compressor CHRYSLER VOYAGER 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1470 of 2399

The PCM compares the upstream and downstream

heated oxygen sensor inputs to measure catalytic con-

vertor efficiency. If the catalyst efficiency drops below

the minimum acceptable percentage, the PCM stores a

diagnostic trouble code in memory, after 2 trips.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C sense

²Battery voltage

²Battery temperature or Calculated Battery Tem-

perature

²Engine coolant temperature

²Engine run time

²Inlet/Intake air temperature

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

²Wide Open Throttle-open loop

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C sense

²Battery voltage

²Inlet/Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Throttle position sensor

²IAC motor (solenoid) control changes in response

to MAP sensor feedback

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates a

hard deceleration (Open Loop). In response, the PCM

may momentarily turn off the injectors. This helps

improve fuel economy, emissions and engine braking.

WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are used by

the PCM:

²Inlet/Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor²Manifold absolute pressure

²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system and disables

EGR (if equipped).

The PCM adjusts injector pulse width to supply a

predetermined amount of additional fuel, based on

MAP and RPM.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to the Emission sec-

tion for On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

FUEL CORRECTION or ADAPTIVE MEMORIES

DESCRIPTION

In Open Loop, the PCM changes pulse width with-

out feedback from the O2 Sensors. Once the engine

warms up to approximately 30 to 35É F, the PCM

goes into closed loopShort Term Correctionand

utilizes feedback from the O2 Sensors. Closed loop

Long Term Adaptive Memoryis maintained above

170É to 190É F unless the PCM senses wide open

throttle. At that time the PCM returns to Open Loop

operation.

OPERATION

Short Term

The first fuel correction program that begins func-

tioning is the short term fuel correction. This system

corrects fuel delivery in direct proportion to the read-

ings from the Upstream O2 Sensor.

The PCM monitors the air/fuel ratio by using the

input voltage from the O2 Sensor. When the voltage

reaches its preset high or low limit, the PCM begins

to add or remove fuel until the sensor reaches its

switch point. The short term corrections then begin.

The PCM makes a series of quick changes in the

injector pulse-width until the O2 Sensor reaches its

opposite preset limit or switch point. The process

then repeats itself in the opposite direction.

Short term fuel correction will keep increasing or

decreasing injector pulse-width based upon the

upstream O2 Sensor input. The maximum range of

authority for short term memory is 25% (+/-) of base

pulse-width. Short term is violated and is lost when

ignition is turned OFF.

RSFUEL INJECTION14-19

FUEL INJECTION (Continued)

ProCarManuals.com

Page 1478 of 2399

FUEL PUMP RELAY

DESCRIPTION

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

OPERATION

The fuel pump relay supplies battery voltage to the

fuel pump. A buss bar in the Power Distribution Cen-

ter (PDC) supplies voltage to the solenoid side and

contact side of the relay. The fuel pump relay power

circuit contains a fuse between the buss bar in the

PDC and the relay. The fuse is located in the PDC.

Refer to the Wiring Diagrams for circuit information.

The PCM controls the fuel pump relay by switch-

ing the ground path for the solenoid side of the relay

on and off. The PCM turns the ground path off when

the ignition switch is in the Off position. When the

ignition switch is in the On position, the PCM ener-

gizes the fuel pump. If the crankshaft position sensor

does not detect engine rotation, the PCM de-ener-

gizes the relay after approximately one second.

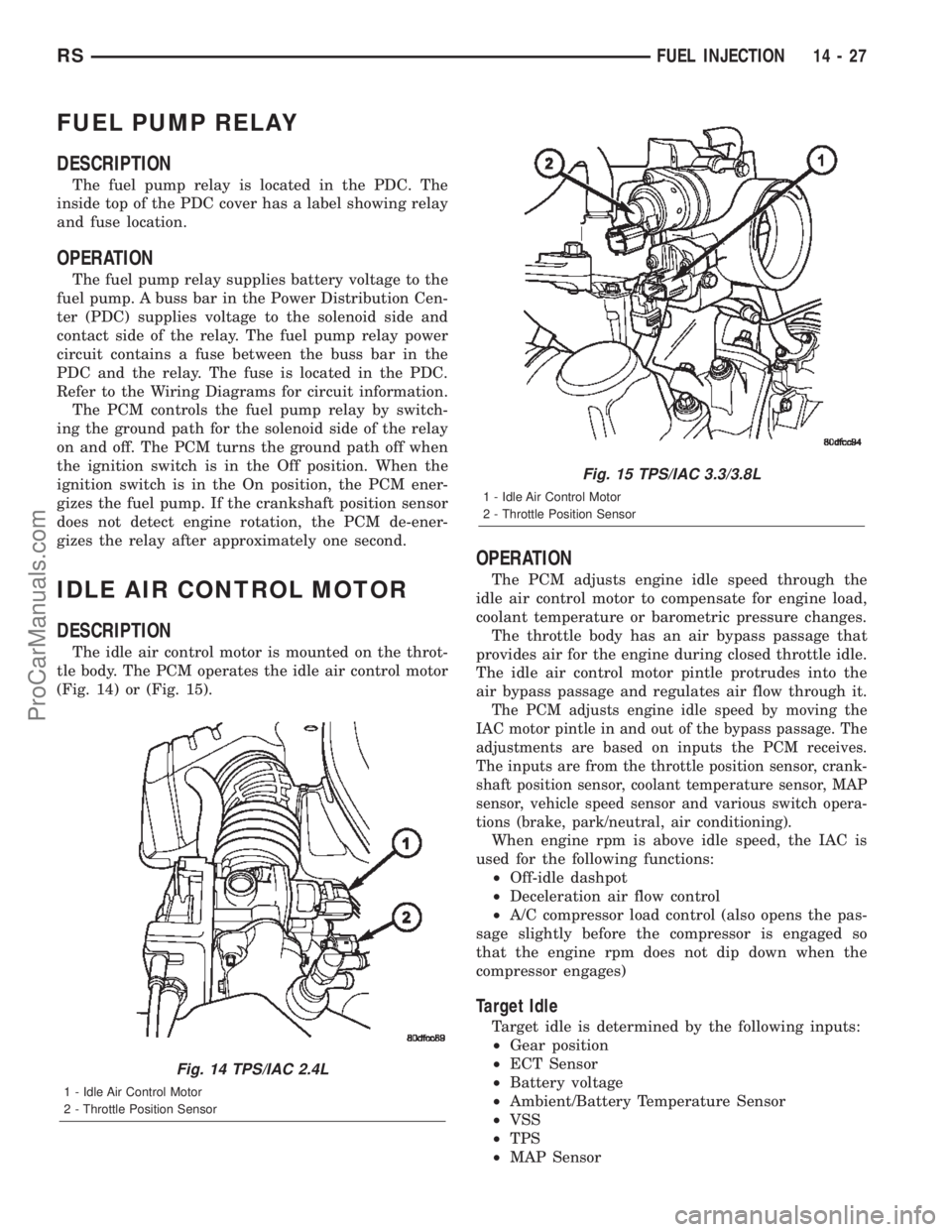

IDLE AIR CONTROL MOTOR

DESCRIPTION

The idle air control motor is mounted on the throt-

tle body. The PCM operates the idle air control motor

(Fig. 14) or (Fig. 15).

OPERATION

The PCM adjusts engine idle speed through the

idle air control motor to compensate for engine load,

coolant temperature or barometric pressure changes.

The throttle body has an air bypass passage that

provides air for the engine during closed throttle idle.

The idle air control motor pintle protrudes into the

air bypass passage and regulates air flow through it.

The PCM adjusts engine idle speed by moving the

IAC motor pintle in and out of the bypass passage. The

adjustments are based on inputs the PCM receives.

The inputs are from the throttle position sensor, crank-

shaft position sensor, coolant temperature sensor, MAP

sensor, vehicle speed sensor and various switch opera-

tions (brake, park/neutral, air conditioning).

When engine rpm is above idle speed, the IAC is

used for the following functions:

²Off-idle dashpot

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

Target Idle

Target idle is determined by the following inputs:

²Gear position

²ECT Sensor

²Battery voltage

²Ambient/Battery Temperature Sensor

²VSS

²TPS

²MAP Sensor

Fig. 14 TPS/IAC 2.4L

1 - Idle Air Control Motor

2 - Throttle Position Sensor

Fig. 15 TPS/IAC 3.3/3.8L

1 - Idle Air Control Motor

2 - Throttle Position Sensor

RSFUEL INJECTION14-27

ProCarManuals.com

Page 1632 of 2399

SPECIAL TOOLS

31TH AUTOMATIC TRANSAXLE

Adapter Blocks C-293±45

Adapter Blocks C-293±52

Puller Press C-293±PA

Pressure Gauge (High) C-3293SP

Dial Indicator C-3339

Spring Compressor C-3575-A

Band Adjusting Adapter C-3705

Oil Pump Puller C-3752

Throttle Setting Gauge C-3763

Seal Puller C-3981B

RS31TH AUTOMATIC TRANSAXLE21-75

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1640 of 2399

(3) Remove clutch pack (Fig. 116).

(4) Using tool C3575A, compress front clutch

return spring and remove snap ring (Fig. 117).(5) Remove retainer, return spring and piston (Fig.

118) (Fig. 119).

Fig. 116 Front Clutch (4-Disc Shown)

1 - FRONT CLUTCH RETAINER

2 - CLUTCH PLATES

3 - DRIVING DISCS

Fig. 117 Front Clutch Return Spring Snap Ring

1 - COMPRESSOR TOOL C-3575-A

2 - FRONT CLUTCH RETAINER

3 - SNAP RING

4 - SNAP RING PLIERS

Fig. 118 Front Clutch Return Spring and Piston

1 - LIP SEALS

2 - PISTON

3 - RETURN SPRING RETAINER

4 - SNAP RING

5 - PISTON RETURN SPRING

6 - FRONT CLUTCH RETAINER

RS31TH AUTOMATIC TRANSAXLE21-83

CLUTCH - FRONT (Continued)

ProCarManuals.com

Page 1642 of 2399

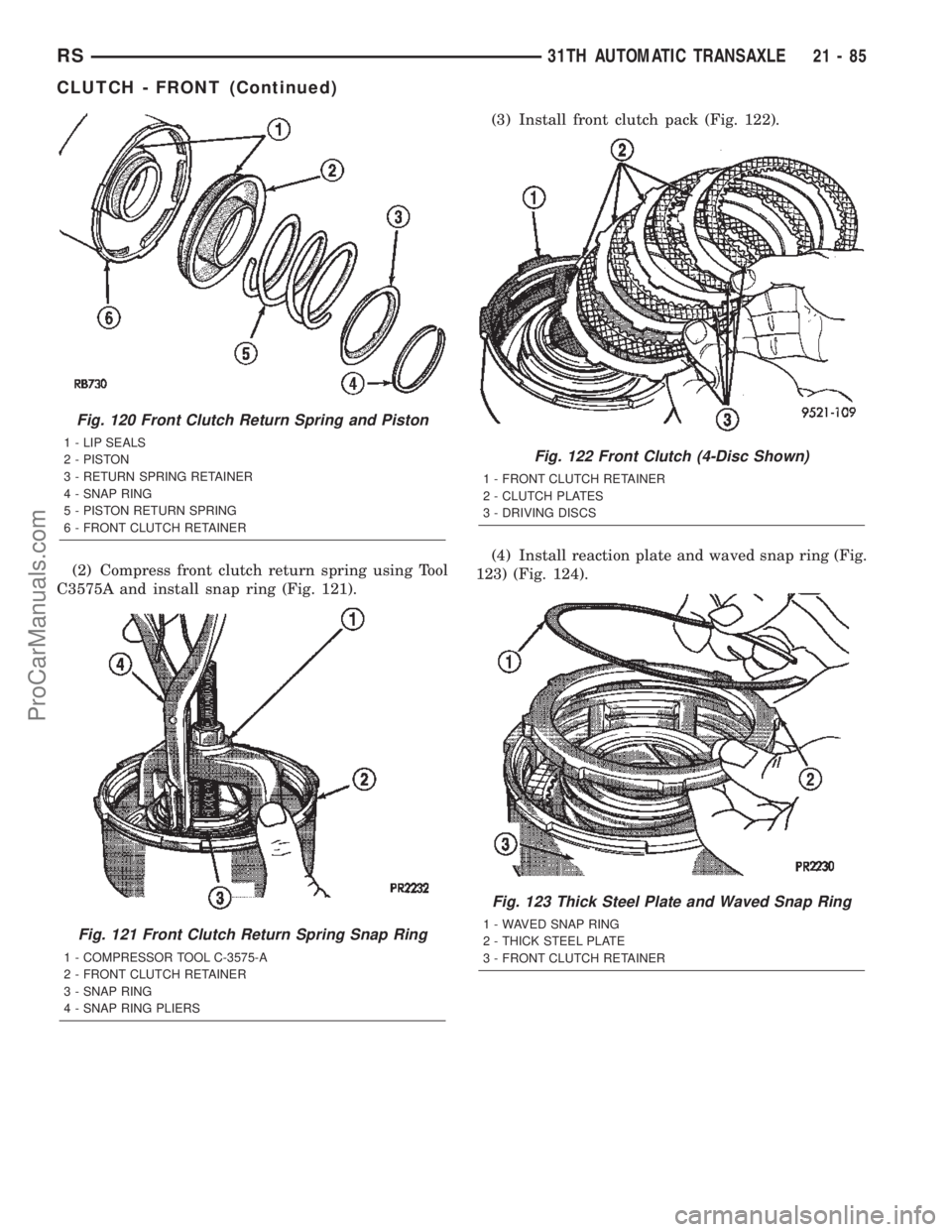

(2) Compress front clutch return spring using Tool

C3575A and install snap ring (Fig. 121).(3) Install front clutch pack (Fig. 122).

(4) Install reaction plate and waved snap ring (Fig.

123) (Fig. 124).

Fig. 120 Front Clutch Return Spring and Piston

1 - LIP SEALS

2 - PISTON

3 - RETURN SPRING RETAINER

4 - SNAP RING

5 - PISTON RETURN SPRING

6 - FRONT CLUTCH RETAINER

Fig. 121 Front Clutch Return Spring Snap Ring

1 - COMPRESSOR TOOL C-3575-A

2 - FRONT CLUTCH RETAINER

3 - SNAP RING

4 - SNAP RING PLIERS

Fig. 122 Front Clutch (4-Disc Shown)

1 - FRONT CLUTCH RETAINER

2 - CLUTCH PLATES

3 - DRIVING DISCS

Fig. 123 Thick Steel Plate and Waved Snap Ring

1 - WAVED SNAP RING

2 - THICK STEEL PLATE

3 - FRONT CLUTCH RETAINER

RS31TH AUTOMATIC TRANSAXLE21-85

CLUTCH - FRONT (Continued)

ProCarManuals.com

Page 1744 of 2399

(57) Install low/reverse spring compressor tool as

shown in (Fig. 74) (Fig. 75).(58) Compress low/reverse piston return spring

and remove snap ring (Fig. 76).

(59) Remove low/reverse spring compressor tool

and low reverse piston return spring (Fig. 77).

Fig. 74 Low/Reverse Spring Compressor Tool

1 - TOOL 6057

2 - TOOL 5059

3 - TOOL 5058±3

Fig. 75 Compressor Tool in Use

1 - LOW/REVERSE CLUTCH RETURN SPRING

2 - SNAP RING (INSTALL AS SHOWN)

3 - TOOL 6057

4 - TOOL 5059

5 - TOOL 5058±3

Fig. 76 Remove Snap Ring

1 - SNAP RING OPENING MUST BE BETWEEN SPRING

LEVERS (AS SHOWN)

2 - SNAP RING PLIERS

3 - TOOL 6057

Fig. 77 Low/Reverse Piston Return Spring

1 - LOW/REVERSE PISTON RETURN SPRING

2 - PISTON

RS41TE AUTOMATIC TRANSAXLE21 - 187

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1750 of 2399

(10) Install low/reverse spring compressor into

position (Fig. 97). Compress low/reverse piston and

install snap ring as shown in (Fig. 98).(11) Install rear carrier bearing cone using Tool

6053 (Fig. 99).

(12) Install rear carrier assembly to transaxle case

(Fig. 100).

Fig. 97 Compressor Tool in Use

1 - LOW/REVERSE CLUTCH RETURN SPRING

2 - SNAP RING (INSTALL AS SHOWN)

3 - TOOL 6057

4 - TOOL 5059

5 - TOOL 5058±3

Fig. 98 Install Snap Ring

1 - SNAP RING OPENING MUST BE BETWEEN SPRING

LEVERS (AS SHOWN)

2 - SNAP RING PLIERS

3 - TOOL 6057

Fig. 99 Install Rear Carrier Bearing Cone

1 - ARBOR PRESS RAM

2 - TOOL 6053

3 - NEW BEARING CONE

4 - REAR CARRIER ASSEMBLY

Fig. 100 Install Rear Carrier Assembly

1 - REAR CARRIER ASSEMBLY

RS41TE AUTOMATIC TRANSAXLE21 - 193

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1790 of 2399

Compressor 5058A

Compressor 5059-A

Installer 5067

Pliers 6051

Installer 6052

Installer 6053

Button 6055

Plate 6056

RS41TE AUTOMATIC TRANSAXLE21 - 233

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1822 of 2399

(8) Install UD piston return spring and Tool 5067

as shown in (Fig. 263).

(9) Using Tool 5059A and an arbor press, Install

the UD spring retainer and snap ring. (Fig. 264) (Fig.

265) Compress just enough to install snap ring.

CAUTION: Compress return spring just enough to

install snap ring.(10) Install the UD clutch pack. Leave out upper

disc, until snap ring is installed (Fig. 266).

Fig. 263 Seal Compressor Special Tool 5067

1 - PISTON RETURN SPRING

2 - SPECIAL TOOL 5067

3 - INPUT SHAFT CLUTCHES RETAINER ASSEMBLY

Fig. 264 UD Return Spring and Retainer

1 - UNDERDRIVE SPRING RETAINER

2 - SNAP RING

3 - SEAL

4 - PISTON RETURN SPRING

Fig. 265 Install UD Spring Retainer and Snap Ring

1 - ARBOR PRESS RAM

2 - SNAP RING PLIERS

3 - SNAP RING

4 - OD/REVERSE PISTON

5 - TOOL 5067

6 - TOOL 5059A

Fig. 266 Underdrive Clutch Pack

1 - CLUTCH PLATE

2 - ONE UD CLUTCH DISC

3 - CLUTCH DISC

RS41TE AUTOMATIC TRANSAXLE21 - 265

INPUT CLUTCH ASSEMBLY (Continued)

ProCarManuals.com

Page 2246 of 2399

pressed, the set temp value will become 55 but the

display will show LO. If the set temp is 85 and the

up button is pressed, the set temp value will become

90 but the display will show HIGH. Temperatures

can be displayed in either metric or Fahrenheit,

which is controlled from the overhead console.

²A rocker switch that selects a cool-down rate.

LO-AUTO or HI-AUTO are displayed when the sys-

tem is in automatic operation.

²A defroster button which turns on the defroster

independently during full automatic control. A

defroster symbol illuminates in the display when the

button is pressed.

²Air recirculation button. A Recirculation symbol

appears in the display when the button is pressed, or

when the system exceeds 80 percent circulated air

under automatic control due to high air conditioning

demand.

²Rear window defogger on/off switch. A graphic

symbol shows when the defroster is on.

²An air conditioning button that allows the com-

pressor to be turned off. A Snowflake symbol is illu-

minated when air conditioning is on, whether under

manual or automatic control.

²Rotary knob for front fan speed selection can

override the automatic controls. LEDs surrounding

the knob show the current setting.

²Rotary knob for control of the Rear system.

²A rotary knob for mode control can override the

automatic controls. LEDs surrounding the knob show

the current setting.

²Computer logic remembers the settings of the

controls when the ignition is turned off and retains

those settings after a restart. If the system is off

when the ignition is turned off it will be off when the

engine is restarted, etc.

²Computer logic provides variable air recircula-

tion under high temperature and humidity condi-

tions. Because recirculation is generally accompanied

by increased fan noise, the proportion of recirculated

to outside air gradually approaches full recirculation

over a broad temperature range.

²A graphic symbol of the windshield that illumi-

nates when the windshield wiper deicer is active.

REAR CONTROL PANEL

A rear control panel centrally mounted on the

headliner includes a vacuum-flourescent digital dis-

play, a rocker control for temperature and rotary con-

trols for adjustment of mode and fan speed control of

the rear unit by intermediate seat passengers.

OPERATION

OPERATION - DUAL ZONE

²The mode control knob enables continously vari-

able proportioning of air flow between modes but has

detents adjacent to each icon.

²The blower control provides five separate speeds.

²When the fan is off, the HVAC computer closes

the recirculation door to prevent outside air from

entering the passenger compartment.

²Interior air may be recirculated to speed up

heating or cooling in all modes except defrost and

mix by pressing the Recirculate button on the control

panel.

²To reduce humidity for rapid defogging the A/C

compressor runs automatically in modes from ªmix'

to full defrost when outside temperatures are above

freezing.

²Air conditioning is available in any mode by

pressing the snowflake, A/C on/off, button.

OPERATION - MANUAL THREE ZONE

FRONT CONTROL PANEL

²Primary control of the rear compartment unit is

on the instrument panel. This control allows the

driver to set the rear compartment fan speed, to turn

the rear unit off, or to give control to the intermedi-

ate seat occupants by switching to the REAR posi-

tion. When the rear unit is controlled from the

instrument panel, rear air temperature is based on

the driver-side temperature control position, and the

mode (floor or overhead air) is based on the front

control's mode position.

²The mode control knob enables continously vari-

able proportioning of air flow between modes but has

detents adjacent to each icon.

²The blower control provides five separate speeds

and Off. When the fan is off, the HVAC computer

closes the recirculation door to prevent outside air

from entering the passenger compartment.

²Interior air may be recirculated to speed up

heating or cooling in all modes exccept defrost and

mix by pressing the Recirculate button on the control

panel.

²To reduce humidity for rapid defogging the A/C

compressor runs automatically in modes from ªmix'

to full defrost when outside temperatures are above

freezing.

²Air conditioning is available in any mode by

pressing the snowflake, A/C on/off, button.

RSHEATING & AIR CONDITIONING24-3

HEATING & AIR CONDITIONING (Continued)

ProCarManuals.com