torque CHRYSLER VOYAGER 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 1509 of 2177

BACK-UP LAMP SWITCH

REMOVAL

(1) Raise vehicle on hoist.

(2) Disconnect back-up lamp switch connector.

(3) Remove back-up lamp switch (Fig. 95).

INSTALLATION

(1) Install back-up lamp switch (Fig. 95) and

torque to 23 N´m (17 ft. lbs.) using Tool 8827.

(2) Connect back-up lamp switch connector.

(3) Lower vehicle.

DIFFERENTIAL

DESCRIPTION

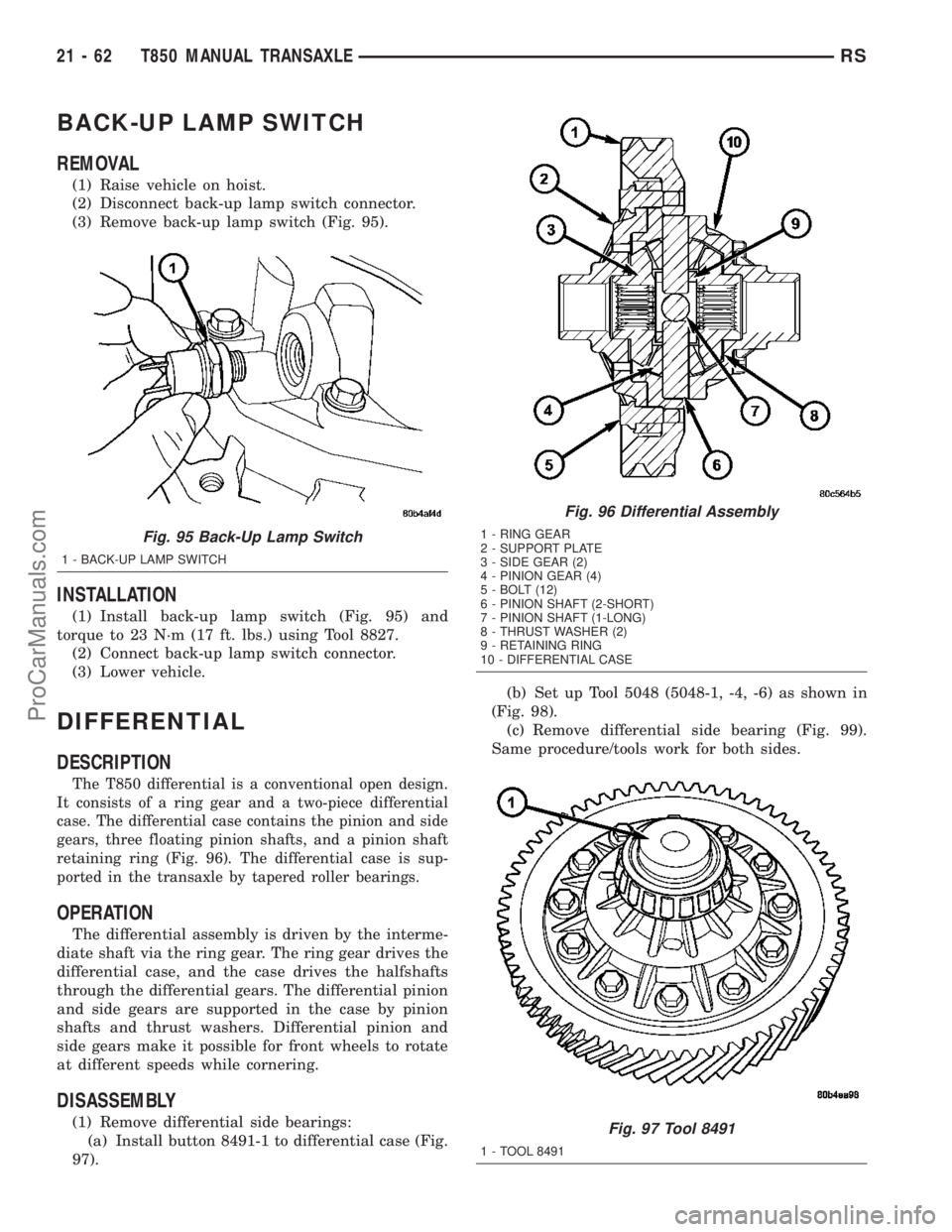

The T850 differential is a conventional open design.

It consists of a ring gear and a two-piece differential

case. The differential case contains the pinion and side

gears, three floating pinion shafts, and a pinion shaft

retaining ring (Fig. 96). The differential case is sup-

ported in the transaxle by tapered roller bearings.

OPERATION

The differential assembly is driven by the interme-

diate shaft via the ring gear. The ring gear drives the

differential case, and the case drives the halfshafts

through the differential gears. The differential pinion

and side gears are supported in the case by pinion

shafts and thrust washers. Differential pinion and

side gears make it possible for front wheels to rotate

at different speeds while cornering.

DISASSEMBLY

(1) Remove differential side bearings:

(a) Install button 8491-1 to differential case (Fig.

97).(b) Set up Tool 5048 (5048-1, -4, -6) as shown in

(Fig. 98).

(c) Remove differential side bearing (Fig. 99).

Same procedure/tools work for both sides.

Fig. 95 Back-Up Lamp Switch

1 - BACK-UP LAMP SWITCH

Fig. 96 Differential Assembly

1 - RING GEAR

2 - SUPPORT PLATE

3 - SIDE GEAR (2)

4 - PINION GEAR (4)

5 - BOLT (12)

6 - PINION SHAFT (2-SHORT)

7 - PINION SHAFT (1-LONG)

8 - THRUST WASHER (2)

9 - RETAINING RING

10 - DIFFERENTIAL CASE

Fig. 97 Tool 8491

1 - TOOL 8491

21 - 62 T850 MANUAL TRANSAXLERS

ProCarManuals.com

Page 1515 of 2177

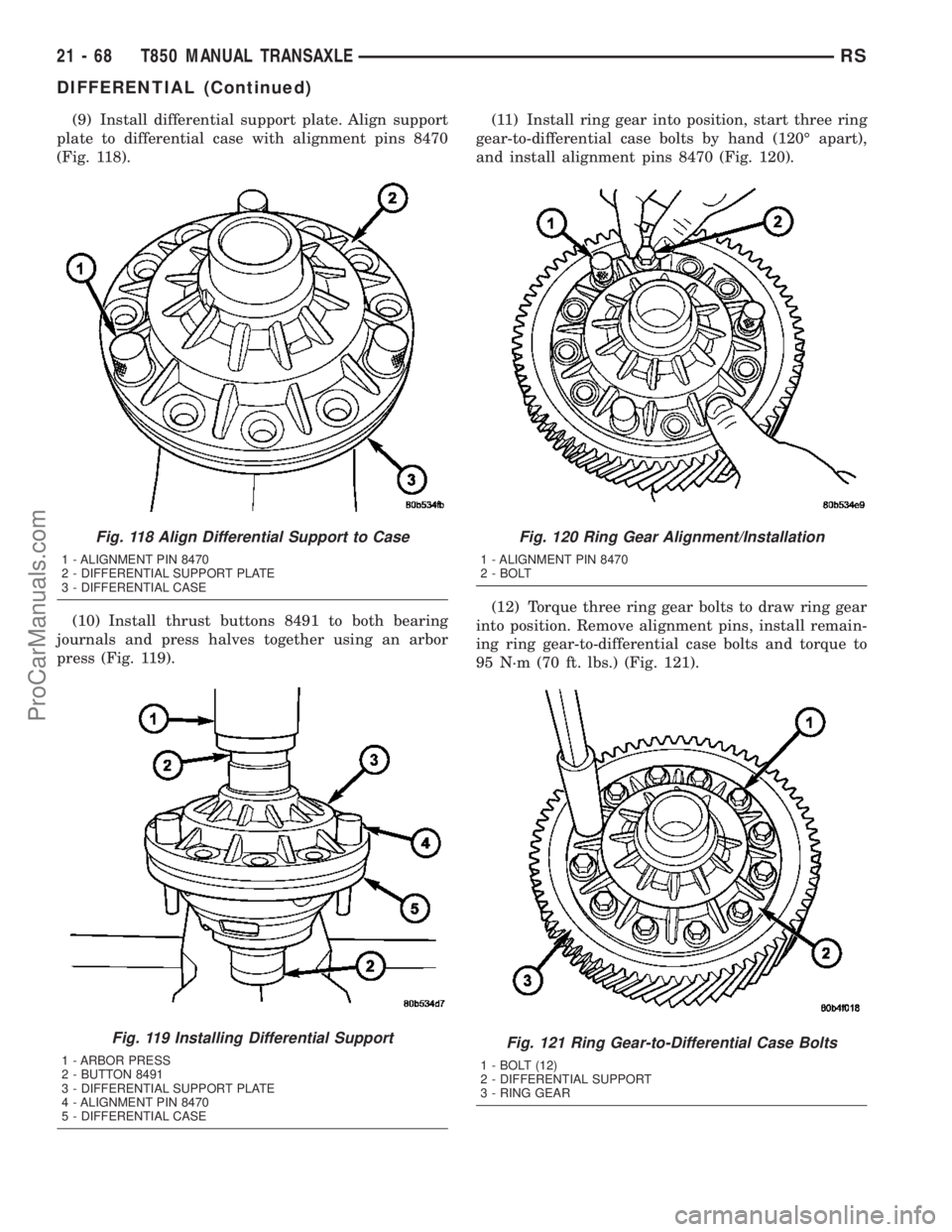

(9) Install differential support plate. Align support

plate to differential case with alignment pins 8470

(Fig. 118).

(10) Install thrust buttons 8491 to both bearing

journals and press halves together using an arbor

press (Fig. 119).(11) Install ring gear into position, start three ring

gear-to-differential case bolts by hand (120É apart),

and install alignment pins 8470 (Fig. 120).

(12) Torque three ring gear bolts to draw ring gear

into position. Remove alignment pins, install remain-

ing ring gear-to-differential case bolts and torque to

95 N´m (70 ft. lbs.) (Fig. 121).

Fig. 118 Align Differential Support to Case

1 - ALIGNMENT PIN 8470

2 - DIFFERENTIAL SUPPORT PLATE

3 - DIFFERENTIAL CASE

Fig. 119 Installing Differential Support

1 - ARBOR PRESS

2 - BUTTON 8491

3 - DIFFERENTIAL SUPPORT PLATE

4 - ALIGNMENT PIN 8470

5 - DIFFERENTIAL CASE

Fig. 120 Ring Gear Alignment/Installation

1 - ALIGNMENT PIN 8470

2 - BOLT

Fig. 121 Ring Gear-to-Differential Case Bolts

1 - BOLT (12)

2 - DIFFERENTIAL SUPPORT

3 - RING GEAR

21 - 68 T850 MANUAL TRANSAXLERS

DIFFERENTIAL (Continued)

ProCarManuals.com

Page 1516 of 2177

(13) Install tapered roller bearings using installer

8473 and an arbor press (Fig. 122). Insert button

8491 on opposite journal to protect journal and/or

bearing during press operation. Repeat the same

operation on opposite side.

(14) Measure and verify differential side gear end

play. (Refer to 21 - TRANSMISSION/TRANSAXLE/

MANUAL/DIFFERENTIAL - ADJUSTMENTS).

ADJUSTMENTS

ADJUSTMENT - DIFFERENTIAL TURNING

TORQUE

NOTE: Differential turning torque should only be

measured with the geartrain out of the transaxle. If

measurement is taken with transaxle assembled, an

inaccurate measurement will result.

NOTE: All differential cover-to-case bolts and exten-

sion housing-to-case bolts must be installed and

torqued to obtain accurate measurement.(1) If transaxle is assembled, remove geartrain

and leave differential in place. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/MANUAL - DISASSEMBLY)

(2) Install differential cover and torque differential

cover-to-case bolts to 54 N´m (40 ft. lbs.).

(3) Install extension housing and torque extension

housing-to-case bolts to 28 N´m (250 in. lbs.).

(4) Place transaxle on work bench so axle center-

line is parallel to the ground.

(5) Install turning torque tool C-4995 to differen-

tial at side opposite extension housing.

(6) Using in. lb./N´m dial indicator, rotate differen-

tial case multiple times and record measurement

(Fig. 123). Differential turning torque should be

within 2.3-3.4 N´m (20-30 in. lbs.). Refer to shim

chart for proper shim selection. If turning torque

measured is less than 2.3 N´m (20 in. lbs.), install a

thicker shim. If turning torque measured is greater

than 3.4 N´m (30 in. lbs.), install a thinner shim.

Fig. 122 Differential Side Bearing Installation

1 - ARBOR PRESS

2 - INSTALLER 8473

3 - BEARING

4 - BUTTON 8491

Fig. 123 Differential Turning Torque Measurement

1 - DIAL TORQUE WRENCH

2 - TOOL C-4995

RST850 MANUAL TRANSAXLE21-69

DIFFERENTIAL (Continued)

ProCarManuals.com

Page 1519 of 2177

FLUID DRAIN

(1) Raise vehicle on hoist.

(2) Remove transaxle drain plug (Fig. 127) and

drain fluid into suitable container.

(3) Install drain plug and torque to 23 N´m (17 ft.

lbs.).

FLUID FILL

(1) Remove transaxle fill plug (Fig. 128).

(2) Add 2.4-2.7L (2.5-2.9 qts.) of MopartATF+4

until fluid is within 3/16º below fill hole.

(3) Install fill plug, ensuring it is properly seated.

(4) Lower vehicle.

GEARSHIFT BOOT

REMOVAL

(1) Remove gearshift knob by pushing down and

rotating1¤4-turn clockwise (Fig. 129).

(2) Remove gearshift boot from center console by

disengaging three (3) retaining clips (Fig. 130).

Fig. 127 Transaxle Drain Plug

1 - TRANSAXLE DRAIN PLUG

2 - DIFFERENTIAL COVER

Fig. 128 Transaxle Fill Plug

1 - FILL PLUG

2 - END COVER

Fig. 129 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 130 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

21 - 72 T850 MANUAL TRANSAXLERS

FLUID (Continued)

ProCarManuals.com

Page 1525 of 2177

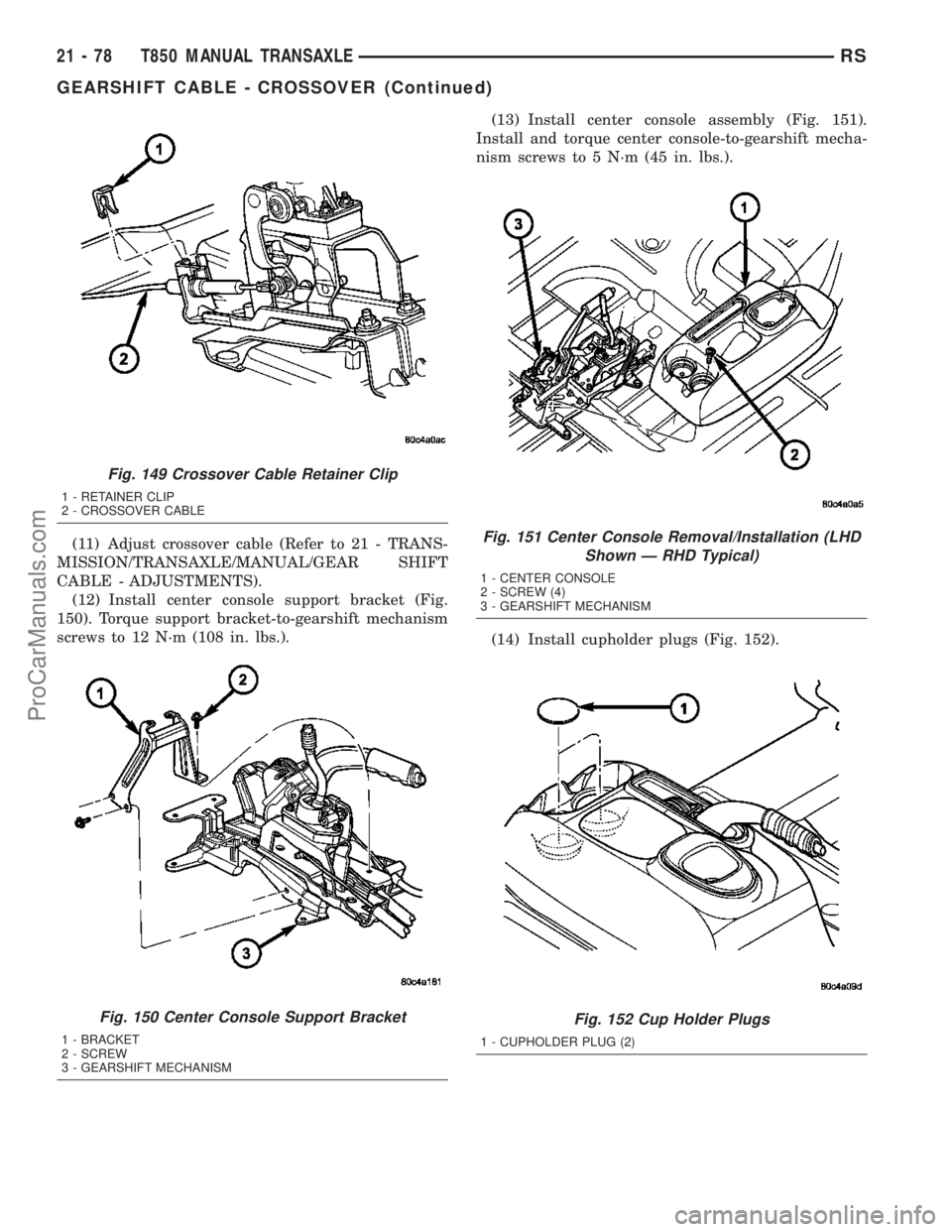

(11) Adjust crossover cable (Refer to 21 - TRANS-

MISSION/TRANSAXLE/MANUAL/GEAR SHIFT

CABLE - ADJUSTMENTS).

(12) Install center console support bracket (Fig.

150). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).(13) Install center console assembly (Fig. 151).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(14) Install cupholder plugs (Fig. 152).

Fig. 149 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 150 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 151 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 152 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

21 - 78 T850 MANUAL TRANSAXLERS

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1527 of 2177

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

157).

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

158).(7) Loosen crossover cable adjustment screw (Fig.

159).

(8) Rock gearshift lever back and forth between

1±2 and 5±R planes. Release lever, allowing shifter

spring to return lever to the neutral position in the

3±4 plane. Place gearshift lever in the 3rd gear posi-

tion.

(9) Torque crossover lever adjustment screw to 8

N´m (70 in. lbs.).No load should be applied to

the shifter lever in any direction (hands off)

while tightening screw.

(10) Verify gearshift lever travel through all gear

ranges with engine off (not running).

(11) Install center console assembly (Fig. 158).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(12) Install cupholder plugs (Fig. 157).

(13) Install gearshift boot to console (Fig. 156).

Secure boot to console with three (3) retainer clips.

(14) Install gearshift knob to gearshift lever (Fig.

155). Orient shift pattern on knob

1¤4-turn clockwise,

push down and rotate1¤4-turn counter-clockwise and

release. Secure boot to knob.

(15) Connect battery negative cable.

Fig. 157 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 158 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 159 Crossover Cable Adjustment Screw

1 - CROSSOVER CABLE

2 - ADJUSTMENT SCREW

21 - 80 T850 MANUAL TRANSAXLERS

GEARSHIFT CABLE - CROSSOVER (Continued)

ProCarManuals.com

Page 1533 of 2177

(11) Install center console support bracket (Fig.

179). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).

(12) Install center console assembly (Fig. 180).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).(13) Install cupholder plugs (Fig. 181).

(14) Install gearshift boot to console (Fig. 182).

Secure with three (3) retainer clips.

Fig. 179 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 180 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 181 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 182 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

21 - 86 T850 MANUAL TRANSAXLERS

GEARSHIFT CABLE - SELECTOR (Continued)

ProCarManuals.com

Page 1536 of 2177

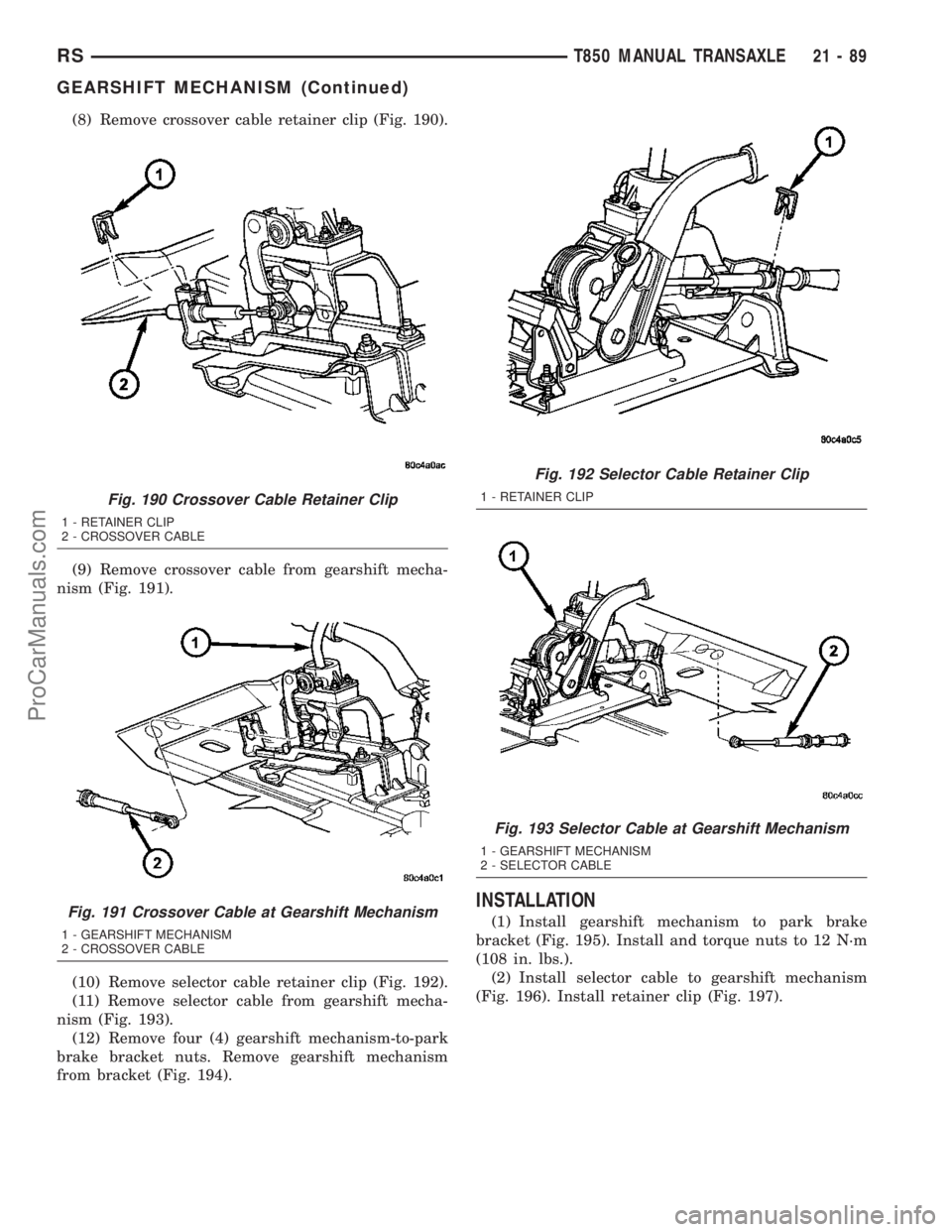

(8) Remove crossover cable retainer clip (Fig. 190).

(9) Remove crossover cable from gearshift mecha-

nism (Fig. 191).

(10) Remove selector cable retainer clip (Fig. 192).

(11) Remove selector cable from gearshift mecha-

nism (Fig. 193).

(12) Remove four (4) gearshift mechanism-to-park

brake bracket nuts. Remove gearshift mechanism

from bracket (Fig. 194).

INSTALLATION

(1) Install gearshift mechanism to park brake

bracket (Fig. 195). Install and torque nuts to 12 N´m

(108 in. lbs.).

(2) Install selector cable to gearshift mechanism

(Fig. 196). Install retainer clip (Fig. 197).

Fig. 190 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 191 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

Fig. 192 Selector Cable Retainer Clip

1 - RETAINER CLIP

Fig. 193 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

RST850 MANUAL TRANSAXLE21-89

GEARSHIFT MECHANISM (Continued)

ProCarManuals.com

Page 1538 of 2177

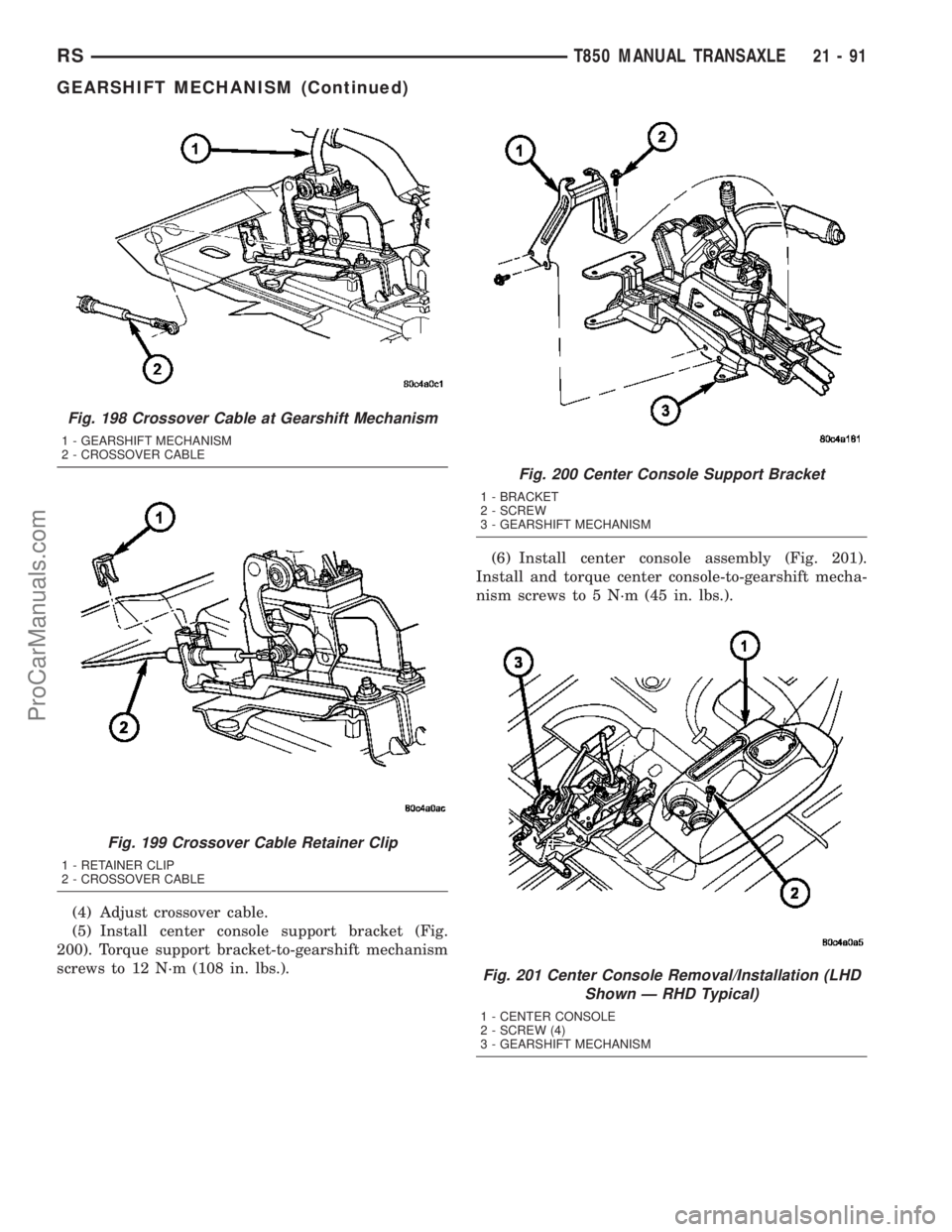

(4) Adjust crossover cable.

(5) Install center console support bracket (Fig.

200). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).(6) Install center console assembly (Fig. 201).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

Fig. 198 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

Fig. 199 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 200 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 201 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

RST850 MANUAL TRANSAXLE21-91

GEARSHIFT MECHANISM (Continued)

ProCarManuals.com

Page 1545 of 2177

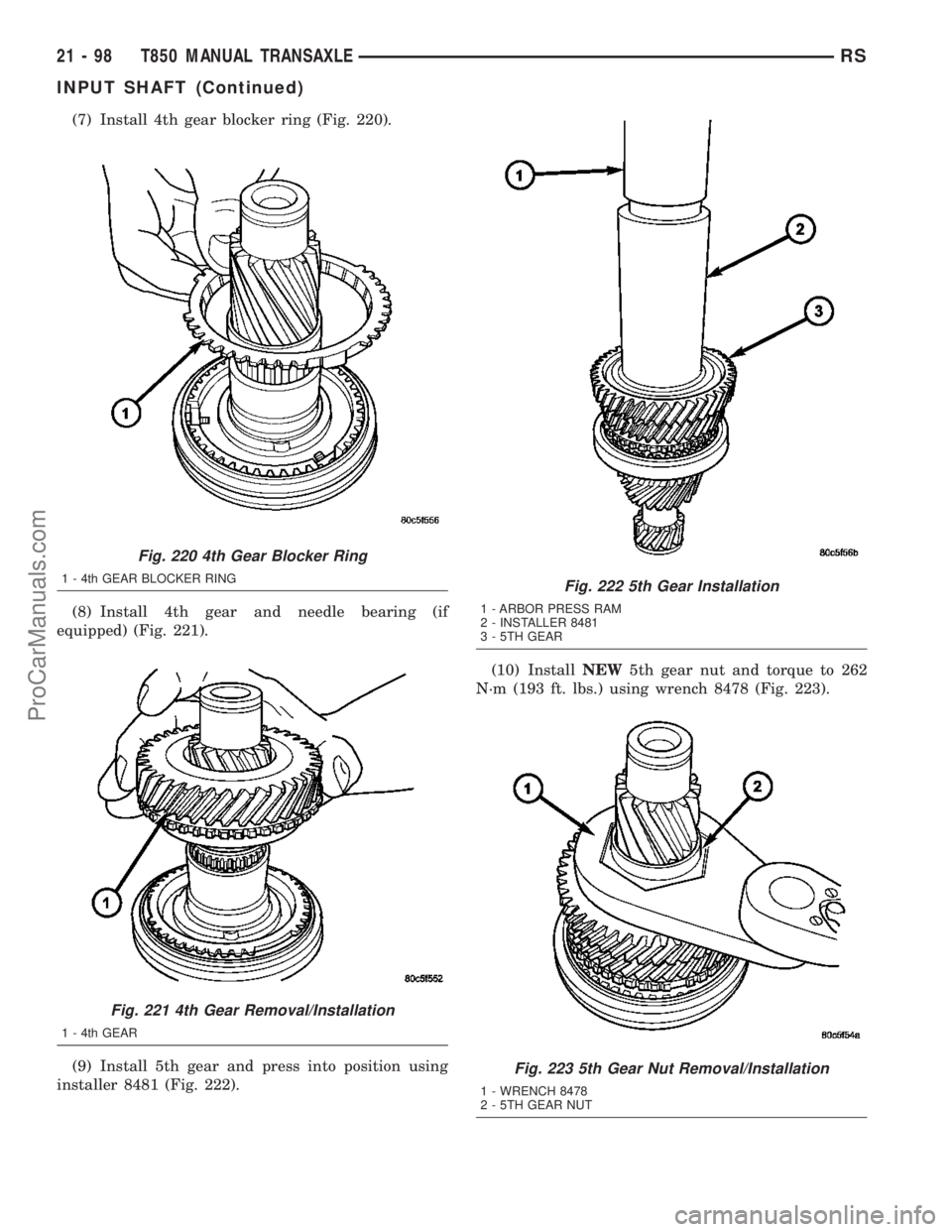

(7) Install 4th gear blocker ring (Fig. 220).

(8) Install 4th gear and needle bearing (if

equipped) (Fig. 221).

(9) Install 5th gear and press into position using

installer 8481 (Fig. 222).(10) InstallNEW5th gear nut and torque to 262

N´m (193 ft. lbs.) using wrench 8478 (Fig. 223).

Fig. 220 4th Gear Blocker Ring

1 - 4th GEAR BLOCKER RING

Fig. 221 4th Gear Removal/Installation

1 - 4th GEAR

Fig. 222 5th Gear Installation

1 - ARBOR PRESS RAM

2 - INSTALLER 8481

3 - 5TH GEAR

Fig. 223 5th Gear Nut Removal/Installation

1 - WRENCH 8478

2 - 5TH GEAR NUT

21 - 98 T850 MANUAL TRANSAXLERS

INPUT SHAFT (Continued)

ProCarManuals.com