torque CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 696 of 2585

(4) Repeat Step 1, and align as necessary until

wiper stops chattering and wipes the windshield

clear.

REMOVAL

CAUTION: The driver side wiper arm must be

parked above the passenger side. Failure to do so

will result in damage to the arms, blades or system.

(1) Lift the arm cap upward.

(2) Remove the nut holding wiper arm to the wiper

pivot.

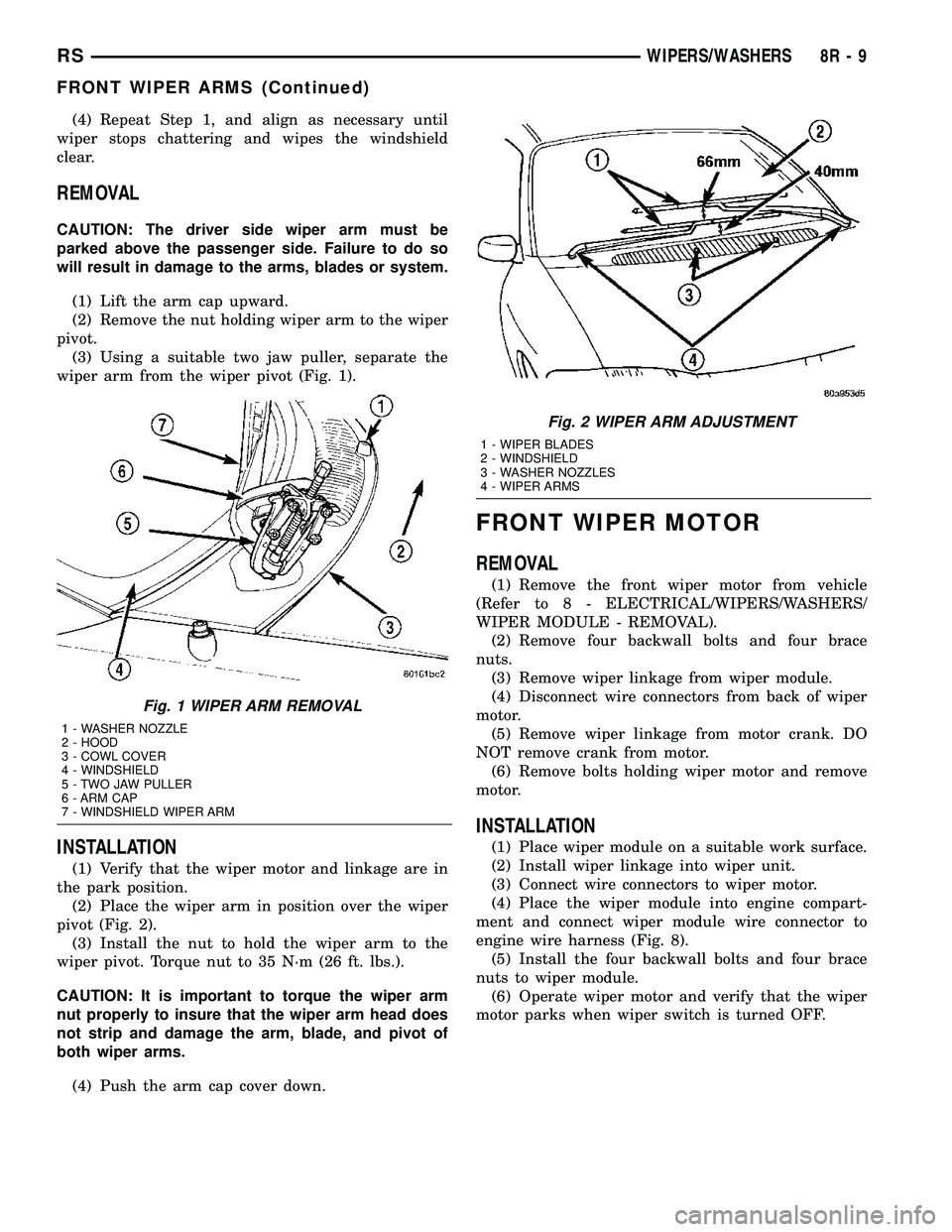

(3) Using a suitable two jaw puller, separate the

wiper arm from the wiper pivot (Fig. 1).

INSTALLATION

(1) Verify that the wiper motor and linkage are in

the park position.

(2) Place the wiper arm in position over the wiper

pivot (Fig. 2).

(3) Install the nut to hold the wiper arm to the

wiper pivot. Torque nut to 35 N´m (26 ft. lbs.).

CAUTION: It is important to torque the wiper arm

nut properly to insure that the wiper arm head does

not strip and damage the arm, blade, and pivot of

both wiper arms.

(4) Push the arm cap cover down.

FRONT WIPER MOTOR

REMOVAL

(1) Remove the front wiper motor from vehicle

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - REMOVAL).

(2) Remove four backwall bolts and four brace

nuts.

(3) Remove wiper linkage from wiper module.

(4) Disconnect wire connectors from back of wiper

motor.

(5) Remove wiper linkage from motor crank. DO

NOT remove crank from motor.

(6) Remove bolts holding wiper motor and remove

motor.

INSTALLATION

(1) Place wiper module on a suitable work surface.

(2) Install wiper linkage into wiper unit.

(3) Connect wire connectors to wiper motor.

(4) Place the wiper module into engine compart-

ment and connect wiper module wire connector to

engine wire harness (Fig. 8).

(5) Install the four backwall bolts and four brace

nuts to wiper module.

(6) Operate wiper motor and verify that the wiper

motor parks when wiper switch is turned OFF.

Fig. 1 WIPER ARM REMOVAL

1 - WASHER NOZZLE

2 - HOOD

3 - COWL COVER

4 - WINDSHIELD

5 - TWO JAW PULLER

6 - ARM CAP

7 - WINDSHIELD WIPER ARM

Fig. 2 WIPER ARM ADJUSTMENT

1 - WIPER BLADES

2 - WINDSHIELD

3 - WASHER NOZZLES

4 - WIPER ARMS

RSWIPERS/WASHERS8R-9

FRONT WIPER ARMS (Continued)

Page 697 of 2585

REAR WASHER PUMP MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Disconnect the washer hose at the in-line con-

nector forward of the cowl grille so that the in-line

connector remains with the washer hose from the

fresh air plenum.

(4) Disconnect the washer hose from the hose clip

located on the front fender side shield.

(5) Remove the filler tube screw.

(6) Hoist and support vehicle on hoist or jack

stands.

(7) Remove the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - REMOVAL).

(8) Disconnect the left right front wheelhouse

splash shield and move aside (Refer to 23 - BODY/

EXTERIOR/WHEELHOUSE SPLASH SHIELD -

REMOVAL).

(9) Drain washer fluid from the reservoir and into

a suitable clean container. This can be done by dis-

connecting the windshield washer hose from the

front (outboard) washer pump and allowing the

washer fluid to drain into a container through a tem-

porary jumper hose connected to the front washer

pump.

(10) Disconnect the electrical body harness connec-

tors to the washer pump motors and the fluid level

sensor. Slide the red lock on the connector to the

release position, then, depress the black tab and pull

the connector off the pump or sensor.

(11) Remove the two reservoir mounting screws.

(12) Disconnect the reservoir from the body mount

by raising the reservoir upward slightly and then

down so that the reservoir filler neck and front

washer hose pull through the opening in the front

fender side shield.

(13) Remove pump from reservoir by pulling pump

upper retention tab away from reservoir cavity and

then lifting pump up from mounting grommet. Do

not damage reservoir/pump sealing surface or punc-

ture reservoir during removal.

(14) Remove pump grommet and discard.

INSTALLATION

(1) Use new grommet when installing a new pump

assembly.

(2) Assure pump upper retention tab is pressed

into reservoir slot and that pump is rotated flat

against the reservoir and that pump connector is fac-

ing up in the fully seated position. Assure the pump

is aligned to and fully seated in the reservoir cavity.

(3) Push filler neck and front washer hose through

the opening in the front fender side shield. Connect

the reservoir to the body mount by lowering the res-

ervoir down.

(4) Install the two reservoir mounting screws.

Torque screws to 8.5 - 11.3 N´m (75 - 100 in. lbs.).

(5) Connect the electrical body harness connectors

to the washer pump motors and the fluid level sen-

sor. Slide the red lock on the connector to the closed

or locked position.

(6) Assure that washer hose is properly routed to

prevent pinching and possible inoperative washers.

(7) Connect the left right front wheelhouse splash

shield and move aside (Refer to 23 - BODY/EXTERI-

OR/WHEELHOUSE SPLASH SHIELD - INSTALLA-

TION).

(8) Install the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - INSTALLATION).

(9) lower vehicle from hoist or jack stands.

(10) Install the filler tube screw. Torque screw to

8.5 - 11.3 N´m (75 - 100 in. lbs.).

(11) Connect the washer hose to the hose clip

located on the front fender side shield.

(12) Connect the washer hose at the in-line con-

nector forward of the cowl grille.

(13) Install the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(14) Connect the battery negative cable.

(15) Verify system operation.

REAR WIPER ARM

REMOVAL

(1) Remove arm nut cap.

(2) Remove wiper arm nut.

(3) Pull wiper from pivot by rocking back and

forth.

INSTALLATION

(1) Verify that wipers are in parked position.

(2) Position arm on pivot.

(3) Install wiper arm nut and torque to 20 N´m

(175 in. lbs.).

8R - 10 WIPERS/WASHERSRS

Page 699 of 2585

When rear washer is requested by depressing and

holding down the switch, the BCM then provides a

ground for the rear washer motor. Until the switch is

released, the motor will be in a continuous wipe

mode, then return to an intermittent wipe mode.

WASHER FLUID LEVEL

SWITCH

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Disconnect the washer hose at the in-line con-

nector forward of the cowl grille so that the in-line

connector remains with the washer hose from the

fresh air plenum.

(4) Disconnect the washer hose from the hose clip

located on the front fender side shield.

(5) Remove the filler tube screw.

(6) Hoist and support vehicle on hoist or jack

stands.

(7) Remove the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - REMOVAL).

(8) Disconnect the left right front wheelhouse

splash shield and move aside (Refer to 23 - BODY/

EXTERIOR/WHEELHOUSE SPLASH SHIELD -

REMOVAL).

(9) Drain washer fluid from the reservoir and into

a suitable clean container. This can be done by dis-

connecting the windshield washer hose from the

front (outboard) washer pump and allowing thewasher fluid to drain into a container through a tem-

porary jumper hose connected to the front washer

pump.

(10) Disconnect the electrical body harness connec-

tors to the washer pump motors and the fluid level

sensor. Slide the red lock on the connector to the

release position, then, depress the black tab and pull

the connector off the pump or sensor.

(11) Remove the two reservoir mounting screws.

(12) Disconnect the reservoir from the body mount

by raising the reservoir upward slightly and then

down so that the reservoir filler neck and front

washer hose pull through the opening in the front

fender side shield.

(13) Remove the sensor from reservoir by using a

side foot to gently pry the sensor from the body of

the reservoir. Do not damage the reservoir/sensor

sealing surface or puncture reservoir during removal.

CAUTION: To avoid damage to the sensor, assure

the reservoir is in an upright position before remov-

ing the sensor from the reservoir. Do not rotate the

sensor during removal.

INSTALLATION

(1) Use a new grommet when installing a new sen-

sor assembly.

(2) Assure that the flat of the sensor is aligned

under the ridge of the reservoir and that the sensor

connector is facing down in the fully seated position.

This will allow for proper operation of the sensor

float switch.

(3) Push filler neck and front washer hose through

the opening in the front fender side shield. Connect

the reservoir to the body mount by lowering the res-

ervoir down.

(4) Install the two reservoir mounting screws.

Torque screws to 8.5 - 11.3 N´m (75 - 100 in. lbs.).

(5) Connect the electrical body harness connectors

to the washer pump motors and the fluid level sen-

sor. Slide the red lock on the connector to the closed

or locked position.

(6) Assure that washer hose is properly routed to

prevent pinching and possible inoperative washers.

(7) Connect the left right front wheelhouse splash

shield and move aside (Refer to 23 - BODY/EXTERI-

OR/WHEELHOUSE SPLASH SHIELD - INSTALLA-

TION).

(8) Install the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - INSTALLATION).

(9) lower vehicle from hoist or jack stands.

(10) Install the filler tube screw. Torque screw to

8.5 - 11.3 N´m (75 - 100 in. lbs.).

(11) Connect the washer hose to the hose clip

located on the front fender side shield.

Fig. 5 REAR WIPER/WASHER SWITCH LOCATION

1 - REAR WIPER/WASHER SWITCH

2 - HVAC CONTROL UNIT

8R - 12 WIPERS/WASHERSRS

REAR WIPER/WASHER SWITCH (Continued)

Page 700 of 2585

(12) Connect the washer hose at the in-line con-

nector forward of the cowl grille.

(13) Install the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(14) Connect the battery negative cable.

(15) Verify system operation.

WASHER HOSES

REMOVAL

(1) Remove washer reservoir from vehicle (Refer to

8 - ELECTRICAL/WIPERS/WASHERS/WASHER

RESERVOIR - REMOVAL).

(2) Disconnect washer hose front the reservoir cav-

ity.

(3) Disconnect the washer hose from the reservoir

pump.

(4) Remove parts as necessary to replace washer

hose (engine compartment, interior components, etc.).

INSTALLATION

(1) Install parts as necessary to after replacing

washer hose (engine compartment, interior compo-

nents, etc.).

(2) Connect the washer hose to the reservoir

pump.

(3) Connect washer hose to the reservoir cavity.

(4) Install the washer reservoir into vehicle (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS/WASHER

RESERVOIR - INSTALLATION).

WASHER RESERVOIR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Disconnect the washer hose at the in-line con-

nector forward of the cowl grille so that the in-line

connector remains with the washer hose from the

fresh air plenum.

(4) Disconnect the washer hose from the hose clip

located on the front fender side shield.

(5) Remove the filler tube screw.

(6) Hoist and support vehicle on hoist or jack

stands.

(7) Remove the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - REMOVAL).(8) Disconnect the left right front wheelhouse

splash shield and move aside (Refer to 23 - BODY/

EXTERIOR/WHEELHOUSE SPLASH SHIELD -

REMOVAL).

(9) Drain washer fluid from the reservoir and into

a suitable clean container. This can be done by dis-

connecting the windshield washer hose from the

front (outboard) washer pump and allowing the

washer fluid to drain into a container through a tem-

porary jumper hose connected to the front washer

pump.

(10) Disconnect the electrical body harness connec-

tors to the washer pump motors and the fluid level

sensor. Slide the red lock on the connector to the

release position, then, depress the black tab and pull

the connector off the pump or sensor.

(11) Remove the two reservoir mounting screws.

(12) Disconnect the reservoir from the body mount

by raising the reservoir upward slightly and then

down so that the reservoir filler neck and front

washer hose pull through the opening in the front

fender side shield.

INSTALLATION

(1) Push filler neck and front washer hose through

the opening in the front fender side shield. Connect

the reservoir to the body mount by lowering the res-

ervoir down.

(2) Install the two reservoir mounting screws.

Torque screws to 8.5 - 11.3 N´m (75 - 100 in. lbs.).

(3) Connect the electrical body harness connectors

to the washer pump motors and the fluid level sen-

sor. Slide the red lock on the connector to the closed

or locked position.

(4) Assure that washer is properly routed to pre-

vent pinching and possible inoperative washers.

(5) Connect the left right front wheelhouse splash

shield and move aside (Refer to 23 - BODY/EXTERI-

OR/WHEELHOUSE SPLASH SHIELD - INSTALLA-

TION).

(6) Install the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - INSTALLATION).

(7) lower vehicle from hoist or jack stands.

(8) Install the filler tube screw. Torque screw to 8.5

- 11.3 N´m (75 - 100 in. lbs.).

(9) Connect the washer hose to the hose clip

located on the front fender side shield.

(10) Connect the washer hose at the in-line con-

nector forward of the cowl grille.

(11) Install the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(12) Connect the battery negative cable.

(13) Verify system operation.

RSWIPERS/WASHERS8R-13

WASHER FLUID LEVEL SWITCH (Continued)

Page 1244 of 2585

SPLICES

SPLICE NUMBER LOCATION FIG.

S101 800mm from T/O for G102 1

S102 500mm from T/O for G102 1

S103 (2.5L) Between T/O for Battery Temperature Sensor and T/O

for C10215

S104 Near T/O for G102 1

S106 (2.4L) 40mm from T/O for Torque Converter Clutch Solenoid 11

S106 (2.5L) Near T/O for Battery Temperature Sensor 15

S106 (3.3L/3.8L) Near T/O for G103 18

S107 (2.4L) In T/O for EGR Solenoid 11

S107 (2.5L) Between T/O for Engine Starter Motor and T/O for

Engine Control Module C116

S107 (3.3L/3.8L Export) Near T/O for Solenoid Pressure Switch 18

S107 (3.3L/3.8L Except

Export)Near T/O for Transmission Range Sensor 11

S108 (3.3L/3.8L) Near T/O for Speed Control Servo 18

S109 (3.3L/3.8L Export) Near T/O for Transmission Control Module N/S

S109 (3.3L/3.8L Except

Export)Near T/O for Solenoid/Pressure switch Assembly 18

S110 Near T/O to G102 1

S111 (2.4L) Near T/O for C101 11

S111 (2.5L) In T/O for Battery (-) 18

S111 (3.3L/3.8L) Near T/O for Output Speed Sensor 18

S112 Near T/O for Integrated Power Module - C3 11

S113 (2.4L) Near T/O for Park/Neutral Position Switch 11

S114 (2.4L) Near T/O for Powertrain Control Module C4 11

S114 (3.3L/3.8L) In T/O to Transmission Control Module 5

S115 (2.4L) Near T/O for Powertrain Control Module C4 11

S115 (3.3L/3.8L) In T/O to Transmission Control Module 5

S116 (2.4L) 180mm from T/O for Torque Converter Clutch Solenoid 11, 13

S116 (2.5L) Near T/O for Mass Air Flow Sensor 16

S116 (3.3L/3.8L) Near T/O for G103 18

S117 (2.4L) Neat T/O for G101 and G103 11

S117 (3.3L/3.8L) Near T/O for Output Speed Sensor 18

S118 (2.4L) Near T/O for Knock Sensor 11, 13

S119 (2.5L) Near T/O for Engine Starter Motor 15

S121 (3.3L/3.8L) Near T/O for Output Speed Sensor 18

S122 (2.4L) In T/O to Engine Starter Motor 13

S122 (3.3L/3.8L) In T/O to Engine Starter Motor 18

S123 In T/O to Low Note Horn 5

S124 (2.4L) Near T/O for Fuel Injector No.2 N/S

S124 (3.3L/3.8L) Near T/O for Fuel Injector No.5 and No.6 N/S

S125 (2.4L) In T/O for Manifold Absolute Pressure Sensor N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-13

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1298 of 2585

ENGINE

TABLE OF CONTENTS

page page

ENGINE 2.4L.............................. 1ENGINE 3.3/3.8L......................... 74

ENGINE 2.4L

TABLE OF CONTENTS

page page

ENGINE 2.4L

DESCRIPTION..........................3

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION............3

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE............4

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL..............6

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK INSPECTION.....................8

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST.........9

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST................................9

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE CORE

AND OIL GALLERY PLUGS..............10

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS.........10

STANDARD PROCEDURE - HYDROSTATIC

LOCKED ENGINE.....................10

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS.........11

STANDARD PROCEDURE - ENGINE

GASKET SURFACE PREPARATION........11

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING

PLASTIGAGE........................12

REMOVAL - ENGINE ASSEMBLY...........13

INSTALLATION - ENGINE ASSEMBLY........16

SPECIFICATIONS

SPECIFICATIONS - 2.4L ENGINE.........17

SPECIFICATIONS - TORQUE............20

SPECIAL TOOLS

2.4L ENGINE.........................21AIR CLEANER ELEMENT

REMOVAL.............................24

INSTALLATION.........................24

AIR CLEANER HOUSING

REMOVAL.............................24

INSTALLATION.........................24

CYLINDER HEAD

DESCRIPTION.........................24

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET............................24

REMOVAL - CYLINDER HEAD.............25

CLEANING............................26

INSPECTION..........................26

INSTALLATION - CYLINDER HEAD..........26

CAMSHAFT OIL SEAL(S)

REMOVAL.............................27

INSTALLATION.........................28

CAMSHAFT(S)

DESCRIPTION.........................28

OPERATION...........................28

STANDARD PROCEDURE - MEASURING

CAMSHAFT END PLAY.................29

REMOVAL.............................29

CLEANING............................29

INSPECTION..........................30

INSTALLATION.........................30

CYLINDER HEAD COVER

REMOVAL.............................31

CLEANING............................31

INSPECTION..........................31

INSTALLATION.........................31

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION.........................32

CLEANING............................32

VALVE SPRINGS & SEALS

REMOVAL

REMOVAL - CYLINDER HEAD ON.........32

RSENGINE9-1

Page 1304 of 2585

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Excessive end play. 6. Check thrust bearing for wear on

flanges.

7. Crankshaft journal out-of-round

or worn.7. Replace crankshaft or grind

journals.

8. Loose flywheel or torque

converter.8. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sensor/switch. 2. Replace oil pressure sensor/

switch.

3. Low oil pressure. 3. Check oil pressure sensor/switch

and main bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean,

or replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new

tube or clean, if necessary.

9. Oil pump cover warped or

cracked.9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

RSENGINE 2.4L9-7

ENGINE 2.4L (Continued)

Page 1306 of 2585

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gauge adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer (Special Tool CH7059) with cable adap-

tors to the DRBIIIt. For Special Tool identification,

(Refer to 9 - ENGINE - SPECIAL TOOLS).

(7) Crank engine until maximum pressure is

reached on gauge. Record this pressure as #1 cylin-

der pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

RSENGINE 2.4L9-9

ENGINE 2.4L (Continued)

Page 1308 of 2585

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Install a new oil filter.

(11) Fill engine with specified amount of approved

oil.

(12) Connect negative battery cable.

(13) Start engine and check for any leaks.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKERis an anaerobic type

gasket material. The material cures in the absence of

air when squeezed between two metallic surfaces. It

will not cure if left in the uncovered tube. The

anaerobic material is for use between two machined

surfaces. Do not use on flexible metal flanges.

MOPARtBED PLATE SEALANTis a unique

(green-in-color) anaerobic type gasket material that

is specially made to seal the area between the bed-plate and cylinder block without disturbing the bear-

ing clearance or alignment of these components. The

material cures slowly in the absence of air when

torqued between two metallic surfaces, and will rap-

idly cure when heat is applied.

MOPARtGASKET SEALANTis a slow drying,

permanently soft sealer. This material is recom-

mended for sealing threaded fittings and gaskets

against leakage of oil and coolant. Can be used on

threaded and machined parts under all tempera-

tures. This material is used on engines with multi-

layer steel (MLS) cylinder head gaskets. This

material also will prevent corrosion. MopartGasket

Sealant is available in a 13 oz. aerosol can or 4oz./16

oz. can w/applicator.

SEALER APPLICATION

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 3)

RSENGINE 2.4L9-11

ENGINE 2.4L (Continued)

Page 1309 of 2585

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 3)

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 3)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING PLASTIGAGE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 4). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

(3) Remove the bearing cap and compare the

width of the flattened Plastigage with the metric

scale provided on the package. Locate the band clos-

est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Compare clearance measurements to specs found in

engine specifications (Refer to 9 - ENGINE - SPECI-

FICATIONS).Plastigage generally is accompa-

nied by two scales. One scale is in inches, the

other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

(4) Install the proper crankshaft bearings to

achieve the specified bearing clearances.

Fig. 3 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

Fig. 4 Plastigage Placed in Lower ShellÐTypical

1 - PLASTIGAGE

9 - 12 ENGINE 2.4LRS

ENGINE 2.4L (Continued)