display CHRYSLER VOYAGER 2001 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 260 of 4284

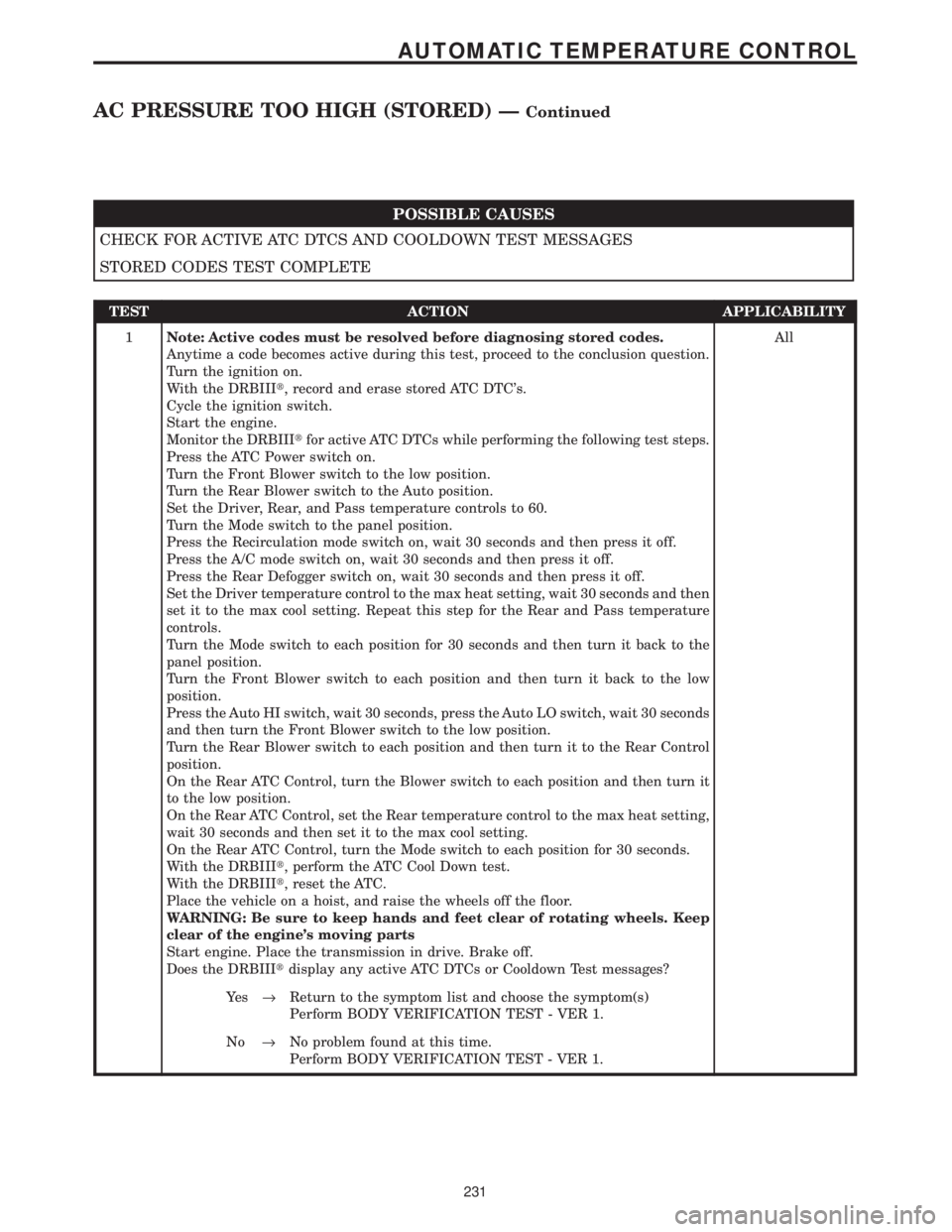

POSSIBLE CAUSES

CHECK FOR ACTIVE ATC DTCS AND COOLDOWN TEST MESSAGES

STORED CODES TEST COMPLETE

TEST ACTION APPLICABILITY

1Note: Active codes must be resolved before diagnosing stored codes.

Anytime a code becomes active during this test, proceed to the conclusion question.

Turn the ignition on.

With the DRBIIIt, record and erase stored ATC DTC's.

Cycle the ignition switch.

Start the engine.

Monitor the DRBIIItfor active ATC DTCs while performing the following test steps.

Press the ATC Power switch on.

Turn the Front Blower switch to the low position.

Turn the Rear Blower switch to the Auto position.

Set the Driver, Rear, and Pass temperature controls to 60.

Turn the Mode switch to the panel position.

Press the Recirculation mode switch on, wait 30 seconds and then press it off.

Press the A/C mode switch on, wait 30 seconds and then press it off.

Press the Rear Defogger switch on, wait 30 seconds and then press it off.

Set the Driver temperature control to the max heat setting, wait 30 seconds and then

set it to the max cool setting. Repeat this step for the Rear and Pass temperature

controls.

Turn the Mode switch to each position for 30 seconds and then turn it back to the

panel position.

Turn the Front Blower switch to each position and then turn it back to the low

position.

Press the Auto HI switch, wait 30 seconds, press the Auto LO switch, wait 30 seconds

and then turn the Front Blower switch to the low position.

Turn the Rear Blower switch to each position and then turn it to the Rear Control

position.

On the Rear ATC Control, turn the Blower switch to each position and then turn it

to the low position.

On the Rear ATC Control, set the Rear temperature control to the max heat setting,

wait 30 seconds and then set it to the max cool setting.

On the Rear ATC Control, turn the Mode switch to each position for 30 seconds.

With the DRBIIIt, perform the ATC Cool Down test.

With the DRBIIIt, reset the ATC.

Place the vehicle on a hoist, and raise the wheels off the floor.

WARNING: Be sure to keep hands and feet clear of rotating wheels. Keep

clear of the engine's moving parts

Start engine. Place the transmission in drive. Brake off.

Does the DRBIIItdisplay any active ATC DTCs or Cooldown Test messages?All

Ye s®Return to the symptom list and choose the symptom(s)

Perform BODY VERIFICATION TEST - VER 1.

No®No problem found at this time.

Perform BODY VERIFICATION TEST - VER 1.

231

AUTOMATIC TEMPERATURE CONTROL

AC PRESSURE TOO HIGH (STORED) ÐContinued

Page 261 of 4284

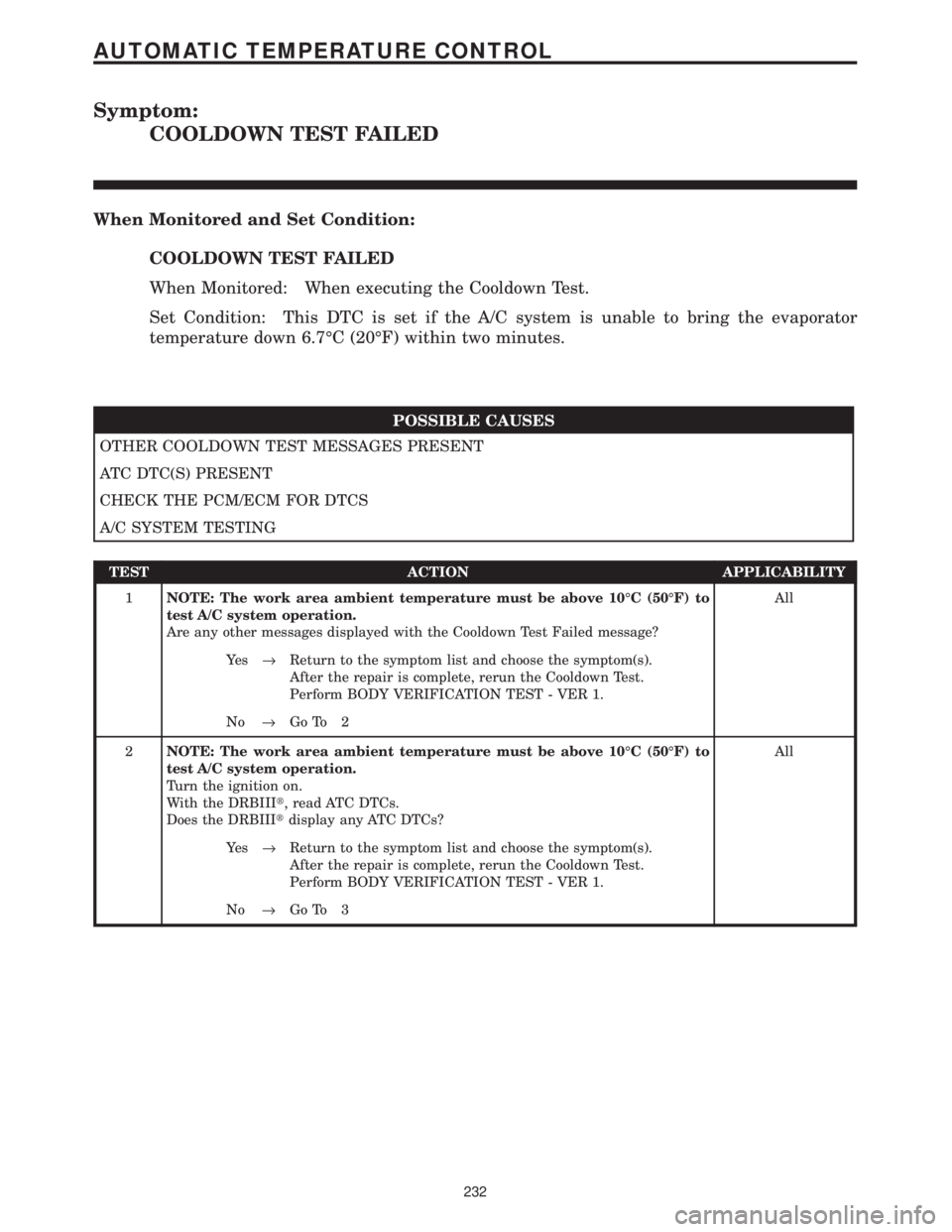

Symptom:

COOLDOWN TEST FAILED

When Monitored and Set Condition:

COOLDOWN TEST FAILED

When Monitored: When executing the Cooldown Test.

Set Condition: This DTC is set if the A/C system is unable to bring the evaporator

temperature down 6.7ÉC (20ÉF) within two minutes.

POSSIBLE CAUSES

OTHER COOLDOWN TEST MESSAGES PRESENT

ATC DTC(S) PRESENT

CHECK THE PCM/ECM FOR DTCS

A/C SYSTEM TESTING

TEST ACTION APPLICABILITY

1NOTE: The work area ambient temperature must be above 10ÉC (50ÉF) to

test A/C system operation.

Are any other messages displayed with the Cooldown Test Failed message?All

Ye s®Return to the symptom list and choose the symptom(s).

After the repair is complete, rerun the Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 2

2NOTE: The work area ambient temperature must be above 10ÉC (50ÉF) to

test A/C system operation.

Turn the ignition on.

With the DRBIIIt, read ATC DTCs.

Does the DRBIIItdisplay any ATC DTCs?All

Ye s®Return to the symptom list and choose the symptom(s).

After the repair is complete, rerun the Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

232

AUTOMATIC TEMPERATURE CONTROL

Page 270 of 4284

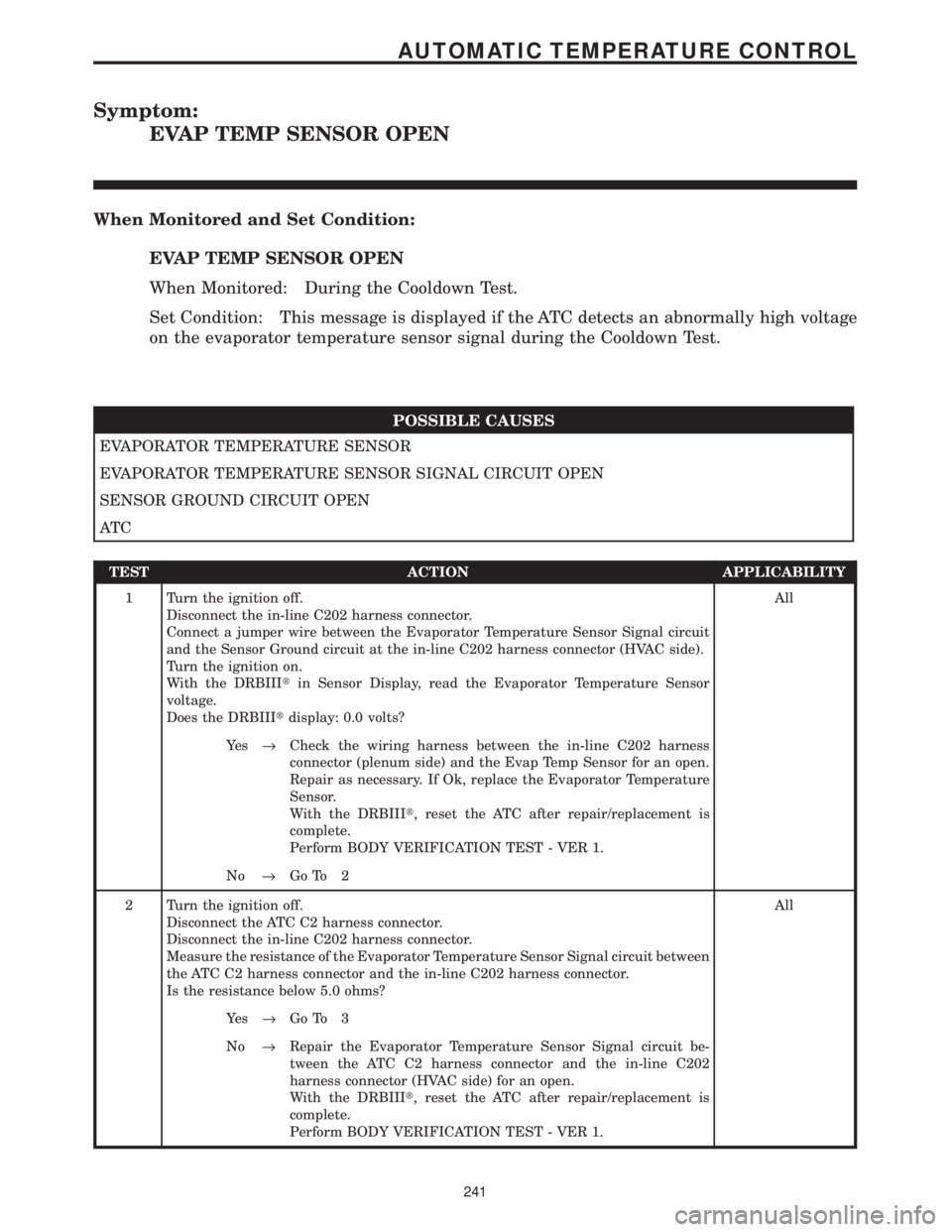

Symptom:

EVAP TEMP SENSOR OPEN

When Monitored and Set Condition:

EVAP TEMP SENSOR OPEN

When Monitored: During the Cooldown Test.

Set Condition: This message is displayed if the ATC detects an abnormally high voltage

on the evaporator temperature sensor signal during the Cooldown Test.

POSSIBLE CAUSES

EVAPORATOR TEMPERATURE SENSOR

EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT OPEN

SENSOR GROUND CIRCUIT OPEN

AT C

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Disconnect the in-line C202 harness connector.

Connect a jumper wire between the Evaporator Temperature Sensor Signal circuit

and the Sensor Ground circuit at the in-line C202 harness connector (HVAC side).

Turn the ignition on.

With the DRBIIItin Sensor Display, read the Evaporator Temperature Sensor

voltage.

Does the DRBIIItdisplay: 0.0 volts?All

Ye s®Check the wiring harness between the in-line C202 harness

connector (plenum side) and the Evap Temp Sensor for an open.

Repair as necessary. If Ok, replace the Evaporator Temperature

Sensor.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 2

2 Turn the ignition off.

Disconnect the ATC C2 harness connector.

Disconnect the in-line C202 harness connector.

Measure the resistance of the Evaporator Temperature Sensor Signal circuit between

the ATC C2 harness connector and the in-line C202 harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 3

No®Repair the Evaporator Temperature Sensor Signal circuit be-

tween the ATC C2 harness connector and the in-line C202

harness connector (HVAC side) for an open.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

241

AUTOMATIC TEMPERATURE CONTROL

Page 272 of 4284

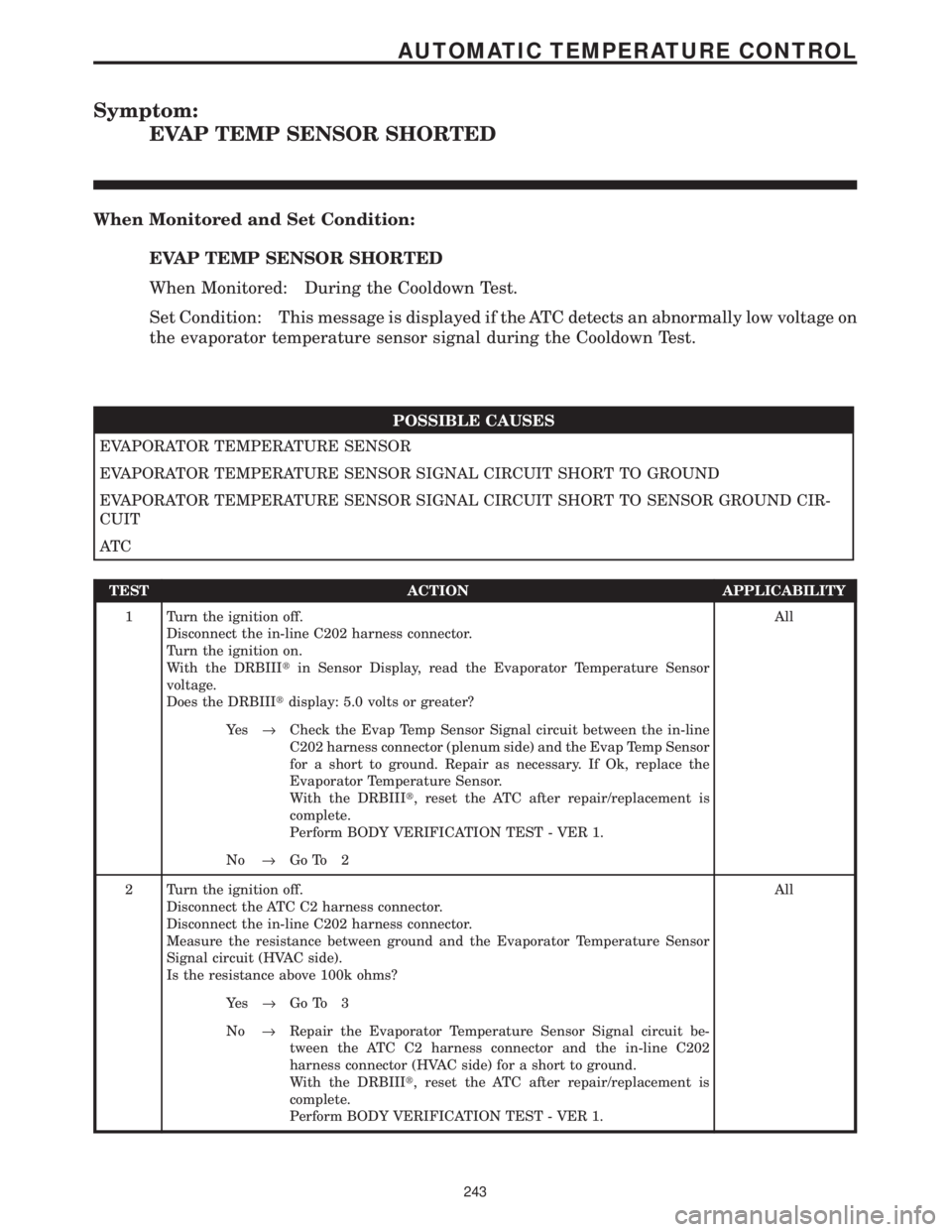

Symptom:

EVAP TEMP SENSOR SHORTED

When Monitored and Set Condition:

EVAP TEMP SENSOR SHORTED

When Monitored: During the Cooldown Test.

Set Condition: This message is displayed if the ATC detects an abnormally low voltage on

the evaporator temperature sensor signal during the Cooldown Test.

POSSIBLE CAUSES

EVAPORATOR TEMPERATURE SENSOR

EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT SHORT TO GROUND

EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT SHORT TO SENSOR GROUND CIR-

CUIT

AT C

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Disconnect the in-line C202 harness connector.

Turn the ignition on.

With the DRBIIItin Sensor Display, read the Evaporator Temperature Sensor

voltage.

Does the DRBIIItdisplay: 5.0 volts or greater?All

Ye s®Check the Evap Temp Sensor Signal circuit between the in-line

C202 harness connector (plenum side) and the Evap Temp Sensor

for a short to ground. Repair as necessary. If Ok, replace the

Evaporator Temperature Sensor.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 2

2 Turn the ignition off.

Disconnect the ATC C2 harness connector.

Disconnect the in-line C202 harness connector.

Measure the resistance between ground and the Evaporator Temperature Sensor

Signal circuit (HVAC side).

Is the resistance above 100k ohms?All

Ye s®Go To 3

No®Repair the Evaporator Temperature Sensor Signal circuit be-

tween the ATC C2 harness connector and the in-line C202

harness connector (HVAC side) for a short to ground.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

243

AUTOMATIC TEMPERATURE CONTROL

Page 276 of 4284

TEST ACTION APPLICABILITY

2 Turn the ignition off.

Disconnect the ATC Remote Sensor harness connector.

Turn the ignition on.

Measure the voltage of the KDB 2 Data circuit.

Is the voltage above 10.0 volts?All

Ye s®Go To 3

No®Go To 13

3 Turn the ignition off.

Disconnect the ATC Remote Sensor harness connector.

Disconnect the ATC C3 harness connector.

Turn the ignition on.

Measure the voltage of the KDB 2 Data circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the KDB 2 Data circuit for a short to voltage.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

4 Turn the ignition off.

Disconnect the ATC Remote Sensor harness connector.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and the red and

black test probes.

Connect the scope input cable to the channel one connector on the DRB. Attach the

red and black leads and the cable to probe adapter to the scope input cable.

Select Lab Scope.

Select Live.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the arrows to set the voltage range to 20 volts, the Offset to 4.0, and

the Probe to x10. Press F2 again and set the divisions to 40ms/Div, then press F2

again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead to the KDB 2

Clock circuit in the ATC Remote Sensor harness connector.

Turn the ignition on.

Observe the voltage display on the DRB Lab Scope.

NOTE: The lab scope pattern should look similar to the example given in the

support material and cycle from approximately 0 volts to 8.0 volts.

Did the lab scope pattern and voltage react as noted above?All

Ye s®Go To 5

No®Go To 9

5 Turn the ignition off.

Disconnect the ATC Remote Sensor harness connector.

Measure the resistance between ground and the Sensor Return circuit.

Is the resistance below 10 ohms?All

Ye s®Go To 6

No®Go To 7

247

AUTOMATIC TEMPERATURE CONTROL

FRONT IR SENSOR NOT CALIBRATED (ACTIVE) ÐContinued

Page 287 of 4284

Symptom:

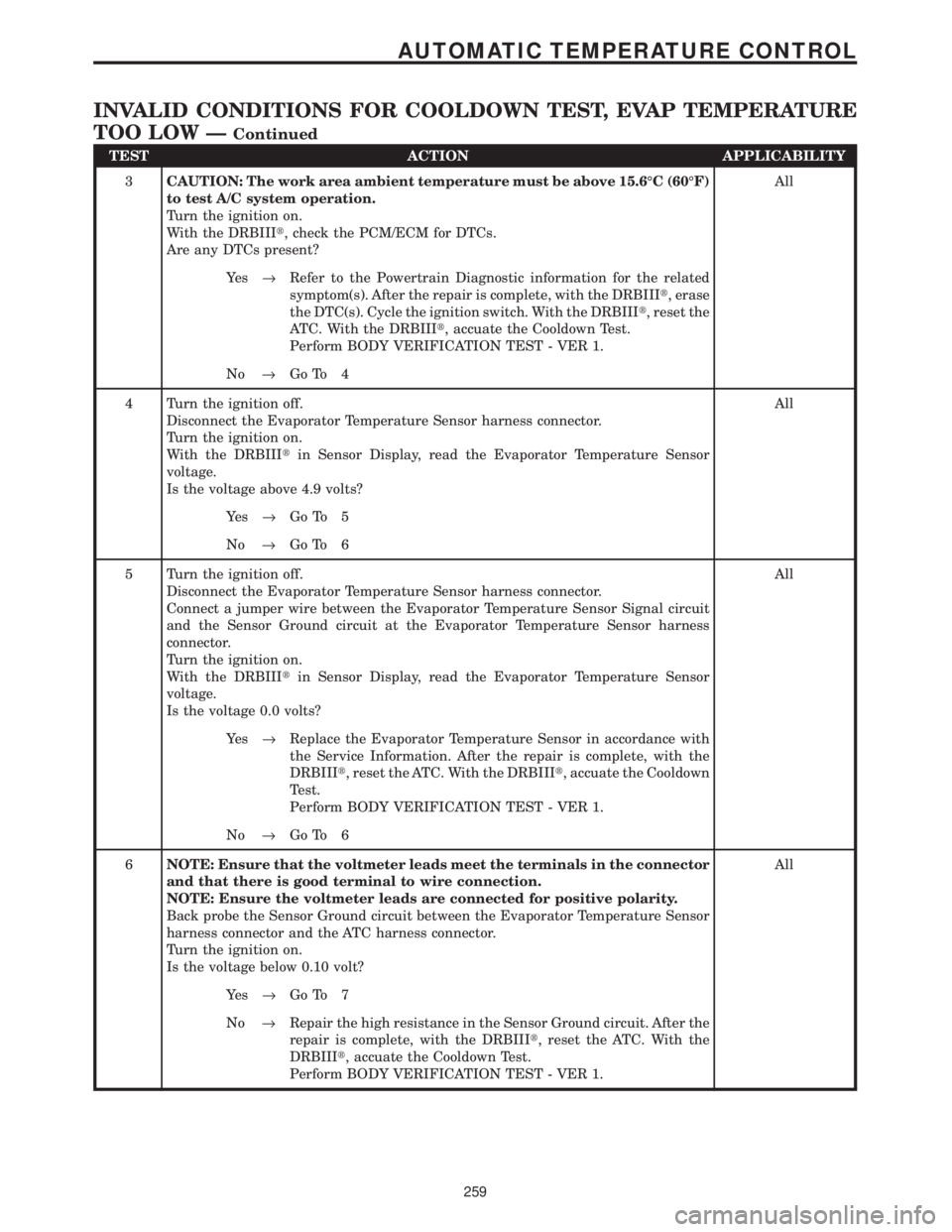

INVALID CONDITIONS FOR COOLDOWN TEST, EVAP TEMPERA-

TURE TOO LOW

When Monitored and Set Condition:

INVALID CONDITIONS FOR COOLDOWN TEST, EVAP TEMPERATURE TOO

LOW

When Monitored: When executing the Cooldown Test.

Set Condition: This message will be displayed if the A/C - Heater Control Module sees

evaporator temperature below 12.7ÉC (55ÉF) when executing the Cooldown Test.

POSSIBLE CAUSES

EVAPORATOR TEMPERATURE TOO LOW

ATC DTC(S) PRESENT

CHECK THE PCM/ECM FOR DTCS

EVAPORATOR TEMPERATURE SENSOR

SENSOR GROUND CIRCUIT HIGH RESISTANCE

EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT HIGH RESISTANCE

AUTOMATIC TEMPERATURE CONTROL

TEST ACTION APPLICABILITY

1CAUTION: The work area ambient temperature must be above 15.6ÉC (60ÉF)

to test A/C system operation.

Start the engine.

Turn the A/C off.

Turn the Blower on high. Allow the blower to run for 5 minutes to ensure that the

Evaporator Temperature Sensor temperature is above 12.7ÉC (55ÉF).

With the DRBIIIt, actuate the Cooldown Test.

Does the DRBIIItdisplay: Cooldown Test Too Cold To Start?All

Ye s®Go To 2

No®Perform additional testing as necessary.

Perform BODY VERIFICATION TEST - VER 1.

2CAUTION: The work area ambient temperature must be above 15.6ÉC (60ÉF)

to test A/C system operation.

Turn the ignition on.

With the DRBIIIt, read ATC DTCs.

Does the DRBIIItdisplay any ATC DTCs?All

Ye s®Return to the symptom list and choose the symptom(s). After the

repair is complete, with the DRBIIIt, erase the DTC(s). Cycle the

ignition switch. With the DRBIIIt, reset the ATC. With the

DRBIIIt, actuate the Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

258

AUTOMATIC TEMPERATURE CONTROL

Page 288 of 4284

TEST ACTION APPLICABILITY

3CAUTION: The work area ambient temperature must be above 15.6ÉC (60ÉF)

to test A/C system operation.

Turn the ignition on.

With the DRBIIIt, check the PCM/ECM for DTCs.

Are any DTCs present?All

Ye s®Refer to the Powertrain Diagnostic information for the related

symptom(s). After the repair is complete, with the DRBIIIt, erase

the DTC(s). Cycle the ignition switch. With the DRBIIIt, reset the

ATC. With the DRBIIIt, accuate the Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

4 Turn the ignition off.

Disconnect the Evaporator Temperature Sensor harness connector.

Turn the ignition on.

With the DRBIIItin Sensor Display, read the Evaporator Temperature Sensor

voltage.

Is the voltage above 4.9 volts?All

Ye s®Go To 5

No®Go To 6

5 Turn the ignition off.

Disconnect the Evaporator Temperature Sensor harness connector.

Connect a jumper wire between the Evaporator Temperature Sensor Signal circuit

and the Sensor Ground circuit at the Evaporator Temperature Sensor harness

connector.

Turn the ignition on.

With the DRBIIItin Sensor Display, read the Evaporator Temperature Sensor

voltage.

Is the voltage 0.0 volts?All

Ye s®Replace the Evaporator Temperature Sensor in accordance with

the Service Information. After the repair is complete, with the

DRBIIIt, reset the ATC. With the DRBIIIt, accuate the Cooldown

Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 6

6NOTE: Ensure that the voltmeter leads meet the terminals in the connector

and that there is good terminal to wire connection.

NOTE: Ensure the voltmeter leads are connected for positive polarity.

Back probe the Sensor Ground circuit between the Evaporator Temperature Sensor

harness connector and the ATC harness connector.

Turn the ignition on.

Is the voltage below 0.10 volt?All

Ye s®Go To 7

No®Repair the high resistance in the Sensor Ground circuit. After the

repair is complete, with the DRBIIIt, reset the ATC. With the

DRBIIIt, accuate the Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

259

AUTOMATIC TEMPERATURE CONTROL

INVALID CONDITIONS FOR COOLDOWN TEST, EVAP TEMPERATURE

TOO LOW Ð

Continued

Page 296 of 4284

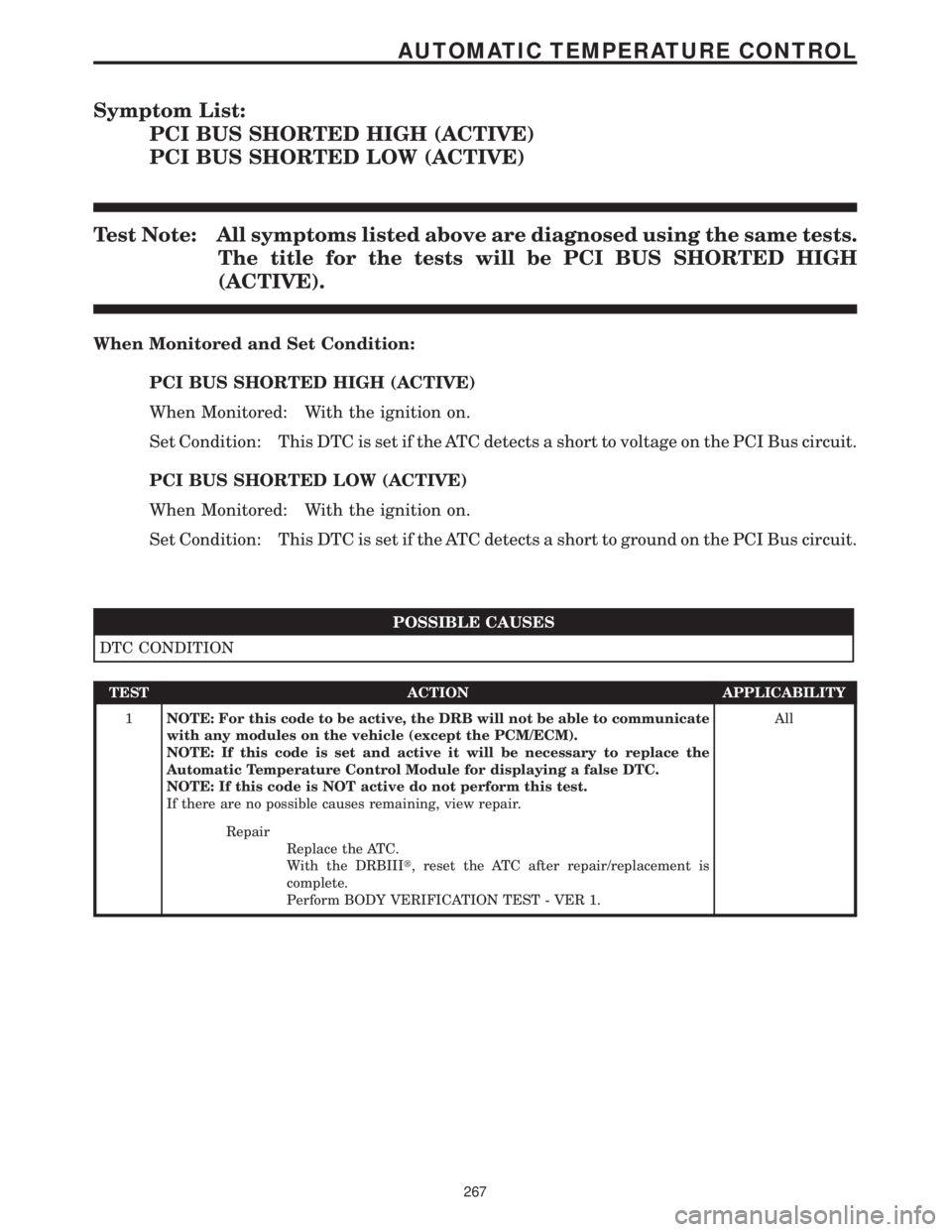

Symptom List:

PCI BUS SHORTED HIGH (ACTIVE)

PCI BUS SHORTED LOW (ACTIVE)

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be PCI BUS SHORTED HIGH

(ACTIVE).

When Monitored and Set Condition:

PCI BUS SHORTED HIGH (ACTIVE)

When Monitored: With the ignition on.

Set Condition: This DTC is set if the ATC detects a short to voltage on the PCI Bus circuit.

PCI BUS SHORTED LOW (ACTIVE)

When Monitored: With the ignition on.

Set Condition: This DTC is set if the ATC detects a short to ground on the PCI Bus circuit.

POSSIBLE CAUSES

DTC CONDITION

TEST ACTION APPLICABILITY

1NOTE: For this code to be active, the DRB will not be able to communicate

with any modules on the vehicle (except the PCM/ECM).

NOTE: If this code is set and active it will be necessary to replace the

Automatic Temperature Control Module for displaying a false DTC.

NOTE: If this code is NOT active do not perform this test.

If there are no possible causes remaining, view repair.All

Repair

Replace the ATC.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

267

AUTOMATIC TEMPERATURE CONTROL

Page 306 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Disconnect the ATC C2 harness connector.

Turn the ignition on.

Measure the voltage of the KDB Data circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the KDB Data circuit for a short to voltage.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

4 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and the red and

black test probes.

Connect the scope input cable to the channel one connector on the DRB. Attach the

red and black leads and the cable to probe adapter to the scope input cable.

Select Lab Scope.

Select Live.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the arrows to set the voltage range to 20 volts, the Offset to 4.0, and

the Probe to x10. Press F2 again and set the divisions to 40ms/Div, then press F2

again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead to the KDB Clock

circuit in the Rear Automatic Temperature Control Switch harness connector.

Turn the ignition on.

Observe the voltage display on the DRB Lab Scope.

NOTE: The lab scope pattern should look similar to the example given in the

support material and cycle from approximately 0 volts to 8.0 volts.

Did the lab scope pattern and voltage react as noted above?All

Ye s®Go To 5

No®Go To 6

5 If there are no possible causes remaining, view repair. All

Repair

Replace the Rear Automatic Temperature Control Switch.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

6 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Disconnect the ATC C2 harness connector.

Turn the ignition on.

Measure the voltage of the KDB Clock circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the KDB Clock circuit for a short to voltage.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 7

277

AUTOMATIC TEMPERATURE CONTROL

REAR IR SENSOR NOT CALIBRATED (ACTIVE) ÐContinued

Page 310 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Disconnect the ATC C2 harness connector.

Turn the ignition on.

Measure the voltage of the KDB Data circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the KDB Data circuit for a short to voltage.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and the red and

black test probes.

Connect the scope input cable to the channel one connector on the DRB. Attach the

red and black leads and the cable to probe adapter to the scope input cable.

Select Lab Scope.

Select Live.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the arrows to set the voltage range to 20 volts, the Offset to 4.0, and

the Probe to x10. Press F2 again and set the divisions to 40ms/Div, then press F2

again when complete.

Connect the Black lead to the chassis ground. Connect the Red lead to the KDB Clock

circuit in the Rear Automatic Temperature Control Switch harness connector.

Turn the ignition on.

Observe the voltage display on the DRB Lab Scope.

NOTE: The lab scope pattern should look similar to the example given in the

support material and cycle from approximately 0 volts to 8.0 volts.

Did the lab scope pattern and voltage react as noted above?All

Ye s®Go To 6

No®Go To 7

6 If there are no possible causes remaining, view repair. All

Repair

Replace the Rear Automatic Temperature Control Switch.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

7 Turn the ignition off.

Disconnect the Rear Automatic Temperature Control Switch harness connector.

Disconnect the ATC C2 harness connector.

Turn the ignition on.

Measure the voltage of the KDB Clock circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the KDB Clock circuit for a short to voltage.

With the DRBIIIt, reset the ATC after repair/replacement is

complete.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 8

281

AUTOMATIC TEMPERATURE CONTROL

REAR KEYBOARD FAULT (ACTIVE) ÐContinued