CHRYSLER VOYAGER 2005 Service Manual

Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 271 of 2339

(3) Install screws holding CD changer.

(4) Reconnect the battery negative cable.

DVD PLAYER

DESCRIPTION

The DVD player (if equipped) is located in the

instrument panel below the radio. The DVD player

can hold one DVD at a time. Three RCA jacks on the

front of the unit allow the use of MP3 players, video

game systems or camcorders.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

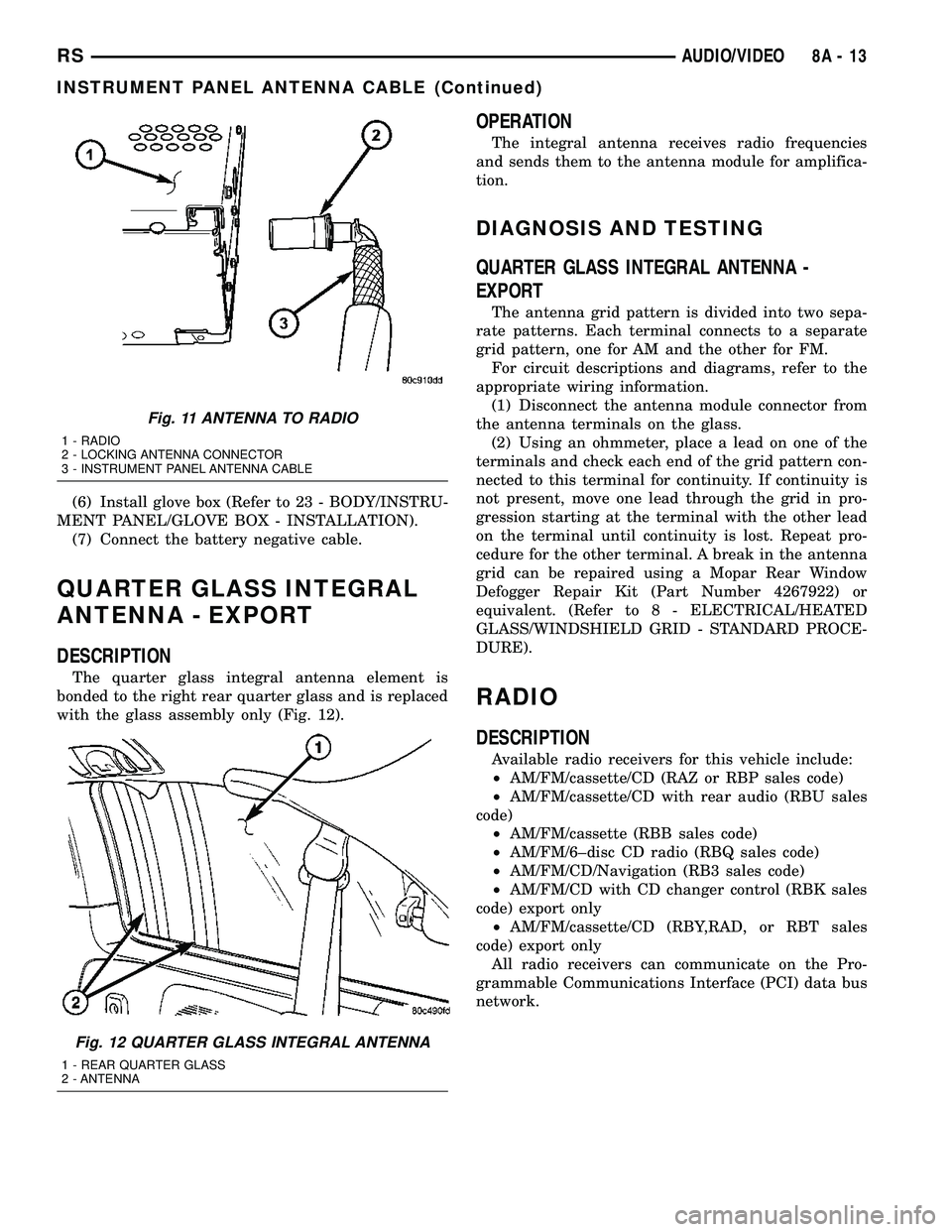

(2) Remove screws holding DVD player (Fig. 10).(3) Disconnect the wire connector from the back of

the DVD player.

(4) Remove the DVD player from the vehicle.

INSTALLATION

(1) Connect the wire harness connector to the DVD

player.

(2) Insert the DVD player into the instrument

panel.

(3) Install mounting screws.

(4) Connect the battery negative cable.

INSTRUMENT PANEL

ANTENNA CABLE

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - REMOVAL).

(3) Disconnect extension cable end from antenna

cable end.

(4) Disconnect cable hanger clip from HVAC unit.

(5) Remove radio as necessary to gain access to

extension cable (Refer to 8 - ELECTRICAL/AUDIO/

RADIO - REMOVAL).

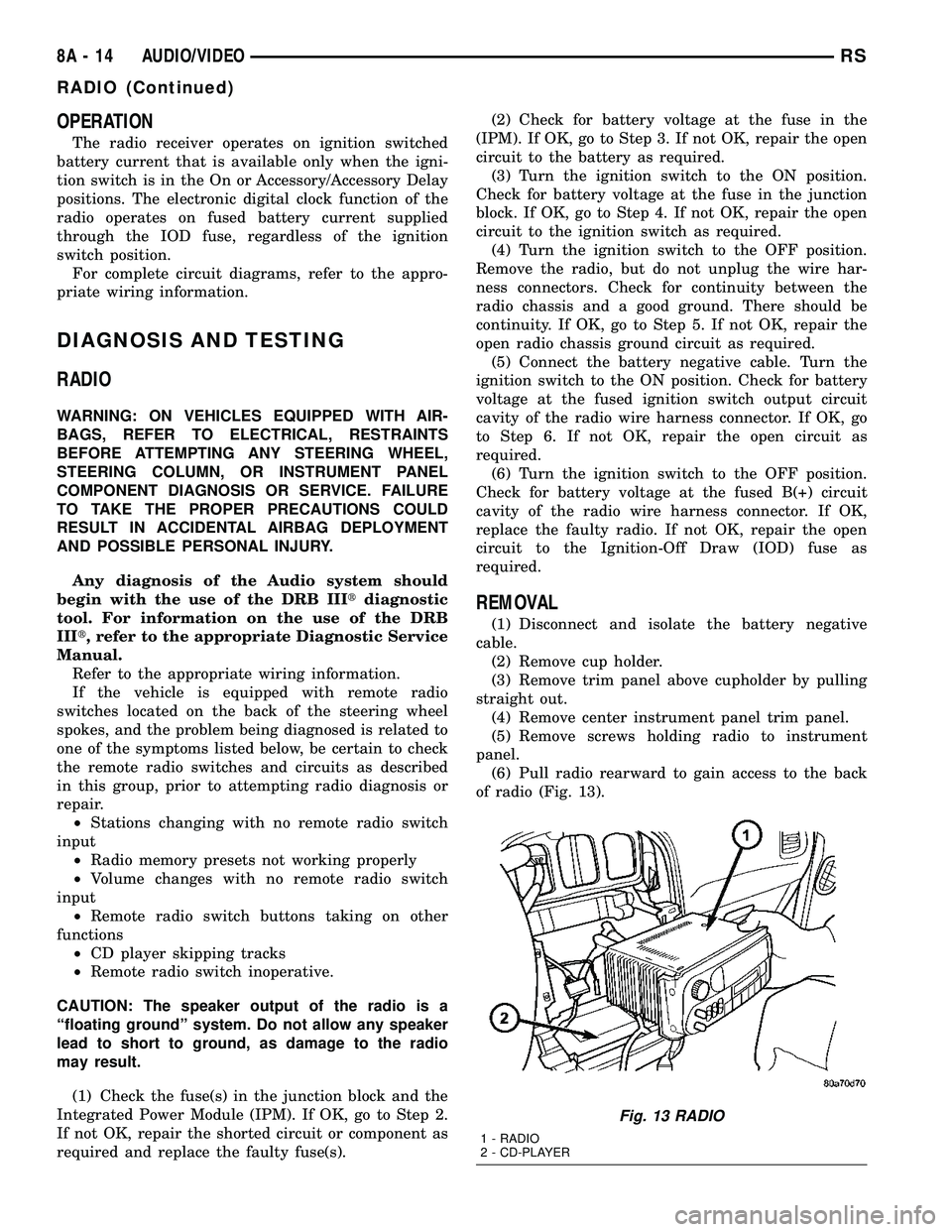

CAUTION: Pulling the antenna cable straight out of

the radio without pulling on the locking antenna

connector could damage the cable or radio.

(6) Disconnect the antenna cable by pulling the

locking antenna connector away from the radio (Fig.

11).

(7) Remove cable from vehicle.

INSTALLATION

(1) Install extension cable to vehicle.

(2) Connect extension cable to back of radio.

(3) Install radio (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - INSTALLATION).

(4) Connect cable hanger clip to HVAC unit.

(5) Connect extension cable end to antenna cable

end.

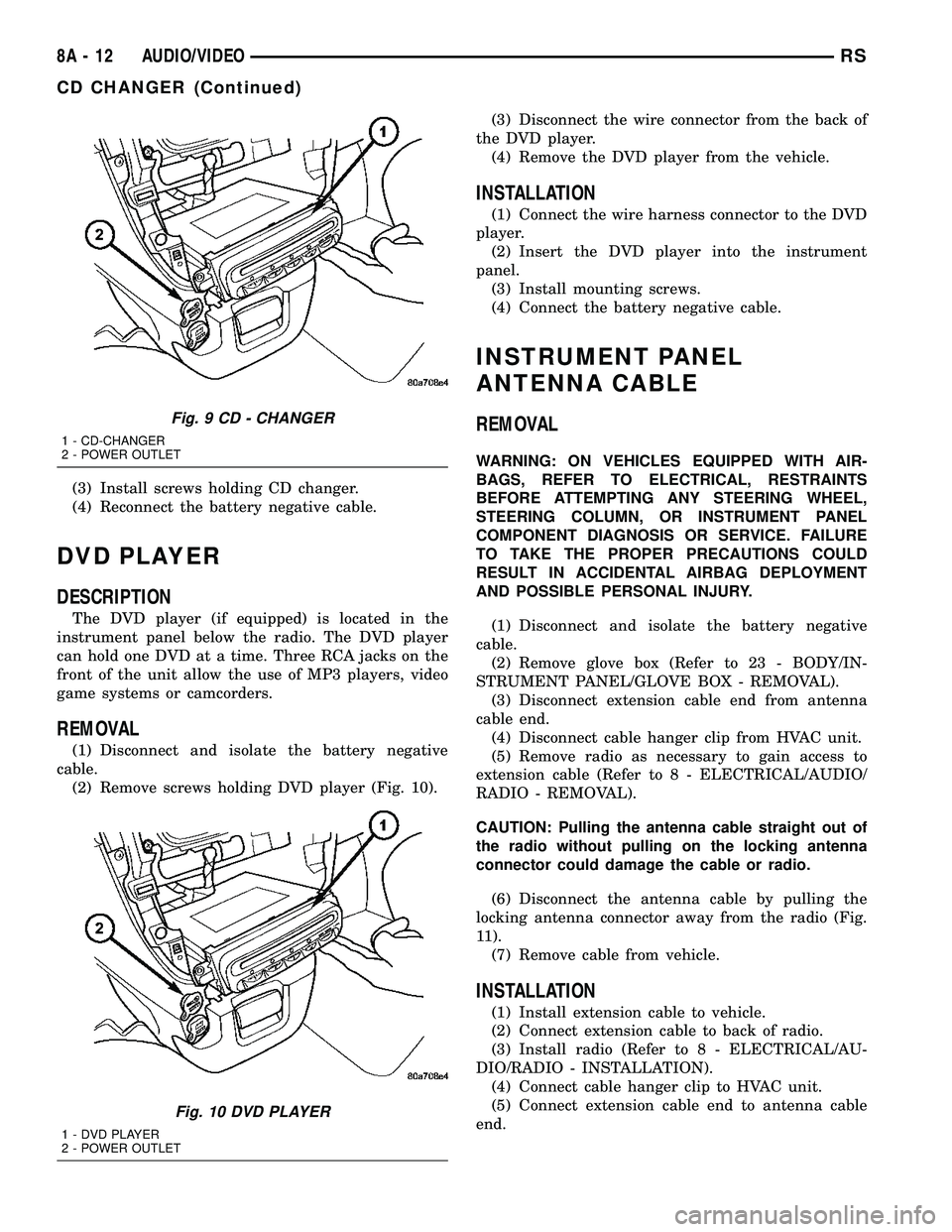

Fig. 9 CD - CHANGER

1 - CD-CHANGER

2 - POWER OUTLET

Fig. 10 DVD PLAYER

1 - DVD PLAYER

2 - POWER OUTLET

8A - 12 AUDIO/VIDEORS

CD CHANGER (Continued)

Page 272 of 2339

(6) Install glove box (Refer to 23 - BODY/INSTRU-

MENT PANEL/GLOVE BOX - INSTALLATION).

(7) Connect the battery negative cable.

QUARTER GLASS INTEGRAL

ANTENNA - EXPORT

DESCRIPTION

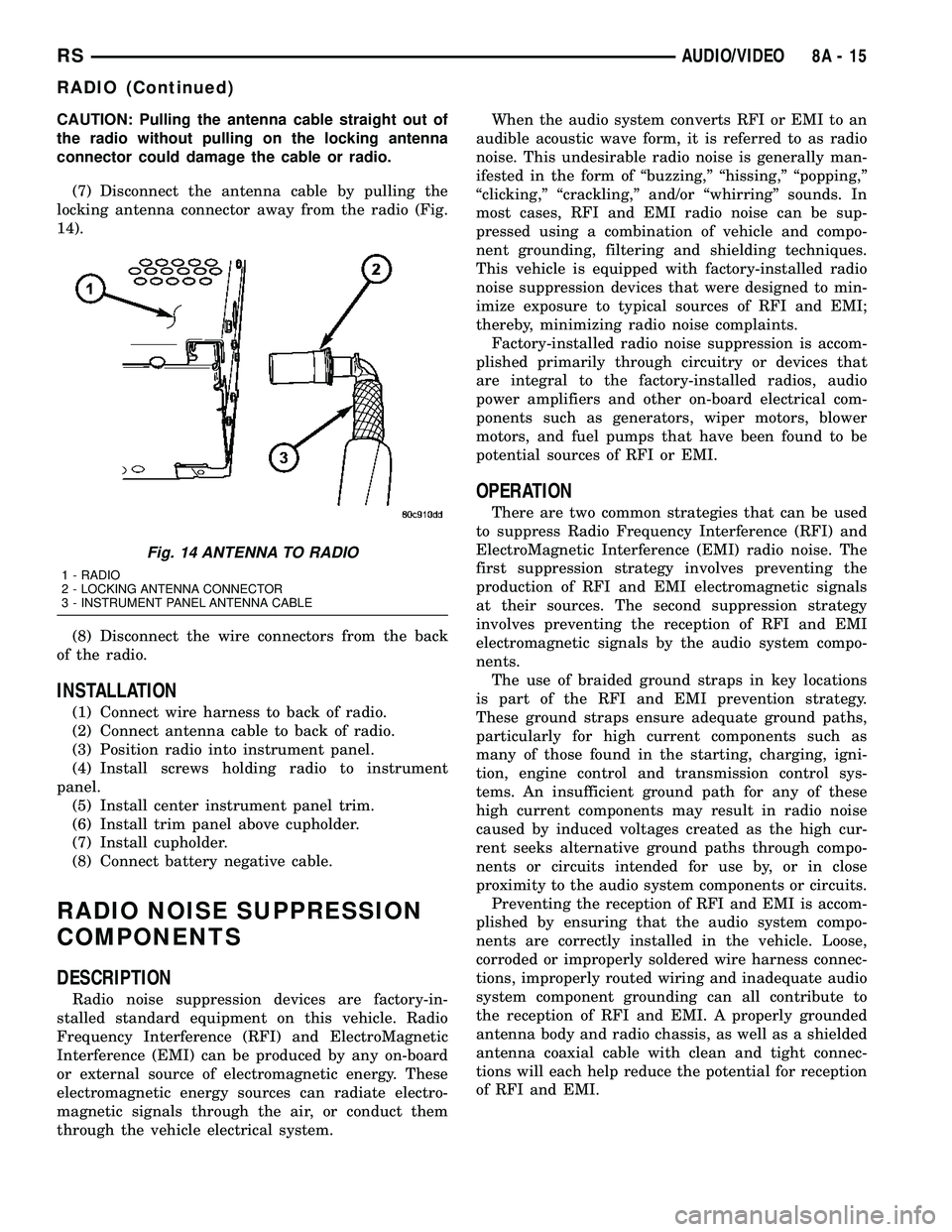

The quarter glass integral antenna element is

bonded to the right rear quarter glass and is replaced

with the glass assembly only (Fig. 12).

OPERATION

The integral antenna receives radio frequencies

and sends them to the antenna module for amplifica-

tion.

DIAGNOSIS AND TESTING

QUARTER GLASS INTEGRAL ANTENNA -

EXPORT

The antenna grid pattern is divided into two sepa-

rate patterns. Each terminal connects to a separate

grid pattern, one for AM and the other for FM.

For circuit descriptions and diagrams, refer to the

appropriate wiring information.

(1) Disconnect the antenna module connector from

the antenna terminals on the glass.

(2) Using an ohmmeter, place a lead on one of the

terminals and check each end of the grid pattern con-

nected to this terminal for continuity. If continuity is

not present, move one lead through the grid in pro-

gression starting at the terminal with the other lead

on the terminal until continuity is lost. Repeat pro-

cedure for the other terminal. A break in the antenna

grid can be repaired using a Mopar Rear Window

Defogger Repair Kit (Part Number 4267922) or

equivalent. (Refer to 8 - ELECTRICAL/HEATED

GLASS/WINDSHIELD GRID - STANDARD PROCE-

DURE).

RADIO

DESCRIPTION

Available radio receivers for this vehicle include:

²AM/FM/cassette/CD (RAZ or RBP sales code)

²AM/FM/cassette/CD with rear audio (RBU sales

code)

²AM/FM/cassette (RBB sales code)

²AM/FM/6±disc CD radio (RBQ sales code)

²AM/FM/CD/Navigation (RB3 sales code)

²AM/FM/CD with CD changer control (RBK sales

code) export only

²AM/FM/cassette/CD (RBY,RAD, or RBT sales

code) export only

All radio receivers can communicate on the Pro-

grammable Communications Interface (PCI) data bus

network.

Fig. 11 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

Fig. 12 QUARTER GLASS INTEGRAL ANTENNA

1 - REAR QUARTER GLASS

2 - ANTENNA

RSAUDIO/VIDEO8A-13

INSTRUMENT PANEL ANTENNA CABLE (Continued)

Page 273 of 2339

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory/Accessory Delay

positions. The electronic digital clock function of the

radio operates on fused battery current supplied

through the IOD fuse, regardless of the ignition

switch position.

For complete circuit diagrams, refer to the appro-

priate wiring information.

DIAGNOSIS AND TESTING

RADIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information.

If the vehicle is equipped with remote radio

switches located on the back of the steering wheel

spokes, and the problem being diagnosed is related to

one of the symptoms listed below, be certain to check

the remote radio switches and circuits as described

in this group, prior to attempting radio diagnosis or

repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) Check the fuse(s) in the junction block and the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).(2) Check for battery voltage at the fuse in the

(IPM). If OK, go to Step 3. If not OK, repair the open

circuit to the battery as required.

(3) Turn the ignition switch to the ON position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 4. If not OK, repair the open

circuit to the ignition switch as required.

(4) Turn the ignition switch to the OFF position.

Remove the radio, but do not unplug the wire har-

ness connectors. Check for continuity between the

radio chassis and a good ground. There should be

continuity. If OK, go to Step 5. If not OK, repair the

open radio chassis ground circuit as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the ON position. Check for battery

voltage at the fused ignition switch output circuit

cavity of the radio wire harness connector. If OK, go

to Step 6. If not OK, repair the open circuit as

required.

(6) Turn the ignition switch to the OFF position.

Check for battery voltage at the fused B(+) circuit

cavity of the radio wire harness connector. If OK,

replace the faulty radio. If not OK, repair the open

circuit to the Ignition-Off Draw (IOD) fuse as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove cup holder.

(3) Remove trim panel above cupholder by pulling

straight out.

(4) Remove center instrument panel trim panel.

(5) Remove screws holding radio to instrument

panel.

(6) Pull radio rearward to gain access to the back

of radio (Fig. 13).

Fig. 13 RADIO

1 - RADIO

2 - CD-PLAYER

8A - 14 AUDIO/VIDEORS

RADIO (Continued)

Page 274 of 2339

CAUTION: Pulling the antenna cable straight out of

the radio without pulling on the locking antenna

connector could damage the cable or radio.

(7) Disconnect the antenna cable by pulling the

locking antenna connector away from the radio (Fig.

14).

(8) Disconnect the wire connectors from the back

of the radio.

INSTALLATION

(1) Connect wire harness to back of radio.

(2) Connect antenna cable to back of radio.

(3) Position radio into instrument panel.

(4) Install screws holding radio to instrument

panel.

(5) Install center instrument panel trim.

(6) Install trim panel above cupholder.

(7) Install cupholder.

(8) Connect battery negative cable.

RADIO NOISE SUPPRESSION

COMPONENTS

DESCRIPTION

Radio noise suppression devices are factory-in-

stalled standard equipment on this vehicle. Radio

Frequency Interference (RFI) and ElectroMagnetic

Interference (EMI) can be produced by any on-board

or external source of electromagnetic energy. These

electromagnetic energy sources can radiate electro-

magnetic signals through the air, or conduct them

through the vehicle electrical system.When the audio system converts RFI or EMI to an

audible acoustic wave form, it is referred to as radio

noise. This undesirable radio noise is generally man-

ifested in the form of ªbuzzing,º ªhissing,º ªpopping,º

ªclicking,º ªcrackling,º and/or ªwhirringº sounds. In

most cases, RFI and EMI radio noise can be sup-

pressed using a combination of vehicle and compo-

nent grounding, filtering and shielding techniques.

This vehicle is equipped with factory-installed radio

noise suppression devices that were designed to min-

imize exposure to typical sources of RFI and EMI;

thereby, minimizing radio noise complaints.

Factory-installed radio noise suppression is accom-

plished primarily through circuitry or devices that

are integral to the factory-installed radios, audio

power amplifiers and other on-board electrical com-

ponents such as generators, wiper motors, blower

motors, and fuel pumps that have been found to be

potential sources of RFI or EMI.

OPERATION

There are two common strategies that can be used

to suppress Radio Frequency Interference (RFI) and

ElectroMagnetic Interference (EMI) radio noise. The

first suppression strategy involves preventing the

production of RFI and EMI electromagnetic signals

at their sources. The second suppression strategy

involves preventing the reception of RFI and EMI

electromagnetic signals by the audio system compo-

nents.

The use of braided ground straps in key locations

is part of the RFI and EMI prevention strategy.

These ground straps ensure adequate ground paths,

particularly for high current components such as

many of those found in the starting, charging, igni-

tion, engine control and transmission control sys-

tems. An insufficient ground path for any of these

high current components may result in radio noise

caused by induced voltages created as the high cur-

rent seeks alternative ground paths through compo-

nents or circuits intended for use by, or in close

proximity to the audio system components or circuits.

Preventing the reception of RFI and EMI is accom-

plished by ensuring that the audio system compo-

nents are correctly installed in the vehicle. Loose,

corroded or improperly soldered wire harness connec-

tions, improperly routed wiring and inadequate audio

system component grounding can all contribute to

the reception of RFI and EMI. A properly grounded

antenna body and radio chassis, as well as a shielded

antenna coaxial cable with clean and tight connec-

tions will each help reduce the potential for reception

of RFI and EMI.

Fig. 14 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

RSAUDIO/VIDEO8A-15

RADIO (Continued)

Page 275 of 2339

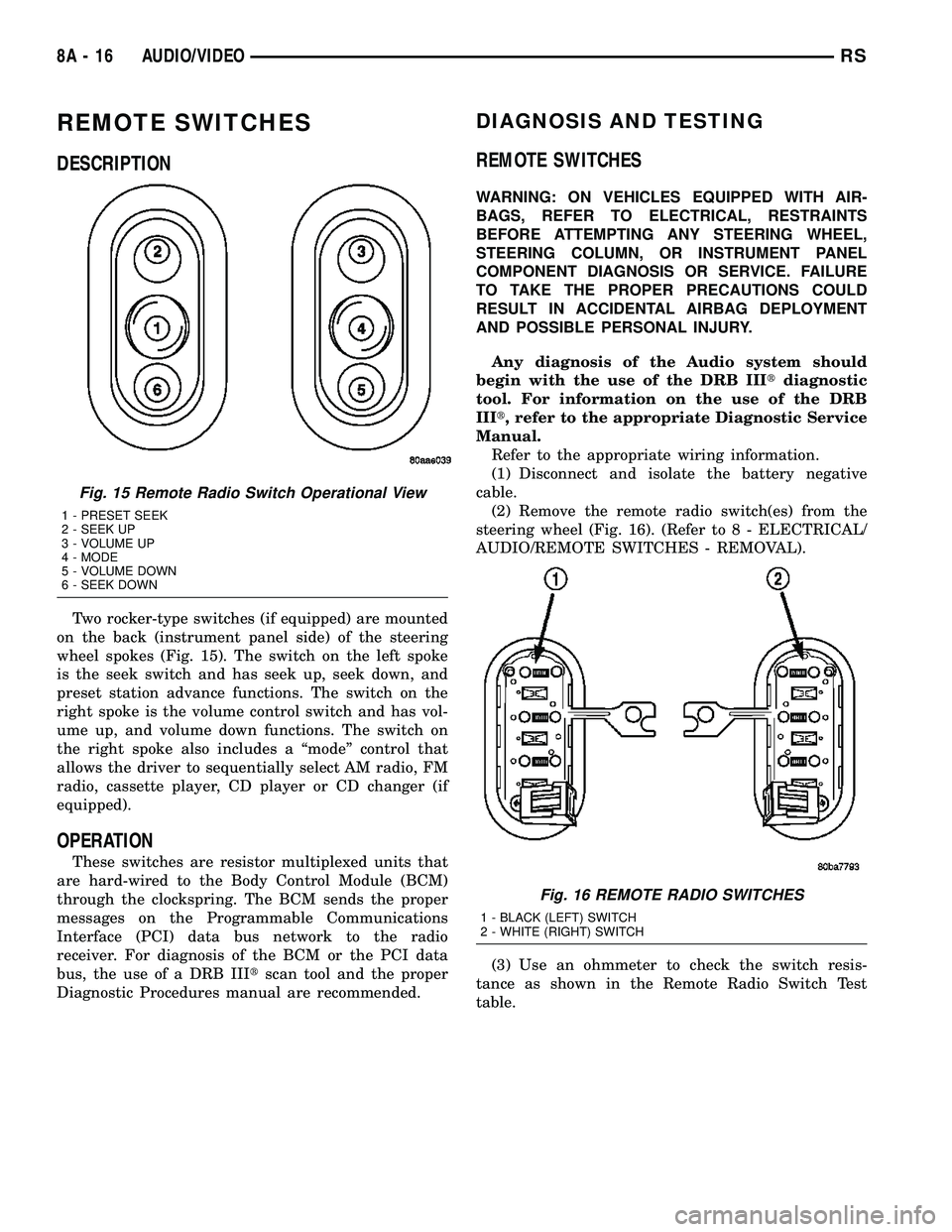

REMOTE SWITCHES

DESCRIPTION

Two rocker-type switches (if equipped) are mounted

on the back (instrument panel side) of the steering

wheel spokes (Fig. 15). The switch on the left spoke

is the seek switch and has seek up, seek down, and

preset station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions. The switch on

the right spoke also includes a ªmodeº control that

allows the driver to sequentially select AM radio, FM

radio, cassette player, CD player or CD changer (if

equipped).

OPERATION

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the proper

messages on the Programmable Communications

Interface (PCI) data bus network to the radio

receiver. For diagnosis of the BCM or the PCI data

bus, the use of a DRB IIItscan tool and the proper

Diagnostic Procedures manual are recommended.

DIAGNOSIS AND TESTING

REMOTE SWITCHES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information.

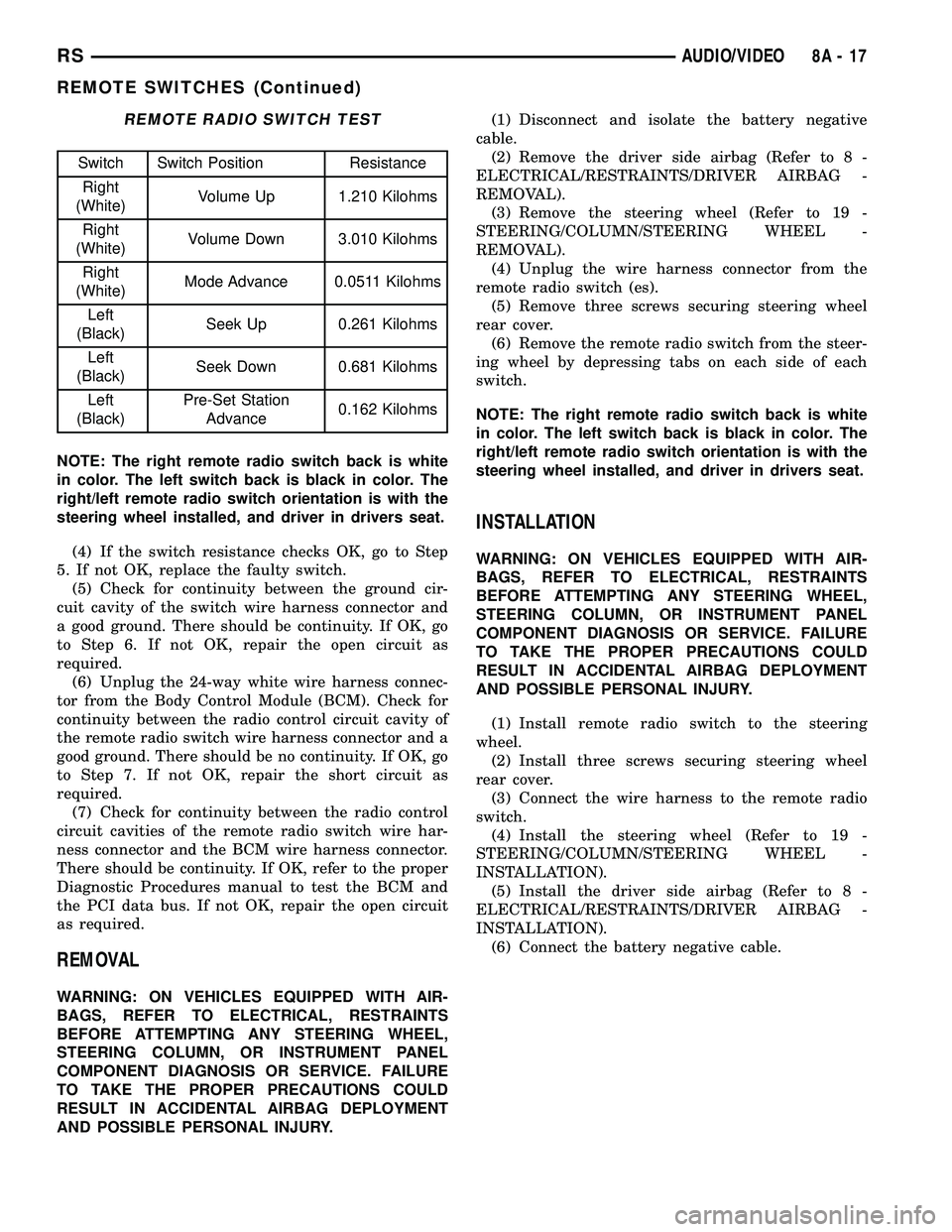

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the remote radio switch(es) from the

steering wheel (Fig. 16). (Refer to 8 - ELECTRICAL/

AUDIO/REMOTE SWITCHES - REMOVAL).

(3) Use an ohmmeter to check the switch resis-

tance as shown in the Remote Radio Switch Test

table.

Fig. 15 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

Fig. 16 REMOTE RADIO SWITCHES

1 - BLACK (LEFT) SWITCH

2 - WHITE (RIGHT) SWITCH

8A - 16 AUDIO/VIDEORS

Page 276 of 2339

REMOTE RADIO SWITCH TEST

Switch Switch Position Resistance

Right

(White)Volume Up 1.210 Kilohms

Right

(White)Volume Down 3.010 Kilohms

Right

(White)Mode Advance 0.0511 Kilohms

Left

(Black)Seek Up 0.261 Kilohms

Left

(Black)Seek Down 0.681 Kilohms

Left

(Black)Pre-Set Station

Advance0.162 Kilohms

NOTE: The right remote radio switch back is white

in color. The left switch back is black in color. The

right/left remote radio switch orientation is with the

steering wheel installed, and driver in drivers seat.

(4) If the switch resistance checks OK, go to Step

5. If not OK, replace the faulty switch.

(5) Check for continuity between the ground cir-

cuit cavity of the switch wire harness connector and

a good ground. There should be continuity. If OK, go

to Step 6. If not OK, repair the open circuit as

required.

(6) Unplug the 24-way white wire harness connec-

tor from the Body Control Module (BCM). Check for

continuity between the radio control circuit cavity of

the remote radio switch wire harness connector and a

good ground. There should be no continuity. If OK, go

to Step 7. If not OK, repair the short circuit as

required.

(7) Check for continuity between the radio control

circuit cavities of the remote radio switch wire har-

ness connector and the BCM wire harness connector.

There should be continuity. If OK, refer to the proper

Diagnostic Procedures manual to test the BCM and

the PCI data bus. If not OK, repair the open circuit

as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side airbag (Refer to 8 -

ELECTRICAL/RESTRAINTS/DRIVER AIRBAG -

REMOVAL).

(3) Remove the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

REMOVAL).

(4) Unplug the wire harness connector from the

remote radio switch (es).

(5) Remove three screws securing steering wheel

rear cover.

(6) Remove the remote radio switch from the steer-

ing wheel by depressing tabs on each side of each

switch.

NOTE: The right remote radio switch back is white

in color. The left switch back is black in color. The

right/left remote radio switch orientation is with the

steering wheel installed, and driver in drivers seat.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Install remote radio switch to the steering

wheel.

(2) Install three screws securing steering wheel

rear cover.

(3) Connect the wire harness to the remote radio

switch.

(4) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(5) Install the driver side airbag (Refer to 8 -

ELECTRICAL/RESTRAINTS/DRIVER AIRBAG -

INSTALLATION).

(6) Connect the battery negative cable.

RSAUDIO/VIDEO8A-17

REMOTE SWITCHES (Continued)

Page 277 of 2339

SPEAKER

DIAGNOSIS AND TESTING

SPEAKER

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

(1) If all speakers are inoperative, check the radio

fuses in the Junction Block (JB). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Check the amplifier fuse (if equipped) in the

junction block. If OK, go to Step 3. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(3) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 4.

(4) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negative

cable. If vehicle isnotequipped with a amplifier,

remove the radio receiver. If vehicle is equipped with

an amplifier. disconnect wire harness connector at

output side of amplifier. Go to Step 4.

(5) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.(6) Disconnect wire harness connector at the inop-

erative speaker. Check for continuity between the

speaker feed (+) circuit cavities of the radio receiver

wire harness connector or if equipped, the amplifier

wire harness connector and the speaker wire harness

connector. Repeat the check between the speaker

return (-) circuit cavities of the radio receiver wire

harness connector and the speaker wire harness con-

nector. In each case, there should be continuity. If

OK, replace the faulty speaker. If not OK, repair the

open speaker feed (+) and/or return (-) circuits(s) as

required.

REMOVAL

D-PILLAR SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove rear header trim (right side speaker).

(3) Remove jack cover (left side speaker).

(4) Remove liftgate scuff plate.

(5) Remove upper seat belt bolt. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT OUT-

BOARD FRONT - REMOVAL).

(6) Partially remove quarter trim panel to access

the D-pillar speaker.

(7) Slide the speaker from the retainer (Fig. 17).

(8) Disconnect the wire harness connector from the

speaker.

Fig. 17 D-PILLAR SPEAKER

1 - SPEAKER

2 - RETAINER

3 - TRIM PANEL

8A - 18 AUDIO/VIDEORS

Page 278 of 2339

FRONT DOOR SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front door trim panel. (Refer to 23

- BODY/DOOR - FRONT/TRIM PANEL -

REMOVAL).

(3) Remove the speaker mounting screws (Fig. 18).

(4) Disconnect wire harness connector and remove

speaker from door.

INSTRUMENT PANEL SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the A-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - REMOVAL).

(3) Remove instrument panel top pad (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP PAD - REMOVAL).

(4) Remove speaker screws (Fig. 19).

(5) Disconnect wire harness connector and remove

speaker.

QUARTER PANEL SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the quarter trim bolster (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM BOLSTER -

REMOVAL).

(3) Remove speaker retaining screws (Fig. 20).

(4) Disconnect wire harness connector and remove

speaker.

INSTALLATION

D-PILLAR SPEAKER

(1) Connect the wire harness connector to the

speaker.

(2) Slide the speaker into the retainer.

(3) Install quarter panel trim.

(4) Install upper seat belt bolt (right side).

(5) Install liftgate scuff plate.

(6) Install rear header trim (right side).

(7) Install jack cover (left side).

(8) Connect battery negative cable.

Fig. 18 DOOR SPEAKER

1 - SPEAKER

2 - WIRE HARNESS CONNECTOR

Fig. 19 INSTRUMENT PANEL SPEAKER

1 - SPEAKER

2 - WIRE HARNESS CONNECTOR

Fig. 20 QUARTER PANEL SPEAKER

1 - SPEAKER

2 - TRIM PANEL

RSAUDIO/VIDEO8A-19

SPEAKER (Continued)

Page 279 of 2339

FRONT DOOR SPEAKER

(1) Connect the wire harness connector and install

speaker to door.

(2) Install the speaker mounting screws.

(3) Install the front door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - INSTALLA-

TION).

(4) Connect battery negative cable.

INSTRUMENT PANEL SPEAKER

(1) Connect the wire harness connector and install

speaker to instrument panel.

(2) Install the speaker mounting screws.

(3) Install instrument panel top pad (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP PAD - INSTALLATION).

(4) Install A-pillar trim (Refer to 23 - BODY/INTE-

RIOR/A-PILLAR TRIM - INSTALLATION).

(5) Connect battery negative cable.

QUARTER PANEL SPEAKER

(1) Connect the wire harness connector and install

speaker to trim panel.

(2) Install the speaker mounting screws.

(3) Install quarter trim bolster (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM BOLSTER -

INSTALLATION).

(4) Connect battery negative cable.

VIDEO SCREEN

DESCRIPTION

The video screen (if equipped) is mounted on the

headliner behind the driver and front passenger seat.

Pressing the release button will allow the screen to

be opened.

OPERATION

Operating instructions for the factory installed

video screen can be found in the owner's manual pro-

vided with this vehicle.

REMOVAL

(1) Disconnect and isolate the battery negative

battery cable.

(2) Remove the lens bezel.

(3) Remove the rear console screws (Fig. 21).

(4) Remove the rear A/C trim bezel.

(5) Disconnect A/C wire harness connector.

(6) Remove remaining mounting screws.

(7) Disconnect wire harness connectors.

INSTALLATION

(1) Connect wire harness connectors.

(2) Install front mounting screws.

(3) Install the rear A/C trim bezel.

(4) Install the rear mounting screws.

(5) Install the lens bezel.

(6) Connect the battery negative cable.

Fig. 21 VIDEO SCREEN

8A - 20 AUDIO/VIDEORS

SPEAKER (Continued)

Page 280 of 2339

CHIME/BUZZER

TABLE OF CONTENTS

page page

CHIME/BUZZER

DESCRIPTION..........................1

OPERATION............................1

WARNING.............................2

DIAGNOSIS AND TESTING - CHIME SYSTEM . . 2

PARK ASSIST DISPLAY

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................4

INSTALLATION..........................4PARK ASSIST MODULE

DESCRIPTION..........................4

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................6

PARK ASSIST SENSOR

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

CHIME/BUZZER

DESCRIPTION

The chime/buzzer system provides the driver with

warning chimes for:

²Seat Belt

²Exterior Lamps ON

²Key-In Ignition

²Engine Temperature Critical

²Turn Signals ON

²Dome Lamp ON

²Low Oil Pressure

²High Speed Warning

²Warning Lamp Announcement

²Key-In Accessory

²Low/High Tire Pressure

²Service Tire Pressure Monitor (TPM)

HIGH SPEED WARNING - EXPORT

The chime will sound, acting as a warning to the

driver that the vehicle speed has exceeded 120 3

Kp/h (75 2 mph).

Refer to the proper body diagnostic information

diagnosis and testing with a scan tool.

PARK ASSIST SYSTEM

The Park Assist System is an electronic parking

aid that alerts the driver to obstacles which are

located immediately behind the vehicle. Objects are

sensed using ultrasonic sound waves. When an object

is detected, the system will give the driver visual and

audible warnings. The system is customer program-

mable through the Electronic Vehicle Information

Center (EVIC) but will be enabled from the factory

as a default.

The major components of the park assist system

are:²Park Assist Module- supplies voltage to the

object detection sensors and park assist display. It

triggers the sensors, analyzes the echo delay times

and calculates obstacle distances. It sends display

information to the park assist display, performs sys-

tem diagnostics, and communicates via the Program-

mable Communication Interface (PCI) date bus

network.

²Park Assist Sensors- there are four sensors

located in the rear bumper that generate ultrasonic

pulses when triggered by the park assist module. The

sensors signal the park assist module when reflected

ultrasonic pulses are received.

²Park Assist Display- there are sixteen Light

Emitting Diode (LED) indicators which provide indi-

cation of relative distance to obstacles. When the sys-

tem is engaged and no obstacles are detected, the

two outermost yellow LED's are lit at reduced bright-

ness to show the system is working. As the distance

to a detected obstacle decreases, more yellow LED's

towards the center of the display illuminate.

For diagnosis and testing of the park assist sys-

tem, use a scan tool and the appropriate body diag-

nostic information.

OPERATION

Refer to the proper Body Diagnostic Procedures

manual for complete chime/buzzer operation and con-

ditions for operation.

HIGH SPEED WARNING - EXPORT

When the vehicle speed sensor sees 120 3 Km/h

(75 2 mph), it sends a PCI data bus message to the

Body Control Module (BCM). The BCM then turns on

the chime to let the driver know that the vehicle has

reached a speed greater than 120 3 Km/h (75 2

mph). This audible message will continue until the

vehicle is slowed below the predetermined speed.

RSCHIME/BUZZER8B-1