engine CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2706 of 4284

REMOVAL - ENGINE ASSEMBLY

(1) Perform fuel pressure release procedure. (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE)

(2) Disconnect the battery.

(3) Remove air cleaner and hoses.

(4) Disconnect the fuel line from fuel rail. (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/QUICK

CONNECT FITTING - STANDARD PROCEDURE)

(5) Remove the wiper module. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL)

(6) Block off heater hoses to the rear heater sys-

tem, if equipped, using pinch-off pliers.

(7) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(8) Disconnect the heater hoses.

(9) Remove the radiator upper support crossmem-

ber. (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - REMOVAL)

(10) Remove the radiator fans. (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL)

(11) Disconnect the throttle cables from the throt-

tle body.

(12) Disconnect the MAP, IAC, and TPS electrical

connectors.

(13) Disconnect the EGR transducer electrical con-

nector.

(14) Disconnect the vacuum hoses from throttle

body.

(15) Disconnect the brake booster and speed con-

trol vacuum hoses.(16) Disengage wire harness clip from the right

side engine mount.

(17) Remove the power steering reservoir from

mounting position and set aside. Do not disconnect

hose.

(18) Disconnect ground strap from rear of cylinder

head.

(19) Disconnect engine coolant temperature (ECT)

sensor and ignition coil electrical connectors.

(20) Disconnect the fuel injector electrical harness

connector and disengage clip from support bracket.

(21) Disconnect crank sensor connector.

(22) Disconnect camshaft sensor connector.

(23) Evacuate air conditioning system.

(24) Disconnect A/C compressor electrical connec-

tor.

(25) Disconnect the A/C lines from compressor.

Cover and seal all openings of hoses and compressor.

(26) Remove the radiator upper hose.

(27) Disengage electrical harness clip at transaxle

dipstick tube.

(28) Remove transaxle dipstick tube. Seal opening

using a suitable plug.

(29) Disconnect cooler hoses from transaxle.

(30) Disconnect transaxle shift linkage and electri-

cal connectors.

(31) Raise vehicle on hoist and drain the engine

oil.

(32) Remove the axle shafts. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/HALF SHAFT - REMOVAL)

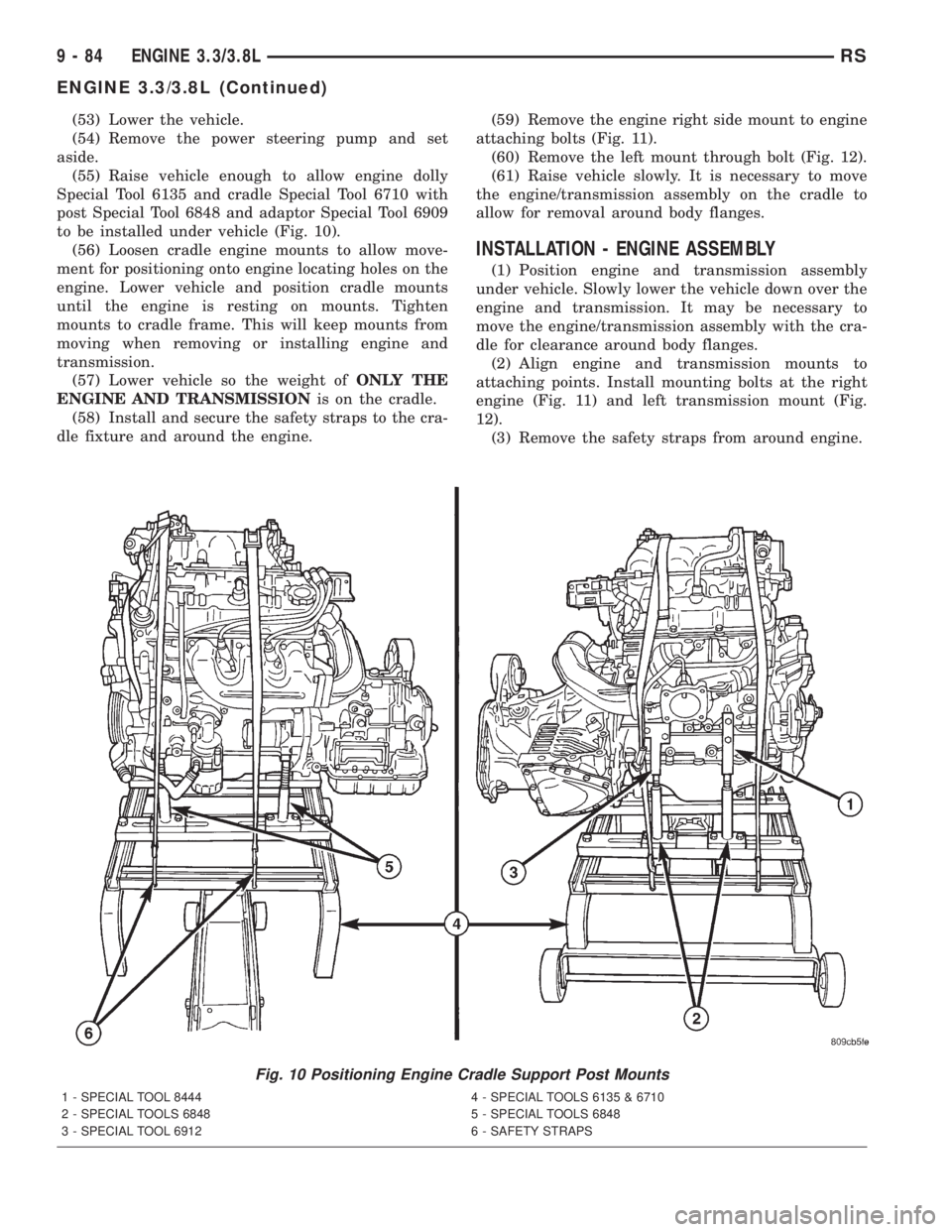

(33) Remove crossmember cradle plate (Fig. 6).

(34)AWD equipped:Remove the power transfer

unit (PTU).

(35) Disconnect exhaust pipe from the manifold

(Fig. 7).

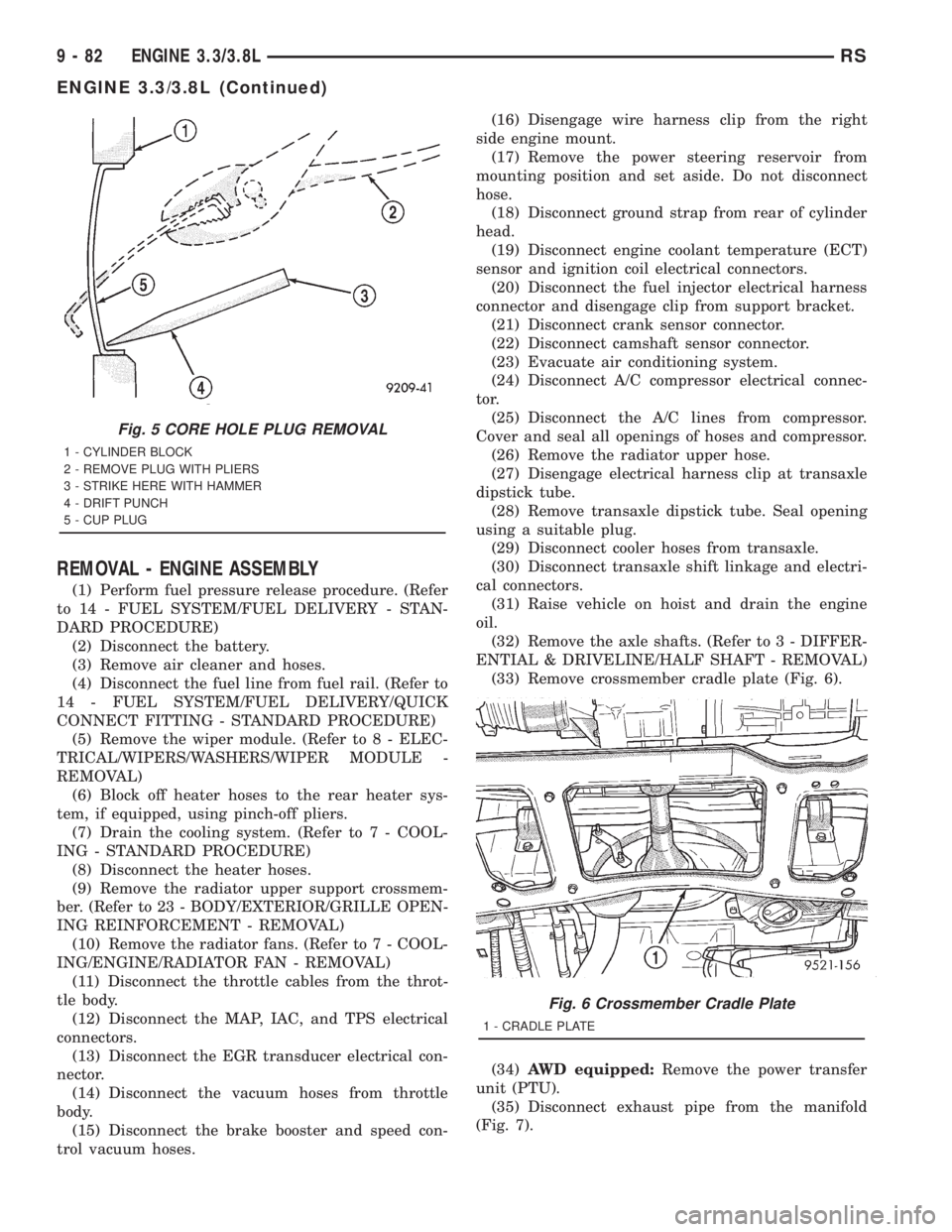

Fig. 5 CORE HOLE PLUG REMOVAL

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

Fig. 6 Crossmember Cradle Plate

1 - CRADLE PLATE

9 - 82 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 2707 of 4284

(36) Remove front engine mount and bracket as an

assembly.

(37) Remove the engine rear mount bracket.

(38) Remove the engine to transaxle struts (Fig. 8).

(39) Remove transaxle case cover (Fig. 8).

(40) Remove flex plate to torque converter bolts.

(41) Remove the power steering pressure hose sup-

port clip attaching bolt.

(42) Disconnect the knock sensor electrical connec-

tor (3.8L only).

(43) Disconnect the engine block heater electrical

connector, if equipped.

(44) Remove the accessory belt splash shield.

(45) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(46) Disconnect the radiator lower hose.

(47) Remove air conditioning compressor from

engine.

(48) Remove the generator. (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL)

(49) Remove the water pump pulley attaching

bolts and position pulley between pump hub and

housing.

(50) Disconnect the oil pressure switch electrical

connector.

(51) Disconnect wiring harness support clip from

dipstick tube.(52) Install Special Tools 6912 and 8444 Adapters

on the right side (rear) of engine block (Fig. 9).

Fig. 7 Catalytic Converter to Exhaust Manifold

1 - FLAG NUT

2 - GASKET

3 - BOLT

4 - CATALYTIC CONVERTER

Fig. 8 POWERTRAIN SUPPORTS AND DUST COVER

1 - BRACKET - ENGINE REAR MOUNT

2 - BOLT - TRANSAXLE CASE COVER

3 - STRUT - TRANSAXLE TO ENGINE HORIZONTAL

4 - BOLT - HORIZONTAL STRUT

5 - BOLT - STRUT TO TRANSAXLE

6 - COVER - TRANSAXLE CASE LOWER

7 - STRUT - TRANSAXLE TO ENGINE

8 - BOLT - STRUT TO ENGINE

9 - BOLT - ENGINE REAR MOUNT BRACKET

Fig. 9 ADAPTER TOOLS MOUNTED ON BLOCK

1 - SPECIAL TOOL 6912

2 - SPECIAL TOOL 8444

RSENGINE 3.3/3.8L9-83

ENGINE 3.3/3.8L (Continued)

Page 2708 of 4284

(53) Lower the vehicle.

(54) Remove the power steering pump and set

aside.

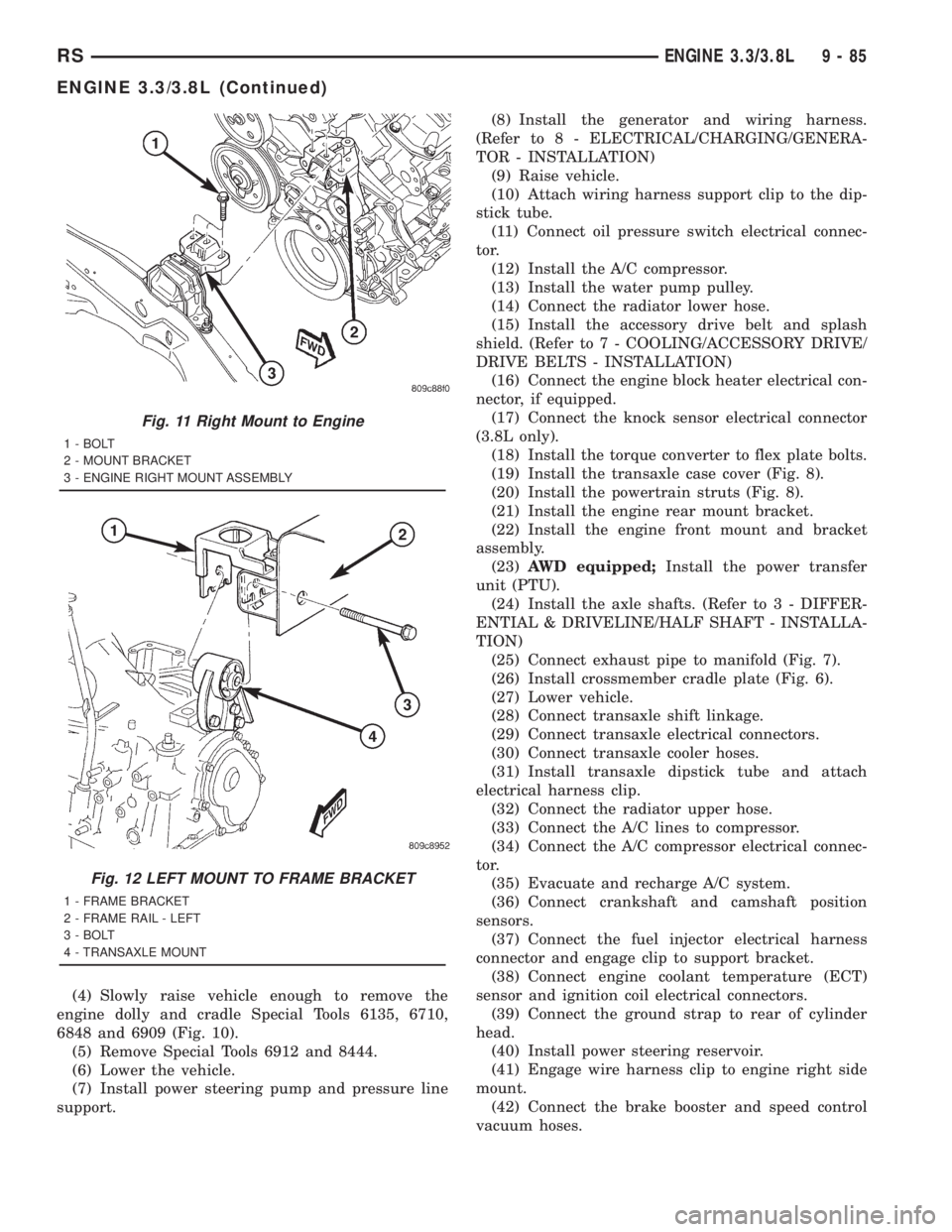

(55) Raise vehicle enough to allow engine dolly

Special Tool 6135 and cradle Special Tool 6710 with

post Special Tool 6848 and adaptor Special Tool 6909

to be installed under vehicle (Fig. 10).

(56) Loosen cradle engine mounts to allow move-

ment for positioning onto engine locating holes on the

engine. Lower vehicle and position cradle mounts

until the engine is resting on mounts. Tighten

mounts to cradle frame. This will keep mounts from

moving when removing or installing engine and

transmission.

(57) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONis on the cradle.

(58) Install and secure the safety straps to the cra-

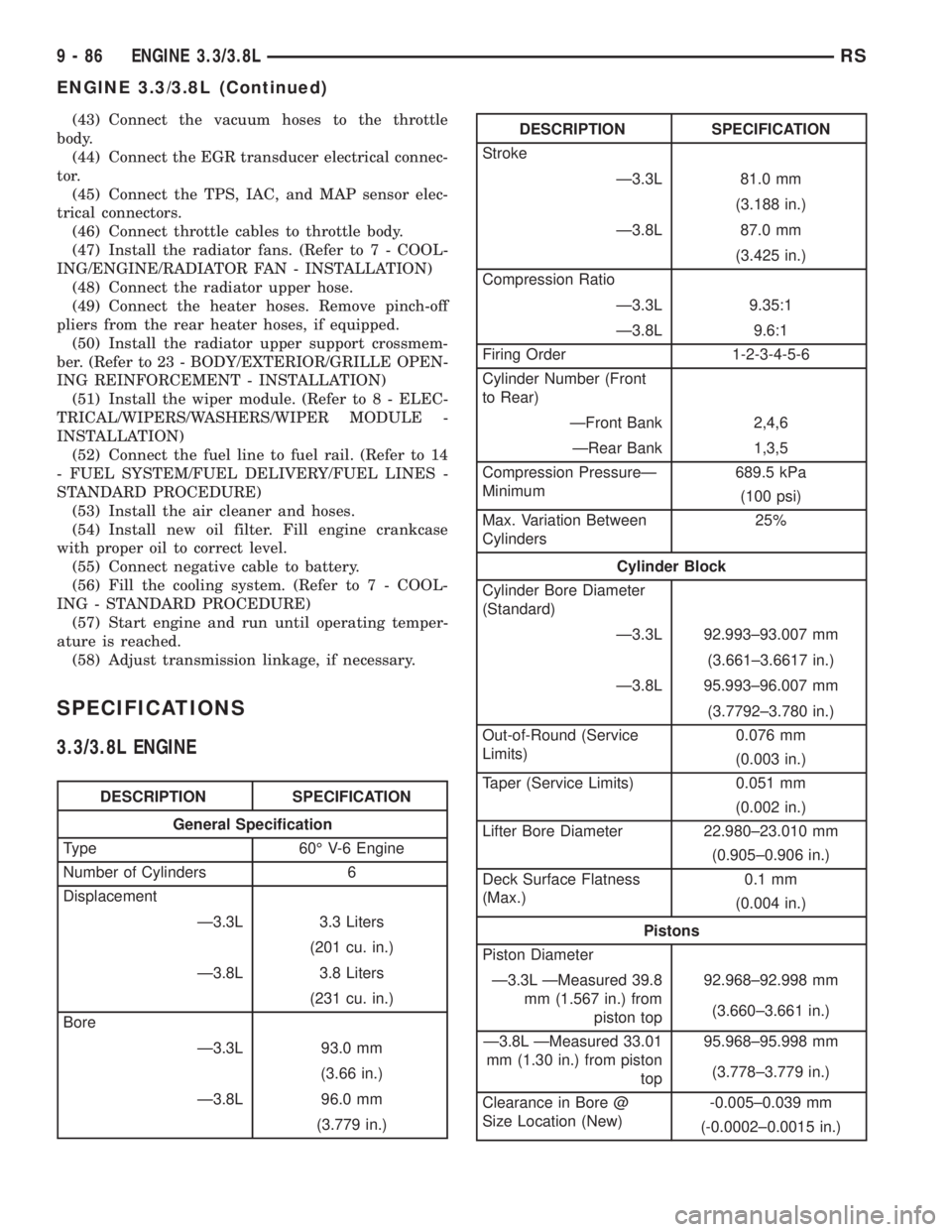

dle fixture and around the engine.(59) Remove the engine right side mount to engine

attaching bolts (Fig. 11).

(60) Remove the left mount through bolt (Fig. 12).

(61) Raise vehicle slowly. It is necessary to move

the engine/transmission assembly on the cradle to

allow for removal around body flanges.

INSTALLATION - ENGINE ASSEMBLY

(1) Position engine and transmission assembly

under vehicle. Slowly lower the vehicle down over the

engine and transmission. It may be necessary to

move the engine/transmission assembly with the cra-

dle for clearance around body flanges.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine (Fig. 11) and left transmission mount (Fig.

12).

(3) Remove the safety straps from around engine.

Fig. 10 Positioning Engine Cradle Support Post Mounts

1 - SPECIAL TOOL 8444 4 - SPECIAL TOOLS 6135 & 6710

2 - SPECIAL TOOLS 6848 5 - SPECIAL TOOLS 6848

3 - SPECIAL TOOL 6912 6 - SAFETY STRAPS

9 - 84 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 2709 of 4284

(4) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135, 6710,

6848 and 6909 (Fig. 10).

(5) Remove Special Tools 6912 and 8444.

(6) Lower the vehicle.

(7) Install power steering pump and pressure line

support.(8) Install the generator and wiring harness.

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION)

(9) Raise vehicle.

(10) Attach wiring harness support clip to the dip-

stick tube.

(11) Connect oil pressure switch electrical connec-

tor.

(12) Install the A/C compressor.

(13) Install the water pump pulley.

(14) Connect the radiator lower hose.

(15) Install the accessory drive belt and splash

shield. (Refer to 7 - COOLING/ACCESSORY DRIVE/

DRIVE BELTS - INSTALLATION)

(16) Connect the engine block heater electrical con-

nector, if equipped.

(17) Connect the knock sensor electrical connector

(3.8L only).

(18) Install the torque converter to flex plate bolts.

(19) Install the transaxle case cover (Fig. 8).

(20) Install the powertrain struts (Fig. 8).

(21) Install the engine rear mount bracket.

(22) Install the engine front mount and bracket

assembly.

(23)AWD equipped;Install the power transfer

unit (PTU).

(24) Install the axle shafts. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION)

(25) Connect exhaust pipe to manifold (Fig. 7).

(26) Install crossmember cradle plate (Fig. 6).

(27) Lower vehicle.

(28) Connect transaxle shift linkage.

(29) Connect transaxle electrical connectors.

(30) Connect transaxle cooler hoses.

(31) Install transaxle dipstick tube and attach

electrical harness clip.

(32) Connect the radiator upper hose.

(33) Connect the A/C lines to compressor.

(34) Connect the A/C compressor electrical connec-

tor.

(35) Evacuate and recharge A/C system.

(36) Connect crankshaft and camshaft position

sensors.

(37) Connect the fuel injector electrical harness

connector and engage clip to support bracket.

(38) Connect engine coolant temperature (ECT)

sensor and ignition coil electrical connectors.

(39) Connect the ground strap to rear of cylinder

head.

(40) Install power steering reservoir.

(41) Engage wire harness clip to engine right side

mount.

(42) Connect the brake booster and speed control

vacuum hoses.

Fig. 11 Right Mount to Engine

1 - BOLT

2 - MOUNT BRACKET

3 - ENGINE RIGHT MOUNT ASSEMBLY

Fig. 12 LEFT MOUNT TO FRAME BRACKET

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

RSENGINE 3.3/3.8L9-85

ENGINE 3.3/3.8L (Continued)

Page 2710 of 4284

(43) Connect the vacuum hoses to the throttle

body.

(44) Connect the EGR transducer electrical connec-

tor.

(45) Connect the TPS, IAC, and MAP sensor elec-

trical connectors.

(46) Connect throttle cables to throttle body.

(47) Install the radiator fans. (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION)

(48) Connect the radiator upper hose.

(49) Connect the heater hoses. Remove pinch-off

pliers from the rear heater hoses, if equipped.

(50) Install the radiator upper support crossmem-

ber. (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - INSTALLATION)

(51) Install the wiper module. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION)

(52) Connect the fuel line to fuel rail. (Refer to 14

- FUEL SYSTEM/FUEL DELIVERY/FUEL LINES -

STANDARD PROCEDURE)

(53) Install the air cleaner and hoses.

(54) Install new oil filter. Fill engine crankcase

with proper oil to correct level.

(55) Connect negative cable to battery.

(56) Fill the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(57) Start engine and run until operating temper-

ature is reached.

(58) Adjust transmission linkage, if necessary.

SPECIFICATIONS

3.3/3.8L ENGINE

DESCRIPTION SPECIFICATION

General Specification

Type 60É V-6 Engine

Number of Cylinders 6

Displacement

Ð3.3L 3.3 Liters

(201 cu. in.)

Ð3.8L 3.8 Liters

(231 cu. in.)

Bore

Ð3.3L 93.0 mm

(3.66 in.)

Ð3.8L 96.0 mm

(3.779 in.)

DESCRIPTION SPECIFICATION

Stroke

Ð3.3L 81.0 mm

(3.188 in.)

Ð3.8L 87.0 mm

(3.425 in.)

Compression Ratio

Ð3.3L 9.35:1

Ð3.8L 9.6:1

Firing Order 1-2-3-4-5-6

Cylinder Number (Front

to Rear)

ÐFront Bank 2,4,6

ÐRear Bank 1,3,5

Compression PressureÐ

Minimum689.5 kPa

(100 psi)

Max. Variation Between

Cylinders25%

Cylinder Block

Cylinder Bore Diameter

(Standard)

Ð3.3L 92.993±93.007 mm

(3.661±3.6617 in.)

Ð3.8L 95.993±96.007 mm

(3.7792±3.780 in.)

Out-of-Round (Service

Limits)0.076 mm

(0.003 in.)

Taper (Service Limits) 0.051 mm

(0.002 in.)

Lifter Bore Diameter 22.980±23.010 mm

(0.905±0.906 in.)

Deck Surface Flatness

(Max.)0.1 mm

(0.004 in.)

Pistons

Piston Diameter

Ð3.3L ÐMeasured 39.8

mm (1.567 in.) from

piston top92.968±92.998 mm

(3.660±3.661 in.)

Ð3.8L ÐMeasured 33.01

mm (1.30 in.) from piston

top95.968±95.998 mm

(3.778±3.779 in.)

Clearance in Bore @

Size Location (New)-0.005±0.039 mm

(-0.0002±0.0015 in.)

9 - 86 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 2711 of 4284

DESCRIPTION SPECIFICATION

Weight

Ð3.3L 36265 grams

(12.7760.1764 oz.)

Ð3.8L 42665 grams

(15.0360.1764 oz.)

Piston Pins

Type Press Fit in Rod

(Serviced as an

Assembly)

Clearance in Piston @

21É C (70É F)0.006±0.019 mm

(0.0002±0.0007 in.)

Clearance in Connecting

Rod(Interference Fit)

Diameter 22.87±22.88 mm

(0.9007±0.9009 in.)

Length

Ð3.3L 67.25±67.75 mm

(2.648±2.667 in.)

Ð3.8L 71.25±71.75

(2.805±2.824 in.)

Piston Rings

Ring End GapÐTop

Compression Ring0.18±0.38 mm

(0.007±0.015 in.)

Wear Limit 1.0 mm

(0.039 in.)

Ring End GapÐ2nd

Compression Ring0.28±0.57 mm

(0.011±0.022 in.)

Wear Limit 1.0 mm

(0.039 in.)

Ring End GapÐOil

Control Steel Rails0.23±0.78 mm

(0.009±0.030 in.)

Wear Limit 1.88 mm

(0.074 in.)

Ring Side ClearanceÐ

Top Compression Ring

Ð3.3L 0.030±0.080 mm

(0.0012±0.0031 in.)

Ð3.8L 0.030±0.069 mm

(0.0012±0.0027 in.)

Wear Limit 0.10 mm

(0.004 in.)DESCRIPTION SPECIFICATION

Ring Side ClearanceÐ

2nd Compression Ring

Ð3.3L 0.030±0.095 mm

(0.0012±0.0037 in.)

Ð3.8L 0.041±0.085 mm

(0.0016±0.0033 in.)

Wear Limit 0.13 mm

(0.005 in.)

Ring Side ClearanceÐOil

Ring Pack0.039±0.200 mm

(0.0015±0.0078 in.)

Wear Limit 0.266 mm

(0.009 in.)

Ring WidthÐTop

Compression Ring

Ð3.3L 1.46±1.49 mm

(0.0575±0.058 in.)

Ð3.8L 1.175±1.190 mm

(0.0462±0.0468 in.)

Ring WidthÐ2nd

Compression Ring

Ð3.3/3.8L1.46±1.49 mm

(0.0575±0.058 in.)

Ring WidthÐOil Ring

(Steel Rails)

Ð3.3L 0.435±0.490 mm

(0.017±0.019 in.)

Ð3.8L 0.435±0.510 mm

(0.017±0.020 in.)

Connecting Rod

Bearing Clearance 0.019±0.065 mm

(0.0008±0.0026 in.)

Wear Limit 0.074 mm

(0.003 in.)

Side Clearance 0.13±0.32 mm

(0.005±0.013 in.)

Wear Limit 0.38 mm

(0.015 in.)

Crankshaft

Material Nodular Iron

Connecting Rod Journal

Diameter57.979±58.005 mm

(2.2827±2.2837 in.)

Main Bearing Journal

Diameter63.993±64.013 mm

(2.5194±2.5202 in.)

RSENGINE 3.3/3.8L9-87

SPECIFICATIONS (Continued)

Page 2712 of 4284

DESCRIPTION SPECIFICATION

Journal Out-of-Round

(Max.)0.025 mm

(0.001 in.)

Journal Taper (Max.) 0.025 mm

(0.001 in.)

End Play 0.09±0.24 mm

(0.0036±0.0095 in.)

Wear Limit 0.381 mm

(0.015 in.)

Main Bearing Diametrical

Clearance

ÐNo. 1, 2, 3, 4 0.011±0.055 mm

(0.0005±0.0022 in.)

Wear Limit 0.076 mm

(0.003 in.)

Camshaft

Journal Diameter

No.1 50.724±50.775 mm

(1.997±1.999 in.)

No.2 50.317±50.368 mm

(1.9809±1.9829 in.)

No.3 49.936±49.987 mm

(1.9659±1.9679 in.)

No.4 49.530±49.581 mm

(1.9499±1.9520 in.)

Bearing ClearanceÐ

Diametrical0.025±0.101 mm

(0.001±0.004 in.)

Bearing Clearance (Max.

allowable)0.127 mm

(0.005 in.)

End Play 0.254±0.508 mm

(0.010±0.020 in.)

(Max. allowable) 0.304 mm

(0.012 in.)

Camshaft Bearing

Diameter

No. 1 50.800±50.825 mm

(1.9999±2.0009 in.)

No. 2 50.393±50.419 mm

(1.9839±1.9849 in.)

No. 3 50.013±50.038 mm

(1.9690±1.9699 in.)

No. 4 49.606±49.632 mm

(1.9529±1.954 in.)DESCRIPTION SPECIFICATION

Exhaust Valve Timing

ClosesÐ3.3L (ATDC) 13É

ClosesÐ3.8L (ATDC) 18É

OpensÐ3.3L (BBDC) 43É

OpensÐ3.8L (BBDC) 46É

DurationÐ3.3L 236É

DurationÐ3.8L 244É

Intake Valve Timing

ClosesÐ3.3L (ABDC 52É

ClosesÐ3.8L (ABDC 63É

OpensÐ3.3L (ATDC) 6É

OpensÐ3.8L (ATDC) 1É

DurationÐ3.3L 226É

DurationÐ3.8L 242É

Valve OverlapÐ3.3L 7É

Valve OverlapÐ3.8L 17É

Lifters

Type Hydraulic Roller

Diameter O.D. 22.949±22.962 mm

(0.903±0.904 in.)

Clearance In Block 0.020±0.061 mm

0.0007±0.0024 in.)

Cylinder Head

Gasket Thickness

(Compressed)0.65±0.75 mm

(0.025±0.029 in.)

Valve Seat

Angle 44.5±45É

Valve Seat Runout

(Service Limits)0.0762 mm

(0.003 in.)

Valve Seat WidthÐIntake

& Exhaust1.50±2.00 mm

(0.057±0.078 in.)

Valve Guide

Guide Bore Diameter

(Std.)6.975±7.00 mm

(0.274±0.275 in.)

Valves

Valve Lift (Zero

Lash)ÐIntake & Exhaust

Ð3.3L 9.80 mm

(0.385 in.)

Ð3.8L 11.0 mm

(0.433 in.)

9 - 88 ENGINE 3.3/3.8LRS

SPECIFICATIONS (Continued)

Page 2713 of 4284

DESCRIPTION SPECIFICATION

Face AngleÐIntake 45±45.5É

Face AngleÐExhaust 45±45.5É

Head DiameterÐIntake 47.87±48.13 mm

(1.88±1.89 in.)

Head DiameterÐExhaust 35.37±35.63 mm

(1.39±1.40 in.)

Valve Margin

Intake 0.825±0.973 mm

(0.032±0.038 in.)

Exhaust 1.565±1.713 mm

(0.061±0.067 in.)

Valve Length (Overall)

Intake 125.84±126.6 mm

(4.95±4.98 in.)

Exhaust 127.2±127.96 mm

(5.00±5.04 in.)

Valve Stem Tip Height

Intake (valve tip to spring

seat washer)48.1±49.7 mm

(1.89±1.95 in.)

Exhaust (valve tip to

spring seat washer)48.53±50.09 mm

(1.91±1.97 in.)

Valve Stem Diameter

Intake (Standard) 6.935±6.953 mm

(0.2730±0.2737 in.)

Exhaust (Standard) 6.906±6.924 mm

(0.2718±0.2725 in.)

Valve Stem to Guide Clearance

Intake 0.025±0.065 mm

(0.001±0.0025 in.)

Max. Allowable (Rocking

Method)0.247 mm

(0.010 in.)

Exhaust 0.059±0.094 mm

(0.002±0.0037 in.)

Max. Allowable (Rocking

Method)0.414 mm

(0.016 in.)

Push Rods

Length 135.438 mm

(5.33 in.)

Valve Springs

Free Length (Approx.) 51.4 mm

(2.02 in.)DESCRIPTION SPECIFICATION

Wire Diameter 3.95±4.77 mm

(0.15±0.19 in.)

Number of Coils 7.52

Spring Tension (Valve

Closed)376.4±424.4 N @ 41.9

mm

(84.6±95.6 lbs. @ 1.65

in.)

Installed Height 41.1±42.7 mm

(1.61±1.68 in.)

Oil Pump

Clearance Over

RotorsÐInner and Outer

(Max.)0.10 mm

(0.004 in.)

Cover Out-of-Flat (Max.) 0.025 mm

(0.001 in.)

Inner Rotor Thickness

(Min.)7.64 mm

(0.301 in.)

Outer Rotor Thickness

(Min.)7.64 mm

(0.301 in.)

Outer Rotor Clearance

(Max.)0.039 mm

(0.015 in.)

Outer Rotor Diameter

(Min.)79.95 mm

(3.148 in.)

Tip Clearance Between

Rotors (Max.)0.20 mm

(0.008 in.)

Oil Pressure

At Curb Idle Speed*

(Minimum with engine at

operating temerature)34.47 kPa

(5 psi)

At 3000 rpm 205±551 kPa

(30±80 psi)

Oil Filter By-pas Valve

Setting62±103 kPa

(9±15 psi)

Oil Pressure Switch

Actuating Pressure14±28 kPa

(2±4 psi)

caution:

*If pressure is ZERO at curb idle, DO NOT run

engine at 3000 rpm.

RSENGINE 3.3/3.8L9-89

SPECIFICATIONS (Continued)

Page 2714 of 4284

SPECIFICATIONS - TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Camshaft SprocketÐBolt 54 40 Ð

Camshaft Thrust

PlateÐBolts12 Ð 105

Connecting Rod

CapÐBolts54 +

1¤4

turn40

+1¤4

turnÐ

Crankshaft Main Bearing

CapÐBolts41 +

1¤4

turn30

+1¤4

turnÐ

Crankshaft Oil Seal

Retainer RearÐBolts12 Ð 105

Crankshaft DamperÐBolt 54 40 Ð

Cylinder HeadÐBolts (Refer to 9 - ENGINE/

CYLINDER HEAD -

INSTALLATION)

Cylinder Head CoverÐ

Bolts12 Ð 105

Flex Plate to Crankshaft 95 70 Ð

Engine Mounting (Refer to 9 - ENGINE/

ENGINE MOUNTING)

Exhaust ManifoldÐBolts 23 Ð 200

Exhaust Crossover

PipeÐBolts54 40 Ð

Intake Manifold -

LowerÐBolts23 Ð 200

Intake Manifold - Lower

Gasket RetainerÐBolts12 Ð 105

Intake Manifold

UpperÐBolts12 Ð 105

Lifter Yoke RetainerÐ

Bolts12 Ð 105

Oil Filter Attaching Fitting 41 30 Ð

Oil Filter 14 10 Ð

Oil Filter AdapterÐBolts 28 Ð 250

Oil PanÐBolts 12 Ð 105

Oil Pan DrainÐPlug 27 20 Ð

Oil Pump Cover

PlateÐScrews12 Ð 105

Oil Pump Pick-up

TubeÐBolt28 Ð 250

Oil Dipstick HousingÐ

Bolts48 35 Ð

Rocker Arm ShaftÐBolts 23 Ð 200

Spark Plug 16 12 Ð

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Timing Chain Case Cover

ÐM8 Bolt 27 20 Ð

ÐM10 Bolt 54 40 Ð

Water PumpÐBolts 12 Ð 105

Water Pump PulleyÐ

Bolts28 Ð 250

SPECIAL TOOLS

3.3/3.8L ENGINE

Dolly, Engine Support 6135

Cradle, Engine Support 6710

Adapter 6909

9 - 90 ENGINE 3.3/3.8LRS

SPECIFICATIONS (Continued)

Page 2715 of 4284

Adapter 8444

Adapter 6912

Puller, 3-Jaw 1026

Insert, Crankshaft 8450

Installer, Crankshaft Pulley/Sprocket 8451

Installer Cup, Crankshaft Sprocket 8452

Indicator, Cylinder Bore C-119

Tester - Valve Spring C-647

RSENGINE 3.3/3.8L9-91

SPECIAL TOOLS (Continued)