automatic transmission CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1722 of 2585

(9) Disconnect gear shift cable from manual valve

lever and upper mount bracket (Fig. 12).

(10) Disconnect crankshaft position sensor (if

equipped). Remove sensor from bellhousing.(11) Reposition leak detection pump harness and

hoses.

(12) Remove rear mount bracket-to-transaxle case

bolts (Fig. 13).

(13) Remove transaxle upper bellhousing-to-block

bolts.

(14) Raise vehicle on hoist.

(15) Remove transaxle oil pan and drain fluid into

suitable container.

(16) Remove front wheel/tire assemblies.

(17) Remove left and right halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - REMOVAL)

(18) AWD models: Remove power transfer unit.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

POWER TRANSFER UNIT - REMOVAL)

(19) Remove rear mount bracket-to-transaxle case

lower (horizontal) bolt (Fig. 13).

(20) Remove front mount/bracket assembly.

(21) Remove starter motor.

(22) Remove lateral bending brace.

(23) Remove inspection cover.

(24) Remove torque converter-to-drive plate bolts.

(25) Support engine/transaxle assembly at engine

oil pan with screw jack and wood block.

(26) Partially remove left wheelhouse splash shield

to gain access to and remove upper mount thru-bolt

(Fig. 14).

(27) Lower engine/transaxle assembly with screw

jack.

(28) Obtain helper and/or transmission jack.

Secure transmission jack to transaxle assembly.

(29) Remove upper mount bracket from transaxle

(Fig. 14).

(30) Remove remaining transaxle bellhousing-to-

engine bolts.

(31) Remove transaxle assembly from vehicle.

DISASSEMBLY

NOTE: If transaxle is being overhauled (clutch

and/or seal replacement) or replaced, it is neces-

sary to perform the PCM/TCM Quick Learn Proce-

dure. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/POWERTRAIN/TRANSMIS-

SION CONTROL MODULE - STANDARD PROCE-

DURE)

NOTE: This procedure does not include final drive

(differential) disassembly.

(1) Remove input and output speed sensors.

(2) Remove three (3) solenoid/pressure switch

assembly-to-case bolts.

(3) Remove solenoid/pressure switch assembly and

gasket (Fig. 15).

Fig. 11 Component Connector LocationÐTypical

1 - SOLENOID/PRESSURE SWITCH ASSY. CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 12 Gearshift Cable at Transaxle - Typical

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

RS41TE AUTOMATIC TRANSAXLE21 - 125

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1758 of 2585

(d) Install pump and gasket to transmission.

Install and torque bolts.

(e) Set up input shaft for measurement with

Indicator Set C3339 and End Play Set 8266 as

shown in (Fig. 144).

(f) Measure the input shaft end play with the

transaxle in the vertical position.Input shaft end

play must be within 0.005 to 0.025 inch.For

example, if end play reading is 0.055 inch, select

No. 4 Thrust Plate which is 0.071 to 0.074 thick.

This should provide an input shaft end play read-

ing of 0.020 inch which is within specifications.

(g) Refer to the No. 4 thrust plate chart to select

the proper No. 4 thrust plate:

Fig. 141 Select Thinnest No. 4 Thrust Plate

1 - OVERDRIVE SHAFT ASSEMBLY

2 - #4 THRUST PLATE (SELECT)

3 - 3 DABS OF PETROLATUM FOR RETENTION

Fig. 142 View Through Input Speed Sensor Hole

1 - INPUT CLUTCH RETAINER

2 - INPUT SPEED SENSOR HOLE

3 - OIL COOLER FITTINGS

Fig. 143 Remove Oil Pump O-Ring

1 - OIL PUMP ASSEMBLY

2 - O-RING

Fig. 144 Measure Input Shaft End Play Using End

Play Set 8266

1 - TOOL 8266±8

2 - TOOL 8266±2

3 - TOOL C-3339

RS41TE AUTOMATIC TRANSAXLE21 - 161

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1763 of 2585

(67) Install oil pan-to-case bolts and torque to 19

N´m (165 in. lbs.).

(68) Install solenoid/pressure switch assembly and

gasket to case (Fig. 161).

(69) Install and tighten solenoid/pressure switch

assembly-to-transaxle case bolts to 12 N´m (110 in.

lbs.) (Fig. 162).(70) Install and torque input and output speed

sensors to case to 27 N´m (20 ft. lbs.).

INSTALLATION

NOTE: If transaxle assembly has been replaced or

overhauled (clutch and/or seal replacement), it is

necessary to perfrom the TCM Quick Learn proce-

dure. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

(1) Using a transmission jack and a helper, posi-

tion transaxle assembly to engine. Install and torque

bellhousing bolts to 95 N´m (70 ft. lbs.).

(2) Install upper mount assembly to transaxle and

torque bolts to 54 N´m (40 ft. lbs.) (Fig. 163).

(3) Raise engine/transaxle assembly into position.

Install and torque upper mount-to-bracket thru-bolt

to 75 N´m (55 ft. lbs.) (Fig. 163).

(4) Remove transmission jack and screw jack.

(5) Secure left wheelhouse splash shield.

(6) Install torque converter-to-drive plate bolts and

torque to 88 N´m (65 ft. lbs.)

(7) Install inspection cover.

(8) Install lateral bending brace.

(9) Install starter motor.

(10) Install front mount/bracket assembly.

Fig. 161 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

Fig. 162 Attaching Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

Fig. 163 Left Mount to Bracket and Transaxle

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

21 - 166 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1764 of 2585

(11) Align and install rear mount bracket-to-case

bolts by hand (Fig. 164). Torque horizontal bolt to

102 N´m (75 ft. lbs.).

(12) AWD models: Install power transfer unit.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

POWER TRANSFER UNIT - INSTALLATION)

(13) Install left and right halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION)

(14) Install front wheel/tire assemblies.

(15) Lower vehicle.

(16) Torque remaining rear mount bracket-to-tran-

saxle vertical bolts (Fig. 164) to 102 N´m (75 ft. lbs.).

(17) Install transaxle upper bellhousing-to-block

bolts and torque to 95 N´m (70 ft. lbs.).

(18) Install and connect crank position sensor (if

equipped).

(19) Connect gearshift cable to upper mount

bracket and transaxle manual valve lever (Fig. 165).

Fig. 164 Rear Mount Bracket - Typical

1 - BOLT - VERTICAL 102 N´m (75 ft. lbs.)

2 - BRACKET - REAR MOUNT

3 - BOLT - HORIZONTAL 102 N´m (75 ft. lbs.)

Fig. 165 Gearshift Cable at Transaxle - Typical

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

RS41TE AUTOMATIC TRANSAXLE21 - 167

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1765 of 2585

(20) Connect solenoid/pressure switch assembly

(Fig. 166).

(21) Connect transmission range sensor connector

(Fig. 166).

(22) Connect input and output speed sensor con-

nectors (Fig. 166).

(23) Remove plugs and install transaxle oil cooler

line service splice kit. Refer to instructions included

with kit.

(24) Remove plug and Install fluid level indicator/

tube assembly.(25) Install coolant recovery bottle (Fig. 167).

(26) Install battery shield.

(27) Connect battery cables.

(28) Fill transaxle with suitable amount of ATF+4

(Automatic Transmission FluidÐType 9602). (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE/FLUID - STANDARD PROCEDURE)

Fig. 166 Component Connector Location - Typical

1 - SOLENOID/PRESSURE SWITCH ASSY. CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 167 Coolant Recovery Bottle

1 - UPPER BOLT ATTACHING TO BATTERY TRAY

2 - COOLANT RECOVERY CONTAINER

3 - UPPER BOLT

4 - HOSE

5 - LOWER BOLT (QTY. 2)

6 - LEFT SIDE FRAME RAIL

21 - 168 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1779 of 2585

INPUT SHAFT

DESCRIPTION METRIC SPECIFICATION

End Play 0.127-0.635mm 0.005-0.025 in.

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt, Differential Cover-to-Case 19 Ð 165

Bolt, Differential Ring Gear-to-Case 95 70 Ð

Bolt, Differential Bearing Retainer-to-

Case28 21 Ð

Bolt, Driveplate-to-Crankshaft 95 70 Ð

Bolt, Extension Housing/Plate-to-Case 28 21 Ð

Bolt, Oil Pan-to-Case 19 Ð 165

Bolt, Output Gear 271 200 Ð

Bolt, Output Gear Stirrup/Strap 23 17 Ð

Bolt, Oil Pump-to-Case 27 20 Ð

Bolt, Reaction Support-to-Case 27 20 Ð

Bolt, Solenoid/Pressure Switch

Assy.-to-Case12 Ð 110

Bolt, Torque Converter-to-Driveplate 75 55 Ð

Bolt, Transfer Gear Cover 20 Ð 175

Bolt, Valve Body-to-Case 12 Ð 105

Fitting, Oil Cooler Line 12 Ð 105

Nut, Tranfer Gear 271 200 Ð

Tap, Transaxle Pressure 5 Ð 45

Screw, L/R Clutch Retainer 5 Ð 45

Screw, Solenoid/Pressure Switch Assy.

Connector4Ð35

Screw, Valve Body-to-Transfer Plate 5 Ð 45

Sensor, Input Speed 27 20 Ð

Sensor, Output Speed 27 20 Ð

Sensor, Transmission Range Sensor 5 Ð 45

21 - 182 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1795 of 2585

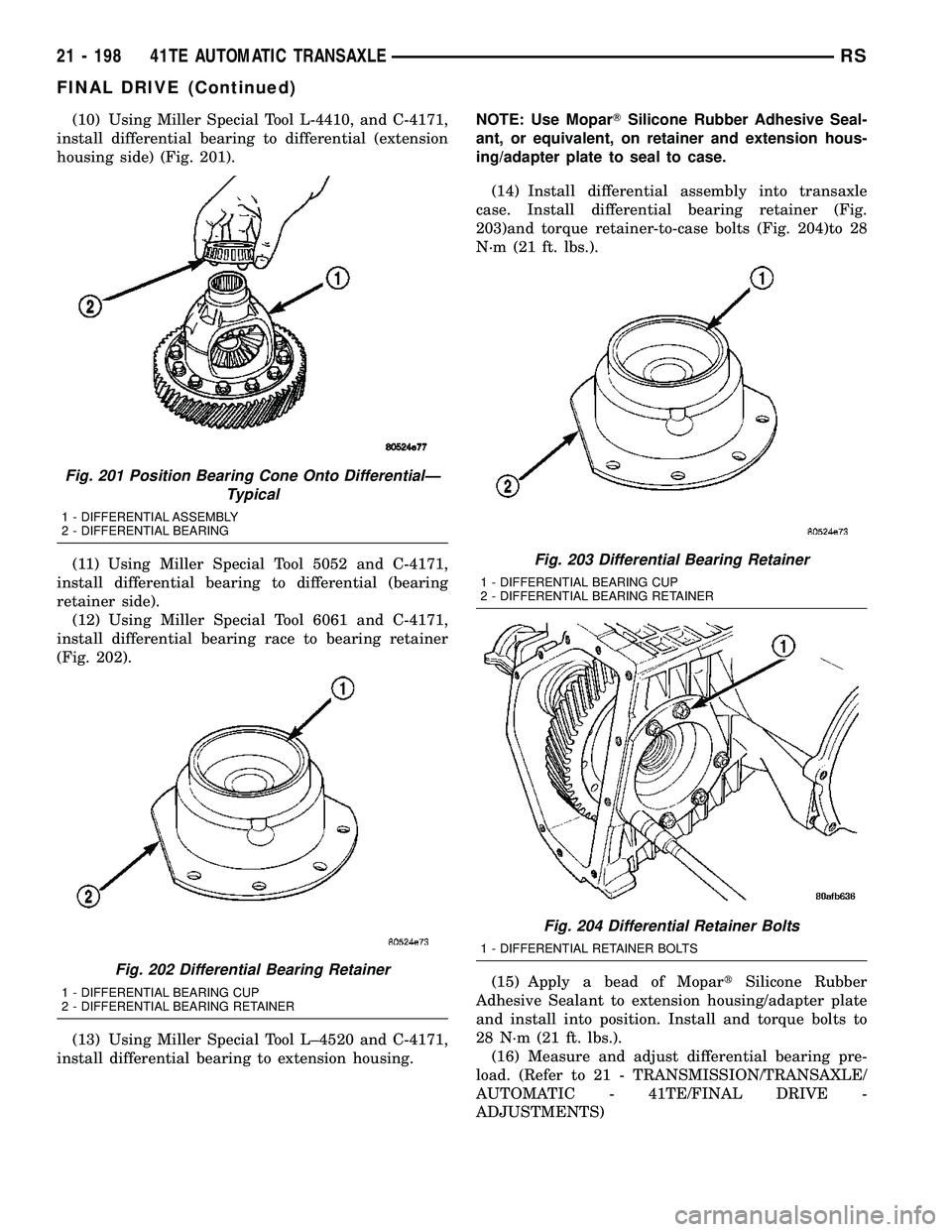

(10) Using Miller Special Tool L-4410, and C-4171,

install differential bearing to differential (extension

housing side) (Fig. 201).

(11) Using Miller Special Tool 5052 and C-4171,

install differential bearing to differential (bearing

retainer side).

(12) Using Miller Special Tool 6061 and C-4171,

install differential bearing race to bearing retainer

(Fig. 202).

(13) Using Miller Special Tool L±4520 and C-4171,

install differential bearing to extension housing.NOTE: Use MoparTSilicone Rubber Adhesive Seal-

ant, or equivalent, on retainer and extension hous-

ing/adapter plate to seal to case.

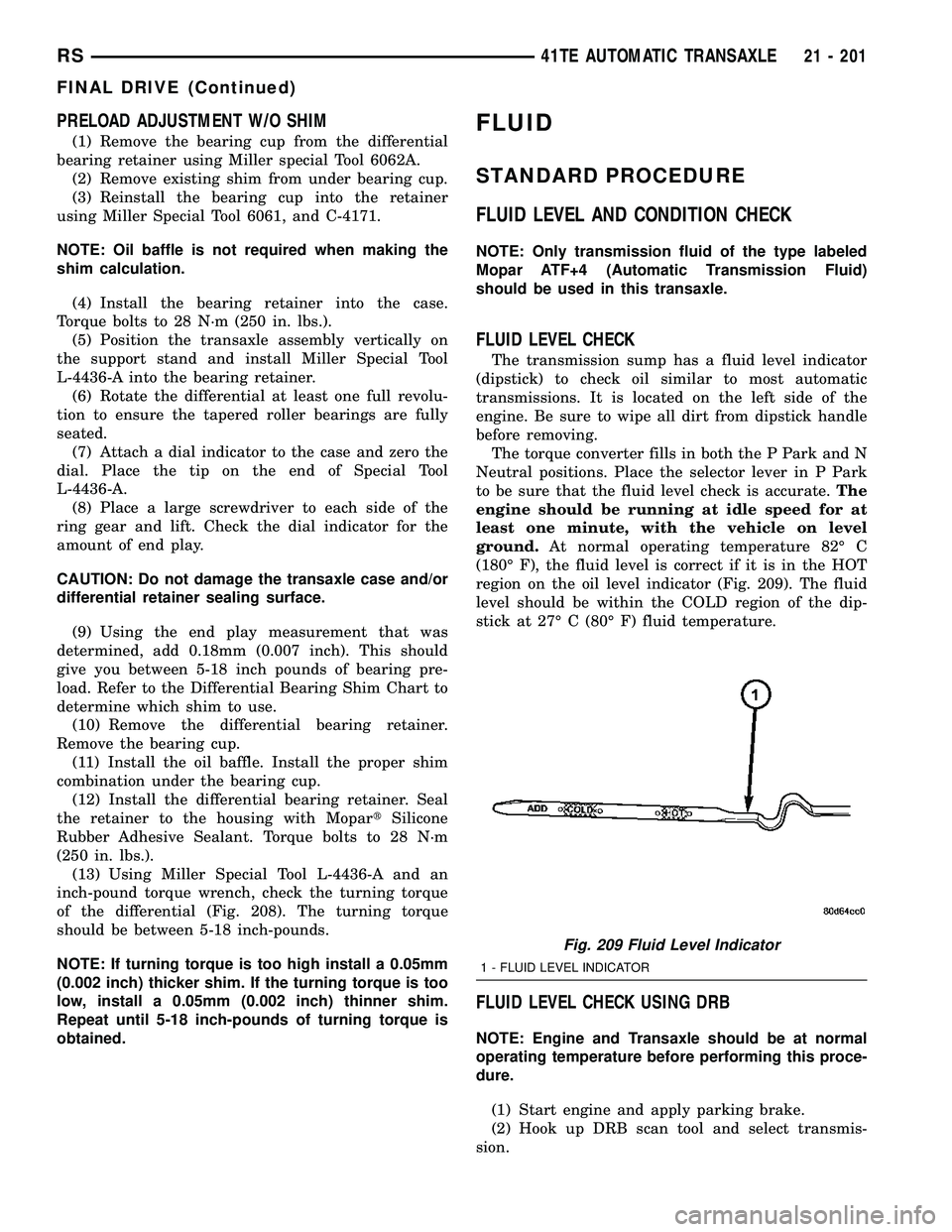

(14) Install differential assembly into transaxle

case. Install differential bearing retainer (Fig.

203)and torque retainer-to-case bolts (Fig. 204)to 28

N´m (21 ft. lbs.).

(15) Apply a bead of MopartSilicone Rubber

Adhesive Sealant to extension housing/adapter plate

and install into position. Install and torque bolts to

28 N´m (21 ft. lbs.).

(16) Measure and adjust differential bearing pre-

load. (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 41TE/FINAL DRIVE -

ADJUSTMENTS)

Fig. 201 Position Bearing Cone Onto DifferentialÐ

Typical

1 - DIFFERENTIAL ASSEMBLY

2 - DIFFERENTIAL BEARING

Fig. 202 Differential Bearing Retainer

1 - DIFFERENTIAL BEARING CUP

2 - DIFFERENTIAL BEARING RETAINER

Fig. 203 Differential Bearing Retainer

1 - DIFFERENTIAL BEARING CUP

2 - DIFFERENTIAL BEARING RETAINER

Fig. 204 Differential Retainer Bolts

1 - DIFFERENTIAL RETAINER BOLTS

21 - 198 41TE AUTOMATIC TRANSAXLERS

FINAL DRIVE (Continued)

Page 1798 of 2585

PRELOAD ADJUSTMENT W/O SHIM

(1) Remove the bearing cup from the differential

bearing retainer using Miller special Tool 6062A.

(2) Remove existing shim from under bearing cup.

(3) Reinstall the bearing cup into the retainer

using Miller Special Tool 6061, and C-4171.

NOTE: Oil baffle is not required when making the

shim calculation.

(4) Install the bearing retainer into the case.

Torque bolts to 28 N´m (250 in. lbs.).

(5) Position the transaxle assembly vertically on

the support stand and install Miller Special Tool

L-4436-A into the bearing retainer.

(6) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated.

(7) Attach a dial indicator to the case and zero the

dial. Place the tip on the end of Special Tool

L-4436-A.

(8) Place a large screwdriver to each side of the

ring gear and lift. Check the dial indicator for the

amount of end play.

CAUTION: Do not damage the transaxle case and/or

differential retainer sealing surface.

(9) Using the end play measurement that was

determined, add 0.18mm (0.007 inch). This should

give you between 5-18 inch pounds of bearing pre-

load. Refer to the Differential Bearing Shim Chart to

determine which shim to use.

(10) Remove the differential bearing retainer.

Remove the bearing cup.

(11) Install the oil baffle. Install the proper shim

combination under the bearing cup.

(12) Install the differential bearing retainer. Seal

the retainer to the housing with MopartSilicone

Rubber Adhesive Sealant. Torque bolts to 28 N´m

(250 in. lbs.).

(13) Using Miller Special Tool L-4436-A and an

inch-pound torque wrench, check the turning torque

of the differential (Fig. 208). The turning torque

should be between 5-18 inch-pounds.

NOTE: If turning torque is too high install a 0.05mm

(0.002 inch) thicker shim. If the turning torque is too

low, install a 0.05mm (0.002 inch) thinner shim.

Repeat until 5-18 inch-pounds of turning torque is

obtained.

FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK

NOTE: Only transmission fluid of the type labeled

Mopar ATF+4 (Automatic Transmission Fluid)

should be used in this transaxle.

FLUID LEVEL CHECK

The transmission sump has a fluid level indicator

(dipstick) to check oil similar to most automatic

transmissions. It is located on the left side of the

engine. Be sure to wipe all dirt from dipstick handle

before removing.

The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate.The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground.At normal operating temperature 82É C

(180É F), the fluid level is correct if it is in the HOT

region on the oil level indicator (Fig. 209). The fluid

level should be within the COLD region of the dip-

stick at 27É C (80É F) fluid temperature.

FLUID LEVEL CHECK USING DRB

NOTE: Engine and Transaxle should be at normal

operating temperature before performing this proce-

dure.

(1) Start engine and apply parking brake.

(2) Hook up DRB scan tool and select transmis-

sion.

Fig. 209 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

RS41TE AUTOMATIC TRANSAXLE21 - 201

FINAL DRIVE (Continued)

Page 1799 of 2585

(3) Select sensors.

(4) Read the transmission temperature value.

(5) Compare the fluid temperature value with the

fluid temperature chart (Fig. 210).

(6) Adjust transmission fluid level shown on the

indicator according to the chart.

(7) Check transmission for leaks.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transaxle vent where it may be mistaken

for a leak.FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle recondition is proba-

bly required. Be sure to examine the fluid on the dip-

stick closely. If there is any doubt about its condition,

drain out a sample for a double check.

MopartATF+4 (Automatic Transmission Fluid)

when new is red in color. The ATF is dyed red so it

can be identified from other fluids used in the vehicle

such as engine oil or antifreeze. The red color is not

permanent and is not an indicator of fluid condition.

As the vehicle is driven, the ATF will begin to look

darker in color and may eventually become brown.

This is normal.ATF+4 also has a unique odor that

may change with age. Consequently,odor and color

cannot be used to indicate the fluid condition

or the need for a fluid change.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

Fig. 210 Transmission Fluid Temperature Chart

1 - MAX. LEVEL

2 - MIN. LEVEL

21 - 202 41TE AUTOMATIC TRANSAXLERS

FLUID (Continued)

Page 1800 of 2585

STANDARD PROCEDURE - FLUID AND FILTER

SERVICE

NOTE: Refer to the maintenance schedules in

LUBRICATION and MAINTENANCE, or the vehicle

owner's manual, for the recommended maintenance

(fluid/filter change) intervals for this transaxle.

NOTE: Only fluids of the type labeled MoparTATF+4

(Automatic Transmission Fluid) should be used. A

filter change should be made at the time of the

transmission oil change. The magnet (on the inside

of the oil pan) should also be cleaned with a clean,

dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

FLUID/FILTER SERVICE (RECOMMENDED)

(1) Raise vehicle on a hoist. Refer to LUBRICA-

TION and MAINTENANCE for proper procedures.

Place a drain container with a large opening, under

transaxle oil pan.

(2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan.

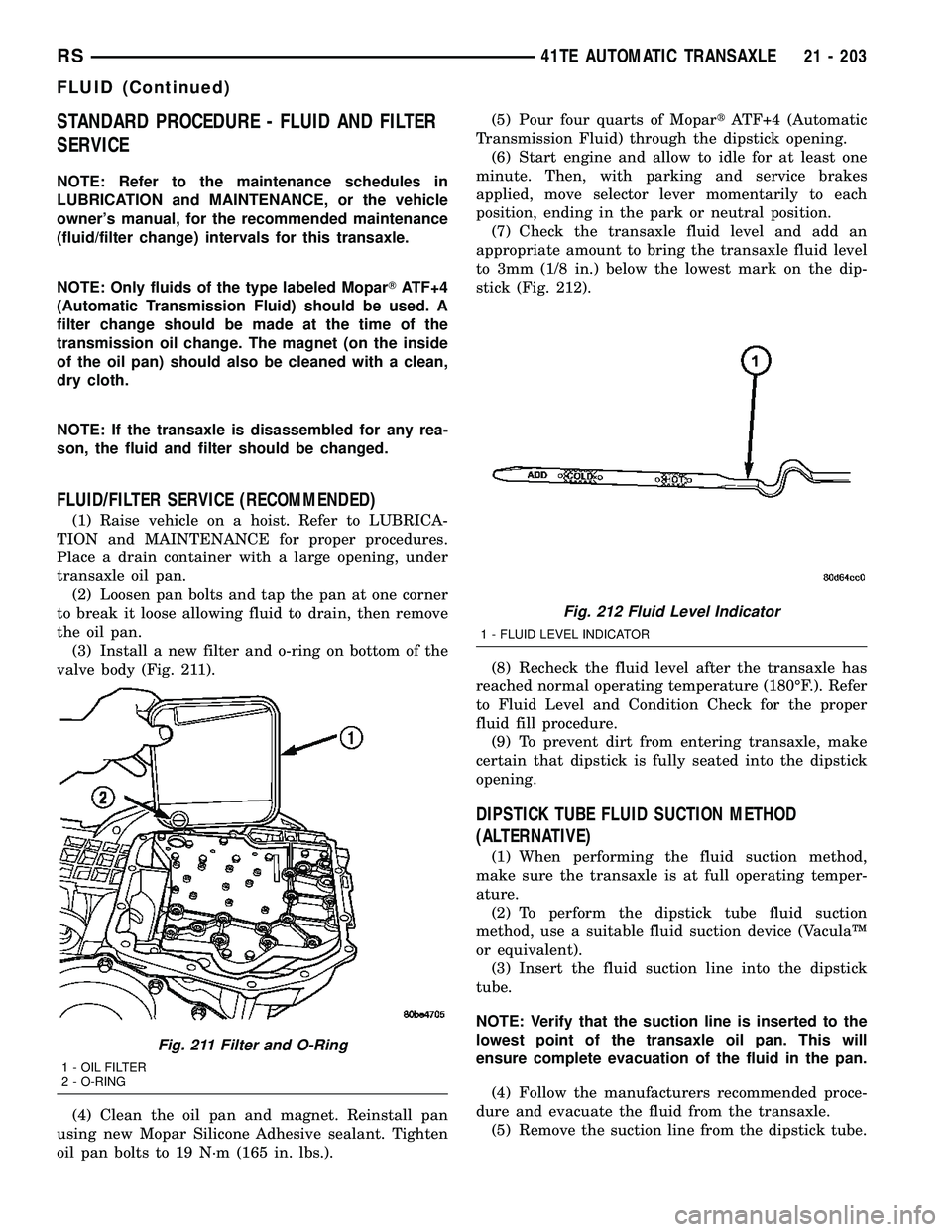

(3) Install a new filter and o-ring on bottom of the

valve body (Fig. 211).

(4) Clean the oil pan and magnet. Reinstall pan

using new Mopar Silicone Adhesive sealant. Tighten

oil pan bolts to 19 N´m (165 in. lbs.).(5) Pour four quarts of MopartATF+4 (Automatic

Transmission Fluid) through the dipstick opening.

(6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

(7) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the lowest mark on the dip-

stick (Fig. 212).

(8) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.). Refer

to Fluid Level and Condition Check for the proper

fluid fill procedure.

(9) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

DIPSTICK TUBE FLUID SUCTION METHOD

(ALTERNATIVE)

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature.

(2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (VaculaŸ

or equivalent).

(3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

(5) Remove the suction line from the dipstick tube.

Fig. 211 Filter and O-Ring

1 - OIL FILTER

2 - O-RING

Fig. 212 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

RS41TE AUTOMATIC TRANSAXLE21 - 203

FLUID (Continued)