remote control CHRYSLER VOYAGER 2004 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 639 of 2585

DOOR LOCK INHIBIT

When the key is in the ignition (in any switch posi-

tion) and either front door is opened, the door lock

switches LOCK functions are disabled. The

UN-LOCK functions are still functional. This protects

against locking the vehicle with the key still in the

ignition. The RKE key fob will still lock the doors.

After the key is removed from the ignition or the

doors are closed, the power door locks will operate

normally.

REMOTE KEYLESS ENTRY

The Remote Keyless Entry (RKE) system allows

the use of a remote battery-powered radio transmit-

ter to communicate with the BCM to actuate the

power lock system. The RKE transmitters are also equipped with a

Panic button. If the Panic button on the RKE trans-

mitter is depressed, the horn will sound and the

exterior lights will flash on the vehicle for about

three minutes, or until the Panic button is depressed

a second time. Pressing the Panic button also acti-

vates the courtesy lamps. Pressing the Panic button

again stops the exterior lamps from flashing and the

horn from sounding. However, the courtesy lamps

will remain illuminated until either the BCM times

out lamp operation or until the turning of the igni-

tion. The panic feature will operate if the ignition is

ON, but only if the Panic button is pressed prior to

starting the vehicle. A vehicle speed of about 25.7

km/h (15 miles-per-hour) will also cancel the panic

event. The RKE system can also perform other functions

on this vehicle. If the vehicle is equipped with the

optional Vehicle Theft Security System (VTSS), the

RKE transmitter will arm the VTSS when the Lock

button is depressed, and disarm the VTSS when the

Unlock button is depressed. The RKE system includes two transmitters when

the vehicle is shipped from the factory, but the sys-

tem can retain the vehicle access codes of up to a

total of eight transmitters. If an RKE transmitter is

inoperative or lost, new transmitter vehicle access

codes can be programmed into the system using a

DRB III tscan tool.

This vehicle also offers several customer program-

mable features, which allows the selection of several

optional electronic features to suit individual prefer-

ences. Customer programmable feature options

affecting the RKE system include: ² Automatic Door Lock - Customer programma-

ble feature that allows the BCM to perform an auto-

matic door lock if the vehicle speed is above 25.7

km/h (15 miles-per-hour). ² Automatic Door Unlock On Exit - Customer

programmable feature that allows the BCM to per- form an automatic door unlock if the vehicle speed is

0, vehicle in park and driver door is opened.

² Flash Lights with Lock and Unlock - Allows

the option of having the park lamps flash as an opti-

cal verification that the RKE system received a valid

Lock request or Unlock request from the RKE trans-

mitter, or having no optical verification. ² Programming Additional Transmitters -

Allows up to a total of four transmitter vehicle access

codes to be stored. ² Remote Unlock Sequence - Allows the option

of having only the driver side front door unlock when

the RKE transmitter Unlock button is depressed the

first time. The remaining doors unlock when the but-

ton is depressed a second time within 5 seconds of

the first unlock press. Another option is having all

doors unlock upon the first depression of the RKE

transmitter Unlock button. ² Sound Horn on Lock - Allows the option of

having the horn sound a short chirp as an audible

verification that the RKE system received a valid

Lock request from the RKE transmitter, or having no

audible verification.

OPERATION

POWER LOCKS

The Body Control Module (BCM) locks or unlocks

the doors when an actuation input signal from a door

lock switch, Central Lock key cylinder or Remote

Keyless Entry (RKE) is received. The BCM turns on

the output drivers and provides a voltage level to the

door lock motor for a specified time.

REMOTE KEYLESS ENTRY

The RKE transmitter uses radio frequency signals

to communicate with the SKREEM module. The

SKREEM is on the PCI bus. When the operator

presses a button on the transmitter, it sends a spe-

cific request to the SKREEM. In turn, the SKREEM

sends the appropriate request over the PCI bus to

the following: ² Integrated Power Module (IPM) - to activate

the park lamps, the headlamps and the horn for the

horn chirp. ² Power Liftgate Module (PLGM) - to control

the liftgate lock and unlock functions. After pressing the lock button on the RKE trans-

mitter, all of the door locks will lock, the illuminated

entry will turn off (if all doors are closed) and the

vehicle theft security system (if equipped) will arm. Pressing the unlock button one time will unlock

the driver door, or all doors based on the customer

programmable feature enabled, the illuminated entry

will turn on the courtesy lamps and the vehicle theft

security system (if equipped) will disarm. Pressing

8Ns - 2 POWER LOCKSRS

POWER LOCKS (Continued)

Page 645 of 2585

The power seat system includes the following com-

ponents: ² Power seat recliners

² Power seat switches

² Power seat tracks

² Circuit breaker

The power seat system with memory and heated

seat options includes the following components: ² Power seat recliner

² Power seat switch

² Power seat track.

² Memory Seat Mirror Module (MSMM)

² Memory set switch

² Heated Seat Module (HSM)

² Heated seat switch

² Electronic Vehicle Information Center (EVIC)

² Programmable Communications Interface (PCI)

data bus network Refer to Wiring Diagrams for complete circuit dia-

grams. Following are general descriptions and opera-

tions for the major components in the power seat

system and memory seat system.

DESCRIPTION - MEMORY SYSTEM

An electronic memory system is available on some

models. The memory system is able to store and

recall the driver side power seat positions (including

the power recliner position) and the driver outside

side view mirror position for two drivers. On vehicles

equipped with a factory radio, the memory system is also able to store and recall radio station presets for

two drivers. The memory system also will store and

recall the last station listened to for each driver, even

if it is not one of the preset stations.

The memory system will automatically return to

its preset settings when the corresponding numbered

button of the memory switch is depressed, or when

the doors are unlocked using the corresponding

Remote Keyless Entry (RKE) transmitter. A customer

programmable feature of the memory system allows

the RKE recall of memory features to be disabled, if

desired. This programmable feature is internal in the

EVIC module, which is located in the overhead con-

sole. A Memory Seat Mirror Module (MSMM) is used to

control and integrate the many electronic functions

and features included in the memory seat and mirror

systems. The memory system includes the following compo-

nents: ² Memory Seat Mirror Module (MSMM)

² Memory set switch

² Position potentiometers on the driver outside

side view mirror ² Position potentiometers on the driver side power

seat track and power seat recliner motors. ² Electronic Vehicle Information Center (EVIC)

² Radio receiver (if PCI data bus capable).

Certain functions of the memory system rely upon

resources shared with other electronic modules in the

vehicle over the Programmable Communications

Interface (PCI) J1850 data bus network. The PCI

data bus network allows the sharing of sensor infor-

mation. This helps to reduce wire harness complexity,

internal controller hardware, and component sensor

current loads. At the same time, this system provides

increased reliability, enhanced diagnostics, and

allows the addition of many new feature capabilities.

Initial diagnosis of these electronic modules or the

PCI data bus network requires the use of a DRBIII t

scan tool and the proper Diagnostic Procedures man-

ual. If this method does not prove conclusive, the use

of a automotive meter such as the Fluke t, the proper

wiring schematics and the service manual diagnostic

routines are required. The other electronic modules that may affect mem-

ory system operation are as follows: ² Body Control Module (BCM) - Refer toBody

Control Module in Electronic Control Modules for

more information. ² Powertrain Control Module (PCM) - Refer to

Powertrain Control Module in Electronic Control

Modules for more information. ² Transmission Control Module (TCM) - Refer

to Transmission Control Module in Electronic

Control Modules for more information.

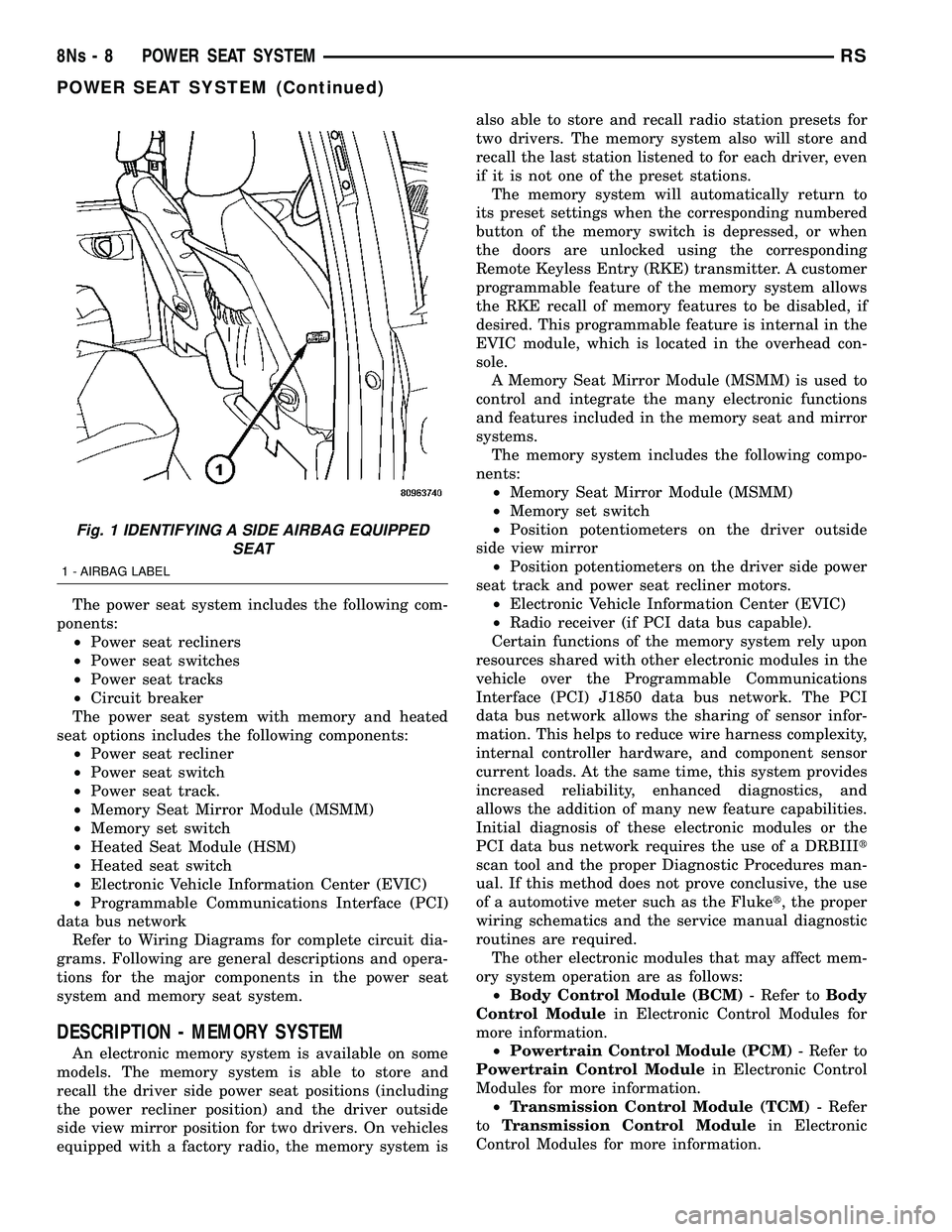

Fig. 1 IDENTIFYING A SIDE AIRBAG EQUIPPED SEAT

1 - AIRBAG LABEL

8Ns - 8 POWER SEAT SYSTEMRS

POWER SEAT SYSTEM (Continued)

Page 646 of 2585

Refer toHeated Seat System for more informa-

tion on the heated seat system. Refer to Remote

Keyless Entry System in Power Lock Systems for

more information on the RKE system. Refer to Wiring Diagrams for complete circuit

diagrams. Following are descriptions, theory of oper-

ation, diagnosis/testing procedures and removal/in-

stallation procedures of the major components in the

memory and power seat systems.

OPERATION

OPERATION - POWER SEAT SYSTEM

The power seat system receives battery current

through fuse #22 in the Intelligent Power Module

and a circuit breaker under the front seats, regard-

less of the ignition switch position. When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the appropri-

ate power seat track adjuster motor. The selected

adjuster motor operates to move the seat track

through its drive unit in the selected direction until

the switch is released, or until the travel limit of the

seat track is reached. When the switch is moved in

the opposite direction, the battery feed and ground

path to the motor are reversed through the switch

contacts. This causes the adjuster motor to run in the

opposite direction. No power seat switch should be held applied in any

direction after the seat track has reached its travel

limit. The power seat track each contain a self-reset-

ting circuit breaker to protect them from overload.

However, consecutive or frequent resetting of the cir-

cuit breaker must not be allowed to continue, or the

motor may be damaged. Refer to the owner's manual

in the vehicle glove box for more information on the

features, use and operation of the power seat system.

OPERATION - MEMORY SYSTEM

The Memory Seat Mirror Module (MSMM) receives

battery current through fuse #22 in the Intelligent

Power Module and the power seat system circuit

breaker, located under the driver side front seat near

the rear edge of the seat cushion pan. The memory

system does not operate with the Ignition-Off Draw

(IOD) fuse removed. The MSMM will drive a maxi-

mum of 2 motors at a time in a given direction. If

conflicting directions are requested, the priority for

response will be approximately as follows: ² Seat Track Rearward or Forward

² Seat Front Down or Up

² Seat Rear Down or Up

² Recliner Rearward or Forward The inputs from these switches to the MSMM is a

current limited battery source fed by the MSMM.

This protects the MSMM printed circuit board traces

from acting as fuses. All of these switch contact

inputs to the MSMM are normally closed to ground,

except when actuated. See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory system. For diagnosis of the MSMM,

the PCI data bus, or the other electronic modules on

the PCI data bus that provide inputs and outputs for

the memory system, the use of a DRBIII tscan tool

and the proper Diagnostic Procedures manual are

recommended.

ELECTRONIC VEHICLE INFORMATION CENTER

The Electronic Vehicle Information Center (EVIC)

serves as the user interface for the memory system.

It displays memory system status messages and pro-

vides the user with the means for enabling and dis-

abling the many customer programmable features

available on the vehicle, including those for the mem-

ory system. See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the EVIC. Refer to Electronic Vehicle Informa-

tion Center in Overhead Console Systems for more

information on the EVIC.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER SEAT

SYSTEM

Following are tests that will help to diagnose the

hard wired components and circuits of the power seat

system. However, if the vehicle is also equipped with

the optional memory system, these tests may not

prove conclusive in the diagnosis of the driver side

power seat. In order to obtain conclusive testing of

the driver side power seat with the memory system

option, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked. The most reliable, efficient, and accurate means to

diagnose the driver side power seat with the memory

system option requires the use of a DRBIII tscan tool

and the proper Diagnostic Procedures manual. The

DRBIII tscan tool can provide confirmation that the

PCI data bus is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages on the PCI data bus, and that the memory sys-

tem is receiving the proper hard wired inputs and

relaying the proper hard wired outputs to perform its

driver side power seat functions.

RS POWER SEAT SYSTEM8Ns-9

POWER SEAT SYSTEM (Continued)

Page 657 of 2585

RESTRAINTS

DESCRIPTION

This vehicle is equipped with a Frontal Impact Air-

bag System, which utilizes the driver/passenger air-

bags and seatbelt pretensioners. This system is

designed to protect occupants in the event of a front

impact collision. These airbags and seatbelt preten-

sioners are all serviceable parts. If these pyrotechnics

are deployed or defective, they must be replaced, as

well as the Occupant Restraint Controller (ORC)

must be diagnosed following procedures outlined in

the service/diagnostic manuals.

Vehicles equipped with the Side Impact Airbag

System, the seat back assembly must be replaced, as

well as the Side Impact Airbag Control Module

(SIACM) must be diagnosed following procedures

outlined in the service/diagnostic manuals.

OPERATION

The Occupant Restraint Controller (ORC) controls

the driver/passenger airbags and seat belt tensioners.

If the ORC determines that the impact is severe

enough, the driver/passenger/side airbags and seat

belt tensioners will deploy. Once a deployment

occurs, these devices, and all damaged parts must be

replaced, as well as the ORC must be diagnosed fol-

lowing procedures outlined in the service/diagnostic

manuals.

The Side Impact Airbag Control Module (SIACM),

the seat back assemblies and all damaged parts must

be replaced, as well as the SIACM must be diagnosed

following procedures outlined in the service/diagnos-

tic manuals.

WARNING

WARNING: THIS SYSTEM IS A SENSITIVE, COM-

PLEX ELECTRO±MECHANICAL UNIT. DISCONNECT

AND ISOLATE THE BATTERY NEGATIVE CABLE

BEFORE BEGINNING AIRBAG SYSTEM COMPO-

NENT REMOVAL OR INSTALLATION PROCEDURES.

THIS WILL DISABLE THE AIRBAG SYSTEM. FAIL-

URE TO DISCONNECT THE BATTERY COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT,

PERSONAL INJURY, OR DEATH.

ALLOW SYSTEM CAPACITOR TO DISCHARGE FOR

TWO MINUTES BEFORE REMOVING AIRBAG COM-

PONENTS.

DO NOT PLACE AN INTACT UNDEPLOYED AIRBAG

FACE DOWN ON A SOLID SURFACE, THE AIRBAG

WILL PROPEL INTO THE AIR IF ACCIDENTALLY

DEPLOYED AND COULD RESULT IN PERSONAL

INJURY. WHEN CARRYING OR HANDLING AN

UNDEPLOYED AIRBAG MODULE, THE TRIM SIDE

OF THE AIRBAG SHOULD BE POINTING AWAYFROM THE BODY TO MINIMIZE POSSIBILITY OF

INJURY IF ACCIDENTAL DEPLOYMENT OCCURS.

REPLACE AIRBAG SYSTEM COMPONENTS WITH

MOPARTREPLACEMENT PARTS. SUBSTITUTE

PARTS MAY APPEAR INTERCHANGEABLE, BUT

INTERNAL DIFFERENCES MAY RESULT IN INFE-

RIOR OCCUPANT PROTECTION.

WEAR SAFETY GLASSES, RUBBER GLOVES, AND

LONG SLEEVED CLOTHING WHEN CLEANING

POWDER RESIDUE FROM VEHICLE AFTER AIRBAG

DEPLOYMENT. SODIUM HYDROXIDE POWDER

RESIDUE EMITTED FROM A DEPLOYED AIRBAG

CAN CAUSE SKIN IRRITATION. FLUSH AFFECTED

AREA WITH COOL WATER IF IRRITATION IS EXPE-

RIENCED. IF NASAL OR THROAT IRRITATION IS

EXPERIENCED, EXIT THE VEHICLE FOR FRESH AIR

UNTIL THE IRRITATION CEASES. IF IRRITATION

CONTINUES, SEE A PHYSICIAN.

DO NOT USE A REPLACEMENT AIRBAG THAT IS

NOT IN THE ORIGINAL PACKAGING, IMPROPER

DEPLOYMENT, PERSONAL INJURY, OR DEATH CAN

RESULT.

THE FACTORY INSTALLED FASTENERS, SCREWS

AND BOLTS USED TO FASTEN AIRBAG COMPO-

NENTS HAVE A SPECIAL COATING AND ARE SPE-

CIFICALLY DESIGNED FOR THE AIRBAG SYSTEM.

DO NOT USE SUBSTITUTE FASTENERS, USE ONLY

ORIGINAL EQUIPMENT FASTENERS LISTED IN THE

PARTS CATALOG WHEN FASTENER REPLACE-

MENT IS REQUIRED.

CAUTION:

Deployed and Nondeployed Air Bags may or may

not have live pyrotechnic material within the air bag

inflator. Do not dispose of Driver and Passenger

Airbags unless you are sure of complete deploy-

ment. Please refer to the Hazardous Substance

Control System for Proper Disposal. Dispose of

deployed air bags in a manner consistent with

state, provincial, local, and federal regulations.

WARNING: DURING, AND FOLLOWING, ANY CHILD

RESTRAINT ANCHOR SERVICE, DUE TO IMPACT

EVENT OR VEHICLE REPAIR, CAREFULLY INSPECT

ALL MOUNTING HARDWARE, TETHER STRAPS

AND ANCHORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. IF A CHILD RESTRAINT

ANCHOR IS FOUND DAMAGED IN ANY WAY, THE

ANCHOR MUST BE REPLACED OR IT COULD

RESULT IN PERSONAL INJURY OR DEATH.

DIAGNOSIS AND TESTING - AIRBAG SYSTEM

(1) With the battery negative remote cable discon-

nected, connect the DRB IIItscan tool to the Data

Link connector.

8O - 2 RESTRAINTSRS

Page 660 of 2585

STANDARD PROCEDURE - CLOCK SPRING

CENTERING

If the rotating tape (wire coil) in the clock spring is

not positioned properly with the steering wheel and

the front wheels, the clock spring may fail. The fol-

lowing procedure MUST BE USED to center the

clock spring if it is not known to be properly posi-

tioned, or if the front wheels were moved from the

straight ahead position.

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood.

(3) Disconnect and isolate the battery negative

cable.

(4) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag compo-

nent service.

(5) Remove driver airbag from steering wheel

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(6) Disconnect wire connectors from back of driver

airbag.

(7) Disconnect the 2±way connector from remote

radio control harness.

(8) Disconnect the 4±way harness connector from

the speed control/horn harness to the clock spring.

(9) Remove steering wheel (Refer to 19 - STEER-

ING/COLUMN/STEERING WHEEL - REMOVAL).

(10) Rotate the clock spring rotor clockwise until

the rotor stops. Do not apply excessive force.

(11) From the end of travel, rotate the rotor two

turns counterclockwise until the wires end up at the

top.

(12) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(13) Connect the 4±way harness connector to the

speed control/horn harness to the clock spring.

(14) Connect the 2±way connector to the remote

radio control harness.

(15) Install the driver airbag (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - INSTAL-

LATION). Torque the two screws to 10 N´m (90 in.

lbs.).

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.(2) Release hood latch and open hood.

(3) Disconnect and isolate the battery negative

cable.

(4) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag compo-

nent service.

(5) Remove driver airbag from steering wheel

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(6) Disconnect wire connectors from back of driver

airbag.

(7) Disconnect the 2±way connector from remote

radio control harness.

(8) Disconnect the 4±way harness connector from

the speed control/horn harness to the clock spring.

(9) Remove steering wheel (Refer to 19 - STEER-

ING/COLUMN/STEERING WHEEL - REMOVAL).

(10) Remove steering column shrouds and discon-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL).

(11) Disconnect 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(12) Remove clock spring from column assembly by

removing the two retaining screws that attach the

clock spring to the column.

INSTALLATION

(1) Install the clock spring on the column.

(2) Connect the 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(3) Install the steering column shrouds and con-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - INSTALLATION).

(4) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(5) Connect the 4±way harness connector to the

speed control/horn harness to the clock spring.

(6) Connect the 2±way connector to the remote

radio control harness.

(7) Install the driver airbag (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - INSTAL-

LATION). Torque the two screws to 10 N´m (90 in.

lbs.).

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

RSRESTRAINTS8O-5

CLOCK SPRING (Continued)

Page 661 of 2585

DRIVER AIRBAG

DESCRIPTION

The Driver Airbag is located in the center of the

steering wheel. The most visible part of the airbag is

the cover/horn switch. The Driver Airbag and Driver

Airbag Cover/Horn Pad are serviced separately from

each other.

OPERATION

The Driver Airbag cover contains the horn switch,

inflator device, and a fabric bag. The airbag cover/

horn switch is serviced separately from the inflator

and bag components.

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly.

²Lower Steering Column Coupler.

²Steering Wheel.

²Clock Spring.

²Driver Airbag

²Passenger Airbag

²Upper Instrument Panel with Pad.

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

REMOVAL

DEPLOYED AIRBAG

(1) Clean powder residue from interior of vehicle

(Fig. 1).

(2) Position steering wheel and front wheels

straight ahead.

(3) Release hood latch and open hood.

(4) Disconnect and isolate the battery negative

cable.

(5) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag compo-

nent service.

(6) Remove two screws retaining driver airbag to

steering wheel.

(7) Disconnect wire connectors from back of driver

airbag.

(8) Disconnect the 2±way connector from remote

radio control harness.(9) Disconnect the 4±way harness connector from

the speed control/horn harness to the clock spring.

(10) Remove steering wheel (Refer to 19 - STEER-

ING/COLUMN/STEERING WHEEL - REMOVAL).

(11) Remove steering column shrouds and discon-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL).

(12) Disconnect 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(13) Remove clock spring from column assembly by

removing the two retaining screws that attach the

clock spring to the column.

NOTE: The clock spring, steering wheel, and com-

plete steering column assembly w/lower steering

column coupler must be replaced also in the event

of a driver airbag deployment

UNDEPLOYED AIRBAG

(1) Release hood latch and open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag compo-

nent service.

(4) Remove two screws retaining driver airbag to

steering wheel.

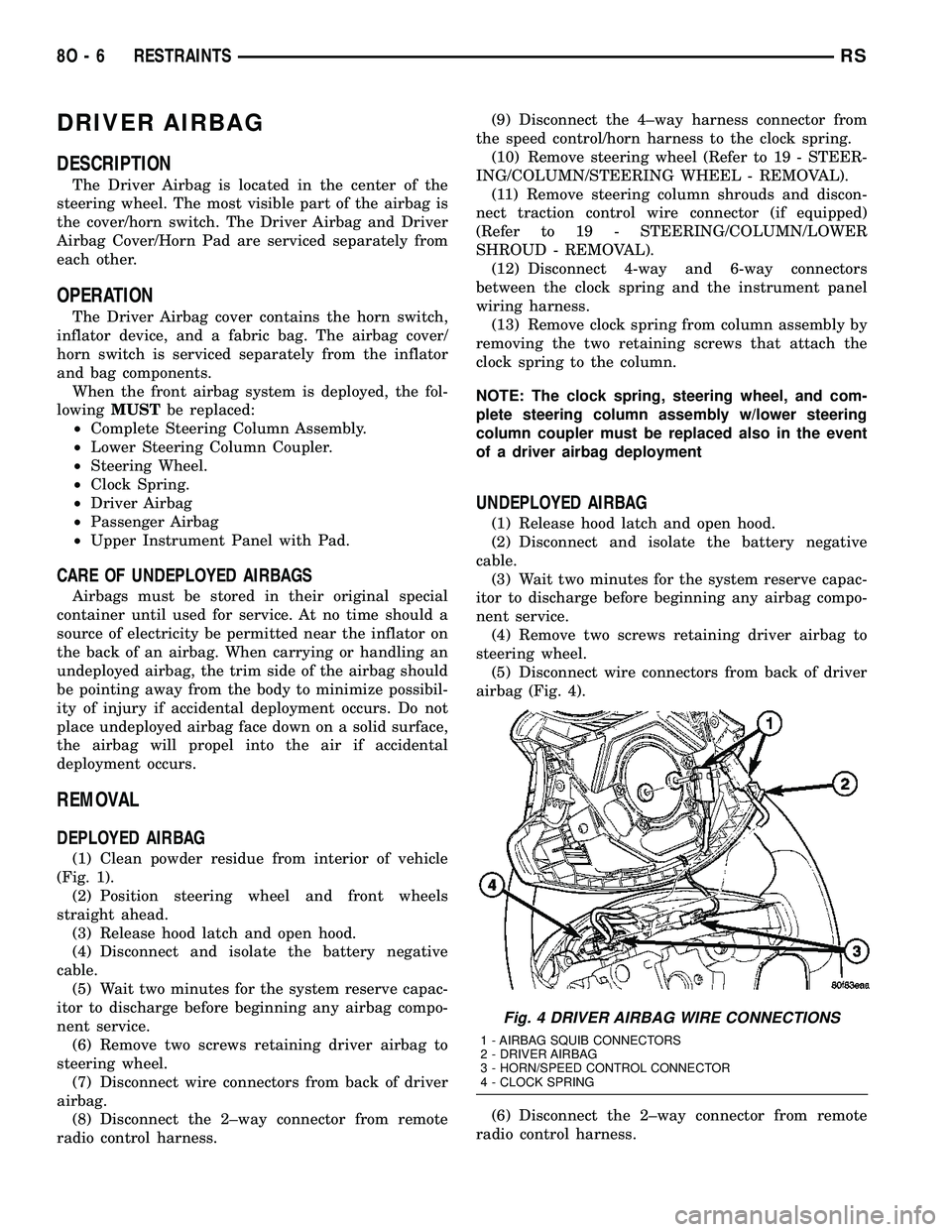

(5) Disconnect wire connectors from back of driver

airbag (Fig. 4).

(6) Disconnect the 2±way connector from remote

radio control harness.

Fig. 4 DRIVER AIRBAG WIRE CONNECTIONS

1 - AIRBAG SQUIB CONNECTORS

2 - DRIVER AIRBAG

3 - HORN/SPEED CONTROL CONNECTOR

4 - CLOCK SPRING

8O - 6 RESTRAINTSRS

Page 662 of 2585

(7) Disconnect the 4±way harness connector from

the speed control/horn harness to the clock spring.

INSTALLATION

DEPLOYED AIRBAG

(1) Perform clean up procedure (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - STANDARD PROCEDURE

- SERVICE AFTER AN AIRBAG DEPLOYMENT).

(2) Install a new steering column assembly and

lower steering column coupler (Refer to 19 - STEER-

ING/COLUMN - INSTALLATION).

(3) Install the new clock spring.

(4) Connect the 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(5) Install the steering column shrouds and con-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - INSTALLATION).

(6) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(7) Connect the 4±way harness connector to the

speed control/horn harness to the clock spring.

(8) Connect the 2±way connector to the remote

radio control harness.

(9) Install the driver airbag and the two screws

retaining the airbag. Tighten screws to 10 N´m (90

in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

UNDEPLOYED AIRBAG

(1) Connect the harness connector on the DAB

cover (horn, speed controls) to the clock spring.

(2) Connect the squib connectors to the DAB.

(3) Position a new airbag into the airbag cavity.

(4) Install the two screws retaining the airbag.

Tighten screws to 10 N´m (90 in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

DRIVER AIRBAG TRIM COVER

REMOVAL

The horn switch is integral to the driver airbag

trim cover. If either component is faulty or damaged,

the entire driver airbag trim cover and horn switch

unit must be replaced.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge.

(2) Remove the driver airbag from the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(3) Remove the plastic wire retainer that captures

the horn switch feed pigtail wire between the upper

left inflator stud and the inflator on the back of the

driver airbag housing and disconnect the speed con-

trol switches (if equipped).

(4) Remove the four nuts that secure the trim

cover retainer to the studs on the back of the driver

airbag housing.

(5) Remove the horn switch ground pigtail wire

eyelet terminal from the upper left airbag housing

stud.

(6) Remove the trim cover retainer from the airbag

housing studs.

(7) Disengage the six trim cover locking blocks

from the lip around the outside edge of the driver

airbag housing and remove the housing from the

cover.

INSTALLATION

(1) Install the housing into the cover. Engage the

six trim cover locking blocks to the lip around the

outside edge of the driver airbag housing.

(2) Install the trim cover retainer to the airbag

housing studs.

(3) Install the horn switch ground pigtail wire eye-

let terminal to the upper left airbag housing stud.

(4) Install the four nuts that secure the upper and

lower trim cover retainers to the studs on the back of

the driver airbag housing. Torque nuts to 6.8 N´m (60

in. lbs.).

(5) Install the plastic wire retainer that captures

the horn switch feed pigtail wire between the upper

left inflator stud and the inflator on the back of the

driver airbag housing.

(6) Connect speed control switches (if equipped).

(7) Install the driver airbag onto the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

RSRESTRAINTS8O-7

DRIVER AIRBAG (Continued)

Page 680 of 2585

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SENTRY KEY

REMOTE ENTRY SYSTEM...............3

DIAGNOSIS AND TESTING - VEHICLE

THEFT SECURITY SYSTEM..............3

HOOD AJAR SWITCH - EXPORT

REMOVAL.............................3

INSTALLATION..........................3

SENTRY KEY REMOTE ENTRY MODULE

DESCRIPTION..........................3OPERATION............................4

DIAGNOSIS AND TESTING - SENTRY KEY

REMOTE ENTRY MODULE...............5

REMOVAL.............................5

INSTALLATION..........................6

TRANSPONDER KEY

DESCRIPTION..........................6

OPERATION............................6

STANDARD PROCEDURE - TRANSPONDER

PROGRAMMING.......................6

VTSS/SKIS INDICATOR LAMP

DESCRIPTION..........................7

OPERATION............................8

VEHICLE THEFT SECURITY

DESCRIPTION

VEHICLE THEFT SECURITY SYSTEM

The Vehicle Theft Security System (VTSS) is

designed to protect against whole vehicle theft. The

system monitors vehicle doors, and ignition action for

unauthorized operation (hood and liftgate for RG -

Export). The alarm activates:

²Sounding of the horn

²Flashing of the headlamps/park/tail lamps

²Flashing of the headlamps

²An engine kill feature (with SKREES)

SENTRY KEY REMOTE ENTRY SYSTEM

The Sentry Key Remote Entry System (SKREES)

is available as a factory-installed option on this vehi-

cle. It is designed to provide passive protection

against unauthorized vehicle use by disabling the

engine, after two (2) seconds of running, whenever an

invalid key is used to start the vehicle. The SKIS is

active whenever the ignition is on and does not

require any customer intervention. The primary com-

ponents of the system are the Sentry Key Remote

Entry Module (SKREEM), Sentry Key (ignition key

with a transponder molded into the head), indicator

light, Body Control Module (BCM), and the Power-

train Control Module (PCM). The SKREEM is

mounted to the steering column with the molded,

integral antenna mounted on the ignition housing.

The indicator light, is located in the Mechanical

Instrument Cluster (MIC).

OPERATION

VEHICLE THEFT SECURITY SYSTEM

Upon failure of proper Sentry Key Remote Entry

Module (SKREEM) communication to the PCM, the

PCM will shut off fuel after two seconds of run time.

The engine will not re-crank on the key cycle that

the failure occurred, a full key down sequence must

be performed for the engine to crank again. After six

consecutive fuel shut-offs, the engine will no longer

crank on subsequent key cycles. The failure must be

corrected and a valid communication process between

the SKREEM and the PCM must occur for the

engine to crank and start again.

The electronics for the VTSS are part of the Body

Control Module (BCM). The system is armed when

the vehicle is locked using the:

²Power door lock switches (with any door ajar)

²Remote Keyless Entry transmitter.

²Door Cylinder Lock Switches (RG only).

For vehicles equipped with Sentry Key Remote

Entry System (SKREES), the doors do not have to be

locked to enable the fuel shut off feature.

After the vehicle is locked and the last door is

closed, the set LED indicator in the Mechanical

Instrument Cluster (MIC) will flash quickly for 16

seconds, indicating that arming is in progress. If no

monitored systems are activated during this period,

the system will arm. The LED will extinguish unless

the liftgate is open. If the liftgate is open, the LED

will flash at a slower rate. This indicates that the

system is armed.

RG Only- If fault is detected on the driver key

cylinder input, the indicator LED will remain solid

RSVEHICLE THEFT SECURITY8Q-1

Page 682 of 2585

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SENTRY KEY

REMOTE ENTRY SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS,

WARNINGS, BEFORE ATTEMPTING COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY OR DEATH.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Sentry Key Remote Entry System (SKREES)

involves the use of a DRBIIITscan tool. Refer to the

proper Body Diagnostic Procedures information.

The Sentry Key Remote Entry System (SKREES)

and the Programmable Communication Interface

(PCI) bus network should be diagnosed using a

DRBIIItscan tool. The DRBIIItwill allow confirma-

tion that the PCI bus is functional, that the Sentry

Key Remote Entry Module (SKREEM) is placing the

proper messages on the PCI bus, and that the Pow-

ertrain Control Module (PCM) is receiving the PCI

bus messages. Refer to the proper Body Diagnostic

Procedures information, and Wiring Diagrams for

complete circuit descriptions and diagrams.

(1) Check the fuses in the Integrated Power Mod-

ule (IPM). If OK, go to Step 2. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(2) Disconnect and isolate the battery negative

remote cable from the remote terminal. Unplug the

wire harness connector at the SKREEM. Check for

continuity between the ground circuit cavity of the

SKREEM wire harness connector and a good ground.

There should be continuity. If OK, go to Step 3. If not

OK, repair the open circuit to ground as required.

(3) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

SKREEM wire harness connector. If OK, go to Step

4. If not OK, repair the open circuit to the fuse in the

IPM as required.

(4) Turn the ignition switch to the ON position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the SKREEM wire

harness connector. If OK, use a DRBIIItscan tool

and the proper Body Diagnostic Procedures informa-

tion to complete the diagnosis of the SKREES. If not

OK, repair the open circuit to the fuse in the IPM as

required.

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. Using a

DRBIIItscan tool. Refer to the proper Body Diagnos-

tic Procedures information for test procedures.

HOOD AJAR SWITCH -

EXPORT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a small flat blade screwdriver, pry trig-

ger switch from the bracket on the left fender well.

(3) Disconnect the hood ajar switch from the wire

connector and remove from vehicle.

INSTALLATION

(1) Connect the hood ajar switch to the wire conec-

tor.

(2) Press the hood ajar switch into position on the

bracket located on the left inner fender well.

(3) Reconnect the battery negative cable.

(4) Close the hood and check for proper operation.

SENTRY KEY REMOTE ENTRY

MODULE

DESCRIPTION

The Sentry Key Remote Entry Module (SKREEM)

performs the functions of the Sentry Key Immobilizer

Module (SKIM), Remote Keyless Entry (RKE) Mod-

ule, and the Tire Pressure Monitoring (TPM) System

(previously part of the Electronic Vehicle Information

Center (EVIC).

The SKREEM is located in the same location as

the SKIM was and is mounted the same way. It looks

identical, but has added capabilities.

SENTRY KEY IMMOBILIZER

The Sentry Key Immobilizer System (SKIS)

authenticates an electronically coded Transponder

Key placed into the ignition and sends a valid/invalid

key message to the Powertrain Control Module

(PCM) based upon the results. The ªVALID/INVALID

KEYº message communication is performed using a

rolling code algorithm via the Programmable Com-

munication Interface (PCI) data bus. A ªVALID KEYº

RSVEHICLE THEFT SECURITY8Q-3

VEHICLE THEFT SECURITY (Continued)

Page 683 of 2585

message must be sent to the Powertrain Control

Module (PCM) within two seconds of ignition ON to

free the engine from immobilization.

The SKREEM contains a Radio Frequency (RF)

transceiver and a microprocessor. The SKREEM

retains in memory the ID numbers of any Sentry Key

that is programmed to it. The maximum number of

keys that may be programmed to each module is

eight (8). The SKREEM also communicates over the

Programmable Communication Interface (PCI) data

bus with the Powertrain Control Module (PCM), the

Body Control Module (BCM), the Mechanical Instru-

ment Cluster (MIC), and the DRB IIItscan tool. The

SKREEM transmits and receives RF signals through

a tuned antenna enclosed within a molded plastic

ring formation that is integral to the SKREEM hous-

ing. When the SKREEM is properly installed on the

steering column, the antenna ring fits snugly around

the circumference of the ignition lock cylinder hous-

ing. If this ring is not mounted properly, communica-

tion problems may arise in the form of transponder-

related faults.

For added system security, each SKREEM is pro-

grammed with a unique9Secret Key9code. This code

is stored in memory and is sent over the PCI bus to

the PCM and to each key that is programmed to

work with the vehicle. The9Secret Key9code is there-

fore a common element found in all components of

the Sentry Key Immobilizer System (SKIS). In the

event that a SKREEM replacement is required, the

9Secret Key9code can be restored from the PCM by

following the SKIM replacement procedure found in

the DRB IIItscan tool. Proper completion of this

task will allow the existing ignition keys to be repro-

grammed. Therefore, new keys will NOT be needed.

In the event that the original9Secret Key9code can

not be recovered, new ignition keys will be required.

The DRB IIItscan tool will alert the technician if

key replacement is necessary. Another security code,

called a PIN, is used to gain secured access to the

SKREEM for service. The SKREEM also stores in its

memory the Vehicle Identification Number (VIN),

which it learns through a bus message from the

assembly plant tester. The SKIS scrambles the infor-

mation that is communicated between its components

in order to reduce the possibility of unauthorized

SKREEM access and/or disabling.

REMOTE KEYLESS ENTRY (RKE)

The RKE transmitter uses radio frequency signals

to communicate with the SKREEM. The SKREEM is

on the PCI bus. When the operator presses a button

on the transmitter, it sends a specific request to the

SKREEM. In turn the SKREEM sends the appropri-

ate request over the PCI Bus to the:²Body Control Module (BCM) to control the door

lock and unlock functions, the liftgate lock and

unlock functions, the arming and disarming of the

Vehicle Theft Security System (VTSS) (if equipped),

and the activation of illuminated entry.

²Integrated Power Module (IPM) to activate the

park lamps, the headlamps, and the horn for horn

chirp. If requested, the BCM sends a request over

the PCI Bus to the:

TIRE PRESSURE MONITORING (TPM)

If equipped with the Tire Pressure Monitoring

(TPM) System, each of the vehicles four wheels will

have a valve stem with a pressure sensor and radio

transmitter built in. Signals from the tire pressure

sensor/transmitter are received and interpreted by

the SKREEM.

A sensor/transmitter in a mounted wheel will

broadcast its detected pressure once per minute

when the vehicle is moving faster than 15 mph (24

km/h). Each sensor/transmitter's broadcast is

uniquely coded so that the SKREEM can determine

the location.

OPERATION

SENTRY KEY IMMOBILIZER

The Sentry Key Remote Entry Module (SKREEM)

receives an encrypted Radio Frequency (RF) signal

from the transponder key. The SKREEM then

decrypts the signal and broadcasts the requested

remote commands to the appropriate modules in the

vehicle over the Programmable Communication

Interface (PCI) data bus. A valid transponder key ID

must be incorporated into the RF signal in order for

the SKREEM to pass the message on to the appro-

priate modules.

Automatic transponder key synchronization is done

by the SKREEM if a valid transponder key is

inserted into the ignition cylinder, and the ignition is

turned ON. This provides a maximum operation win-

dow for RKE functions.

Each Sentry Key Remote Entry System (SKREES)

consists of a SKREEM and a transponder key. Each

system has a secret key code unique to that system.

The secret key is electronically coded in the

SKREEM and in all programmed transponder keys.

It is used for immobilization and RKE functions for

data security. In addition, each transponder key will

have a unique identification.

When the ignition switch is moved to the RUN

position, the SKREEM transmits an Radio Frequency

(RF) signal to the transponder in the ignition key.

The SKREEM then waits for a response RF signal

from the transponder in the key. If the response

received identifies the key as valid, the SKREEM

8Q - 4 VEHICLE THEFT SECURITYRS

SENTRY KEY REMOTE ENTRY MODULE (Continued)