Ignition CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1468 of 2399

FUEL INJECTION

OPERATION

OPERATION - INJECTION SYSTEM

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

The PCM can adapt its programming to meet

changing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are theprimaryinputs that determine

injector pulse width.

OPERATION - MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCM

programming. Inputs from the upstream and down-

stream heated oxygen sensors are not monitored dur-

ing OPEN LOOP modes, except for heated oxygensensor diagnostics (they are checked for shorted con-

ditions at all times).

During CLOSED LOOP modes the PCM monitors

the inputs from the upstream and downstream

heated oxygen sensors. The upstream heated oxygen

sensor input tells the PCM if the calculated injector

pulse width resulted in the ideal air-fuel ratio of 14.7

to one. By monitoring the exhaust oxygen content

through the upstream heated oxygen sensor, the

PCM can fine tune injector pulse width. Fine tuning

injector pulse width allows the PCM to achieve opti-

mum fuel economy combined with low emissions.

For the PCM to enter CLOSED LOOP operation,

the following must occur:

(1) Engine coolant temperature must be over 35ÉF.

²If the coolant is over 35ÉF the PCM will wait 38

seconds.

²If the coolant is over 50ÉF the PCM will wait 15

seconds.

²If the coolant is over 167ÉF the PCM will wait 3

seconds.

(2) For other temperatures the PCM will interpo-

late the correct waiting time.

(3) O2 sensor must read either greater than 0.745

volts or less than 0.29 volt.

(4) The multi-port fuel injection systems has the

following modes of operation:

²Ignition switch ON (Zero RPM)

²Engine start-up

²Engine warm-up

²Cruise

²Idle

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

(5) The engine start-up (crank), engine warm-up,

deceleration with fuel shutoff and wide open throttle

modes are OPEN LOOP modes. Under most operat-

ing conditions, the acceleration, deceleration (with

A/C on), idle and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injec-

tion system, the following actions occur:

²The PCM monitors the engine coolant tempera-

ture sensor and throttle position sensor input. The

PCM determines basic fuel injector pulse width from

this input.

²The PCM determines atmospheric air pressure

from the MAP sensor input to modify injector pulse

width.

When the key is in the ON position and the engine

is not running (zero rpm), the Auto Shutdown (ASD)

and fuel pump relays de-energize after approximately

RSFUEL INJECTION14-17

ProCarManuals.com

Page 1469 of 2399

1 second. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injectors and heated

oxygen sensors.

ENGINE START-UP MODE

This is an OPEN LOOP mode. If the vehicle is in

park or neutral (automatic transaxles) or the clutch

pedal is depressed (manual transaxles) the ignition

switch energizes the starter relay. The following

actions occur when the starter motor is engaged.

²If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the Auto Shutdown (ASD) relay and fuel pump relay.

If the PCM does not receive both signals within

approximately one second, it will not energize the

ASD relay and fuel pump relay. The ASD and fuel

pump relays supply battery voltage to the fuel pump,

fuel injectors, ignition coil, (EGR solenoid and PCV

heater if equipped) and heated oxygen sensors.

²The PCM energizes the injectors (on the 69É

degree falling edge) for a calculated pulse width until

it determines crankshaft position from the camshaft

position sensor and crankshaft position sensor sig-

nals. The PCM determines crankshaft position within

1 engine revolution.

²After determining crankshaft position, the PCM

begins energizing the injectors in sequence. It adjusts

injector pulse width and controls injector synchroni-

zation by turning the individual ground paths to the

injectors On and Off.

²When the engine idles within 64 RPM of its

target RPM, the PCM compares current MAP sensor

value with the atmospheric pressure value received

during the Ignition Switch On (zero RPM) mode.

Once the ASD and fuel pump relays have been

energized, the PCM determines injector pulse width

based on the following:

²MAP

²Engine RPM

²Battery voltage

²Engine coolant temperature

²Inlet/Intake air temperature (IAT)

²Throttle position

²The number of engine revolutions since cranking

was initiated

During Start-up the PCM maintains ignition tim-

ing at 9É BTDC.

ENGINE WARM-UP MODE

This is an OPEN LOOP mode. The following inputs

are received by the PCM:

²Manifold Absolute Pressure (MAP)

²Crankshaft position (engine speed)

²Engine coolant temperature

²Inlet/Intake air temperature (IAT)

²Camshaft position²Knock sensor

²Throttle position

²A/C switch

²Battery voltage

²Vehicle speed

²Speed control

²O2 sensors

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts ignition timing and engine idle

speed. Engine idle speed is adjusted through the idle

air control motor.

CRUISE OR IDLE MODE

When the engine is at operating temperature this

is a CLOSED LOOP mode. During cruising or idle

the following inputs are received by the PCM:

²Manifold absolute pressure

²Crankshaft position (engine speed)

²Inlet/Intake air temperature

²Engine coolant temperature

²Camshaft position

²Knock sensor

²Throttle position

²Exhaust gas oxygen content

²A/C control positions

²Battery voltage

²Vehicle speed

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts engine idle speed and ignition

timing. The PCM adjusts the air/fuel ratio according

to the oxygen content in the exhaust gas (measured

by the upstream and downstream heated oxygen sen-

sor).

The PCM monitors for engine misfire. During

active misfire and depending on the severity, the

PCM either continuously illuminates or flashes the

malfunction indicator lamp (Check Engine light on

instrument panel). Also, the PCM stores an engine

misfire DTC in memory, if 2nd trip with fault.

The PCM performs several diagnostic routines.

They include:

²Oxygen sensor monitor

²Downstream heated oxygen sensor diagnostics

during open loop operation (except for shorted)

²Fuel system monitor

²EGR monitor (if equipped)

²Purge system monitor

²Catalyst efficiency monitor

²All inputs monitored for proper voltage range,

rationality.

²All monitored components (refer to the Emission

section for On-Board Diagnostics).

14 - 18 FUEL INJECTIONRS

FUEL INJECTION (Continued)

ProCarManuals.com

Page 1470 of 2399

The PCM compares the upstream and downstream

heated oxygen sensor inputs to measure catalytic con-

vertor efficiency. If the catalyst efficiency drops below

the minimum acceptable percentage, the PCM stores a

diagnostic trouble code in memory, after 2 trips.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C sense

²Battery voltage

²Battery temperature or Calculated Battery Tem-

perature

²Engine coolant temperature

²Engine run time

²Inlet/Intake air temperature

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

²Wide Open Throttle-open loop

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C sense

²Battery voltage

²Inlet/Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Throttle position sensor

²IAC motor (solenoid) control changes in response

to MAP sensor feedback

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates a

hard deceleration (Open Loop). In response, the PCM

may momentarily turn off the injectors. This helps

improve fuel economy, emissions and engine braking.

WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are used by

the PCM:

²Inlet/Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor²Manifold absolute pressure

²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system and disables

EGR (if equipped).

The PCM adjusts injector pulse width to supply a

predetermined amount of additional fuel, based on

MAP and RPM.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to the Emission sec-

tion for On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

FUEL CORRECTION or ADAPTIVE MEMORIES

DESCRIPTION

In Open Loop, the PCM changes pulse width with-

out feedback from the O2 Sensors. Once the engine

warms up to approximately 30 to 35É F, the PCM

goes into closed loopShort Term Correctionand

utilizes feedback from the O2 Sensors. Closed loop

Long Term Adaptive Memoryis maintained above

170É to 190É F unless the PCM senses wide open

throttle. At that time the PCM returns to Open Loop

operation.

OPERATION

Short Term

The first fuel correction program that begins func-

tioning is the short term fuel correction. This system

corrects fuel delivery in direct proportion to the read-

ings from the Upstream O2 Sensor.

The PCM monitors the air/fuel ratio by using the

input voltage from the O2 Sensor. When the voltage

reaches its preset high or low limit, the PCM begins

to add or remove fuel until the sensor reaches its

switch point. The short term corrections then begin.

The PCM makes a series of quick changes in the

injector pulse-width until the O2 Sensor reaches its

opposite preset limit or switch point. The process

then repeats itself in the opposite direction.

Short term fuel correction will keep increasing or

decreasing injector pulse-width based upon the

upstream O2 Sensor input. The maximum range of

authority for short term memory is 25% (+/-) of base

pulse-width. Short term is violated and is lost when

ignition is turned OFF.

RSFUEL INJECTION14-19

FUEL INJECTION (Continued)

ProCarManuals.com

Page 1475 of 2399

OPERATION

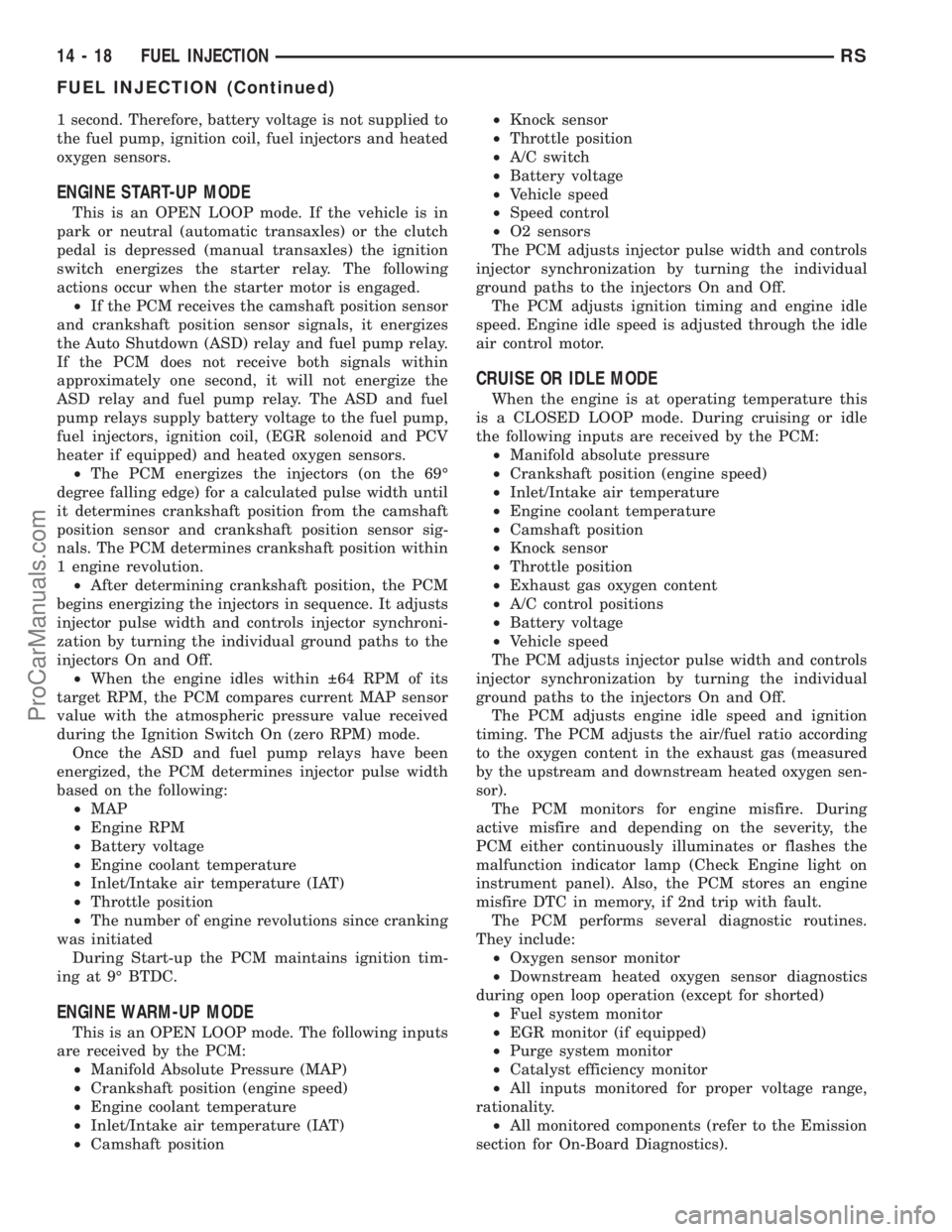

The crankshaft position sensor detects slots cut

into the transmission driveplate extension (Fig. 6).

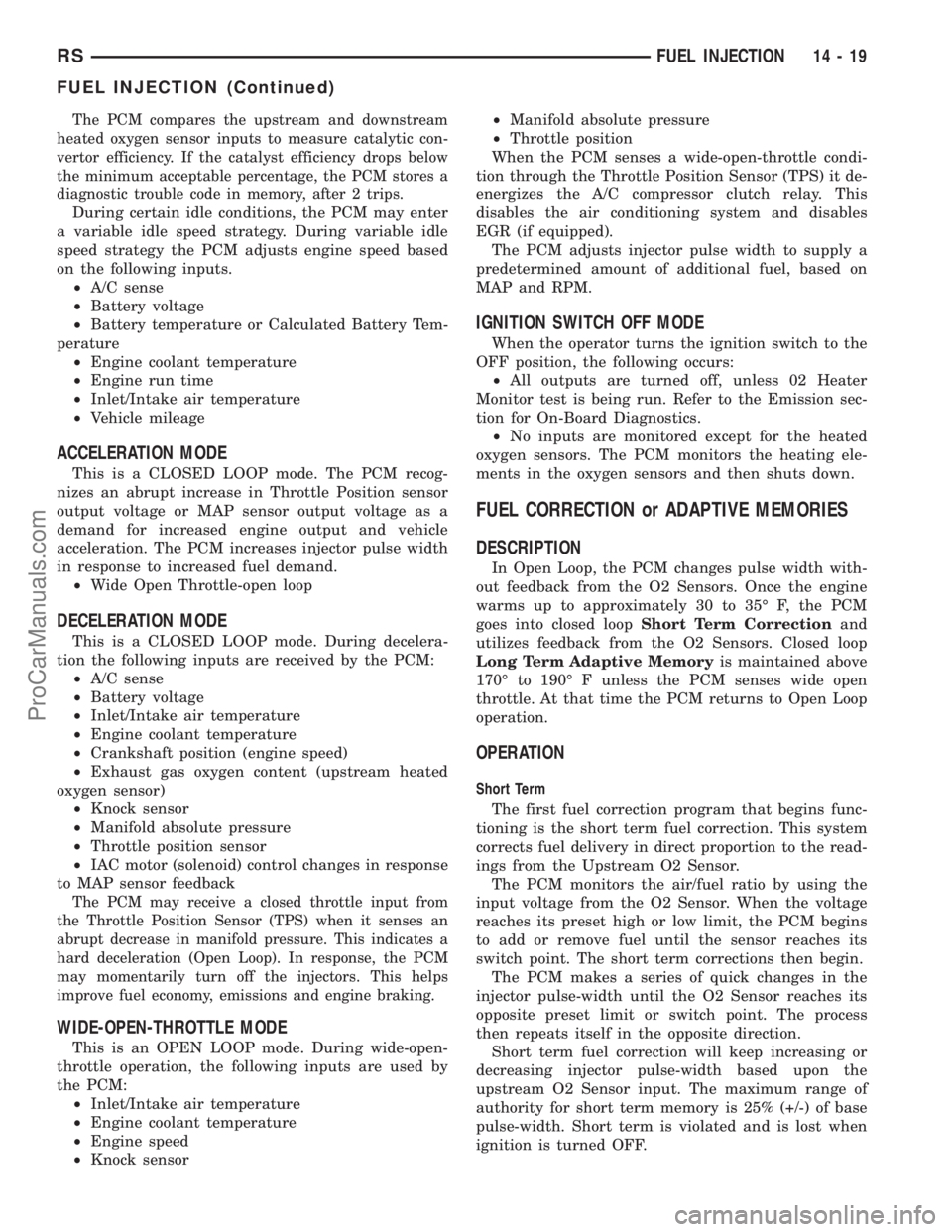

There are 3 sets of slots. Each set contains 4 slots,

for a total of 12 slots (Fig. 7). Basic timing is set by

the position of the last slot in each group. Once the

Powertrain Control Module (PCM) senses the last

slot, it determines crankshaft position (which piston

will next be at TDC) from the camshaft position sen-

sor input. The 4 pulses generated by the crankshaft

position sensor represent the 69É, 49É, 29É, and 9É

BTDC marks. It may take the PCM one engine rev-

olution to determine crankshaft position.

The PCM uses crankshaft position reference to

determine injector sequence, ignition timing and the

presence of misfire. Once the PCM determines crank-

shaft position, it begins energizing the injectors in

sequence.

REMOVAL

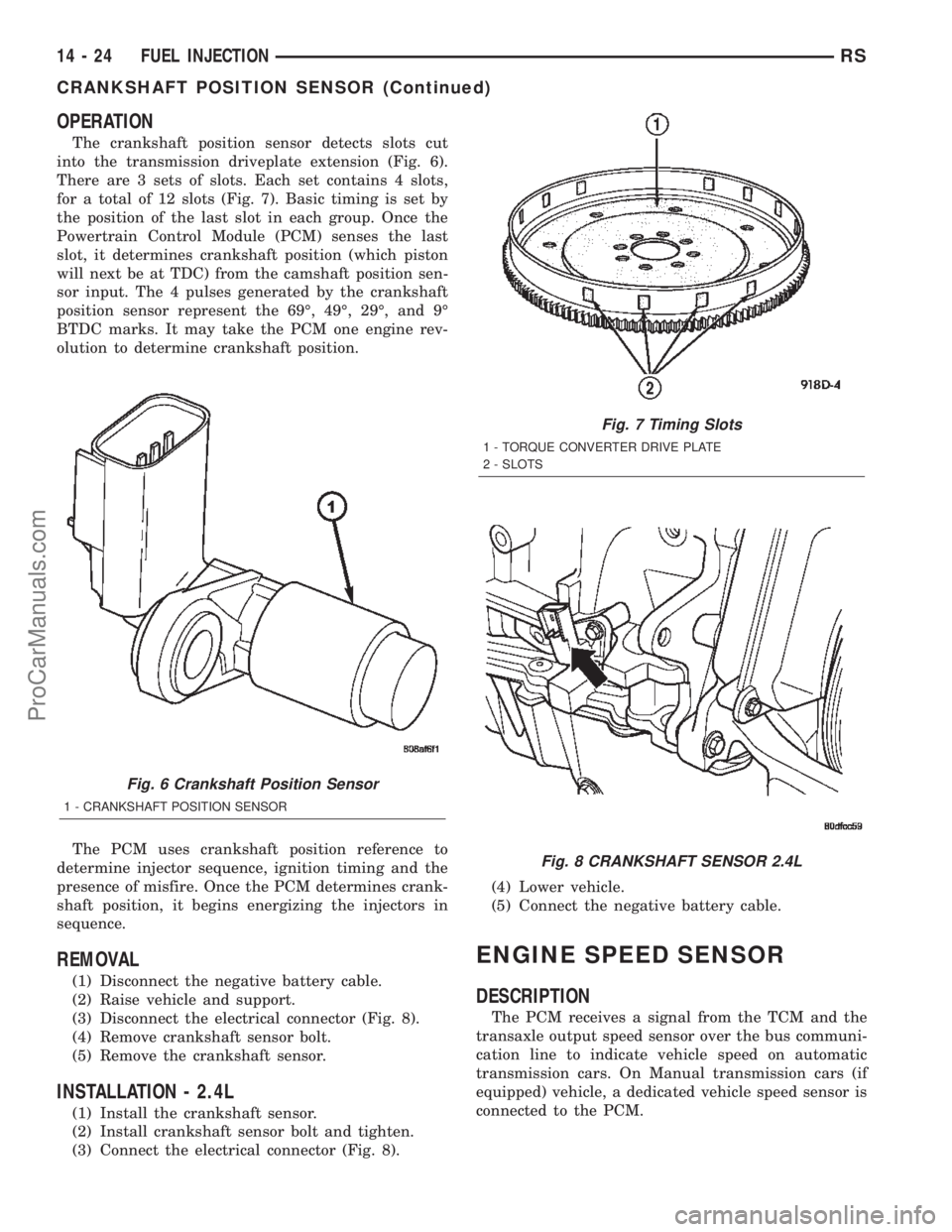

(1) Disconnect the negative battery cable.

(2) Raise vehicle and support.

(3) Disconnect the electrical connector (Fig. 8).

(4) Remove crankshaft sensor bolt.

(5) Remove the crankshaft sensor.

INSTALLATION - 2.4L

(1) Install the crankshaft sensor.

(2) Install crankshaft sensor bolt and tighten.

(3) Connect the electrical connector (Fig. 8).(4) Lower vehicle.

(5) Connect the negative battery cable.

ENGINE SPEED SENSOR

DESCRIPTION

The PCM receives a signal from the TCM and the

transaxle output speed sensor over the bus communi-

cation line to indicate vehicle speed on automatic

transmission cars. On Manual transmission cars (if

equipped) vehicle, a dedicated vehicle speed sensor is

connected to the PCM.

Fig. 6 Crankshaft Position Sensor

1 - CRANKSHAFT POSITION SENSOR

Fig. 7 Timing Slots

1 - TORQUE CONVERTER DRIVE PLATE

2 - SLOTS

Fig. 8 CRANKSHAFT SENSOR 2.4L

14 - 24 FUEL INJECTIONRS

CRANKSHAFT POSITION SENSOR (Continued)

ProCarManuals.com

Page 1478 of 2399

FUEL PUMP RELAY

DESCRIPTION

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

OPERATION

The fuel pump relay supplies battery voltage to the

fuel pump. A buss bar in the Power Distribution Cen-

ter (PDC) supplies voltage to the solenoid side and

contact side of the relay. The fuel pump relay power

circuit contains a fuse between the buss bar in the

PDC and the relay. The fuse is located in the PDC.

Refer to the Wiring Diagrams for circuit information.

The PCM controls the fuel pump relay by switch-

ing the ground path for the solenoid side of the relay

on and off. The PCM turns the ground path off when

the ignition switch is in the Off position. When the

ignition switch is in the On position, the PCM ener-

gizes the fuel pump. If the crankshaft position sensor

does not detect engine rotation, the PCM de-ener-

gizes the relay after approximately one second.

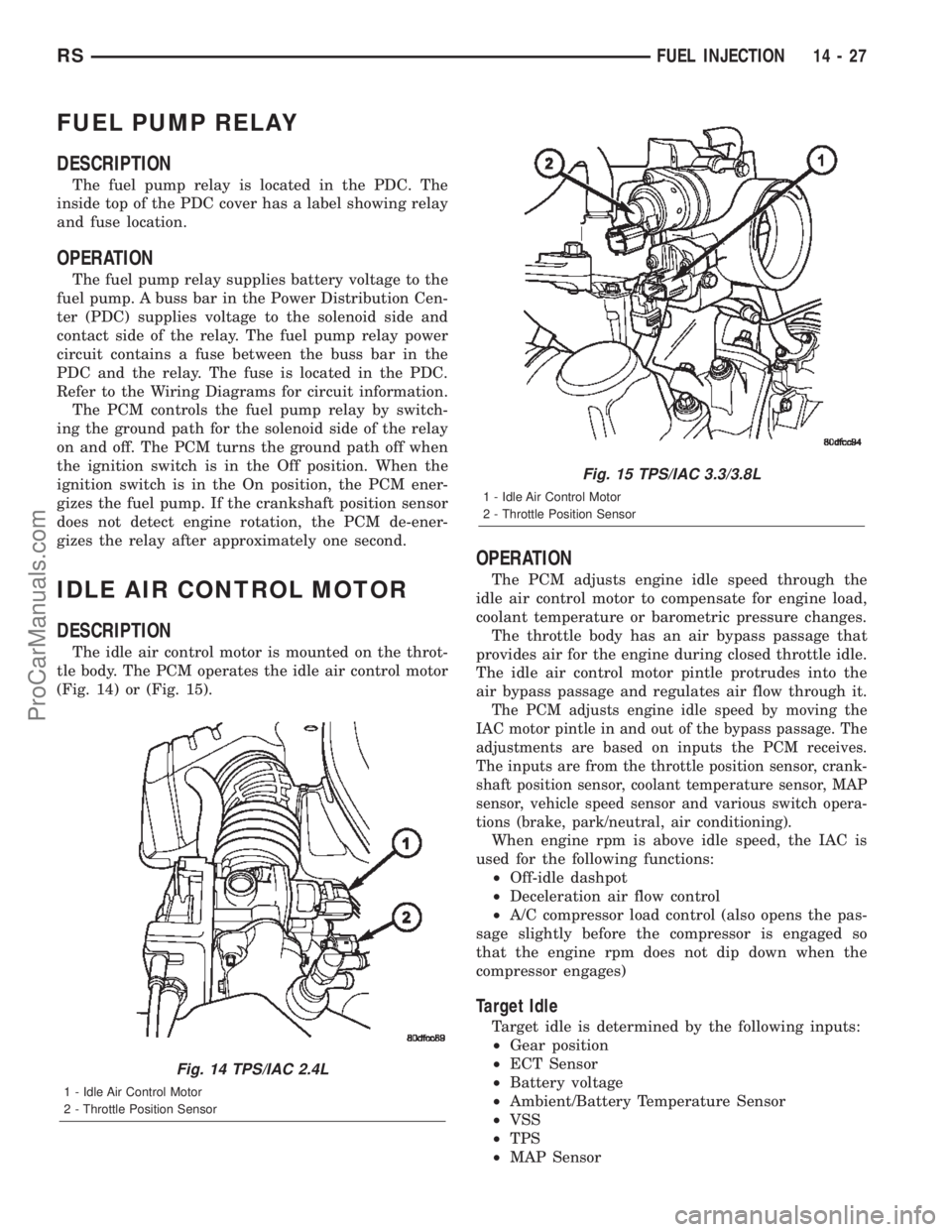

IDLE AIR CONTROL MOTOR

DESCRIPTION

The idle air control motor is mounted on the throt-

tle body. The PCM operates the idle air control motor

(Fig. 14) or (Fig. 15).

OPERATION

The PCM adjusts engine idle speed through the

idle air control motor to compensate for engine load,

coolant temperature or barometric pressure changes.

The throttle body has an air bypass passage that

provides air for the engine during closed throttle idle.

The idle air control motor pintle protrudes into the

air bypass passage and regulates air flow through it.

The PCM adjusts engine idle speed by moving the

IAC motor pintle in and out of the bypass passage. The

adjustments are based on inputs the PCM receives.

The inputs are from the throttle position sensor, crank-

shaft position sensor, coolant temperature sensor, MAP

sensor, vehicle speed sensor and various switch opera-

tions (brake, park/neutral, air conditioning).

When engine rpm is above idle speed, the IAC is

used for the following functions:

²Off-idle dashpot

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

Target Idle

Target idle is determined by the following inputs:

²Gear position

²ECT Sensor

²Battery voltage

²Ambient/Battery Temperature Sensor

²VSS

²TPS

²MAP Sensor

Fig. 14 TPS/IAC 2.4L

1 - Idle Air Control Motor

2 - Throttle Position Sensor

Fig. 15 TPS/IAC 3.3/3.8L

1 - Idle Air Control Motor

2 - Throttle Position Sensor

RSFUEL INJECTION14-27

ProCarManuals.com

Page 1479 of 2399

REMOVAL

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. Never use lubricants on O-rings or

seals, damage may result. If assembly of component

is difficult, use water to aid assembly. Use care when

removing hoses to prevent damage to hose or hose

nipple.

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from idle air con-

trol motor.

(3) Remove idle air control motor mounting screws.

(4) Remove motor from throttle body. Ensure the

O-rings is removed with the motor.

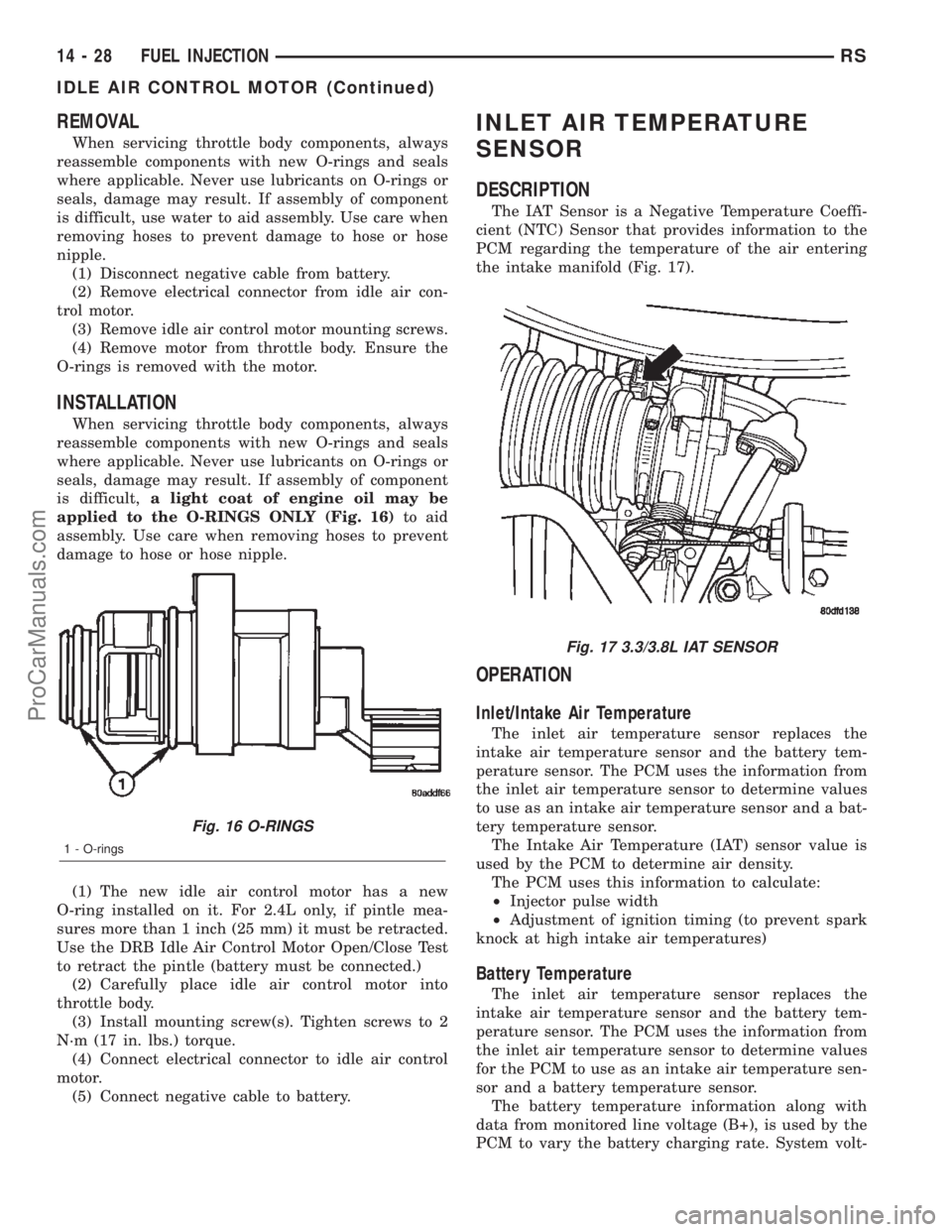

INSTALLATION

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. Never use lubricants on O-rings or

seals, damage may result. If assembly of component

is difficult,a light coat of engine oil may be

applied to the O-RINGS ONLY (Fig. 16)to aid

assembly. Use care when removing hoses to prevent

damage to hose or hose nipple.

(1) The new idle air control motor has a new

O-ring installed on it. For 2.4L only, if pintle mea-

sures more than 1 inch (25 mm) it must be retracted.

Use the DRB Idle Air Control Motor Open/Close Test

to retract the pintle (battery must be connected.)

(2) Carefully place idle air control motor into

throttle body.

(3) Install mounting screw(s). Tighten screws to 2

N´m (17 in. lbs.) torque.

(4) Connect electrical connector to idle air control

motor.

(5) Connect negative cable to battery.

INLET AIR TEMPERATURE

SENSOR

DESCRIPTION

The IAT Sensor is a Negative Temperature Coeffi-

cient (NTC) Sensor that provides information to the

PCM regarding the temperature of the air entering

the intake manifold (Fig. 17).

OPERATION

Inlet/Intake Air Temperature

The inlet air temperature sensor replaces the

intake air temperature sensor and the battery tem-

perature sensor. The PCM uses the information from

the inlet air temperature sensor to determine values

to use as an intake air temperature sensor and a bat-

tery temperature sensor.

The Intake Air Temperature (IAT) sensor value is

used by the PCM to determine air density.

The PCM uses this information to calculate:

²Injector pulse width

²Adjustment of ignition timing (to prevent spark

knock at high intake air temperatures)

Battery Temperature

The inlet air temperature sensor replaces the

intake air temperature sensor and the battery tem-

perature sensor. The PCM uses the information from

the inlet air temperature sensor to determine values

for the PCM to use as an intake air temperature sen-

sor and a battery temperature sensor.

The battery temperature information along with

data from monitored line voltage (B+), is used by the

PCM to vary the battery charging rate. System volt-

Fig. 16 O-RINGS

1 - O-rings

Fig. 17 3.3/3.8L IAT SENSOR

14 - 28 FUEL INJECTIONRS

IDLE AIR CONTROL MOTOR (Continued)

ProCarManuals.com

Page 1486 of 2399

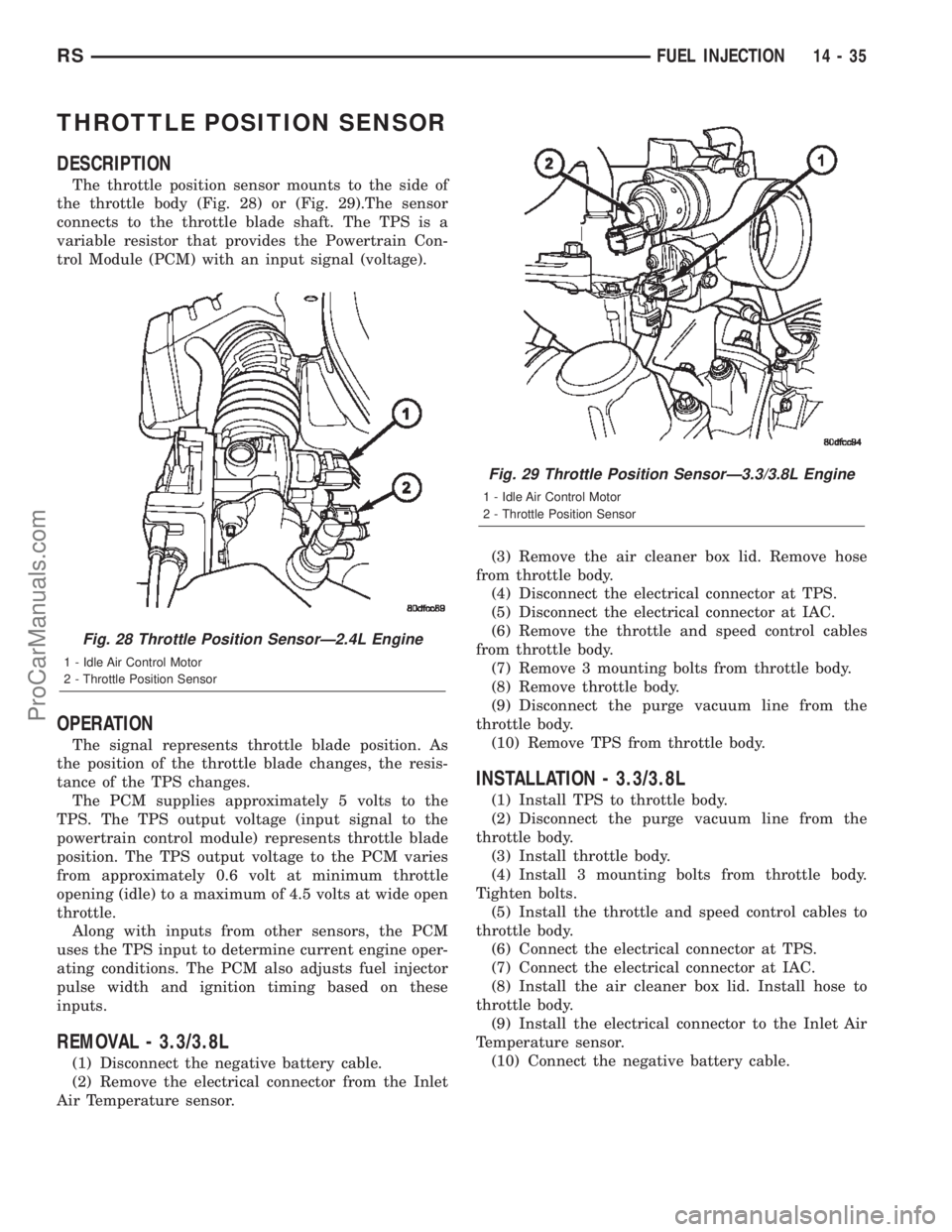

THROTTLE POSITION SENSOR

DESCRIPTION

The throttle position sensor mounts to the side of

the throttle body (Fig. 28) or (Fig. 29).The sensor

connects to the throttle blade shaft. The TPS is a

variable resistor that provides the Powertrain Con-

trol Module (PCM) with an input signal (voltage).

OPERATION

The signal represents throttle blade position. As

the position of the throttle blade changes, the resis-

tance of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

powertrain control module) represents throttle blade

position. The TPS output voltage to the PCM varies

from approximately 0.6 volt at minimum throttle

opening (idle) to a maximum of 4.5 volts at wide open

throttle.

Along with inputs from other sensors, the PCM

uses the TPS input to determine current engine oper-

ating conditions. The PCM also adjusts fuel injector

pulse width and ignition timing based on these

inputs.

REMOVAL - 3.3/3.8L

(1) Disconnect the negative battery cable.

(2) Remove the electrical connector from the Inlet

Air Temperature sensor.(3) Remove the air cleaner box lid. Remove hose

from throttle body.

(4) Disconnect the electrical connector at TPS.

(5) Disconnect the electrical connector at IAC.

(6) Remove the throttle and speed control cables

from throttle body.

(7) Remove 3 mounting bolts from throttle body.

(8) Remove throttle body.

(9) Disconnect the purge vacuum line from the

throttle body.

(10) Remove TPS from throttle body.

INSTALLATION - 3.3/3.8L

(1) Install TPS to throttle body.

(2) Disconnect the purge vacuum line from the

throttle body.

(3) Install throttle body.

(4) Install 3 mounting bolts from throttle body.

Tighten bolts.

(5) Install the throttle and speed control cables to

throttle body.

(6) Connect the electrical connector at TPS.

(7) Connect the electrical connector at IAC.

(8) Install the air cleaner box lid. Install hose to

throttle body.

(9) Install the electrical connector to the Inlet Air

Temperature sensor.

(10) Connect the negative battery cable.

Fig. 28 Throttle Position SensorÐ2.4L Engine

1 - Idle Air Control Motor

2 - Throttle Position Sensor

Fig. 29 Throttle Position SensorÐ3.3/3.8L Engine

1 - Idle Air Control Motor

2 - Throttle Position Sensor

RSFUEL INJECTION14-35

ProCarManuals.com

Page 1489 of 2399

Test all fuel supply lines for restrictions or block-

age. Flush or replace as necessary. Bleed fuel system

of air once a fuel supply line has been replaced. Refer

to Air Bleed Procedure for procedures.

To test for fuel line restrictions, a vacuum restric-

tion test may be performed.

HIGH-PRESSURE LINES

Restricted (kinked or bent) high-pressure lines can

cause starting problems, poor engine performance,

engine mis-fire and white smoke from exhaust.

Examine all high-pressure lines for any damage.

Each radius on each high-pressure line must be

smooth and free of any bends or kinks.

Replace damaged, restricted or leaking high-pres-

sure fuel lines with correct replacement line.

CAUTION: High pressure lines cannot contact each

other or other components. Do not attempt to weld

high-pressure fuel lines or to repair lines that are

damaged. If line is kinked or bent, it must be

replaced. Use only recommended lines when

replacement of high-pressure fuel line is necessary.

STANDARD PROCEDURE

STANDARD PROCEDURES - DRAINING WATER

FROM FUEL FILTER

Refer to Fuel Filter/Water Separator removal/in-

stallation for procedures.

STANDARD PROCEDURE - FUEL SYSTEM AIR

PURGE

(1) Remove engine cover (Refer to 9 - ENGINE

COVER - REMOVAL).

(2) Remove cap from air purge fitting on the fuel

supply line. This fitting is located just behind the

alternator (Fig. 1).

(3) Attach a hose of about 1 or 2 meters to this fit-

ting using an appropriate connector.

(4) Direct the end of the hose into an appropriate

fuel container.

(5) Turn the ignition to the ªONº position,Do not

crank the engine.Keep key on until about 1 liter of

fuel has been pumped into the container.

(6) While keeping end of hose below fuel level in

conatiner, turn the ignition ªOFFº.

(7) Remove hose from air purge fitting on the fuel

supply line and replace cap.

(8) Install engine cover (Refer to 9 - ENGINE

COVER - INSTALLATION).

STANDARD PROCEDURES - CLEANING FUEL

SYSTEM COMPONENTS

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines, fuel rail, and fuel injection

pump. Very tight tolerances are used with these

parts. Dirt contamination could cause rapid part

wear and possible plugging of fuel injector nozzle

tip holes. This in turn could lead to possible engine

misfire. Always wash/clean any fuel system compo-

nent thoroughly before disassembly and then air

dry. Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

Fig. 1 AIR PURGE VALVE

1 - AIR PURGE VALVE CAP

2 - AIR PURGE VALVE

3 - ALTERNATOR

4 - ENGINE FRONT COVER

14a - 2 FUEL SYSTEMRG

FUEL SYSTEM 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 1494 of 2399

CAUTION: The high-pressure fuel lines cannot con-

tact each other or other components. Do not

attempt to weld high-pressure fuel lines or to repair

lines that are damaged. Only use the recommended

lines when replacement of high-pressure fuel line is

necessary.

FUEL TRANSFER PUMP

DESCRIPTION

The fuel transfer pump (fuel lift pump) is located

under the vehicle in front of the rear axle assembly

(Fig. 5). The 12±volt electric vane-type pump is oper-

ated and controlled by the Engine Control Module

(ECM).

OPERATION

The purpose of the fuel transfer pump is to supply

(transfer) a low-pressure fuel source:fromthe fuel

tank,throughthe fuel filter/water separator andto

the fuel injection pump. Here, the low-pressure is

raised to a high-pressure by the fuel injection pump

for operation of the high-pressure fuel injectors.

The fuel transfer pump is controlled by the Engine

Control Module(ECM). The ECM turns the fuel

transfer pump on for 30 seconds when the ignition

ket is turned ªONº.

With the ignition ªONº and fuel tranfer pump run-

ning, the low-pressure fuel pressure should be 13-17

psi.

FUEL INJECTION PUMP

DESCRIPTION

A radial-piston pump is used as the high pressure

pump for fuel pressure generation (Fig. 6).

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL)

(3) Remove air cleaner housing assembly.

(4) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(5) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

Fig. 5 FUEL TRANSFER(LIFT) PUMP LOCATION

1 - LIFT PUMP RETAINING BOLTS

2 - LIFT PUMP

3 - FUEL FILTER/WATER SEPARATOR HOUSING

4 - FUEL HEATER

5 - CHECK BALL

6 - O-RING

7 - FLOW DIVERTER

8 - FUEL FILTER

9 - O-RING

10 - FUEL FILTER BOWL ASSEMBLY

Fig. 6 FUEL INJECTION PUMP

1 - FUEL INJECTION PUMP

2 - INJECTION PUMP PRESSURE SOLENOID

RGFUEL DELIVERY14a-7

FUEL LINES (Continued)

ProCarManuals.com

Page 1497 of 2399

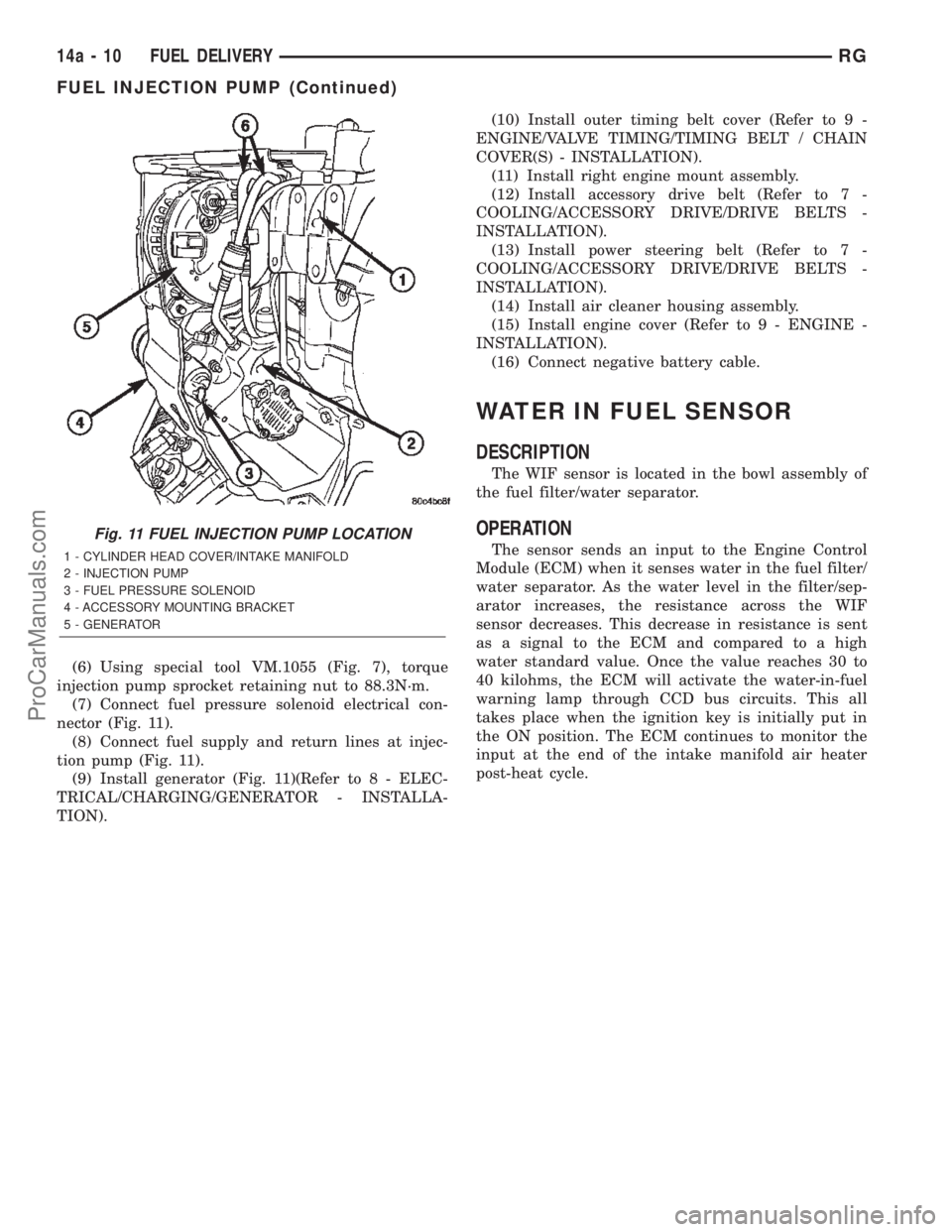

(6) Using special tool VM.1055 (Fig. 7), torque

injection pump sprocket retaining nut to 88.3N´m.

(7) Connect fuel pressure solenoid electrical con-

nector (Fig. 11).

(8) Connect fuel supply and return lines at injec-

tion pump (Fig. 11).

(9) Install generator (Fig. 11)(Refer to 8 - ELEC-

TRICAL/CHARGING/GENERATOR - INSTALLA-

TION).(10) Install outer timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(11) Install right engine mount assembly.

(12) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Install power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(14) Install air cleaner housing assembly.

(15) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(16) Connect negative battery cable.

WATER IN FUEL SENSOR

DESCRIPTION

The WIF sensor is located in the bowl assembly of

the fuel filter/water separator.

OPERATION

The sensor sends an input to the Engine Control

Module (ECM) when it senses water in the fuel filter/

water separator. As the water level in the filter/sep-

arator increases, the resistance across the WIF

sensor decreases. This decrease in resistance is sent

as a signal to the ECM and compared to a high

water standard value. Once the value reaches 30 to

40 kilohms, the ECM will activate the water-in-fuel

warning lamp through CCD bus circuits. This all

takes place when the ignition key is initially put in

the ON position. The ECM continues to monitor the

input at the end of the intake manifold air heater

post-heat cycle.

Fig. 11 FUEL INJECTION PUMP LOCATION

1 - CYLINDER HEAD COVER/INTAKE MANIFOLD

2 - INJECTION PUMP

3 - FUEL PRESSURE SOLENOID

4 - ACCESSORY MOUNTING BRACKET

5 - GENERATOR

14a - 10 FUEL DELIVERYRG

FUEL INJECTION PUMP (Continued)

ProCarManuals.com