CHRYSLER VOYAGER 2002 Service Manual

Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1811 of 2399

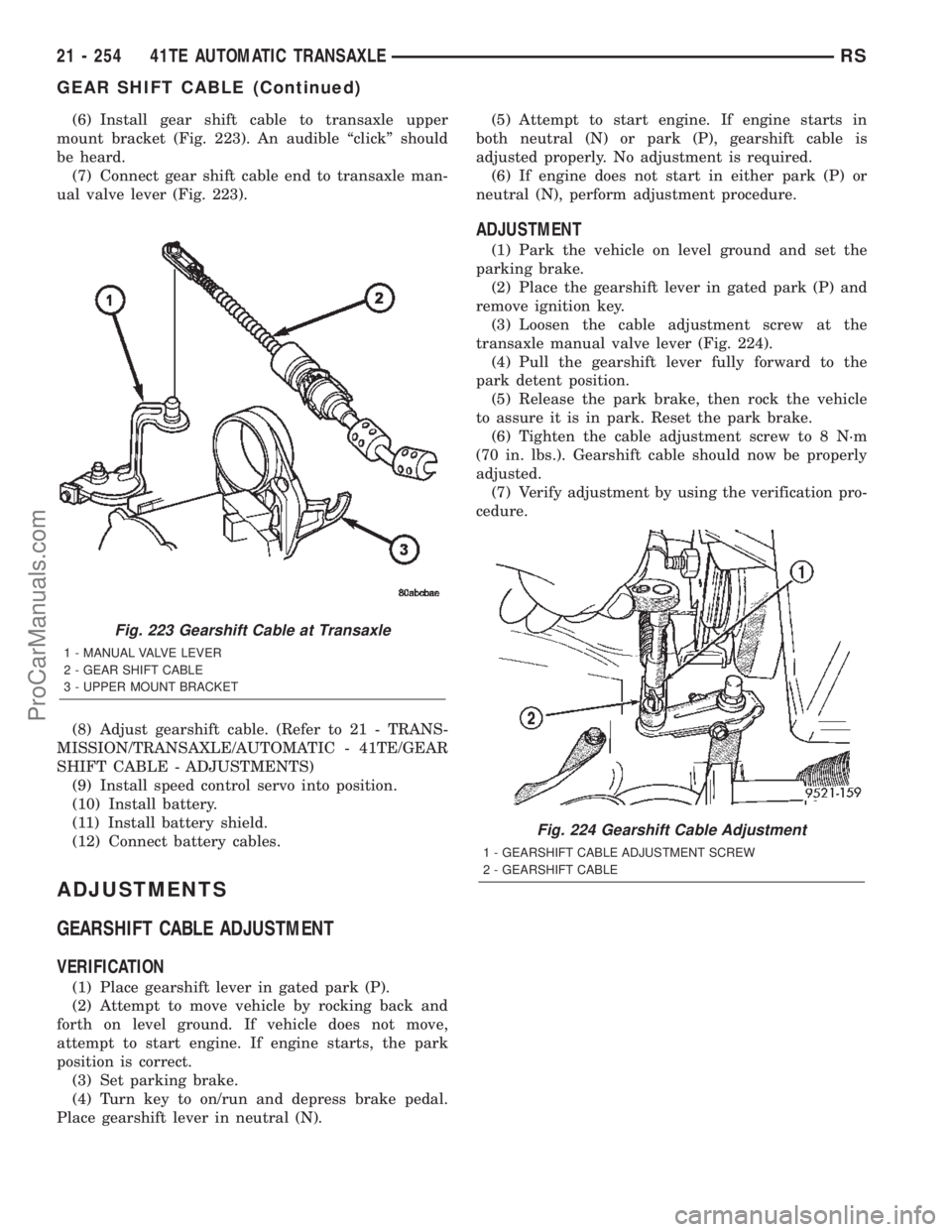

(6) Install gear shift cable to transaxle upper

mount bracket (Fig. 223). An audible ªclickº should

be heard.

(7) Connect gear shift cable end to transaxle man-

ual valve lever (Fig. 223).

(8) Adjust gearshift cable. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 41TE/GEAR

SHIFT CABLE - ADJUSTMENTS)

(9) Install speed control servo into position.

(10) Install battery.

(11) Install battery shield.

(12) Connect battery cables.

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT

VERIFICATION

(1) Place gearshift lever in gated park (P).

(2) Attempt to move vehicle by rocking back and

forth on level ground. If vehicle does not move,

attempt to start engine. If engine starts, the park

position is correct.

(3) Set parking brake.

(4) Turn key to on/run and depress brake pedal.

Place gearshift lever in neutral (N).(5) Attempt to start engine. If engine starts in

both neutral (N) or park (P), gearshift cable is

adjusted properly. No adjustment is required.

(6) If engine does not start in either park (P) or

neutral (N), perform adjustment procedure.

ADJUSTMENT

(1) Park the vehicle on level ground and set the

parking brake.

(2) Place the gearshift lever in gated park (P) and

remove ignition key.

(3) Loosen the cable adjustment screw at the

transaxle manual valve lever (Fig. 224).

(4) Pull the gearshift lever fully forward to the

park detent position.

(5) Release the park brake, then rock the vehicle

to assure it is in park. Reset the park brake.

(6) Tighten the cable adjustment screw to 8 N´m

(70 in. lbs.). Gearshift cable should now be properly

adjusted.

(7) Verify adjustment by using the verification pro-

cedure.

Fig. 223 Gearshift Cable at Transaxle

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

Fig. 224 Gearshift Cable Adjustment

1 - GEARSHIFT CABLE ADJUSTMENT SCREW

2 - GEARSHIFT CABLE

21 - 254 41TE AUTOMATIC TRANSAXLERS

GEAR SHIFT CABLE (Continued)

ProCarManuals.com

Page 1812 of 2399

HOLDING CLUTCHES

DESCRIPTION

Two hydraulically applied multi-disc clutches are

used to hold planetary geartrain components station-

ary while the input clutches drive others. The 2/4

and Low/Reverse clutches are considered holding

clutches and are contained at the rear of the trans-

axle case. (Fig. 225) .

OPERATION

NOTE: Refer to the ªElements In Useº chart in Diag-

nosis and Testing for a collective view of which

clutch elements are applied at each position of the

selector lever.

2/4 CLUTCH

The 2/4 clutch is hydraulically applied in second

and fourth gears by pressurized fluid against the 2/4

clutch piston. When the 2/4 clutch is applied, the

front sun gear assembly is held or grounded to the

transaxle case.

LOW/REVERSE CLUTCH

The Low/Reverse clutch is hydraulically applied in

park, reverse, neutral, and first gears by pressurized

fluid against the Low/Reverse clutch piston. When

the Low/Reverse clutch is applied, the front planet

carrier/rear annulus assembly is held or grounded to

the transaxle case.

INPUT CLUTCH ASSEMBLY

DISASSEMBLY

(1) Mount input clutch assembly to Input Clutch

Pressure Fixture (Tool 8391).

(2) Tap down reverse clutch reaction plate to

release pressure from snap ring (Fig. 226).

Fig. 225 2/4 and Low/Reverse Clutches

1 - FRONT PLANET CARRIER/REAR ANNULUS

2 - 2/4 CLUTCH

3 - L/R CLUTCH

4 - REAR PLANET CARRIER/FRONT ANNULUS

5 - REAR SUN GEAR

6 - FRONT SUN GEAR ASSEMBLY

Fig. 226 Tapping Reaction Plate

1 - #4 THRUST PLATE (SELECT)

2 - TAP DOWN REVERSE CLUTCH REACTION PLATE TO

REMOVE OR INSTALL SNAP RING

3 - INPUT SHAFT CLUTCHES RETAINER ASSEMBLY

4 - REVERSE CLUTCH REACTION PLATE

RS41TE AUTOMATIC TRANSAXLE21 - 255

ProCarManuals.com

Page 1813 of 2399

(3) Remove reverse clutch snap ring (Fig. 227).

(4) Pry up and remove reverse clutch reaction

plate (Fig. 228) (Fig. 229).(5) Remove the reverse clutch pack (two frictions/

one steel) (Fig. 230).

NOTE: Tag reverse clutch pack for reassembly iden-

tification.

Fig. 227 Reverse Clutch Snap Ring

1 - REACTION PLATE

2 - SCREWDRIVER

3 - REVERSE CLUTCH SNAP RING (SELECT)

Fig. 228 Pry Reverse Clutch Reaction Plate

1 - REVERSE CLUTCH REACTION PLATE

2 - SCREWDRIVER

3 - SCREWDRIVER

Fig. 229 Reverse Clutch Reaction Plate

1 - REVERSE CLUTCH REACTION PLATE (INSTALL FLAT SIDE

DOWN)

Fig. 230 Reverse Clutch Pack

1 - REVERSE CLUTCH PLATE

2 - REVERSE CLUTCH DISC

21 - 256 41TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1814 of 2399

(6) Remove the OD/Reverse pressure plate snap

ring (Fig. 231).

(7) Remove OD/Reverse pressure plate (Fig. 232).(8) Remove OD/Reverse pressure plate wave snap

ring (Fig. 233).

(9) Remove OD shaft/hub and OD clutch pack (Fig.

234) (Fig. 235).

NOTE: Tag overdrive clutch pack for reassembly

identification.

Fig. 231 OD/Reverse Pressure Plate Snap Ring

1 - OD/REVERSE PRESSURE PLATE

2 - SCREWDRIVER

3 - OD/REVERSE PRESSURE PLATE SNAP RING

Fig. 232 OD/Reverse Pressure Plate

1 - OD/REVERSE PRESSURE PLATE (STEP SIDE DOWN)

2 - (STEP SIDE DOWN)

Fig. 233 Waved Snap Ring

1 - OVERDRIVE SHAFT ASSEMBLY

2 - OD/REVERSE CLUTCH WAVED SNAP RING

3 - SCREWDRIVER

Fig. 234 Remove OD Clutch Pack

1 - OVERDRIVE SHAFT ASSEMBLY AND OD CLUTCH PACK

2 - #3 THRUST PLATE

3 - #3 THRUST WASHER

4 - UNDERDRIVE SHAFT ASSEMBLY

RS41TE AUTOMATIC TRANSAXLE21 - 257

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1815 of 2399

(10) Remove and inspect #3 & #4 thrust washers

(Fig. 236).(11) Remove the underdrive shaft assembly (Fig.

237).

(12) Remove the #2 needle bearing (Fig. 238).

Fig. 235 Overdrive Clutch Pack

1 - OVERDRIVE CLUTCH PLATE

2 - OVERDRIVE SHAFT ASSEMBLY

3 - OVERDRIVE CLUTCH DISC

Fig. 236 #3&4 Thrust Washers

1 - #3 THRUST PLATE (3 TABS)

2 - OD SHAFT ASSEMBLY

3 - #4 THRUST PLATE (3 SLOTS)

Fig. 237 Underdrive Shaft Assembly

1 - #3 THRUST WASHER (5 TABS)

2 - UNDERDRIVE SHAFT ASSEMBLY

Fig. 238 No. 2 Needle Bearing

1 - #2 NEEDLE BEARING (NOTE 3 TABS)

21 - 258 41TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1816 of 2399

(13) Remove the OD/UD reaction plate tapered

snap ring (Fig. 239).

NOTE: The OD/UD clutch reaction plate has a step

on both sides. Install the OD/UD clutches reaction

plate tapered step side up.

(14) Remove the OD/UD reaction plate (Fig. 240).(15) Remove the first UD clutch disc (Fig. 241).

(16) Remove the UD clutch flat snap ring (Fig.

242).

Fig. 239 OD/UD Reaction Plate Tapered Snap Ring

1 - OVERDRIVE/UNDERDRIVE CLUTCHES REACTION PLATE

TAPERED SNAP RING

2 - SCREWDRIVER (DO NOT SCRATCH REACTION PLATE)

Fig. 240 OD/UD Reaction Plate

1 - OD/UD CLUTCH REACTION PLATE (TAPERED STEP SIDE

UP)

Fig. 241 Remove One UD Clutch Disc

1 - ONE UNDERDRIVE CLUTCH DISC

Fig. 242 UD Clutch Flat Snap Ring

1 - UNDERDRIVE CLUTCH REACTION PLATE FLAT SNAP RING

2 - SCREWDRIVER

RS41TE AUTOMATIC TRANSAXLE21 - 259

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1817 of 2399

NOTE: Tag underdrive clutch pack for reassembly

identification.

(17) Remove the UD clutch pack (Fig. 243).

CAUTION: Compress return spring just enough to

remove or install snap ring.

(18) Using Tool 5059A and an arbor press, com-

press UD clutch piston enough to remove snap ring

(Fig. 244) (Fig. 245).(19) Remove spring retainer (Fig. 245).

(20) Remove UD clutch piston (Fig. 246).

Fig. 243 Underdrive Clutch Pack

1 - CLUTCH PLATE

2 - ONE UD CLUTCH DISC

3 - CLUTCH DISC

Fig. 244 UD Spring Retainer Snap Ring

1 - SNAP RING PLIERS

2 - ARBOR PRESS RAM

3 - SNAP RING

4 - SPECIAL TOOL 5059A

Fig. 245 UD Return Spring and Retainer

1 - UNDERDRIVE SPRING RETAINER

2 - SNAP RING

3 - SEAL

4 - PISTON RETURN SPRING

Fig. 246 Underdrive Clutch Piston

1 - PISTON

21 - 260 41TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1818 of 2399

(21) Remove input hub tapered snap ring (Fig.

247).

(22) Tap on input hub with soft faced hammer and

separate input hub from OD/Reverse piston and

clutch retainer (Fig. 248) (Fig. 249).(23) Separate clutch retainer from OD/Reverse pis-

ton (Fig. 250).

Fig. 247 Input Hub Tapered Snap Ring

1 - INPUT SHAFT

2 - INPUT HUB SNAP RING (TAPERED SIDE UP WITH TABS IN

CAVITY)

3 - SNAP RING PLIERS

Fig. 248 Tap on Input Hub

1 - INPUT SHAFT AND HUB ASSEMBLY

2 - PLASTIC HAMMER

Fig. 249 Input Hub Removed

1 - INPUT SHAFT AND HUB ASSEMBLY

2 - INPUT CLUTCHES RETAINER

3 - O-RING

4 - SEAL

5 - OVERDRIVE/REVERSE PISTON

Fig. 250 Pull Retainer from Piston

1 - OVERDRIVE/REVERSE PISTON

2 - INPUT CLUTCHES RETAINER

RS41TE AUTOMATIC TRANSAXLE21 - 261

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1819 of 2399

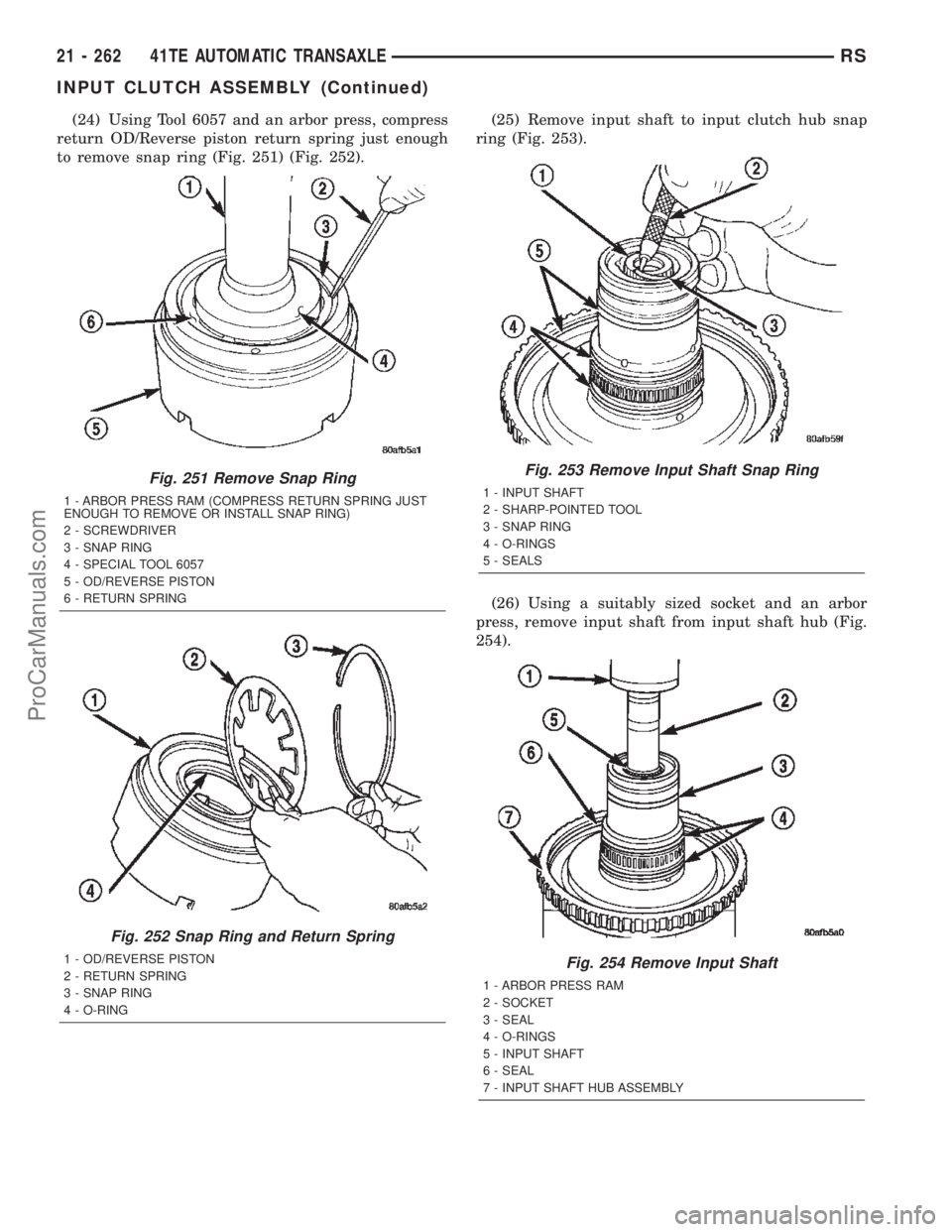

(24) Using Tool 6057 and an arbor press, compress

return OD/Reverse piston return spring just enough

to remove snap ring (Fig. 251) (Fig. 252).(25) Remove input shaft to input clutch hub snap

ring (Fig. 253).

(26) Using a suitably sized socket and an arbor

press, remove input shaft from input shaft hub (Fig.

254).

Fig. 251 Remove Snap Ring

1 - ARBOR PRESS RAM (COMPRESS RETURN SPRING JUST

ENOUGH TO REMOVE OR INSTALL SNAP RING)

2 - SCREWDRIVER

3 - SNAP RING

4 - SPECIAL TOOL 6057

5 - OD/REVERSE PISTON

6 - RETURN SPRING

Fig. 252 Snap Ring and Return Spring

1 - OD/REVERSE PISTON

2 - RETURN SPRING

3 - SNAP RING

4 - O-RING

Fig. 253 Remove Input Shaft Snap Ring

1 - INPUT SHAFT

2 - SHARP-POINTED TOOL

3 - SNAP RING

4 - O-RINGS

5 - SEALS

Fig. 254 Remove Input Shaft

1 - ARBOR PRESS RAM

2 - SOCKET

3 - SEAL

4 - O-RINGS

5 - INPUT SHAFT

6 - SEAL

7 - INPUT SHAFT HUB ASSEMBLY

21 - 262 41TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1820 of 2399

ASSEMBLY

Use petrolatum on all seals to ease assembly of

components.

(1) Using an arbor press, install input shaft to

input shaft hub (Fig. 255).

(2) Install input shaft snap ring (Fig. 256).(3) Using an arbor press and Tool 6057, Install

OD/Reverse piston return spring and snap ring (Fig.

257) (Fig. 258).

Fig. 255 Install Input Shaft

1 - INPUT SHAFT

2 - ARBOR PRESS RAM

3 - INPUT SHAFT HUB ASSEMBLY

Fig. 256 Install Input Shaft Snap Ring

1 - INPUT SHAFT

2 - SCREWDRIVER (DO NOT SCRATCH BEARING SURFACE)

3 - SNAP RING

4 - O-RINGS

5 - SEALS

Fig. 257 Return Spring and Snap Ring

1 - OD/REVERSE PISTON

2 - RETURN SPRING

3 - SNAP RING

4 - O-RING

Fig. 258 Install Snap Ring

1 - ARBOR PRESS RAM (COMPRESS RETURN SPRING JUST

ENOUGH TO REMOVE OR INSTALL SNAP RING)

2 - SCREWDRIVER

3 - SNAP RING

4 - SPECIAL TOOL 6057

5 - OD/REVERSE PISTON

6 - RETURN SPRING

RS41TE AUTOMATIC TRANSAXLE21 - 263

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com