electr CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 2275 of 2399

quarter inner panel. Tighten the screw to 11 N´m (97

in. lbs.).

(7) Install and tighten the screw that secures the

back of the rear heater-A/C unit housing to the right

D-pillar. Tighten the screw to 11 N´m (97 in. lbs.).

(8) Install and tighten the two screws that secure

the top of the quarter trim panel attaching bracket to

the quarter inner panel. Tighten the screws to 1.7

N´m (15 in. lbs.).

(9) Reinstall the right quarter trim panel and

right D-pillar trim panel onto the quarter inner

panel. (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - INSTALLATION).

(10) Reconnect the battery negative cable.

(11) Perform the heater-A/C control calibration

procedure. (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - FRONT/A/C-HEATER CON-

TROL - STANDARD PROCEDURE - HEATER-A/C

CONTROL CALIBRATION).

BLOWER MOTOR RELAY

DESCRIPTION

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

The blower motor relay (Fig. 5) is a International

Standards Organization (ISO) mini-relay. Relays con-

forming to the ISO specifications have common phys-

ical dimensions, current capacities, terminalpatterns, and terminal functions. The ISO mini-relay

terminal functions are the same as a conventional

ISO relay. However, the ISO mini-relay terminal pat-

tern (or footprint) is different, the current capacity is

lower, and the physical dimensions are smaller than

those of the conventional ISO relay. The blower

motor relay is located in the Intelligent Power Mod-

ule (IPM), which is in the engine compartment near

the battery. See the fuse and relay layout map

molded into the inner surface of the IPM cover for

compressor clutch relay identification and location.

The black, molded plastic case is the most visible

component of the blower motor relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The factory-installed blower motor relay cannot be

adjusted or repaired. If the relay is damaged or

faulty, it must be replaced.

OPERATION

The blower motor relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control the high current

output to the blower motor resistor (manual heater-

A/C control) or blower power module (automatic heat-

er-A/C control). The movable common feed contact

point is held against the fixed normally closed con-

tact point by spring pressure. When the relay coil is

energized, an electromagnetic field is produced by the

coil windings. This electromagnetic field draws the

movable relay contact point away from the fixed nor-

mally closed contact point, and holds it against the

fixed normally open contact point. When the relay

coil is de-energized, spring pressure returns the mov-

able contact point back against the fixed normally

closed contact point. The resistor or diode is con-

nected in parallel with the relay coil in the relay, and

helps to dissipate voltage spikes and electromagnetic

interference that can be generated as the electromag-

netic field of the relay coil collapses.

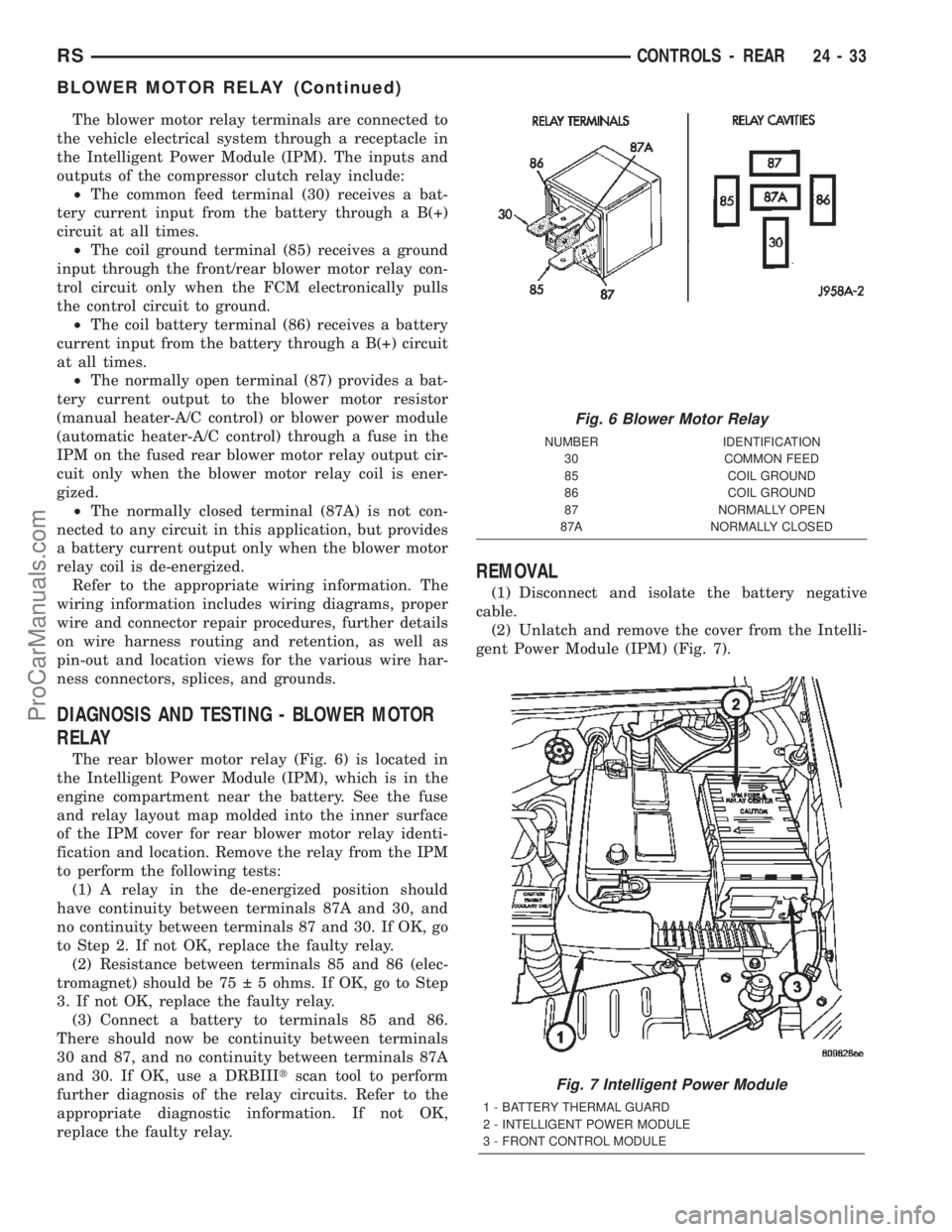

Fig. 5 Blower Motor Relay

24 - 32 CONTROLS - REARRS

BLEND DOOR ACTUATOR (Continued)

ProCarManuals.com

Page 2276 of 2399

The blower motor relay terminals are connected to

the vehicle electrical system through a receptacle in

the Intelligent Power Module (IPM). The inputs and

outputs of the compressor clutch relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(automatic heater-A/C control) through a fuse in the

IPM on the fused rear blower motor relay output cir-

cuit only when the blower motor relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the blower motor

relay coil is de-energized.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RELAY

The rear blower motor relay (Fig. 6) is located in

the Intelligent Power Module (IPM), which is in the

engine compartment near the battery. See the fuse

and relay layout map molded into the inner surface

of the IPM cover for rear blower motor relay identi-

fication and location. Remove the relay from the IPM

to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, use a DRBIIItscan tool to perform

further diagnosis of the relay circuits. Refer to the

appropriate diagnostic information. If not OK,

replace the faulty relay.

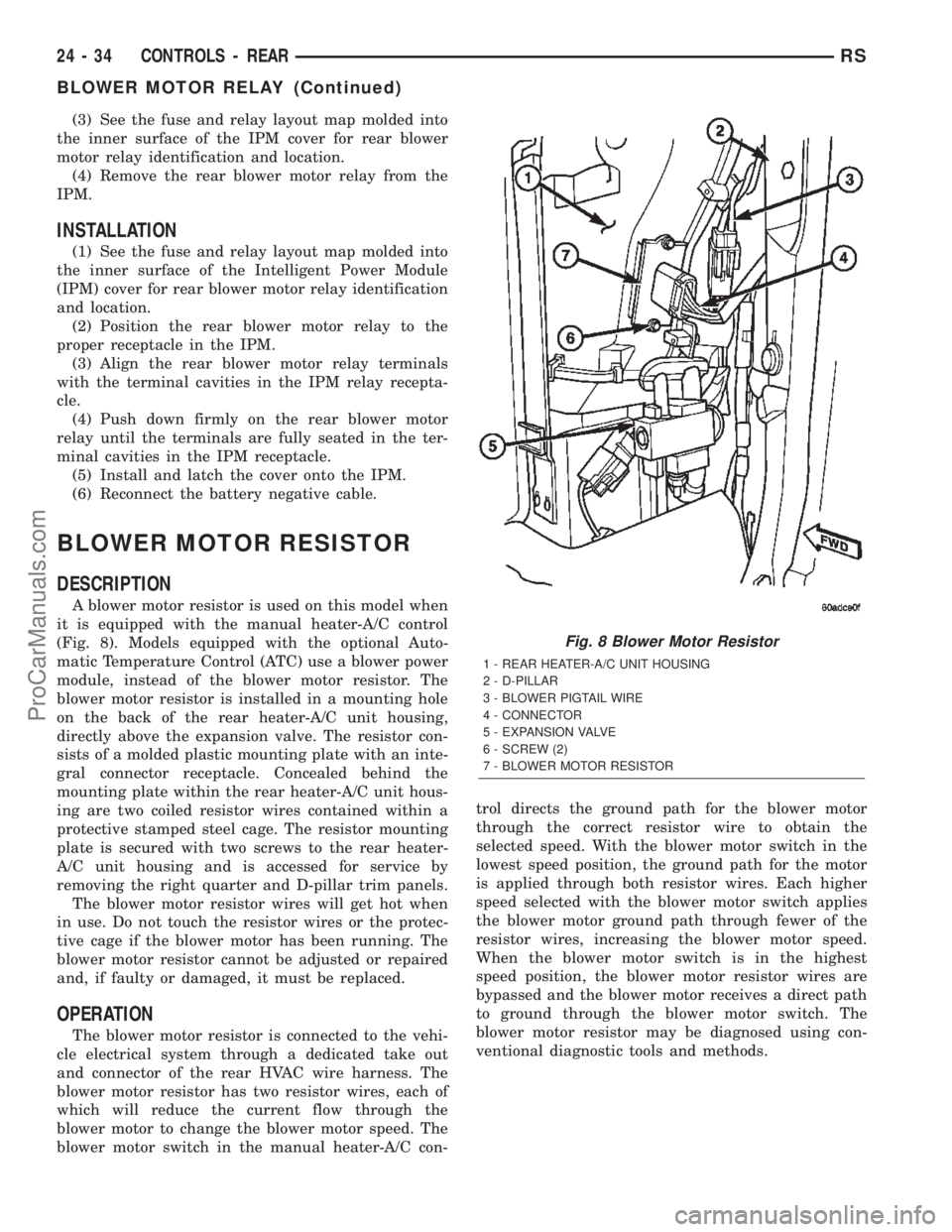

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Intelli-

gent Power Module (IPM) (Fig. 7).

Fig. 6 Blower Motor Relay

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL GROUND

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 7 Intelligent Power Module

1 - BATTERY THERMAL GUARD

2 - INTELLIGENT POWER MODULE

3 - FRONT CONTROL MODULE

RSCONTROLS - REAR24-33

BLOWER MOTOR RELAY (Continued)

ProCarManuals.com

Page 2277 of 2399

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for rear blower

motor relay identification and location.

(4) Remove the rear blower motor relay from the

IPM.

INSTALLATION

(1) See the fuse and relay layout map molded into

the inner surface of the Intelligent Power Module

(IPM) cover for rear blower motor relay identification

and location.

(2) Position the rear blower motor relay to the

proper receptacle in the IPM.

(3) Align the rear blower motor relay terminals

with the terminal cavities in the IPM relay recepta-

cle.

(4) Push down firmly on the rear blower motor

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install and latch the cover onto the IPM.

(6) Reconnect the battery negative cable.

BLOWER MOTOR RESISTOR

DESCRIPTION

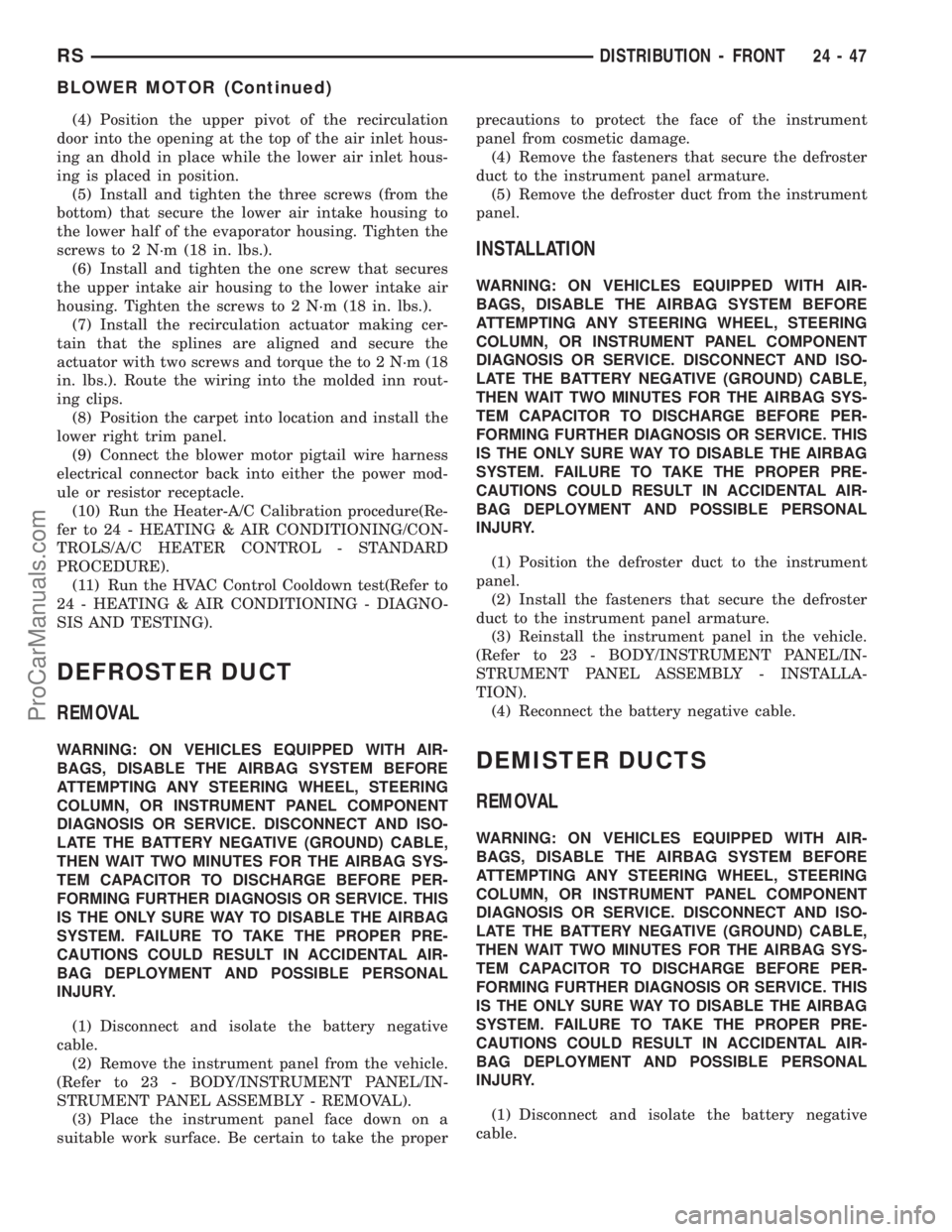

A blower motor resistor is used on this model when

it is equipped with the manual heater-A/C control

(Fig. 8). Models equipped with the optional Auto-

matic Temperature Control (ATC) use a blower power

module, instead of the blower motor resistor. The

blower motor resistor is installed in a mounting hole

on the back of the rear heater-A/C unit housing,

directly above the expansion valve. The resistor con-

sists of a molded plastic mounting plate with an inte-

gral connector receptacle. Concealed behind the

mounting plate within the rear heater-A/C unit hous-

ing are two coiled resistor wires contained within a

protective stamped steel cage. The resistor mounting

plate is secured with two screws to the rear heater-

A/C unit housing and is accessed for service by

removing the right quarter and D-pillar trim panels.

The blower motor resistor wires will get hot when

in use. Do not touch the resistor wires or the protec-

tive cage if the blower motor has been running. The

blower motor resistor cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The blower motor resistor is connected to the vehi-

cle electrical system through a dedicated take out

and connector of the rear HVAC wire harness. The

blower motor resistor has two resistor wires, each of

which will reduce the current flow through the

blower motor to change the blower motor speed. The

blower motor switch in the manual heater-A/C con-trol directs the ground path for the blower motor

through the correct resistor wire to obtain the

selected speed. With the blower motor switch in the

lowest speed position, the ground path for the motor

is applied through both resistor wires. Each higher

speed selected with the blower motor switch applies

the blower motor ground path through fewer of the

resistor wires, increasing the blower motor speed.

When the blower motor switch is in the highest

speed position, the blower motor resistor wires are

bypassed and the blower motor receives a direct path

to ground through the blower motor switch. The

blower motor resistor may be diagnosed using con-

ventional diagnostic tools and methods.

Fig. 8 Blower Motor Resistor

1 - REAR HEATER-A/C UNIT HOUSING

2 - D-PILLAR

3 - BLOWER PIGTAIL WIRE

4 - CONNECTOR

5 - EXPANSION VALVE

6 - SCREW (2)

7 - BLOWER MOTOR RESISTOR

24 - 34 CONTROLS - REARRS

BLOWER MOTOR RELAY (Continued)

ProCarManuals.com

Page 2280 of 2399

(10) Remove the mode door actuator from between

the rear heater-A/C unit housing and the quarter

inner panel.

INSTALLATION

(1) Position the mode door actuator between the

rear heater-A/C unit housing and the quarter inner

panel.

(2) Reconnect the rear HVAC wire harness connec-

tor for the mode door actuator to the actuator connec-

tor receptacle.

(3) Position the mode door actuator onto the rear

heater-A/C unit housing. If necessary, rotate the

actuator slightly to align the splines on the actuator

output shaft with those in the mode door linkage.

(4) Install and tighten the two screws that secure

the mode door actuator to the rear heater-A/C unit

housing. Tighten the screws to 2 N´m (18 in. lbs.).

(5) Push the top of the rear heater-A/C unit hous-

ing back into position against the right quarter inner

panel.

(6) Install and tighten the screw that secures the

front of the rear heater-A/C unit housing to the right

quarter inner panel. Tighten the screw to 11 N´m (97

in. lbs.).

(7) Install and tighten the screw that secures the

back of the rear heater-A/C unit housing to the right

D-pillar. Tighten the screw to 11 N´m (97 in. lbs.).

(8) Install and tighten the two screws that secure

the top of the quarter trim panel attaching bracket to

the quarter inner panel. Tighten the screws to 1.7

N´m (15 in. lbs.).

(9) Reinstall the right quarter trim panel and

right D-pillar trim panel onto the quarter inner

panel. (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - INSTALLATION).

(10) Reconnect the battery negative cable.

(11) Perform the heater-A/C control calibration

procedure. (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - FRONT/A/C-HEATER CON-

TROL - STANDARD PROCEDURE - HEATER-A/C

CONTROL CALIBRATION).

POWER MODULE

DESCRIPTION

A blower power module is used on this model when

it is equipped with the optional Automatic Tempera-

ture Control (ATC) (Fig. 11). Models equipped with

the standard manual heater-A/C control use a blower

motor resistor, instead of the blower power module.

The blower power module is installed in a mounting

hole in the back of the rear heater-A/C unit housing,

directly above the expansion valve. The module con-

sists of a molded plastic mounting plate with twointegral connector receptacles. Concealed behind the

mounting plate within the evaporator housing is the

power module electronic circuitry and a large finned,

heat sink. The module mounting plate is secured

with two screws to the rear heater-A/C unit housing

and is accessed for service by removing the right

quarter and D-pillar trim panels.

The power module heat sink will get hot when in

use. Do not touch the heat sink if the blower motor

has been running. The blower power module cannot

be adjusted or repaired and, if faulty or damaged, it

must be replaced.

OPERATION

The blower power module is connected to the vehi-

cle electrical system through a dedicated take out

and connector of the rear HVAC wire harness. A sec-

ond connector receptacle receives the pigtail wire

connector from the blower motor. The blower power

module allows the microprocessor-based Automatic

Temperature Control (ATC) heater-A/C control mod-

ule to calculate and provide infinitely variable blower

motor speeds based upon either manual blower

switch input or the ATC programming using a Pulse

Width Modulated (PWM) circuit strategy. The PWM

Fig. 11 Power Module

1 - REAR HEATER-A/C UNIT HOUSING

2 - SCREW (2)

3 - D-PILLAR

4 - BLOWER PIGTAIL WIRE

5 - REAR HVAC WIRE HARNESS

6 - EXPANSION VALVE

7 - BLOWER POWER MODULE

RSCONTROLS - REAR24-37

MODE DOOR ACTUATOR (Continued)

ProCarManuals.com

Page 2286 of 2399

INSTALLATION

INSTALLATION - CENTER BEZEL OUTLETS

(1) Position the center bezel outlets and housing

onto the center bezel as a unit.

(2) Engage the retainer features on the top of the

outlet housing with their receptacles at the top of the

center bezel, then roll the bottom of the outlet hous-

ing downwards towards the center bezel.

(3) Install and tighten the three screws that secure

the bottom of the outlet housing to the center bezel.

Tighten the screws to 2 N´m (17 in. lbs.).

(4) If the vehicle is equipped with the optional

ATC system, reconnect the ATC remote infrared tem-

perature sensor jumper harness to the sensor connec-

tor receptacle located on the bottom of the center

outlet housing.

(5) Reinstall the center bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(6) Reconnect the battery negative cable.

INSTALLATION - DEMISTER OUTLET

(1) Position the demister outlet over the demister

duct opening in the instrument panel top pad.

(2) Using hand pressure, press the demister outlet

firmly and evenly into the instrument panel top pad

opening until the snap features on the outlet are

fully engaged.

INSTALLATION - FRONT DOOR REAR OUTLET

(1) Position the front door rear outlet through the

outside of the front door trim panel outlet opening.

(2) While keeping the outlet aligned with the door

duct opening behind the trim panel, use hand pres-

sure to press the outlet firmly and evenly through

the outside of the front door trim panel outlet open-

ing until the four latch features (two top and two bot-

tom) that secure the outlet to the inside of the

opening are fully engaged.

(3) Reinstall the trim panel onto the front door

inner panel. (Refer to 23 - BODY/DOOR - FRONT/

TRIM PANEL - INSTALLATION).

(4) Reconnect the battery negative cable.

INSTALLATION - INSTRUMENT PANEL OUTLET

(1) Position the instrument panel outlet into the

panel duct opening in the instrument panel top pad.

(2) Using hand pressure, press the instrument

panel outlet firmly and evenly into the instrument

panel top pad opening until the snap features on the

outlet are fully engaged.

BLOWER MOTOR

DESCRIPTION

The blower motor is a 12-volt, Direct Current (DC)

motor with a squirrel cage-type blower wheel that is

secured to the blower motor shaft (Fig. 7). The

blower motor and wheel are located near the passen-

ger side end of the heater-A/C unit within the two

halves of the intake air housing in the passenger

compartment below the instrument panel. The

blower motor and blower motor wheel are a factory

balanced unit and cannot be adjusted or repaired. If

faulty or damaged, the blower motor and blower

wheel must be replaced as a unit.

OPERATION

The blower motor will operate whenever the igni-

tion switch is in the On position and the heater-A/C

control power is turned on. The blower motor can

only be turned off by turning off the power at the

heater-A/C control. The blower motor receives battery

current whenever the front blower motor relay is

energized. The front blower motor relay output cir-

cuit is protected by a fuse in the Intelligent Power

Module (IPM) located in the engine compartment

near the battery. In the Manual system, the blower

motor speed is controlled by regulating the path to

ground through the blower control switch and the

blower motor resistor. In the ATC system, the blower

motor speed is controlled by an electronic blower

power module, which uses a pulse width modulated

input from the ATC module and feedback from the

blower motor to regulate the blower motor ground

Fig. 7 Blower Motor

1 - BLOWER MOTOR

2 - RUBBER GROMMET

3 - BLOWER MOTOR CONNECTOR

4 - MOUNTING TABS

RSDISTRIBUTION - FRONT24-43

AIR OUTLETS (Continued)

ProCarManuals.com

Page 2289 of 2399

(7) Feed the blower motor pigtail wires and electri-

cal connector through the grommet hole in the lower

intake air housing.

(8) Relocate the recirculation air door as necessary

to access and remove the three screws that securethe blower motor to the blower housing in the lower

half of the evaporator housing (Fig. 11).

(9) Gently flex the recirculation air door far

enough to remove the blower motor and blower wheel

from the blower housing in the lower half of the

evaporator housing.

INSTALLATION

The blower motor and blower wheel are serviced

only as a balanced unit. If either component is faulty

or damaged, the entire unit must be replaced.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING),

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING),

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - HEATER PLUMB-

ING).

(1) Gently flex the recirculation air door far

enough to position the blower motor and blower

wheel into the blower housing in the lower half of the

evaporator housing.

(2) Install and tighten the four screws that secure

the blower motor to the blower housing in the lower

half of the evaporator housing. Tighten the screws to

2 N´m (18 in. lbs.).

(3) Feed the blower motor pigtail wires and electri-

cal connector through the grommet hole in the lower

intake air housing and seat the rubber grommet.

Fig. 9 Lower Intake Air Housing

1 - LOWER INTAKE AIR HOUSING

2 - RECIRCULATION AIR DOOR ACTUATOR

3 - BLOWER MOTOR PIGTAIL WIRE CONNECTOR

4 - RUBBER GROMMET

5 - BLOWER MOTOR RESISTOR/POWER MODULE

6 - LOWER EVAPORATOR HOUSING

7 - UPPER INTAKE AIR HOUSING

8 - RECIRCULATION AIR DOOR

Fig. 10 Rubber Grommet - Typical

1 - BLOWER MOTOR PIGTAIL WIRE GROMMET

Fig. 11 Blower Motor Mounting Tabs

1 - BLOWER MOTOR

2 - RUBBER GROMMET

3 - BLOWER MOTOR CONNECTOR

4 - MOUNTING TABS

24 - 46 DISTRIBUTION - FRONTRS

BLOWER MOTOR (Continued)

ProCarManuals.com

Page 2290 of 2399

(4) Position the upper pivot of the recirculation

door into the opening at the top of the air inlet hous-

ing an dhold in place while the lower air inlet hous-

ing is placed in position.

(5) Install and tighten the three screws (from the

bottom) that secure the lower air intake housing to

the lower half of the evaporator housing. Tighten the

screws to 2 N´m (18 in. lbs.).

(6) Install and tighten the one screw that secures

the upper intake air housing to the lower intake air

housing. Tighten the screws to 2 N´m (18 in. lbs.).

(7) Install the recirculation actuator making cer-

tain that the splines are aligned and secure the

actuator with two screws and torque the to 2 N´m (18

in. lbs.). Route the wiring into the molded inn rout-

ing clips.

(8) Position the carpet into location and install the

lower right trim panel.

(9) Connect the blower motor pigtail wire harness

electrical connector back into either the power mod-

ule or resistor receptacle.

(10) Run the Heater-A/C Calibration procedure(Re-

fer to 24 - HEATING & AIR CONDITIONING/CON-

TROLS/A/C HEATER CONTROL - STANDARD

PROCEDURE).

(11) Run the HVAC Control Cooldown test(Refer to

24 - HEATING & AIR CONDITIONING - DIAGNO-

SIS AND TESTING).

DEFROSTER DUCT

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel from the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL ASSEMBLY - REMOVAL).

(3) Place the instrument panel face down on a

suitable work surface. Be certain to take the properprecautions to protect the face of the instrument

panel from cosmetic damage.

(4) Remove the fasteners that secure the defroster

duct to the instrument panel armature.

(5) Remove the defroster duct from the instrument

panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the defroster duct to the instrument

panel.

(2) Install the fasteners that secure the defroster

duct to the instrument panel armature.

(3) Reinstall the instrument panel in the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL ASSEMBLY - INSTALLA-

TION).

(4) Reconnect the battery negative cable.

DEMISTER DUCTS

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

RSDISTRIBUTION - FRONT24-47

BLOWER MOTOR (Continued)

ProCarManuals.com

Page 2296 of 2399

system control switch on the front heater-A/C control

is not in the Off position. The blower motor can only

be turned off by turning off the rear system at the

front heater-A/C control. The blower motor receives

battery current whenever the rear blower motor

relay is energized. The rear blower motor relay out-

put circuit is protected by a fuse in the Intelligent

Power Module (IPM) located in the engine compart-

ment near the battery. In the MTC system, the

blower motor speed is controlled by regulating the

path to ground through the blower control switch and

the blower motor resistor. In the ATC system, the

blower motor speed is controlled by an electronic

blower power module, which uses a pulse width mod-

ulated input from the ATC module and feedback from

the blower motor to regulate the blower motor

ground path it provides. The blower motor and wheel

are used to control the velocity of air moving through

the rear heater-A/C unit housing. The blower motor

controls the velocity of the air flowing through the

rear heater-A/C housing by spinning the blower

wheel within the housing at the selected speed or, in

the ATC system, at the selected or programmed

speed.

DIAGNOSIS AND TESTING - BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

(1) Check the fuse (Fuse 12 - 25 ampere) in the

Intelligent Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the rear heater-A/C control power is

turned on. Check for battery voltage at the fuse

(Fuse 12 - 25 ampere) in the IPM. If OK, go to Step

3. If not OK, proceed to diagnosis of the rear blower

motor relay. (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - REAR/BLOWER MOTOR

RELAY - DIAGNOSIS AND TESTING).

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear HVAC wire harness connector for

the rear blower motor resistor (Manual Temperature

Control) or the rear blower power module (Automatic

Temperature Control) from the resistor or module

connector receptacle. Reconnect the battery negative

cable. Turn the ignition switch to the On position. Be

certain that the rear heater-A/C control power is

turned on. Check for battery voltage at the fused

rear blower motor relay output circuit cavity of the

rear HVAC wire harness connector for the rear

blower motor resistor (MTC) or the rear blower

power module (ATC). If OK, go to Step 4. If not OK,

repair the open fused front blower motor relay output

circuit to the IPM as required.(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear blower motor pigtail wire connec-

tor from the take out and connector of the rear

HVAC wire harness (MTC) or the connector recepta-

cle of the rear blower power module (ATC). Use

jumper wires to connect a battery and ground feeds

to the blower motor pigtail wire connector. The

blower motor should operate. If OK with MTC, pro-

ceed to diagnosis of the rear blower motor resistor.

(Refer to 24 - HEATING & AIR CONDITIONING/

CONTROLS - REAR/BLOWER MOTOR RESISTOR -

DIAGNOSIS AND TESTING). If OK with ATC, use a

DRBIII scan tool to diagnose the rear blower power

module. Refer to the appropriate diagnostic informa-

tion. If not OK with MTC or ATC, replace the faulty

rear blower motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart (Fig. 4).

REMOVAL

The rear blower motor and blower wheel are ser-

viced only as a balanced unit. If either component is

faulty or damaged, the entire unit must be replaced.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING),

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING),

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - HEATER PLUMB-

ING).

(1) Remove the rear heater-A/C unit housing from

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/REAR HEATER-

A/C HOUSING - REMOVAL).

(2) Disconnect the rear blower motor pigtail wire

connector. With manual temperature control, the

blower pigtail wire is connected to a take out and

connector of the rear HVAC wire harness. With auto-

matic temperature control, the blower pigtail wire is

connected to a receptacle on the blower power mod-

ule.

(3) Remove the three screws that secure the

blower motor to the outboard side of the rear heater-

A/C unit housing (Fig. 5).

(4) Remove the blower motor and blower wheel

from the rear heater-A/C unit housing.

RSDISTRIBUTION - REAR24-53

BLOWER MOTOR (Continued)

ProCarManuals.com

Page 2305 of 2399

CAUTION: All tools, including the refrigerant recy-

cling equipment, the manifold gauge set, and test

hoses should be kept clean and dry. Keep the work

area clean. Contamination of the refrigerant system

through careless work habits must be avoided. The

refrigerant system will remain chemically stable as

long as pure, moisture-free R-134a refrigerant and

refrigerant oil is used. Dirt, moisture, or air can

upset this chemical stability. Operational troubles

or serious damage can occur if foreign material is

introduced to the refrigerant system.

COMPRESSOR

DESCRIPTION

The compressor used on this vehicle can be one of

two models, depending upon the air conditioning sys-

tem in the vehicle. All vehicles use the Nippondenso

10S20 compressor. This compressor use an aluminum

swash plate, teflon coated pistons and aluminum

sleeveless cylinder walls. This compressor includes

an integral high pressure relief valve. The compres-

sor is secured low in the right front corner of the

engine compartment to a mounting bracket on the

cylinder block (2.4L engine), or directly to the cylin-

der block (3.3L and 3.8L engines) is integral to the

compressor. This compressor cannot be repaired. If

faulty or damaged, the entire compressor must be

replaced. The compressor clutch, pulley, and clutch

coil are available for service replacement.

OPERATION

The compressor is driven by the engine through an

electric clutch, drive pulley and belt arrangement.

The compressor is lubricated by refrigerant oil that is

circulated throughout the refrigerant system with the

refrigerant. The compressor draws in low-pressure

refrigerant vapor from the evaporator through its

suction port. It then compresses the refrigerant into

a high-pressure, high-temperature refrigerant vapor.

The compressor pumps high-pressure refrigerant

vapor to the condenser through the compressor dis-

charge port. The mechanical high pressure relief

valve is designed to vent refrigerant from the system

to protect against damage to the compressor or other

system components, caused by condenser air flow

restrictions or an overcharge of refrigerant. The valve

only vents enough refrigerant to reduce the system

pressure, then re-seats itself. The valve opens at a

discharge pressure of 3445 to 4135 kPA (500 to 600

psi) or above, and closes when a minimum discharge

pressure of 2756 kPa (400 psi) is reached.

DIAGNOSIS AND TESTING - COMPRESSOR

NOISE DIAGNOSIS

Excessive noise while the air conditioning compres-

sor is operating can be caused by loose compressor

mounts, a loose compressor clutch, or high operating

pressures in the refrigerant system. Verify compres-

sor drive belt condition, proper compressor mounting,

correct refrigerant charge level, and compressor head

pressure before compressor repair is performed.

With the close tolerances within the compressor, it

is possible to experience a temporary lockup. The

longer the compressor is inactive, the more likely the

condition is to occur. This condition is the result of

normal refrigerant migration within the refrigerant

system caused by ambient temperature changes. The

refrigerant migration may wash the refrigerant oil

out of the compressor.

NOTE: Prior to a vehicle being removed from ser-

vice or stored for more than two weeks, the com-

pressor should be operated to ensure adequate

refrigerant oil distribution throughout the system

components. Turn on the air conditioner for a min-

imum of five minutes with outside air and the high-

est blower speed selected.

BELT NOISE

If the compressor drive belt slips at initial start-up,

it does not necessarily mean the compressor has

failed. The following procedure can be used to iden-

tify a compressor drive belt noise problem.

²Start the vehicle and run at idle.

²Turn the air conditioner On and listen for belt

squeal.

²If belt squeal is heard, turn the air conditioner

Off immediately.

If the belt squeal stops when the air conditioner is

turned Off, perform the following repair procedures.

(1) Using an appropriate sized oil filter wrench or

a strap wrench, grasp the outer diameter of the com-

pressor clutch hub. While facing the compressor,

rotate the hub clockwise, then counterclockwise. If

the hub rotates, proceed to the next step. If the hub

will not rotate, the compressor is internally damaged,

and must be replaced.

(2) Turn the hub clockwise five complete revolu-

tions and remove the tool.

(3) Start the vehicle and run at idle.

(4) Turn the air conditioner On. Observe the com-

pressor and the system for normal operation, noting

cooling performance and noise levels. Operate for five

minutes before turning the air conditioner Off. If

acceptable cooling performance is observed during

compressor operation, the compressor does not need

to be replaced.

24 - 62 PLUMBING - FRONTRS

PLUMBING - FRONT (Continued)

ProCarManuals.com

Page 2308 of 2399

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

INSTALLATION - COMPRESSOR MOUNTING

BRACKET - 2.4L ENGINE

(1) Position the compressor mounting bracket onto

the engine.

(2) Install and tighten the four screws that secure

the compressor mounting bracket to the engine.

Tighten the screws to 54 N´m (40 ft. lbs.).

(3) Reinstall the compressor onto the mounting

bracket. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/COMPRESSOR - INSTALLA-

TION).

CONDENSER

DESCRIPTION

The condenser is integral to a cooling module

which includes the radiator, the electric cooling fan,

the fan shroud, air seals and an automatic transmis-

sion oil cooler. The cooling module is located in the

air flow in the front of the engine compartment

behind the radiator grille. The condenser cannot be

repaired or adjusted and, if faulty or damaged, it

must be replaced. The condenser may be removed

from the cooling module for service without removing

the cooling module from the vehicle.

OPERATION

The condenser is a heat exchanger that allows the

high-pressure refrigerant gas being discharged by the

compressor to give up its heat to the air passing over

the condenser fins. When the refrigerant gas gives up

its heat, it condenses. When the refrigerant leaves

the condenser, it has become a high-pressure liquid

refrigerant. The volume of air flowing over the con-

denser fins is critical to the proper cooling perfor-

mance of the air conditioning system. Therefore, it is

important that there are no objects placed in front of

the radiator grille openings in the front of the vehicle

or foreign material on the condenser fins that might

obstruct air flow. Also, any factory-installed air seals

or shrouds must be properly reinstalled following

radiator or condenser service.

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).NOTE: Before removing the condenser, note the

location of each of the radiator and condenser air

seals. These air seals are used to direct air through

the condenser and radiator. The air seals must be

reinstalled in their proper locations in order for the

air conditioning and engine cooling systems to per-

form as designed.

(1) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - FRONT/REFRIGERANT -

STANDARD PROCEDURE - REFRIGERANT

RECOVERY).

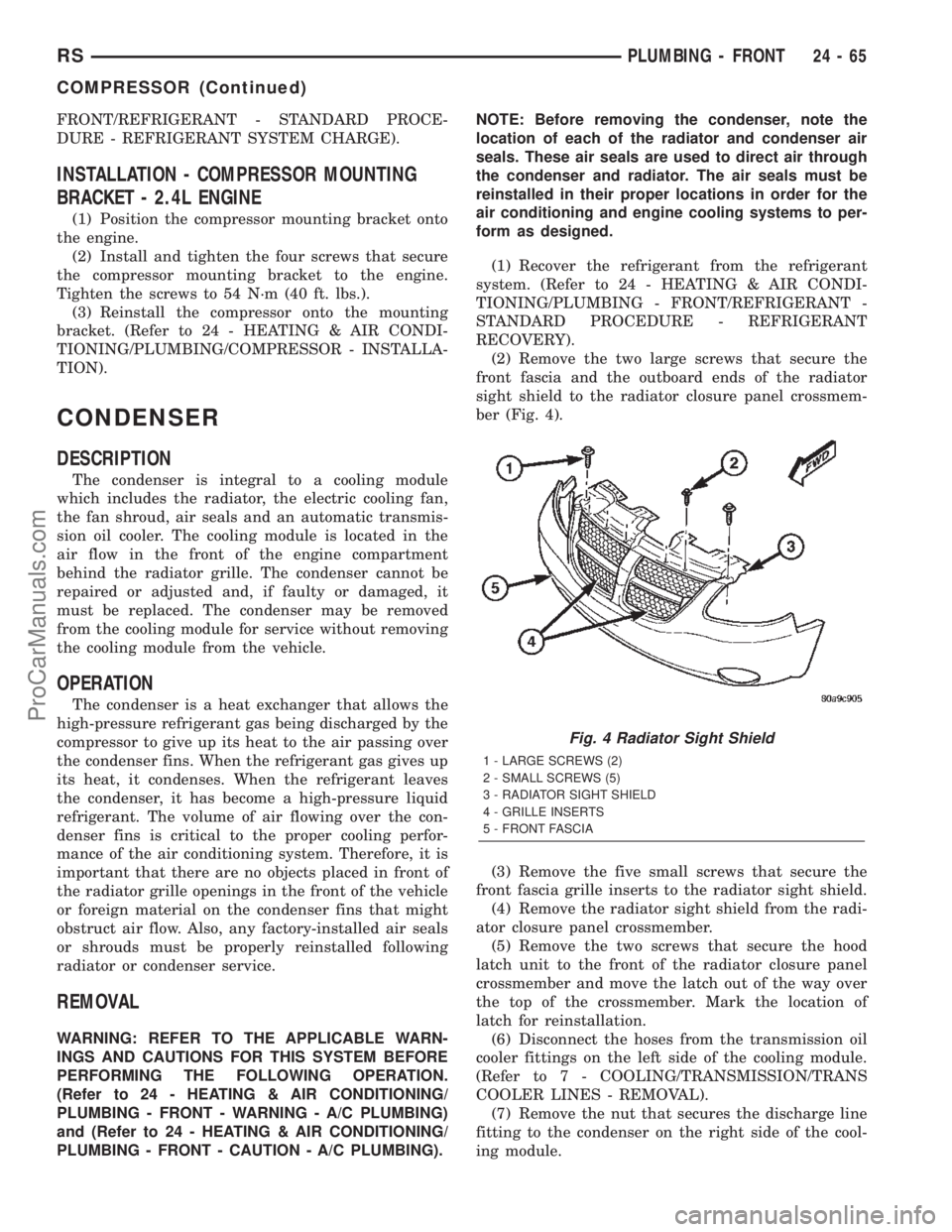

(2) Remove the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber (Fig. 4).

(3) Remove the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

(4) Remove the radiator sight shield from the radi-

ator closure panel crossmember.

(5) Remove the two screws that secure the hood

latch unit to the front of the radiator closure panel

crossmember and move the latch out of the way over

the top of the crossmember. Mark the location of

latch for reinstallation.

(6) Disconnect the hoses from the transmission oil

cooler fittings on the left side of the cooling module.

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER LINES - REMOVAL).

(7) Remove the nut that secures the discharge line

fitting to the condenser on the right side of the cool-

ing module.

Fig. 4 Radiator Sight Shield

1 - LARGE SCREWS (2)

2 - SMALL SCREWS (5)

3 - RADIATOR SIGHT SHIELD

4 - GRILLE INSERTS

5 - FRONT FASCIA

RSPLUMBING - FRONT24-65

COMPRESSOR (Continued)

ProCarManuals.com