CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3571 of 4284

EXTERIOR NAME PLATES -

TAPE ATTACHED

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) Using a nonmetallic prying device, such as a

plastic or wood trim stick gently pry up at corners

and remove.

(4) Clean off all traces of adhesive or double sided

tape from the panel with a general purpose adhesive

remover.

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Align badgeing to reference points.

(3) Install and press securely to full adhesive con-

tact

(4) Clean away any reference points.

EXTERIOR NAME PLATES -

ADHESIVE ATTACHED

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) With your fingernail lift up and peel away

badgeing/tape from panel, using a heat gun as you

go.

(4) Clean off all traces of adhesive from the pan-

el(s) with a general purpose adhesive remover.

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Remove paper carrier and align badgeing/tape

to reference points or adjacent panel.

(3) Install and press securely, using a plastic

spreader to eliminate all air bubbles.

(4) Remove top protective carrier.

(5) Clean away any reference points.

FRONT FENDER

REMOVAL

(1) Remove headlamp housing. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - REMOVAL)

(2) Remove mud guard.

(3) Remove inner splash shield.

(4) Remove fender to fascia nuts.(5) Remove outboard cowl grille/fender bracket

screw.

(6) Remove fender bolt to lower rocker panel.

(7) Remove fender bolt to lower cowl.

(8) Pull fascia away from fender.

(9) Remove bolts attaching fender to upper rail.

(10) Remove fender from vehicle (Fig. 8).

INSTALLATION

(1) Place fender in position on vehicle.

(2) From inside engine compartment, start the

center upper rail bolt. install all the bolts attaching

fender to upper rail and tighten.

(3) Install fender to lower cowl panel bolt.

(4) Install fender to rocker panel bolt.

(5) Place fascia into position.

(6) Install outboard cowl grille/fender bracket

screw.

(7) Install fender to fascia nuts.

(8) Install inner splash shield.

(9) Install mud guard.

(10) Install headlamp assembly. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - INSTALLATION)

(11) Check fender for flush and gap.

FUEL FILL DOOR

REMOVAL

(1) Remove left quarter trim panel.

Fig. 8 Fender

1 - FASTENERS

2 - FENDER

3 - FASTENERS

RSEXTERIOR23 - 191

Page 3572 of 4284

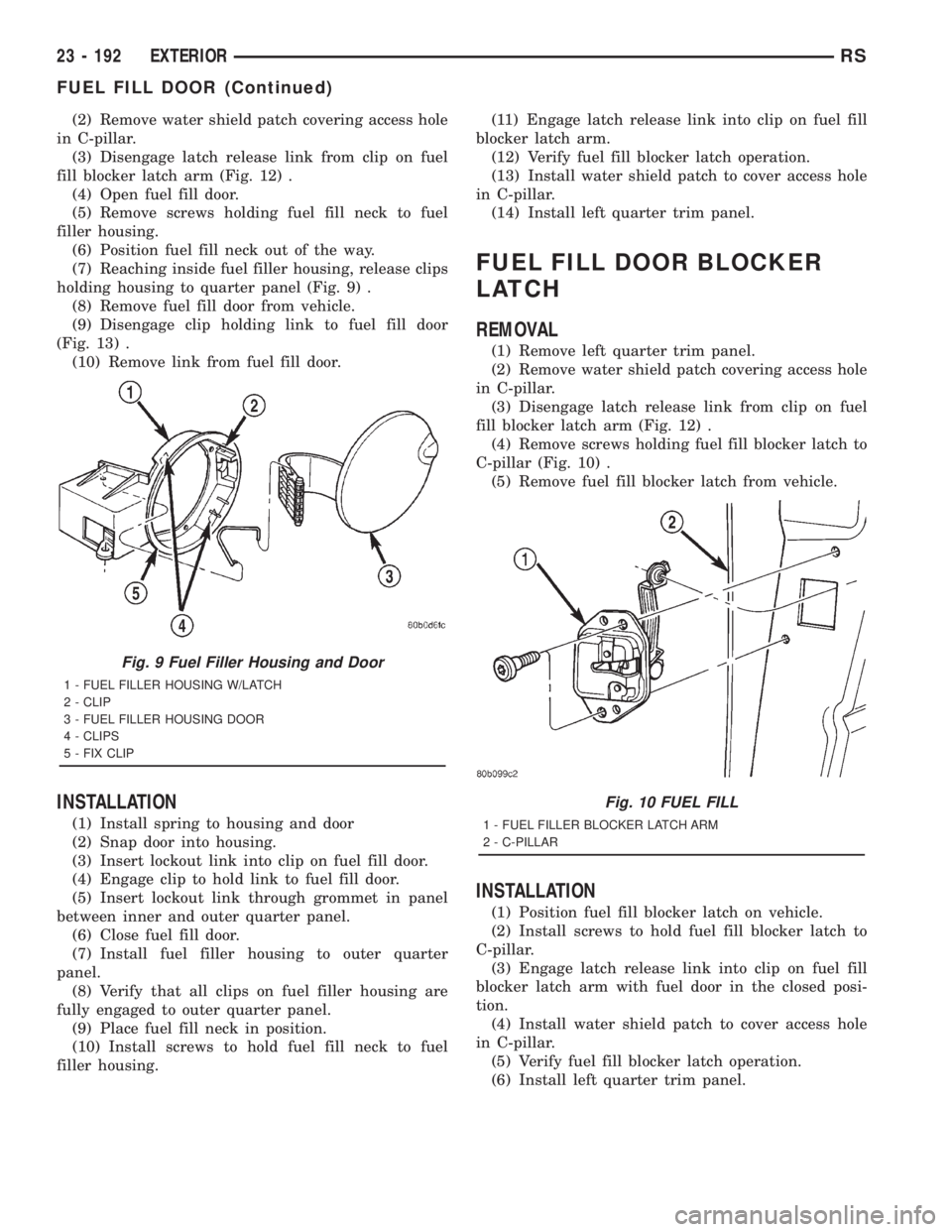

(2) Remove water shield patch covering access hole

in C-pillar.

(3) Disengage latch release link from clip on fuel

fill blocker latch arm (Fig. 12) .

(4) Open fuel fill door.

(5) Remove screws holding fuel fill neck to fuel

filler housing.

(6) Position fuel fill neck out of the way.

(7) Reaching inside fuel filler housing, release clips

holding housing to quarter panel (Fig. 9) .

(8) Remove fuel fill door from vehicle.

(9) Disengage clip holding link to fuel fill door

(Fig. 13) .

(10) Remove link from fuel fill door.

INSTALLATION

(1) Install spring to housing and door

(2) Snap door into housing.

(3) Insert lockout link into clip on fuel fill door.

(4) Engage clip to hold link to fuel fill door.

(5) Insert lockout link through grommet in panel

between inner and outer quarter panel.

(6) Close fuel fill door.

(7) Install fuel filler housing to outer quarter

panel.

(8) Verify that all clips on fuel filler housing are

fully engaged to outer quarter panel.

(9) Place fuel fill neck in position.

(10) Install screws to hold fuel fill neck to fuel

filler housing.(11) Engage latch release link into clip on fuel fill

blocker latch arm.

(12) Verify fuel fill blocker latch operation.

(13) Install water shield patch to cover access hole

in C-pillar.

(14) Install left quarter trim panel.

FUEL FILL DOOR BLOCKER

LATCH

REMOVAL

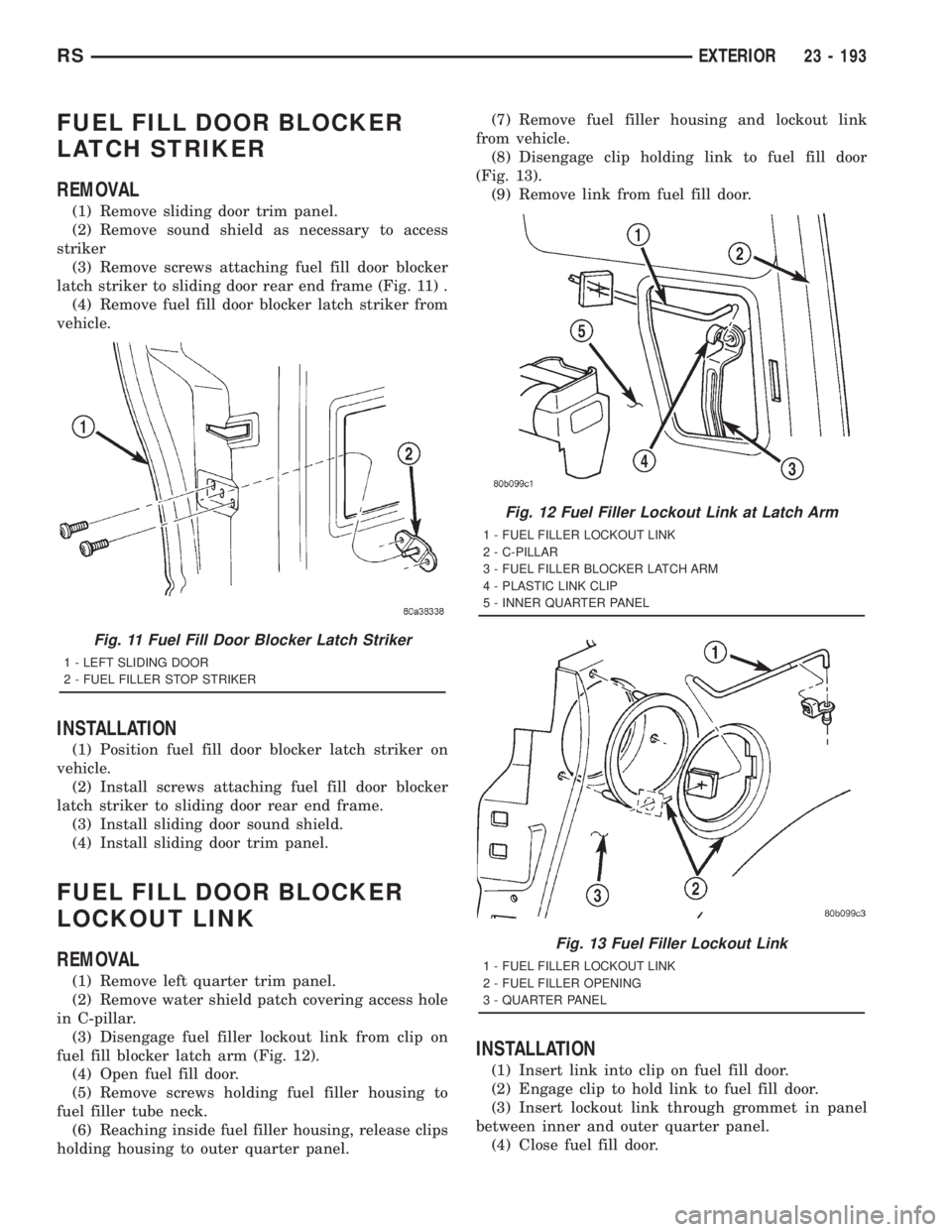

(1) Remove left quarter trim panel.

(2) Remove water shield patch covering access hole

in C-pillar.

(3) Disengage latch release link from clip on fuel

fill blocker latch arm (Fig. 12) .

(4) Remove screws holding fuel fill blocker latch to

C-pillar (Fig. 10) .

(5) Remove fuel fill blocker latch from vehicle.

INSTALLATION

(1) Position fuel fill blocker latch on vehicle.

(2) Install screws to hold fuel fill blocker latch to

C-pillar.

(3) Engage latch release link into clip on fuel fill

blocker latch arm with fuel door in the closed posi-

tion.

(4) Install water shield patch to cover access hole

in C-pillar.

(5) Verify fuel fill blocker latch operation.

(6) Install left quarter trim panel.

Fig. 9 Fuel Filler Housing and Door

1 - FUEL FILLER HOUSING W/LATCH

2 - CLIP

3 - FUEL FILLER HOUSING DOOR

4 - CLIPS

5 - FIX CLIP

Fig. 10 FUEL FILL

1 - FUEL FILLER BLOCKER LATCH ARM

2 - C-PILLAR

23 - 192 EXTERIORRS

FUEL FILL DOOR (Continued)

Page 3573 of 4284

FUEL FILL DOOR BLOCKER

LATCH STRIKER

REMOVAL

(1) Remove sliding door trim panel.

(2) Remove sound shield as necessary to access

striker

(3) Remove screws attaching fuel fill door blocker

latch striker to sliding door rear end frame (Fig. 11) .

(4) Remove fuel fill door blocker latch striker from

vehicle.

INSTALLATION

(1) Position fuel fill door blocker latch striker on

vehicle.

(2) Install screws attaching fuel fill door blocker

latch striker to sliding door rear end frame.

(3) Install sliding door sound shield.

(4) Install sliding door trim panel.

FUEL FILL DOOR BLOCKER

LOCKOUT LINK

REMOVAL

(1) Remove left quarter trim panel.

(2) Remove water shield patch covering access hole

in C-pillar.

(3) Disengage fuel filler lockout link from clip on

fuel fill blocker latch arm (Fig. 12).

(4) Open fuel fill door.

(5) Remove screws holding fuel filler housing to

fuel filler tube neck.

(6) Reaching inside fuel filler housing, release clips

holding housing to outer quarter panel.(7) Remove fuel filler housing and lockout link

from vehicle.

(8) Disengage clip holding link to fuel fill door

(Fig. 13).

(9) Remove link from fuel fill door.

INSTALLATION

(1) Insert link into clip on fuel fill door.

(2) Engage clip to hold link to fuel fill door.

(3) Insert lockout link through grommet in panel

between inner and outer quarter panel.

(4) Close fuel fill door.

Fig. 11 Fuel Fill Door Blocker Latch Striker

1 - LEFT SLIDING DOOR

2 - FUEL FILLER STOP STRIKER

Fig. 12 Fuel Filler Lockout Link at Latch Arm

1 - FUEL FILLER LOCKOUT LINK

2 - C-PILLAR

3 - FUEL FILLER BLOCKER LATCH ARM

4 - PLASTIC LINK CLIP

5 - INNER QUARTER PANEL

Fig. 13 Fuel Filler Lockout Link

1 - FUEL FILLER LOCKOUT LINK

2 - FUEL FILLER OPENING

3 - QUARTER PANEL

RSEXTERIOR23 - 193

Page 3574 of 4284

(5) Install fuel filler housing to outer quarter

panel.

(6) Verify that all clips on fuel filler housing are

fully engaged to outer quarter panel.

(7) Engage fuel filler lockout link into clip on fuel

fill blocker latch arm.

(8) Install water shield patch covering access hole

in C-pillar.

(9) Install left quarter trim panel.

GRILLE OPENING

REINFORCEMENT

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching hood latch to cross-

member and position latch out of the way.

(3) Remove radiator sight shield.

(4) Remove engine air inlet resonator.

(5) Remove hood cable.

(6) Remove hood prop rod.

(7) Remove screw attaching coolant recovery bottle

to crossmember.

(8) Remove bolts attaching radiator isolators to

crossmember.

(9) Remove bolts attaching ends of crossmember to

radiator closure panel (Fig. 14) .

(10) Lift crossmember upward and away from

radiator closure panel.

(11) Remove crossmember from vehicle.

INSTALLATION

(1) Place radiator closure panel crossmember in

position on vehicle.

(2) Insert ends of crossmember between layered

metal sections of radiator closure panel at each side

of radiator.

(3) Align with paint breaks around bolt heads.

(4) Install bolts attaching ends of crossmember to

radiator closure panel (Fig. 14) . Tighten bolts to 19

N´m (14 ft. lbs.) torque.

(5) Install bolts attaching radiator isolators to

crossmember.

(6) Install screw attaching coolant recovery bottle

to crossmember.

(7) Install bolt attaching air cleaner housing to

crossmember.

(8) Install engine air inlet resonator.

(9) Install radiator sight shield.

(10) Install hood prop rod.

(11) Align hood latch by placing latch over net

pierce tabs. If alignment is required, flatten tabs.

(12) Install bolts attaching hood latch to cross-

member. Tighten bolts to 13.5 N´m (10 ft. lbs.)

torque.

(13) Verify hood latch operation and hood align-

ment.

FRONT WHEELHOUSE

SPLASH SHIELD

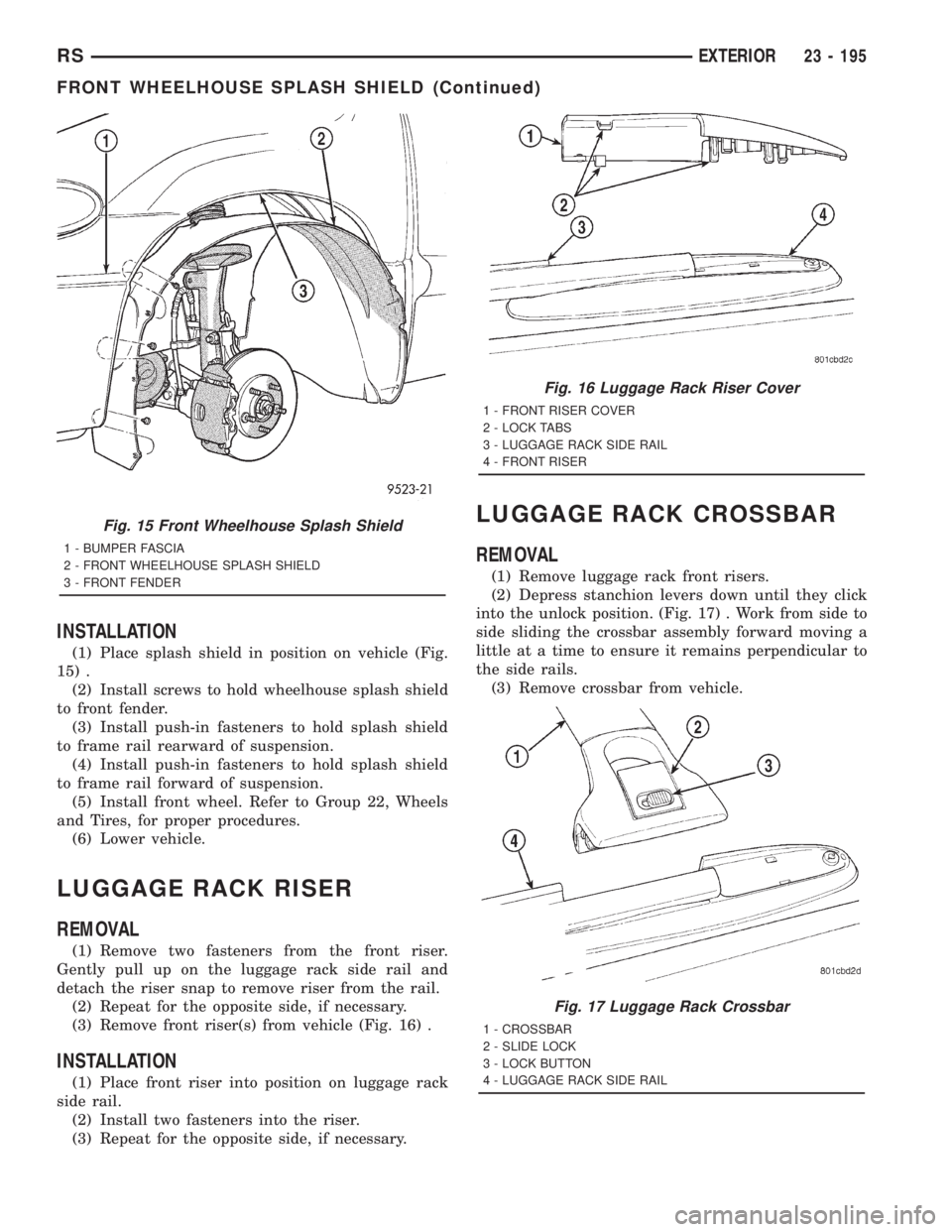

REMOVAL

(1) Hoist and support vehicle on safety stands.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE)

(2) Remove front wheel. Refer to section 22, Tires/

Wheels, for recommended procedures.

(3) Remove push-in fasteners holding splash shield

to frame rail forward of suspension.

(4) Remove push-in fasteners holding splash shield

to frame rail rearward of suspension.

(5) Remove screws holding wheelhouse splash

shield to front fender.

(6) Remove splash shield from vehicle (Fig. 15).

Fig. 14 Radiator Closure Panel Crossmember

1 - RADIATOR CLOSURE PANEL CROSSMEMBER

2 - FRONT FASCIA

23 - 194 EXTERIORRS

FUEL FILL DOOR BLOCKER LOCKOUT LINK (Continued)

Page 3575 of 4284

INSTALLATION

(1) Place splash shield in position on vehicle (Fig.

15) .

(2) Install screws to hold wheelhouse splash shield

to front fender.

(3) Install push-in fasteners to hold splash shield

to frame rail rearward of suspension.

(4) Install push-in fasteners to hold splash shield

to frame rail forward of suspension.

(5) Install front wheel. Refer to Group 22, Wheels

and Tires, for proper procedures.

(6) Lower vehicle.

LUGGAGE RACK RISER

REMOVAL

(1) Remove two fasteners from the front riser.

Gently pull up on the luggage rack side rail and

detach the riser snap to remove riser from the rail.

(2) Repeat for the opposite side, if necessary.

(3) Remove front riser(s) from vehicle (Fig. 16) .

INSTALLATION

(1) Place front riser into position on luggage rack

side rail.

(2) Install two fasteners into the riser.

(3) Repeat for the opposite side, if necessary.

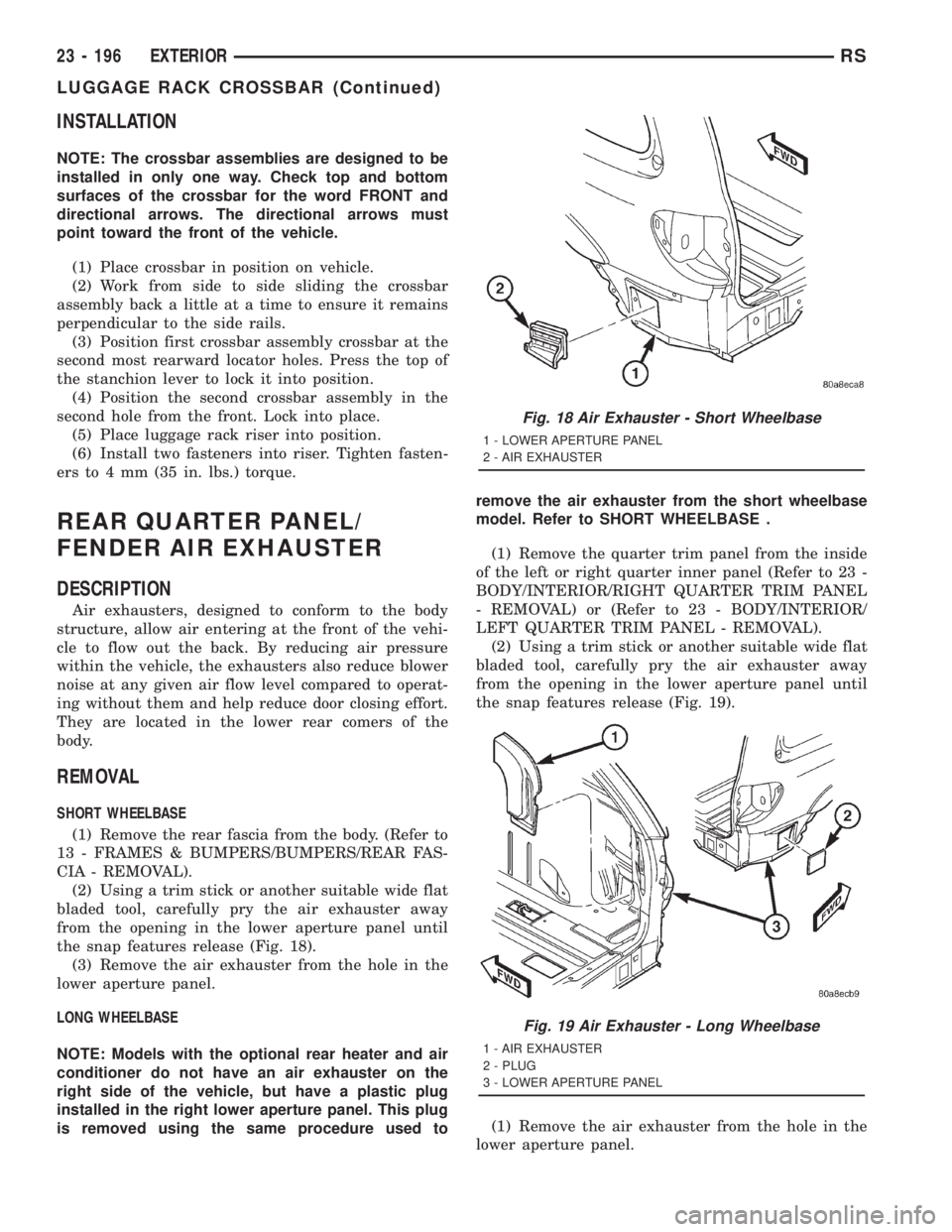

LUGGAGE RACK CROSSBAR

REMOVAL

(1) Remove luggage rack front risers.

(2) Depress stanchion levers down until they click

into the unlock position. (Fig. 17) . Work from side to

side sliding the crossbar assembly forward moving a

little at a time to ensure it remains perpendicular to

the side rails.

(3) Remove crossbar from vehicle.

Fig. 15 Front Wheelhouse Splash Shield

1 - BUMPER FASCIA

2 - FRONT WHEELHOUSE SPLASH SHIELD

3 - FRONT FENDER

Fig. 16 Luggage Rack Riser Cover

1 - FRONT RISER COVER

2 - LOCK TABS

3 - LUGGAGE RACK SIDE RAIL

4 - FRONT RISER

Fig. 17 Luggage Rack Crossbar

1 - CROSSBAR

2 - SLIDE LOCK

3 - LOCK BUTTON

4 - LUGGAGE RACK SIDE RAIL

RSEXTERIOR23 - 195

FRONT WHEELHOUSE SPLASH SHIELD (Continued)

Page 3576 of 4284

INSTALLATION

NOTE: The crossbar assemblies are designed to be

installed in only one way. Check top and bottom

surfaces of the crossbar for the word FRONT and

directional arrows. The directional arrows must

point toward the front of the vehicle.

(1) Place crossbar in position on vehicle.

(2) Work from side to side sliding the crossbar

assembly back a little at a time to ensure it remains

perpendicular to the side rails.

(3) Position first crossbar assembly crossbar at the

second most rearward locator holes. Press the top of

the stanchion lever to lock it into position.

(4) Position the second crossbar assembly in the

second hole from the front. Lock into place.

(5) Place luggage rack riser into position.

(6) Install two fasteners into riser. Tighten fasten-

ers to 4 mm (35 in. lbs.) torque.

REAR QUARTER PANEL/

FENDER AIR EXHAUSTER

DESCRIPTION

Air exhausters, designed to conform to the body

structure, allow air entering at the front of the vehi-

cle to flow out the back. By reducing air pressure

within the vehicle, the exhausters also reduce blower

noise at any given air flow level compared to operat-

ing without them and help reduce door closing effort.

They are located in the lower rear comers of the

body.

REMOVAL

SHORT WHEELBASE

(1) Remove the rear fascia from the body. (Refer to

13 - FRAMES & BUMPERS/BUMPERS/REAR FAS-

CIA - REMOVAL).

(2) Using a trim stick or another suitable wide flat

bladed tool, carefully pry the air exhauster away

from the opening in the lower aperture panel until

the snap features release (Fig. 18).

(3) Remove the air exhauster from the hole in the

lower aperture panel.

LONG WHEELBASE

NOTE: Models with the optional rear heater and air

conditioner do not have an air exhauster on the

right side of the vehicle, but have a plastic plug

installed in the right lower aperture panel. This plug

is removed using the same procedure used toremove the air exhauster from the short wheelbase

model. Refer to SHORT WHEELBASE .

(1) Remove the quarter trim panel from the inside

of the left or right quarter inner panel (Refer to 23 -

BODY/INTERIOR/RIGHT QUARTER TRIM PANEL

- REMOVAL) or (Refer to 23 - BODY/INTERIOR/

LEFT QUARTER TRIM PANEL - REMOVAL).

(2) Using a trim stick or another suitable wide flat

bladed tool, carefully pry the air exhauster away

from the opening in the lower aperture panel until

the snap features release (Fig. 19).

(1) Remove the air exhauster from the hole in the

lower aperture panel.

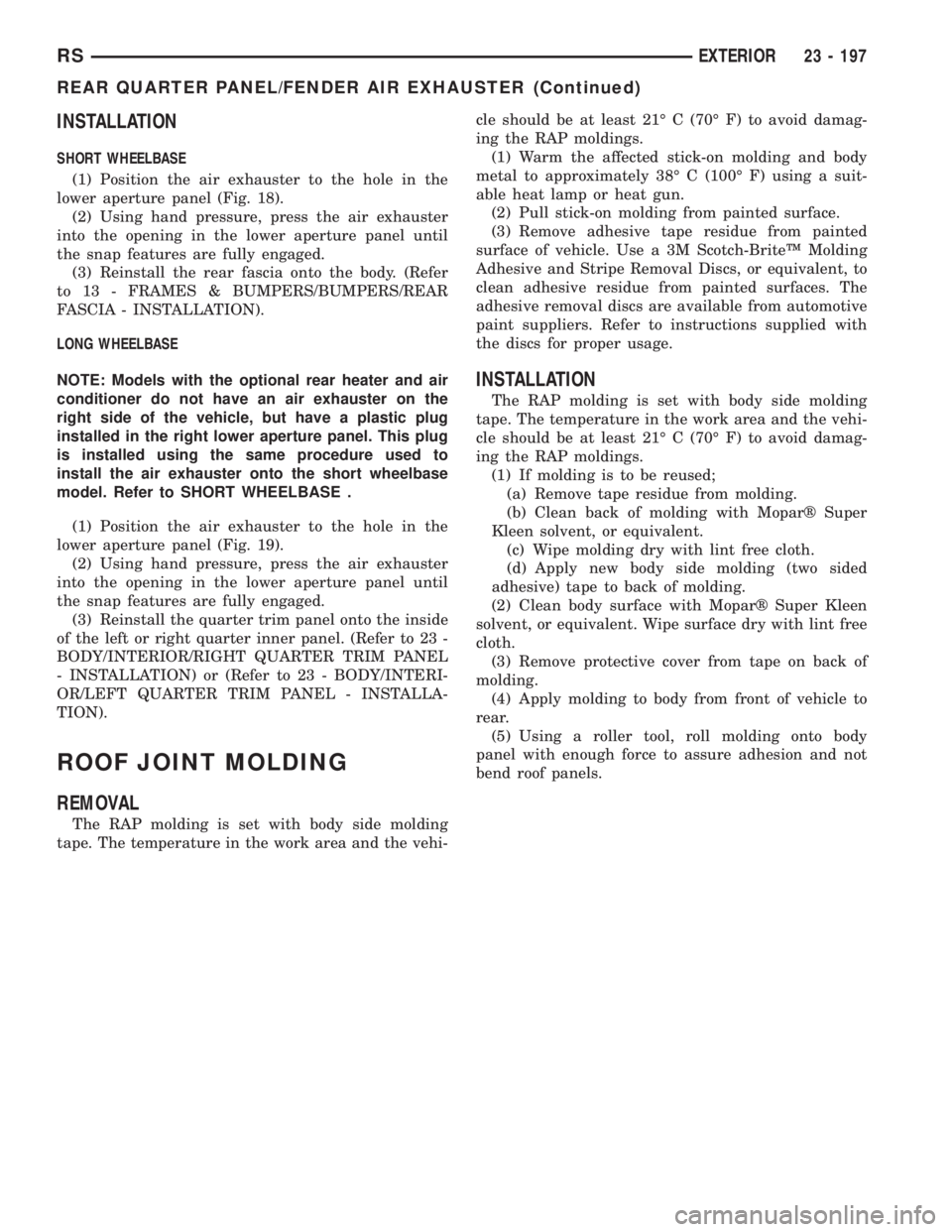

Fig. 18 Air Exhauster - Short Wheelbase

1 - LOWER APERTURE PANEL

2 - AIR EXHAUSTER

Fig. 19 Air Exhauster - Long Wheelbase

1 - AIR EXHAUSTER

2 - PLUG

3 - LOWER APERTURE PANEL

23 - 196 EXTERIORRS

LUGGAGE RACK CROSSBAR (Continued)

Page 3577 of 4284

INSTALLATION

SHORT WHEELBASE

(1) Position the air exhauster to the hole in the

lower aperture panel (Fig. 18).

(2) Using hand pressure, press the air exhauster

into the opening in the lower aperture panel until

the snap features are fully engaged.

(3) Reinstall the rear fascia onto the body. (Refer

to 13 - FRAMES & BUMPERS/BUMPERS/REAR

FASCIA - INSTALLATION).

LONG WHEELBASE

NOTE: Models with the optional rear heater and air

conditioner do not have an air exhauster on the

right side of the vehicle, but have a plastic plug

installed in the right lower aperture panel. This plug

is installed using the same procedure used to

install the air exhauster onto the short wheelbase

model. Refer to SHORT WHEELBASE .

(1) Position the air exhauster to the hole in the

lower aperture panel (Fig. 19).

(2) Using hand pressure, press the air exhauster

into the opening in the lower aperture panel until

the snap features are fully engaged.

(3) Reinstall the quarter trim panel onto the inside

of the left or right quarter inner panel. (Refer to 23 -

BODY/INTERIOR/RIGHT QUARTER TRIM PANEL

- INSTALLATION) or (Refer to 23 - BODY/INTERI-

OR/LEFT QUARTER TRIM PANEL - INSTALLA-

TION).

ROOF JOINT MOLDING

REMOVAL

The RAP molding is set with body side molding

tape. The temperature in the work area and the vehi-cle should be at least 21É C (70É F) to avoid damag-

ing the RAP moldings.

(1) Warm the affected stick-on molding and body

metal to approximately 38É C (100É F) using a suit-

able heat lamp or heat gun.

(2) Pull stick-on molding from painted surface.

(3) Remove adhesive tape residue from painted

surface of vehicle. Use a 3M Scotch-BriteŸ Molding

Adhesive and Stripe Removal Discs, or equivalent, to

clean adhesive residue from painted surfaces. The

adhesive removal discs are available from automotive

paint suppliers. Refer to instructions supplied with

the discs for proper usage.

INSTALLATION

The RAP molding is set with body side molding

tape. The temperature in the work area and the vehi-

cle should be at least 21É C (70É F) to avoid damag-

ing the RAP moldings.

(1) If molding is to be reused;

(a) Remove tape residue from molding.

(b) Clean back of molding with Moparž Super

Kleen solvent, or equivalent.

(c) Wipe molding dry with lint free cloth.

(d) Apply new body side molding (two sided

adhesive) tape to back of molding.

(2) Clean body surface with Moparž Super Kleen

solvent, or equivalent. Wipe surface dry with lint free

cloth.

(3) Remove protective cover from tape on back of

molding.

(4) Apply molding to body from front of vehicle to

rear.

(5) Using a roller tool, roll molding onto body

panel with enough force to assure adhesion and not

bend roof panels.

RSEXTERIOR23 - 197

REAR QUARTER PANEL/FENDER AIR EXHAUSTER (Continued)

Page 3578 of 4284

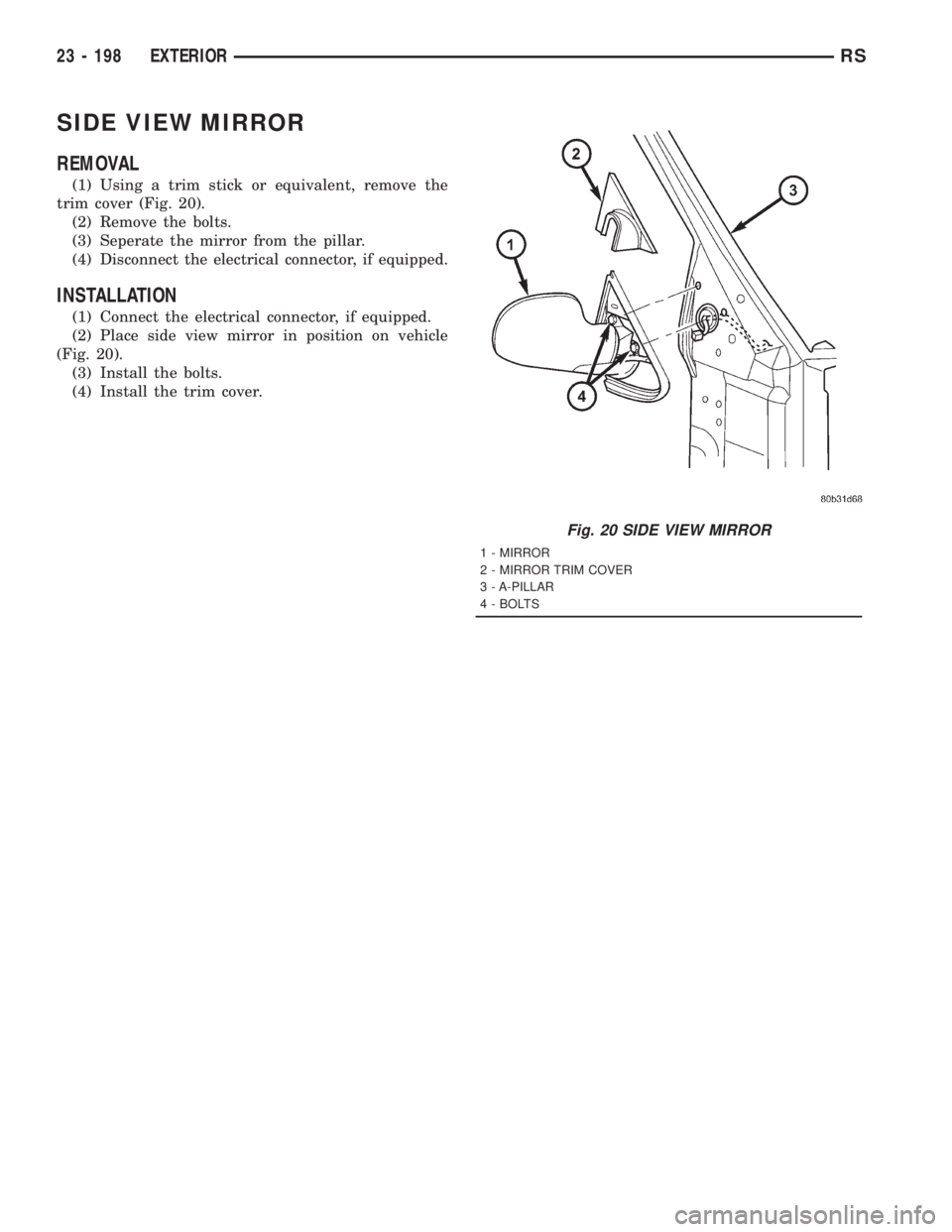

SIDE VIEW MIRROR

REMOVAL

(1) Using a trim stick or equivalent, remove the

trim cover (Fig. 20).

(2) Remove the bolts.

(3) Seperate the mirror from the pillar.

(4) Disconnect the electrical connector, if equipped.

INSTALLATION

(1) Connect the electrical connector, if equipped.

(2) Place side view mirror in position on vehicle

(Fig. 20).

(3) Install the bolts.

(4) Install the trim cover.

Fig. 20 SIDE VIEW MIRROR

1 - MIRROR

2 - MIRROR TRIM COVER

3 - A-PILLAR

4 - BOLTS

23 - 198 EXTERIORRS

Page 3579 of 4284

HOOD

TABLE OF CONTENTS

page page

HINGE

REMOVAL.............................199

INSTALLATION..........................199

HOOD

REMOVAL.............................200

INSTALLATION..........................200

LATCH

REMOVAL.............................200INSTALLATION..........................200

LATCH RELEASE CABLE

REMOVAL.............................201

INSTALLATION..........................201

LATCH STRIKER

REMOVAL.............................201

INSTALLATION..........................201

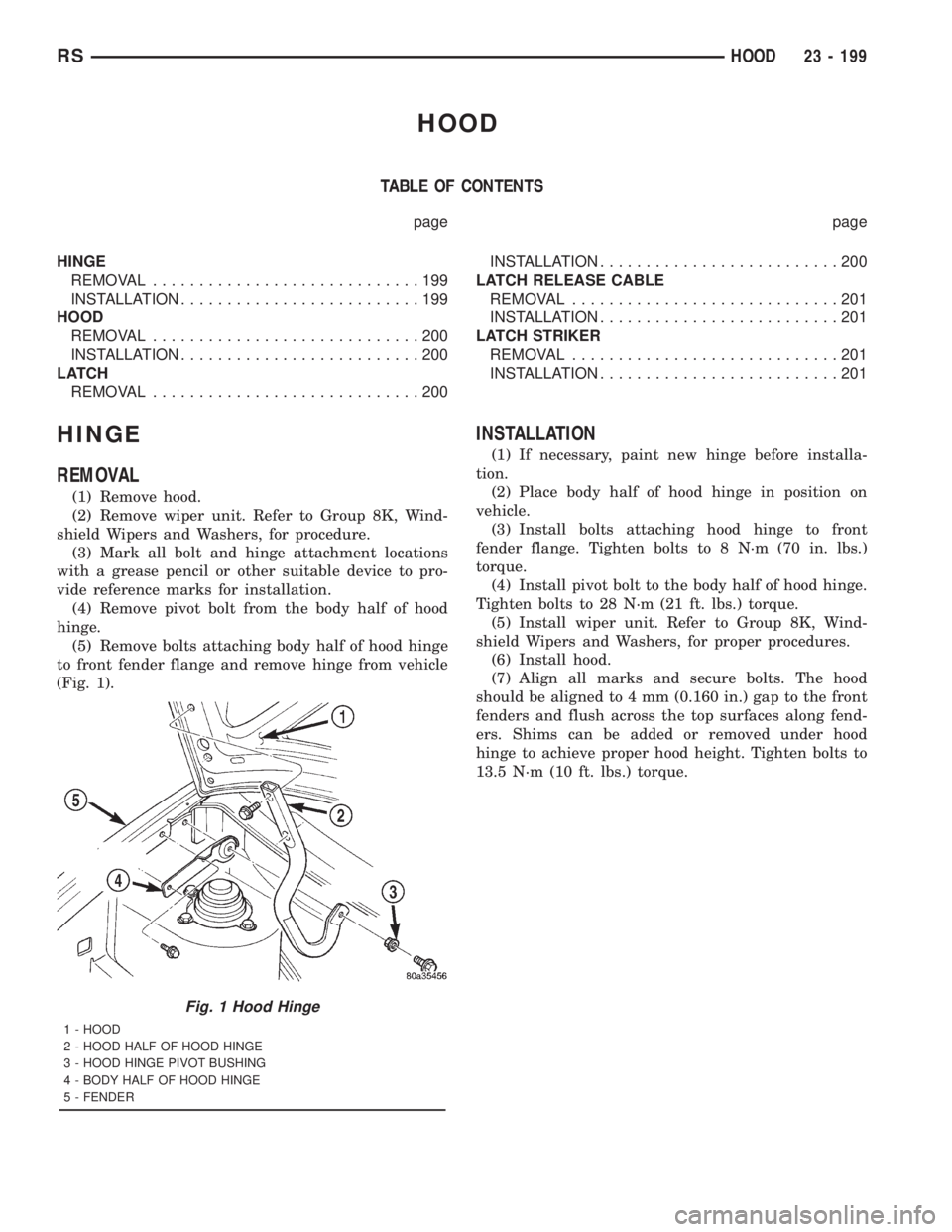

HINGE

REMOVAL

(1) Remove hood.

(2) Remove wiper unit. Refer to Group 8K, Wind-

shield Wipers and Washers, for procedure.

(3) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation.

(4) Remove pivot bolt from the body half of hood

hinge.

(5) Remove bolts attaching body half of hood hinge

to front fender flange and remove hinge from vehicle

(Fig. 1).

INSTALLATION

(1) If necessary, paint new hinge before installa-

tion.

(2) Place body half of hood hinge in position on

vehicle.

(3) Install bolts attaching hood hinge to front

fender flange. Tighten bolts to 8 N´m (70 in. lbs.)

torque.

(4) Install pivot bolt to the body half of hood hinge.

Tighten bolts to 28 N´m (21 ft. lbs.) torque.

(5) Install wiper unit. Refer to Group 8K, Wind-

shield Wipers and Washers, for proper procedures.

(6) Install hood.

(7) Align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers. Shims can be added or removed under hood

hinge to achieve proper hood height. Tighten bolts to

13.5 N´m (10 ft. lbs.) torque.

Fig. 1 Hood Hinge

1 - HOOD

2 - HOOD HALF OF HOOD HINGE

3 - HOOD HINGE PIVOT BUSHING

4 - BODY HALF OF HOOD HINGE

5 - FENDER

RSHOOD23 - 199

Page 3580 of 4284

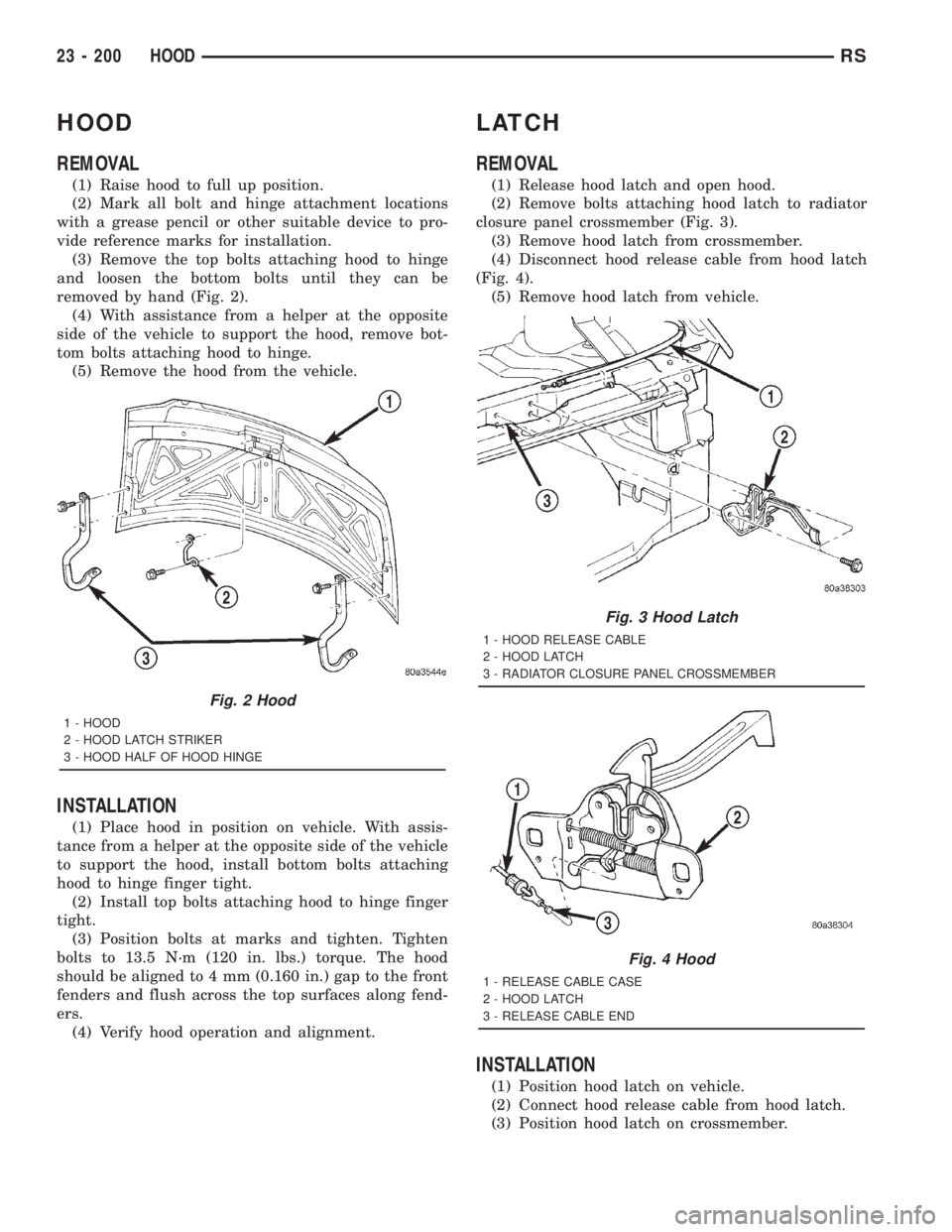

HOOD

REMOVAL

(1) Raise hood to full up position.

(2) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation.

(3) Remove the top bolts attaching hood to hinge

and loosen the bottom bolts until they can be

removed by hand (Fig. 2).

(4) With assistance from a helper at the opposite

side of the vehicle to support the hood, remove bot-

tom bolts attaching hood to hinge.

(5) Remove the hood from the vehicle.

INSTALLATION

(1) Place hood in position on vehicle. With assis-

tance from a helper at the opposite side of the vehicle

to support the hood, install bottom bolts attaching

hood to hinge finger tight.

(2) Install top bolts attaching hood to hinge finger

tight.

(3) Position bolts at marks and tighten. Tighten

bolts to 13.5 N´m (120 in. lbs.) torque. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers.

(4) Verify hood operation and alignment.

LATCH

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching hood latch to radiator

closure panel crossmember (Fig. 3).

(3) Remove hood latch from crossmember.

(4) Disconnect hood release cable from hood latch

(Fig. 4).

(5) Remove hood latch from vehicle.

INSTALLATION

(1) Position hood latch on vehicle.

(2) Connect hood release cable from hood latch.

(3) Position hood latch on crossmember.

Fig. 2 Hood

1 - HOOD

2 - HOOD LATCH STRIKER

3 - HOOD HALF OF HOOD HINGE

Fig. 3 Hood Latch

1 - HOOD RELEASE CABLE

2 - HOOD LATCH

3 - RADIATOR CLOSURE PANEL CROSSMEMBER

Fig. 4 Hood

1 - RELEASE CABLE CASE

2 - HOOD LATCH

3 - RELEASE CABLE END

23 - 200 HOODRS