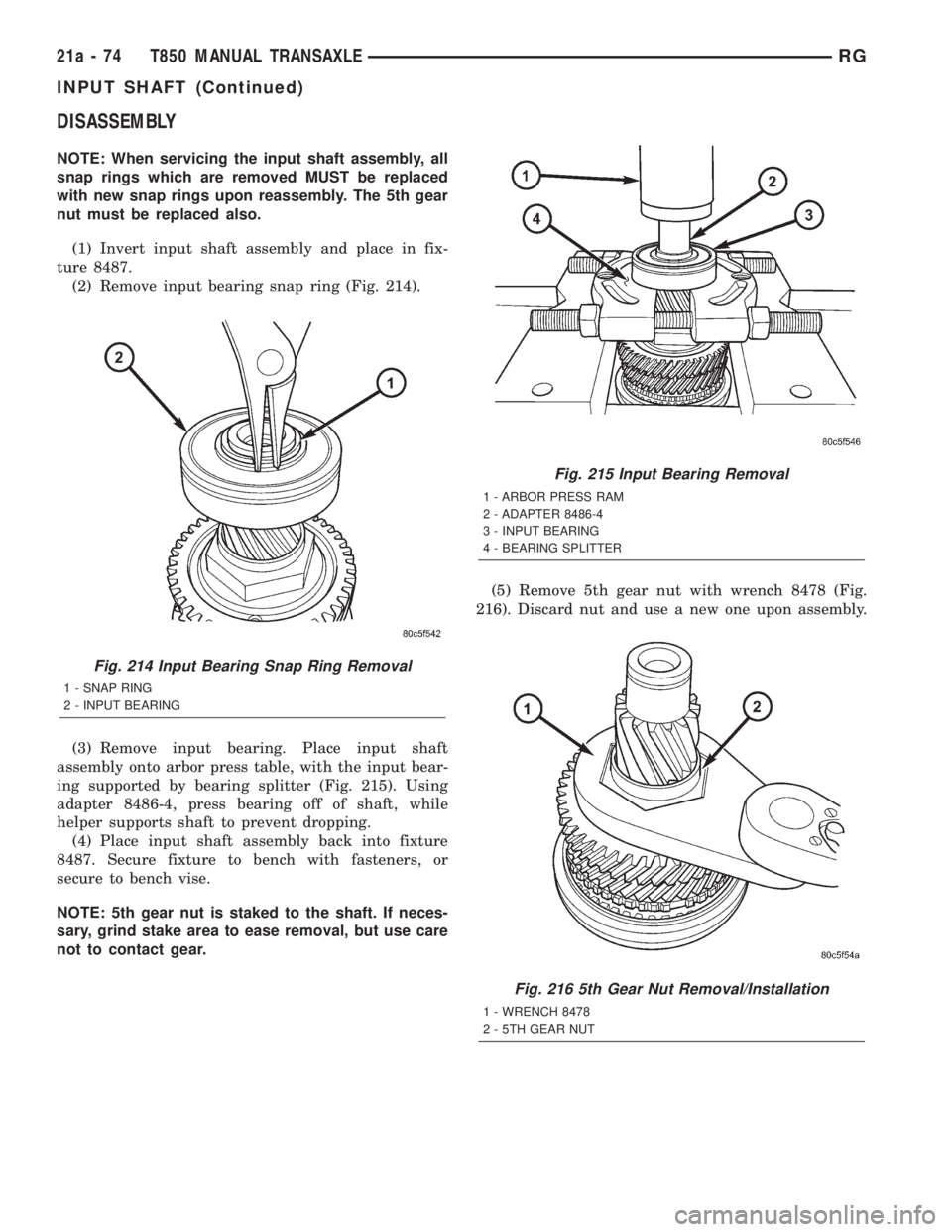

NOTE: When servicing the input shaft assembly, all

snap rings which are removed MUST be replaced

with new snap rings upon reassembly. The 5th gear

nut must be replaced also.

(1) Invert input shaft assembly and place in fix-

ture 8487.

(2) Remove input bearing snap ring (Fig. 214).

(3) Remove input bearing. Place input shaft

assembly onto arbor press table, with the input bear-

ing supported by bearing splitter (Fig. 215). Using

adapter 8486-4, press bearing off of shaft, while

helper supports shaft to prevent dropping.

(4) Place input shaft assembly back into fixture

8487. Secure fixture to bench with fasteners, or

secure to bench vise.

NOTE: 5th gear nut is staked to the shaft. If neces-

sary, grind stake area to ease removal, but use care

not to contact gear.(5) Remove 5th gear nut with wrench 8478 (Fig.

216). Discard nut and use a new one upon assembly.

Fig. 214 Input Bearing Snap Ring Removal

1 - SNAP RING

2 - INPUT BEARING

Fig. 215 Input Bearing Removal

1 - ARBOR PRESS RAM

2 - ADAPTER 8486-4

3 - INPUT BEARING

4 - BEARING SPLITTER

Fig. 216 5th Gear Nut Removal/Installation

1 - WRENCH 8478

2 - 5TH GEAR NUT

21a - 74 T850 MANUAL TRANSAXLERG

INPUT SHAFT (Continued)