remote control CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1232 of 2585

8W-91 CONNECTOR/GROUND/SPLICE LOCATION

TABLE OF CONTENTS

page

CONNECTOR/GROUND/SPLICE LOCATION

DESCRIPTION..........................1

CONNECTOR/GROUND/SPLICE

LOCATION

DESCRIPTION

This section provides illustrations identifying con-

nector, ground, and splice locations in the vehicle.

Connector, ground, and splice indexes are provided.Use the wiring diagrams in each section for connec-

tor, ground, and splice identification. Refer to the

appropriate index for the proper figure number. For

items that are not shown in this section N/S is placed

in the Fig. column.

CONNECTORS

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

A/C Compressor Clutch LTGY Top of A/C Compressor 10, 11, 15, 17, 18

A/C-Heater Control C1 (MTC) BK/RD Rear of Control 20, 23, 25

A/C-Heater Control C2 (MTC) BK/BL Rear of Control 20, 23, 25

A/C Pressure Sensor GY At Throttle Body 10, 15, 16, 17

Accelerator Pedal Position

Sensor (Diesel)BK At Accelerator Pedal 42

Adjustable Pedals Module

(Except Export)Near Brake Lamp Switch N/S

Adjustable Pedals Switch (Except

Export)DKGY Left Side Kick Panel 41

Adjustable Pedals Relay (Except

Export)Left Side Engine Compartment 6

Airbag Control Module (ORC)

(Base)YL/RD Right Side of Instrument Panel 24

Airbag Control Module C1

(ORC)(Premium)YL Right Side Instrument Panel N/S

Airbag Control Module C2

(ORC)(Premium)YL Right Side Instrument Panel 20, 24

Ambient Temperature Sensor

(Except Base)BK On Radiator Closure Panel 1

ATC Remote Sensor Above ATC Control N/S

Automatic Day/Night Mirror BK At Mirror N/S

Auto Temp Control C1 NAT Rear of Control 20

Auto Temp Control C2 BK Rear of Control 20

Auto Temp Control C3 Rear of Control N/S

Back-Up Lamp Switch BK On Transmission 16

Battery Temperature Sensor BK At Battery N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-1

Page 1238 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Left High Beam Lamp (Export) BK At Lamp N/S

Left Instrument Panel Speaker BK At Speaker 20, 21, 27

Left Liftgate Flood Lamp GY At Lamp 49

Left Low Beam Lamp (Export) BK At Lamp N/S

Left Mid Reading Lamp

(Premium/Luxury)GY At Lamp N/S

Left Park Lamp (Export) BK At Lamp 5

Left Power Mirror BK At Mirror 27

Left Rear Lamp Assembly BK At Lamp 47

Left Rear Pillar Speaker BK Left of Liftgate 47

Left Rear Reading Lamp (Luxury) GY At Lamp N/S

Left Rear Speaker (Highline) BK/RD At Speaker 47

Left Rear Speaker (Lowline) At Speaker N/S

Left Rear Vent Motor NAT At Motor 46, 47

Left Rear Wheel Speed Sensor BK Center Rear of Floor Pan 47

Left Remote Radio Switch BK Steering Wheel N/S

Left Repeater Lamp (Export) GY Left Front Fender 4, 36

Left Seat Airbag YL Left Seat N/S

Left Side Impact Sensor

1(Premium ORC)DKGY Left B Pillar 40

Left Sliding Door Control Module

C1BK Left Sliding Door N/S

Left Sliding Door Control Module

C2Left Sliding Door N/S

Left Sliding Door Latch Sensing

SwitchBK Left Sliding Door N/S

Left Sliding Door Lock Motor BK Left Sliding Door N/S

Left Sliding Door Lock Motor/Ajar

Switch (Manual Sliding Door)BK Left Sliding Door N/S

Left Sliding Door Motor BK Left Sliding Door N/S

Left Speed Control Switch WT Steering Wheel N/S

Left Turn Signal Lamp (Export) OR AT Lamp N/S

Left Visor/Vanity Lamp (Except

Base)BK At Lamp N/S

License Lamp DKGY At Lamp 49

Lift Pump Motor (Diesel) BK Left Rear Engine Compartment N/S

Liftgate Ajar Switch (Manual

Release)BK At Latch 49

Liftgate Ajar Switch (Power

Release)BK Lower Liftgate 49

Liftgate Cinch/Release Motor

(Power Liftgate)BL Liftgate 49

Liftgate Left Pinch Sensor (Power

Liftgate)BK Left Side of Liftgate 49

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1241 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Radio C2 (CD Changer) Rear of Radio 20

Radio C2 (DVD/CD Changer) At Radio N/S

Rear A/C-Heater Unit (3 Zone

MTC)LTGN Right Quarter Panel 48

Rear Auto Temp Control Switch

(ATC)BK Rear of Switch 40

Rear Blower Front Control Switch

(3 Zone MTC)BK Rear of Switch N/S

Rear Blower Motor Power Module

C1 (3 Zone MTC)RD/BK Right Quarter N/S

Rear Blower Motor Power Module

C2 (3 Zone MTC)BK Right Quarter N/S

Rear Blower Rear Control Switch

C1 (3 Zone MTC)BK Overhead 50

Rear Blower Rear Control Switch

C2 (3 Zone MTC)BK Overhead 50

Rear Dome Lamp (Except

Luxury)GY At Lamp N/S

Rear Intrusion Sensor (United

Kingdom)At Sensor N/S

Rear Mode Motor (3 Zone ATC) GY At Motor N/S

Rear Power Outlet GY Left Quarter Panel 47

Rear Temperature Motor (3 Zone

ATC)GY Right Quarter N/S

Rear Washer Pump Motor BK Right Fender Well 3

Rear Wiper Motor GY At Motor 49

Recirculation Door Actuator GY Right Side of HVAC N/S

Remote Keyless Entry Antenna

(JAPAN)BK Right Upper Instrument Panel 28

Right B-Pillar Switch (Power

Sliding Door)GY Right B Pillar 39

Right Cinch/Release Motor

(Power Sliding Door)GY Rear of Sliding Door 45

Right Cylinder Lock Switch

(Export)BK Right Front Door 44

Right Door Speaker (Highline) BK/RD At Speaker N/S

Right Door Speaker (Lowline) In Door N/S

Right Fog Lamp (Export) WT At Lamp 3

Right Fog Lamp (Except Export) BK At Lamp N/S

Right Front Door Ajar Switch

(Base)BK At B Pillar N/S

Right Front Door Lock Motor/Ajar

Switch (Except Base)BK Right Front Door 44

Right Front Impact Sensor

(Except Export)BK Near T/O for C303 N/S

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1242 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Right Front Park/Turn Signal

Lamp (Except Export)BK At Lamp 1, 3

Right Front Wheel Speed Sensor GY Right Fender Side Shield 3,10, 16, 17

Right Full Open Switch (Power

Sliding Door)BK Right Sliding Door 45

Right Headlamp (Except Export) BK At Lamp 1, 3

Right Headlamp Leveling Motor

(Export)WT At Right Headlamp N/S

Right High Beam Lamp (Export) BK At Right Headlamp N/S

Right Instrument Panel Speaker BK At Speaker 20, 23, 24

Right Liftgate Flood Lamp GY At Lamp 49

Right Low Beam Lamp (Export) BK At Right Headlamp N/S

Right Mid Reading Lamp

(Premium/ Luxury)GY At Lamp N/S

Right Park Lamp (Export) BK AT Lamp N/S

Right Power Mirror BK At Mirror 20, 24, 28

Right Rear Lamp Assembly BK At Lamp 48

Right Rear Pillar Speaker BK At Speaker 48

Right Rear Reading Lamp

(Luxury)GY At Lamp N/S

Right Rear Speaker (Highline) BK/RD At Speaker 48

Right Rear Speaker (Lowline) At Speaker N/S

Right Rear Vent Motor NAT At Motor 48

Right Rear Wheel Speed Sensor BK Right Rear of Floor Pan 48

Right Remote Radio Switch BK At Steering Wheel N/S

Right Repeater Lamp (Export) GY Right Front Fender 39

Right Seat Airbag YL At Passenger Seat N/S

Right Side Impact Sensor 1

(Premium ORC)DKGY Right B Pillar 39

Right Sliding Door Control

Module C1BK Rear of Door 45, 46

Right Sliding Door Control

Module C2Rear of Door 45, 46

Right Sliding Door Latch Sensing

SwitchBK At Sliding Door 45

Right Sliding Door Lock Motor BK Rear of Door 45

Right Sliding Door Lock

Motor/Ajar Switch (Manual Sliding

Door)BK At Latch N/S

Right Sliding Door Motor BK At Sliding Door 45

Right Speed Control Switch BK At Steering Wheel N/S

Right Stop/Turn Signal Relay BK LT Quarter Panel N/S

Right Turn Signal Lamp OR At Lamp N/S

Right Visor/Vanity Lamp BK At Lamp N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-11

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1243 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Sentry Key Remote Entry Module

(Skreem)BK At Steering Column 20, 21, 22, 23, 31

Siren (United Kingdom) BK Left Front Body N/S

Speed Control Servo (Gas) BK Near Controller Antilock Brake 11, 17, 18

Sunroof Module (Except Export) BK At Sunroof N/S

Sunroof Switch (Except Export) Nat Near Overhead Console N/S

Thatcham Alarm Module C1

(United Kingdom)BK Top Right Side of Instrument Panel

Near SpeakerN/S

Throttle Position Sensor (Gas) GY On Throttle Body 10, 11, 17

Traction Control Switch BK Rear of Swtich 21, 22, 31

Trailer Tow Connector (Except

Export)BK Left Quarter Panel N/S

Transmission Range Sensor DKGY Top of Transmission 14, 19

Transmission Solenoid/Pressure

Switch AssemblyBK Side of Transmission 14, 18 19

Vehicle Speed Sensor (MTX) BK Rear of Transmission 16

Washer Fluid Level Switch BK Bottom of Reservoir 3

Washer Pump Motor BK Right Fender Well 3

Water in Fuel Sensor (Diesel) BK Left Rear Engine Compartment N/S

Wiper Module DKGY Left Side Cowl 6

GROUNDS

GROUND NUMBER LOCATION FIG.

G100 Body Ground Near Powertrain Control Module N/S

G101 Above Starter 13, 18

G102 Left Headlamp Area 1

G103 Above Starter 15

G200 Right Side of Instrument Panel 20, 24, 29

G201 Right Side of Instrument Panel 20, 24, 29

G202 Near Radio N/S

G300 Left B Pillar 32

G301 Right B Pillar 33, 39

G302 Left Rear Quarter 47

G303 Liftgate Ground 49

8W - 91 - 12 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1568 of 2585

SHROUD - UPPER

REMOVAL

(1) Remove the two shroud-to-shroud mounting

screws from the lower shroud (Fig. 32).

(2) Unsnap the upper shroud from the lower on

the left side as follows:

(a) Hook a finger on the left hand around the

rear of the shrouds at the seam (Fig. 33), near the

snap points.

(b) Grasp the upper shroud at the rear using the

right hand (Fig. 33).

(c) As the left hand's hooked finger is pulled out-

ward against the seam, pull the upper shroud

upward using the right hand, disconnecting the

shroud snaps.

(3) Unsnap the upper shroud from the lower on

the right side as follows:

(a) Hook a finger on the right hand around the

rear of the shrouds at the seam (Fig. 34), near the

snap points.

(b) Grasp the upper shroud at the rear using the

left hand (Fig. 34).

(c) As the right hand's hooked finger is pulled

outward against the seam, pull the upper shroud

upward using the left hand, disconnecting the

shroud snaps.

(4) Lift the upper shroud straight up off the steer-

ing column. If vehicle is equipped with traction con-

trol, disconnect wiring connector at traction control

switch pig tail. If vehicle is equipped with power fold-

away mirrors (Export), disconnect wiring connector

at mirror switch pig tail. Remove upper shroud.

(5) If vehicle is equipped with traction control,

remove traction control switch from shroud.

(6) If vehicle is equipped with power foldaway mir-

rors (Export), remove power fold-away switch from

upper shroud.

INSTALLATION

(1) If the vehicle is equipped with power foldaway

mirrors (Export), install the power fold-away switch

in the upper shroud.

(2) If vehicle is equipped with traction control,

install the traction control switch in the upper

shroud.

(3) Place the upper shroud over the lower shroud,

aligning the snap clips and alignment tabs. If the

vehicle is equipped with traction control, connect the

wiring connector at the traction control switch pig

tail before lining the shrouds up to one another.

(4) Snap the upper shroud to the lower shroud.

Once snapped into place, verify there are no gaps

between the two mating surfaces of the shrouds.(5) Install the two shroud-to-shroud mounting

screws (Fig. 32). Tighten the screws to 2 N´m (17 in.

lbs.) torque.

(6) Ensure that the shrouds are snug and fit is

acceptable.

STEERING WHEEL

REMOVAL

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING)(Refer to 8 - ELECTRICAL/RE-

STRAINTS - WARNING).

(1) Adjust the steering wheel so that the tires are

in thestraight-aheadposition.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the two bolts from the rear of the

steering wheel attaching the driver airbag. Lift the

airbag from the steering wheel.

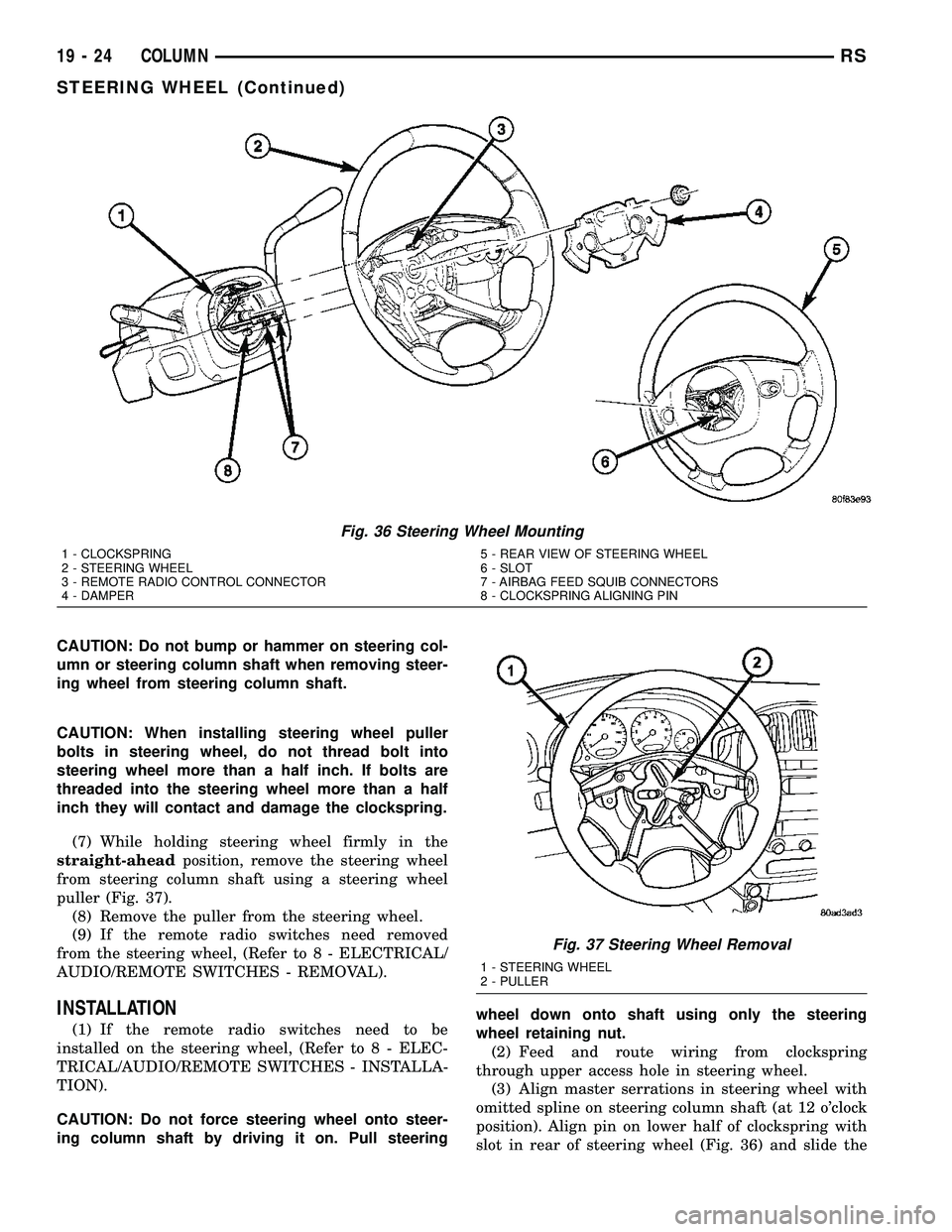

(4) Disconnect airbag squib wiring connectors from

the airbag and the horn/speed control switch pigtail

connector from the clockspring (Fig. 35). If the steer-

ing wheel is equipped with remote radio controls, dis-

connect the connector from the clockspring (Fig. 36).

Properly store the driver airbag out of the way.

(Refer to 8 - ELECTRICAL/RESTRAINTS - WARN-

ING)

(5) Remove the steering wheel retaining nut from

the steering column shaft (Fig. 36).

(6) Remove the steering wheel damper from the

steering wheel (Fig. 36).

Fig. 35 Airbag Wiring Connections

1 - AIRBAG FEED SQUIB CONNECTORS

2 - DRIVER AIRBAG

3 - HORN/SPEED CONTROL CONNECTOR

4 - CLOCKSPRING

RSCOLUMN19-23

Page 1569 of 2585

CAUTION: Do not bump or hammer on steering col-

umn or steering column shaft when removing steer-

ing wheel from steering column shaft.

CAUTION: When installing steering wheel puller

bolts in steering wheel, do not thread bolt into

steering wheel more than a half inch. If bolts are

threaded into the steering wheel more than a half

inch they will contact and damage the clockspring.

(7) While holding steering wheel firmly in the

straight-aheadposition, remove the steering wheel

from steering column shaft using a steering wheel

puller (Fig. 37).

(8) Remove the puller from the steering wheel.

(9) If the remote radio switches need removed

from the steering wheel, (Refer to 8 - ELECTRICAL/

AUDIO/REMOTE SWITCHES - REMOVAL).

INSTALLATION

(1) If the remote radio switches need to be

installed on the steering wheel, (Refer to 8 - ELEC-

TRICAL/AUDIO/REMOTE SWITCHES - INSTALLA-

TION).

CAUTION: Do not force steering wheel onto steer-

ing column shaft by driving it on. Pull steeringwheel down onto shaft using only the steering

wheel retaining nut.

(2) Feed and route wiring from clockspring

through upper access hole in steering wheel.

(3) Align master serrations in steering wheel with

omitted spline on steering column shaft (at 12 o'clock

position). Align pin on lower half of clockspring with

slot in rear of steering wheel (Fig. 36) and slide the

Fig. 36 Steering Wheel Mounting

1 - CLOCKSPRING

2 - STEERING WHEEL

3 - REMOTE RADIO CONTROL CONNECTOR

4 - DAMPER5 - REAR VIEW OF STEERING WHEEL

6 - SLOT

7 - AIRBAG FEED SQUIB CONNECTORS

8 - CLOCKSPRING ALIGNING PIN

Fig. 37 Steering Wheel Removal

1 - STEERING WHEEL

2 - PULLER

19 - 24 COLUMNRS

STEERING WHEEL (Continued)

Page 1570 of 2585

steering wheel onto the steering column shaft by

hand. Use care not to pinch any wiring.

NOTE: Before installing the damper on the steering

wheel, inspect the damper to ensure the rubber iso-

lator on the damper is not deteriorated or damaged.

If the damper is installed with a damaged isolator, a

buzz, squeak or rattle condition may develop.

(4) Install the steering wheel damper on the steer-

ing wheel (Fig. 36).

(5) Install the steering wheel retaining nut.

Tighten the steering wheel retaining nut to 61 N´m

(45 ft. lbs.) torque.(6) If the steering wheel is equipped with remote

radio controls, connect the wiring connector to the

clockspring (Fig. 36).

(7) Connect the airbag squib wiring connectors to

the airbag and the horn/speed control switch pigtail

connector to the clockspring (Fig. 35).

(8) Install the driver airbag in the steering wheel.

Install and tighten the airbag attaching bolts to 10

N´m (90 in. lbs.) torque.

(9) To properly connect the battery and test the

airbag system, (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

RSCOLUMN19-25

STEERING WHEEL (Continued)

Page 1595 of 2585

(6) Attach return hose tubes to suspension cradle

crossmember using routing clamp and bolt (Fig. 20).

Tighten clamp bolt to 23 N´m (200 in. lbs.) torque.

(7) Install the power steering fluid cooler on the

cradle crossmember reinforcement (Fig. 23). Install

the mounting bolts and tighten to 11 N´m (100 in.

lbs.). When installing mounting bolts, include pres-

sure hose routing clamp.

(8) Tighten hose tube nut at power steering gear

port to 31 N´m (275 in. lbs.) torque.

(9) Install front emissions vapor canister. (Refer to

25 - EMISSIONS CONTROL/EVAPORATIVE EMIS-

SIONS/VAPOR CANISTER - INSTALLATION)

(10) Lower vehicle.

(11) Install return hose tube into retainer on ABS

bracket (Fig. 20). Close the bracket.

(12) Install return hose onto reservoir (Fig. 21).

Slide the hose clamp into position on fluid reservoir

and attach it.Be sure hose clamp in installed

past bead on fluid reservoir fitting.

(13) Fill and bleed power steering system using

the Power Steering Pump Initial Operation Proce-

dure. (Refer to 19 - STEERING/PUMP - STANDARD

PROCEDURE)

(14) Inspect system for leaks.

HOSE - POWER STEERING

SUPPLY

REMOVAL

REMOVAL - 2.4L ENGINE

(1) Remove filler cap from power steering fluid res-

ervoir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove hose clamp securing supply hose to

power steering pump, then remove supply hose from

pump fitting.

(5) Lower vehicle.

(6) Remove hose clamp attaching power steering

fluid supply hose to power steering fluid reservoir,

then remove supply hose.

(7) Remove the power steering fluid supply hose

from the vehicle.

REMOVAL - 3.3L/3.8L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Place an oil drain pan under vehicle to catch

any draining power steering fluid.

(4) Remove clamp attaching supply hose to power

steering fluid reservoir. Disconnect hose from reser-

voir (Fig. 21).

(5) Pull upward on hose routing clip releasing it

from bracket on cylinder head cover (Fig. 21).

NOTE: It may be necessary to remove air cleaner

housing to gain greater access to supply hose at

power steering pump. (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL)

(6) Remove clamp attaching supply hose to power

steering pump. Disconnect hose from pump and

remove from vehicle (Fig. 21).

INSTALLATION

INSTALLATION - 2.4L ENGINE

(1) Install and correctly route power steering fluid

supply hose from remote fluid reservoir to power

steering pump.

(2) Install fluid supply hose onto power steering

fluid reservoir. Install hose clamp.Be sure hose

clamp is installed past bead on fluid reservoir

fitting.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Install power steering fluid supply hose on

power steering pump supply fitting. Install hose

clamp.Be sure hose clamp is installed past bead

on pump fitting.

(5) Lower vehicle.

(6) Fill and bleed power steering system using

Power Steering Pump Initial Operation Procedure.

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE)

(7) Inspect system for leaks.

INSTALLATION - 3.3L/3.8L ENGINE

(1) Install supply hose onto supply fitting on power

steering pump (Fig. 21). Slide the hose clamp into

position on fluid reservoir and attach it.Be sure

hose clamp in installed past bead on fluid res-

ervoir fitting.

19 - 50 PUMPRS

HOSE - POWER STEERING RETURN (Continued)

Page 2124 of 2585

(5) Wipe all lubricant from exterior of lock cylinder

and key.

ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

(2) Apply specified lubricant to all pivoting and

sliding contact areas of component.

LUBRICANT USAGE

ENGINE OIL

²Door Hinges ± Hinge Pin and Pivot Contact

Areas

²Hood Hinges ± Pivot Points

²Liftgate Hinges

MOPARTSPRAY WHITE LUBE OR EQUIVALENT

²Door Check Straps

²Liftgate Latches²Liftgate Prop Pivots

²Ash Receiver

²Fuel Filler Door Remote Control Latch Mecha-

nism

²Parking Brake Mechanism

²Sliding Seat Tracks

²Liftgate Latch

MOPARTMultipurpose GREASE OR EQUIVALENT

²All Other Hood Mechanisms

MOPARTLOCK CYLINDER LUBRICANT OR

EQUIVALENT

²Door Lock Cylinders

²Liftgate Lock Cylinder

SPECIAL TOOLS

BODY

INDEX

DESCRIPTION FIGURE

STICK, TRIM C 4755 16

REMOVER, MOLDINGS C-4829 17

PLIERS, HEADLINER CLIP 6967 18

Fig. 16 STICK, TRIM C 4755

Fig. 17 REMOVER, MOLDINGS C-4829

Fig. 18 PLIERS, HEADLINER CLIP 6967

RSBODY23-13

BODY (Continued)