display CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3789 of 4284

TABLE OF CONTENTS

1.0 INTRODUCTION.........................................................1

1.1SYSTEM COVERAGE...............................................1

1.2SIX-STEP TROUBLESHOOTING PROCEDURE..........................1

2.0 IDENTIFICATION OF SYSTEM.............................................1

3.0 SYSTEM DESCRIPTION AND FUNCTIONAL OPERATION......................1

3.1GENERAL DESCRIPTION............................................1

3.2FUNCTIONAL OPERATION...........................................1

3.2.1FUEL CONTROL.............................................1

3.2.2ON-BOARD DIAGNOSTICS....................................2

3.2.3OTHER CONTROLS..........................................4

3.2.4PCM OPERATING MODES....................................4

3.2.5NON-MONITORED CIRCUITS..................................5

3.2.6SKIS OVERVIEW............................................5

3.2.7SKIM ON-BOARD DIAGNOSTICS...............................6

3.2.8SKIS OPERATION............................................6

3.2.9PROGRAMMING THE POWERTRAIN CONTROL MODULE..........6

3.2.10PROGRAMMING THE SENTRY KEY IMMOBILIZER MODULE.......7

3.2.11PROGRAMMING THE IGNITION KEYS TO THE SENTRY KEY

IMMOBILIZER MODULE.......................................7

3.3DIAGNOSTIC TROUBLE CODES......................................7

3.3.1HARD CODE................................................7

3.3.2INTERMITTENT CODE........................................8

3.3.3DISTANCE SINCE MI SET.....................................8

3.3.4HANDLING NO DTC PROBLEMS...............................8

3.4USING THE DRBIIIT................................................10

3.5DRBIIITERROR MESSAGES AND BLANK SCREEN.....................10

3.5.1DRBIIITDOES NOT POWER UP...............................10

3.5.2DISPLAY IS NOT VISIBLE....................................10

4.0 DISCLAIMERS, SAFETY, WARNINGS......................................10

4.1DISCLAIMERS.....................................................10

4.2SAFETY..........................................................10

4.2.1TECHNICIAN SAFETY INFORMATION..........................10

4.2.2VEHICLE PREPARATION FOR TESTING........................11

4.2.3SERVICING SUB ASSEMBLIES................................11

4.2.4DRBIIITSAFETY INFORMATION..............................11

4.3WARNINGS AND CAUTIONS.........................................11

4.3.1ROAD TEST WARNINGS.....................................11

4.3.2VEHICLE DAMAGE CAUTIONS................................11

5.0 REQUIRED TOOLS AND EQUIPMENT.....................................12

6.0 GLOSSARY OF TERMS..................................................12

7.0 DIAGNOSTIC INFORMATION AND PROCEDURES...........................15

CHARGING

P0622-GENERATOR FIELD NOT SWITCHING PROPERLY.....................16

P1594-CHARGING SYSTEM VOLTAGE TOO HIGH...........................18

i

Page 3795 of 4284

1.0 INTRODUCTION

The procedures contained in this manual include

specifications, instructions, and graphics needed to

diagnose the PCM Powertrain System. The diag-

nostics in this manual are based on the failure

condition or symptom being present at time of

diagnosis.

Please follow the recommendations below when

choosing your diagnostic path.

1. First make sure the DRBIIItis communicating

with the appropriate modules; ie., if the DRBIIIt

displays a No Response condition, you must

diagnose this first before proceeding.

2. Read DTC's (diagnostic trouble codes) with the

DRBIIIt.

3. If no DTC's are present, identify the customer

complaint.

4. Once the DTC or customer complaint is identi-

fied, locate the matching test in the Table of

Contents and begin to diagnose the symptom.

All component location views are in Section 8.0.

All connector pinouts are in Section 9.0. All system

schematics are in Section 10.0.

An * placed before the symptom description indi-

cates a customer complaint.

When repairs are required, refer to the appropri-

ate service information for the proper removal and

repair procedure.

Diagnostic procedures change every year. New

diagnostic systems may be added; carryover sys-

tems may be enhanced. READ THIS DIAGNOSTIC

INFORMATION BEFORE TRYING TO DIAG-

NOSE A VEHICLE CODE. It is recommended that

you review the entire diagnostic information to

become familiar with all new and changed diagnos-

tic procedures.

If you have any comments or recommendations

after reviewing the diagnostic information, please

fill out the form at the back of the book and mail it

back to us.

1.1 SYSTEM COVERAGE

This diagnostic procedures manual covers the

following 2001 Town and Country; Caravan/Grand

Caravan; and Voyager/Grand Voyager vehicles

equipped with the 2.4L and the 3.3L/3.8L engines.

1.2 SIX-STEP TROUBLESHOOTING

PROCEDURE

Diagnosis of the powertrain control module

(PCM) is done in six basic steps:

²verification of complaint

²verification of any related symptoms

²symptom analysis

²problem isolation

²repair of isolated problem

²verification of proper operation

2.0 IDENTIFICATION OF

SYSTEM

The Powertrain Control Module (PCM) monitors

and controls:

²Fuel System

²Idle Air Control System

²Ignition System

²Charging System

²Speed Control System

²Cooling system

3.0 SYSTEM DESCRIPTION AND

FUNCTIONAL OPERATION

3.1 GENERAL DESCRIPTION

These Sequential Fuel Injection (SFI) engine sys-

tems have the latest in technical advances. The

on-board Euro Stage III OBD diagnostics incorpo-

rated with the Powertrain Control Module (PCM)

are intended to assist the field technician in repair-

ing vehicle problems by the quickest means.

3.2 FUNCTIONAL OPERATION

3.2.1 FUEL CONTROL

The PCM controls the air/fuel ratio of the engine

by varying fuel injector on time. Mass air flow is

calculated using the speed density method using

enigne speed, manifold absolute pressure, and air

temperature change.

Different fuel calculation strategies are used de-

pending on the operational state of the engine.

During crank mode, a prime shot fuel pulse is

delivered followed by fuel pulses determined by a

crank time strategy. Cold engine operation is deter-

mined via an open loop strategy until the O2

sensors have reached operating temperature. At

this point, the strategy enters a closed loop mode

where fuel requirements are based upon the state of

the O2 sensors, engine speed, MAP, throttle posi-

tion, air temperature, battery voltage, and coolant

temperature.

1

GENERAL INFORMATION

Page 3799 of 4284

Once the auto shutdown and fuel pump relays

have been energized, the PCM determines the fuel

injector pulse width based on the following:

± engine coolant temperature

± manifold absolute pressure

± intake air temperature

± engine revolutions

± throttle position

The PCM determines the spark advance based on

the following:

± engine coolant temperature

± crankshaft position

± intake air temperature

± manifold absolute pressure

± throttle position

Engine Warm-Up Modeþ This is an open loop

mode. The PCM adjusts injector pulse width and

controls injector synchronization by controlling the

fuel injectors' ground paths. The PCM adjusts igni-

tion timing and engine idle speed. The PCM adjusts

the idle speed by controlling the idle air control

motor.

Cruise or Idle Modeþ When the engine is at

normal operating temperature, this is a closed loop

mode.

Acceleration Modeþ This is a closed loop mode.

The PCM recognizes an increase in throttle position

and a decrease in Manifold Vacuum as engine load

increases. In response, the PCM increases the in-

jector pulse width to meet the increased load. The

A/C compressor may be de-energized for a short

period of time.

Decelerationþ This is a closed loop mode. The

PCM recognizes a decrease in throttle position and

an increase in Manifold Vacuum as engine load

decreases. In response, the PCM decreases the

injector pulse width to meet the decreased load.

Full injector shut off may be obtained during high

speed deceleration.

Wide Open Throttle Modeþ This is an open

loop mode. The throttle position sensor notifies the

PCM of a wide open throttle condition. Once a wide

open throttle is sensed, the PCM de-energizes the

A/C compressor clutch relay for 20 seconds.

3.2.5 NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems, and conditions even though they could

have malfunctions that result in driveability prob-

lems. A diagnostic code may not be displayed for the

following conditions. However, problems with these

systems may cause a diagnostic code to be displayed

for other systems. For example, a fuel pressure

problem will not register a diagnostic code directly,

but could cause a rich or lean condition. This couldcause an oxygen sensor, fuel system, or misfire

monitor trouble code to be stored in the PCM.

Engine Timingþ The PCM cannot detect an

incorrectly indexed timing chain, camshaft

sprocket, or crankshaft sprocket. The PCM also

cannot detect an incorrectly indexed distributor.(*)

Fuel Pressureþ Fuel pressure is controlled by

the fuel pressure regulator. The PCM cannot detect

a clogged fuel pump inlet filter, clogged in-line filter,

or a pinched fuel supply.(*)

Fuel Injectorsþ The PCM cannot detect if a fuel

injector is clogged, the pintle is sticking, or the

wrong injectors are installed.(*)

Fuel Requirementsþ Poor quality gasoline can

cause problems such as hard starting, stalling, and

stumble. Use of methanol-gasoline blends may re-

sult in starting and driveability problems. See indi-

vidual symptoms and their definitions in Section

6.0 (Glossary of Terms).

PCM Groundsþ The PCM cannot detect a poor

system ground. However, a diagnostic trouble code

may be stored in the PCM as a result of this

condition.

Throttle Body Air Flowþ The PCM cannot

detect a clogged or restricted air cleaner inlet or

filter element.(*)

Exhaust Systemþ The PCM cannot detect a

plugged, restricted, or leaking exhaust system.(*)

Cylinder Compressionþ The PCM cannot de-

tect uneven, low, or high engine cylinder compres-

sion.(*)

Excessive Oil Consumptionþ Although the

PCM monitors the exhaust stream oxygen content

through the oxygen sensor when the system is in a

closed loop, it cannot determine excessive oil con-

sumption.

NOTE: ANY OF THESE CONDITIONS

COULD RESULT IN A RICH OR LEAN

CONDITION CAUSING AN OXYGEN SENSOR

TROUBLE CODE TO BE STORED IN THE

PCM, OR THE VEHICLE MAY EXHIBIT ONE

OR MORE OF THE DRIVEABILITY

SYMPTOMS LISTED IN THE TABLE OF

CONTENTS.

3.2.6 SKIS OVERVIEW

The Sentry Key Immobilizer System (SKIS) is

designed to prevent unauthorized vehicle opera-

tion. The system consists of a Sentry Key Immobi-

lizer Module (SKIM), ignition key(s) equipped with

a transponder chip and PCM. When the ignition

switch is turned on, the SKIM interrogates the

ignition key. If the ignition key is Valid or Invalid,

the SKIM sends a PCI Bus message to the PCM

indicating ignition key status. Upon receiving this

5

GENERAL INFORMATION

Page 3801 of 4284

3. Select PCM REPLACED.

4. Enter secured access mode by entering the vehi-

cle four-digit PIN.

NOTE: IF THREE ATTEMPTS ARE MADE TO

ENTER THE SECURE ACCESS MODE USING

AN INCORRECT PIN, SECURED ACCESS

MODE WILL BE LOCKED OUT FOR ONE

HOUR. TO EXIT THIS LOCKOUT MODE,

TURN THE IGNITION TO THE RUN POSITION

FOR ONE HOUR THEN ENTER THE

CORRECT PIN. (ENSURE ALL ACCESSORIES

ARE TURNED OFF. ALSO MONITOR THE

BATTERY STATE AND CONNECT A BATTERY

CHARGER IF NECESSARY).

5. Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

3.2.10 PROGRAMMING THE SENTRY KEY

IMMOBILIZER MODULE

NOTE: IF THE PCM AND THE SKIM ARE

REPLACED AT THE SAME TIME, PROGRAM

THE VIN INTO THE PCM FIRST. ALL VEHICLE

KEYS WILL THEN NEED TO BE REPLACED

AND PROGRAMMED TO THE NEW SKIM.

1. Turn the ignition on (transmission in park/

neutral).

2. Use the DRB and select THEFT ALARM, SKIM

then MISCELLANEOUS.

3. Select SKIM MODULE REPLACEMENT (GAS-

OLINE).

4. Program the vehicle four-digit PIN into the

SKIM.

5. Select COUNTRY CODE and enter the correct

country.

NOTE: BE SURE TO ENTER THE CORRECT

COUNTRY CODE. IF THE INCORRECT

COUNTRY CODE IS PROGRAMMED INTO

SKIM, THE SKIM MUST BE REPLACED.

6. Select UPDATE VIN (the SKIM will learn the

VIN from the PCM).

7. Press ENTER to transfer the VIN (the PCM will

send the VIN to the SKIM).

8. The DRB will ask if you want to transfer the

secret key. Select ENTER to transfer secret key

from the PCM. This will ensure the current

vehicle ignition keys will still operate the SKIS

system.

3.2.11 PROGRAMMING THE IGNITION

KEYS TO THE SENTRY KEY

IMMOBILIZER MODULE

1. Turn the ignition on (transmission in park/

neutral).

2. Use the DRB and select THEFT ALARM, SKIM,

then MISCELLANEOUS.

3. Select PROGRAM IGNITION KEYS.

4. Enter secured access mode by entering the vehi-

cle four-digit PIN.

NOTE: A MAXIMUM OF EIGHT KEYS CAN BE

LEARNED TO EACH SKIM AT ONE TIME.

ONCE A KEY IS LEARNED TO A SKIM IT (THE

KEY) CANNOT BE TRANSFERRED TO

ANOTHER VEHICLE.

If ignition key programming is unsuccessful, the

DRB will display one of the following messages:

Programming Not Attempted- The DRB at-

tempts to read the programmed key status and

there are no keys programmed in the SKIM mem-

ory.

Programming Key Failed -(Possible Used Key

From Wrong Vehicle) - SKIM is unable to program

key due to one of the following:

± faulty ignition key transponder

± ignition key is programmed to another vehicle.

8 Keys Already Learned, Programming Not

Done- SKIM transponder ID memory is full.

1. Obtain ignition keys to be programmed from

customer (8 keys maximum)

2. Using the DRB, erase all ignition keys by select-

ing MISCELLANEOUS and ERASE ALL CUR-

RENT IGN. KEYS

3. Program all ignition keys.

Learned Key In Ignition- Ignition key transpon-

der ID is currently programmed in SKIM memory.

3.3 DIAGNOSTIC TROUBLE CODES

Each diagnostic trouble code is diagnosed by

following a specific testing procedure. The diagnos-

tic test procedures contain step-by-step instructions

for determining the cause of trouble codes as well as

no trouble code problems. It is not necessary to

perform all of the tests in this book to diagnose an

individual code.

Always begin by reading the diagnostic trouble

codes using the DRBIIIt.

3.3.1 HARD CODE

A diagnostic trouble code that comes back within

one cycle of the ignition key is a hard code. This

means that the defect is there every time the

7

GENERAL INFORMATION

Page 3804 of 4284

SYMPTOM DIAGNOSTIC TEST

POOR FUEL ECONOMY CHECKING PCM POWER AND GND CKT

CHECKING THE FUEL PRESSURE

CHECKING ECT SENSOR

CHECKING THROTTLE POSITION SENSOR

CHECKING MAP SENSOR

CHECKING IDLE AIR CONTROL MOTOR OPERATION

CHECKING IAT SENSOR

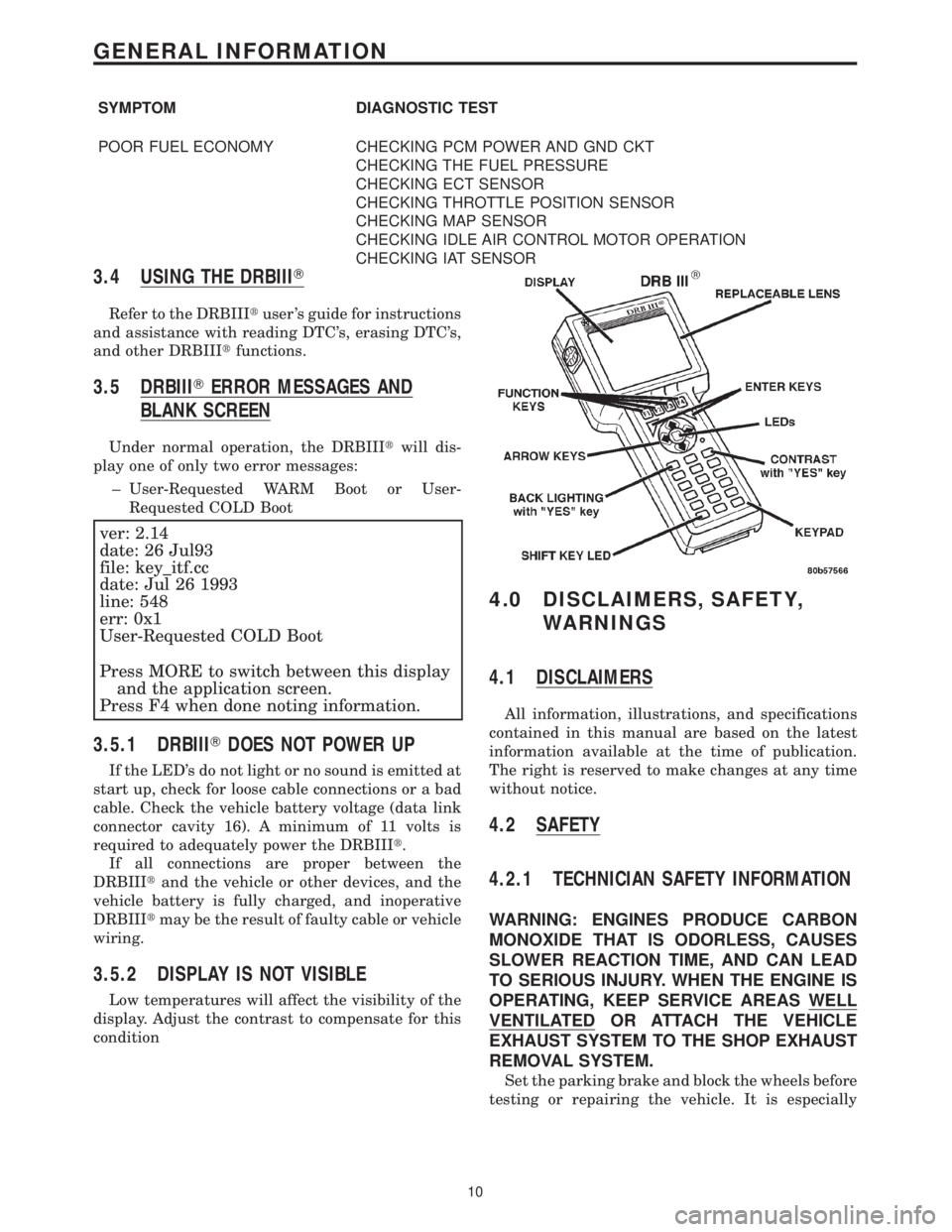

3.4 USING THE DRBIIIT

Refer to the DRBIIItuser 's guide for instructions

and assistance with reading DTC's, erasing DTC's,

and other DRBIIItfunctions.

3.5 DRBIIITERROR MESSAGES AND

BLANK SCREEN

Under normal operation, the DRBIIItwill dis-

play one of only two error messages:

± User-Requested WARM Boot or User-

Requested COLD Boot

ver: 2.14

date: 26 Jul93

file: key_itf.cc

date: Jul 26 1993

line: 548

err: 0x1

User-Requested COLD Boot

Press MORE to switch between this display

and the application screen.

Press F4 when done noting information.

3.5.1 DRBIIITDOES NOT POWER UP

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage (data link

connector cavity 16). A minimum of 11 volts is

required to adequately power the DRBIIIt.

If all connections are proper between the

DRBIIItand the vehicle or other devices, and the

vehicle battery is fully charged, and inoperative

DRBIIItmay be the result of faulty cable or vehicle

wiring.

3.5.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition

4.0 DISCLAIMERS, SAFETY,

WARNINGS

4.1 DISCLAIMERS

All information, illustrations, and specifications

contained in this manual are based on the latest

information available at the time of publication.

The right is reserved to make changes at any time

without notice.

4.2 SAFETY

4.2.1 TECHNICIAN SAFETY INFORMATION

WARNING: ENGINES PRODUCE CARBON

MONOXIDE THAT IS ODORLESS, CAUSES

SLOWER REACTION TIME, AND CAN LEAD

TO SERIOUS INJURY. WHEN THE ENGINE IS

OPERATING, KEEP SERVICE AREAS WELL

VENTILATED OR ATTACH THE VEHICLE

EXHAUST SYSTEM TO THE SHOP EXHAUST

REMOVAL SYSTEM.

Set the parking brake and block the wheels before

testing or repairing the vehicle. It is especially

10

GENERAL INFORMATION

Page 3818 of 4284

Symptom:

P1685-WRONG OR INVALID KEY MSG RECEIVED FROM SKIM

When Monitored and Set Condition:

P1685-WRONG OR INVALID KEY MSG RECEIVED FROM SKIM

When Monitored: With the ignition on.

Set Condition: The PCM does not receive a Valid Key message from the SKIM.

POSSIBLE CAUSES

INCORRECT VIN IN PCM

INVALID SKIM KEY NOT PRESENT

NO COMMUNICATION WITH SKIM

NO VIN PROGRAMMED IN THE PCM

PCM

SKIM TROUBLE CODES SET

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRB III, read the PCM DTCs. Look for P1685.

Is the Starts Since Set counter for DTC P1685 displayed and equal to 0?All

Ye s®Go To 2

No®Go To 7

2 With the DRB III, attempt to communicate with the SKIM.

Turn the ignition on.

Can the DRB III communicate with the SKIM?All

Ye s®Go To 3

No®Refer to symptom BUS +/- SIGNAL OPEN FROM SKIM in the

COMMUNICATION category.

3 Turn the ignition on.

With the DRB III, check for SKIM DTCs.

Are any DTCs present in the SKIM?All

Ye s®Repair all SKIM DTCs.

Perform SKIS VERIFICATION TEST.

No®Go To 4

4 Turn the ignition on.

With the DRB III, display the VIN that is programmed in the PCM.

Has a VIN been programmed into the PCM?All

Ye s®Go To 5

No®Program the correct VIN into the PCM and retest.

Perform SKIS VERIFICATION TEST.

24

COMMUNICATION

Page 3819 of 4284

TEST ACTION APPLICABILITY

5 Turn the ignition on.

With the DRB III, display the VIN that is programmed in the PCM.

Was the correct VIN programmed into the PCM?All

Ye s®Go To 6

No®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform SKIS VERIFICATION TEST.

6 Turn the ignition off.

Replace and program the Sentry Key Immobilizer Module in accordance with the

Service Information.

Turn the ignition on.

With the DRB III, erase all SKIM and PCM DTCs.

Attempt to start and idle the engine.

With the DRB III, read the PCM DTCs.

Does the DRB III display this code?All

Ye s®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform SKIS VERIFICATION TEST.

No®Test Complete.

7NOTE: This DTC could have been set if the SKIM harness connector was

disconnected, or if the SKIM was replaced recently.

NOTE: All keys that the customer uses for this vehicle must be tested to

verify they are operating properly.

Turn the ignition on.

Verify the correct VIN is programmed into the PCM and SKIM.

Turn the ignition off.

With the next customer key turn the ignition key on and crank the engine to start.

With the DRB III, read the PCM DTCs. Look for P1685

Is the Starts Since Set counter for DTC P1685 displayed and equal to 0?All

Ye s®Replace the Ignition Key.

Perform SKIS VERIFICATION TEST.

No®Test Complete.

NOTE: If this DTC cannot be reset, it could have been an actual theft

attempt.

25

COMMUNICATION

P1685-WRONG OR INVALID KEY MSG RECEIVED FROM SKIM Ð

Continued

Page 3821 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Replace the Sentry Key Immobilizer Module in accordance with the Service Infor-

mation.

Turn the ignition on.

Display and erase all PCM and SKIM DTCs.

Perform 5 ignition key cycles leaving the ignition key on for 90 seconds per cycle.

With the DRB, display PCM DTCs.

Does the DRB display the same DTC?All

Ye s®Replace and program the PCM in accordance with the Service

Information.

Perform SKIS VERIFICATION TEST.

No®Test Complete.

5WARNING: KEEP CLEAR OF THE ENGINE'S MOVING PARTS.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running and at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform SKIS VERIFICATION TEST.

No®Test Complete.

27

COMMUNICATION

P1686-NO SKIM BUS MESSAGE RECEIVED ÐContinued

Page 3824 of 4284

Symptom List:

P1696-PCM FAILURE EEPROM WRITE DENIED

P1697-PCM FAILURE SRI MILE NOT STORED

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P1696-PCM FAILURE EEPROM

WRITE DENIED.

When Monitored and Set Condition:

P1696-PCM FAILURE EEPROM WRITE DENIED

When Monitored: Ignition key on, Continuous.

Set Condition: An attempt to program/write to the internal EEPROM failed, Also checks

at powerdown.

P1697-PCM FAILURE SRI MILE NOT STORED

When Monitored: Ignition key on, Continuous.

Set Condition: An attempt to program/write to the internal EEPROM failed, Also checks

at powerdown.

POSSIBLE CAUSES

DRB DISPLAYS WRITE FAILURE

DRB DISPLAYS WRITE REFUSED 2ND TIME

DRB DISPLAYS SRI MILEAGE INVALID

COMPARE SRI MILEAGE WITH ODOMETER

TEST ACTION APPLICABILITY

1 With the DRBIIIt, perform the SRI Memory Test.

Does the DRBIIItdisplay Write Failure?All

Ye s®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Go To 2

2 With the DRBIIIt, perform the SRI Memory Test.

Does the DRBIIItdisplay Write Refused?All

Ye s®Go To 3

No®Go To 4

30

COMMUNICATION

Page 3825 of 4284

TEST ACTION APPLICABILITY

3 With the DRBIIIt, perform the SRI Memory Test a second time.

NOTE: Retest the SRI Memory two more times.

Does the DRBIIItdisplay Write Refused again?All

Ye s®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Test Complete.

4 With the DRBIIIt, perform the SRI Memory Test.

Does the DRBIIItdisplay SRI Mileage Invalid?All

Ye s®Update the mileage and retest the SRI Memory.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Go To 5

5 Compare the SRI Mileage stored with the Instrument Panel Odometer.

Is the mileage within the specified range displayed on the DRBIIIt?All

Ye s®Test Complete.

No®Update the mileage and retest the SRI Memory.

Perform POWERTRAIN VERIFICATION TEST VER-1.

31

COMMUNICATION

P1696-PCM FAILURE EEPROM WRITE DENIED ÐContinued