CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 4011 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the Leak Detection Pump harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the Ignition Switch Output

circuit in the LDP harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 4

No®Repair the Fused Ignition Switch Output circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

4 Turn the ignition off.

Disconnect the Leak Detection Pump harness connector.

Disconnect the Powertrain Control Module harness connector.

Measure the resistance of the LDP Solenoid Control circuit in the LDP harness

connector to ground.

Is the resistance below 5.0 Ohms?All

Ye s®Repair the LDP Solenoid Control circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

No®Go To 5

5 Turn the ignition off.

Disconnect the Leak Detection Pump harness connector.

Disconnect the Powertrain Control Module harness connector.

Measure the resistance of the LDP Solenoid Control circuit between the LDP

Solenoid harness connector and the PCM harness connector.

Is the resistance below 5.0 Ohms?All

Ye s®Go To 6

No®Repair the LDP Solenoid Control circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

7 At this time, the conditions required to set the DTC are not present.

Note: Use the Freeze Frame Data to help you duplicate the conditions that

set the DTC. Pay particular attention to the DTC set conditions, such as,

VSS, MAP, ECT, and Load.

Note: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

Note: Visually inspect the related wire harness connectors. Look for broken,

bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB's) that may apply.

Perform a wiggle test of the LDP wiring while the circuit is actuated with the DRB.

Listen for the LDP to quit actuating. Also watch for the Good Trip Counter to change

to 0.

Were any problems found?All

Ye s®Repair wiring harness/connectors as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

No®Test Complete.

217

DRIVEABILITY - GAS

P1495-LEAK DETECTION PUMP SOLENOID CIRCUIT ÐContinued

Page 4012 of 4284

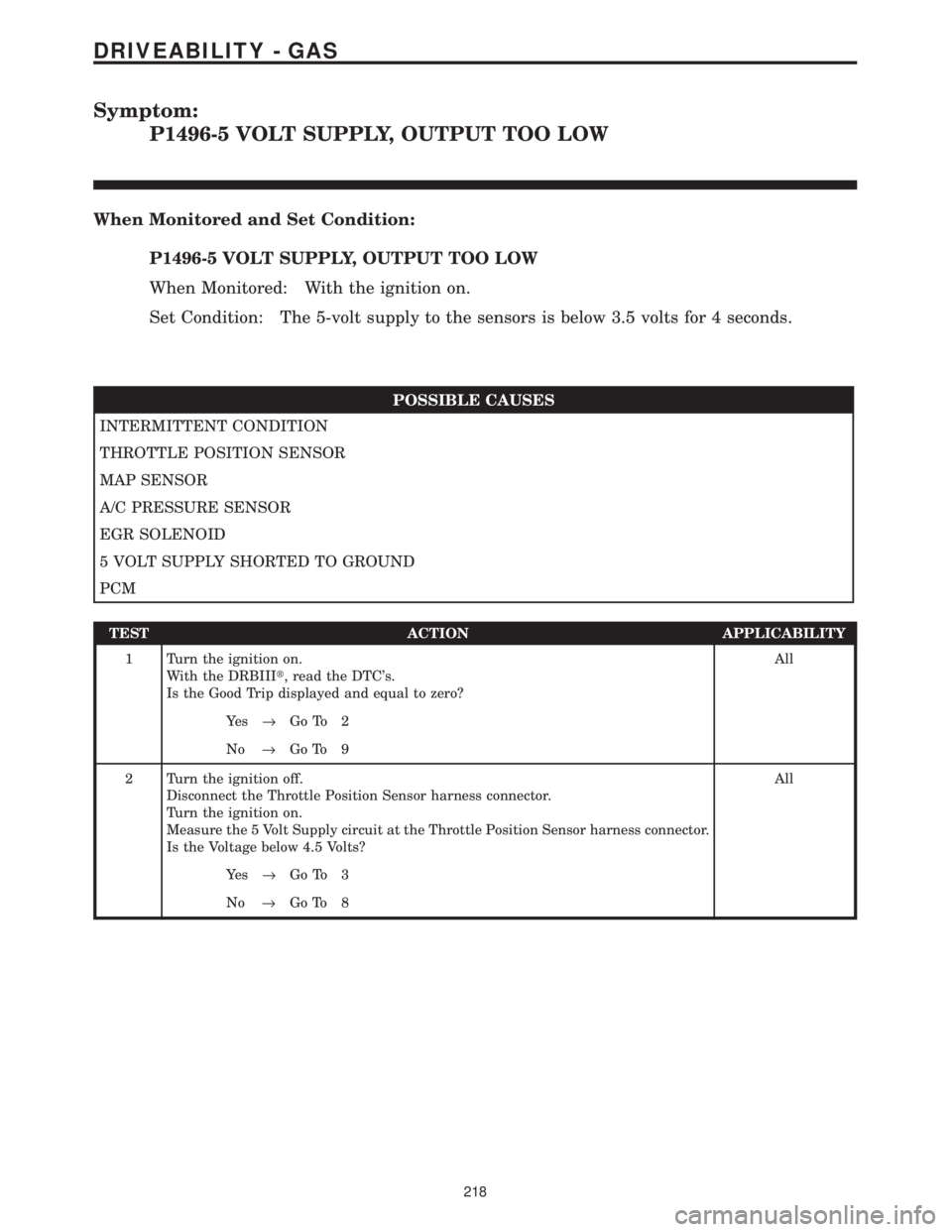

Symptom:

P1496-5 VOLT SUPPLY, OUTPUT TOO LOW

When Monitored and Set Condition:

P1496-5 VOLT SUPPLY, OUTPUT TOO LOW

When Monitored: With the ignition on.

Set Condition: The 5-volt supply to the sensors is below 3.5 volts for 4 seconds.

POSSIBLE CAUSES

INTERMITTENT CONDITION

THROTTLE POSITION SENSOR

MAP SENSOR

A/C PRESSURE SENSOR

EGR SOLENOID

5 VOLT SUPPLY SHORTED TO GROUND

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read the DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 9

2 Turn the ignition off.

Disconnect the Throttle Position Sensor harness connector.

Turn the ignition on.

Measure the 5 Volt Supply circuit at the Throttle Position Sensor harness connector.

Is the Voltage below 4.5 Volts?All

Ye s®Go To 3

No®Go To 8

218

DRIVEABILITY - GAS

Page 4013 of 4284

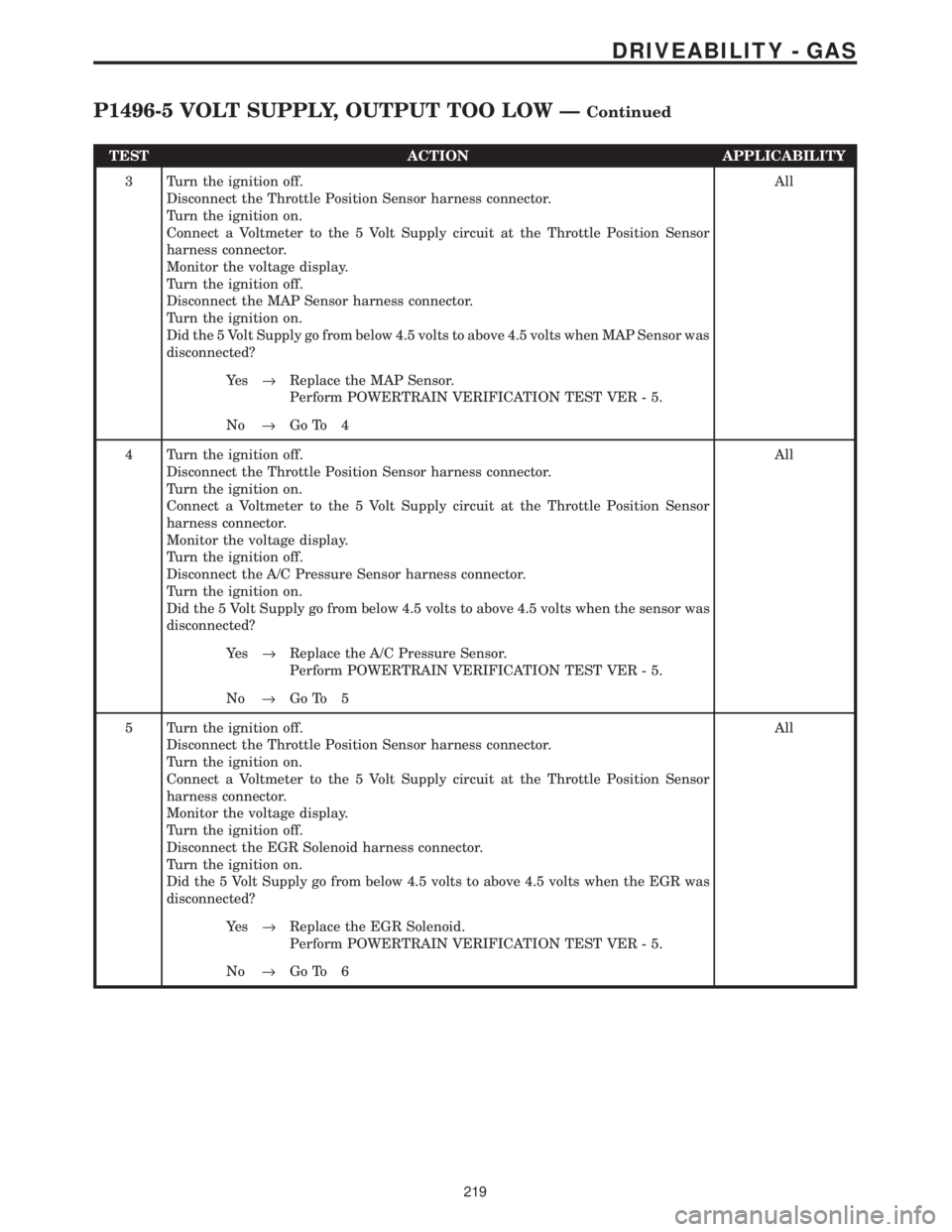

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the Throttle Position Sensor harness connector.

Turn the ignition on.

Connect a Voltmeter to the 5 Volt Supply circuit at the Throttle Position Sensor

harness connector.

Monitor the voltage display.

Turn the ignition off.

Disconnect the MAP Sensor harness connector.

Turn the ignition on.

Did the 5 Volt Supply go from below 4.5 volts to above 4.5 volts when MAP Sensor was

disconnected?All

Ye s®Replace the MAP Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 4

4 Turn the ignition off.

Disconnect the Throttle Position Sensor harness connector.

Turn the ignition on.

Connect a Voltmeter to the 5 Volt Supply circuit at the Throttle Position Sensor

harness connector.

Monitor the voltage display.

Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Turn the ignition on.

Did the 5 Volt Supply go from below 4.5 volts to above 4.5 volts when the sensor was

disconnected?All

Ye s®Replace the A/C Pressure Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 Turn the ignition off.

Disconnect the Throttle Position Sensor harness connector.

Turn the ignition on.

Connect a Voltmeter to the 5 Volt Supply circuit at the Throttle Position Sensor

harness connector.

Monitor the voltage display.

Turn the ignition off.

Disconnect the EGR Solenoid harness connector.

Turn the ignition on.

Did the 5 Volt Supply go from below 4.5 volts to above 4.5 volts when the EGR was

disconnected?All

Ye s®Replace the EGR Solenoid.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 6

219

DRIVEABILITY - GAS

P1496-5 VOLT SUPPLY, OUTPUT TOO LOW ÐContinued

Page 4014 of 4284

TEST ACTION APPLICABILITY

6 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Throttle Position Sensor harness connector.

Disconnect the MAP Sensor harness connector.

Disconnect the PCM harness connectors.

Disconnect the A/C Pressure Sensor harness connector.

Disconnect the EGR Solenoid harness connector.

Measure the resistance of the 5 Volt Supply circuit in the Throttle Position Sensor

harness connector to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the 5 Volt Supply Circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 7

7 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

8NOTE: The Throttle Position Sensor harness connector must be connected

during this test.

Disconnect the MAP Sensor harness connector.

Turn the ignition on.

Measure the 5 Volt Supply circuit in the MAP Sensor harness connector.

Is the Voltage below 4.5 Volts?All

Ye s®Replace the Throttle Position Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 9

9WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

220

DRIVEABILITY - GAS

P1496-5 VOLT SUPPLY, OUTPUT TOO LOW ÐContinued

Page 4015 of 4284

Symptom:

P1602-PCM NOT PROGRAMMED

When Monitored and Set Condition:

P1602-PCM NOT PROGRAMMED

When Monitored: Ignition key on.

Set Condition: PCM has not been programmed.

POSSIBLE CAUSES

PCM PROGRAMMED

TEST ACTION APPLICABILITY

1 Attempt to program PCM in accordance with the Service Information.

Turn the ignition on.

Start the engine.

NOTE: If the engine will not start, crank the engine over for 15 seconds.

Crank at least 2 time with the ignition switch returning to the off position

each time.

Allow the engine to reach normal operating temperature.

With the DRBIIIt, read DTCs.

Does the DTC reset?All

Ye s®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Test Complete.

221

DRIVEABILITY - GAS

Page 4016 of 4284

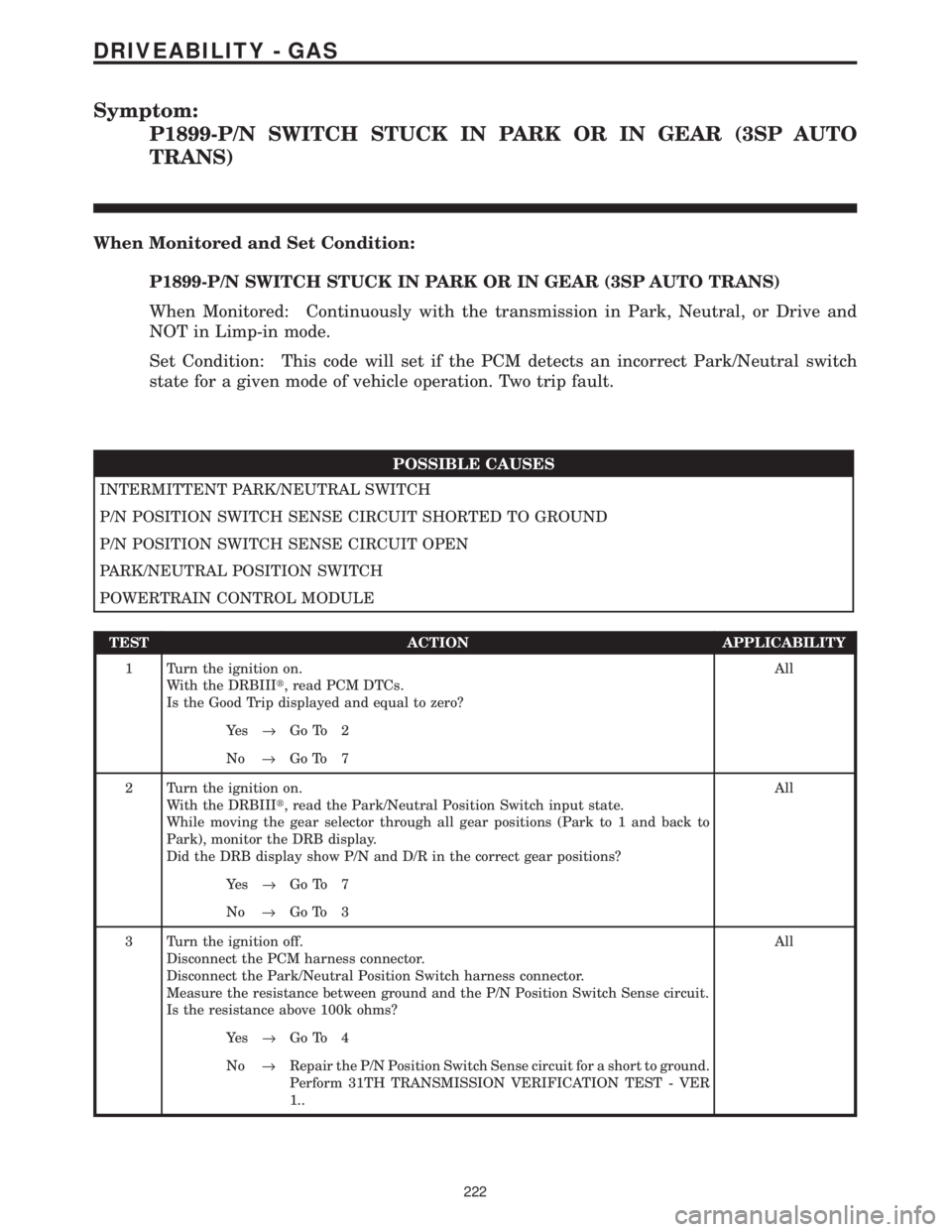

Symptom:

P1899-P/N SWITCH STUCK IN PARK OR IN GEAR (3SP AUTO

TRANS)

When Monitored and Set Condition:

P1899-P/N SWITCH STUCK IN PARK OR IN GEAR (3SP AUTO TRANS)

When Monitored: Continuously with the transmission in Park, Neutral, or Drive and

NOT in Limp-in mode.

Set Condition: This code will set if the PCM detects an incorrect Park/Neutral switch

state for a given mode of vehicle operation. Two trip fault.

POSSIBLE CAUSES

INTERMITTENT PARK/NEUTRAL SWITCH

P/N POSITION SWITCH SENSE CIRCUIT SHORTED TO GROUND

P/N POSITION SWITCH SENSE CIRCUIT OPEN

PARK/NEUTRAL POSITION SWITCH

POWERTRAIN CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read PCM DTCs.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition on.

With the DRBIIIt, read the Park/Neutral Position Switch input state.

While moving the gear selector through all gear positions (Park to 1 and back to

Park), monitor the DRB display.

Did the DRB display show P/N and D/R in the correct gear positions?All

Ye s®Go To 7

No®Go To 3

3 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Park/Neutral Position Switch harness connector.

Measure the resistance between ground and the P/N Position Switch Sense circuit.

Is the resistance above 100k ohms?All

Ye s®Go To 4

No®Repair the P/N Position Switch Sense circuit for a short to ground.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

222

DRIVEABILITY - GAS

Page 4017 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Park/Neutral Position Switch harness connector.

Measure the resistance of the P/N Position Switch Sense circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 5

No®Repair the P/N Position Switch Sense circuit for an open.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

5 Turn the ignition off.

Disconnect the PCM harness connector.

Move the Gear selector through all gear positions, from Park to 1st and back.

While moving the gear selector through each gear, measure the resistance between

ground and the P/N Position Switch Sense circuit.

Did the resistance change from above 10.0 ohms to below 10.0 ohms?All

Ye s®Go To 6

No®Replace the Park/Neutral Position Switch.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Module in accordance with

the Service Information.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER 1..

7 At this time, the conditions required to set the DTC are not present.

NOTE: Use the Freeze Frame Data to help duplicate the conditions that set

the DTC. Pay particular attention to the DTC set conditions, such as, VSS,

MAP, ECT, and Load.

NOTE: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

NOTE: Refer to any technical service bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

No®Test Complete.

223

DRIVEABILITY - GAS

P1899-P/N SWITCH STUCK IN PARK OR IN GEAR (3SP AUTO TRANS) Ð

Continued

Page 4018 of 4284

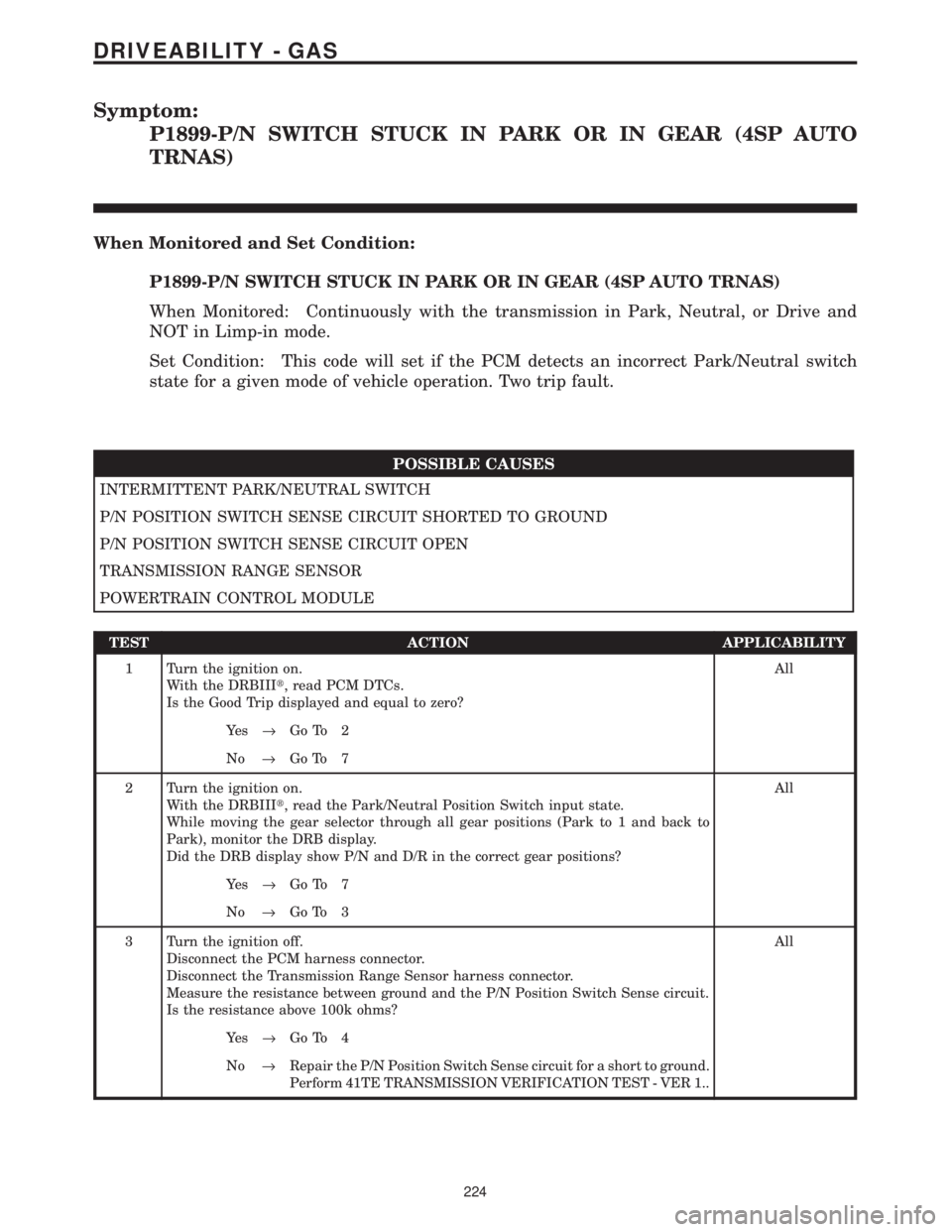

Symptom:

P1899-P/N SWITCH STUCK IN PARK OR IN GEAR (4SP AUTO

TRNAS)

When Monitored and Set Condition:

P1899-P/N SWITCH STUCK IN PARK OR IN GEAR (4SP AUTO TRNAS)

When Monitored: Continuously with the transmission in Park, Neutral, or Drive and

NOT in Limp-in mode.

Set Condition: This code will set if the PCM detects an incorrect Park/Neutral switch

state for a given mode of vehicle operation. Two trip fault.

POSSIBLE CAUSES

INTERMITTENT PARK/NEUTRAL SWITCH

P/N POSITION SWITCH SENSE CIRCUIT SHORTED TO GROUND

P/N POSITION SWITCH SENSE CIRCUIT OPEN

TRANSMISSION RANGE SENSOR

POWERTRAIN CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read PCM DTCs.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition on.

With the DRBIIIt, read the Park/Neutral Position Switch input state.

While moving the gear selector through all gear positions (Park to 1 and back to

Park), monitor the DRB display.

Did the DRB display show P/N and D/R in the correct gear positions?All

Ye s®Go To 7

No®Go To 3

3 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Transmission Range Sensor harness connector.

Measure the resistance between ground and the P/N Position Switch Sense circuit.

Is the resistance above 100k ohms?All

Ye s®Go To 4

No®Repair the P/N Position Switch Sense circuit for a short to ground.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

224

DRIVEABILITY - GAS

Page 4019 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Transmission Range Sensor harness connector.

Measure the resistance of the P/N Position Switch Sense circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 5

No®Repair the P/N Position Switch Sense circuit for an open.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

5 Turn the ignition off.

Disconnect the PCM harness connector.

Move the Gear selector through all gear positions, from Park to 1st and back.

While moving the gear selector through each gear, measure the resistance between

ground and the P/N Position Switch Sense circuit.

Did the resistance change from above 10.0 ohms to below 10.0 ohms?All

Ye s®Go To 6

No®Replace the Transmission Range Sensor.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Module in accordance with

the Service Information.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

7 At this time, the conditions required to set the DTC are not present.

NOTE: Use the Freeze Frame Data to help duplicate the conditions that set

the DTC. Pay particular attention to the DTC set conditions, such as, VSS,

MAP, ECT, and Load.

NOTE: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

NOTE: Refer to any technical service bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

No®Test Complete.

225

DRIVEABILITY - GAS

P1899-P/N SWITCH STUCK IN PARK OR IN GEAR (4SP AUTO TRNAS) Ð

Continued

Page 4020 of 4284

Symptom:

*CHECKING ECT SENSOR

POSSIBLE CAUSES

ECT SENSOR OPERATION

ECT SENSOR

TEST ACTION APPLICABILITY

1NOTE: The engine coolant temperature must be below 62ÉC (150ÉF).

Turn the ignition on.

With the DRBIIIt, monitor the ECT value.

Start the engine.

Does the ECT reach 82ÉC (180ÉF) and was it a smooth transition?All

Ye s®Engine Coolant Temperature sensor is operating normally.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Replace the Engine Coolant Temperature Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

226

DRIVEABILITY - GAS