CHRYSLER VOYAGER 2002 Service Manual

Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1821 of 2399

(4) Install the OD/Reverse piston assembly to the

input clutch retainer as shown in (Fig. 259).

(5) Install the input hub/shaft assy. to the OD/Re-

verse piston/clutch retainer assy. (Fig. 260).(6) Install input hub tapered snap ring (Fig. 261).

(7) Install UD clutch piston (Fig. 262).

Fig. 259 Install OD/Reverse Piston

1 - PUSH DOWN TO INSTALL OVERDRIVE/REVERSE PISTON

2 - INPUT CLUTCHES RETAINER

Fig. 260 Install Input Shaft Hub Assembly

1 - PUSH DOWN TO INSTALL INPUT SHAFT HUB ASSEMBLY

(ROTATE TO ALIGN SPLINES)

2 - OD/REV. PISTON

Fig. 261 Install Input Hub Tapered Snap Ring

1 - INPUT SHAFT

2 - INPUT HUB SNAP RING (TAPERED SIDE UP WITH TABS IN

CAVITY)

3 - SNAP RING PLIERS

Fig. 262 Underdrive Clutch Piston

1 - PISTON

21 - 264 41TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1822 of 2399

(8) Install UD piston return spring and Tool 5067

as shown in (Fig. 263).

(9) Using Tool 5059A and an arbor press, Install

the UD spring retainer and snap ring. (Fig. 264) (Fig.

265) Compress just enough to install snap ring.

CAUTION: Compress return spring just enough to

install snap ring.(10) Install the UD clutch pack. Leave out upper

disc, until snap ring is installed (Fig. 266).

Fig. 263 Seal Compressor Special Tool 5067

1 - PISTON RETURN SPRING

2 - SPECIAL TOOL 5067

3 - INPUT SHAFT CLUTCHES RETAINER ASSEMBLY

Fig. 264 UD Return Spring and Retainer

1 - UNDERDRIVE SPRING RETAINER

2 - SNAP RING

3 - SEAL

4 - PISTON RETURN SPRING

Fig. 265 Install UD Spring Retainer and Snap Ring

1 - ARBOR PRESS RAM

2 - SNAP RING PLIERS

3 - SNAP RING

4 - OD/REVERSE PISTON

5 - TOOL 5067

6 - TOOL 5059A

Fig. 266 Underdrive Clutch Pack

1 - CLUTCH PLATE

2 - ONE UD CLUTCH DISC

3 - CLUTCH DISC

RS41TE AUTOMATIC TRANSAXLE21 - 265

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1823 of 2399

(11) Install the UD clutch flat snap ring (Fig. 267).

(12) Install the last UD clutch disc (Fig. 268).(13) Install the OD/UD clutch reaction plate and

snap ring (Fig. 269) (Fig. 270). The OD/UD clutches

reaction plate has a step on both sides. Install the

OD/UD clutches reaction plate tapered step side up.

Fig. 267 UD Clutch Flat Snap Ring

1 - UNDERDRIVE CLUTCH REACTION PLATE FLAT SNAP RING

2 - SCREWDRIVER

Fig. 268 Install Last UD Clutch Disc

1 - ONE UNDERDRIVE CLUTCH DISC

Fig. 269 OD/UD Reaction Plate

1 - OD/UD CLUTCH REACTION PLATE (TAPERED STEP SIDE

UP)

Fig. 270 Tapered Snap Ring

1 - OVERDRIVE/UNDERDRIVE CLUTCHES REACTION PLATE

TAPERED SNAP RING

2 - SCREWDRIVER (DO NOT SCRATCH REACTION PLATE)

21 - 266 41TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1824 of 2399

NOTE: Snap ring ends must be located within one

finger of the input clutch hub. Be sure that snap

ring is fully seated, by pushing with screwdriver,

into snap ring groove all the way around.

(14) Seat tapered snap ring to ensure proper

installation (Fig. 271).

(15) Install input clutch assembly to the Input

Clutch Pressure Fixture±Tool 8391 (Fig. 272).(16) Set up dial indicator on the UD clutch pack as

shown in (Fig. 273).

(17) Using moderate pressure, press down and

hold (near indicator) the UD clutch pack with screw-

driver or suitable tool and zero dial indicator (Fig.

274). When releasing pressure on clutch pack, indica-

tor reading should advance 0.005±0.010.

CAUTION: Do not apply more than 30 psi (206 kPa)

to the underdrive clutch pack.

(18) Apply 30 psi (206 kPa) to the underdrive hose

on Tool 8391 and measure UD clutch clearance. Mea-

sure and record UD clutch pack measurement in four

(4) places, 90É apart.

Fig. 271 Seating Tapered Snap Ring

1 - OVERDRIVE/UNDERDRIVE CLUTCHES REACTION PLATE

TAPERED SNAP RING

2 - SCREWDRIVER

Fig. 272 Input Clutch Assembly on Pressure Fixture

Tool 8391

1 - INPUT CLUTCH ASSEMBLY

2 - INPUT CLUTCH PRESSURE FIXTURE 8391

Fig. 273 Set Up Dial Indicator to Measure UD Clutch

Clearance

1 - DIAL INDICATOR

2 - UNDERDRIVE CLUTCH

RS41TE AUTOMATIC TRANSAXLE21 - 267

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1825 of 2399

(19) Take average of four measurements and com-

pare with UD clutch pack clearance specification.

Underdrive clutch pack clearance must be 0.94-

1.50 mm (0.037-0.059 in.).

(20) If necessary, select the proper reaction plate

to achieve specifications:

UNDERDRIVE REACTION PLATE THICKNESS

4659939AB 5.837-5.937 mm (0.230-0.234 in.)

4659940AB 6.147-6.248 mm (0.242-0.246 in.)

4659941AB 6.457-6.557 mm (0.254-0.258 in.)

(21) Install the OD clutch pack (four frictions/three

steels) (Fig. 275).

(22) Install OD pressure plate waved snap ring

(Fig. 276).

(23) Install the OD/Reverse pressure plate with

large step down (towards OD clutch pack) (Fig. 277).

Fig. 274 Press Down on UD Clutch Pack and Zero

Dial Indicator

1 - DIAL INDICATOR

2 - UNDERDRIVE CLUTCH

Fig. 275 Install OD Clutch Pack

1 - OVERDRIVE CLUTCH PACK

Fig. 276 Install Waved Snap Ring

1 - OVERDRIVE PRESSURE PLATE WAVED SNAP RING

2 - SCREWDRIVER

Fig. 277 OD/Reverse Pressure Plate

1 - OVERDRIVE/REVERSE PRESSURE PLATE

2 - (STEP SIDE DOWN)

21 - 268 41TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1826 of 2399

(24) Install OD pressure plate flat snap ring (Fig.

278).

(25) Measure OD clutch pack clearance. Set up

dial indicator on top of the OD/Reverse pressure

plate as shown in (Fig. 279).(26) Zero dial indicator and apply 30 psi (206 kPa)

air pressure to the overdrive clutch hose on Tool

8391. Measure and record OD clutch pack measure-

ment in four (4) places, 90É apart.

(27) Take average of four measurements and com-

pare with OD clutch pack clearance specification.

The overdrive (OD) clutch pack clearance is

1.07-3.25 mm (0.042-0.128 in.).

If not within specifications, the clutch is not

assembled properly. There is no adjustment for the

OD clutch clearance.

(28) Install reverse clutch pack (two frictions/one

steel) (Fig. 280).

(29) Install reverse clutch reaction plate with the

flat side down towards reverse clutch (Fig. 281).

Fig. 278 Install Flat Snap Ring

1 - ARBOR PRESS RAM

2 - TOOL 5059A

3 - FLAT SNAP RING

Fig. 279 Measure OD Clutch Pack Clearance

1 - DIAL INDICATOR

2 - OD/REVERSE REACTION PLATE

Fig. 280 Install Reverse Clutch Pack

1 - REVERSE CLUTCH PLATE

2 - REVERSE CLUTCH DISCS

Fig. 281 Install Reaction Plate

1 - REVERSE CLUTCH REACTION PLATE (FLAT SIDE DOWN)

RS41TE AUTOMATIC TRANSAXLE21 - 269

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1827 of 2399

(30) Tap reaction plate down to allow installation

of the reverse clutch snap ring. Install reverse clutch

snap ring (Fig. 282).

(31) Pry up reverse reaction plate to seat against

snap ring (Fig. 283).

(32) Set up a dial indicator on the reverse clutch

pack as shown in (Fig. 284).

(33) Using moderate pressure, press down and

hold (near indicator) reverse clutch disc with screw-

driver or suitable tool and zero dial indicator (Fig.285). When releasing pressure, indicator should

advance 0.005-0.010. as clutch pack relaxes.

Fig. 282 Install Reverse Clutch Snap Ring

1 - REVERSE CLUTCH SNAP RING (SELECT)

2 - SCREWDRIVER

3 - REVERSE CLUTCH REACTION PLATE

Fig. 283 Pry Up Reaction Plate to Seat Against Snap

Ring

1 - SCREWDRIVER

2 - SNAP RING

3 - SCREWDRIVER

4 - MUST RAISE REVERSE REACTION PLATE TO RAISE SNAP

RING

Fig. 284 Measure Reverse Clutch Pack Clearance

1 - DIAL INDICATOR

2 - REVERSE CLUTCH

Fig. 285 Press Down on Reverse Clutch and Zero

Indicator

1 - DIAL INDICATOR

2 - REVERSE CLUTCH

21 - 270 41TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1828 of 2399

(34) Apply 30 psi (206 kPa) air pressure to the

reverse clutch hose on Tool 8391. Measure and record

reverse clutch pack measurement in four (4) places,

90É apart.

(35) Take average of four measurements and com-

pare with reverse clutch pack clearance specification.

The reverse clutch pack clearance is 0.89-1.37

mm (0.035-0.054 in.).Select the proper reverse

clutch snap ring to achieve specifications:

REVERSE CLUTCH SNAP RING THICKNESS

4377195 1.53-1.58 mm (0.060-0.062 in.)

4412871 1.77-1.83 mm (0.070-0.072 in.)

4412872 2.02-2.07 mm (0.080-0.082 in.)

4412873 2.27-2.32 mm (0.090-0.091 in.)

(36) To complete the assembly, reverse clutch and

overdrive clutch must be removed.

(37) Install the #2 needle bearing (Fig. 286).

(38) Install the underdrive shaft assembly (Fig.

287).

(39) Install the #3 thrust washer to the underdrive

shaft assembly. Be sure five tabs are seated properly

(Fig. 288).

(40) Install the #3 thrust plate to the bottom of the

overdrive shaft assembly. Retain with petrolatum or

transmission assembly gel (Fig. 289).

Fig. 287 Install Underdrive Shaft Assembly

1 - UNDERDRIVE SHAFT ASSEMBLY

2 - #2 NEEDLE BEARING

Fig. 288 Install No. 3 Thrust Washer

1 - #3 THRUST WASHER (NOTE 5 TABS)

2 - UNDERDRIVE SHAFT ASSEMBLY

Fig. 289 Install No. 3 Thrust Plate

1 - OVERDRIVE SHAFT ASSEMBLY

2 - DABS OF PETROLATUM (FOR RETENTION)

3 - #3 THRUST PLATE (NOTE 3 TABS)

Fig. 286 Install No. 2 Needle Bearing

1 - #2 NEEDLE BEARING (NOTE 3 SMALL TABS)

2 - TABS UP

RS41TE AUTOMATIC TRANSAXLE21 - 271

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1829 of 2399

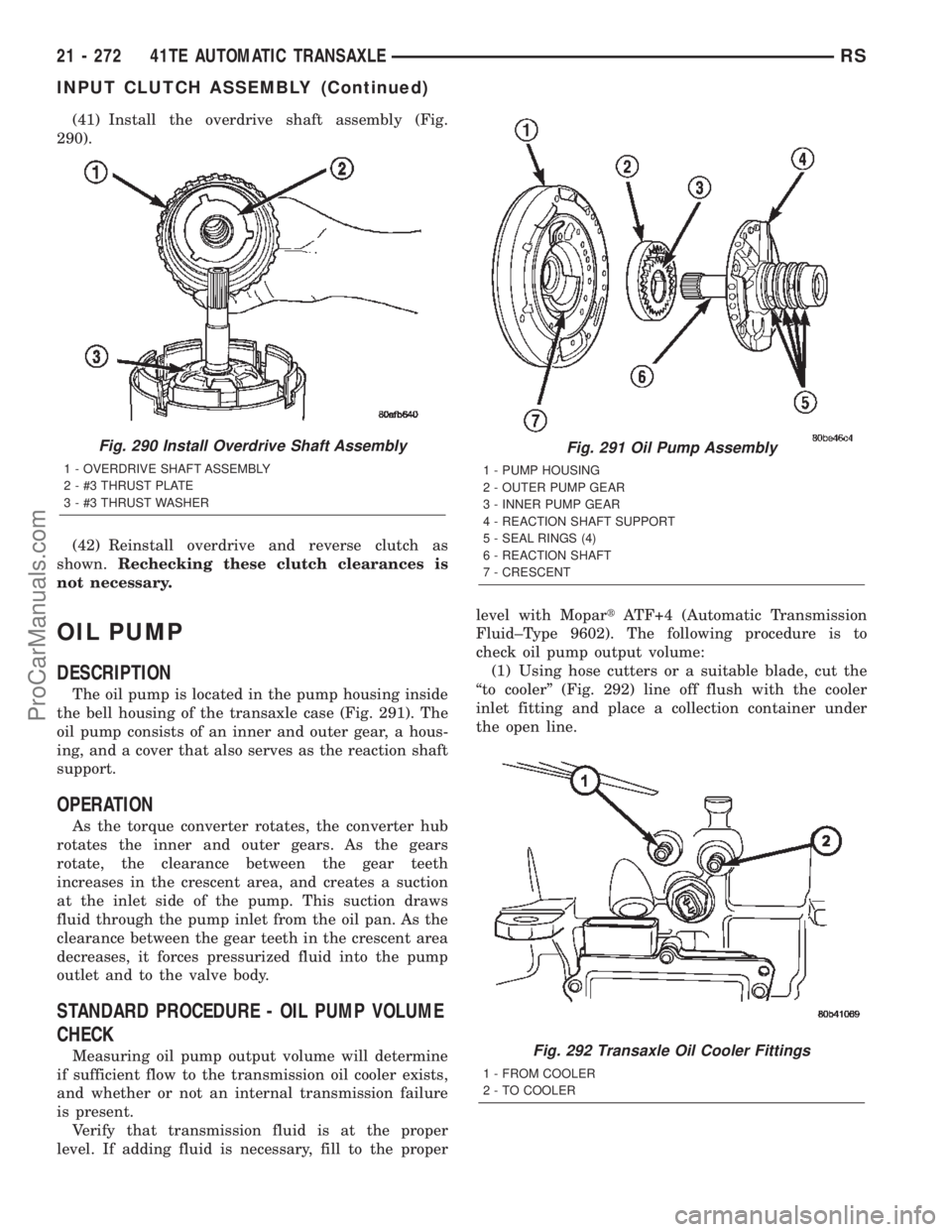

(41) Install the overdrive shaft assembly (Fig.

290).

(42) Reinstall overdrive and reverse clutch as

shown.Rechecking these clutch clearances is

not necessary.

OIL PUMP

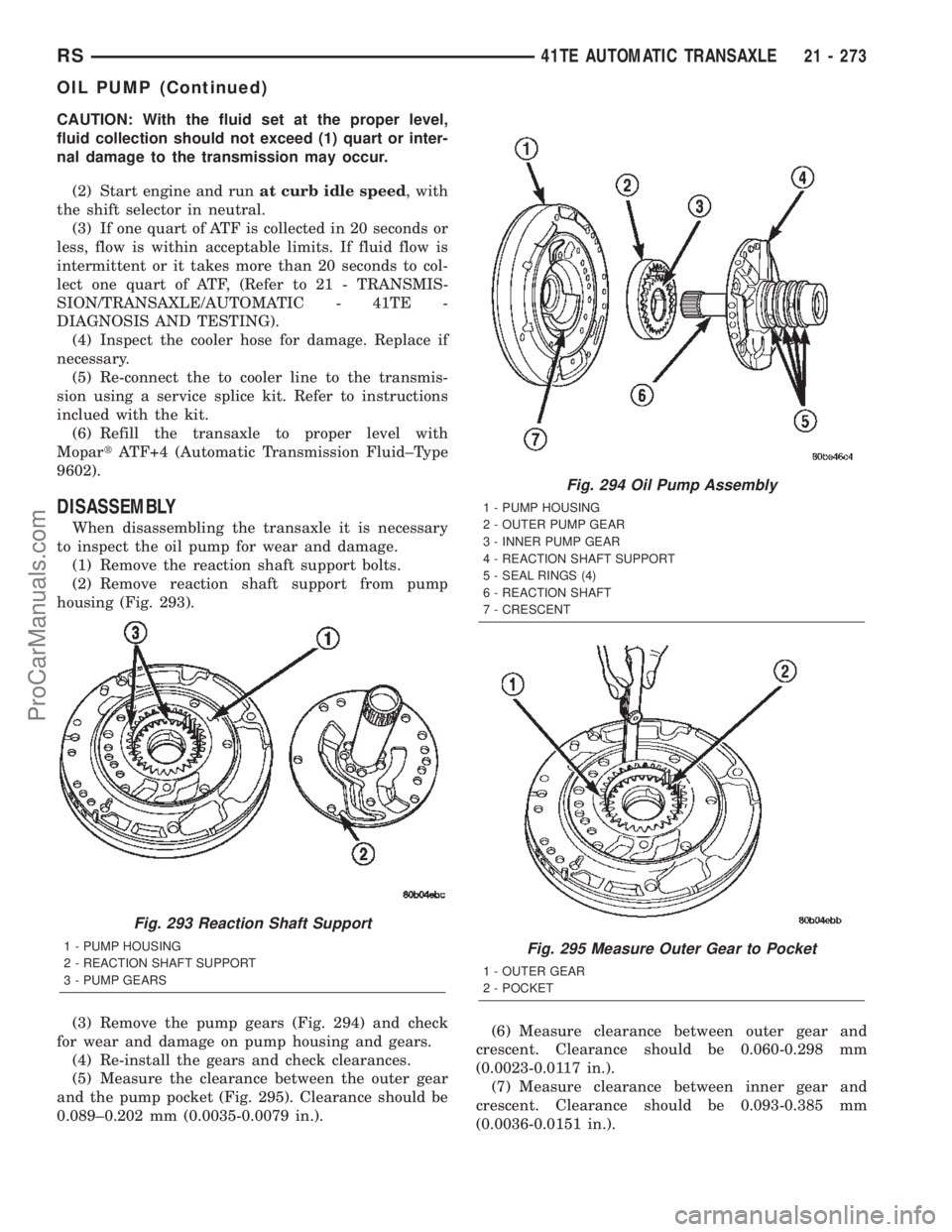

DESCRIPTION

The oil pump is located in the pump housing inside

the bell housing of the transaxle case (Fig. 291). The

oil pump consists of an inner and outer gear, a hous-

ing, and a cover that also serves as the reaction shaft

support.

OPERATION

As the torque converter rotates, the converter hub

rotates the inner and outer gears. As the gears

rotate, the clearance between the gear teeth

increases in the crescent area, and creates a suction

at the inlet side of the pump. This suction draws

fluid through the pump inlet from the oil pan. As the

clearance between the gear teeth in the crescent area

decreases, it forces pressurized fluid into the pump

outlet and to the valve body.

STANDARD PROCEDURE - OIL PUMP VOLUME

CHECK

Measuring oil pump output volume will determine

if sufficient flow to the transmission oil cooler exists,

and whether or not an internal transmission failure

is present.

Verify that transmission fluid is at the proper

level. If adding fluid is necessary, fill to the properlevel with MopartATF+4 (Automatic Transmission

Fluid±Type 9602). The following procedure is to

check oil pump output volume:

(1) Using hose cutters or a suitable blade, cut the

ªto coolerº (Fig. 292) line off flush with the cooler

inlet fitting and place a collection container under

the open line.

Fig. 290 Install Overdrive Shaft Assembly

1 - OVERDRIVE SHAFT ASSEMBLY

2 - #3 THRUST PLATE

3 - #3 THRUST WASHER

Fig. 291 Oil Pump Assembly

1 - PUMP HOUSING

2 - OUTER PUMP GEAR

3 - INNER PUMP GEAR

4 - REACTION SHAFT SUPPORT

5 - SEAL RINGS (4)

6 - REACTION SHAFT

7 - CRESCENT

Fig. 292 Transaxle Oil Cooler Fittings

1 - FROM COOLER

2 - TO COOLER

21 - 272 41TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 1830 of 2399

CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(2) Start engine and runat curb idle speed, with

the shift selector in neutral.

(3) If one quart of ATF is collected in 20 seconds or

less, flow is within acceptable limits. If fluid flow is

intermittent or it takes more than 20 seconds to col-

lect one quart of ATF, (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 41TE -

DIAGNOSIS AND TESTING).

(4) Inspect the cooler hose for damage. Replace if

necessary.

(5) Re-connect the to cooler line to the transmis-

sion using a service splice kit. Refer to instructions

inclued with the kit.

(6) Refill the transaxle to proper level with

MopartATF+4 (Automatic Transmission Fluid±Type

9602).

DISASSEMBLY

When disassembling the transaxle it is necessary

to inspect the oil pump for wear and damage.

(1) Remove the reaction shaft support bolts.

(2) Remove reaction shaft support from pump

housing (Fig. 293).

(3) Remove the pump gears (Fig. 294) and check

for wear and damage on pump housing and gears.

(4) Re-install the gears and check clearances.

(5) Measure the clearance between the outer gear

and the pump pocket (Fig. 295). Clearance should be

0.089±0.202 mm (0.0035-0.0079 in.).(6) Measure clearance between outer gear and

crescent. Clearance should be 0.060-0.298 mm

(0.0023-0.0117 in.).

(7) Measure clearance between inner gear and

crescent. Clearance should be 0.093-0.385 mm

(0.0036-0.0151 in.).

Fig. 293 Reaction Shaft Support

1 - PUMP HOUSING

2 - REACTION SHAFT SUPPORT

3 - PUMP GEARS

Fig. 294 Oil Pump Assembly

1 - PUMP HOUSING

2 - OUTER PUMP GEAR

3 - INNER PUMP GEAR

4 - REACTION SHAFT SUPPORT

5 - SEAL RINGS (4)

6 - REACTION SHAFT

7 - CRESCENT

Fig. 295 Measure Outer Gear to Pocket

1 - OUTER GEAR

2 - POCKET

RS41TE AUTOMATIC TRANSAXLE21 - 273

OIL PUMP (Continued)

ProCarManuals.com