electr CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1 of 2399

GROUP TAB LOCATOR

INIntroduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

6Clutch

7Cooling

7aCooling - 2.5L Turbo Diesel

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8EaElectronic Control Modules

8FEngine Systems

8FaEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8IaIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

9aEngine

11Exhaust System

11aExhaust System and Turbocharger

13Frame & Bumpers

14Fuel System

14aFuel System

19Steering

21Transmission

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

25aEmissions Control 2.5L Turbo Diesel

Service Manual Comment Forms

ProCarManuals.com

Page 3 of 2399

DIGIT 21

Price Class

²H = Highline

²L = Lowline

²P = Premium

²S = Luxury

²X = Premium

DIGITS 22 AND 23

Body Type

²52 = Short Wheel Base

²53 = Long Wheel Base

BODY CODE PLATE LINE 2

DIGITS 1, 2 AND 3

Paint Procedure

DIGIT 4

Open Space

DIGITS 5 THROUGH 7

Primary Paint (Refer to 23 - BODY/PAINT - SPEC-

IFICATIONS).

DIGIT 8 AND 9

Open Space

DIGITS 10 THROUGH 12

Secondary Paint

DIGIT 13 AND 14

Open Space

DIGITS 15 THROUGH 18

Interior Trim Code

DIGIT 19

Open Space

DIGITS 20, 21, AND 22

Engine Code

²EDZ = 2.4L 4 cyl. 16-Valve DOHC Gasoline

(MPI)

²EGA = 3.3L 6 cyl. Gasoline (SMPI)

²EGH = 3.8L 6 cyl. Gasoline (SMPI)

²EGM = 3.3L 6 cyl. Ethanol Flexible Fuel

²ENJ = 2.5L 4 cyl. 16-Valve Turbo Diesel

DIGIT 23

Open Space

BODY CODE PLATE LINE 1

DIGITS 1, 2, AND 3

Transaxle Codes

²DGC = 31TH 3-Speed Automatic Transaxle

²DGL = 41AE/TE 4-Speed Electronic Automatic

²DDR = T850 5-Speed Manual Transaxle

DIGIT 4

Open Space

DIGIT 5

Market Code

²C = Canada

²B = International

²M = Mexico

²U = United States

DIGIT 6

Open Space

DIGITS 7 THROUGH 23

Vehicle Identification Number

²Refer to Vehicle Identification Number (VIN)

paragraph for proper breakdown of VIN code.

IF TWO BODY CODE PLATES ARE REQUIRED

The last code shown on either plate will be fol-

lowed by END. When two plates are required, the

last code space on the first plate will indicate (CTD)

When a second plate is required, the first four

spaces of each line will not be used due to overlap of

the plates.

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts (Fig. 2) and (Fig. 3).

2 INTRODUCTIONRS

BODY CODE PLATE (Continued)

ProCarManuals.com

Page 20 of 2399

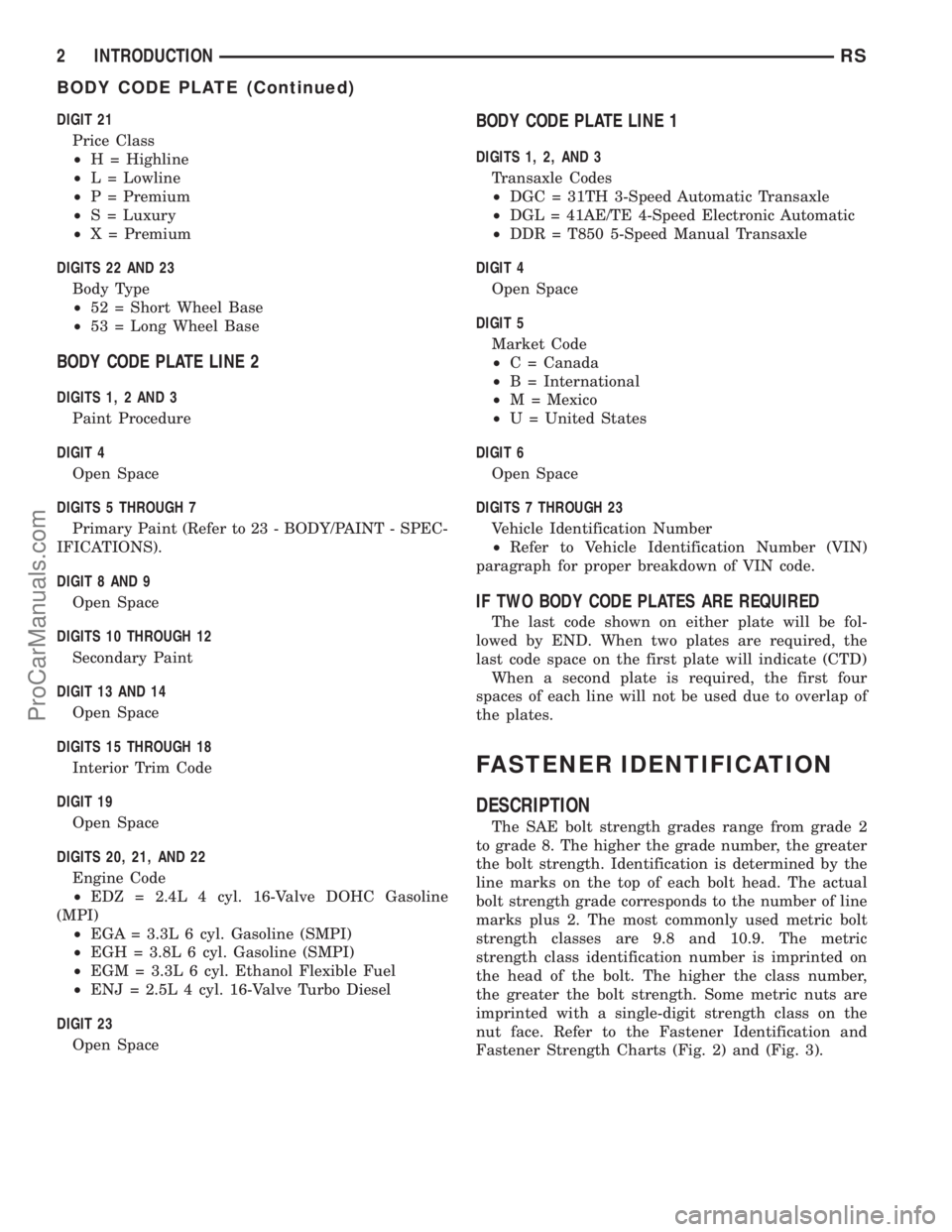

The hoisting points are identified by S.A.E.

inverted triangle hoisting symbols (Fig. 5). The front

hoisting points are at the bottom of the font rail

below the hoisting symbol approximately 250 mm

behind the front suspension crossmember. When

using outboard lift hoists, verify that the hoist lift

pads have been properly adjusted to eliminate con-

tact between the hoist arm and the down standing

flange on the sill. The rear hoisting points are the

leaf spring front mounting brackets. The hoist pad

must be positioned to pick up the flanges on the

bracket, not the leaf spring.

When servicing the leaf springs or the leaf spring

mounting brackets, special provisions are required to

support the rear of the vehicle. Position the rear

hoist pads under the horizontal surface on the bot-

tom of the sill, inboard adjacent to the flange and

centered fore/aft between the jacking indicator tabs

on the lower flange.DO NOT HOIST ON THE

FLANGE.Place a soft pad between the hoist and the

painted surface on the sill to avoid scratching the fin-

ish.JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS. (Refer to 8 - ELECTRICAL/BAT-

TERY SYSTEM/BATTERY - STANDARD PROCE-

DURE).

WARNING: DO NOT JUMP START A FROZEN BAT-

TERY, PERSONAL INJURY CAN RESULT.

WARNING: DO NOT JUMP START WHEN MAINTE-

NANCE FREE BATTERY INDICATOR DOT IS BRIGHT

COLOR.

WARNING: DO NOT ALLOW JUMPER CABLE

CLAMPS TO TOUCH EACH OTHER WHEN CON-

NECTED TO A BOOSTER SOURCE.

WARNING: DO NOT USE OPEN FLAME NEAR BAT-

TERY

WARNING: REMOVE METALLIC JEWELRY WORN

ON HANDS OR WRISTS TO AVOID INJURY BY

ACCIDENTAL ARCING OF BATTERY CURRENT.

WARNING: WHEN USING A HIGH OUTPUT BOOST-

ING DEVICE, DO NOT ALLOW BATTERY VOLTAGE

TO EXCEED 16 VOLTS.

WARNING: REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: DO NOT ATTEMPT TO PUSH OR TOW

THE VEHICLE TO START IT. THE VEHICLE CANNOT

BE STARTED THIS WAY. PUSHING WITH ANOTHER

VEHICLE MAY DAMAGE THE TRANSAXLE OR THE

REAR OF THE VEHICLE.

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Clear or bright color test indicator, if equipped.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

Fig. 5 HOISTING AND JACKING POINTS

1- DRIVE ON LIFT

2 - FRAME CONTACT LIFT (SINGLE POST)

2 - CHASSIS LIFT (NON-AXLE DUAL POST)

2 - OUTBOARD LIFT (DUAL POST)

2 - FLOOR JACK

3 - S.A.E. HOISTING SYMBOLS

RSLUBRICATION & MAINTENANCE0-7

HOISTING (Continued)

ProCarManuals.com

Page 21 of 2399

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

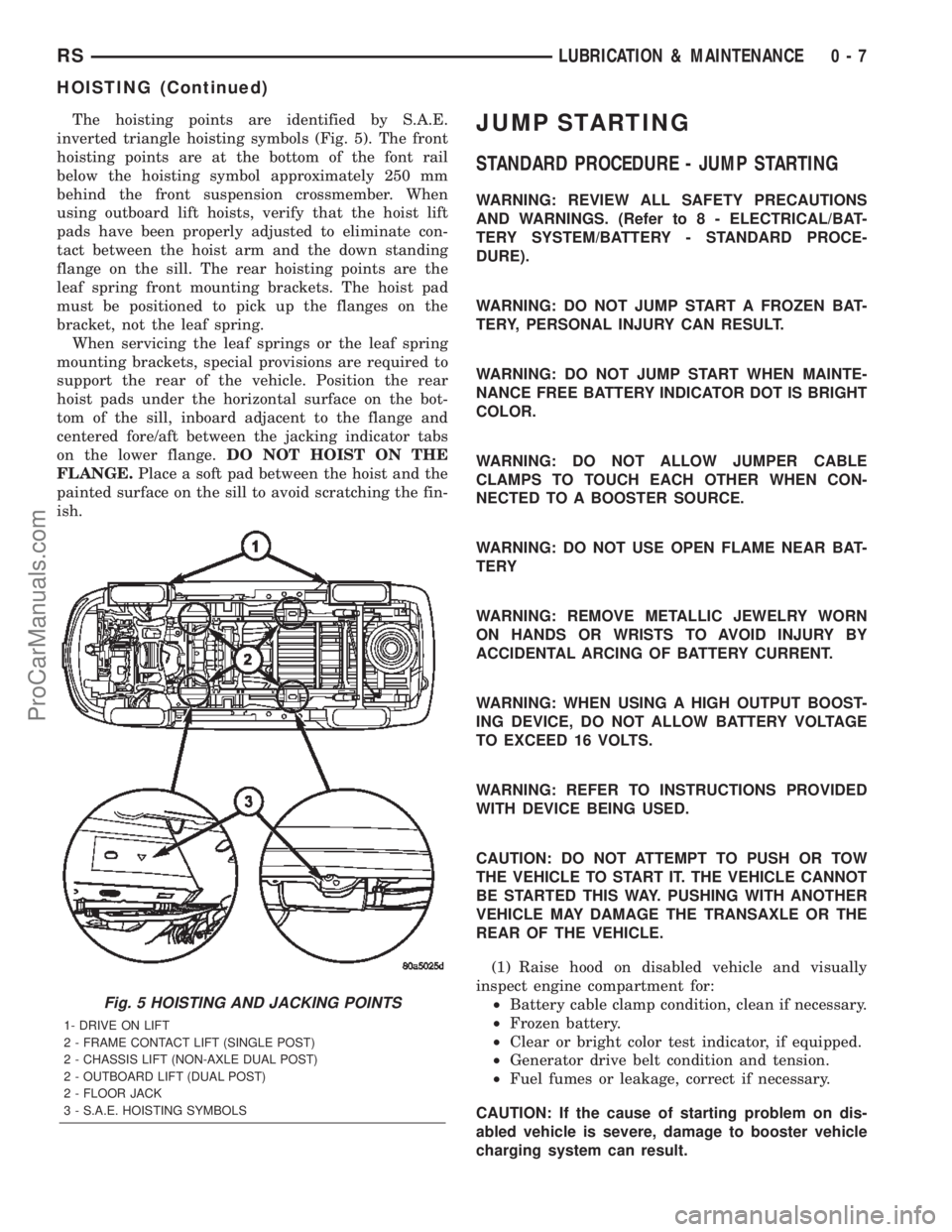

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 6).

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - STANDARD PROCEDURE).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter may over-

heat and could fail.

(7) If engine does not start within 15 seconds, stop

cranking engine and allow starter to cool (15 min-

utes), before cranking again.DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

STANDARD PROCEDURE - TOWING

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

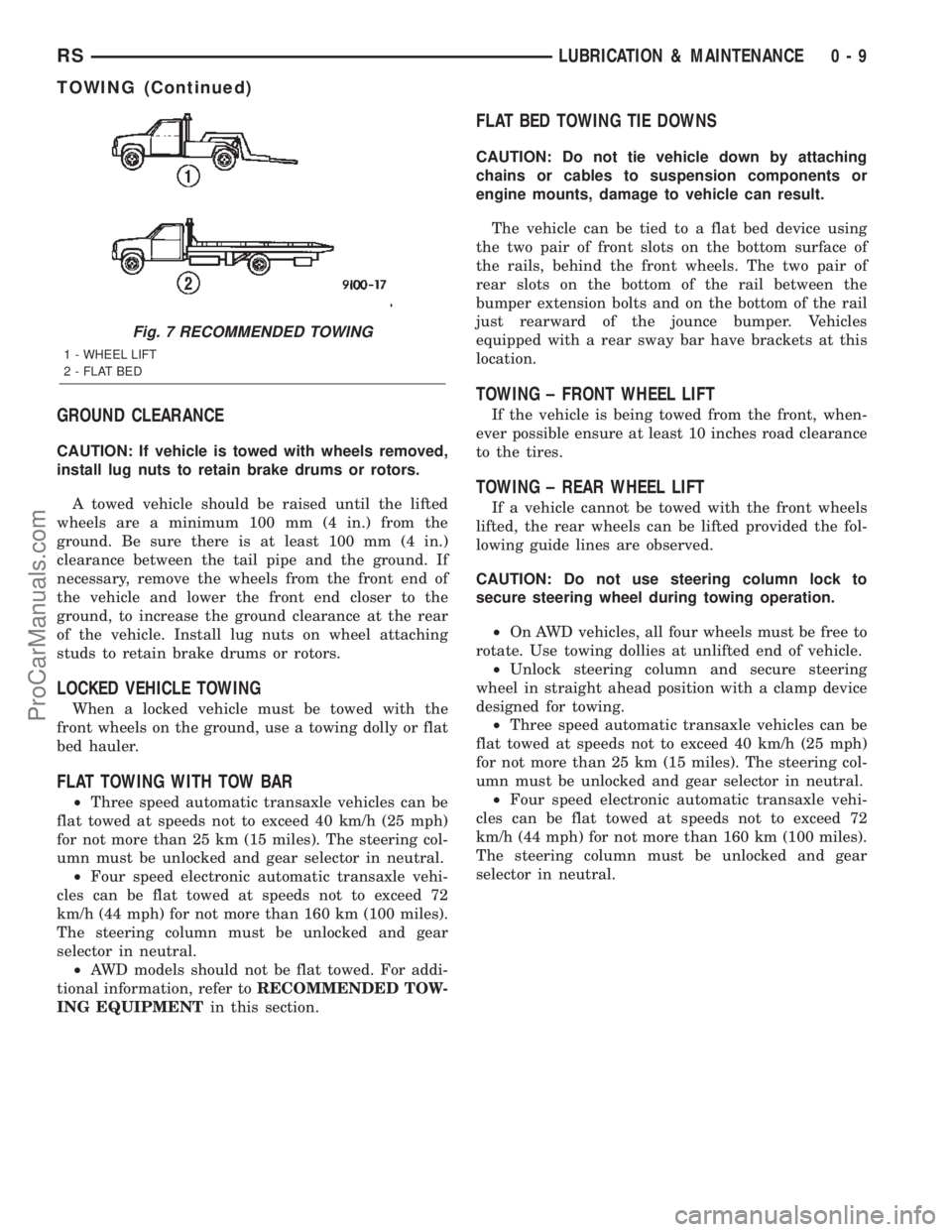

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use:

²FWD vehicles, use of a flat bed towing device or

a wheel lift is recommended (Fig. 7).

²AWD vehicles, a flat bed towing device or a

wheel lift and towing dolly is recommended (Fig. 7).

When using a wheel lift towing device, be sure the

disabled vehicle has at least 100 mm (4 in.) ground

clearance. If minimum ground clearance cannot be

reached, use a towing dolly. If a flat bed device is

used, the approach angle should not exceed 15

degrees.

Fig. 6 JUMPER CABLE CLAMP CONNECTIONS

1 - BATTERY NEGATIVE TERMINAL

2 - POSITIVE JUMPER CABLE

3 - TEST INDICATOR (IF EQUIPPED)

4 - BATTERY POSITIVE TERMINAL

5 - BATTERY

6 - NEGATIVE JUMPER CABLE

0 - 8 LUBRICATION & MAINTENANCERS

JUMP STARTING (Continued)

ProCarManuals.com

Page 22 of 2399

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the front end of

the vehicle and lower the front end closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

²AWD models should not be flat towed. For addi-

tional information, refer toRECOMMENDED TOW-

ING EQUIPMENTin this section.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

The vehicle can be tied to a flat bed device using

the two pair of front slots on the bottom surface of

the rails, behind the front wheels. The two pair of

rear slots on the bottom of the rail between the

bumper extension bolts and on the bottom of the rail

just rearward of the jounce bumper. Vehicles

equipped with a rear sway bar have brackets at this

location.

TOWING ± FRONT WHEEL LIFT

If the vehicle is being towed from the front, when-

ever possible ensure at least 10 inches road clearance

to the tires.

TOWING ± REAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lifted, the rear wheels can be lifted provided the fol-

lowing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²On AWD vehicles, all four wheels must be free to

rotate. Use towing dollies at unlifted end of vehicle.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

Fig. 7 RECOMMENDED TOWING

1 - WHEEL LIFT

2 - FLAT BED

RSLUBRICATION & MAINTENANCE0-9

TOWING (Continued)

ProCarManuals.com

Page 132 of 2399

SUPPORT PLATE - DRUM BRAKE

REMOVAL.............................64

INSTALLATION.........................64

WHEEL CYLINDERS

REMOVAL.............................65

INSPECTION..........................65

INSTALLATION.........................65

PARKING BRAKE

DESCRIPTION

DESCRIPTION........................65

DESCRIPTION - EXPORT...............66

OPERATION...........................66

STANDARD PROCEDURE

STANDARD PROCEDURE - PARKING

BRAKE AUTOMATIC ADJUSTER TENSION

RELEASE...........................66

STANDARD PROCEDURE - PARKING

BRAKE AUTOMATIC ADJUSTER TENSION

RESET.............................67

CABLES - PARKING BRAKE

REMOVAL

REMOVAL - PARKING BRAKE CABLE

(FRONT)............................67

REMOVAL - PARKING BRAKE CABLE

(INTERMEDIATE)......................68

REMOVAL - PARKING BRAKE CABLE

(RIGHT REAR)........................69

REMOVAL - PARKING BRAKE CABLE (LEFT

REAR)..............................70INSTALLATION

INSTALLATION - PARKING BRAKE CABLE

(FRONT)............................71

INSTALLATION - PARKING BRAKE CABLE

(INTERMEDIATE)......................71

INSTALLATION - PARKING BRAKE CABLE

(RIGHT REAR)........................72

INSTALLATION - PARKING BRAKE CABLE

(LEFT REAR).........................72

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE CABLES . 72

CABLES - PARKING BRAKE (EXPORT)

REMOVAL - FRONT CABLE...............72

INSTALLATION - FRONT CABLE............72

LEVER - PARKING BRAKE

REMOVAL.............................72

INSTALLATION.........................73

LEVER - PARKING BRAKE (EXPORT)

REMOVAL - PARKING BRAKE LEVER AND

FRONT CABLE.......................74

INSTALLATION - PARKING BRAKE LEVER

AND FRONT CABLE...................75

SHOES - PARKING BRAKE

REMOVAL.............................75

INSTALLATION.........................81

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE SHOES . . 83

BRAKES - BASE

DESCRIPTION

DESCRIPTION - BASE BRAKES

The base brake system consists of the following

components:

²Brake pedal

²Power brake booster

²Master cylinder

²Brake tubes and hoses

²Proportioning valve (non-ABS vehicles only)

²Disc brakes

²Drum brakes

²Brake lamp switch

²Brake fluid level switch

²Parking brakes

Front disc brakes control the braking of the front

wheels; rear braking is controlled by rear drum

brakes or rear disc brakes depending on options.

The hydraulic brake system is diagonally split on

both the non-antilock braking systems and antilock

braking systems. That means the left front and right

rear brakes are on one hydraulic circuit and the right

front and left rear are on the other.For information on the brake lamp switch, (Refer

to 8 - ELECTRICAL/LAMPS/LIGHTING - EXTERI-

OR/BRAKE LAMP SWITCH - DESCRIPTION)

Vehicles equipped with the optional antilock brake

system (ABS) use a system designated Mark 20e. It

is available with or without traction control. This

system shares most base brake hardware used on

vehicles without ABS. ABS components are described

in detail in ANTILOCK BRAKE SYSTEM.

DESCRIPTION - BASE BRAKES (EXPORT)

Four-Wheel Disc Antilock Brakes are standard on

all models.

OPERATION - BASE BRAKES

When a vehicle needs to be stopped, the driver

applies the brake pedal. The brake pedal pushes the

input rod of the power brake booster into the booster.

The booster uses vacuum to ease pedal effort as force

is transferred through the booster to the master cyl-

inder. The booster's output rod pushes in the master

cylinder's primary and secondary pistons applying

hydraulic pressure through the chassis brake tubes

to the brakes at each tire and wheel assembly.

The parking brakes are foot-operated. When

applied, the parking brake lever pulls on cables that

actuate brake shoes at each rear wheel. These shoes

RSBRAKES - BASE5-3

ProCarManuals.com

Page 140 of 2399

ADJUSTABLE PEDAL SWITCH

DESCRIPTION

The adjustable pedal switch is mounted on the left

side of the lower steering column shroud (Fig. 5). The

adjustable pedal switch adjusts the adjustable pedal

assembly fore-and-aft. The pedal assembly moves in

the direction the switch is actuated.

DIAGNOSIS AND TESTING - ADJUSTABLE

PEDAL SWITCH

Refer to Appropriate Diagnostic Information.

REMOVAL

NOTE: Before proceeding, review all Steering Col-

umn and Airbag Warnings and Cautions. (Refer to

19 - STEERING/COLUMN - WARNING)(Refer to 8 -

ELECTRICAL/RESTRAINTS - WARNING)

(1) Remove battery ground cable terminal from

battery negative post and isolate.

(2) Under instrument panel, remove silencer panel

below lower steering column cover.

(3) Remove screws securing lower steering column

cover/knee blocker, then remove it (Fig. 6).

(4) Disconnect parking brake release link at

release handle.

(5) Compress tabs on sides of data link diagnostic

connector and remove it from knee blocker reinforce-

ment plate.

(6) Remove screws securing knee blocker reinforce-

ment plate in place, then remove reinforcement plate

(Fig. 6).

(7) Remove screws fastening upper and lower

steering column shrouds to steering column (Fig. 7).

(8) Remove the lower shroud with adjustable pedal

switch; disconnect switch wiring connector along left

side of column as shroud is removed (Fig. 8).

Fig. 4 MASTER CYLINDER AND BOOSTER

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

Fig. 5 Adjustable Pedal Switch Location

1 - ADJUSTABLE PEDAL SWITCH

2 - LOWER STEERING COLUMN SHROUD

Fig. 6 Lower Steering Column Cover And

Reinforcement

1 - INSTRUMENT PANEL

2 - REINFORCEMENT PLATE

3 - LOWER STEERING COLUMN COVER/KNEE BLOCKER

RSBRAKES - BASE5-11

BRAKE FLUID LEVEL SWITCH (Continued)

ProCarManuals.com

Page 148 of 2399

Replacebothdisc brake shoes (inboard and out-

board) on each caliper. It is necessary to replace the

shoes on the opposite side of the vehicle as well as

the shoes failing inspection.

If the brake shoe assemblies do not require

replacement, be sure to reinstall the brake shoes in

the original position they were removed from.

INSTALLATION

INSTALLATION - FRONT DISC BRAKE SHOES

NOTE: There may be more than 1 lining material

released. Make sure proper linings are being

installed.

(1) Begin on one side of the vehicle or the other.

(2) Completely retract the caliper piston back into

its bore in the brake caliper (This is required for cal-

iper installation on the brake rotor with new brake

shoes installed).

(3) If applied, remove the protective paper from

the noise suppression gasket on the rear of both the

inner and outer brake shoe assemblies.

(4) Install the new inboard brake shoe into the cal-

iper piston by firmly pressing its retaining clip into

the piston bore. Be sure the inboard brake shoe is

positioned squarely against the face of the caliper

piston.

(5) Lubricate both adapter abutments where the

shoes slide with a small amount of MopartDielectric

grease, or equivalent.

(6) Slide the new outboard brake shoe into the cal-

iper adapter with the lining up against the outside of

the brake rotor.

CAUTION: Use care when installing the caliper

assembly onto the caliper adapter, so the caliper

guide pin bushings do not get damaged by the

adapter bosses.

(7) Carefully position the brake caliper over the

brake rotor and adapter.

(8) Install the caliper guide pin bolts and tighten

to a torque of 35 N´m (26 ft. lbs.).Extreme caution

should be taken not to cross thread the caliper

guide pin bolts.

(9) Install the caps over the caliper guide pin bolts.

(10) Install the new caliper hold down spring (anti-

rattle clip) on the outboard side of the caliper. Start

the spring into the holes on the caliper, then stretch

the clip legs past the abutments on the caliper

adapter.

(11) Repeat the above procedure on other side of

the vehicle.(12) Install the wheel and tire assemblies. Tighten

the wheel mounting nuts in proper sequence until all

nuts are torqued to half specification, then repeat the

tightening sequence to the full specified torque of 135

N´m (100 ft. lbs.).

(13) Lower vehicle.

(14) Pump the brake pedal several times. This will

set the shoes to the brake rotor.

(15) Check and adjust brake fluid level as neces-

sary.

(16) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoes.

INSTALLATION - FRONT DISC BRAKE SHOES

(DISC/DRUM BRAKES)

NOTE: Perform steps Step 1 through Step 5on each

side of the vehicle.

(1) Place the brake shoes in the adapter anti-rattle

clips.

(2) Completely retract the caliper piston back into

the bore of the caliper.

CAUTION: Use care when installing the caliper onto

the disc brake adapter to avoid damaging the boots

on the caliper guide pins.

(3) Install the disc brake caliper over the brake

shoes on the brake caliper adapter.

(4) Align the caliper guide pin bolt holes with the

guide pins. Install the caliper guide pin bolts and

tighten them to a torque of 35 N´m (26 ft. lbs.) (Fig.

22).

(5) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(6) Lower the vehicle.

(7) Pump the brake pedal several times. This will

set the shoes to the brake rotor.

(8) Check and adjust the brake fluid level as nec-

essary.

(9) Road test the vehicle and make several stops to

wear off any foreign material on the brakes and to

seat the brake shoes.

BRAKE PADS/SHOES - REAR

DISC

REMOVAL - REAR DISC BRAKE SHOES

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

RSBRAKES - BASE5-19

BRAKE PADS/SHOES - FRONT (Continued)

ProCarManuals.com

Page 157 of 2399

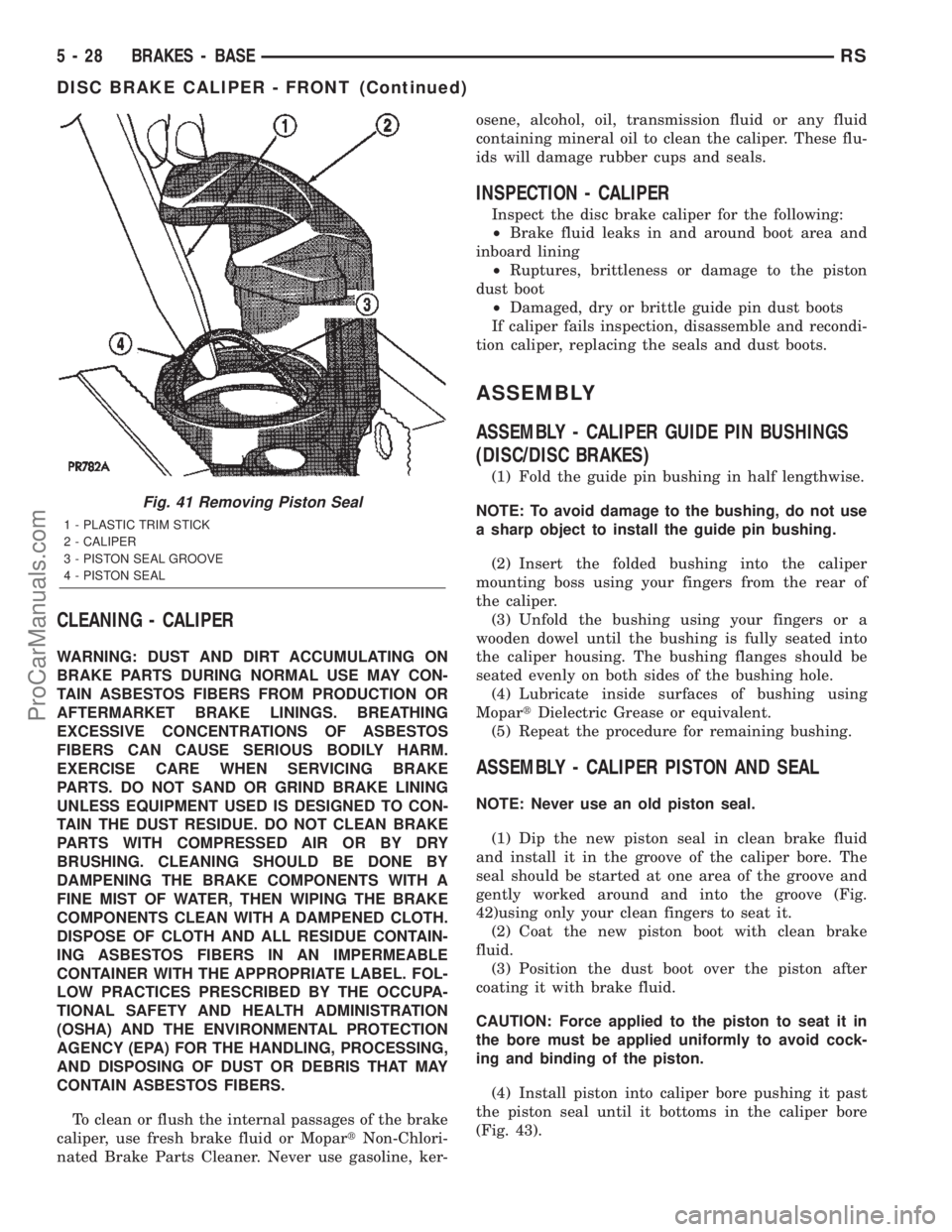

CLEANING - CALIPER

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH.

DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

To clean or flush the internal passages of the brake

caliper, use fresh brake fluid or MopartNon-Chlori-

nated Brake Parts Cleaner. Never use gasoline, ker-osene, alcohol, oil, transmission fluid or any fluid

containing mineral oil to clean the caliper. These flu-

ids will damage rubber cups and seals.

INSPECTION - CALIPER

Inspect the disc brake caliper for the following:

²Brake fluid leaks in and around boot area and

inboard lining

²Ruptures, brittleness or damage to the piston

dust boot

²Damaged, dry or brittle guide pin dust boots

If caliper fails inspection, disassemble and recondi-

tion caliper, replacing the seals and dust boots.

ASSEMBLY

ASSEMBLY - CALIPER GUIDE PIN BUSHINGS

(DISC/DISC BRAKES)

(1) Fold the guide pin bushing in half lengthwise.

NOTE: To avoid damage to the bushing, do not use

a sharp object to install the guide pin bushing.

(2) Insert the folded bushing into the caliper

mounting boss using your fingers from the rear of

the caliper.

(3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated into

the caliper housing. The bushing flanges should be

seated evenly on both sides of the bushing hole.

(4) Lubricate inside surfaces of bushing using

MopartDielectric Grease or equivalent.

(5) Repeat the procedure for remaining bushing.

ASSEMBLY - CALIPER PISTON AND SEAL

NOTE: Never use an old piston seal.

(1) Dip the new piston seal in clean brake fluid

and install it in the groove of the caliper bore. The

seal should be started at one area of the groove and

gently worked around and into the groove (Fig.

42)using only your clean fingers to seat it.

(2) Coat the new piston boot with clean brake

fluid.

(3) Position the dust boot over the piston after

coating it with brake fluid.

CAUTION: Force applied to the piston to seat it in

the bore must be applied uniformly to avoid cock-

ing and binding of the piston.

(4) Install piston into caliper bore pushing it past

the piston seal until it bottoms in the caliper bore

(Fig. 43).

Fig. 41 Removing Piston Seal

1 - PLASTIC TRIM STICK

2 - CALIPER

3 - PISTON SEAL GROOVE

4 - PISTON SEAL

5 - 28 BRAKES - BASERS

DISC BRAKE CALIPER - FRONT (Continued)

ProCarManuals.com

Page 165 of 2399

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

JUNCTION BLOCK

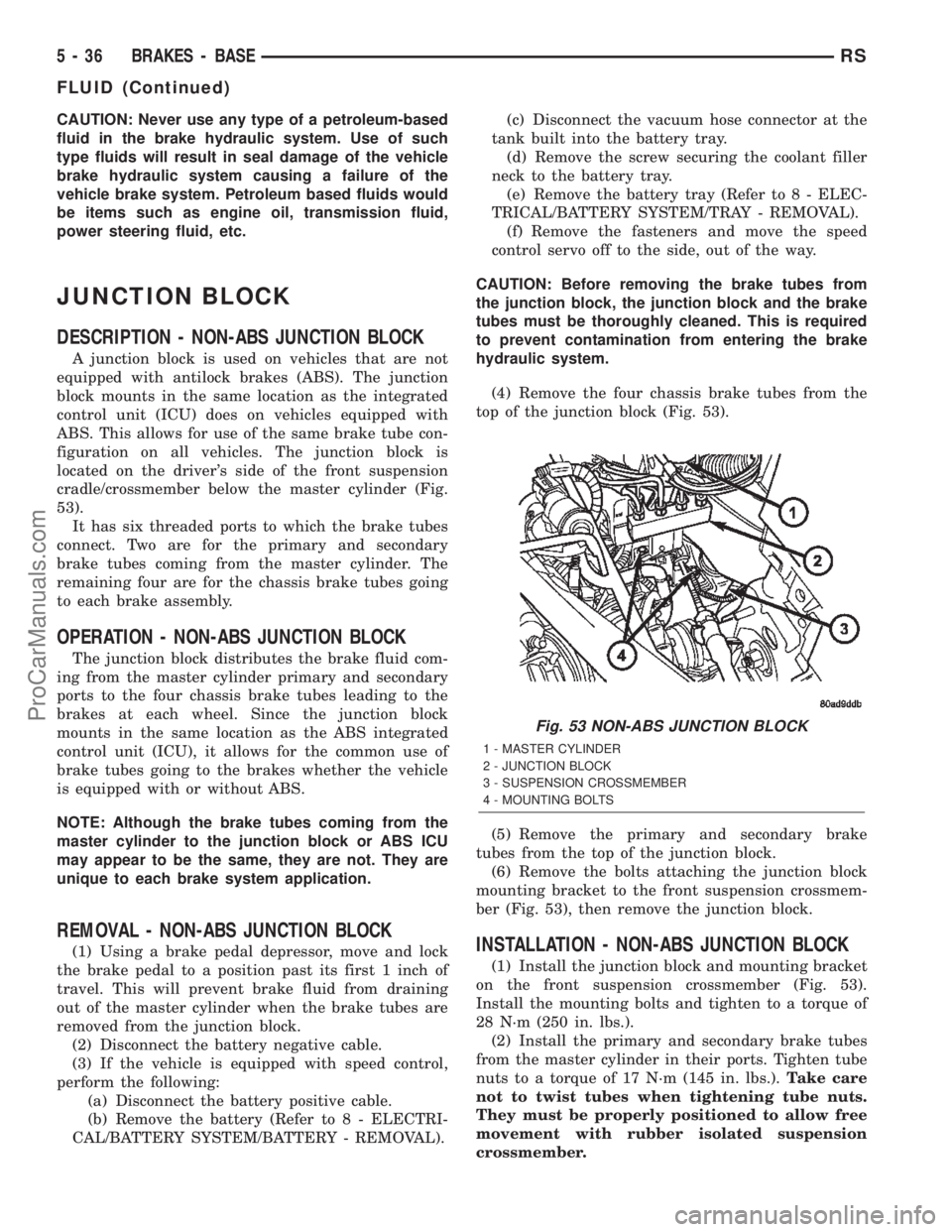

DESCRIPTION - NON-ABS JUNCTION BLOCK

A junction block is used on vehicles that are not

equipped with antilock brakes (ABS). The junction

block mounts in the same location as the integrated

control unit (ICU) does on vehicles equipped with

ABS. This allows for use of the same brake tube con-

figuration on all vehicles. The junction block is

located on the driver's side of the front suspension

cradle/crossmember below the master cylinder (Fig.

53).

It has six threaded ports to which the brake tubes

connect. Two are for the primary and secondary

brake tubes coming from the master cylinder. The

remaining four are for the chassis brake tubes going

to each brake assembly.

OPERATION - NON-ABS JUNCTION BLOCK

The junction block distributes the brake fluid com-

ing from the master cylinder primary and secondary

ports to the four chassis brake tubes leading to the

brakes at each wheel. Since the junction block

mounts in the same location as the ABS integrated

control unit (ICU), it allows for the common use of

brake tubes going to the brakes whether the vehicle

is equipped with or without ABS.

NOTE: Although the brake tubes coming from the

master cylinder to the junction block or ABS ICU

may appear to be the same, they are not. They are

unique to each brake system application.

REMOVAL - NON-ABS JUNCTION BLOCK

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block.

(2) Disconnect the battery negative cable.

(3) If the vehicle is equipped with speed control,

perform the following:

(a) Disconnect the battery positive cable.

(b) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).(c) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(d) Remove the screw securing the coolant filler

neck to the battery tray.

(e) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(f) Remove the fasteners and move the speed

control servo off to the side, out of the way.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hydraulic system.

(4) Remove the four chassis brake tubes from the

top of the junction block (Fig. 53).

(5) Remove the primary and secondary brake

tubes from the top of the junction block.

(6) Remove the bolts attaching the junction block

mounting bracket to the front suspension crossmem-

ber (Fig. 53), then remove the junction block.INSTALLATION - NON-ABS JUNCTION BLOCK

(1) Install the junction block and mounting bracket

on the front suspension crossmember (Fig. 53).

Install the mounting bolts and tighten to a torque of

28 N´m (250 in. lbs.).

(2) Install the primary and secondary brake tubes

from the master cylinder in their ports. Tighten tube

nuts to a torque of 17 N´m (145 in. lbs.).Take care

not to twist tubes when tightening tube nuts.

They must be properly positioned to allow free

movement with rubber isolated suspension

crossmember.

Fig. 53 NON-ABS JUNCTION BLOCK

1 - MASTER CYLINDER

2 - JUNCTION BLOCK

3 - SUSPENSION CROSSMEMBER

4 - MOUNTING BOLTS

5 - 36 BRAKES - BASERS

FLUID (Continued)

ProCarManuals.com