electr CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 2365 of 2399

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times, also

during diagnostic.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

DESCRIPTION - MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the a DRBIIItscan tool.

The following is a list of the system monitors:

²EGR Monitor (if equipped)²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Evaporative System Leak Detection Monitor (if

equipped)

Following is a description of each system monitor,

and its DTC.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

OXYGEN SENSOR (O2S) MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperatures of 300É to 350ÉC (572É to 662ÉF),

the sensor generates a voltage that is inversely pro-

portional to the amount of oxygen in the exhaust.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. The PCM is

programmed to maintain the optimum air/fuel ratio.

At this mixture ratio, the catalyst works best to

remove hydrocarbons (HC), carbon monoxide (CO)

and nitrous oxide (NOx) from the exhaust.

The O2S is also the main sensing element for the

EGR (if equipped), Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate

²Reduced output voltage

²Dynamic shift

²Shorted or open circuits

Response rate is the time required for the sensor to

switch from lean to rich once it is exposed to a richer

than optimum A/F mixture or vice versa. As the sen-

sor starts malfunctioning, it could take longer to

detect the changes in the oxygen content of the

exhaust gas.

The output voltage of the O2S ranges from 0 to 1

volt. A good sensor can easily generate any output

voltage in this range as it is exposed to different con-

centrations of oxygen. To detect a shift in the A/F

mixture (lean or rich), the output voltage has to

change beyond a threshold value. A malfunctioning

sensor could have difficulty changing beyond the

threshold value.

OXYGEN SENSOR HEATER MONITOR

If there is an oxygen sensor (O2S) DTC as well as

a O2S heater DTC, the O2S fault MUST be repaired

first. After the O2S fault is repaired, verify that the

heater circuit is operating correctly.

25 - 6 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)

ProCarManuals.com

Page 2369 of 2399

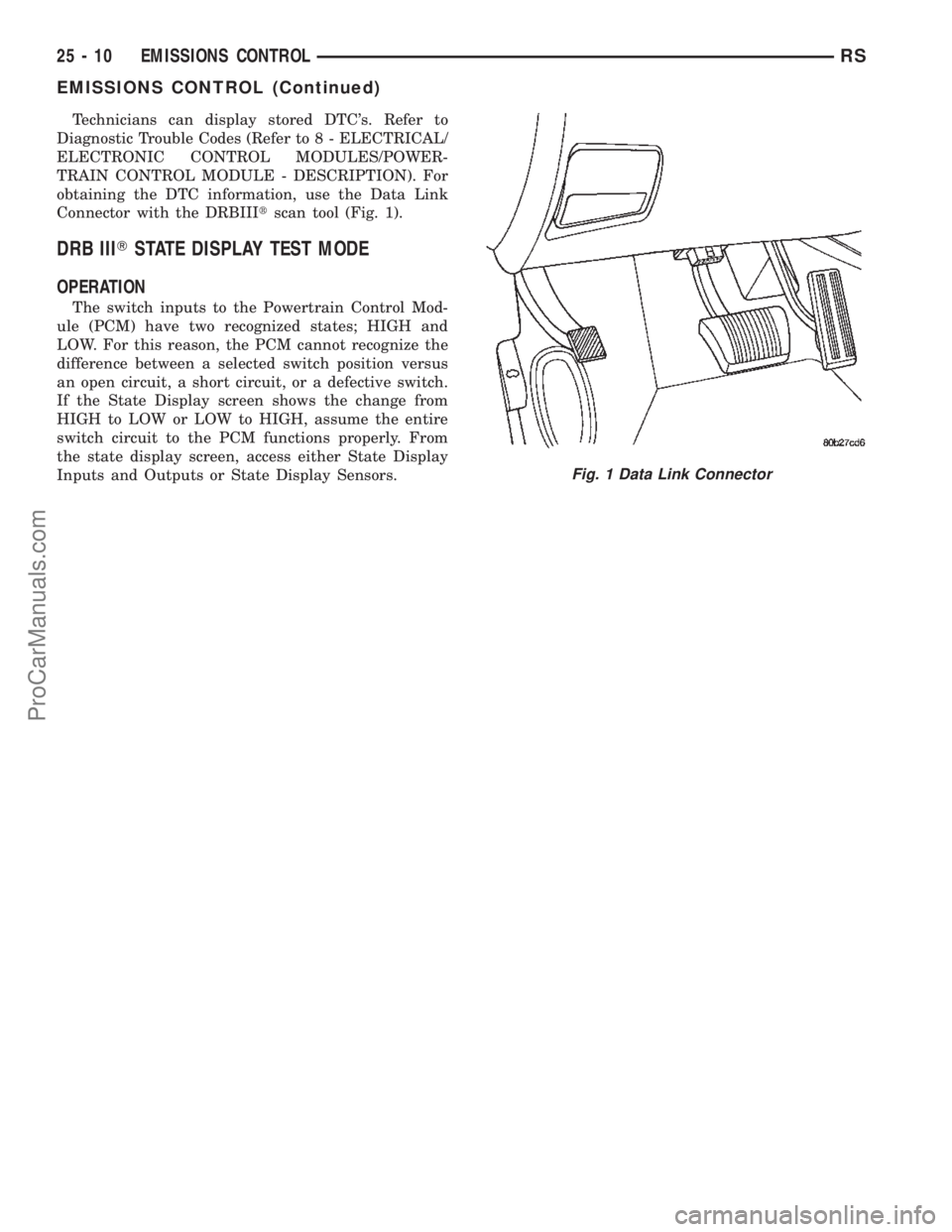

Technicians can display stored DTC's. Refer to

Diagnostic Trouble Codes (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/POWER-

TRAIN CONTROL MODULE - DESCRIPTION). For

obtaining the DTC information, use the Data Link

Connector with the DRBIIItscan tool (Fig. 1).

DRB IIITSTATE DISPLAY TEST MODE

OPERATION

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

Fig. 1 Data Link Connector

25 - 10 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)

ProCarManuals.com

Page 2372 of 2399

EVAP/PURGE SOLENOID

DESCRIPTION

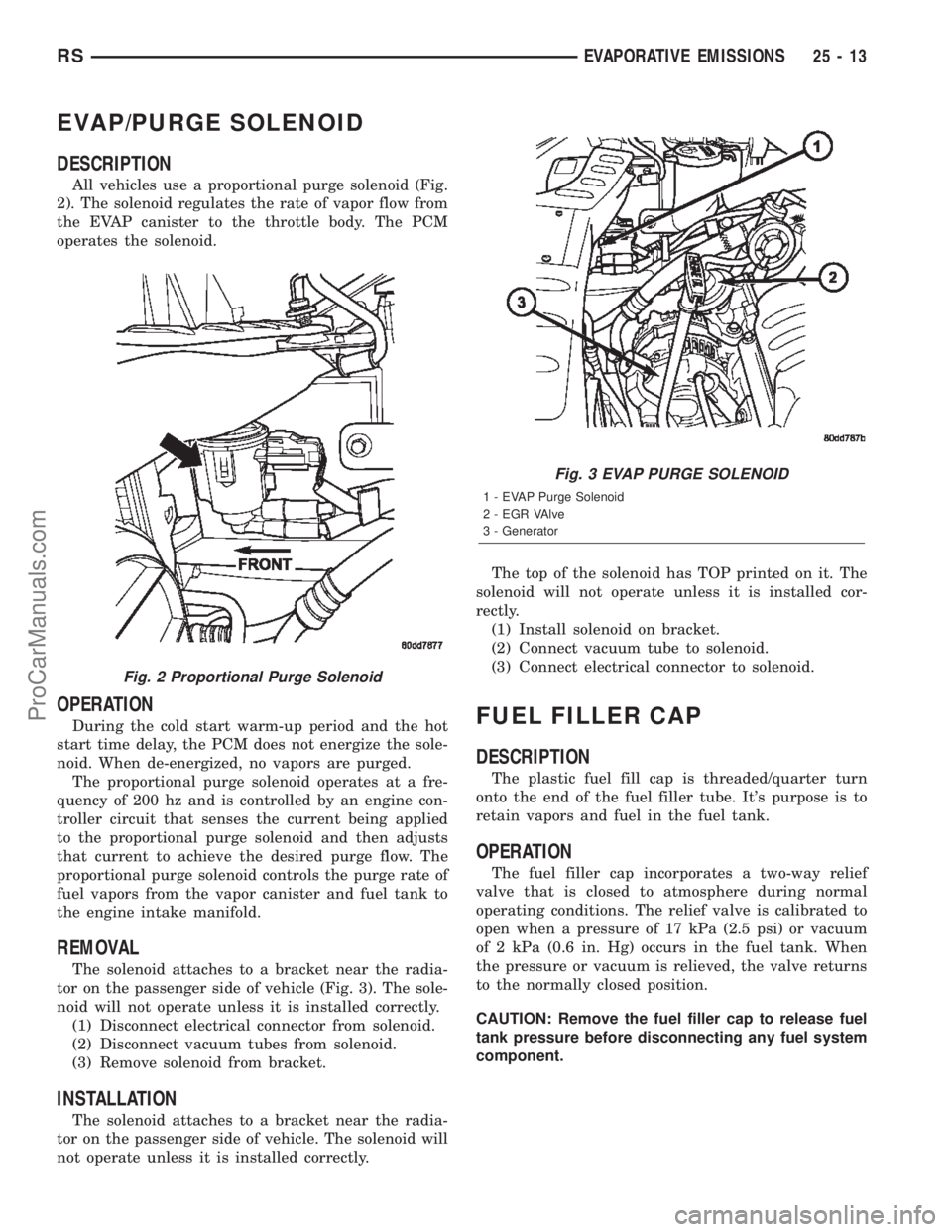

All vehicles use a proportional purge solenoid (Fig.

2). The solenoid regulates the rate of vapor flow from

the EVAP canister to the throttle body. The PCM

operates the solenoid.

OPERATION

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged.

The proportional purge solenoid operates at a fre-

quency of 200 hz and is controlled by an engine con-

troller circuit that senses the current being applied

to the proportional purge solenoid and then adjusts

that current to achieve the desired purge flow. The

proportional purge solenoid controls the purge rate of

fuel vapors from the vapor canister and fuel tank to

the engine intake manifold.

REMOVAL

The solenoid attaches to a bracket near the radia-

tor on the passenger side of vehicle (Fig. 3). The sole-

noid will not operate unless it is installed correctly.

(1) Disconnect electrical connector from solenoid.

(2) Disconnect vacuum tubes from solenoid.

(3) Remove solenoid from bracket.

INSTALLATION

The solenoid attaches to a bracket near the radia-

tor on the passenger side of vehicle. The solenoid will

not operate unless it is installed correctly.The top of the solenoid has TOP printed on it. The

solenoid will not operate unless it is installed cor-

rectly.

(1) Install solenoid on bracket.

(2) Connect vacuum tube to solenoid.

(3) Connect electrical connector to solenoid.

FUEL FILLER CAP

DESCRIPTION

The plastic fuel fill cap is threaded/quarter turn

onto the end of the fuel filler tube. It's purpose is to

retain vapors and fuel in the fuel tank.

OPERATION

The fuel filler cap incorporates a two-way relief

valve that is closed to atmosphere during normal

operating conditions. The relief valve is calibrated to

open when a pressure of 17 kPa (2.5 psi) or vacuum

of 2 kPa (0.6 in. Hg) occurs in the fuel tank. When

the pressure or vacuum is relieved, the valve returns

to the normally closed position.

CAUTION: Remove the fuel filler cap to release fuel

tank pressure before disconnecting any fuel system

component.

Fig. 2 Proportional Purge Solenoid

Fig. 3 EVAP PURGE SOLENOID

1 - EVAP Purge Solenoid

2 - EGR VAlve

3 - Generator

RSEVAPORATIVE EMISSIONS25-13

ProCarManuals.com

Page 2373 of 2399

LEAK DETECTION PUMP

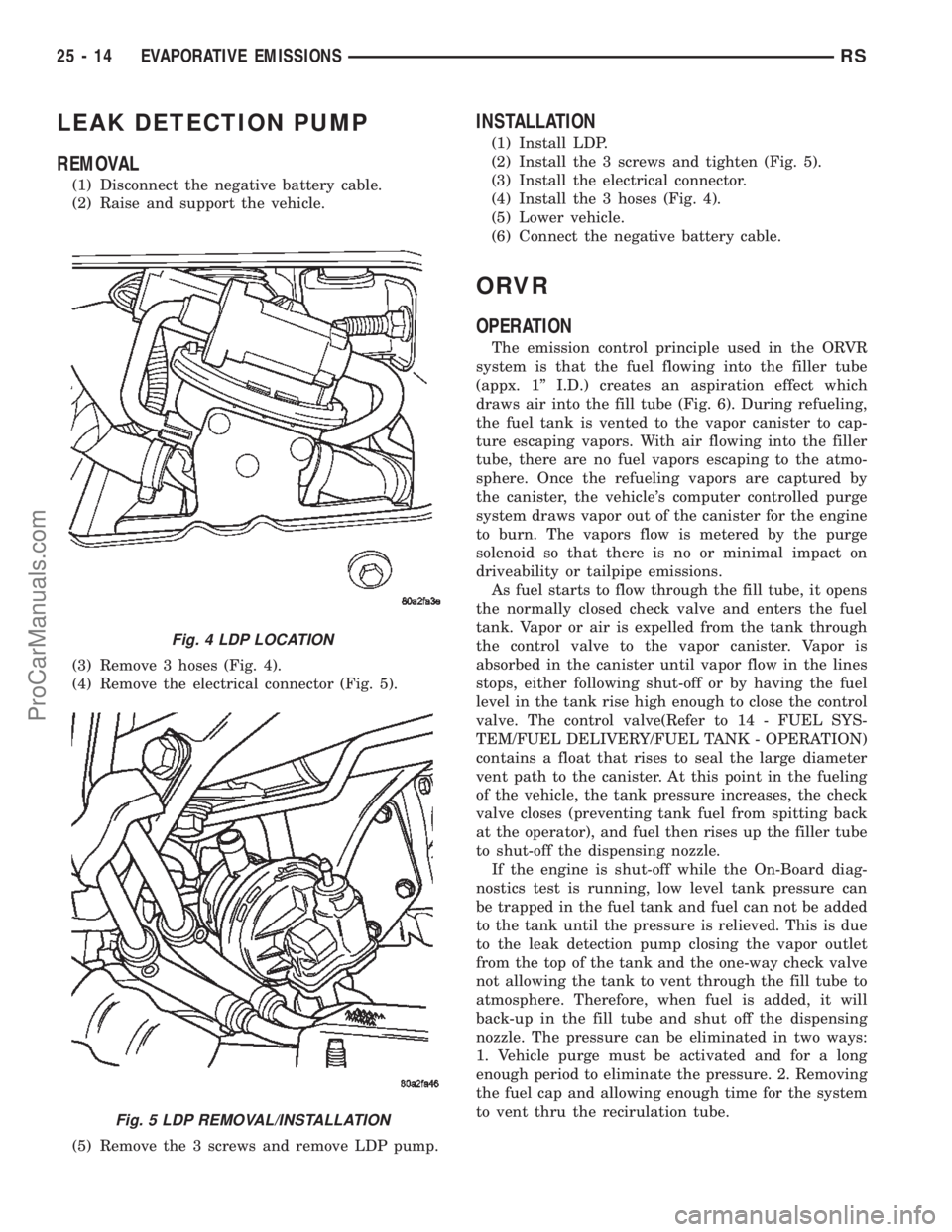

REMOVAL

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

(3) Remove 3 hoses (Fig. 4).

(4) Remove the electrical connector (Fig. 5).

(5) Remove the 3 screws and remove LDP pump.

INSTALLATION

(1) Install LDP.

(2) Install the 3 screws and tighten (Fig. 5).

(3) Install the electrical connector.

(4) Install the 3 hoses (Fig. 4).

(5) Lower vehicle.

(6) Connect the negative battery cable.

ORVR

OPERATION

The emission control principle used in the ORVR

system is that the fuel flowing into the filler tube

(appx. 1º I.D.) creates an aspiration effect which

draws air into the fill tube (Fig. 6). During refueling,

the fuel tank is vented to the vapor canister to cap-

ture escaping vapors. With air flowing into the filler

tube, there are no fuel vapors escaping to the atmo-

sphere. Once the refueling vapors are captured by

the canister, the vehicle's computer controlled purge

system draws vapor out of the canister for the engine

to burn. The vapors flow is metered by the purge

solenoid so that there is no or minimal impact on

driveability or tailpipe emissions.

As fuel starts to flow through the fill tube, it opens

the normally closed check valve and enters the fuel

tank. Vapor or air is expelled from the tank through

the control valve to the vapor canister. Vapor is

absorbed in the canister until vapor flow in the lines

stops, either following shut-off or by having the fuel

level in the tank rise high enough to close the control

valve. The control valve(Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL TANK - OPERATION)

contains a float that rises to seal the large diameter

vent path to the canister. At this point in the fueling

of the vehicle, the tank pressure increases, the check

valve closes (preventing tank fuel from spitting back

at the operator), and fuel then rises up the filler tube

to shut-off the dispensing nozzle.

If the engine is shut-off while the On-Board diag-

nostics test is running, low level tank pressure can

be trapped in the fuel tank and fuel can not be added

to the tank until the pressure is relieved. This is due

to the leak detection pump closing the vapor outlet

from the top of the tank and the one-way check valve

not allowing the tank to vent through the fill tube to

atmosphere. Therefore, when fuel is added, it will

back-up in the fill tube and shut off the dispensing

nozzle. The pressure can be eliminated in two ways:

1. Vehicle purge must be activated and for a long

enough period to eliminate the pressure. 2. Removing

the fuel cap and allowing enough time for the system

to vent thru the recirulation tube.

Fig. 4 LDP LOCATION

Fig. 5 LDP REMOVAL/INSTALLATION

25 - 14 EVAPORATIVE EMISSIONSRS

ProCarManuals.com

Page 2380 of 2399

(2) Disconnect the fresh air makeup hose on rear

valve cover.

(3) Remove the air box bolt.

(4) Remove the hose clamp at throttle body.

(5) Unlatch 2 clamps for air box cover.

(6) Remove air box cover.

(7) Disconnect the washer fluid fill hose.

(8) Remove air box.

(9) Remove the 2 bolts at the EGR valve.

(10) Remove the 2 bolts at the intake manifold.

(11) Remove front EGR tube.

REMOVAL - REAR TUBE - 3.5L

(1) Remove the battery, refer to the Battery sec-

tion.

(2) Remove the Battery tray/vacuum reservoir.

(3) Remove the speed control servo and bracket

and relocate.

(4) Remove the 2 bolts from the EGR valve.

(5) Remove the 2 bolts from the rear cylinder

head.

(6) Remove the EGR rear tube.

INSTALLATION

INSTALLATION - 2.4L

(1) Loose install EGR tube and gasket with attach-

ing bolts at intake manifold.

(2) Loose install EGR tube and gasket with attach-

ing bolts at EGR valve.

(3) Tighten bolts to EGR valve to 11.9 N´m (105

20 ins. lbs.).

(4) Tighten bolts to Intake manifold to 11.9 N´m

(105 20 ins. lbs.).

INSTALLATION - FRONT TUBE - 3.5L

(1) Install front EGR tube and gaskets.

(2) Install the 2 bolts at the EGR valve.

(3) Install the 2 bolts at the intake manifold.

(4) Tighten all 4 bolts.

(5) Install air box.

(6) Connect the washer fluid fill hose.

(7) Install air box cover.

(8) Latch 2 clamps for air box cover.

(9) Install the hose clamp at throttle body.

(10) Install the air box bolt.

(11) Connect the fresh air makeup hose on rear

valve cover.

(12) Connect the negative battery cable.

INSTALLATION - REAR TUBE - 3.5L

(1) Install the EGR rear tube.

(2) Install the 2 bolts to the rear cylinder head.

(3) Install the 2 bolts to the EGR valve.

(4) Tighten the 4 bolts.(5) Install the speed control servo and bracket,

refer to the speed control section.

(6) Install the Battery tray/vacuum reservoir refer

to the battery section.

(7) Install the battery, refer to the Battery section.

VA LV E

DESCRIPTION

The EGR system consists of:

²EGR tube (connects a passage in the intake

manifold to the exhaust port in the cylinder head)

²EGR valve

²Electronic EGR Transducer

²Connecting hoses

OPERATION

Refer to Monitored Systems - EGR Monitor in this

group for more information.

The engines use Exhaust Gas Recirculation (EGR)

systems. The EGR system reduces oxides of nitrogen

(NOx) in engine exhaust and helps prevent detona-

tion (engine knock). Under normal operating condi-

tions, engine cylinder temperature can reach more

than 3000ÉF. Formation of NOx increases proportion-

ally with combustion temperature. To reduce the

emission of these oxides, the cylinder temperature

must be lowered. The system allows a predetermined

amount of hot exhaust gas to recirculate and dilute

Fig. 1 EGR VALVE AND TUBE 2.4L

1 - EGR Tube

2 - EGR Valve

RSEXHAUST GAS RECIRCULATION25-21

TUBE (Continued)

ProCarManuals.com

Page 2381 of 2399

the incoming air/fuel mixture. The diluted air/fuel

mixture reduces peak flame temperature during com-

bustion.

The electric EGR transducer contains an electri-

cally operated solenoid and a back-pressure trans-

ducer (Fig. 3). The Powertrain Control Module (PCM)

operates the solenoid. The PCM determines when to

energize the solenoid. Exhaust system back-pressure

controls the transducer.

When the PCM energizes the solenoid, vacuum

does not reach the transducer. Vacuum flows to the

transducer when the PCM de-energizes the solenoid.

When exhaust system back-pressure becomes high

enough, it fully closes a bleed valve in the trans-

ducer. When the PCM de-energizes the solenoid and

back-pressure closes the transducer bleed valve, vac-

uum flows through the transducer to operate the

EGR valve.

De-energizing the solenoid, but not fully closing the

transducer bleed hole (because of low back-pressure),

varies the strength of vacuum applied to the EGR

valve. Varying the strength of the vacuum changes

the amount of EGR supplied to the engine. This pro-

vides the correct amount of exhaust gas recirculation

for different operating conditions.

This system does not allow EGR at idle.

A failed or malfunctioning EGR system can cause

engine spark knock, sags or hesitation, rough idle,

engine stalling and increased emissions.

Fig. 2 EGR VALVE AND TUBE 3.3/3.8L

Fig. 3 EGR Valve and Transducer - Typical

1 - DIAPHRAGM

2 - PISTON

3 - SPRING

4 - EGR VALVE ASSEMBLY

5 - VACUUM MOTOR

6 - VACUUM MOTOR FITTING

7 - VACUUM OUTLET FITTING TO EGR VALVE

8 - EGR VALVE CONTROL ASSEMBLY

9 - ELECTRIC SOLENOID PORTION OF VALVE CONTROL

10 - VACUUM INLET FITTING FROM ENGINE

11 - BACK-PRESSURE HOSE

12 - TRANSDUCER PORTION OF VALVE CONTROL

13 - ELECTRICAL CONNECTION POINT

14 - EGR VALVE BACK-PRESSURE FITTING

15 - EXHAUST GAS INLET

16 - STEM PROTECTOR AND BUSHING

17 - BASE

18 - MOVEMENT INDICATOR

19 - POPPET VALVE

20 - SEAT

21 - EXHAUST GAS OUTLET

25 - 22 EXHAUST GAS RECIRCULATIONRS

VALVE (Continued)

ProCarManuals.com

Page 2382 of 2399

REMOVAL

REMOVAL - 2.4L

The EGR valve and Electrical EGR Transducer are

serviced as an assembly (Fig. 1).

(1) Disconnect vacuum tube from electric EGR

transducer. Inspect vacuum tube for damage.

(2) Remove electrical connector from solenoid.

(3) Remove EGR tube bolts from EGR valve.

(4) Remove EGR valve from cylinder head adaptor.

(5) Clean gasket surface and discard old gasket.

Check for any signs of leakage or cracked surfaces.

Repair or replace as necessary.

REMOVAL - 3.5L

(1) Disconnect the negative battery cable.

(2) Disconnect the fresh air makeup hose on rear

valve cover.

(3) Remove the air box bolt.

(4) Remove the hose clamp at throttle body.

(5) Unlatch 2 clamps for air box cover.

(6) Remove air box cover.

(7) Unlock the electrical connector.

(8) Disconnect the electrical connector from the

EGR valve.

(9) Remove the 2 bolts for the front EGR tube

(10) Remove the 2 bolts for the rear EGR tube

(11) Remove the 2 EGR valve mounting bolts.

(12) Remove the EGR valve.

INSTALLATION

INSTALLATION - 2.4L

The EGR valve and Electrical EGR Transducer are

serviced as an assembly (Fig. 1).

(1) Assemble EGR valve with new gasket onto the

cylinder head adaptor.

(2) Loose assemble the bolts from EGR valve to

EGR tube.

(3) Loose assemble the bolts from EGR valve to

cylinder head.

(4) Tighten bolts from EGR valve to cylinder head

to 22.8 N´m (200 25 in. lbs.) torque.

(5) Tighten bolts from EGR valve to EGR tube to

11.9 N´m (105 20 in. lbs.) torque.

(6) Reconnect vacuum hose and electrical connec-

tor to electrical EGR transducer.

INSTALLATION - 3.5L

(1) Install the EGR valve.

(2) Install the 2 bolts for the rear EGR tube

(3) Install the 2 bolts for the front EGR tube

(4) Tighten the EGR tube bolts.

(5) Tighten the EGR valve mounting bolts.

(6) Connect the electrical connector to the EGR

valve.

(7) Lock the electrical connector.

(8) Install air box cover.

(9) Latch 2 clamps for air box cover.

(10) Install the hose clamp at throttle body.

(11) Connect the fresh air makeup hose on rear

valve cover.

(12) Connect the negative battery cable.

RSEXHAUST GAS RECIRCULATION25-23

VALVE (Continued)

ProCarManuals.com

Page 2388 of 2399

EMISSIONS CONTROL 2.5L TURBO DIESEL

TABLE OF CONTENTS

page page

EMISSIONS CONTROL 2.5L TURBO DIESEL

DESCRIPTION..........................1

SPECIFICATIONS - TORQUE...............2EXHAUST GAS RECIRCULATION............3

ON-BOARD DIAGNOSTICS.................6

EMISSIONS CONTROL 2.5L

TURBO DIESEL

DESCRIPTION

The 2.5L diesel Engine Control Module (ECM) con-

trols many different circuits in the fuel injection

pump and engine systems. If the ECM senses a prob-

lem with a monitored circuit that indicates an actual

problem, a Diagnostic Trouble Code (DTC) will be

stored in the ECM's memory, and eventually may

illuminate the MIL (Malfunction Indicator Lamp)

constantly while the key is on. If the problem is

repaired, or is intermittent, the ECM will erase the

DTC after 40 warm-up cycles without the the fault

detected. A warm-up cycle consists of starting the

vehicle when the engine is cold, then the engine is

warmed up to a certain temperature, and finally, the

engine temperature falls to a normal operating tem-

perature, then the key is turned off.

Certain criteria must be met for a DTC to be

entered into ECM memory. The criteria may be a

specific range of engine rpm, engine or fuel tempera-

ture and/or input voltage to the ECM. A DTC indi-

cates that the ECM has identified an abnormal

signal in a circuit or the system.

There are several operating conditions that the

ECM does not monitor and set a DTC for. Refer to

the following Monitored Circuits and Non±Monitored

Circuits in this section.

ECM MONITORED SYSTEMS

The ECM can detect certain problems in the elec-

trical system.

Open or Shorted Circuit± The ECM will not

distinguish between an open or a short to ground,

however the ECM can determine if there is excessive

current on a circuit, such as a short to voltage or a

decrease in component resistance.

Output Device Current Flow± The ECM senses

whether the output devices are electrically connected.

If there is a problem with the circuit, the ECM

senses whether the circuit is open, shorted to ground

(±), or shorted to (+) voltage.Fuel Pressure:Fuel pressure is controlled by the

fuel injection pump and fuel pressure solenoid. The

ECM uses a fuel pressure sensor to determine if a

fuel pressure problem exists.

Fuel Injector Malfunctions:The ECM can deter-

mine if a fuel injector has an electrical problem. The

fuel injectors on the diesel engine arecontrolledby

the ECM.

ECM NON±MONITORED SYSTEMS

The ECM does not monitor the following circuits,

systems or conditions that could have malfunctions

that result in driveability problems. A DTC will not

be displayed for these conditions.

Cylinder Compression:The ECM cannot detect

uneven, low, or high engine cylinder compression.

Exhaust System:The ECM cannot detect a

plugged, restricted or leaking exhaust system.

Vacuum Assist:Leaks or restrictions in the vac-

uum circuits of the Exhaust Gas Recirculation Sys-

tem (EGR) are not monitored by the ECM.

ECM System Ground:The ECM cannot deter-

mine a poor system ground. However, a DTC may be

generated as a result of this condition.

ECM/PCM Connector Engagement:The ECM

cannot determine spread or damaged connector pins.

However, a DTC may be generated as a result of this

condition.

HIGH AND LOW LIMITS

The ECM compares input signals from each input

device. It has high and low limits that are pro-

grammed into it for that device. If the inputs are not

within specifications and other DTC criteria are met,

a DTC will be stored in memory. Other DTC criteria

might include engine rpm limits or input voltages

from other sensors or switches. The other inputs

might have to be sensed by the ECM when it senses

a high or low input voltage from the control system

device in question.

RGEMISSIONS CONTROL 2.5L TURBO DIESEL25a-1

ProCarManuals.com

Page 2391 of 2399

VA LV E

DESCRIPTION

The EGR system consists of (Fig. 1):

²EGR valve

²EGR tube

²Vacuum hoses

²EGR cooler

²EGR solenoid

OPERATION

The engines use Exhaust Gas Recirculation (EGR)

systems. The EGR system reduces oxides of nitrogen

(NOx) in engine exhaust and helps prevent detona-

tion (engine knock). Under normal operating condi-

tions, engine cylinder temperature can reach more

than 3000ÉF. Formation of NOx increases proportion-

ally with combustion temperature. To reduce the

emission of these oxides, the cylinder temperature

must be lowered. The system allows a predetermined

amount of hot exhaust gas to recirculate and dilute

the incoming air/fuel mixture. The diluted air/fuel

mixture reduces peak flame temperature during com-

bustion.

REMOVAL

(1) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(2) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(3) Disconnect EGR valve vacuum line.

(4) Remove EGR cooler to EGR valve retaining

bolts (Fig. 1).

(5) Remove EGR valve retaining nuts (Fig. 1) and

EGR valve.

INSTALLATION

(1) Clean gasket mating surfaces.

(2) Install EGR valve (Fig. 1). Torque nuts to

32.4N´m.

(3) Connect EGR cooler to EGR valve (Fig. 1).

Torque bolts to 32.4N´m

(4) Install front wiper unit (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(5) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

Fig. 1 EGR COMPONENTS

1 - HOSE CLAMP

2 - COOLANT HOSE

3 - HOSE CLAMP

4 - EGR VALVE RETAINING NUT

5 - E G R VA LV E

6 - COOLANT HOSE

7 - EGR VALVE GASKET

8 - EGR VALVE RETAINING STUDS

9 - EGR COOLER RETAINING BOLT

10 - HOSE CLAMP

11 - HOSE CLAMP

12 - EGR COOLER

13 - EGR COOLER TO EGR VALVE RETAINING BOLT

14 - TURBOCHARGER BRACKET

15 - TURBOCHARGER BRACKET RETAINING BOLT

16 - TURBOCHARGER DOWNPIPE

17 - TURBOCHARGER DOWNPIPE RETAINING NUT

18 - DOWNPIPE GASKET

19 - DOWNPIPE STUD

25a - 4 EXHAUST GAS RECIRCULATIONRG

ProCarManuals.com

Page 2392 of 2399

VALVE COOLER

DESCRIPTION

The EGR valve on this engine uses a cooler to cool

the exhaust gases before the returned to the intake

manifold (Fig. 2). The EGR cooler attaches to the

EGR valve and is cooled with engine coolant.

REMOVAL

(1) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(2) Partially drain cooling system (Refer to 7 -

COOLING/ENGINE/COOLANT - STANDARD PRO-

CEDURE).

(3) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(4) Disconnect coolant supply and return lines at

EGR cooler (Fig. 2).

(5) Remove EGR cooler to exhaust manifold retain-

ing bolt (Fig. 2).

(6) Remove EGR cooler to EGR valve retaining

bolts (Fig. 2) and remove cooler.

INSTALLATION

(1) Clean gasket sealing surfaces.

(2) Connect EGR valve cooler and new gasket to

EGR valve (Fig. 2). Torque bolts to 32.4N´m.

(3) Install EGR valve cooler to exhaust manifold

attaching bolt (Fig. 2). Torque bolt to 32.4N´m.

(4) Connect EGR cooler coolant supply and return

hoses to cooler (Fig. 2).

(5) Install front wiper unit (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(6) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(7) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

Fig. 2 EGR COMPONENTS

1 - HOSE CLAMP

2 - COOLANT HOSE

3 - HOSE CLAMP

4 - EGR VALVE RETAINING NUT

5 - E G R VA LV E

6 - COOLANT HOSE

7 - EGR VALVE GASKET

8 - EGR VALVE RETAINING STUDS

9 - EGR COOLER RETAINING BOLT

10 - HOSE CLAMP

11 - HOSE CLAMP

12 - EGR COOLER

13 - EGR COOLER TO EGR VALVE RETAINING BOLT

14 - TURBOCHARGER BRACKET

15 - TURBOCHARGER BRACKET RETAINING BOLT

16 - TURBOCHARGER DOWNPIPE

17 - TURBOCHARGER DOWNPIPE RETAINING NUT

18 - DOWNPIPE GASKET

19 - DOWNPIPE STUD

RGEXHAUST GAS RECIRCULATION25a-5

ProCarManuals.com