CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3971 of 4284

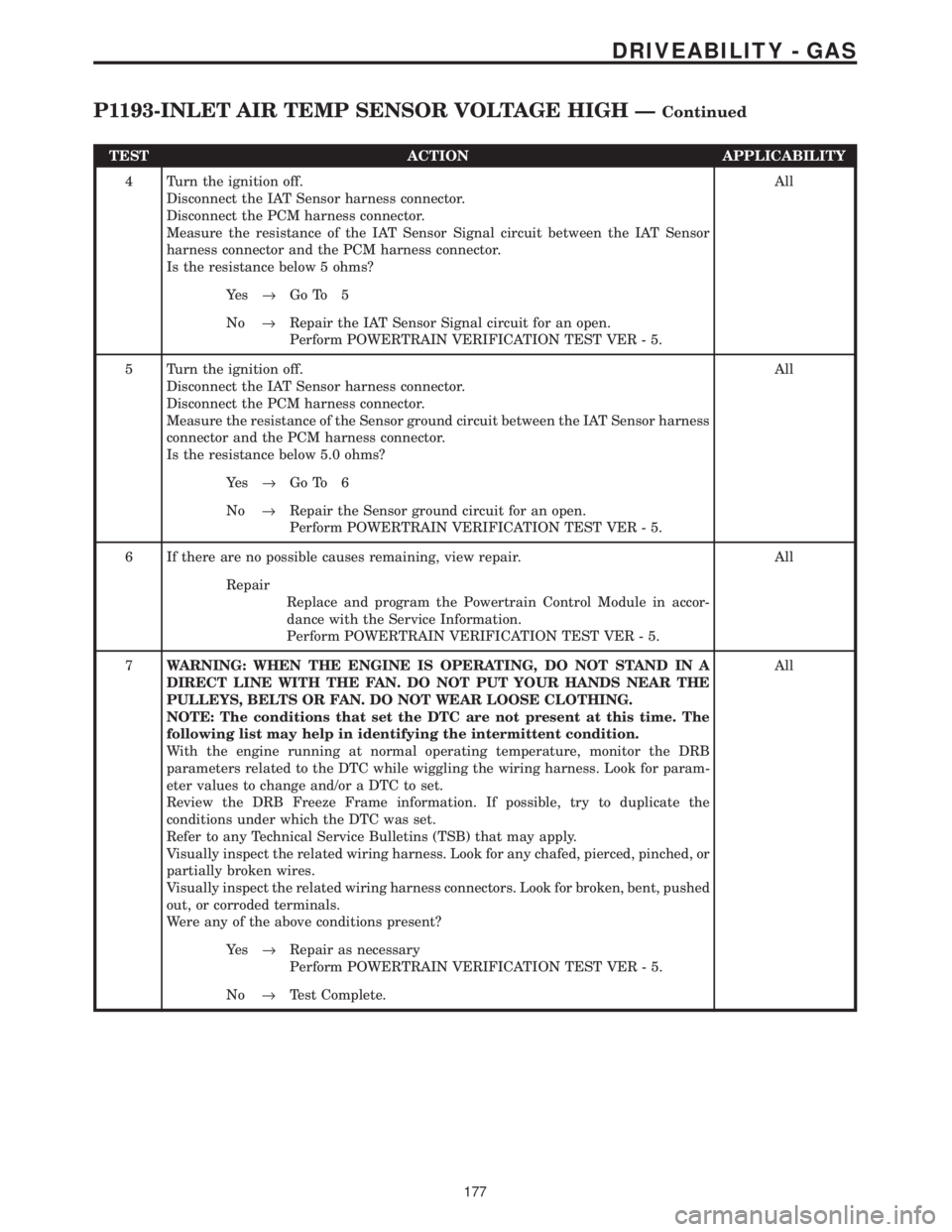

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the IAT Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the IAT Sensor Signal circuit between the IAT Sensor

harness connector and the PCM harness connector.

Is the resistance below 5 ohms?All

Ye s®Go To 5

No®Repair the IAT Sensor Signal circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

5 Turn the ignition off.

Disconnect the IAT Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Sensor ground circuit between the IAT Sensor harness

connector and the PCM harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 6

No®Repair the Sensor ground circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

177

DRIVEABILITY - GAS

P1193-INLET AIR TEMP SENSOR VOLTAGE HIGH ÐContinued

Page 3972 of 4284

Symptom:

P1195-1/1 O2 SENSOR SLOW DURING CATALYST MONITOR

When Monitored and Set Condition:

P1195-1/1 O2 SENSOR SLOW DURING CATALYST MONITOR

When Monitored: With the engine running, coolant greater than 70ÉC (158ÉF), open

throttle, steady to slightly increasing vehicle speed greater than 18 mph but less than 55

mph, with a light load on the engine, for a period no less than 5 minutes.

Set Condition: The oxygen sensor signal voltage is switching from below 0.39 volt to

above 0.6 volts and back fewer times than required.

POSSIBLE CAUSES

INTERMITTENT CONDITION

EXHAUST LEAK

O2 SENSOR SIGNAL CIRCUIT VOLTAGE DROP

O2 SENSOR GROUND CIRCUIT VOLTAGE DROP

O2 SENSOR

TEST ACTION APPLICABILITY

1NOTE: Check for contaminates that may have damaged the O2 Sensor:

contaminated fuel, unapproved silicone, oil and coolant.

Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 6

2 Start the engine.

Inspect the exhaust for leak between the engine and the O2 sensor.

Inspect the exhaust for leaks between the engine and the appropriate rear O2 Sensor.

Are there any exhaust leaks?All

Ye s®Repair or replace the leaking exhaust parts as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

178

DRIVEABILITY - GAS

Page 3973 of 4284

TEST ACTION APPLICABILITY

3NOTE: Ensure the voltmeter leads meet the terminals in the connector and

that there is good terminal to wire connection.

NOTE: Ensure the voltmeter leads are connected for positive polarity

Backprobe between the O2 Sensor Signal circuit at the O2 Sensor harness connector

and PCM harness connector.

Start the engine.

Allow the engine to idle.

Is the voltage below 0.10 volt?All

Ye s®Go To 4

No®Repair the high resistance on the O2 Sensor Signal circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

4NOTE: Ensure the voltmeter leads meet the terminals in the connector and

that there is good terminal to wire connection.

NOTE: Ensure the voltmeter leads are connected for positive polarity

Backprobe between the O2 Sensor ground circuit at the O2 Sensor harness connector

and PCM harness connector.

Start the engine.

Allow the engine to idle.

Is the voltage below 0.10 volt?All

Ye s®Go To 5

No®Repair the high resistance on the O2 Sensor ground circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

5 If there are no possible causes remaining, view repair. All

Repair

Replace the O2 Sensor

Perform POWERTRAIN VERIFICATION TEST VER - 5.

6NOTE: Check for contaminates that may have damaged the O2 Sensor:

contaminated fuel, unapproved silicone, oil and coolant.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

179

DRIVEABILITY - GAS

P1195-1/1 O2 SENSOR SLOW DURING CATALYST MONITOR ÐContinued

Page 3974 of 4284

Symptom:

P1281-ENGINE IS COLD TOO LONG

When Monitored and Set Condition:

P1281-ENGINE IS COLD TOO LONG

When Monitored: The ignition key on, engine running.

Set Condition: The engine does not warm to 71ÉC (160ÉF) while driving (throttle off idle)

greater than 20 MPH for 20 minutes after start.

POSSIBLE CAUSES

COOLING SYSTEM PROBLEM

TEST ACTION APPLICABILITY

1NOTE: The best way to diagnose this DTC is to allow the vehicle to remain

outside overnight in order to have a completely cold soaked engine.

NOTE: Extremely cold outside ambient temperatures may cause this DTC to

set.

Verify that the coolant level is correct. If not, repair as necessary

NOTE: Ensure the ECT Sensor is operating correctly.

With the DRBIIIt, monitor the Engine Coolant Temperature value during the warm

up cycle. Make sure the transition of the temperature change is smooth.

Did the engine temperature reach a minimum of 71ÉC (160ÉF)?All

Ye s®Test Complete.

No®Refer to the Service Information for cooling system performance

diagnosis. The most probable cause is a Thermostat problem.

Also, refer to any related TSBs.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

180

DRIVEABILITY - GAS

Page 3975 of 4284

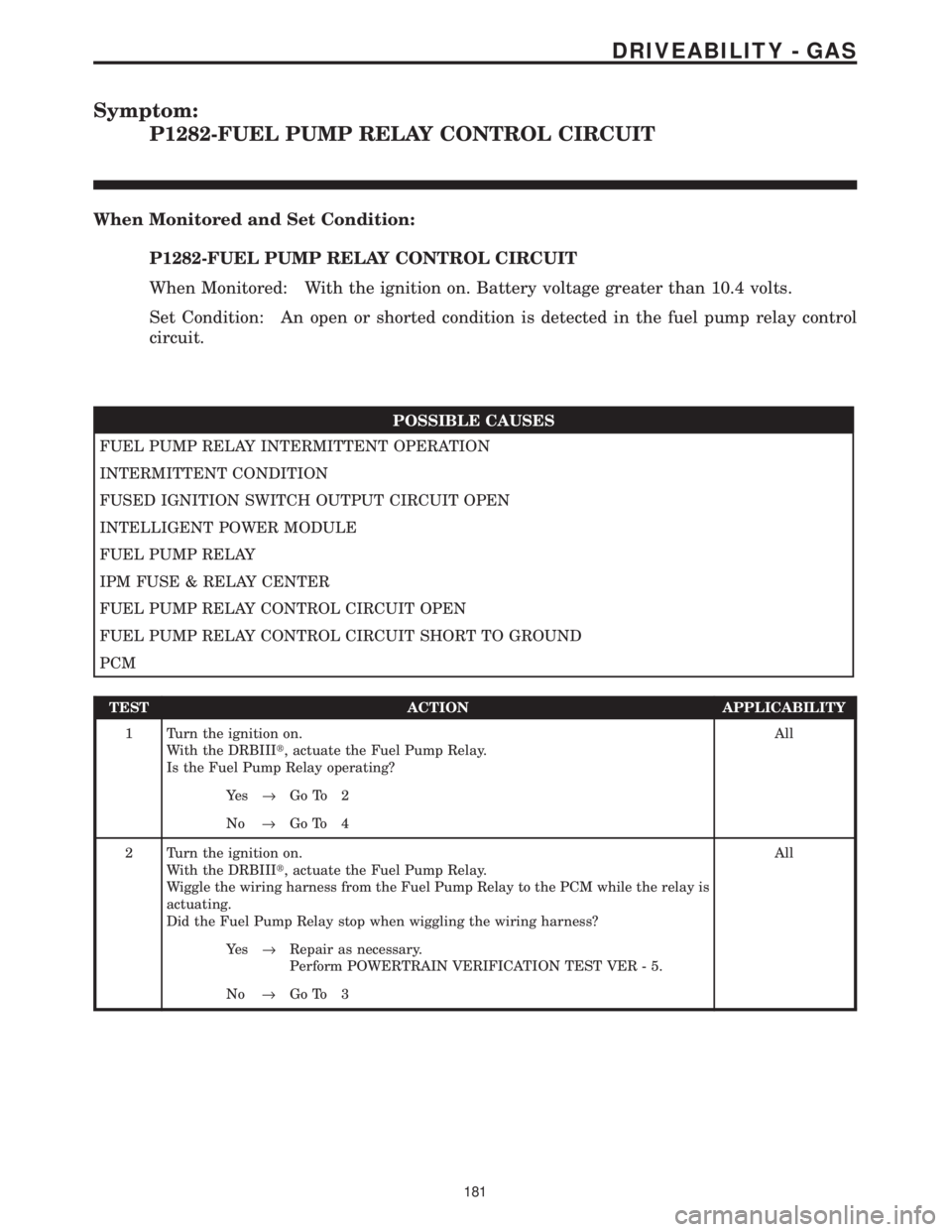

Symptom:

P1282-FUEL PUMP RELAY CONTROL CIRCUIT

When Monitored and Set Condition:

P1282-FUEL PUMP RELAY CONTROL CIRCUIT

When Monitored: With the ignition on. Battery voltage greater than 10.4 volts.

Set Condition: An open or shorted condition is detected in the fuel pump relay control

circuit.

POSSIBLE CAUSES

FUEL PUMP RELAY INTERMITTENT OPERATION

INTERMITTENT CONDITION

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

INTELLIGENT POWER MODULE

FUEL PUMP RELAY

IPM FUSE & RELAY CENTER

FUEL PUMP RELAY CONTROL CIRCUIT OPEN

FUEL PUMP RELAY CONTROL CIRCUIT SHORT TO GROUND

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, actuate the Fuel Pump Relay.

Is the Fuel Pump Relay operating?All

Ye s®Go To 2

No®Go To 4

2 Turn the ignition on.

With the DRBIIIt, actuate the Fuel Pump Relay.

Wiggle the wiring harness from the Fuel Pump Relay to the PCM while the relay is

actuating.

Did the Fuel Pump Relay stop when wiggling the wiring harness?All

Ye s®Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

181

DRIVEABILITY - GAS

Page 3976 of 4284

TEST ACTION APPLICABILITY

3WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

4 Turn the ignition off.

Remove the Fuel Pump Relay from the IPM.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the Fused Ignition Switch

circuit in the IPM.

Does the test light illuminate?All

Ye s®Go To 5

No®Go To 10

5 Turn the ignition off.

Remove the Fuel Pump Relay from the IPM.

Turn the ignition on.

Using a 12-volt test light connected to 12-volts, probe the Fuel Pump Relay Control

circuit in the IPM.

With the DRBIIIt, actuate the Fuel Pump Relay.

Does the test light flash on and off?All

Ye s®Replace the Fuel Pump Relay.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 6

6 Turn the ignition off.

Disconnect the Intelligent Power Module C3 harness connector.

Turn the ignition on.

Using a 12-volt test light connected to 12-volts, probe the Fuel Pump Relay Control

circuit in the IPM harness connector..

With the DRBIIIt, actuate the Fuel Pump Relay.

Does the test light flash on and off?All

Ye s®Replace the IPM Fused & Relay Center.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 7

182

DRIVEABILITY - GAS

P1282-FUEL PUMP RELAY CONTROL CIRCUIT ÐContinued

Page 3977 of 4284

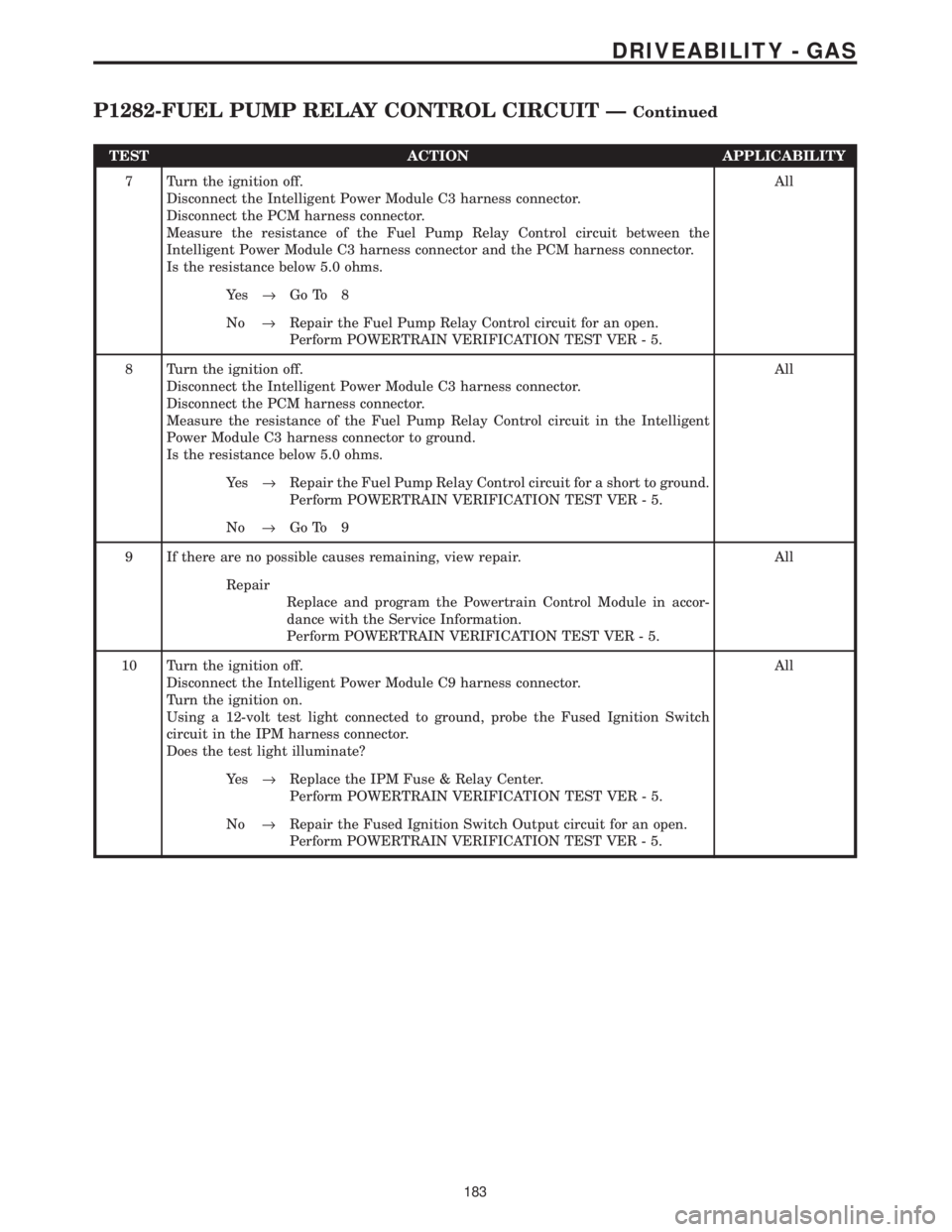

TEST ACTION APPLICABILITY

7 Turn the ignition off.

Disconnect the Intelligent Power Module C3 harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Fuel Pump Relay Control circuit between the

Intelligent Power Module C3 harness connector and the PCM harness connector.

Is the resistance below 5.0 ohms.All

Ye s®Go To 8

No®Repair the Fuel Pump Relay Control circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

8 Turn the ignition off.

Disconnect the Intelligent Power Module C3 harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Fuel Pump Relay Control circuit in the Intelligent

Power Module C3 harness connector to ground.

Is the resistance below 5.0 ohms.All

Ye s®Repair the Fuel Pump Relay Control circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 9

9 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

10 Turn the ignition off.

Disconnect the Intelligent Power Module C9 harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the Fused Ignition Switch

circuit in the IPM harness connector.

Does the test light illuminate?All

Ye s®Replace the IPM Fuse & Relay Center.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Repair the Fused Ignition Switch Output circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

183

DRIVEABILITY - GAS

P1282-FUEL PUMP RELAY CONTROL CIRCUIT ÐContinued

Page 3978 of 4284

Symptom:

P1294-TARGET IDLE NOT REACHED (2.4L)

When Monitored and Set Condition:

P1294-TARGET IDLE NOT REACHED (2.4L)

When Monitored: With the engine idling and the transmission in drive, if automatic.

There must not be a MAP sensor trouble code or a Throttle Position Sensor trouble code.

Set Condition: The engine idle is not within 200 rpm above or 100 rpm below the target

idle for 11 seconds. One trip fault.

POSSIBLE CAUSES

IAC MOTOR OPERATION INTERMITTENT

INTERMITTENT CONDITION

IAC MOTOR OPERATION INTERMITTENT

IAC MOTOR

IAC DRIVER CIRCUIT OPEN

VACUUM LEAKS

AIR INDUCTION SYSTEM

THROTTLE BODY AND THROTTLE LINKAGE

PCM IAC MOTOR

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?2.4L 4 CYL DOHC

16V MPI

Ye s®Go To 2

No®Go To 10

2 Start the engine.

Allow the engine idle to stabilize for 60 seconds.

Using the DRBIIIt, perform the IAC wiggle test.

NOTE: The engine idle should raise and lower with the display.

Does the RPM raise and lower correctly?2.4L 4 CYL DOHC

16V MPI

Ye s®Go To 3

No®Go To 6

184

DRIVEABILITY - GAS

Page 3979 of 4284

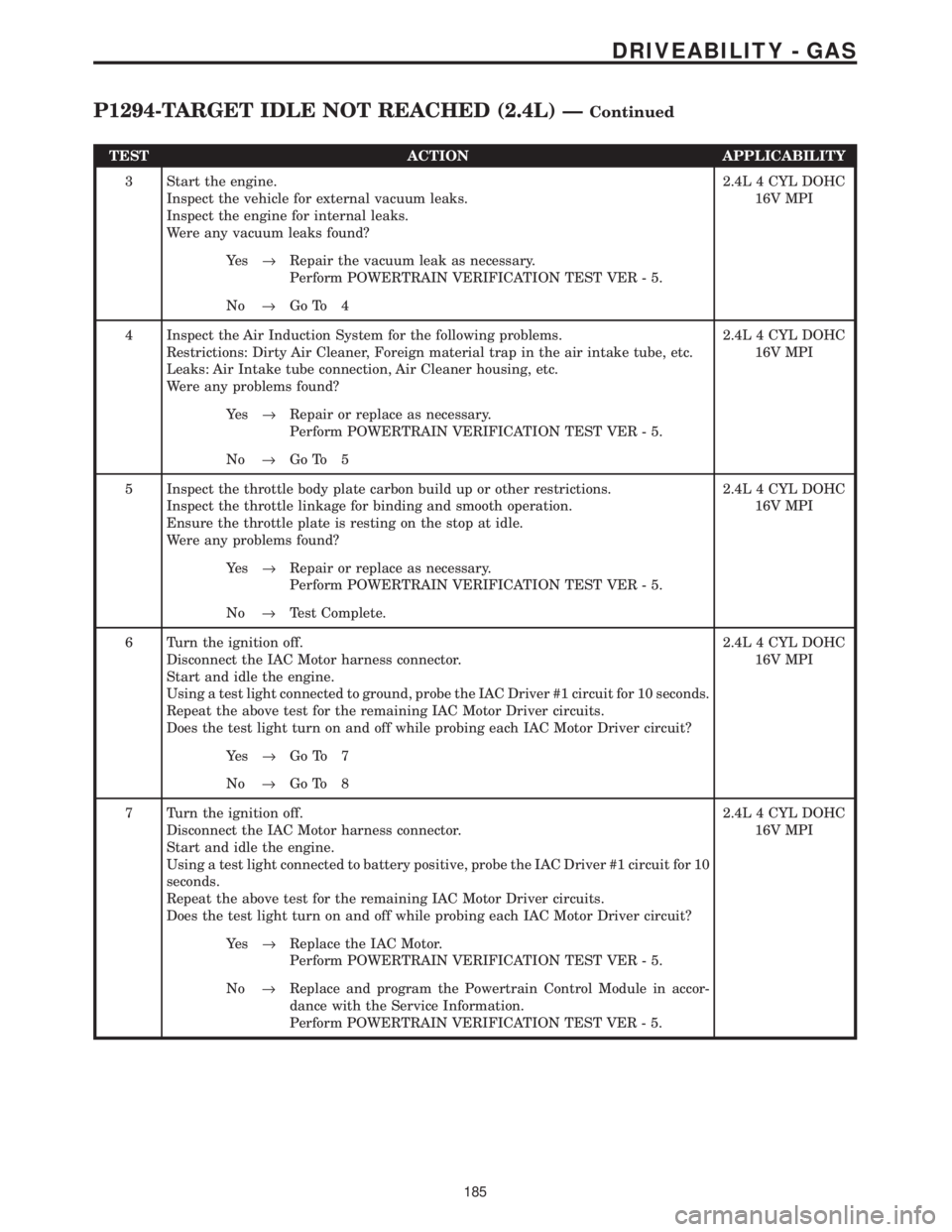

TEST ACTION APPLICABILITY

3 Start the engine.

Inspect the vehicle for external vacuum leaks.

Inspect the engine for internal leaks.

Were any vacuum leaks found?2.4L 4 CYL DOHC

16V MPI

Ye s®Repair the vacuum leak as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 4

4 Inspect the Air Induction System for the following problems.

Restrictions: Dirty Air Cleaner, Foreign material trap in the air intake tube, etc.

Leaks: Air Intake tube connection, Air Cleaner housing, etc.

Were any problems found?2.4L 4 CYL DOHC

16V MPI

Ye s®Repair or replace as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 Inspect the throttle body plate carbon build up or other restrictions.

Inspect the throttle linkage for binding and smooth operation.

Ensure the throttle plate is resting on the stop at idle.

Were any problems found?2.4L 4 CYL DOHC

16V MPI

Ye s®Repair or replace as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

6 Turn the ignition off.

Disconnect the IAC Motor harness connector.

Start and idle the engine.

Using a test light connected to ground, probe the IAC Driver #1 circuit for 10 seconds.

Repeat the above test for the remaining IAC Motor Driver circuits.

Does the test light turn on and off while probing each IAC Motor Driver circuit?2.4L 4 CYL DOHC

16V MPI

Ye s®Go To 7

No®Go To 8

7 Turn the ignition off.

Disconnect the IAC Motor harness connector.

Start and idle the engine.

Using a test light connected to battery positive, probe the IAC Driver #1 circuit for 10

seconds.

Repeat the above test for the remaining IAC Motor Driver circuits.

Does the test light turn on and off while probing each IAC Motor Driver circuit?2.4L 4 CYL DOHC

16V MPI

Ye s®Replace the IAC Motor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

185

DRIVEABILITY - GAS

P1294-TARGET IDLE NOT REACHED (2.4L) ÐContinued

Page 3980 of 4284

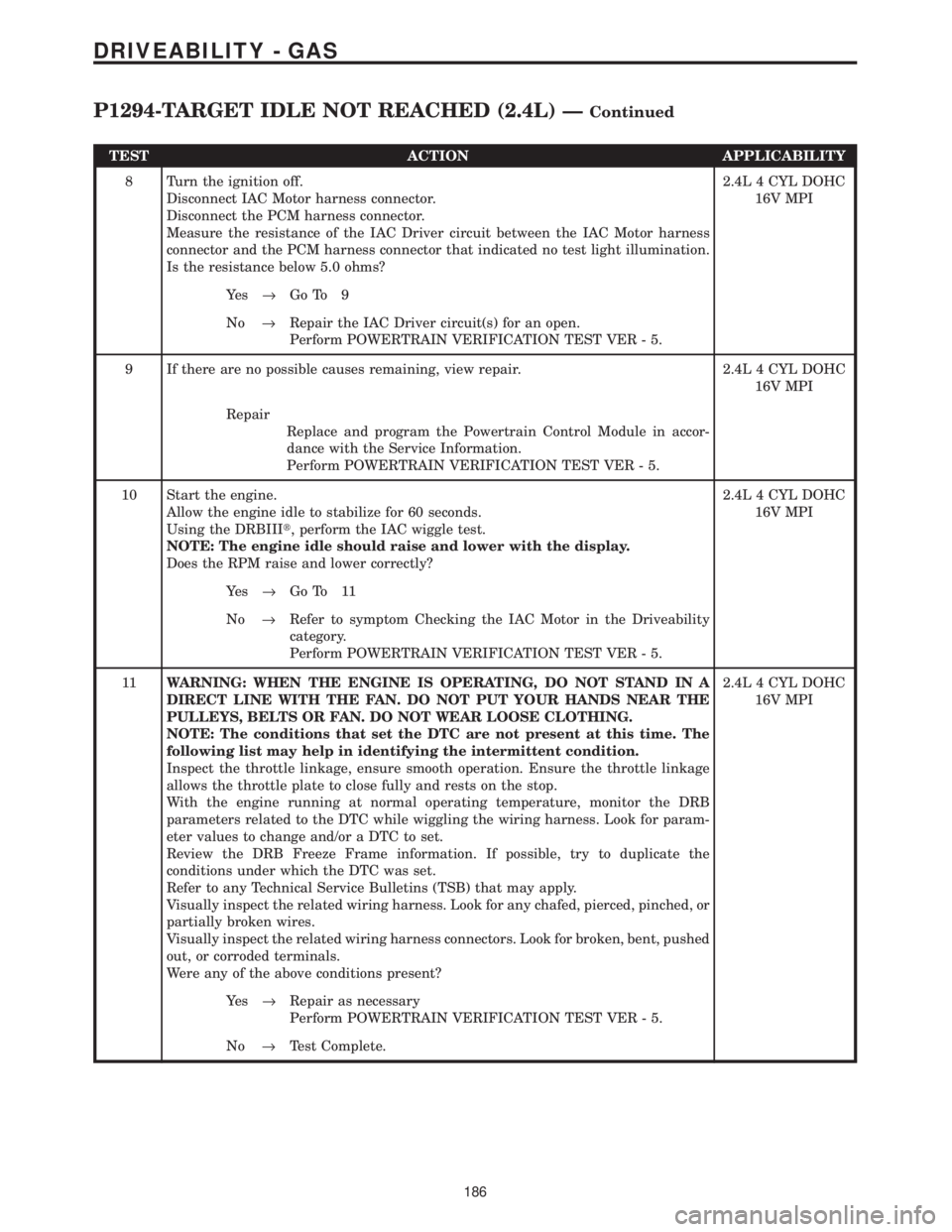

TEST ACTION APPLICABILITY

8 Turn the ignition off.

Disconnect IAC Motor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the IAC Driver circuit between the IAC Motor harness

connector and the PCM harness connector that indicated no test light illumination.

Is the resistance below 5.0 ohms?2.4L 4 CYL DOHC

16V MPI

Ye s®Go To 9

No®Repair the IAC Driver circuit(s) for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

9 If there are no possible causes remaining, view repair. 2.4L 4 CYL DOHC

16V MPI

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

10 Start the engine.

Allow the engine idle to stabilize for 60 seconds.

Using the DRBIIIt, perform the IAC wiggle test.

NOTE: The engine idle should raise and lower with the display.

Does the RPM raise and lower correctly?2.4L 4 CYL DOHC

16V MPI

Ye s®Go To 11

No®Refer to symptom Checking the IAC Motor in the Driveability

category.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

11WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

Inspect the throttle linkage, ensure smooth operation. Ensure the throttle linkage

allows the throttle plate to close fully and rests on the stop.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?2.4L 4 CYL DOHC

16V MPI

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

186

DRIVEABILITY - GAS

P1294-TARGET IDLE NOT REACHED (2.4L) ÐContinued