CHRYSLER VOYAGER 2002 Service Manual

Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 2091 of 2399

(4) Remove A-pillar trim panels.

(5) Disconnect wire connectors to windshield

defroster grid.

(6) Place protective covers over instrument panel

and hood.

(7) Remove windshield molding. Using pliers, pull

outward on molding at the bottom of A-pillars.

(8) Using a sharp cold knife, cut urethane adhe-

sive holding the windshield to the A-pillars, roof

header and cowl pinch weld fences (Fig. 1). A power

cutting device can be used if available.

(9) Remove windshield from vehicle.

WINDSHIELD REMOVAL ± INTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove instrument panel top cover. Refer to

Group 8E, Instrument Panel and Systems.

(3) Remove A-pillar trim covers.

(4) Disconnect wire connectors to windshield

defroster grid.

(5) Place protective covers over instrument panel

and hood.

(6) Using a reciprocating or oscillating power

knife, cut urethane adhesive holding the windshield

to the A-pillars, roof header and cowl pinch weld

fences. Refer to instructions provided with the equip-

ment being used.

(7) Remove windshield from vehicle.

INSTALLATION

The urethane adhesive holding the windshield to

the opening pinch weld (fence) can be cut using a

sharp cold knife from the exterior of the vehicle.

Using the cold knife method is effective if the wind-

shield is already broken. If the glass must be sal-

vaged, cutting the urethane adhesive from the

interior of the vehicle using a reciprocating or oscil-

lating power knife is recommended.

CAUTION: Open the left front door glass before

installing windshield to avoid pressurizing the pas-senger compartment. If a door is slammed before

urethane bonding is cured, water leaks can result.

Allow the urethane at least 24 hours to cure before

returning the vehicle to use.

To avoid stressing the replacement windshield, the

urethane bonding material on the windshield fence

should be smooth and consistent to the shape of

the replacement windshield . The support spacers

should be cleaned and properly installed on weld

studs or repair screws at bottom of windshield

opening.

(1) Place replacement windshield into windshield

opening and position glass in the center of the open-

ing against the compression spacers.

(2) Verify the glass lays evenly against the pinch

weld fence at the sides, top and bottom of the

replacement windshield. If not, the pinch weld fence

must be formed to the shape of the new glass.

(3) Remove replacement windshield from wind-

shield opening.

(4) Position the windshield inside up on a suitable

work surface with two padded, wood 10 cm by 10 cm

by 50 cm (4 in. by 4 in. by 20 in.) blocks, placed par-

allel 75 cm (2.5 ft.) apart (Fig. 2).

WARNING: DO NOT USE SOLVENT BASED GLASS

CLEANER TO CLEAN WINDSHIELD BEFORE

APPLYING GLASS PREP AND PRIMER. POOR

ADHESION CAN RESULT.

(5) Clean inside of windshield with ammonia based

glass cleaner and lint-free cloth.

(6) Install molding to perimeter of windshield.

(7) Apply Glass Prep adhesion promoter 25 mm (1

in.) wide around perimeter of windshield and wipe

with clean/dry lint-free cloth until no streaks are vis-

ible.

(8) Apply Glass Primer 25 mm (1 in.) wide around

perimeter of windshield. Allow at least three minutes

drying time.

(9) Using a razor knife, remove as much original

urethane as possible. Do not damage paint on wind-

shield fence.

(10) Apply pinch weld primer 19 mm (0.75 in.)

wide around the windshield fence. Allow at least

three minutes drying time.

(11) If a low viscosity urethane adhesive is used,

install compression spacers on the fence around the

windshield opening (Fig. 3).

(12) Apply a 10 mm (0.4 in.) bead of urethane on

center line of windshield fence.

(13) With the aid of a helper, position the wind-

shield over the windshield opening.

(14) Slowly lower windshield glass to windshield

opening fence. Guide the molding into proper position

as necessary. Push windshield inward until molding

is flush to roof line and A-pillars (Fig. 3).

Fig. 1 CUT URETHANE AROUND WINDSHIELD

1 - COLD KNIFE

2 - WINDSHIELD

23 - 108 STATIONARY GLASSRS

WINDSHIELD (Continued)

ProCarManuals.com

Page 2092 of 2399

(15) Clean access urethane from exterior with

MopartSuper Kleen or equivalent.

(16) Apply 150 mm (6 in.) lengths of 50 mm (2 in.)

masking tape spaced 250 mm (10 in.) apart to hold

molding in place until urethane cures.

(17) Engage wire connectors to windshield

defroster grid.

(18) Install A-pillar trim panels.

(19) Install cowl cover and wipers.

(20) Install inside rear view mirror.

(21) After urethane has cured, remove tape strips

and water test windshield to verify repair.SLIDING DOOR GLASS

REMOVAL

The temperature of the vehicle should be at least

21É C (70É F) before removing the stationary quarter/

sliding door glass. Butyl sealer becomes more pliable

at high temperatures.

(1) Remove interior trim as necessary to gain

access attaching locations on back of glass.

(2) Remove nuts holding stationary glass to fence.

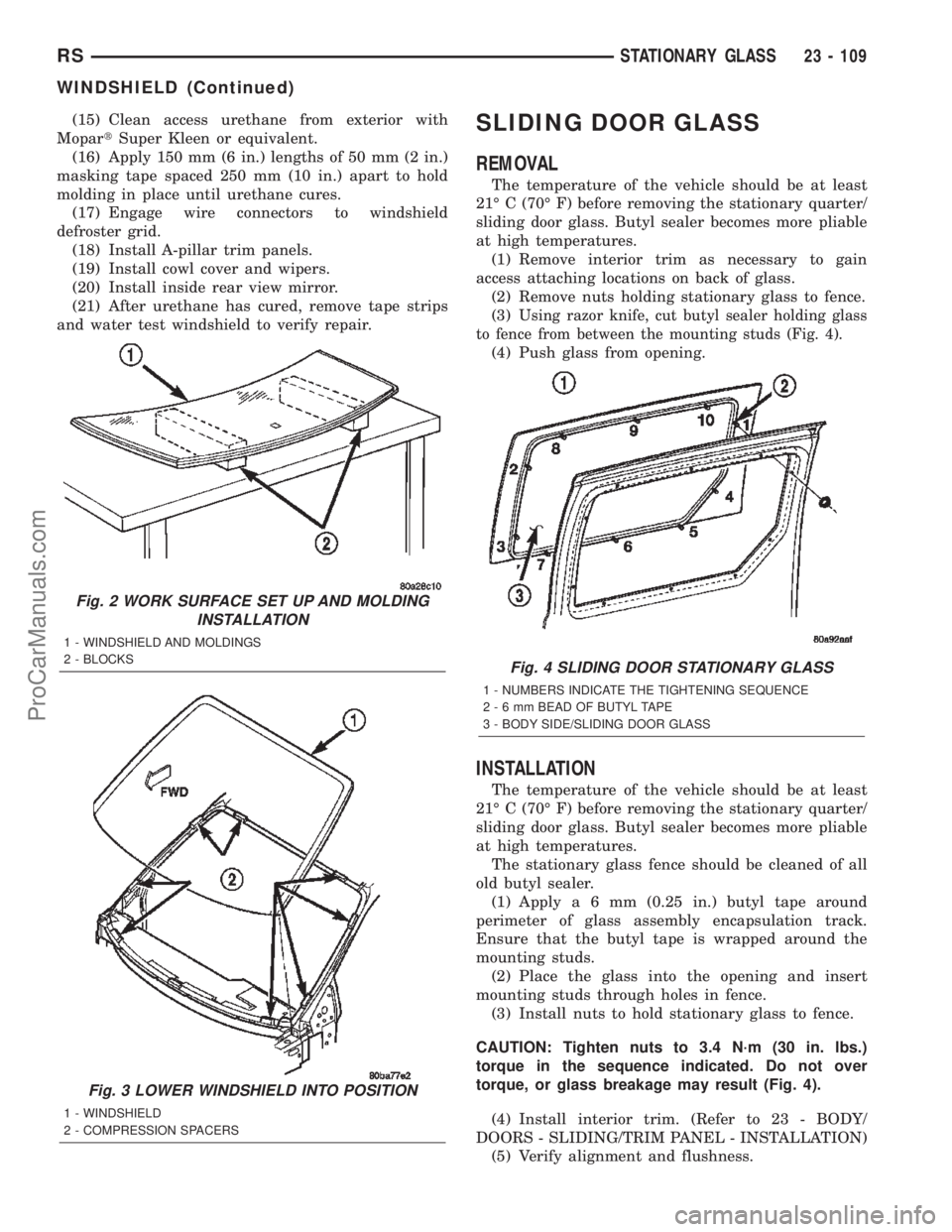

(3)

Using razor knife, cut butyl sealer holding glass

to fence from between the mounting studs (Fig. 4).

(4) Push glass from opening.

INSTALLATION

The temperature of the vehicle should be at least

21É C (70É F) before removing the stationary quarter/

sliding door glass. Butyl sealer becomes more pliable

at high temperatures.

The stationary glass fence should be cleaned of all

old butyl sealer.

(1) Applya6mm(0.25 in.) butyl tape around

perimeter of glass assembly encapsulation track.

Ensure that the butyl tape is wrapped around the

mounting studs.

(2) Place the glass into the opening and insert

mounting studs through holes in fence.

(3) Install nuts to hold stationary glass to fence.

CAUTION: Tighten nuts to 3.4 N´m (30 in. lbs.)

torque in the sequence indicated. Do not over

torque, or glass breakage may result (Fig. 4).

(4) Install interior trim. (Refer to 23 - BODY/

DOORS - SLIDING/TRIM PANEL - INSTALLATION)

(5) Verify alignment and flushness.

Fig. 2 WORK SURFACE SET UP AND MOLDING

INSTALLATION

1 - WINDSHIELD AND MOLDINGS

2 - BLOCKS

Fig. 3 LOWER WINDSHIELD INTO POSITION

1 - WINDSHIELD

2 - COMPRESSION SPACERS

Fig. 4 SLIDING DOOR STATIONARY GLASS

1 - NUMBERS INDICATE THE TIGHTENING SEQUENCE

2-6mmBEAD OF BUTYL TAPE

3 - BODY SIDE/SLIDING DOOR GLASS

RSSTATIONARY GLASS23 - 109

WINDSHIELD (Continued)

ProCarManuals.com

Page 2093 of 2399

QUARTER WINDOW

REMOVAL

(1) Remove C-pillar trim.

(2) Open quarter glass to vent position.

(3) Disengage quarter window retainer from vent

motor arm.

(4) Remove nuts attaching quarter glass to C-pillar

(Fig. 5).

(5) Use magnetic socket to prevent dropping into

the pillar.

(6) Remove quarter glass from vehicle.

INSTALLATION

(1) Place quarter glass in position on vehicle.

(2) Install nuts attaching quarter glass to C-pillar.

(3) Engage quarter window retainer to vent motor

arm.

(4) Install screw attaching quarter window

retainer to vent motor arm.

(5) Close quarter glass.

(6) Install C-pillar trim.

REAR DOOR GLASS

REMOVAL

Refer to the Safety Precautions in this section for

description of tools and adhesive systems that are

recommended for use in this procedure.

REAR WINDOW REMOVAL ± EXTERIOR METHOD

(1) Remove rear window wiper arm, if equipped.

(2) Remove screws attaching moldings to liftgate

at the sides of the rear window (Fig. 6).(3) Using pliers, pull outward on molding at the

top and bottom of liftgate.

(4) Using a sharp cold knife, cut urethane adhe-

sive attaching the rear window to the liftgate. A

power cutting device can be used if available (Fig. 1).

(5) Remove rear window from vehicle.

REAR WINDOW REMOVAL ± INTERIOR METHOD

(1) Remove rear window wiper arm, if equipped.

(2) Remove screws attaching moldings to liftgate

at the sides of the rear window (Fig. 6).

(3) Remove liftgate inside lamps and trim covers.

(4) Remove center high mounted stop lamp.

(5) Using a reciprocating or oscillating power

knife, cut urethane adhesive holding the rear window

to the liftgate. Refer to instructions provided with

the equipment being used.

(6) Remove rear window from vehicle.

INSTALLATION

Refer to the Safety Precautions in this section for

description of tools and adhesive systems that are

recommended for use in this procedure.

CAUTION: Open the left front door glass before

installing rear window to avoid pressurizing the

passenger compartment. If a door is slammed

before urethane bonding is cured, water leaks can

result.

Allow the urethane at least 24 hours to cure before

returning the vehicle to use.

To avoid stressing the replacement rear window,

the urethane bonding material on the rear window

fence should be smooth and consistent to the

shape of the replacement glass.

Fig. 5 QUARTER GLASS

1 - VENT CONTROL

2 - QUARTER GLASS

3 - CLIP

Fig. 6 REAR WINDOW SIDE MOLDINGS

1 - COMPRESSION SPACERS

2 - REAR WINDOW WITH MOLDING

3 - LIFT GATE

23 - 110 STATIONARY GLASSRS

ProCarManuals.com

Page 2094 of 2399

(1) Place replacement glass into rear window open-

ing.

(2) Verify the glass lays evenly against the pinch

weld fence at the sides, top and bottom of the

replacement rear window. If not, the fence must be

formed to the shape of the new glass.

(3) Using a grease pencil, mark the glass and lift-

gate in several locations to aid installation.

(4) Remove replacement glass from liftgate open-

ing.

(5) Position the rear window inside up on a suit-

able work surface with two padded, wood 10 cm by

10 cm by 50 cm (4 in. by 4 in. by 20 in.) blocks,

placed parallel 75 cm (2.5 ft.) apart (Fig. 2).

WARNING: DO NOT USE SOLVENT BASED GLASS

CLEANER TO CLEAN REAR WINDOW BEFORE

APPLYING GLASS PREP AND PRIMER. POOR

ADHESION CAN RESULT.

(6) Clean inside of rear window with ammonia

based glass cleaner and lint-free cloth.

(7) Apply molding to top and bottom of rear win-

dow.

(8) Apply Glass Prep adhesion promoter 25 mm (1

in.) wide around perimeter of rear window and wipe

with clean/dry lint-free cloth until no streaks are vis-

ible.

(9) Apply Glass Primer 25 mm (1 in.) wide around

perimeter of rear window. Allow at least three min-

utes drying time.

(10) Apply Pinch weld Primer 19 mm (0.75 in.)

wide around the rear window fence. Allow at least

three minutes drying time.

(11) If a low viscosity urethane adhesive is used,

install compression spacers on the fence around the

rear window opening (Fig. 7).(12) Apply a 10 mm (0.4 in.) bead of urethane

along center line of rear window fence.

(13) With the aid of a helper, position the rear

window over the rear window opening and align the

reference marks.

(14) Slowly lower the glass to rear window opening

fence. Guide the molding into proper position as nec-

essary. Push glass inward until molding is flush to

liftgate surface (Fig. 7).

(15) Clean excess urethane from exterior with

MopartSuper Kleen, or equivalent.

(16) Apply 150 mm (6 in.) lengths of 50 mm (2 in.)

masking tape spaced 250 mm (10 in.) apart to hold

molding in place until urethane cures.

(17) Install rear window side moldings and wiper

arm (Fig. 6).

(18) Install interior trim.

(19) After urethane has cured, remove tape strips

and water test rear window to verify repair.

Fig. 7 LOWER REAR WINDOW INTO POSITION

1 - REAR WINDOW WITH MOLDING

2 - LIFTGATE

RSSTATIONARY GLASS23 - 111

REAR DOOR GLASS (Continued)

ProCarManuals.com

Page 2095 of 2399

WEATHERSTRIP/SEALS

TABLE OF CONTENTS

page page

FRONT DOOR GLASS RUN WEATHERSTRIP

REMOVAL............................112

INSTALLATION........................112

FRONT DOOR OUTER BELT MOLDING

REMOVAL............................113

INSTALLATION........................113

FRONT DOOR WEATHERSTRIP

REMOVAL............................113INSTALLATION........................113

SLIDING DOOR WEATHERSTRIP

REMOVAL............................114

INSTALLATION........................114

FRONT DOOR INNER BELT MOLDING

REMOVAL............................114

INSTALLATION........................114

FRONT DOOR GLASS RUN

WEATHERSTRIP

REMOVAL

(1) Remove door frame closeout moldings.

(2) Pull weatherstrip from glass run channel at

rear of door frame, working from the bottom to the

top.

(3) Disengage clip attaching weatherstrip to door

frame.

(4) Pull weatherstrip from lip along top of door

frame (Fig. 1).

(5) Remove door trim panel.

(6) Remove door speaker, if equipped.

(7) Remove watershed as necessary to gain access

to screw attaching front lower corner of glass run

weatherstrip to inner door panel.

(8) Remove screw attaching glass run weatherstrip

to inner door panel.

(9) Remove inner belt weatherstrip.

(10) Pull weatherstrip from front glass run chan-

nel.

(11) Remove glass run weatherstrip from vehicle.

INSTALLATION

(1) Position glass run weatherstrip on vehicle (Fig.

1).

(2) Push weatherstrip into front glass run channel.

(3) Install screw attaching glass run weatherstrip

to inner door panel.

(4) Install inner belt weatherstrip.

(5) Install watershed.

(6) Push weatherstrip groove onto lip along top of

door frame.

(7) Engage clip into slot in door frame.

(8) Push weatherstrip into channel at rear of door

frame, working from the top to bottom.

(9) Install door frame closeout moldings.

(10) Install door speaker, if equipped.

(11) Install door trim panel.

23 - 112 WEATHERSTRIP/SEALSRS

ProCarManuals.com

Page 2096 of 2399

FRONT DOOR OUTER BELT

MOLDING

REMOVAL

(1) Remove the side view mirror. (Refer to 23 -

BODY/EXTERIOR/SIDE VIEW MIRROR -

REMOVAL)

(2) Remove door trim panel.

(3) Roll door glass down.

(4) Using a hook tool, disengage interlocking lip at

the base of the inward edge of the belt molding (Fig.

1).

(5) Remove belt molding from door.

INSTALLATION

(1) Place belt molding in position on door (Fig. 1).

(2) Engage interlocking lip at the base of the

inward edge of the belt molding on door panel.

(3) Install door trim panel.

FRONT DOOR WEATHERSTRIP

REMOVAL

(1) Open front door.

(2) Using fork tool (C-4829), remove push pin fas-

teners attaching front door weatherstrip to end

frames and bottom of door (Fig. 2).

(3) Pull weatherstrip from retaining channel

around window frame.

(4) Remove weatherstrip from vehicle.

INSTALLATION

(1) Position weatherstrip on door.

(2) Install push pin fasteners attaching front door

weatherstrip to end frames and bottom of door (Fig.

2).

(3) Install weatherstrip into retaining channel

around window frame.

(4) Close front door.

Fig. 1 FRONT DOOR WEATHERSTRIP

1 - DOOR GLASS RUN WEATHERSTRIP

2 - FRONT INNER DOOR

3 - DOOR BELT OUTER WEATHERSTRIP4 - DOOR MOUNTED WEATHERSTRIP

5 - DOOR OUTER BELT WEATHERSTRIP

RSWEATHERSTRIP/SEALS23 - 113

FRONT DOOR GLASS RUN WEATHERSTRIP (Continued)

ProCarManuals.com

Page 2097 of 2399

SLIDING DOOR

WEATHERSTRIP

REMOVAL

(1) Open sliding door.

(2) Remove door opening sill plate.

(3) Loosen B-pillar trim covers.

(4) Loosen quarter panel trim panels.

(5) From splice at the bottom center of door open-

ing, pull weatherstrip from pinch flange around door

opening.

INSTALLATION

(1) Place splice at the bottom center of door open-

ing, pushing weatherstrip onto pinch flange around

door opening.

(2) Tighten quarter panel trim panels.

(3) Tighten B-pillar trim covers.

(4) Install door opening sill plate.

(5) Close sliding and check alignment.

FRONT DOOR INNER BELT

MOLDING

REMOVAL

(1) Remove door trim panel.

(2) Peel upper corner seals away form inner belt

molding to clear removal path.

(3) Pull inner belt molding upward to disengage

retaining channel in bottom of molding from door

panel flange (Fig. 1).

(4) Remove inner belt molding from vehicle.

INSTALLATION

(1) Place inner belt molding in position on door

(Fig. 1).

(2) Push inner belt molding downward to engage

retaining channel onto door panel flange.

(3) Install upper corner seals in proper location.

(4) Install door trim panel.

Fig. 2 Front Door Weatherstrip

1 - RETAINING CHANNEL

2 - PUSH-IN FASTENER

3 - WEATHERSTRIP

4 - FRONT DOOR

23 - 114 WEATHERSTRIP/SEALSRS

FRONT DOOR WEATHERSTRIP (Continued)

ProCarManuals.com

Page 2098 of 2399

BODY STRUCTURE

TABLE OF CONTENTS

page page

GAP AND FLUSH

SPECIFICATIONS

GAP AND FLUSH MEASUREMENTS......115

OPENING DIMENSIONS

SPECIFICATIONS

BODY OPENING DIMENSIONS..........118

SEALER LOCATIONS

SPECIFICATIONS

BODY SEALING LOCATIONS...........121STUCTURAL ADHESIVE LOCATIONS

SPECIFICATIONS

STRUCTURAL ADHESIVE LOCATIONS....147

WELD LOCATIONS

SPECIFICATIONS

WELD LOCATIONS...................156

GAP AND FLUSH

SPECIFICATIONS

GAP AND FLUSH MEASUREMENTS

INDEX

DESCRIPTION FIGURE

GAP & FLUSH MEASUREMENTS 1

RSBODY STRUCTURE23 - 115

ProCarManuals.com

Page 2099 of 2399

Fig. 1 GAP & FLUSH MEASUREMENTS

23 - 116 BODY STRUCTURERS

GAP AND FLUSH (Continued)

ProCarManuals.com

Page 2100 of 2399

SPECIFICATIONS

ITEM LOCATION GAP FLUSH

A HOOD TO FASCIA (VOYAGER ONLY)

8.0 2.0

PARALLEL WITHIN 2.0 RIGHT TO

LEFT2.5 OVER FLUSH TO HOOD

1.5 CONSISTENT WITHIN 2.0

B HEADLAMP MODULE TO

HOOD8.0 2.0

PARALLEL WITHIN 2.0 RIGHT TO

LEFT

C HOOD TO FENDER (FOR &

AFT)0.0 1.5

LEFT TO RIGHT WITHIN 1.5

D HOOD TO FENDER 4.0 1.5

PARALLEL WITHIN 2.5 1.5 LEFT

TO RIGHTUNDER FLUSH

2.0

E FENDER TO DOOR 5.0 1.5

PARALLEL WITHIN 2.0UNDER FLUSH 0.5 1.5

CONSISTENT WITHIN 2.0

F FRONT DOOR TO9A9PILLAR

COVERUNDER FLUSH 0.5 2.0

G9A9PILLAR COVER TO

SLIDING DOOR5.0 PARALLEL WITHIN 1.0 1.0 UNDER FLUSH

CONSISTENT WITHIN 3.0

H FRONT DOOR APPLIQUE TO

SLIDING DOOR GLASS5.0 2.0

PARALLEL WITHIN 2.01.0 UNDER FLUSH 2.0

CONSISTENT WITHIN 3.0

I FRONT DOOR TO SLIDING

DOOR5.0 2.0

PARALLEL WITHIN 2.0 2.0 CONSISTENT WITHIN

2.0

J SLIDING DOOR TO REAR

APERTURE GLASS5.0 2.0

PARALLEL WITHIN 1.5 3.0 CONSISTENT WITHIN

3.0

K SLIDING DOOR TO REAR

APERTURE5.0 1.5

PARALLEL WITHIN 2.0 1.5 CONSISTENT WITHIN

1.5

L TAIL LAMP TO BODY SIDE

APERTURE1.0 1.0

PARALLEL WITHIN 1.5OVER FLUSH

M TAIL LAMP TO LIFTGATE 4.0 2.0 OVER FLUSH

N LIFTGATE TO BODY SIDE

APERTURE4.0 1.5 UNDER FLUSH 1.0 2.5

CONSISTENT WITHIN 2.0

O LIFTGATE TO ROOF 8.0 2.0 1.5

P LIFTGATE TO FASCIA 8.0 2.5

PARALLEL WITHIN 3.0

Q LIFTGATE TO REAR FASCIA UNDER FLUSH TO 1.0

MAXIMUM OVER FLUSH

R FUEL FILLER DOOR TO BODY

SIDE APERTUREUNDER FLUSH 0.5 1.0

NOTE: All measurements are in mm.

RSBODY STRUCTURE23 - 117

GAP AND FLUSH (Continued)

ProCarManuals.com