electr CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 2034 of 2399

(4) Clean off all traces of adhesive or double sided

tape from the panel with a general purpose adhesive

remover.

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Align badgeing to reference points.

(3) Install and press securely to full adhesive con-

tact

(4) Clean away any reference points.

EXTERIOR NAME PLATES -

ADHESIVE ATTACHED

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) With your fingernail lift up and peel away

badgeing/tape from panel, using a heat gun as you

go.

(4) Clean off all traces of adhesive from the pan-

el(s) with a general purpose adhesive remover.

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Remove paper carrier and align badgeing/tape

to reference points or adjacent panel.

(3) Install and press securely, using a plastic

spreader to eliminate all air bubbles.

(4) Remove top protective carrier.

(5) Clean away any reference points.

FRONT FENDER

REMOVAL

(1) Remove headlamp housing. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - REMOVAL)

(2) Remove mud guard.

(3) Remove inner splash shield.

(4) Remove fender to fascia nuts.

(5)

Remove outboard cowl grille/fender bracket screw.

(6) Remove fender bolt to lower rocker panel.

(7) Remove fender bolt to lower cowl.

(8) Pull fascia away from fender.

(9) Remove bolts attaching fender to upper rail.

(10) Remove fender from vehicle (Fig. 8).

INSTALLATION

(1) Place fender in position on vehicle.

(2) From inside engine compartment, start the

center upper rail bolt. install all the bolts attaching

fender to upper rail and tighten.

(3) Install fender to lower cowl panel bolt.

(4) Install fender to rocker panel bolt.

(5) Place fascia into position.

(6) Install outboard cowl grille/fender bracket

screw.

(7) Install fender to fascia nuts.

(8) Install inner splash shield.

(9) Install mud guard.

(10) Install headlamp assembly. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - INSTALLATION)

(11) Check fender for flush and gap.

Fig. 8 FENDER

1 - FASTENERS 2 - FENDER

3 - FASTENERS

RSEXTERIOR23-51

EXTERIOR NAME PLATES - TAPE ATTACHED (Continued)

ProCarManuals.com

Page 2041 of 2399

INSTALLATION

SHORT WHEELBASE

(1) Position the air exhauster to the hole in the

lower aperture panel (Fig. 19).

(2) Using hand pressure, press the air exhauster

into the opening in the lower aperture panel until

the snap features are fully engaged.

(3) Reinstall the rear fascia onto the body. (Refer

to 13 - FRAMES & BUMPERS/BUMPERS/REAR

FASCIA - INSTALLATION).

LONG WHEELBASE

NOTE: Models with the optional rear heater and air

conditioner do not have an air exhauster on the

right side of the vehicle, but have a plastic plug

installed in the right lower aperture panel. This plug

is installed using the same procedure used to

install the air exhauster onto the short wheelbase

model. Refer to SHORT WHEELBASE .

(1) Position the air exhauster to the hole in the

lower aperture panel (Fig. 20).

(2) Using hand pressure, press the air exhauster

into the opening in the lower aperture panel until

the snap features are fully engaged.

(3) Reinstall the quarter trim panel onto the inside

of the left or right quarter inner panel. (Refer to 23 -

BODY/INTERIOR/RIGHT QUARTER TRIM PANEL

- INSTALLATION) or (Refer to 23 - BODY/INTERI-

OR/LEFT QUARTER TRIM PANEL - INSTALLA-

TION).

ROOF JOINT MOLDING

REMOVAL

The RAP molding is set with body side molding

tape. The temperature in the work area and the vehi-

cle should be at least 21É C (70É F) to avoid damag-

ing the RAP moldings.

(1) Warm the affected stick-on molding and body

metal to approximately 38É C (100É F) using a suit-

able heat lamp or heat gun.

(2) Pull stick-on molding from painted surface.(3) Remove adhesive tape residue from painted

surface of vehicle. Use a 3M Scotch-BriteŸ Molding

Adhesive and Stripe Removal Discs, or equivalent, to

clean adhesive residue from painted surfaces. The

adhesive removal discs are available from automotive

paint suppliers. Refer to instructions supplied with

the discs for proper usage.

INSTALLATION

The RAP molding is set with body side molding

tape. The temperature in the work area and the vehi-

cle should be at least 21É C (70É F) to avoid damag-

ing the RAP moldings.

(1) If molding is to be reused;

(a) Remove tape residue from molding.

(b) Clean back of molding with MopartSuper

Kleen solvent, or equivalent.

(c) Wipe molding dry with lint free cloth.

(d) Apply new body side molding (two sided

adhesive) tape to back of molding.

(2) Clean body surface with MopartSuper Kleen

solvent, or equivalent. Wipe surface dry with lint free

cloth.

(3) Remove protective cover from tape on back of

molding.

(4) Apply molding to body from front of vehicle to

rear.

(5) Using a roller tool, roll molding onto body

panel with enough force to assure adhesion and not

bend roof panels.

SIDE VIEW MIRROR

REMOVAL

(1) Using a trim stick or equivalent, remove the

trim cover (Fig. 21).

(2) Remove the bolts.

(3) Remove the mirror from the pillar.

(4) Disconnect the electrical connector, if equipped.

INSTALLATION

(1) Connect the electrical connector, if equipped.

(2) Place side view mirror in position on vehicle

(Fig. 21).

(3) Install the bolts.

(4) Install the trim cover.

23 - 58 EXTERIORRS

REAR QUARTER PANEL/FENDER AIR EXHAUSTER (Continued)

ProCarManuals.com

Page 2042 of 2399

SIDE VIEW MIRROR GLASS

REMOVAL

WARNING: ALWAYS WEAR EYE AND HAND PRO-

TECTION WHEN SERVICING THE MIRROR ASSEM-

BLY. FAILURE TO OBSERVE THESE WARNINGS

MAY RESULT IN PERSONAL INJURY FROM BRO-

KEN GLASS.

(1) Carefully pull/pry the broken glass holder from

the mirror assembly.(2) Disconnect the heated mirror electrical connec-

tors from the terminals on the mirror glass holder, if

equipped.

INSTALLATION

CAUTION: It is important to make sure the motor is

square to the glass holder (attaching fingers) prior

to glass holder attachment, otherwise the glass

holder could be installed incorrectly causing poor

retention and possible repeat failure.

(1) Position the new mirror glass holder to the

mirror assembly.

NOTE: Position the mirror glass holder so that the

moisture drain hole on the mirror glass holder

assembly is facing downward.

(2) Align the mirror glass holder's attaching fin-

gers to the mirror motor housing.

NOTE: Ensure that the protective rubber cover of

the mirror motor housing is positioned correctly

around the bottom of the fingers area.

(3) Using one hand, firmly press the mirror glass

holder assembly into place while at the same time

supporting the housing assembly from the backside

with the other hand.

NOTE: Pressure must be applied equally over the

center portion of the mirror to engage the mirror

glass holder's attaching fingers to the correspond-

ing fingers on the housing assembly. One or more

clicks may be heard when finger engagement takes

place.

(4) Verify retention of the mirror glass holder

assembly by gently pulling outward on the mirror

glass holder.

Fig. 21 SIDE VIEW MIRROR

1 - MIRROR

2 - MIRROR TRIM COVER

3 - A-PILLAR

4 - BOLTS

RSEXTERIOR23-59

SIDE VIEW MIRROR (Continued)

ProCarManuals.com

Page 2065 of 2399

FLOOR CONSOLE TRAY

REMOVAL

(1) Remove the floor console. Refer to the Owner's

Manual for proper procedures.

(2) Remove the four screws and remove the tray.

INSTALLATION

(1) Install the floor console tray and install the

screws.

(2) Install the floor console. Refer to the Owner's

Manual for proper procedures.

FLOOR CONSOLE TRAY -

BRACKET ASSEMBLY

REMOVAL

(1) Remove the floor carpet. (Refer to 23 - BODY/

INTERIOR/CARPETS AND FLOOR MATS -

REMOVAL)

(2) Disconnect the electrical connector.

(3) Remove the four screws and remove the

bracket assembly.

INSTALLATION

(1) Install the bracket assembly and install the

four screws.

(2) Connect the electrical connector.

(3) Install the floor carpet. (Refer to 23 - BODY/

INTERIOR/CARPETS AND FLOOR MATS -

INSTALLATION)

23 - 82 INTERIORRS

ProCarManuals.com

Page 2245 of 2399

FRONT CONTROL PANEL

The front control panel and integral computer is

mounted in the instrument panel.

The instrument panel mounted control and inte-

gral computer contains:

²a power button which allows the system to be

completely turned off.

²rear window defogger on/off switch.

²slide controls for completely independent side-to-

side temperature control of the discharge air. The full

range of temperature that the system can produce in

any mode is available on either side of the vehicle by

independently positioning the slide controls on the

instrument panel.

²air recirculation button. The Recirculate button

contains an LED that illuminates to show when the

function is in operation.

²an air conditioning button that allows the com-

pressor to be turned on/off. The Snowflake button

contains an LED that illuminates to shown when the

function is in operation.

²rotary knobs for front and rear fan speed selec-

tion.

²a rotary knob for mode control.

REAR CONTROL PANEL

A rear control panel centrally mounted on the

headliner has a rotary adjustment for temperature

and fan speed control of the rear unit by intermedi-

ate seat passengers when the front control rear knob

is set to the rear position.

DESCRIPTION - THREE ZONE AUTOMATIC

TEMPERATURE CONTROL

The Three-Zone Automatic Temperature Control

(ATC) allows occupants to select a comfort tempera-

ture, which is the perceived temperature level not

the actual passenger compartment air temperature.

The Three Zone Automatic Temperature Control

system includes a dust and odor air filter. The filter

element is the same size as the air conditioning evap-

orator to ensure ample capacity. A door at the base of

the heater and air conditioning housing below the

glove box provides easy access to the filter element.

The ATC computer utilizes integrated circuitry and

information carried on the Programmable Communi-

cations Interface (PCI) data bus network to monitor

many sensors and switch inputs throughout the vehi-

cle. In response to those inputs, the internal circuitry

and programming of the ATC computer allow it to

control electronic functions and features of the ATC

system. The inputs to the ATC computer are:

²Vehicle Speed/Engine RPM± The ATC com-

puter monitors engine RPM, vehicle speed and Man-

ifold Absolute Pressure information from the PCM.²Coolant Temperature± ATC computer moni-

tors Coolant temperature received from the PCM and

converts it to degrees Fahrenheit.

²Ambient Temperature± ATC computer moni-

tors Ambient temperature from the Compass Mini

Trip Computer (CMTC) and converts it to degrees

Fahrenheit.

²Engine Miscellaneous Sensor Status±ATC

computer monitors A/C disable information from the

PCM.

²Refrigerant Pressure± ATC computer moni-

tors Barometric Pressure, Intake Air Temperature,

High Side Pressure and Methanol Content as broad-

cast by the PCM.

²Door Ajar Status± The ATC computer moni-

tors Driver Front Door, Passenger Front Door, Left

Rear Door, Right Rear Door and Liftgate ajar infor-

mation, as identified by the Body Control Module

(BCM), to determine if all in-car temperatures should

be maintained.

²Dimming± The ATC computer monitors dim-

ming status from the BCM to determine the required

level of brightness and will dim accordingly.

²Vehicle Odometer± The ATC computer moni-

tors the vehicle odometer information from the BCM

to prevent flashing the VF tube icons if the manual

motor calibration or manual cool down tests have

failed. Flashing of the display icons will cease when

the vehicle odometer is greater than 3 miles.

²English Metric± The ATC computer monitors

the English/Metric information broadcast by the

CMTC. The set temp displays for both the front and

rear control heads will be set accordingly.

²Vehicle Identification Number± The ATC

computer monitors the last eight characters of the

VIN broadcast by the PCM and compares it to the

information stored in EEPROM. If it is different, the

new number will be stored over the old one and a

motor calibration shall be initiated.

²A/C System Information± The ATC computer

will send a message for Evaporator Temperature too

Low, Fan Blower Relay status, Evaporator Sensor

Failure, Rear Window Defogger Relay and A/C Select.

FRONT CONTROL PANEL

The front control panel and integral computer is

mounted in the instrument panel.

The instrument panel mounted control and inte-

gral computer contains:

²A power button which allows the system to be

completely turned off. The display is blank when the

system is off.

²Three rocker switches that select comfort tem-

peratures from 15É to 30É C (59É to 85É F), which are

shown in the vacuum-fluorescent digital control dis-

play. If the set temp is 59 and the down button is

24 - 2 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

ProCarManuals.com

Page 2250 of 2399

If coolant flow is verified and the heater floor out-

let temperature is insufficient, a mechanical problem

may exist.

POSSIBLE LOCATION OR CAUSE OF INSUFFICIENT HEAT

²Obstructed cowl air intake.

²Obstructed heater system outlets.

²Blend-air door not functioning properly.TEMPERATURE CONTROL

If heater floor outlet temperature cannot be

adjusted with the heater-A/C control temperature

control lever, one of the following could require ser-

vice:

²Blend-air door binding.

²Faulty blend-air door motor.

²Improper engine coolant temperature.

²Faulty heater-A/C control.

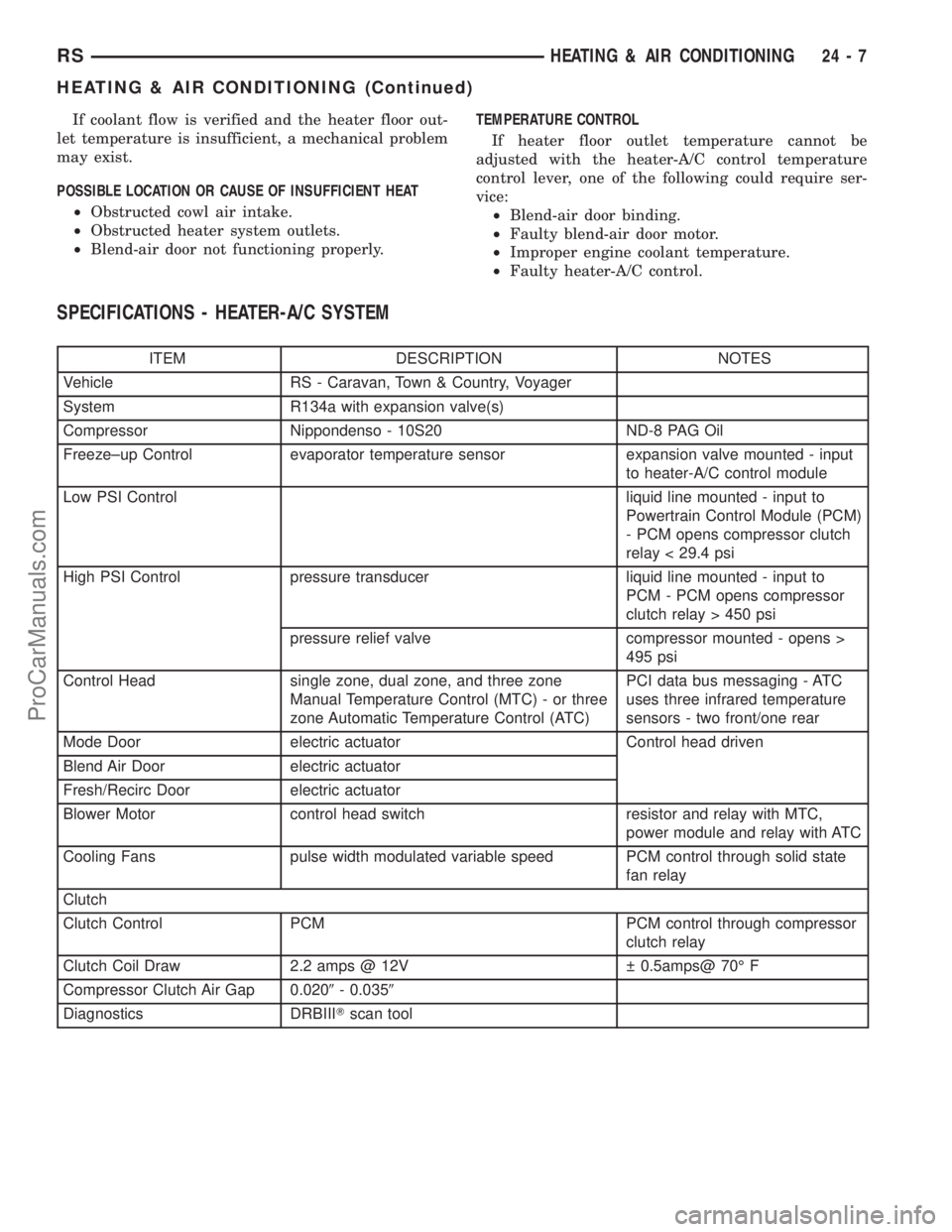

SPECIFICATIONS - HEATER-A/C SYSTEM

ITEM DESCRIPTION NOTES

Vehicle RS - Caravan, Town & Country, Voyager

System R134a with expansion valve(s)

Compressor Nippondenso - 10S20 ND-8 PAG Oil

Freeze±up Control evaporator temperature sensor expansion valve mounted - input

to heater-A/C control module

Low PSI Control liquid line mounted - input to

Powertrain Control Module (PCM)

- PCM opens compressor clutch

relay < 29.4 psi

High PSI Control pressure transducer liquid line mounted - input to

PCM - PCM opens compressor

clutch relay > 450 psi

pressure relief valve compressor mounted - opens >

495 psi

Control Head single zone, dual zone, and three zone

Manual Temperature Control (MTC) - or three

zone Automatic Temperature Control (ATC)PCI data bus messaging - ATC

uses three infrared temperature

sensors - two front/one rear

Mode Door electric actuator Control head driven

Blend Air Door electric actuator

Fresh/Recirc Door electric actuator

Blower Motor control head switch resistor and relay with MTC,

power module and relay with ATC

Cooling Fans pulse width modulated variable speed PCM control through solid state

fan relay

Clutch

Clutch Control PCM PCM control through compressor

clutch relay

Clutch Coil Draw 2.2 amps @ 12V 0.5amps@ 70É F

Compressor Clutch Air Gap 0.0209- 0.0359

Diagnostics DRBIIITscan tool

RSHEATING & AIR CONDITIONING24-7

HEATING & AIR CONDITIONING (Continued)

ProCarManuals.com

Page 2253 of 2399

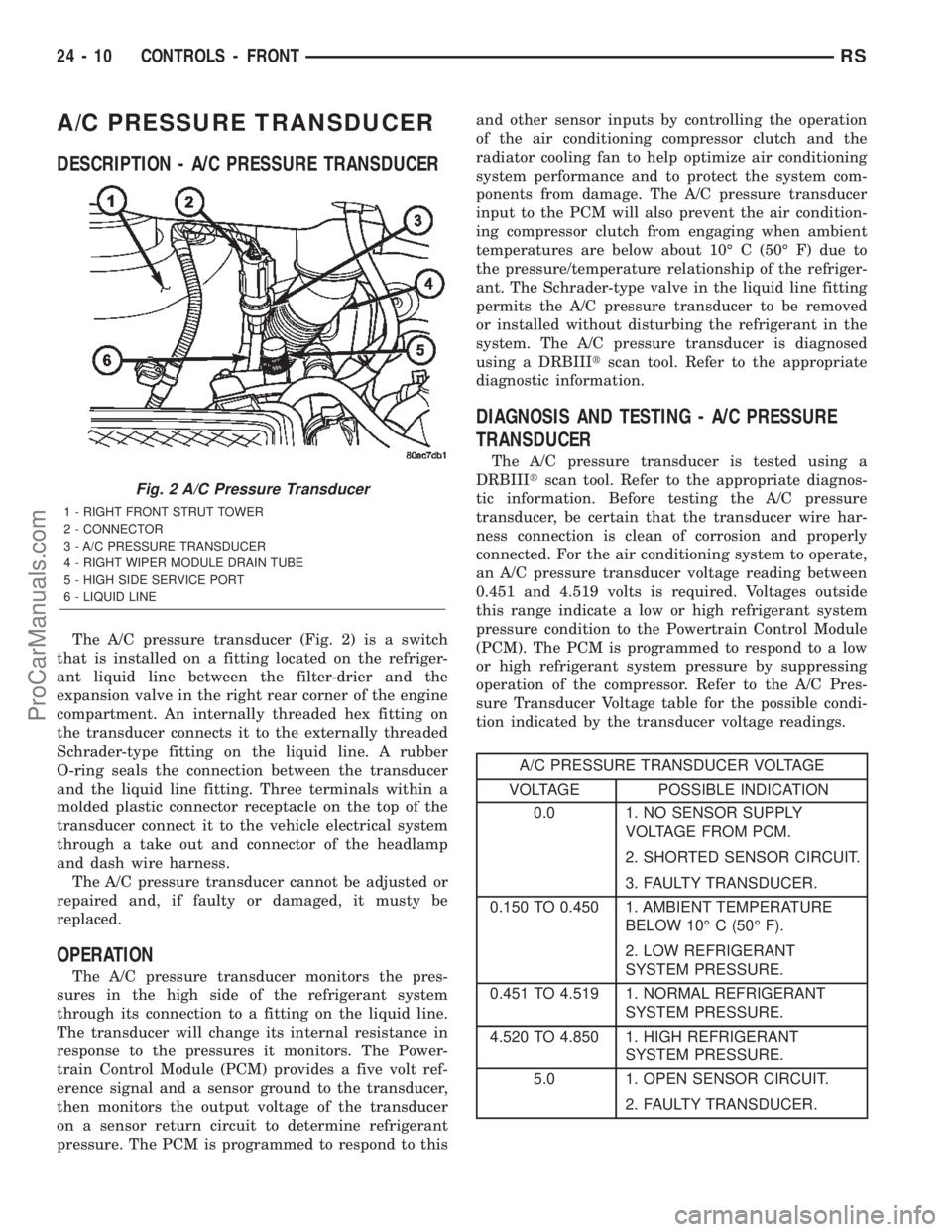

A/C PRESSURE TRANSDUCER

DESCRIPTION - A/C PRESSURE TRANSDUCER

The A/C pressure transducer (Fig. 2) is a switch

that is installed on a fitting located on the refriger-

ant liquid line between the filter-drier and the

expansion valve in the right rear corner of the engine

compartment. An internally threaded hex fitting on

the transducer connects it to the externally threaded

Schrader-type fitting on the liquid line. A rubber

O-ring seals the connection between the transducer

and the liquid line fitting. Three terminals within a

molded plastic connector receptacle on the top of the

transducer connect it to the vehicle electrical system

through a take out and connector of the headlamp

and dash wire harness.

The A/C pressure transducer cannot be adjusted or

repaired and, if faulty or damaged, it musty be

replaced.

OPERATION

The A/C pressure transducer monitors the pres-

sures in the high side of the refrigerant system

through its connection to a fitting on the liquid line.

The transducer will change its internal resistance in

response to the pressures it monitors. The Power-

train Control Module (PCM) provides a five volt ref-

erence signal and a sensor ground to the transducer,

then monitors the output voltage of the transducer

on a sensor return circuit to determine refrigerant

pressure. The PCM is programmed to respond to thisand other sensor inputs by controlling the operation

of the air conditioning compressor clutch and the

radiator cooling fan to help optimize air conditioning

system performance and to protect the system com-

ponents from damage. The A/C pressure transducer

input to the PCM will also prevent the air condition-

ing compressor clutch from engaging when ambient

temperatures are below about 10É C (50É F) due to

the pressure/temperature relationship of the refriger-

ant. The Schrader-type valve in the liquid line fitting

permits the A/C pressure transducer to be removed

or installed without disturbing the refrigerant in the

system. The A/C pressure transducer is diagnosed

using a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER

The A/C pressure transducer is tested using a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information. Before testing the A/C pressure

transducer, be certain that the transducer wire har-

ness connection is clean of corrosion and properly

connected. For the air conditioning system to operate,

an A/C pressure transducer voltage reading between

0.451 and 4.519 volts is required. Voltages outside

this range indicate a low or high refrigerant system

pressure condition to the Powertrain Control Module

(PCM). The PCM is programmed to respond to a low

or high refrigerant system pressure by suppressing

operation of the compressor. Refer to the A/C Pres-

sure Transducer Voltage table for the possible condi-

tion indicated by the transducer voltage readings.

A/C PRESSURE TRANSDUCER VOLTAGE

VOLTAGE POSSIBLE INDICATION

0.0 1. NO SENSOR SUPPLY

VOLTAGE FROM PCM.

2. SHORTED SENSOR CIRCUIT.

3. FAULTY TRANSDUCER.

0.150 TO 0.450 1. AMBIENT TEMPERATURE

BELOW 10É C (50É F).

2. LOW REFRIGERANT

SYSTEM PRESSURE.

0.451 TO 4.519 1. NORMAL REFRIGERANT

SYSTEM PRESSURE.

4.520 TO 4.850 1. HIGH REFRIGERANT

SYSTEM PRESSURE.

5.0 1. OPEN SENSOR CIRCUIT.

2. FAULTY TRANSDUCER.

Fig. 2 A/C Pressure Transducer

1 - RIGHT FRONT STRUT TOWER

2 - CONNECTOR

3 - A/C PRESSURE TRANSDUCER

4 - RIGHT WIPER MODULE DRAIN TUBE

5 - HIGH SIDE SERVICE PORT

6 - LIQUID LINE

24 - 10 CONTROLS - FRONTRS

ProCarManuals.com

Page 2254 of 2399

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the headlamp and dash wire har-

ness connector for the A/C pressure transducer from

the transducer connector receptacle (Fig. 3).

(3) Using an open end wrench, unscrew the A/C

pressure transducer from the fitting on the liquid

line between the filter-drier and the expansion valve.

(4) Remove the seal from the A/C pressure trans-

ducer fitting and discard.

INSTALLATION

(1) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the A/C pressure

transducer fitting.

(2) Using an open end wrench, install and tighten

the A/C pressure transducer onto the fitting on the

liquid line between the filter-drier and the expansion

valve.

(3) Reconnect the headlamp and dash wire harness

connector for the A/C pressure transducer to the

transducer connector receptacle.

(4) Reconnect the battery negative cable.

BLEND DOOR ACTUATOR

DESCRIPTION

The blend door actuators are reversible, 12-volt

Direct Current (DC), servo motors. Models with the

single zone heater and air conditioner system have a

single blend air door, which is controlled by a singleblend door actuator. Models with the optional dual

zone front heater and air conditioner system have

dual blend air doors, which are controlled by two

blend door actuators. The single zone blend door

actuator is located on the driver side end of the heat-

er-A/C housing unit, close to the dash panel. In the

dual zone system, the same blend door actuator used

for the single zone system becomes the passenger

blend door actuator, and is mechanically connected to

only the passenger side blend air door. In the dual

zone system, a second separate blend door actuator is

also located on the driver side end of the heater-A/C

housing unit close to the instrument panel, and is

mechanically connected to only the driver side blend

air door.

The blend door actuators are interchangeable with

each other, as well as with the actuators for the

mode door and the recirculation air door. Each actua-

tor is contained within an identical black molded

plastic housing with an integral wire connector

receptacle. Two integral mounting tabs allow the

actuator to be secured with two screws to the heater-

A/C unit housing. Each actuator also has an identical

output shaft with splines that connects it to the link-

age that drives the proper blend air door. The blend

door actuators do not require mechanical indexing to

the blend door linkage, as they are electronically cal-

ibrated by the heater-A/C control module. The blend

door actuators cannot be adjusted or repaired and, if

damaged or faulty, they must be replaced.

OPERATION

Each blend door actuator is connected to the heat-

er-A/C control module through the vehicle electrical

system by a dedicated two-wire take out and connec-

tor of the HVAC wire harness. The blend door actua-

tor can move the blend air door in two directions.

When the heater-A/C control module pulls the volt-

age on one side of the motor connection high and the

other connection low, the blend air door will move in

one direction. When the module reverses the polarity

of the voltage to the motor, the blend air door moves

in the opposite direction. When the module makes

the voltage to both connections high or both connec-

tions low, the blend air door stops and will not move.

These same motor connections also provide a feed-

back signal to the heater-A/C control module. This

feedback signal allows the module to monitor the

operation and relative positions of the blend door

actuator and the blend air door. The heater-A/C con-

trol module learns the blend air door stop positions

during the calibration procedure and will store a

Diagnostic Trouble Code (DTC) for any problems it

detects in the blend door actuator circuits. The blend

door actuator can be diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

Fig. 3 A/C Pressure Transducer

1 - RIGHT FRONT STRUT TOWER

2 - CONNECTOR

3 - A/C PRESSURE TRANSDUCER

4 - RIGHT WIPER MODULE DRAIN TUBE

5 - HIGH SIDE SERVICE PORT

6 - LIQUID LINE

RSCONTROLS - FRONT24-11

A/C PRESSURE TRANSDUCER (Continued)

ProCarManuals.com

Page 2256 of 2399

(5) Install and tighten the three screws that secure

the heater core shield to the left end of the heater/air

conditioner housing. Tighten the screws to 2 N´m (17

in. lbs.).

(6) Reinstall the silencer under the driver side end

of the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/INSTRUMENT PANEL

SILENCER - INSTALLATION).

(7) Reconnect the battery negative cable.

(8) Perform the heater-A/C control calibration pro-

cedure. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

BLOWER MOTOR RELAY

DESCRIPTION

The blower motor relay (Fig. 6) is a International

Standards Organization (ISO) mini-relay. Relays con-

forming to the ISO specifications have common phys-

ical dimensions, current capacities, terminal

patterns, and terminal functions. The ISO mini-relay

terminal functions are the same as a conventional

ISO relay. However, the ISO mini-relay terminal pat-

tern (or footprint) is different, the current capacity is

lower, and the physical dimensions are smaller than

those of the conventional ISO relay. The blower

motor relay is located in the Intelligent Power Mod-

ule (IPM), which is in the engine compartment near

the battery. See the fuse and relay layout mapmolded into the inner surface of the IPM cover for

blower motor relay identification and location.

The black, molded plastic case is the most visible

component of the blower motor relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal.

OPERATION

The blower motor relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control the high current

output to the blower motor resistor (manual heater-

A/C control) or blower power module (ATC control).

The movable common feed contact point is held

against the fixed normally closed contact point by

spring pressure. When the relay coil is energized, an

electromagnetic field is produced by the coil wind-

ings. This electromagnetic field draws the movable

relay contact point away from the fixed normally

closed contact point, and holds it against the fixed

normally open contact point. When the relay coil is

de-energized, spring pressure returns the movable

contact point back against the fixed normally closed

contact point. The resistor or diode is connected in

parallel with the relay coil in the relay, and helps to

dissipate voltage spikes and electromagnetic interfer-

ence that can be generated as the electromagnetic

field of the relay coil collapses.

The blower motor relay terminals are connected to

the vehicle electrical system through a receptacle in

the Intelligent Power Module (IPM). The inputs and

outputs of the blower motor relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(automatic heater-A/C control) through a fuse in the

IPM on the fused front blower motor relay output cir-

cuit only when the blower motor relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the blower motor

relay coil is de-energized.

Fig. 6 Blower Motor Relay

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

RSCONTROLS - FRONT24-13

BLEND DOOR ACTUATOR (Continued)

ProCarManuals.com

Page 2258 of 2399

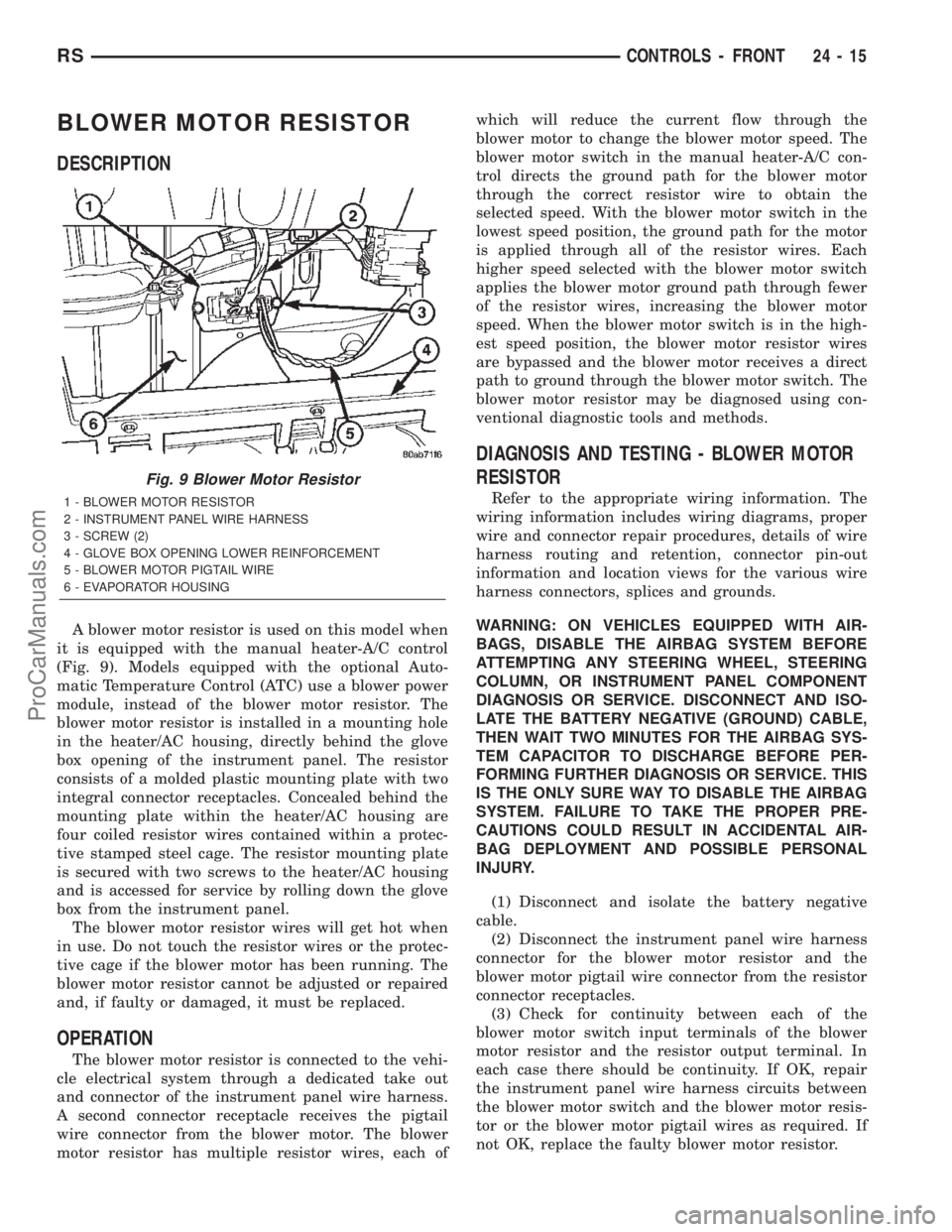

BLOWER MOTOR RESISTOR

DESCRIPTION

A blower motor resistor is used on this model when

it is equipped with the manual heater-A/C control

(Fig. 9). Models equipped with the optional Auto-

matic Temperature Control (ATC) use a blower power

module, instead of the blower motor resistor. The

blower motor resistor is installed in a mounting hole

in the heater/AC housing, directly behind the glove

box opening of the instrument panel. The resistor

consists of a molded plastic mounting plate with two

integral connector receptacles. Concealed behind the

mounting plate within the heater/AC housing are

four coiled resistor wires contained within a protec-

tive stamped steel cage. The resistor mounting plate

is secured with two screws to the heater/AC housing

and is accessed for service by rolling down the glove

box from the instrument panel.

The blower motor resistor wires will get hot when

in use. Do not touch the resistor wires or the protec-

tive cage if the blower motor has been running. The

blower motor resistor cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The blower motor resistor is connected to the vehi-

cle electrical system through a dedicated take out

and connector of the instrument panel wire harness.

A second connector receptacle receives the pigtail

wire connector from the blower motor. The blower

motor resistor has multiple resistor wires, each ofwhich will reduce the current flow through the

blower motor to change the blower motor speed. The

blower motor switch in the manual heater-A/C con-

trol directs the ground path for the blower motor

through the correct resistor wire to obtain the

selected speed. With the blower motor switch in the

lowest speed position, the ground path for the motor

is applied through all of the resistor wires. Each

higher speed selected with the blower motor switch

applies the blower motor ground path through fewer

of the resistor wires, increasing the blower motor

speed. When the blower motor switch is in the high-

est speed position, the blower motor resistor wires

are bypassed and the blower motor receives a direct

path to ground through the blower motor switch. The

blower motor resistor may be diagnosed using con-

ventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the instrument panel wire harness

connector for the blower motor resistor and the

blower motor pigtail wire connector from the resistor

connector receptacles.

(3) Check for continuity between each of the

blower motor switch input terminals of the blower

motor resistor and the resistor output terminal. In

each case there should be continuity. If OK, repair

the instrument panel wire harness circuits between

the blower motor switch and the blower motor resis-

tor or the blower motor pigtail wires as required. If

not OK, replace the faulty blower motor resistor.

Fig. 9 Blower Motor Resistor

1 - BLOWER MOTOR RESISTOR

2 - INSTRUMENT PANEL WIRE HARNESS

3 - SCREW (2)

4 - GLOVE BOX OPENING LOWER REINFORCEMENT

5 - BLOWER MOTOR PIGTAIL WIRE

6 - EVAPORATOR HOUSING

RSCONTROLS - FRONT24-15

ProCarManuals.com