CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3301 of 4284

(8) Install engine front mount bracket. Install and

torque bracket-to-transaxle bolts to 102 N´m (75 ft.

lbs.). Install and torque bracket-to-engine bolts to 68

N´m (50 ft. lbs.). Torque through-bolt and nut to 68

N´m (50 ft. lbs.).

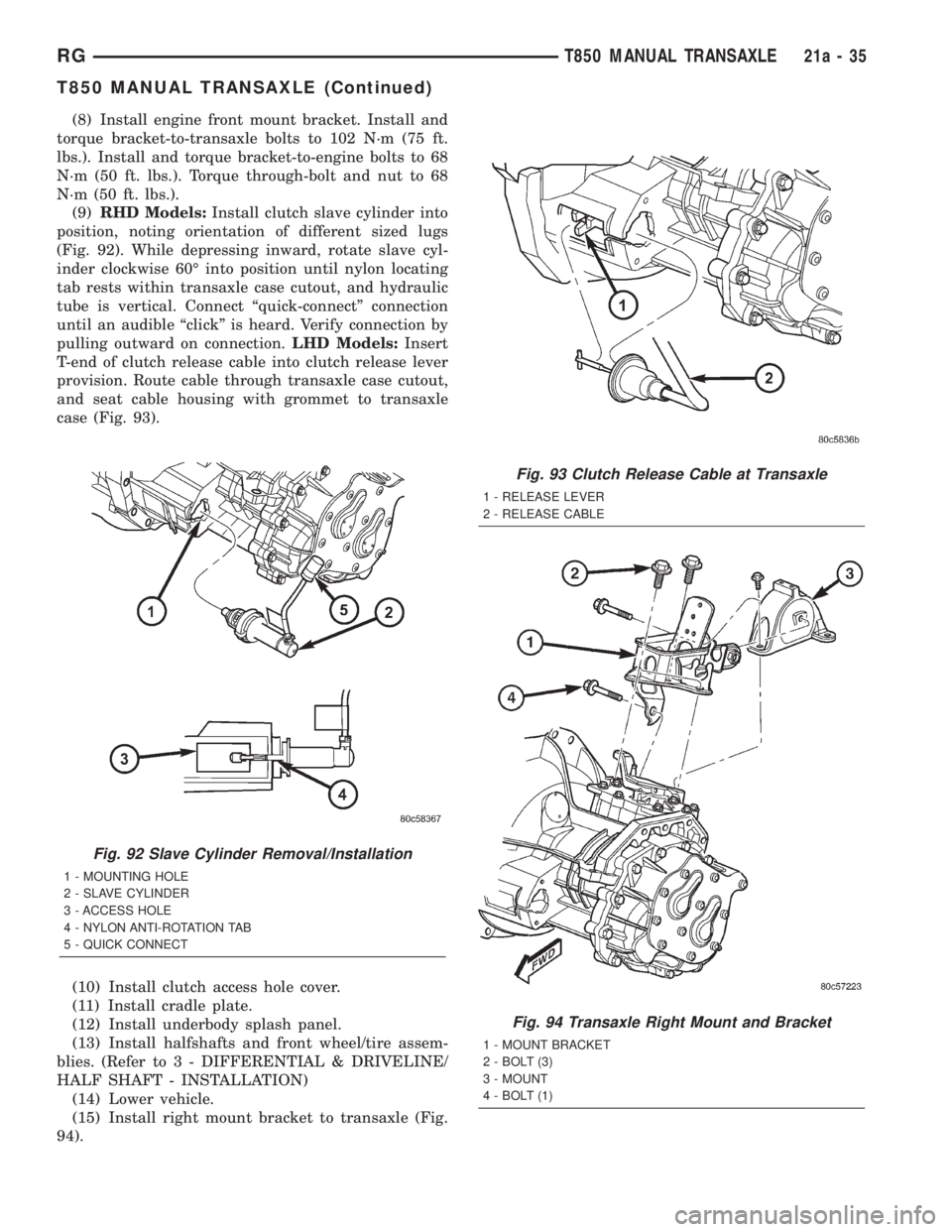

(9)RHD Models:Install clutch slave cylinder into

position, noting orientation of different sized lugs

(Fig. 92). While depressing inward, rotate slave cyl-

inder clockwise 60É into position until nylon locating

tab rests within transaxle case cutout, and hydraulic

tube is vertical. Connect ªquick-connectº connection

until an audible ªclickº is heard. Verify connection by

pulling outward on connection.LHD Models:Insert

T-end of clutch release cable into clutch release lever

provision. Route cable through transaxle case cutout,

and seat cable housing with grommet to transaxle

case (Fig. 93).

(10) Install clutch access hole cover.

(11) Install cradle plate.

(12) Install underbody splash panel.

(13) Install halfshafts and front wheel/tire assem-

blies. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

HALF SHAFT - INSTALLATION)

(14) Lower vehicle.

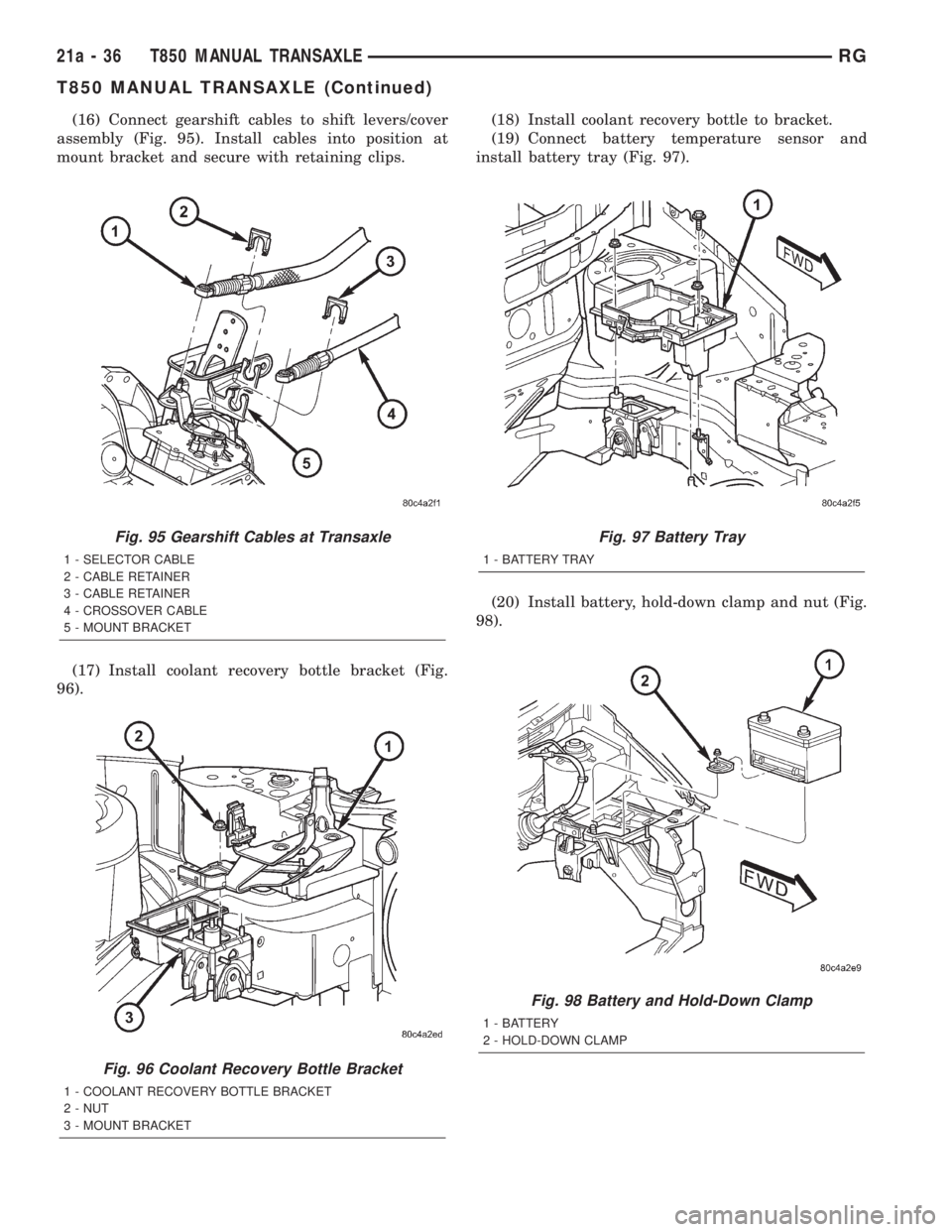

(15) Install right mount bracket to transaxle (Fig.

94).

Fig. 92 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 93 Clutch Release Cable at Transaxle

1 - RELEASE LEVER

2 - RELEASE CABLE

Fig. 94 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

RGT850 MANUAL TRANSAXLE21a-35

T850 MANUAL TRANSAXLE (Continued)

Page 3302 of 4284

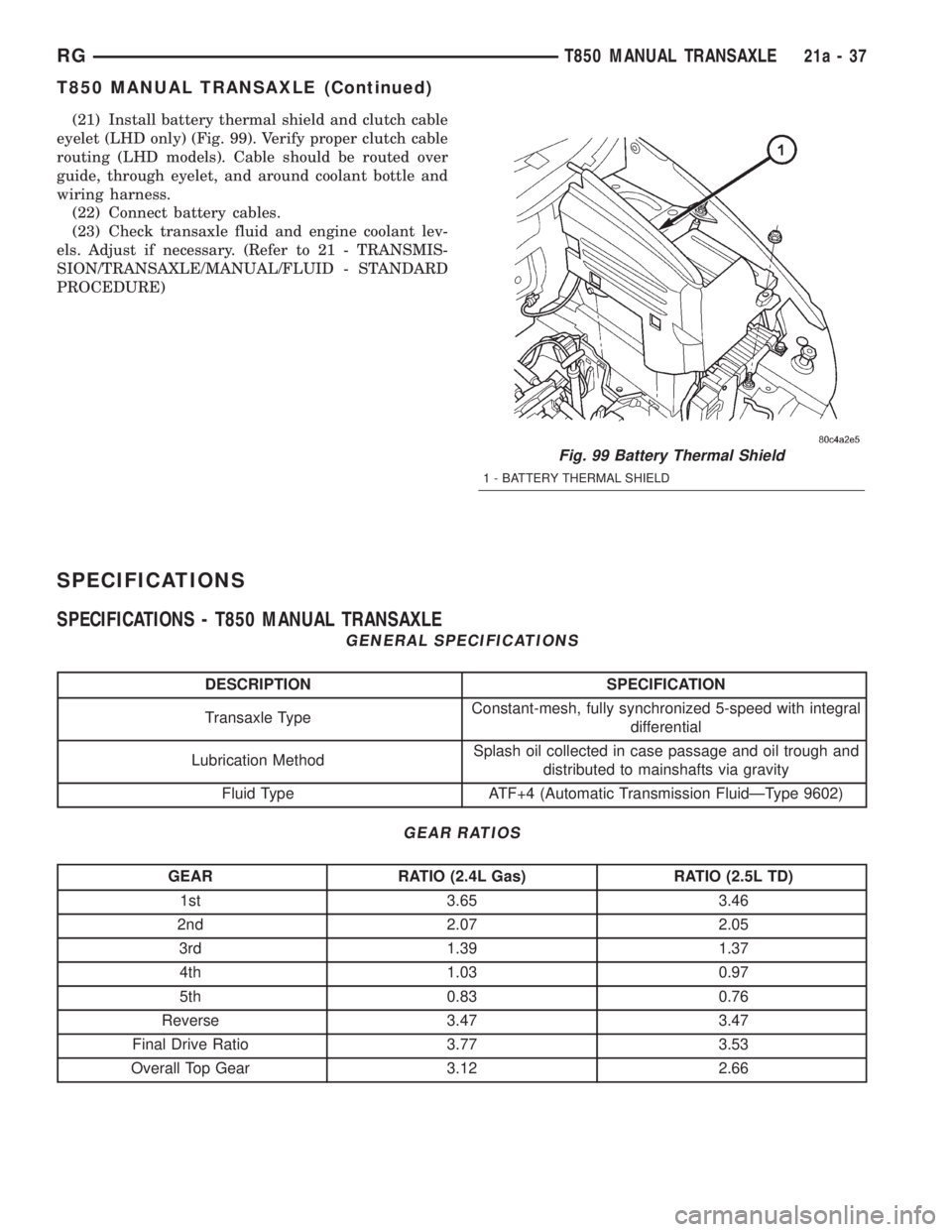

(16) Connect gearshift cables to shift levers/cover

assembly (Fig. 95). Install cables into position at

mount bracket and secure with retaining clips.

(17) Install coolant recovery bottle bracket (Fig.

96).(18) Install coolant recovery bottle to bracket.

(19) Connect battery temperature sensor and

install battery tray (Fig. 97).

(20) Install battery, hold-down clamp and nut (Fig.

98).

Fig. 95 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 96 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 97 Battery Tray

1 - BATTERY TRAY

Fig. 98 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

21a - 36 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3303 of 4284

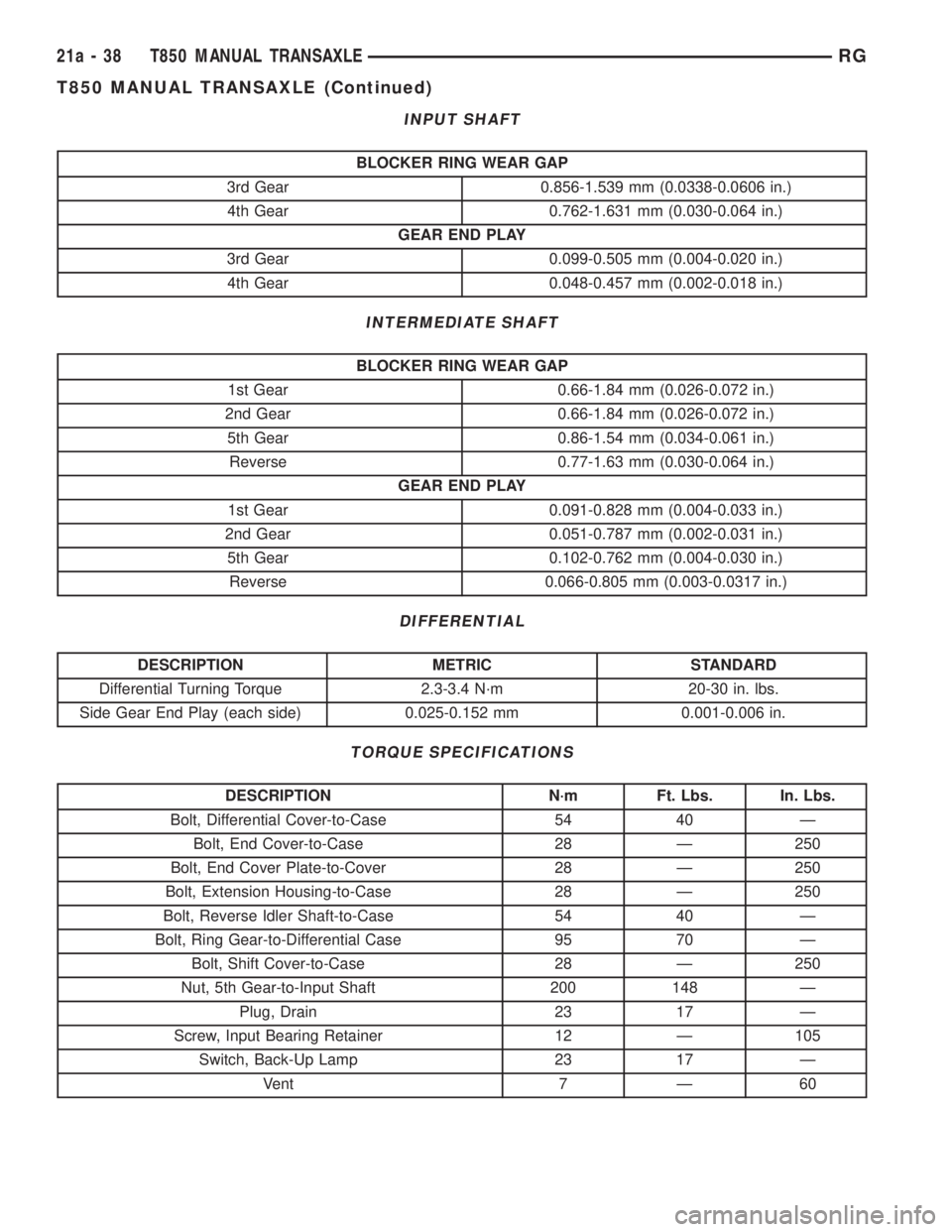

(21) Install battery thermal shield and clutch cable

eyelet (LHD only) (Fig. 99). Verify proper clutch cable

routing (LHD models). Cable should be routed over

guide, through eyelet, and around coolant bottle and

wiring harness.

(22) Connect battery cables.

(23) Check transaxle fluid and engine coolant lev-

els. Adjust if necessary. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL/FLUID - STANDARD

PROCEDURE)

SPECIFICATIONS

SPECIFICATIONS - T850 MANUAL TRANSAXLE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Transaxle TypeConstant-mesh, fully synchronized 5-speed with integral

differential

Lubrication MethodSplash oil collected in case passage and oil trough and

distributed to mainshafts via gravity

Fluid Type ATF+4 (Automatic Transmission FluidÐType 9602)

GEAR RATIOS

GEAR RATIO (2.4L Gas) RATIO (2.5L TD)

1st 3.65 3.46

2nd 2.07 2.05

3rd 1.39 1.37

4th 1.03 0.97

5th 0.83 0.76

Reverse 3.47 3.47

Final Drive Ratio 3.77 3.53

Overall Top Gear 3.12 2.66

Fig. 99 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

RGT850 MANUAL TRANSAXLE21a-37

T850 MANUAL TRANSAXLE (Continued)

Page 3304 of 4284

INPUT SHAFT

BLOCKER RING WEAR GAP

3rd Gear 0.856-1.539 mm (0.0338-0.0606 in.)

4th Gear 0.762-1.631 mm (0.030-0.064 in.)

GEAR END PLAY

3rd Gear 0.099-0.505 mm (0.004-0.020 in.)

4th Gear 0.048-0.457 mm (0.002-0.018 in.)

INTERMEDIATE SHAFT

BLOCKER RING WEAR GAP

1st Gear 0.66-1.84 mm (0.026-0.072 in.)

2nd Gear 0.66-1.84 mm (0.026-0.072 in.)

5th Gear 0.86-1.54 mm (0.034-0.061 in.)

Reverse 0.77-1.63 mm (0.030-0.064 in.)

GEAR END PLAY

1st Gear 0.091-0.828 mm (0.004-0.033 in.)

2nd Gear 0.051-0.787 mm (0.002-0.031 in.)

5th Gear 0.102-0.762 mm (0.004-0.030 in.)

Reverse 0.066-0.805 mm (0.003-0.0317 in.)

DIFFERENTIAL

DESCRIPTION METRIC STANDARD

Differential Turning Torque 2.3-3.4 N´m 20-30 in. lbs.

Side Gear End Play (each side) 0.025-0.152 mm 0.001-0.006 in.

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt, Differential Cover-to-Case 54 40 Ð

Bolt, End Cover-to-Case 28 Ð 250

Bolt, End Cover Plate-to-Cover 28 Ð 250

Bolt, Extension Housing-to-Case 28 Ð 250

Bolt, Reverse Idler Shaft-to-Case 54 40 Ð

Bolt, Ring Gear-to-Differential Case 95 70 Ð

Bolt, Shift Cover-to-Case 28 Ð 250

Nut, 5th Gear-to-Input Shaft 200 148 Ð

Plug, Drain 23 17 Ð

Screw, Input Bearing Retainer 12 Ð 105

Switch, Back-Up Lamp 23 17 Ð

Vent 7 Ð 60

21a - 38 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3305 of 4284

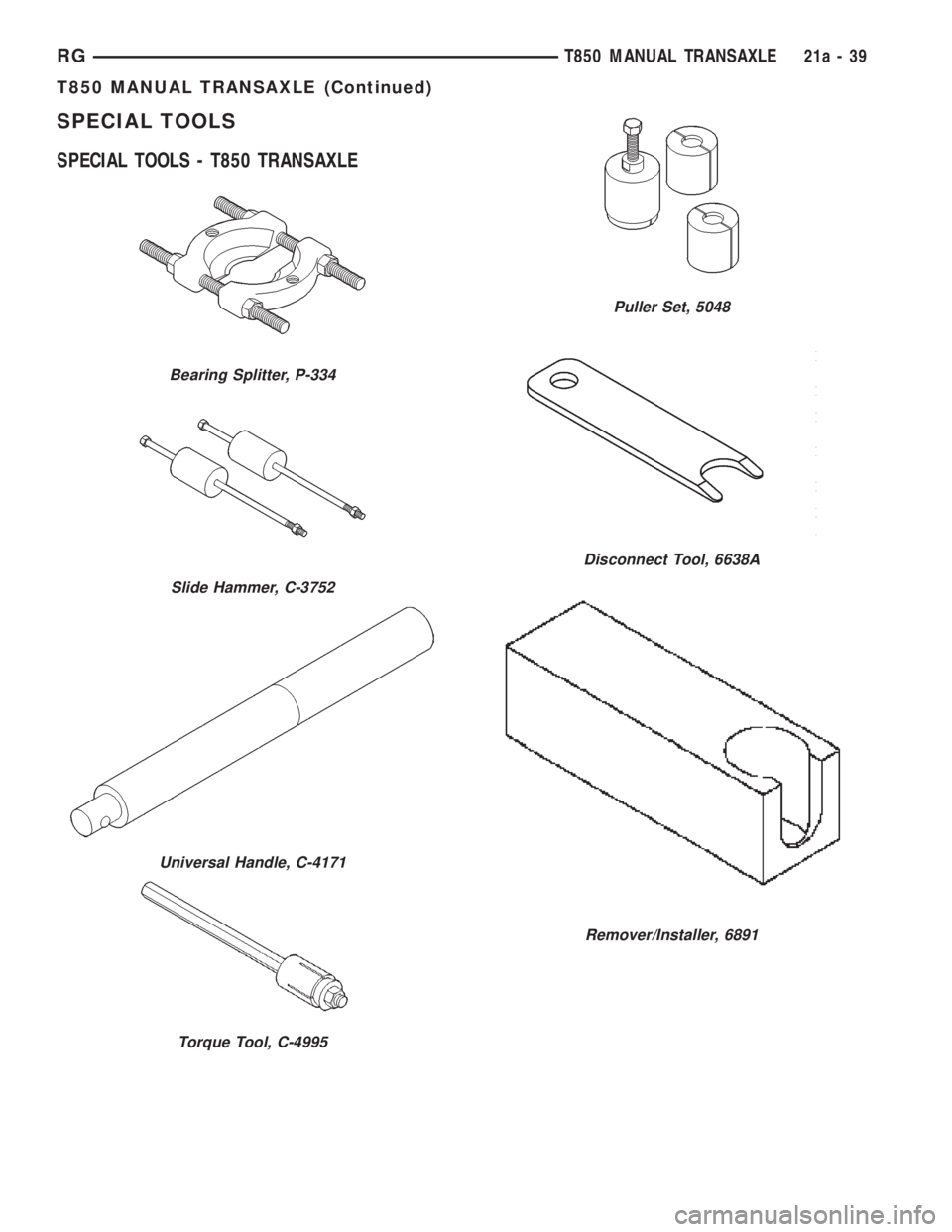

SPECIAL TOOLS

SPECIAL TOOLS - T850 TRANSAXLE

Bearing Splitter, P-334

Slide Hammer, C-3752

Universal Handle, C-4171

Torque Tool, C-4995

Puller Set, 5048

Disconnect Tool, 6638A

Remover/Installer, 6891

RGT850 MANUAL TRANSAXLE21a-39

T850 MANUAL TRANSAXLE (Continued)

Page 3306 of 4284

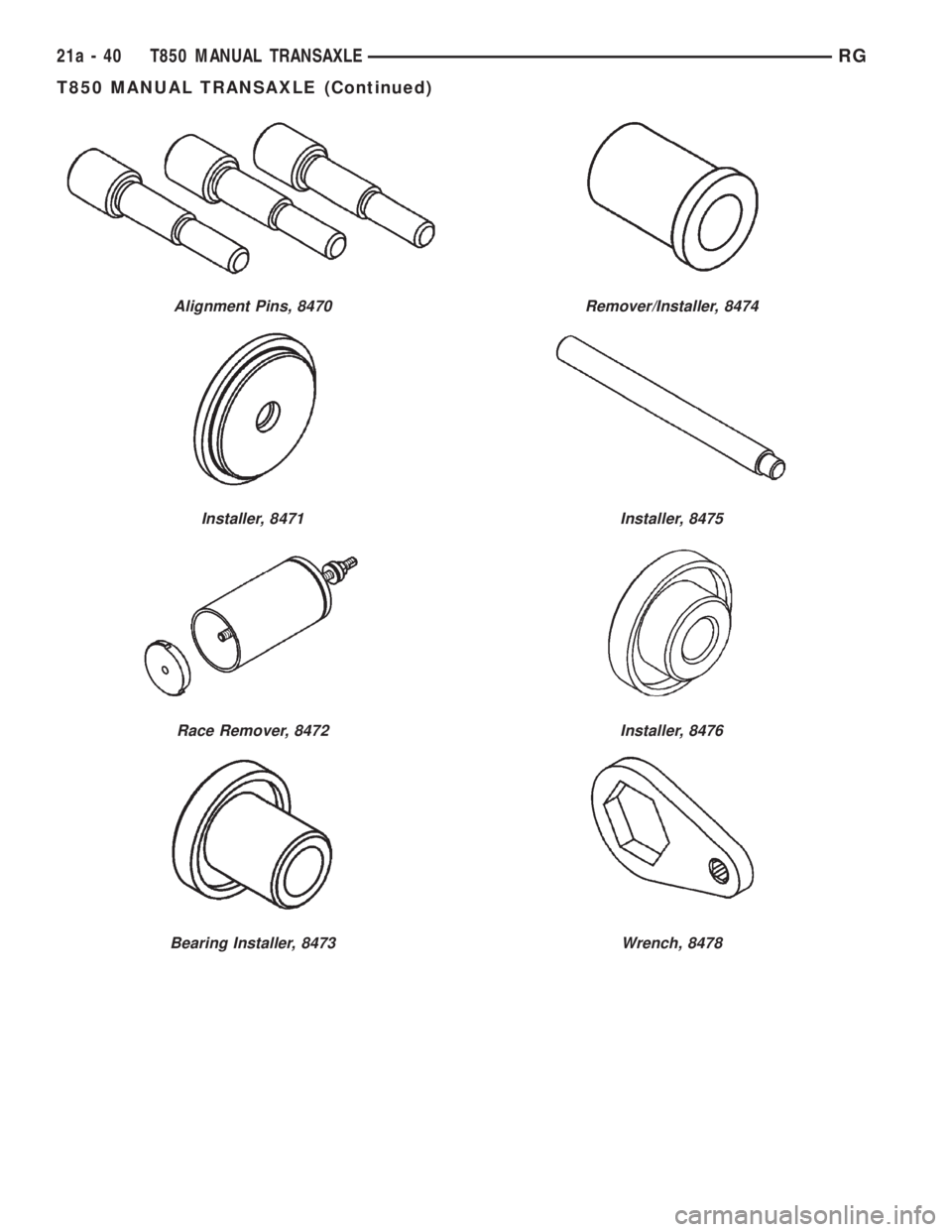

Alignment Pins, 8470

Installer, 8471

Race Remover, 8472

Bearing Installer, 8473

Remover/Installer, 8474

Installer, 8475

Installer, 8476

Wrench, 8478

21a - 40 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3307 of 4284

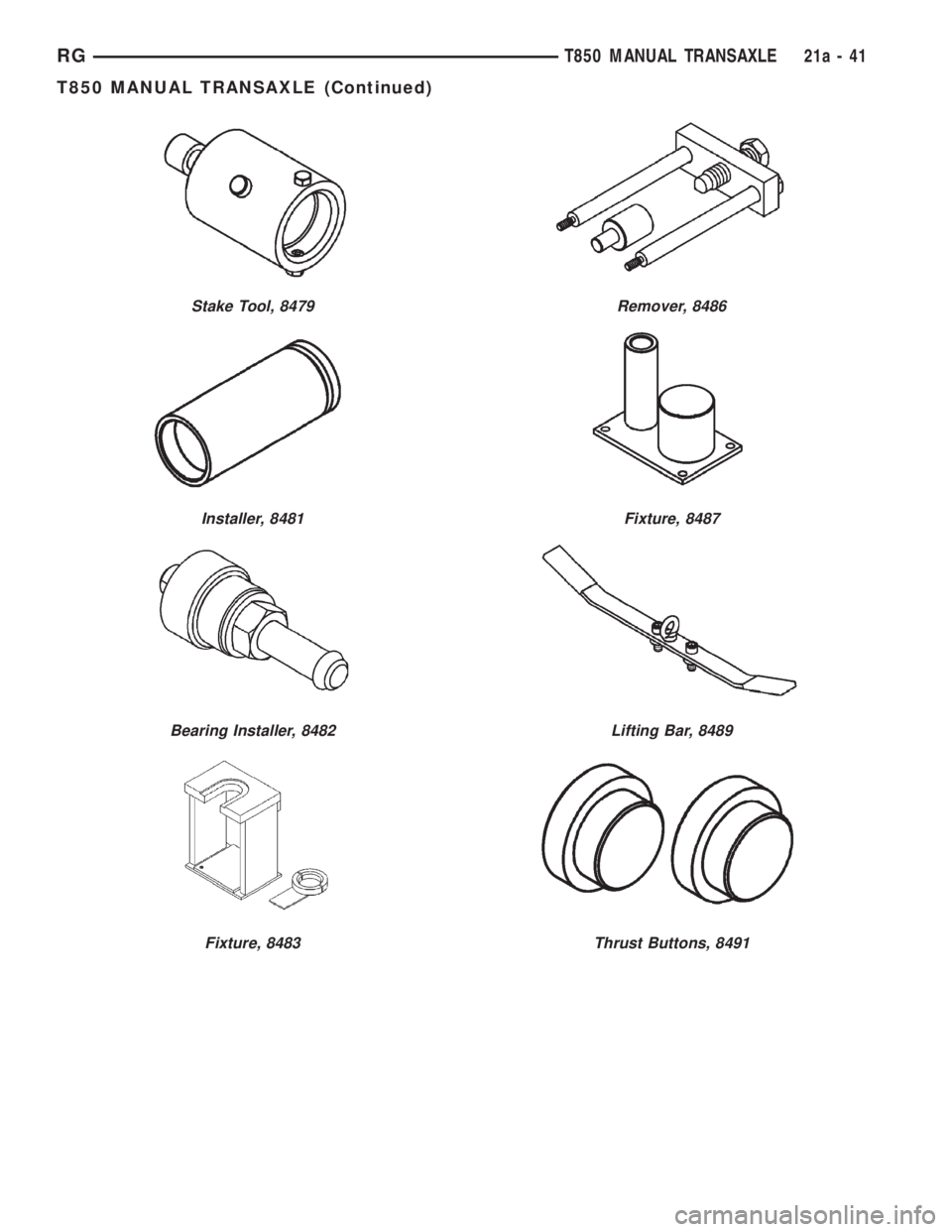

Stake Tool, 8479

Installer, 8481

Bearing Installer, 8482

Fixture, 8483

Remover, 8486

Fixture, 8487

Lifting Bar, 8489

Thrust Buttons, 8491

RGT850 MANUAL TRANSAXLE21a-41

T850 MANUAL TRANSAXLE (Continued)

Page 3308 of 4284

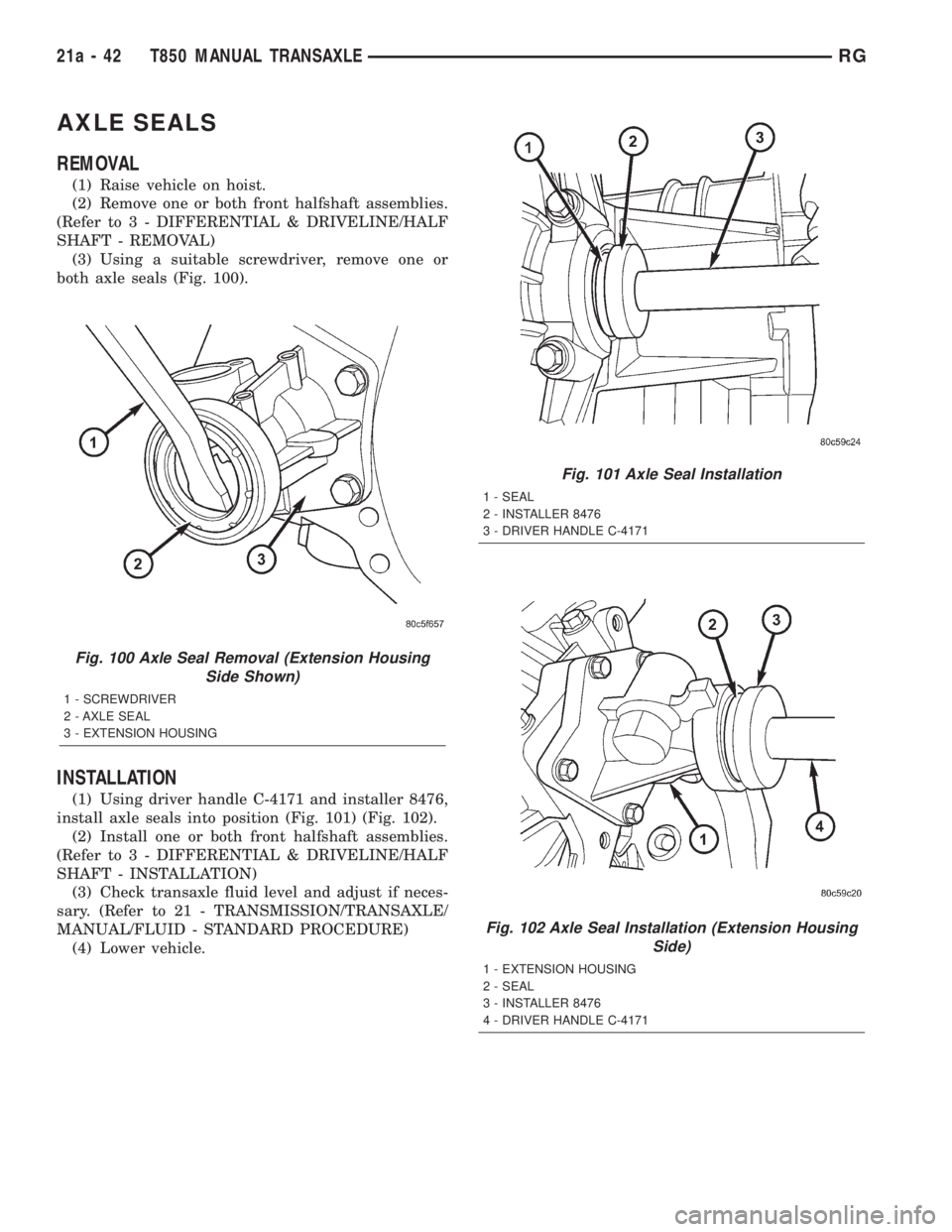

AXLE SEALS

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove one or both front halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - REMOVAL)

(3) Using a suitable screwdriver, remove one or

both axle seals (Fig. 100).

INSTALLATION

(1) Using driver handle C-4171 and installer 8476,

install axle seals into position (Fig. 101) (Fig. 102).

(2) Install one or both front halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION)

(3) Check transaxle fluid level and adjust if neces-

sary. (Refer to 21 - TRANSMISSION/TRANSAXLE/

MANUAL/FLUID - STANDARD PROCEDURE)

(4) Lower vehicle.

Fig. 100 Axle Seal Removal (Extension Housing

Side Shown)

1 - SCREWDRIVER

2 - AXLE SEAL

3 - EXTENSION HOUSING

Fig. 101 Axle Seal Installation

1 - SEAL

2 - INSTALLER 8476

3 - DRIVER HANDLE C-4171

Fig. 102 Axle Seal Installation (Extension Housing

Side)

1 - EXTENSION HOUSING

2 - SEAL

3 - INSTALLER 8476

4 - DRIVER HANDLE C-4171

21a - 42 T850 MANUAL TRANSAXLERG

Page 3309 of 4284

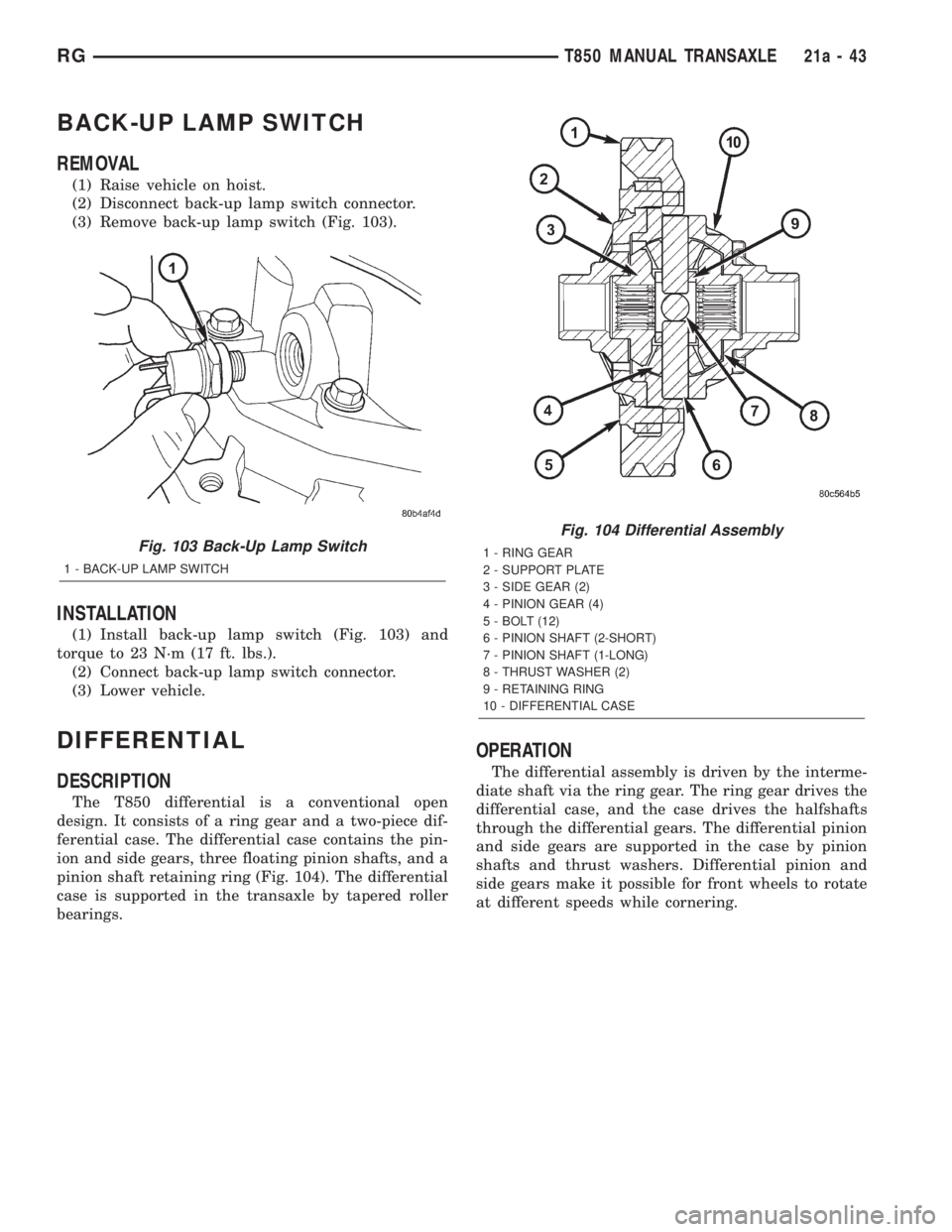

BACK-UP LAMP SWITCH

REMOVAL

(1) Raise vehicle on hoist.

(2) Disconnect back-up lamp switch connector.

(3) Remove back-up lamp switch (Fig. 103).

INSTALLATION

(1) Install back-up lamp switch (Fig. 103) and

torque to 23 N´m (17 ft. lbs.).

(2) Connect back-up lamp switch connector.

(3) Lower vehicle.

DIFFERENTIAL

DESCRIPTION

The T850 differential is a conventional open

design. It consists of a ring gear and a two-piece dif-

ferential case. The differential case contains the pin-

ion and side gears, three floating pinion shafts, and a

pinion shaft retaining ring (Fig. 104). The differential

case is supported in the transaxle by tapered roller

bearings.

OPERATION

The differential assembly is driven by the interme-

diate shaft via the ring gear. The ring gear drives the

differential case, and the case drives the halfshafts

through the differential gears. The differential pinion

and side gears are supported in the case by pinion

shafts and thrust washers. Differential pinion and

side gears make it possible for front wheels to rotate

at different speeds while cornering.

Fig. 103 Back-Up Lamp Switch

1 - BACK-UP LAMP SWITCH

Fig. 104 Differential Assembly

1 - RING GEAR

2 - SUPPORT PLATE

3 - SIDE GEAR (2)

4 - PINION GEAR (4)

5 - BOLT (12)

6 - PINION SHAFT (2-SHORT)

7 - PINION SHAFT (1-LONG)

8 - THRUST WASHER (2)

9 - RETAINING RING

10 - DIFFERENTIAL CASE

RGT850 MANUAL TRANSAXLE21a-43

Page 3310 of 4284

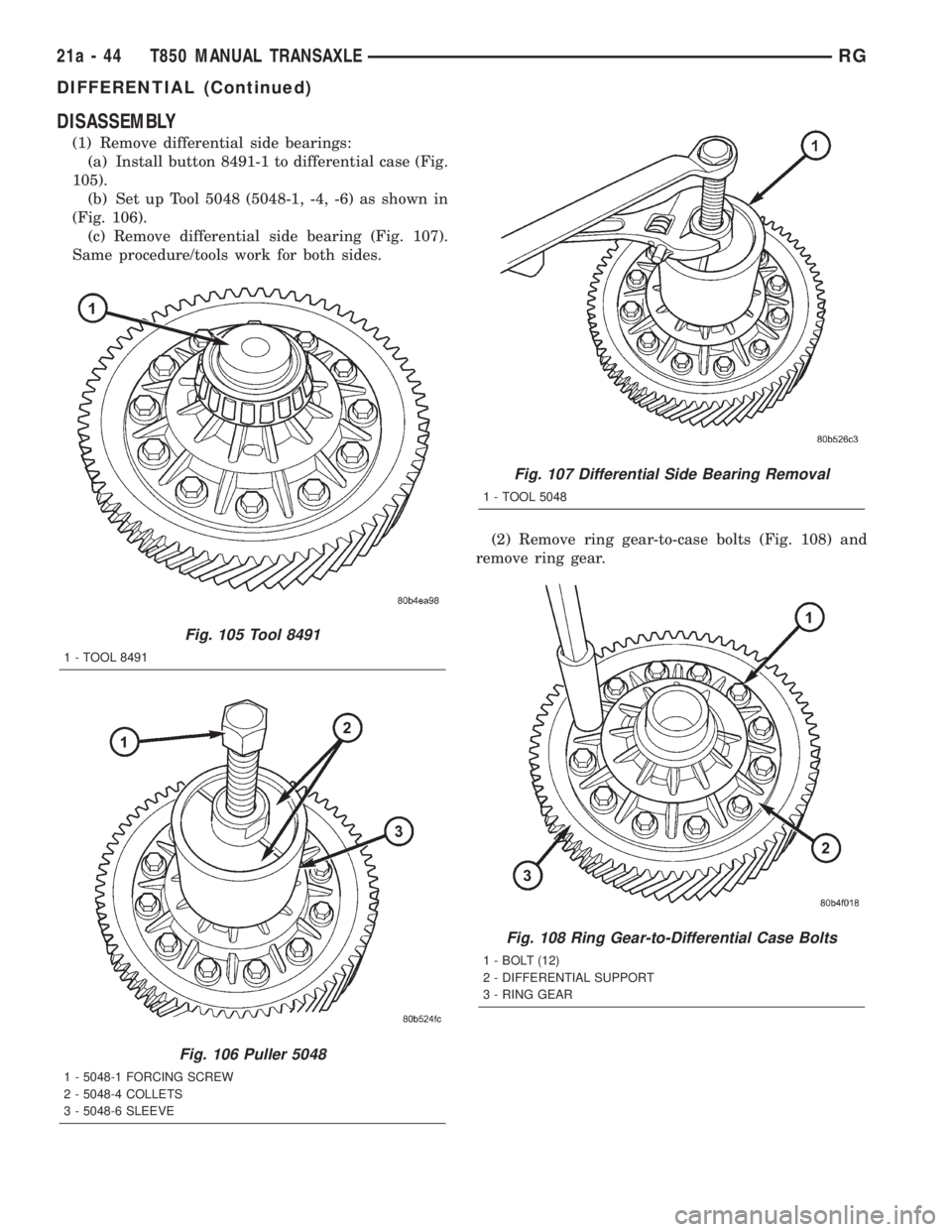

DISASSEMBLY

(1) Remove differential side bearings:

(a) Install button 8491-1 to differential case (Fig.

105).

(b) Set up Tool 5048 (5048-1, -4, -6) as shown in

(Fig. 106).

(c) Remove differential side bearing (Fig. 107).

Same procedure/tools work for both sides.

(2) Remove ring gear-to-case bolts (Fig. 108) and

remove ring gear.

Fig. 105 Tool 8491

1 - TOOL 8491

Fig. 106 Puller 5048

1 - 5048-1 FORCING SCREW

2 - 5048-4 COLLETS

3 - 5048-6 SLEEVE

Fig. 107 Differential Side Bearing Removal

1 - TOOL 5048

Fig. 108 Ring Gear-to-Differential Case Bolts

1 - BOLT (12)

2 - DIFFERENTIAL SUPPORT

3 - RING GEAR

21a - 44 T850 MANUAL TRANSAXLERG

DIFFERENTIAL (Continued)