service CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1420 of 2585

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE - MAIN BEARING

FITTING

Bearing caps are not interchangeable and should

be marked at removal to insure correct assembly

(Fig. 67). Upper and lower bearing halves are NOT

interchangeable. Lower main bearing halves of 1, 3

and 4 are interchangeable. Upper main bearing

halves of 1, 3 and 4 are interchangeable.

Upper and lower number 2 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 68). All bearing cap bolts removed

during service procedures are to be cleaned and

lubricated with engine oil before installation. Bearing

shells are available in standard and the following

undersizes: 0.025 mm (0.001 in.) and 0.254 mm

(0.010 in). Never install an undersize bearing that

will reduce clearance below specifications.

CRANKSHAFT BEARING OIL CLEARANCE

Inspect the crankshaft bearing journals. (Refer to 9

- ENGINE/ENGINE BLOCK/CRANKSHAFT -

INSPECTION)

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or the equivalent. The fol-

lowing is the recommended procedures for the use of

Plastigage with the engine in the vehicle or engine

on a repair stand.PLASTIGAGE METHODÐENGINE IN-VEHICLE

NOTE: The total clearance of the main bearings can

only be determined with the engine in the vehicle

by removing the weight of the crankshaft. This can

be accomplished by either of two following meth-

ods:

(1) Preferred method:

a. Shim the bearings adjacent to the bearing to be

checked in order to remove the clearance between

upper bearing shell and the crankshaft. This can be

accomplished by placing a minimum of 0.254 mm

(0.010 in.) shim (e. g. cardboard, matchbook cover,

etc.) between the bearing shell and the bearing cap

on the adjacent bearings and tightening bolts to

14±20 N´m (10±15 ft. lbs.).

²When checking #1 main bearing shim #2 main

bearing.

²When checking #2 main bearing shim #1 & #3

main bearing.

²When checking #3 main bearing shim #2 & #4

main bearing.

²When checking #4 main bearing shim #3 main

bearing.

NOTE: Remove all shims before reassembling

engine.

(2) Alternative Method:

a. Support the weight of the crankshaft with a

jack under the counterweight adjacent to the bearing

being checked.

(3) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

Fig. 67 Main Bearing Cap Identification

Fig. 68 Main Bearing Identification

1 - OIL GROOVES

2 - OIL HOLES

3 - UPPER BEARINGS

4 - LOWER BEARINGS

RSENGINE 3.3/3.8L9 - 123

Page 1459 of 2585

VALVE SEAT

DESCRIPTION SPECIFICATION

Metric Standard

Angle 44.5 - 45É

Seat Diameter -

Intake34.37 - 34.63

mm1.353 - 1.363 in.

Seat Diameter -

Exhaust27.06 - 27.32

mm1.065 - 1.075 in.

Runout (Max.) 0.05 mm 0.002 in.

Valve Seat

Width - Intake

and Exhaust0.9 - 1.3 mm 0.035 - 0.051 in.

Service Limit -

Intake2.0 mm 0.079 in.

Service Limit -

Exhaust2.5 mm 0.098 in.

VALVE GUIDE

DESCRIPTION SPECIFICATION

Metric Standard

Diameter I.D. 5.975 - 6.000

mm0.235 - 0.236 in.

Guide Bore

Diameter11.0 - 11.02

mm0.4330 - 0.4338

in.

Guide Height

(spring seat to

guide tip)13.25 - 13.75

mm0.521 - 0.541 in.

VALVES

DESCRIPTION SPECIFICATION

Metric Standard

Face Angle -

Intake and

Exhaust44.5 - 45É

Head Diameter

- Intake34.67 - 34.93

mm1.364 - 1.375 in.

Head Diameter

- Exhaust28.32 - 28.52

mm1.114 - 1.122 in.

Valve Length

(Overall)

Intake 112.76 - 113.32

mm4.439 - 4.461 in.

Exhaust 110.89 - 111.69

mm4.365 - 4.397 in.

Valve Stem

Diameter

Intake 5.934 - 5.952

mm0.2337 - 0.2344

in.

Exhaust 5.906 - 5.924

mm0.2326 - 0.2333

in.

VALVE MARGIN

DESCRIPTION SPECIFICATION

Metric Standard

Intake 1.2 - 1.7 mm 0.047 - 0.066 in.

Service Limit 0.95 mm .0037 in.

Exhaust 0.985 - 1.315

mm0.038 - 0.051 in.

Service Limit 1.05 mm .039 in.

VALVE STEM TIP

DESCRIPTION SPECIFICATION

Metric Standard

Intake 48.04 mm 1.891 in.

Exhaust 47.99 mm 1.889 in.

9s - 4 ENGINE 2.4L SUPPLEMENTRS

ENGINE 2.4L SUPPLEMENT (Continued)

Page 1460 of 2585

VALVE STEM TO GUIDE CLEARANCE

DESCRIPTION SPECIFICATION

Metric Standard

Intake 0.048 - 0.066

mm0.0018 - 0.0025

in.

Max. Allowable 0.076 mm 0.003 in.

Service Limit 0.25 mm 0.010 in.

Exhaust 0.0736 - 0.094

mm0.0029 - 0.0037

in.

Max. Allowable 0.101 mm 0.004 in.

Service Limit 0.25 mm 0.010 in.

VALVE SPRINGS

DESCRIPTION SPECIFICATION

Metric Standard

Free Length

(Approx.)48.4 mm 1.905 in.

Nominal Force

(Valve Closed)338 N @ 38.0

mm75.98 lbs. @

1.496 in.

Nominal Force

(Valve Open)607 N @ 29.75

mm136 lbs. @

1.172 in.

Installed Height 38.00 mm 1.496 in.

Number of Coils 7.82

Wire Diameter 3.86 mm 1.496 in

OIL PUMP

DESCRIPTION SPECIFICATION

Metric Standard

Clearance Over

Rotors (Max.)0.10 mm 0.004 in.

Cover

Out-of-Flat

(Max.)0.025 mm 0.001 in.

Inner Rotor

Thickness (Min.)9.40 mm 0.370 in.

Outer Rotor

Thickness (Min.)9.40 mm 0.370 in.

Outer Rotor

Clearance

(Max.)0.039 mm 0.015 in.

Outer Rotor

Diameter (Min.)79.95 mm 3.148 in.

Tip Clearance

Between Rotors

(Max.)0.20 mm 0.008 in.

OIL PRESSURE

DESCRIPTION SPECIFICATION

Metric Standard

At Curb Idle

Speed*25 kPa 4 psi

At 3000 rpm 170 - 550 kPa 25 - 80 psi

CAUTION:

*If pressure is ZERO at curb idle, DO NOT run engine

at 3000 rpm.

RSENGINE 2.4L SUPPLEMENT9s-5

ENGINE 2.4L SUPPLEMENT (Continued)

Page 1466 of 2585

ENGINE 3.3/3.8L

SUPPLEMENT

SPECIFICATIONS

3.3/3.8L ENGINE

GENERAL DESCRIPTION

DESCRIPTION SPECIFICATION

Metric Standard

Engine Type 60É V-6 Engine

Number of

Cylinders6

Displacement

3.3L3.3Liters 201 cu.in.

Displacement

3.8L3.8 Liters 231 cu. in.

Bore 3.3L 93.0 mm 201 cu.in.

Bore 3.8L 96.0 mm 3.779 cu.in.

Stroke 3.3L 81 mm 3.188 in.

Stroke 87 mm 3.425 in.

Compression

Ratio 3.3L- 9.35:1

Compression

Ratio 3.8L- 9.6:1

Firing Order - 1-2-3-4-5-6

Compression

Pressure-

Minimum689.5 kPa 100 psi.

Cylinder

Compression

(Max. Difference

Between

Cylinders- 25%

CYLINDER BLOCK

DESCRIPTION SPECIFICATION

Metric Standard

Cylinder Bore

Diameter

(Standard) 3.3L92.993-93.007

mm3.661-3.6617 in.

Cylinder Bore

Diameter

(Standard) 3.8L95.993-96.007

mm3.7792-3.780 in.

Out of Round

(Service Limits)0.076 mm 0.003 in.

Taper (Service

Limits)0.051 mm 0.002 in.

Lifter Bore

Diameter22.980-23.010

mm0.905-0.906 in.

Deck Surface

Flatness (Max.)0.1 mm 0.004 in.

CRANKSHAFT

DESCRIPTION SPECIFICATION

Metric Standard

Connecting Rod

Journal

Diameter57.979-58.005

mm2.2827-2.2837

in.

Main Bearing

Journal

Diameter63.993-64.013

mm2.5194-2.5202

in.

Journal

Out-of-Round

(Max.)0.025 mm 0.001 in.

Journal Taper

(Max.)0.025 mm 0.001 in

End Play 0.09-0.24 mm 0.0036-0.0095

in.

Wear Limit 0.381 mm 0.015 in.

Main Bearing

Diametrical

Clearance

1-2-3-40.011-0.055

mm0.0005-0.0022

in.

Wear Limit 0.076 mm 0.003 in.

RSENGINE 3.3/3.8L SUPPLEMENT9s-11

Page 1467 of 2585

CONNECTING RODS

DESCRIPTION SPECIFICATION

Metric Standard

Bearing

Clearance0.019-0.065

mm.0.017-0.020 in.

Wear Limit 0.074 mm 0.003 in.

Side Clearance 0.13-0.32 mm 0.005-0.013 in.

Wear Limit 0.38 mm 0.015 in.

PISTONS

DESCRIPTION SPECIFICATION

Metric Standard

Piston Diameter

3.3L-Measured

39.8 mm (1.567

in) From Piston

To p92.968-92.998

mm.3.660-3.661 in.

Piston Diameter

3.8L-Measured

33.01 mm (1.30

in) From Piston

To p95.968-95.998

mm.3.778-3.779 in.

Clearance in

Bore @ Size

Location (New)-0.005-0.039

mm-0.0002±0.0015

in.

Weight 3.3L 362 5 grams 12.77 0.1764

oz.

Weight 3.8L 426 5 grams 15.03 0.1764

oz.

PISTON PINS

DESCRIPTION SPECIFICATION

Metric Standard

Type Press Fit in Rod (Serviced as a

Assembly)

Clearance in

Piston @ 21C

(70ÉF)0.006-0.019

mm0.0002-0.0007

in.

Clearance in

Connecting RodInterference Fit

Diameter 22.87-22.88

mm0.9007-0.9009

in.

Length 3.3L 67.25-67.75

mm2.648-2.667 in.

Length 3.8L 71.25-71.75

mm2.805-2.824 in.

PISTON RINGS

DESCRIPTION SPECIFICATION

Metric Standard

Ring End Gap

To p

Compression

Ring0.18-0.38 mm 0.007-0.015 in.

Second

Compression

Ring0.28-0.57 mm 0.011-0.022 in.

Oil Control

(Steel Rails)0.23-0.78 mm 0.009-0.030 in.

Wear Limit-

Compression

Rings1.0 mm 0.039 in.

Wear Limit-Oil

Control Steel

Rails1.88 mm 0.074 in.

Ring Side

Clearance

To p

Compression

Ring 3.3L0.030-0.080

mm0.0012-0.0031

in.

To p

Compression

Ring 3.8L0.030-0.069

mm0.0012-0.0027

in.

Second

Compression

Ring 3.3L0.030-0.095

mm0.0012-0.0037

in.

Second

Compression

Ring 3.8L0.041-0.085

mm0.0016-0.0033

in.

Oil Ring (Steel

Ring)0.039-0.200

mm0.0015-0.0078

in.

Wear Limit- Top

Ring0.10 mm 0.004 in.

Wear Limit-2nd

Ring0.13 mm 0.005

Wear Limit Oil

Ring Pack0.266 mm 0.009

Ring Width-Top

Compression

Ring 3.3L1.46-1.49 mm 0.0575-0.058 in.

Ring Width-Top

Compression

Ring 3.8L1.175-1.190

mm0.0462-0.0468

9s - 12 ENGINE 3.3/3.8L SUPPLEMENTRS

ENGINE 3.3/3.8L SUPPLEMENT (Continued)

Page 1469 of 2585

CYLINDER HEAD

DESCRIPTION SPECIFICATION

Metric Standard

Gasket

Thickness

(Compressed)0.65-0.75 mm 0.0007-0.0024

in.

VALVES

DESCRIPTION SPECIFICATION

Metric Standard

Face Angle-

Intake- 45-45.5É

Face Angle-

Exhaust- 45-45.5É

Head Diameter-

Intake47.87-48.13

mm1.88-1.89 in.

Head Diameter-

Exhaust35.37-35.63

mm1.39-1.40 in.

Valve Lift (Zero

Lash)-Intake

and Exhaust-

3.3L9.80 mm 0.385 in.

Valve Lift (Zero

Lash)-Intake

and Exhaust-

3.8L11.0 mm 0.433 in.

Valve Length-

Intake125.84-126.6

mm4.95-4.98 in.

Valve Length-

Exhaust127.20-127.96 5.00-5.04 in.

Valve Stem to

Tip Height

(valve tip to

spring seat

washer)-Intake48.1-49.7 mm 1.89-1.95 in.

Valve Stem to

Tip Height

(valve tip to

spring seat

washer)-

Exhaust48.53-50.09

mm1.91-1.97 in.

VALVE SEAT

DESCRIPTION SPECIFICATION

Metric Standard

Angle - 44.5-45É

Run Out

(Service Limits)0.0762 mm 0.003 in.

Width-Intake

and Exhaust1.50-2.00 mm 0.057-0.078 in.

VALVE GUIDE

DESCRIPTION SPECIFICATION

Metric Standard

Guide Bore

Diameter (Std.)6.975-7.00 mm 0.274-0.275 in.

VALVE MARGIN

DESCRIPTION SPECIFICATION

Metric Standard

Intake 0.825-0.973

mm0.032-0.038 in.

Exhaust 1.565-1.713

mm0.061-0.067 in.

VALVE STEM DIAMETER

DESCRIPTION SPECIFICATION

Metric Standard

Intake

(Standard)6.935-6.953

mm0.2718-0.2725

in.

Exhaust

(Standard)6.906-6.924

mm0.2718-0.2725

in.

9s - 14 ENGINE 3.3/3.8L SUPPLEMENTRS

ENGINE 3.3/3.8L SUPPLEMENT (Continued)

Page 1473 of 2585

²Standard dimension = less than 0.05 mm (0.002

inch.)

²Service Limit = 0.2 mm (0.008 inch.)

²Grinding Limit = Maximum of 0.2 mm (0.008

inch.) is permitted.

CAUTION: 0.20 mm (0.008 in.) MAX is a combined

total dimension of the stock removal limit from cyl-

inder head and block top surface (Deck) together.

INSTALLATION - CYLINDER HEAD

(1) Clean all sealing surfaces of engine block and

cylinder heads. (Refer to 9 - ENGINE - STANDARD

PROCEDURE)

(2) Position new gasket(s) on engine block (Fig. 4).

The left bank gasket is identified with the ªLº

stamped in the exposed area of the gasket located at

front of engine (shown in (Fig. 4)). The right bank

gasket is identified with a ªRº stamped in the

exposed area of the gasket also, but is located at the

rear of the engine.(3)The cylinder head bolts are torqued using

the torque yield method, they should be exam-

ined BEFORE reuse. If the threads are necked

down, the bolts must be replaced(Fig. 5).

(4) Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale the bolt should be replaced.

(5) Tighten the cylinder head bolts 1±8 in the

sequence shown in (Fig. 6). Using the 4 step torque

turn method, tighten according to the following val-

ues:

²Step 1: Bolts1±8to61N´m(45ft.lbs.)

²Step 2: Bolts1±8to88N´m(65ft.lbs.)

²Step 3: Bolts1±8(again) to 88 N´m (65 ft. lbs.)

²Step 4: Bolts1±8turn an additional 1/4 Turn.

(Do not use a torque wrench for this step.)

NOTE: Bolt torque after 1/4 turn should be over 122

N´m (90 ft. lbs.). If not, replace the bolt.

(6) Inspect push rods and replace worn or bent

rods.

(7) Install the push rods.

(8) Install the rocker arm and shaft assemblies.

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARMS - INSTALLATION)

(9) Install the cylinder head covers. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

Fig. 3 Checking Cylinder Head FlatnessÐTypical

Fig. 4 Head Gasket Installation

1 - CYLINDER HEAD GASKET

2 - LOCATION IDENTIFICATION (L = LEFT BANK, R = RIGHT

BANK)

Fig. 5 Checking Bolts for Stretching (Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 6 CYLINDER HEAD TIGHTENING SEQUENCE

9s - 18 ENGINE 3.3/3.8L SUPPLEMENTRS

CYLINDER HEAD (Continued)

Page 1475 of 2585

(3) Assemble gasket to cylinder cover by inserting

the bolt assemblies through each bolt hole on the

cover and gasket (Fig. 9).

(4) Install cylinder head cover and bolts (Fig. 10).

(5) Tighten cylinder head cover bolts to 12 N´m

(105 in. lbs.) (Fig. 10).

(6) Connect PCV hose to cylinder head cover.

(7) Connect spark plug wires to spark plugs.

(8) Install wiper module. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION)

(9) Connect negative cable to battery.

CYLINDER HEAD COVER-LEFT

REMOVAL

(1) Disconnect spark plug wires from spark plugs.

(2) Disconnect crankcase vent hose from cylinder

head cover.

(3) Remove cylinder head cover bolts.(4) Remove cylinder head cover and gasket.

INSTALLATION

(1) Clean cylinder head and cover mating surfaces.

Inspect cylinder head cover surface for flatness.

Replace gasket as necessary.

(2) Assemble gasket to cylinder cover by inserting

the fasteners through each bolt hole on cover and

gasket (Fig. 9).

(3) Install the cylinder head cover and bolts (Fig.

10).

(4) Tighten cylinder head cover bolts to 12 N´m

(105 in. lbs.) (Fig. 10).

(5) Connect crankcase vent hose.

(6) Connect spark plug wires to spark plugs.

Fig. 9 CYLINDER HEAD COVER GASKET

1 - CYLINDER HEAD COVER

2 - BOLT

3 - SEAL (SERVICED WITH BOLT)

4 - GASKET

Fig. 10 Cylinder Head Cover

1 - CYLINDER HEAD COVER

2 - BOLT

9s - 20 ENGINE 3.3/3.8L SUPPLEMENTRS

CYLINDER HEAD COVER-RIGHT (Continued)

Page 1486 of 2585

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION..........................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EXCESSIVE

EXHAUST SYSTEM NOISE...............2

DIAGNOSIS AND TESTING - EXHAUST

SYSTEM RESTRICTION CHECK...........2

INSPECTION...........................3

ADJUSTMENTS.........................3

SPECIFICATIONS

TORQUE.............................3

SPECIAL TOOLS

EXHAUST SYSTEM.....................4

CATALYTIC CONVERTER

DESCRIPTION..........................4

OPERATION............................4

REMOVAL.............................5INSPECTION...........................5

INSTALLATION..........................6

CROSS-OVER PIPE - 3.3/3.8L

REMOVAL.............................6

INSTALLATION..........................6

HEAT SHIELDS

DESCRIPTION..........................6

OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................7

MUFFLER

REMOVAL.............................7

INSTALLATION..........................7

RESONATOR

REMOVAL.............................9

INSTALLATION..........................9

EXHAUST SYSTEM

DESCRIPTION

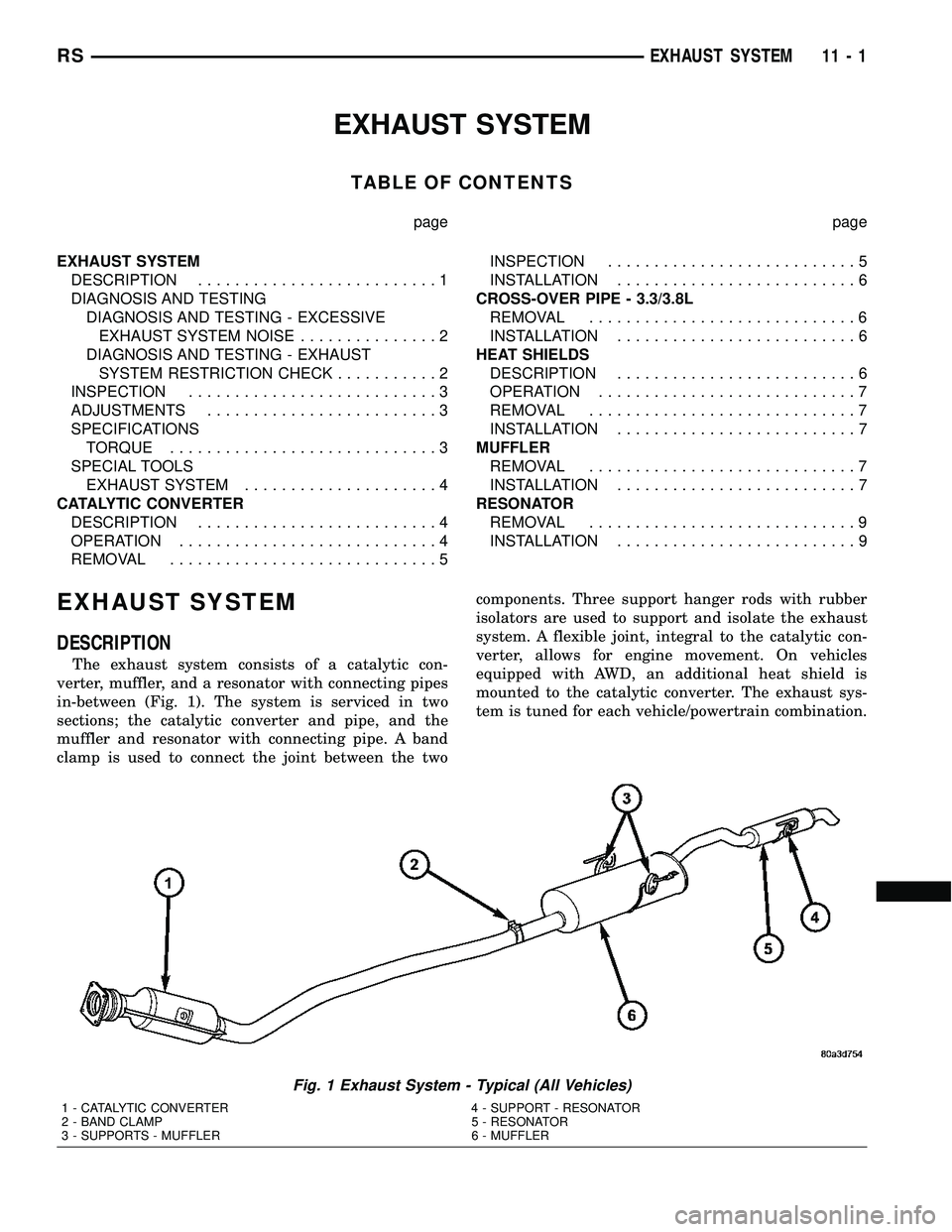

The exhaust system consists of a catalytic con-

verter, muffler, and a resonator with connecting pipes

in-between (Fig. 1). The system is serviced in two

sections; the catalytic converter and pipe, and the

muffler and resonator with connecting pipe. A band

clamp is used to connect the joint between the twocomponents. Three support hanger rods with rubber

isolators are used to support and isolate the exhaust

system. A flexible joint, integral to the catalytic con-

verter, allows for engine movement. On vehicles

equipped with AWD, an additional heat shield is

mounted to the catalytic converter. The exhaust sys-

tem is tuned for each vehicle/powertrain combination.

Fig. 1 Exhaust System - Typical (All Vehicles)

1 - CATALYTIC CONVERTER 4 - SUPPORT - RESONATOR

2 - BAND CLAMP 5 - RESONATOR

3 - SUPPORTS - MUFFLER 6 - MUFFLER

RSEXHAUST SYSTEM11-1

Page 1487 of 2585

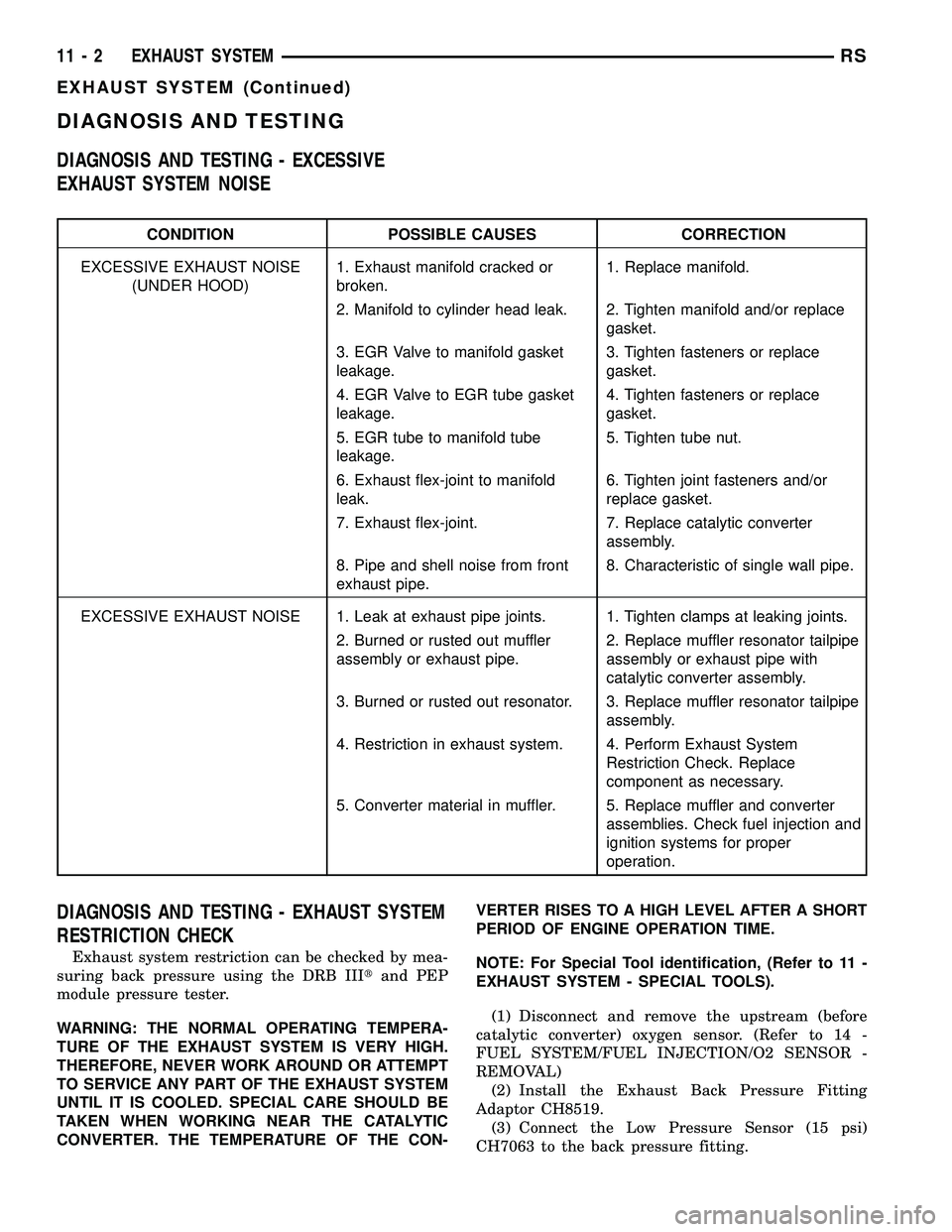

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EXCESSIVE

EXHAUST SYSTEM NOISE

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE EXHAUST NOISE

(UNDER HOOD)1. Exhaust manifold cracked or

broken.1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace

gasket.

3. EGR Valve to manifold gasket

leakage.3. Tighten fasteners or replace

gasket.

4. EGR Valve to EGR tube gasket

leakage.4. Tighten fasteners or replace

gasket.

5. EGR tube to manifold tube

leakage.5. Tighten tube nut.

6. Exhaust flex-joint to manifold

leak.6. Tighten joint fasteners and/or

replace gasket.

7. Exhaust flex-joint. 7. Replace catalytic converter

assembly.

8. Pipe and shell noise from front

exhaust pipe.8. Characteristic of single wall pipe.

EXCESSIVE EXHAUST NOISE 1. Leak at exhaust pipe joints. 1. Tighten clamps at leaking joints.

2. Burned or rusted out muffler

assembly or exhaust pipe.2. Replace muffler resonator tailpipe

assembly or exhaust pipe with

catalytic converter assembly.

3. Burned or rusted out resonator. 3. Replace muffler resonator tailpipe

assembly.

4. Restriction in exhaust system. 4. Perform Exhaust System

Restriction Check. Replace

component as necessary.

5. Converter material in muffler. 5. Replace muffler and converter

assemblies. Check fuel injection and

ignition systems for proper

operation.

DIAGNOSIS AND TESTING - EXHAUST SYSTEM

RESTRICTION CHECK

Exhaust system restriction can be checked by mea-

suring back pressure using the DRB IIItand PEP

module pressure tester.

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

NOTE: For Special Tool identification, (Refer to 11 -

EXHAUST SYSTEM - SPECIAL TOOLS).

(1) Disconnect and remove the upstream (before

catalytic converter) oxygen sensor. (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/O2 SENSOR -

REMOVAL)

(2) Install the Exhaust Back Pressure Fitting

Adaptor CH8519.

(3) Connect the Low Pressure Sensor (15 psi)

CH7063 to the back pressure fitting.

11 - 2 EXHAUST SYSTEMRS

EXHAUST SYSTEM (Continued)