CHRYSLER VOYAGER 2001 Service Manual

VOYAGER 2001

CHRYSLER

CHRYSLER

https://www.carmanualsonline.info/img/25/56872/w960_56872-0.png

CHRYSLER VOYAGER 2001 Service Manual

Trending: airbag off, alarm, manual transmission, fan, oil additives, AUX, bolt pattern

Page 3341 of 4284

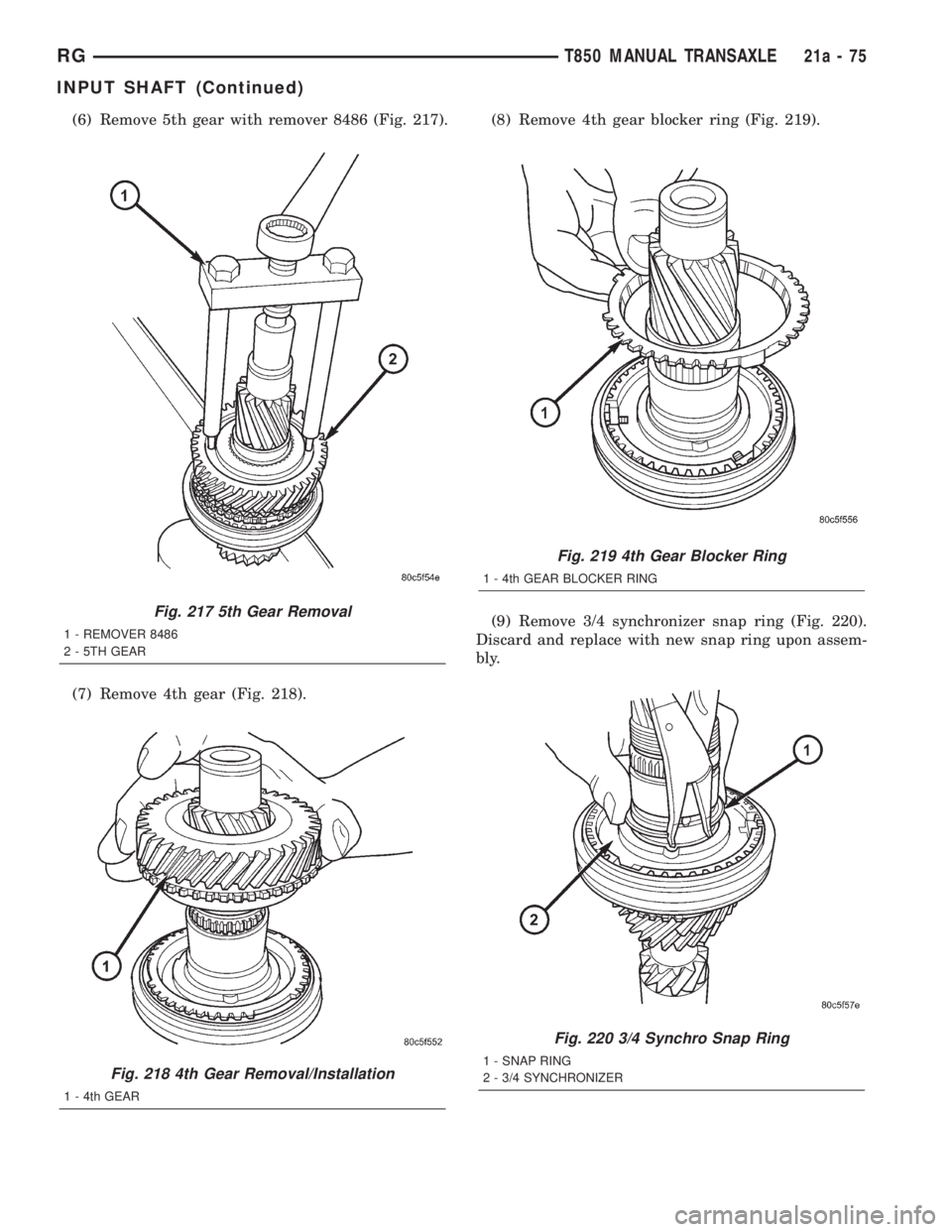

(6) Remove 5th gear with remover 8486 (Fig. 217).

(7) Remove 4th gear (Fig. 218).(8) Remove 4th gear blocker ring (Fig. 219).

(9) Remove 3/4 synchronizer snap ring (Fig. 220).

Discard and replace with new snap ring upon assem-

bly.

Fig. 217 5th Gear Removal

1 - REMOVER 8486

2 - 5TH GEAR

Fig. 218 4th Gear Removal/Installation

1 - 4th GEAR

Fig. 219 4th Gear Blocker Ring

1 - 4th GEAR BLOCKER RING

Fig. 220 3/4 Synchro Snap Ring

1 - SNAP RING

2 - 3/4 SYNCHRONIZER

RGT850 MANUAL TRANSAXLE21a-75

INPUT SHAFT (Continued)

Page 3342 of 4284

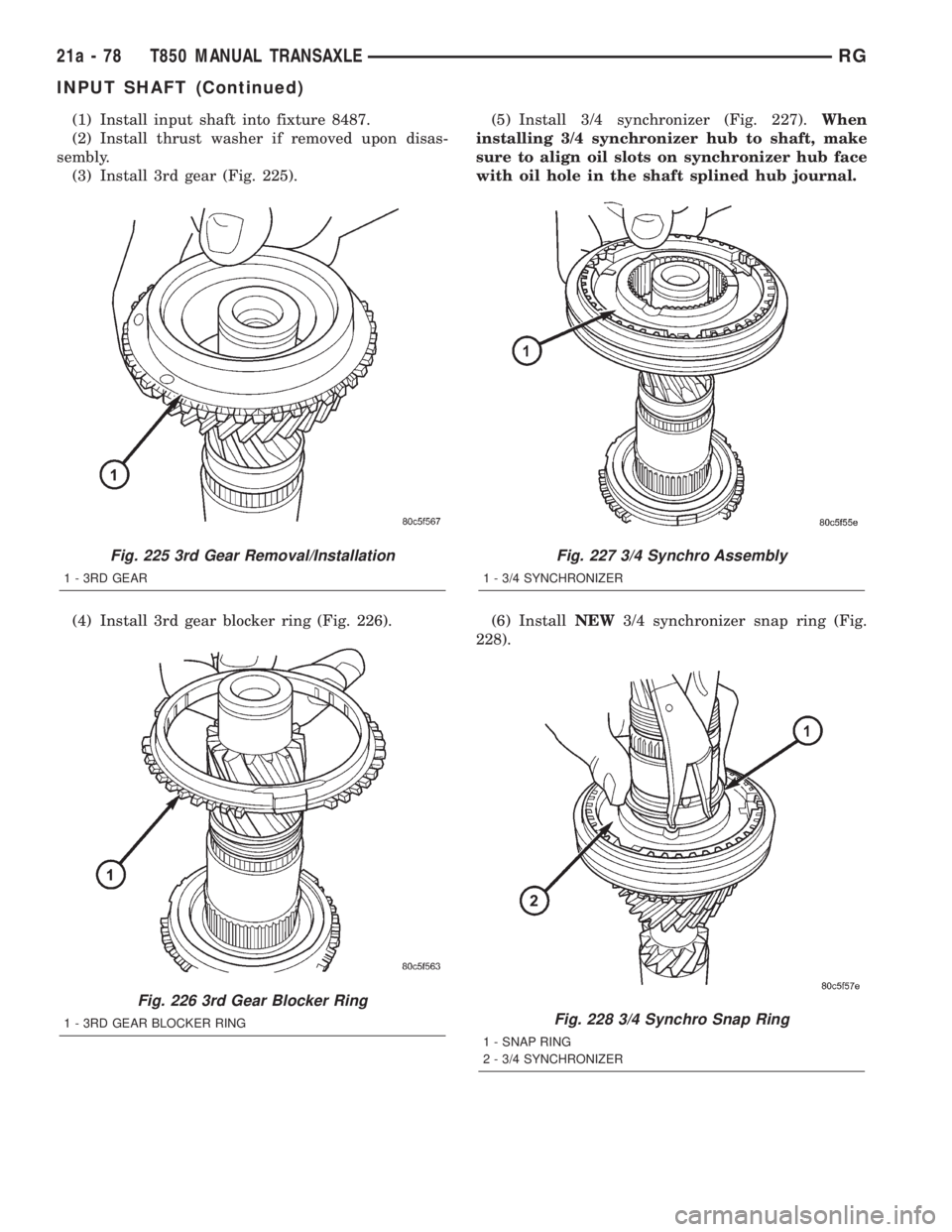

(10) Remove 3/4 synchronizer (Fig. 221).

(11) Remove 3rd gear blocker ring (Fig. 222).(12) Remove 3rd gear (Fig. 223).

(13) Inspect third gear thrust washer for signs of

excessive wear. To replace, drive off of input shaft

with suitable drift and hammer.

Fig. 221 3/4 Synchro Assembly

1 - 3/4 SYNCHRONIZER

Fig. 222 3rd Gear Blocker Ring

1 - 3RD GEAR BLOCKER RING

Fig. 223 3rd Gear Removal/Installation

1 - 3RD GEAR

21a - 76 T850 MANUAL TRANSAXLERG

INPUT SHAFT (Continued)

Page 3343 of 4284

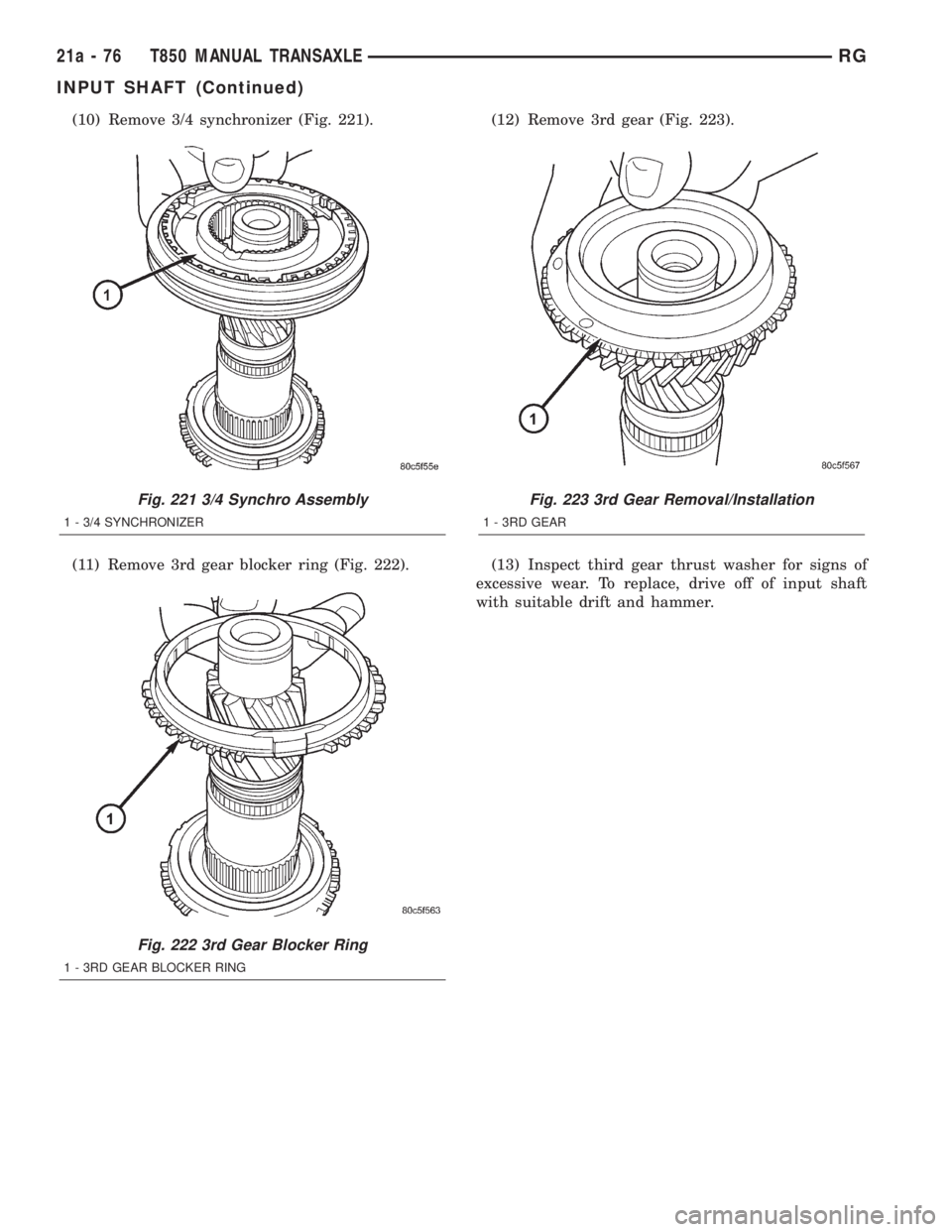

ASSEMBLY

NOTE: When servicing the input shaft assembly, all

snap rings MUST be replaced with new ones upon

assembly. 5th gear nut must also be replaced.

NOTE: When installing 3/4 synchronizer hub to

shaft, make sure to align oil slots on synchronizer

hub face with oil hole in the shaft splined hub jour-

nal.

NOTE: Refer to (Fig. 224) for input shaft assembly

reference.

Fig. 224 Input Shaft Assembly

1 - INPUT SHAFT 6 - 5TH GEAR NUT

2 - THRUST WASHER 7 - SNAP RING

3 - 3RD GEAR 8 - INPUT BEARING (SEALED)

4 - 4TH GEAR 9 - SNAP RING

5 - 5TH GEAR 10 - 3/4 SYNCHRONIZER

RGT850 MANUAL TRANSAXLE21a-77

INPUT SHAFT (Continued)

Page 3344 of 4284

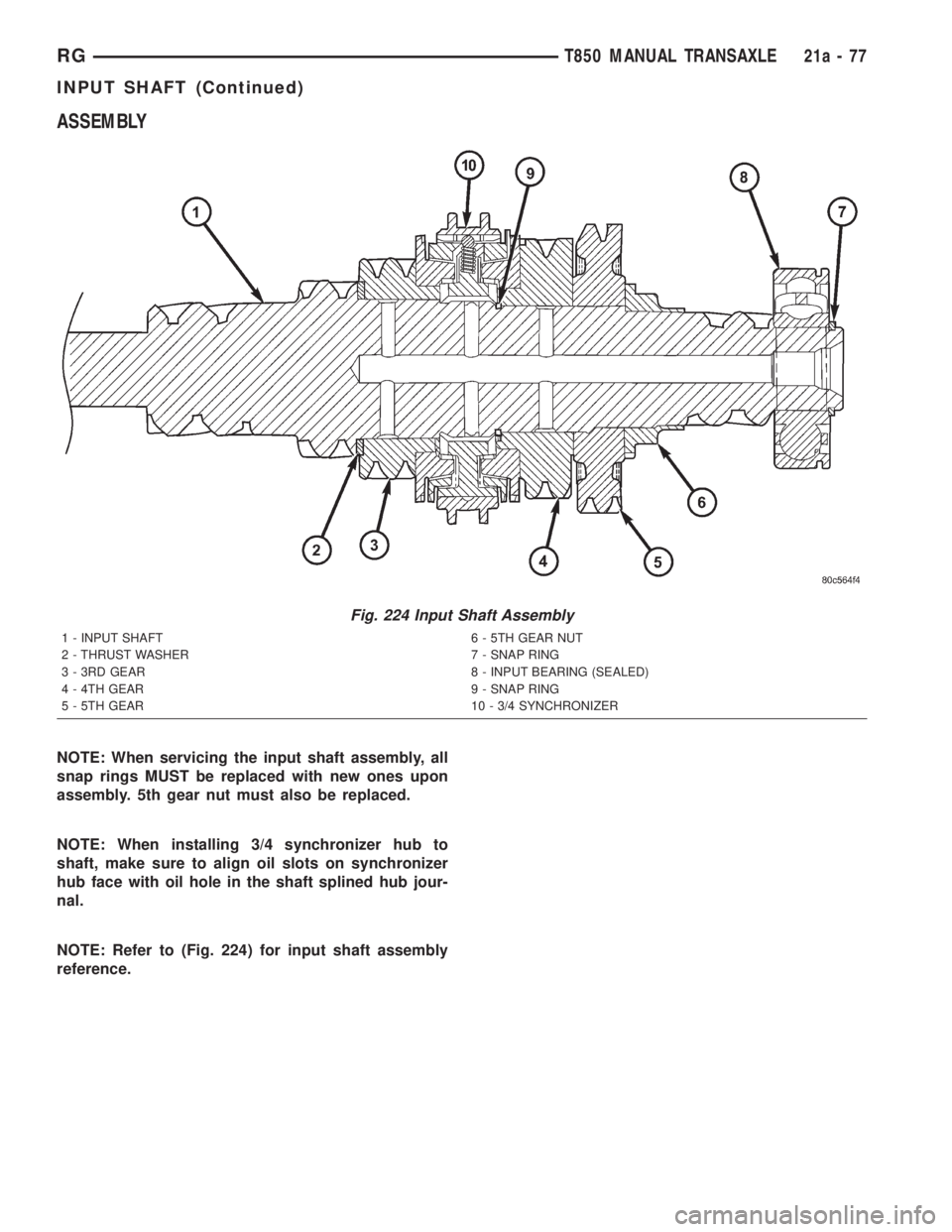

(1) Install input shaft into fixture 8487.

(2) Install thrust washer if removed upon disas-

sembly.

(3) Install 3rd gear (Fig. 225).

(4) Install 3rd gear blocker ring (Fig. 226).(5) Install 3/4 synchronizer (Fig. 227).When

installing 3/4 synchronizer hub to shaft, make

sure to align oil slots on synchronizer hub face

with oil hole in the shaft splined hub journal.

(6) InstallNEW3/4 synchronizer snap ring (Fig.

228).

Fig. 225 3rd Gear Removal/Installation

1 - 3RD GEAR

Fig. 226 3rd Gear Blocker Ring

1 - 3RD GEAR BLOCKER RING

Fig. 227 3/4 Synchro Assembly

1 - 3/4 SYNCHRONIZER

Fig. 228 3/4 Synchro Snap Ring

1 - SNAP RING

2 - 3/4 SYNCHRONIZER

21a - 78 T850 MANUAL TRANSAXLERG

INPUT SHAFT (Continued)

Page 3345 of 4284

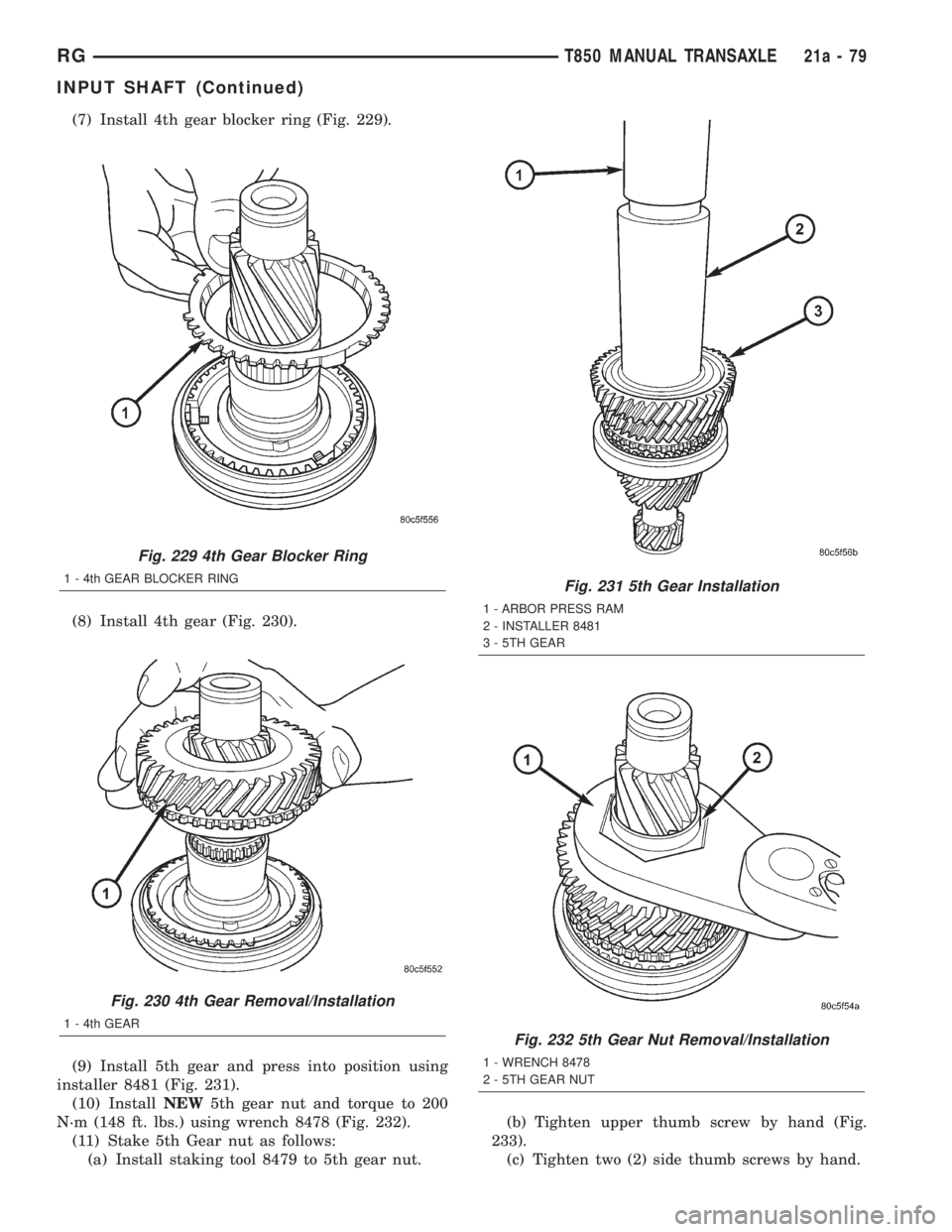

(7) Install 4th gear blocker ring (Fig. 229).

(8) Install 4th gear (Fig. 230).

(9) Install 5th gear and press into position using

installer 8481 (Fig. 231).

(10) InstallNEW5th gear nut and torque to 200

N´m (148 ft. lbs.) using wrench 8478 (Fig. 232).

(11) Stake 5th Gear nut as follows:

(a) Install staking tool 8479 to 5th gear nut.(b) Tighten upper thumb screw by hand (Fig.

233).

(c) Tighten two (2) side thumb screws by hand.

Fig. 229 4th Gear Blocker Ring

1 - 4th GEAR BLOCKER RING

Fig. 230 4th Gear Removal/Installation

1 - 4th GEAR

Fig. 231 5th Gear Installation

1 - ARBOR PRESS RAM

2 - INSTALLER 8481

3 - 5TH GEAR

Fig. 232 5th Gear Nut Removal/Installation

1 - WRENCH 8478

2 - 5TH GEAR NUT

RGT850 MANUAL TRANSAXLE21a-79

INPUT SHAFT (Continued)

Page 3346 of 4284

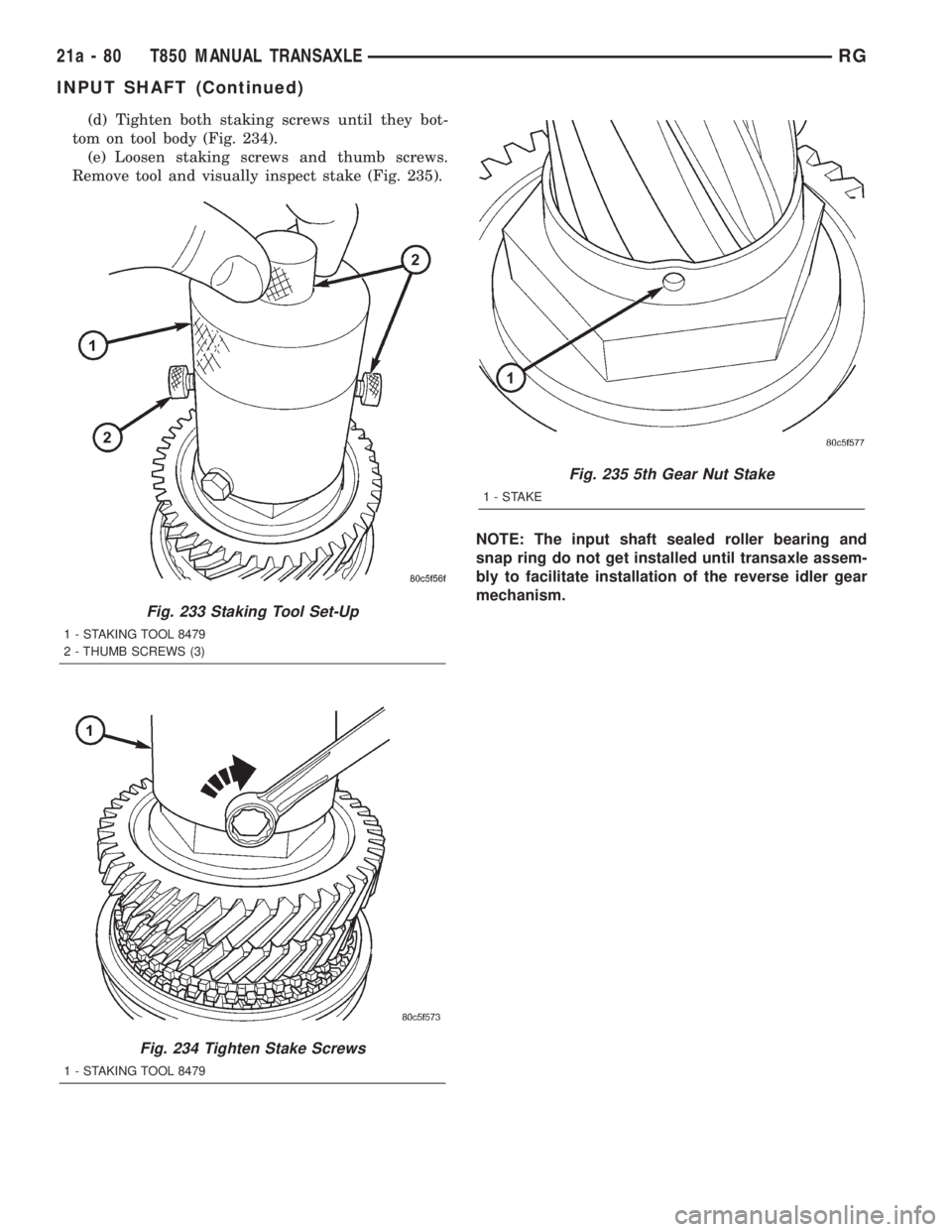

(d) Tighten both staking screws until they bot-

tom on tool body (Fig. 234).

(e) Loosen staking screws and thumb screws.

Remove tool and visually inspect stake (Fig. 235).

NOTE: The input shaft sealed roller bearing and

snap ring do not get installed until transaxle assem-

bly to facilitate installation of the reverse idler gear

mechanism.

Fig. 233 Staking Tool Set-Up

1 - STAKING TOOL 8479

2 - THUMB SCREWS (3)

Fig. 234 Tighten Stake Screws

1 - STAKING TOOL 8479

Fig. 235 5th Gear Nut Stake

1-STAKE

21a - 80 T850 MANUAL TRANSAXLERG

INPUT SHAFT (Continued)

Page 3347 of 4284

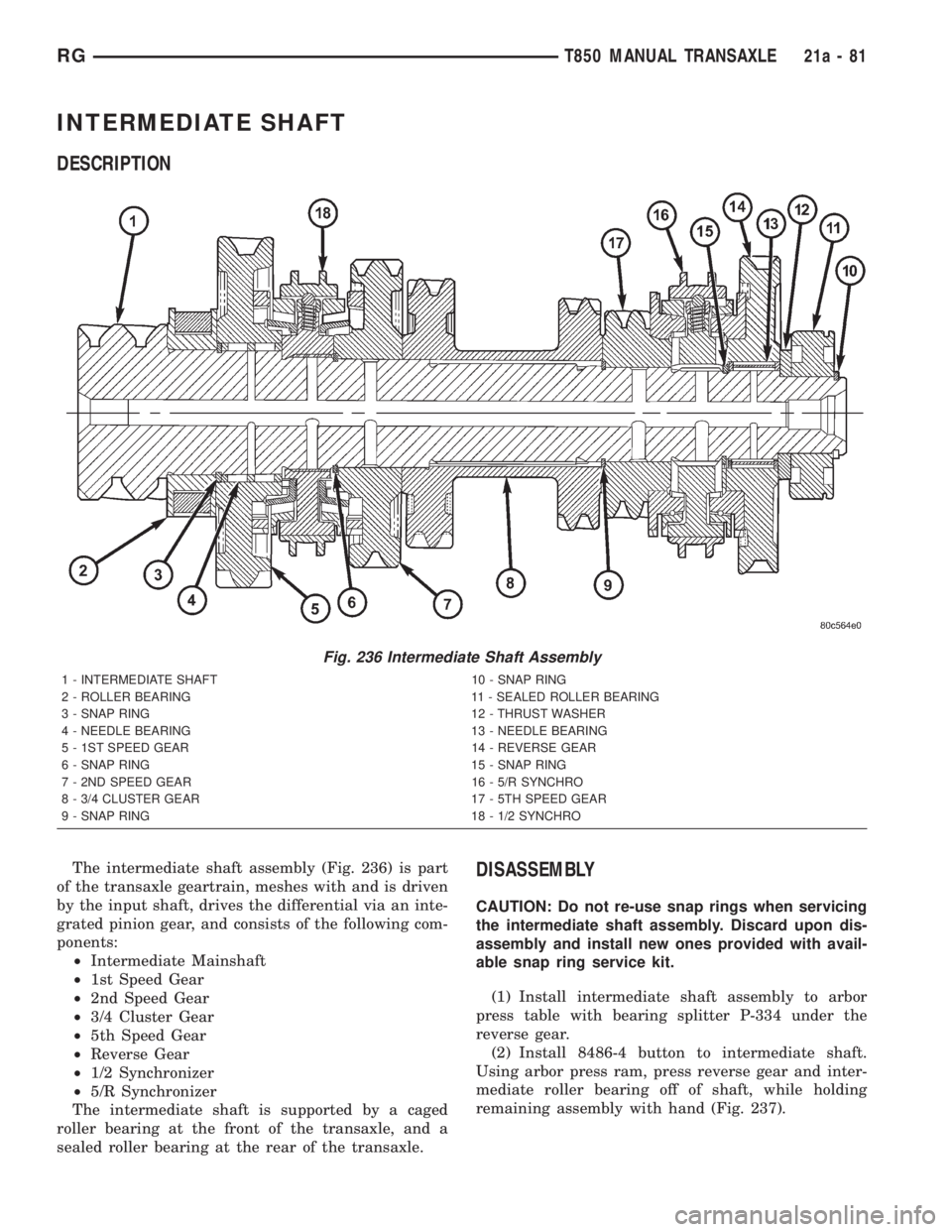

INTERMEDIATE SHAFT

DESCRIPTION

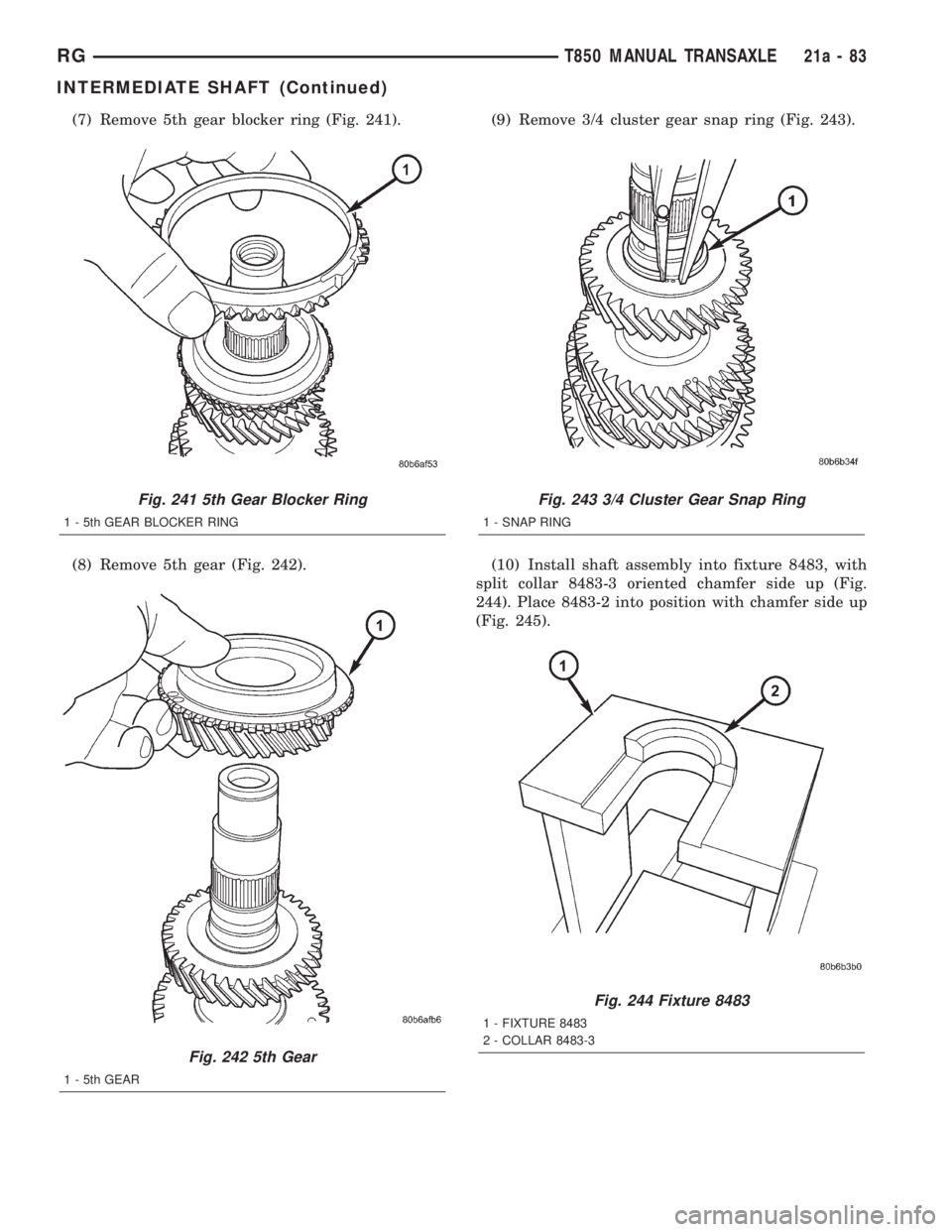

The intermediate shaft assembly (Fig. 236) is part

of the transaxle geartrain, meshes with and is driven

by the input shaft, drives the differential via an inte-

grated pinion gear, and consists of the following com-

ponents:

²Intermediate Mainshaft

²1st Speed Gear

²2nd Speed Gear

²3/4 Cluster Gear

²5th Speed Gear

²Reverse Gear

²1/2 Synchronizer

²5/R Synchronizer

The intermediate shaft is supported by a caged

roller bearing at the front of the transaxle, and a

sealed roller bearing at the rear of the transaxle.DISASSEMBLY

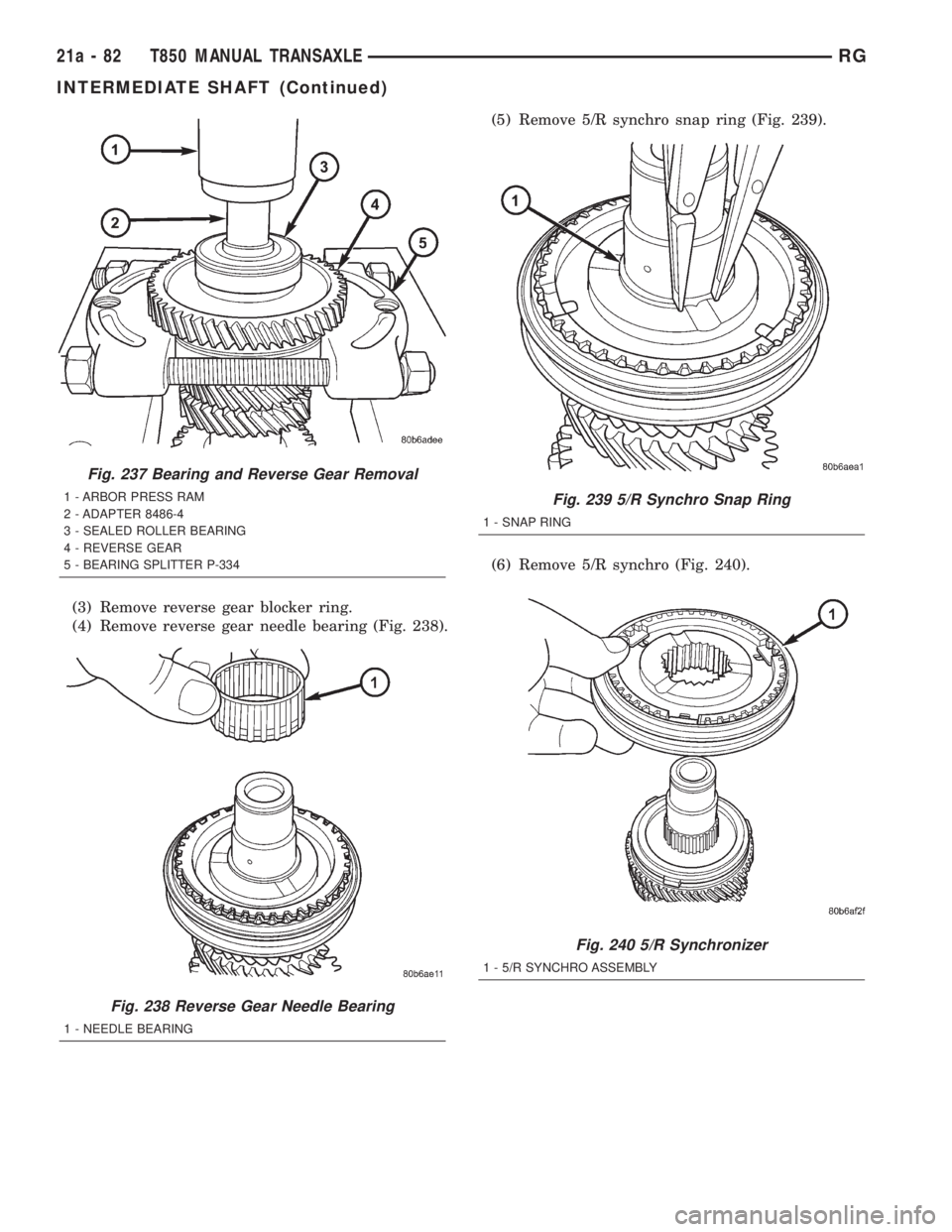

CAUTION: Do not re-use snap rings when servicing

the intermediate shaft assembly. Discard upon dis-

assembly and install new ones provided with avail-

able snap ring service kit.

(1) Install intermediate shaft assembly to arbor

press table with bearing splitter P-334 under the

reverse gear.

(2) Install 8486-4 button to intermediate shaft.

Using arbor press ram, press reverse gear and inter-

mediate roller bearing off of shaft, while holding

remaining assembly with hand (Fig. 237).

Fig. 236 Intermediate Shaft Assembly

1 - INTERMEDIATE SHAFT 10 - SNAP RING

2 - ROLLER BEARING 11 - SEALED ROLLER BEARING

3 - SNAP RING 12 - THRUST WASHER

4 - NEEDLE BEARING 13 - NEEDLE BEARING

5 - 1ST SPEED GEAR 14 - REVERSE GEAR

6 - SNAP RING 15 - SNAP RING

7 - 2ND SPEED GEAR 16 - 5/R SYNCHRO

8 - 3/4 CLUSTER GEAR 17 - 5TH SPEED GEAR

9 - SNAP RING 18 - 1/2 SYNCHRO

RGT850 MANUAL TRANSAXLE21a-81

Page 3348 of 4284

(3) Remove reverse gear blocker ring.

(4) Remove reverse gear needle bearing (Fig. 238).(5) Remove 5/R synchro snap ring (Fig. 239).

(6) Remove 5/R synchro (Fig. 240).

Fig. 237 Bearing and Reverse Gear Removal

1 - ARBOR PRESS RAM

2 - ADAPTER 8486-4

3 - SEALED ROLLER BEARING

4 - REVERSE GEAR

5 - BEARING SPLITTER P-334

Fig. 238 Reverse Gear Needle Bearing

1 - NEEDLE BEARING

Fig. 239 5/R Synchro Snap Ring

1 - SNAP RING

Fig. 240 5/R Synchronizer

1 - 5/R SYNCHRO ASSEMBLY

21a - 82 T850 MANUAL TRANSAXLERG

INTERMEDIATE SHAFT (Continued)

Page 3349 of 4284

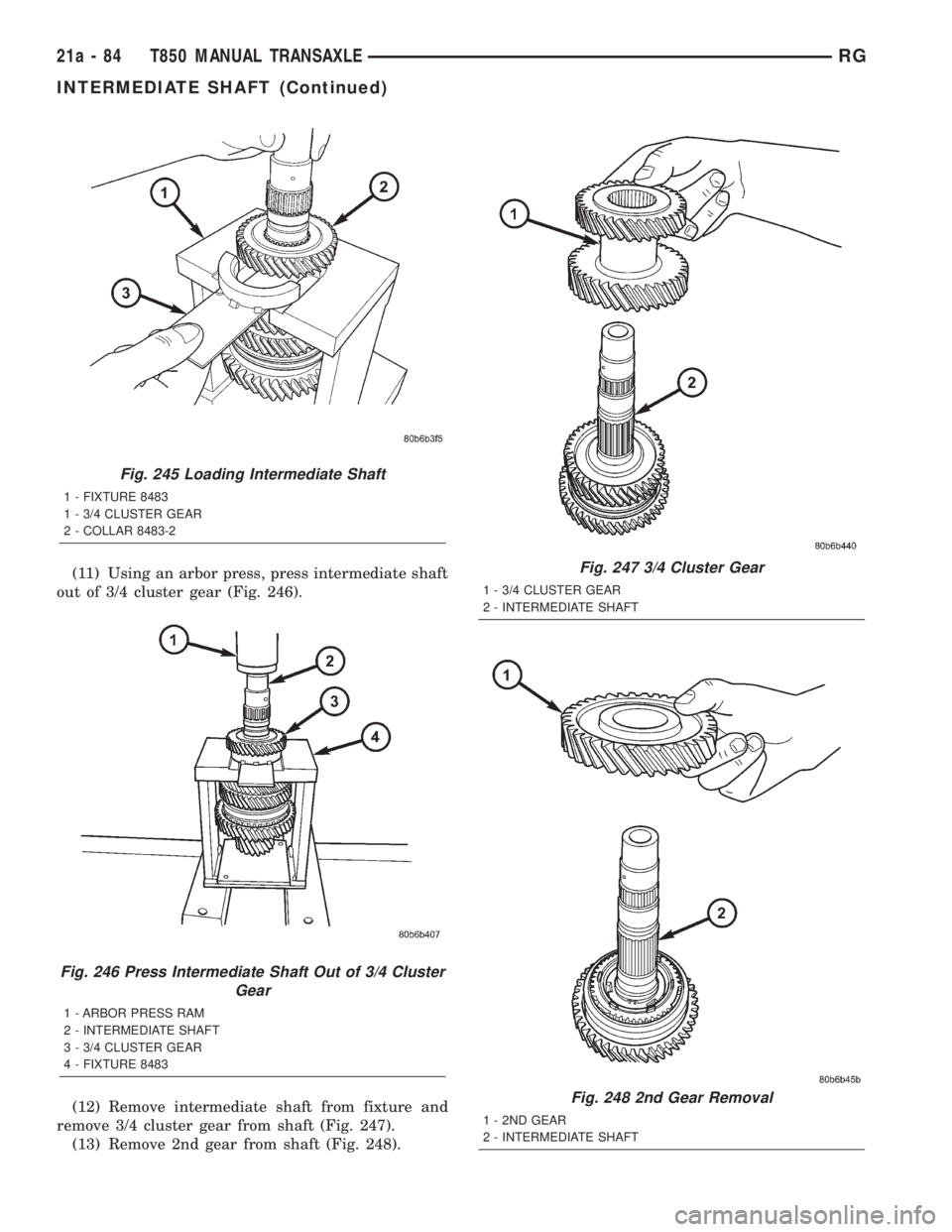

(7) Remove 5th gear blocker ring (Fig. 241).

(8) Remove 5th gear (Fig. 242).(9) Remove 3/4 cluster gear snap ring (Fig. 243).

(10) Install shaft assembly into fixture 8483, with

split collar 8483-3 oriented chamfer side up (Fig.

244). Place 8483-2 into position with chamfer side up

(Fig. 245).

Fig. 241 5th Gear Blocker Ring

1 - 5th GEAR BLOCKER RING

Fig. 242 5th Gear

1 - 5th GEAR

Fig. 243 3/4 Cluster Gear Snap Ring

1 - SNAP RING

Fig. 244 Fixture 8483

1 - FIXTURE 8483

2 - COLLAR 8483-3

RGT850 MANUAL TRANSAXLE21a-83

INTERMEDIATE SHAFT (Continued)

Page 3350 of 4284

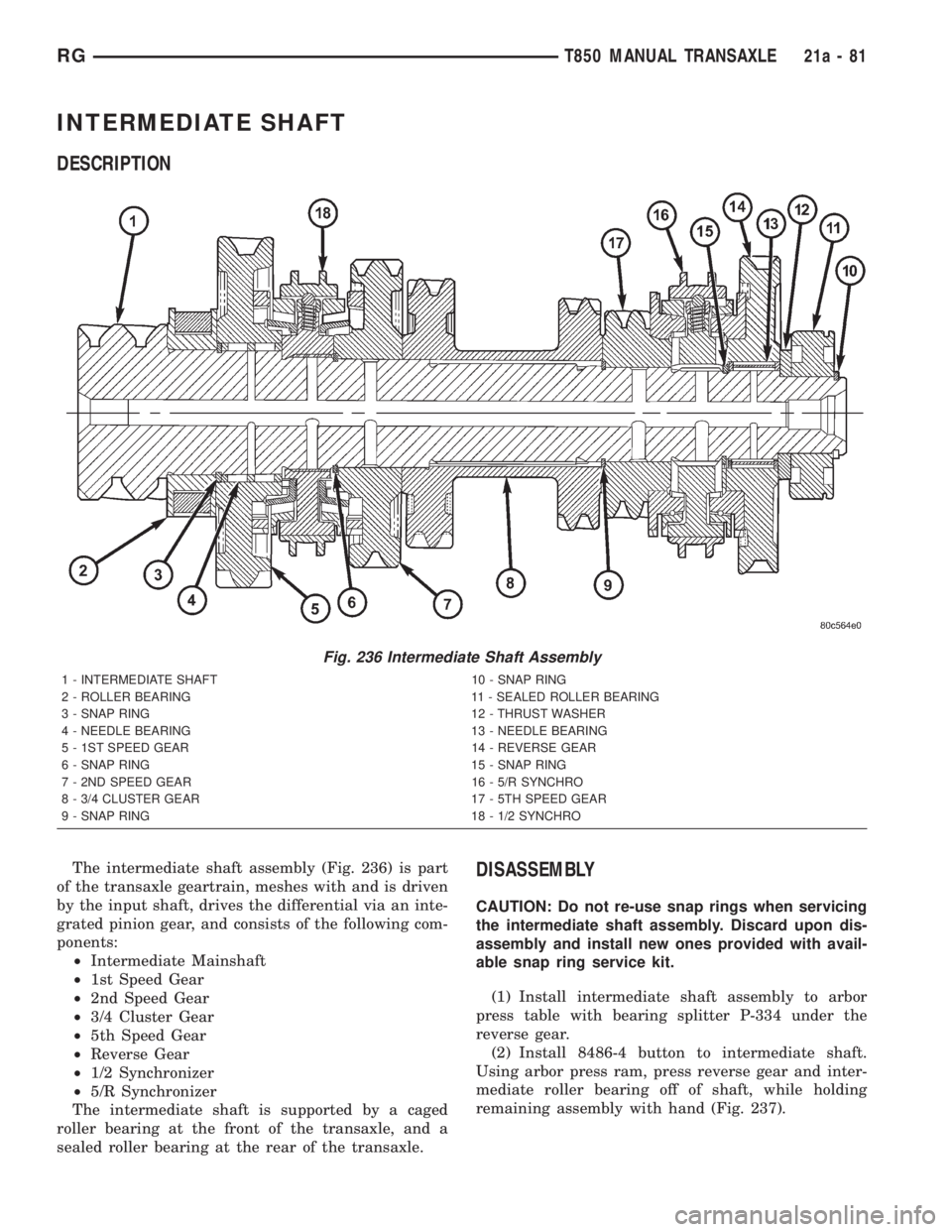

(11) Using an arbor press, press intermediate shaft

out of 3/4 cluster gear (Fig. 246).

(12) Remove intermediate shaft from fixture and

remove 3/4 cluster gear from shaft (Fig. 247).

(13) Remove 2nd gear from shaft (Fig. 248).

Fig. 245 Loading Intermediate Shaft

1 - FIXTURE 8483

1 - 3/4 CLUSTER GEAR

2 - COLLAR 8483-2

Fig. 246 Press Intermediate Shaft Out of 3/4 Cluster

Gear

1 - ARBOR PRESS RAM

2 - INTERMEDIATE SHAFT

3 - 3/4 CLUSTER GEAR

4 - FIXTURE 8483

Fig. 247 3/4 Cluster Gear

1 - 3/4 CLUSTER GEAR

2 - INTERMEDIATE SHAFT

Fig. 248 2nd Gear Removal

1 - 2ND GEAR

2 - INTERMEDIATE SHAFT

21a - 84 T850 MANUAL TRANSAXLERG

INTERMEDIATE SHAFT (Continued)

Trending: ECU, fuel cap, keyless, coolant temperature, wheel bolts, OBD port, recommended oil