torque CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1657 of 2339

(69) Install and tighten solenoid/pressure switch

assembly-to-transaxle case bolts to 12 N´m (110 in.

lbs.) (Fig. 158).

(70) Install and torque input and output speed

sensors to case to 27 N´m (20 ft. lbs.).

INSTALLATION

NOTE: If transaxle assembly has been replaced or

overhauled (clutch and/or seal replacement), it is

necessary to perfrom the ªQuick-Learnº procedure.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

STANDARD PROCEDURE)

(1) Using a transmission jack and a helper, posi-

tion transaxle assembly to engine. Install and torque

bellhousing bolts to 95 N´m (70 ft. lbs.).

(2) Install upper mount assembly to transaxle and

torque bolts to 54 N´m (40 ft. lbs.) (Fig. 159).

(3) Raise engine/transaxle assembly into position.

Install and torque upper mount-to-bracket thru-bolt

to 75 N´m (55 ft. lbs.) (Fig. 159).

(4) Remove transmission jack and screw jack.

(5) Secure left wheelhouse splash shield.

(6) Install torque converter-to-drive plate bolts and

torque to 88 N´m (65 ft. lbs.)

(7) Install inspection cover.

(8) Install lateral bending brace.

(9) Install starter motor.

(10) Install front mount/bracket assembly.

(11) Align and install rear mount bracket-to-case

bolts by hand (Fig. 160). Torque horizontal bolt to

102 N´m (75 ft. lbs.).(12) AWD models: Install power transfer unit.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

POWER TRANSFER UNIT - INSTALLATION)

(13) Install left and right halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION)

(14) Install front wheel/tire assemblies.

(15) Lower vehicle.

(16) Torque remaining rear mount bracket-to-tran-

saxle vertical bolts (Fig. 160) to 102 N´m (75 ft. lbs.).

(17) Install transaxle upper bellhousing-to-block

bolts and torque to 95 N´m (70 ft. lbs.).

(18) Install and connect crank position sensor (if

equipped).

(19) Connect gearshift cable to upper mount

bracket and transaxle manual valve lever (Fig. 161).

(20) Connect solenoid/pressure switch assembly

(Fig. 162).

(21) Connect transmission range sensor connector

(Fig. 162).

(22) Connect input and output speed sensor con-

nectors (Fig. 162).

(23) Remove plugs and connect transaxle oil cooler

lines. (Refer to 7 - COOLING/TRANSMISSION -

STANDARD PROCEDURE)

(24) Remove plug and Install fluid level indicator/

tube assembly.

Fig. 158 Solenoid Pack-to-Transaxle Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

Fig. 159 Left Mount to Bracket and Transaxle

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

21 - 196 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1672 of 2339

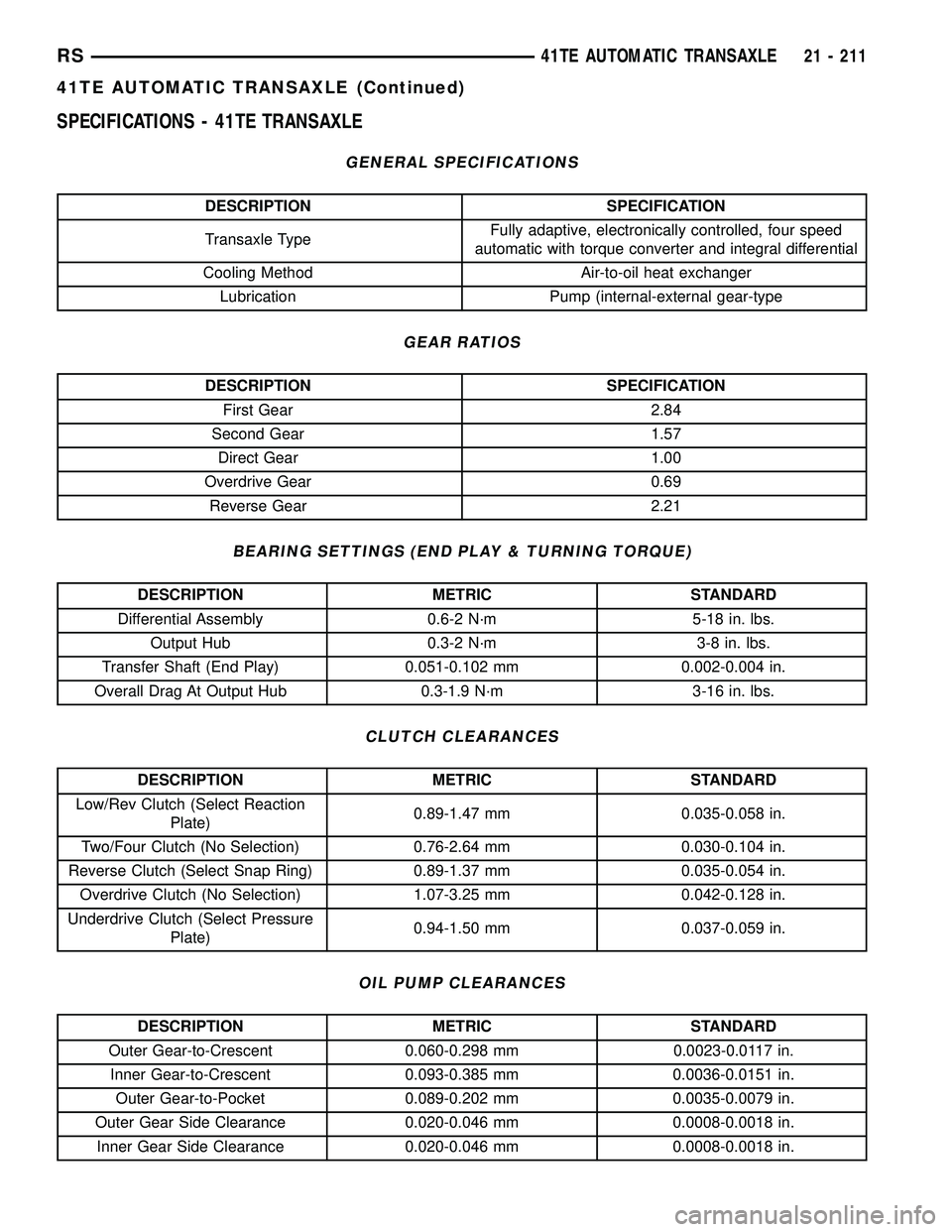

SPECIFICATIONS - 41TE TRANSAXLE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Transaxle TypeFully adaptive, electronically controlled, four speed

automatic with torque converter and integral differential

Cooling Method Air-to-oil heat exchanger

Lubrication Pump (internal-external gear-type

GEAR RATIOS

DESCRIPTION SPECIFICATION

First Gear 2.84

Second Gear 1.57

Direct Gear 1.00

Overdrive Gear 0.69

Reverse Gear 2.21

BEARING SETTINGS (END PLAY & TURNING TORQUE)

DESCRIPTION METRIC STANDARD

Differential Assembly 0.6-2 N´m 5-18 in. lbs.

Output Hub 0.3-2 N´m 3-8 in. lbs.

Transfer Shaft (End Play) 0.051-0.102 mm 0.002-0.004 in.

Overall Drag At Output Hub 0.3-1.9 N´m 3-16 in. lbs.

CLUTCH CLEARANCES

DESCRIPTION METRIC STANDARD

Low/Rev Clutch (Select Reaction

Plate)0.89-1.47 mm 0.035-0.058 in.

Two/Four Clutch (No Selection) 0.76-2.64 mm 0.030-0.104 in.

Reverse Clutch (Select Snap Ring) 0.89-1.37 mm 0.035-0.054 in.

Overdrive Clutch (No Selection) 1.07-3.25 mm 0.042-0.128 in.

Underdrive Clutch (Select Pressure

Plate)0.94-1.50 mm 0.037-0.059 in.

OIL PUMP CLEARANCES

DESCRIPTION METRIC STANDARD

Outer Gear-to-Crescent 0.060-0.298 mm 0.0023-0.0117 in.

Inner Gear-to-Crescent 0.093-0.385 mm 0.0036-0.0151 in.

Outer Gear-to-Pocket 0.089-0.202 mm 0.0035-0.0079 in.

Outer Gear Side Clearance 0.020-0.046 mm 0.0008-0.0018 in.

Inner Gear Side Clearance 0.020-0.046 mm 0.0008-0.0018 in.

RS41TE AUTOMATIC TRANSAXLE21 - 211

41TE AUTOMATIC TRANSAXLE (Continued)

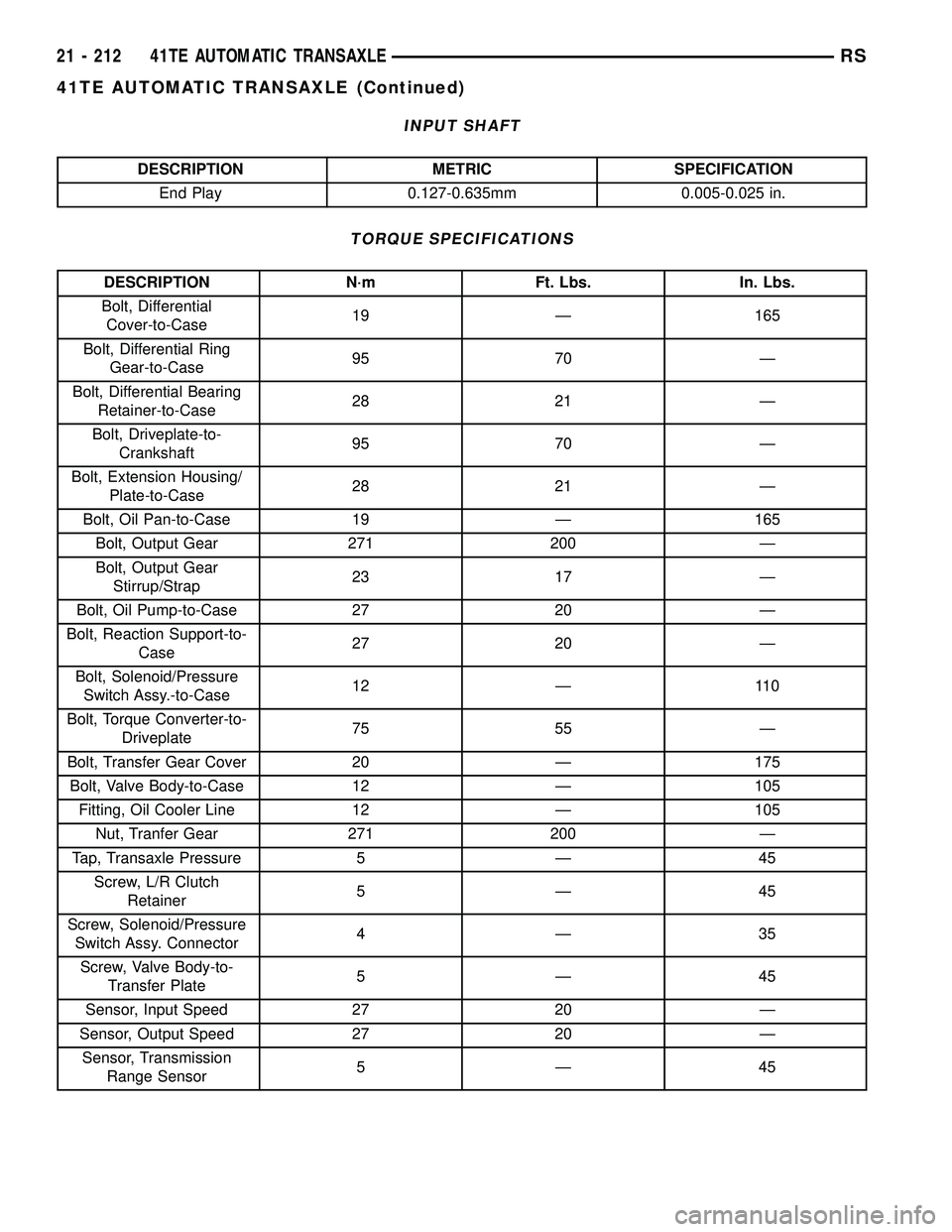

Page 1673 of 2339

INPUT SHAFT

DESCRIPTION METRIC SPECIFICATION

End Play 0.127-0.635mm 0.005-0.025 in.

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt, Differential

Cover-to-Case19 Ð 165

Bolt, Differential Ring

Gear-to-Case95 70 Ð

Bolt, Differential Bearing

Retainer-to-Case28 21 Ð

Bolt, Driveplate-to-

Crankshaft95 70 Ð

Bolt, Extension Housing/

Plate-to-Case28 21 Ð

Bolt, Oil Pan-to-Case 19 Ð 165

Bolt, Output Gear 271 200 Ð

Bolt, Output Gear

Stirrup/Strap23 17 Ð

Bolt, Oil Pump-to-Case 27 20 Ð

Bolt, Reaction Support-to-

Case27 20 Ð

Bolt, Solenoid/Pressure

Switch Assy.-to-Case12 Ð 110

Bolt, Torque Converter-to-

Driveplate75 55 Ð

Bolt, Transfer Gear Cover 20 Ð 175

Bolt, Valve Body-to-Case 12 Ð 105

Fitting, Oil Cooler Line 12 Ð 105

Nut, Tranfer Gear 271 200 Ð

Tap, Transaxle Pressure 5 Ð 45

Screw, L/R Clutch

Retainer5Ð45

Screw, Solenoid/Pressure

Switch Assy. Connector4Ð35

Screw, Valve Body-to-

Transfer Plate5Ð45

Sensor, Input Speed 27 20 Ð

Sensor, Output Speed 27 20 Ð

Sensor, Transmission

Range Sensor5Ð45

21 - 212 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1681 of 2339

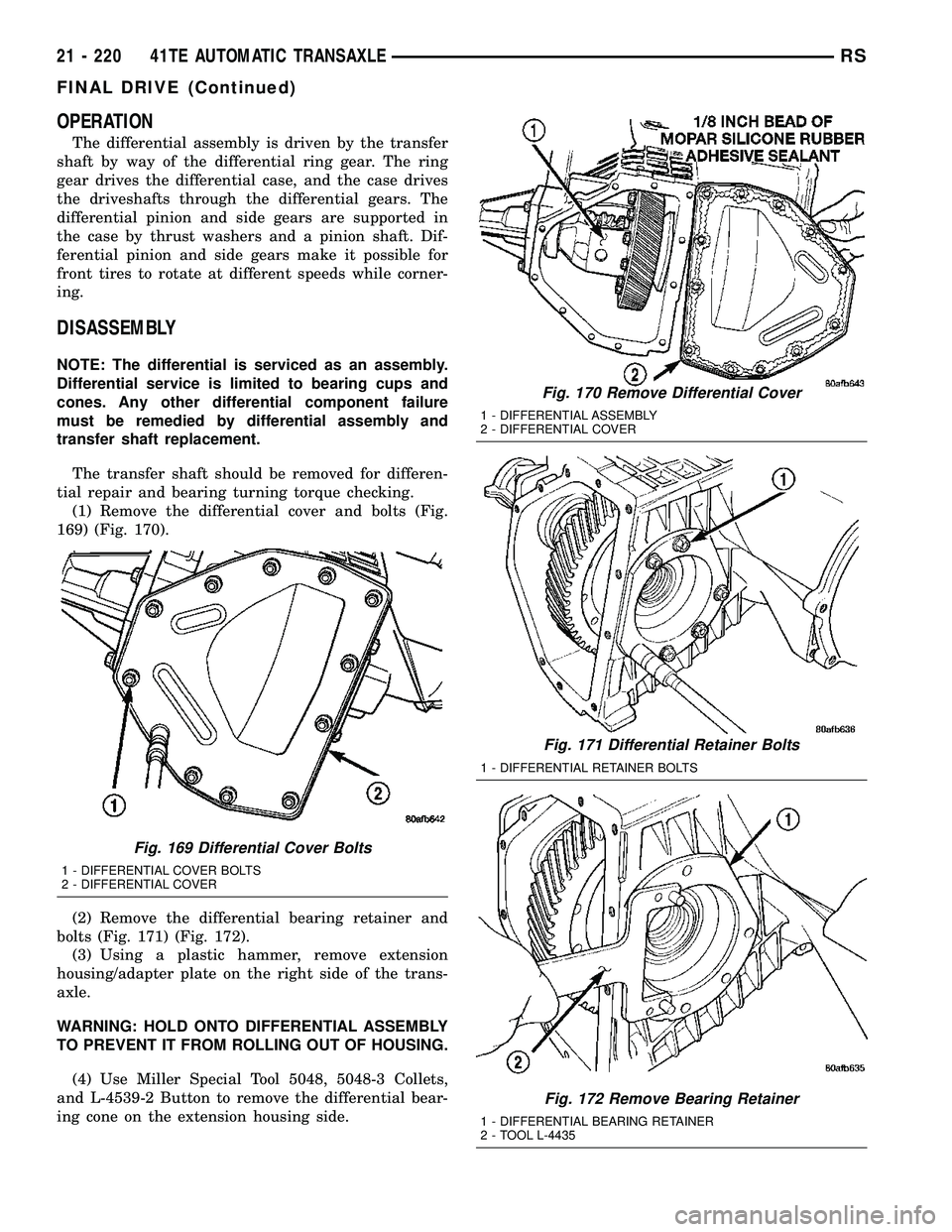

OPERATION

The differential assembly is driven by the transfer

shaft by way of the differential ring gear. The ring

gear drives the differential case, and the case drives

the driveshafts through the differential gears. The

differential pinion and side gears are supported in

the case by thrust washers and a pinion shaft. Dif-

ferential pinion and side gears make it possible for

front tires to rotate at different speeds while corner-

ing.

DISASSEMBLY

NOTE: The differential is serviced as an assembly.

Differential service is limited to bearing cups and

cones. Any other differential component failure

must be remedied by differential assembly and

transfer shaft replacement.

The transfer shaft should be removed for differen-

tial repair and bearing turning torque checking.

(1) Remove the differential cover and bolts (Fig.

169) (Fig. 170).

(2) Remove the differential bearing retainer and

bolts (Fig. 171) (Fig. 172).

(3) Using a plastic hammer, remove extension

housing/adapter plate on the right side of the trans-

axle.

WARNING: HOLD ONTO DIFFERENTIAL ASSEMBLY

TO PREVENT IT FROM ROLLING OUT OF HOUSING.

(4) Use Miller Special Tool 5048, 5048-3 Collets,

and L-4539-2 Button to remove the differential bear-

ing cone on the extension housing side.

Fig. 169 Differential Cover Bolts

1 - DIFFERENTIAL COVER BOLTS

2 - DIFFERENTIAL COVER

Fig. 170 Remove Differential Cover

1 - DIFFERENTIAL ASSEMBLY

2 - DIFFERENTIAL COVER

Fig. 171 Differential Retainer Bolts

1 - DIFFERENTIAL RETAINER BOLTS

Fig. 172 Remove Bearing Retainer

1 - DIFFERENTIAL BEARING RETAINER

2 - TOOL L-4435

21 - 220 41TE AUTOMATIC TRANSAXLERS

FINAL DRIVE (Continued)

Page 1687 of 2339

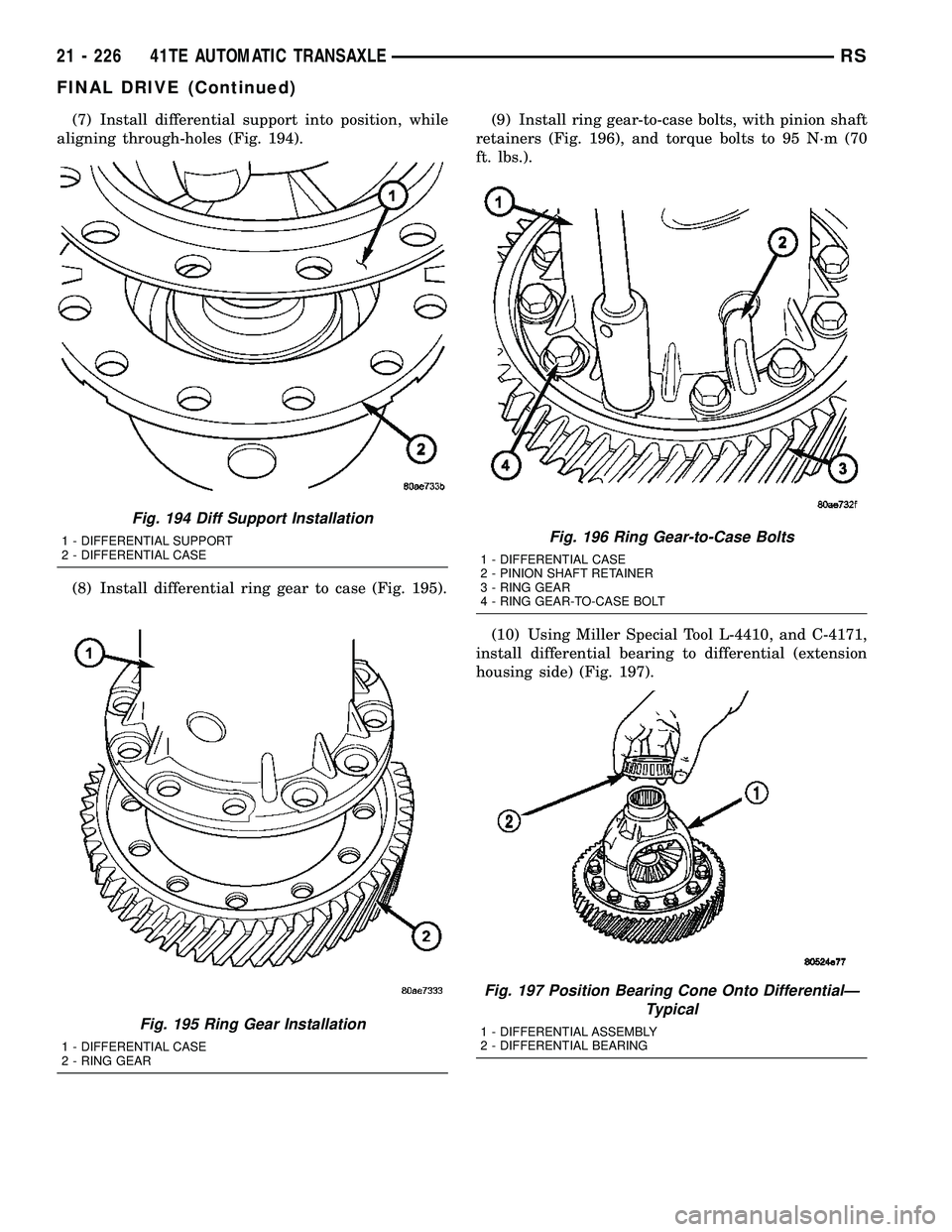

(7) Install differential support into position, while

aligning through-holes (Fig. 194).

(8) Install differential ring gear to case (Fig. 195).(9) Install ring gear-to-case bolts, with pinion shaft

retainers (Fig. 196), and torque bolts to 95 N´m (70

ft. lbs.).

(10) Using Miller Special Tool L-4410, and C-4171,

install differential bearing to differential (extension

housing side) (Fig. 197).

Fig. 194 Diff Support Installation

1 - DIFFERENTIAL SUPPORT

2 - DIFFERENTIAL CASE

Fig. 195 Ring Gear Installation

1 - DIFFERENTIAL CASE

2 - RING GEAR

Fig. 196 Ring Gear-to-Case Bolts

1 - DIFFERENTIAL CASE

2 - PINION SHAFT RETAINER

3 - RING GEAR

4 - RING GEAR-TO-CASE BOLT

Fig. 197 Position Bearing Cone Onto DifferentialÐ

Typical

1 - DIFFERENTIAL ASSEMBLY

2 - DIFFERENTIAL BEARING

21 - 226 41TE AUTOMATIC TRANSAXLERS

FINAL DRIVE (Continued)

Page 1688 of 2339

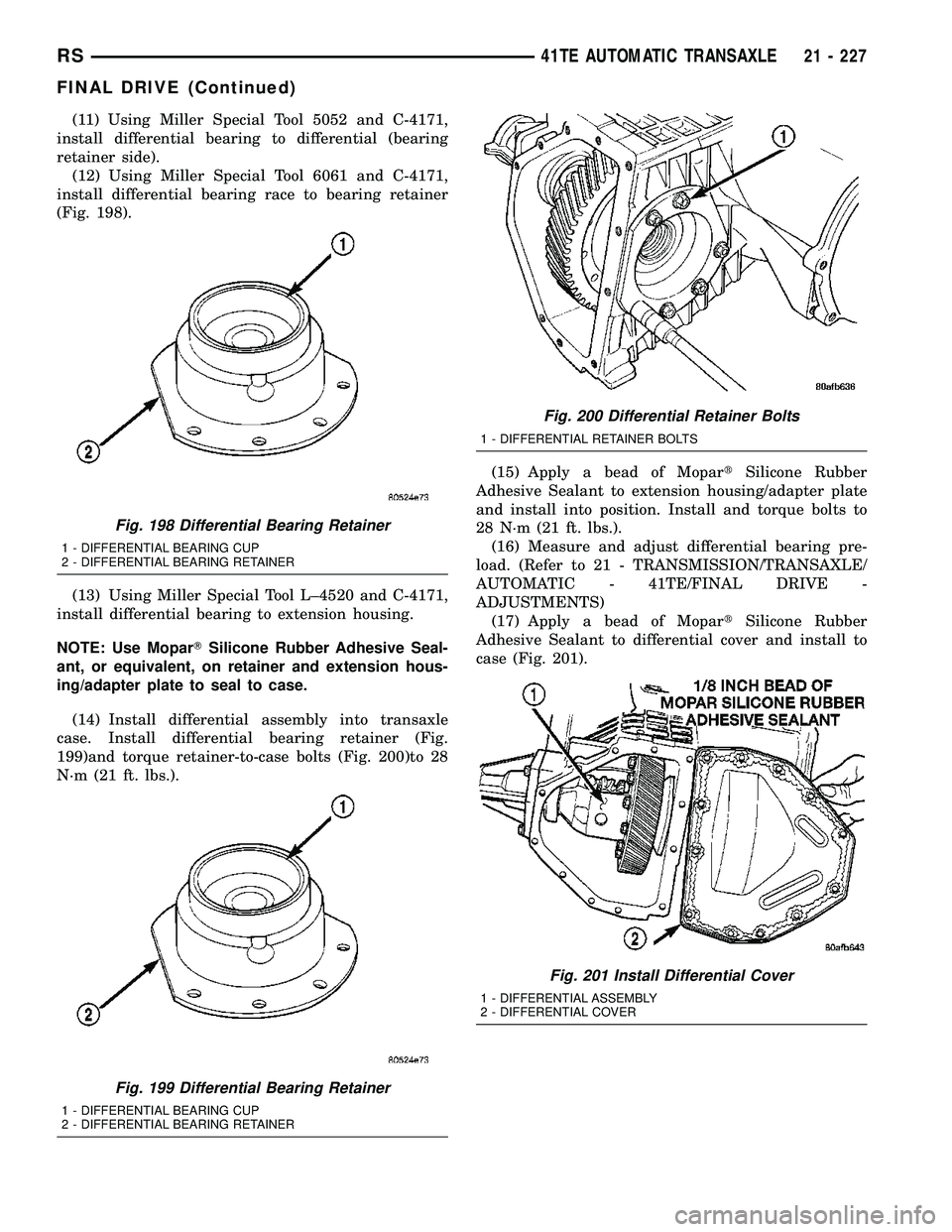

(11) Using Miller Special Tool 5052 and C-4171,

install differential bearing to differential (bearing

retainer side).

(12) Using Miller Special Tool 6061 and C-4171,

install differential bearing race to bearing retainer

(Fig. 198).

(13) Using Miller Special Tool L±4520 and C-4171,

install differential bearing to extension housing.

NOTE: Use MoparTSilicone Rubber Adhesive Seal-

ant, or equivalent, on retainer and extension hous-

ing/adapter plate to seal to case.

(14) Install differential assembly into transaxle

case. Install differential bearing retainer (Fig.

199)and torque retainer-to-case bolts (Fig. 200)to 28

N´m (21 ft. lbs.).(15) Apply a bead of MopartSilicone Rubber

Adhesive Sealant to extension housing/adapter plate

and install into position. Install and torque bolts to

28 N´m (21 ft. lbs.).

(16) Measure and adjust differential bearing pre-

load. (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 41TE/FINAL DRIVE -

ADJUSTMENTS)

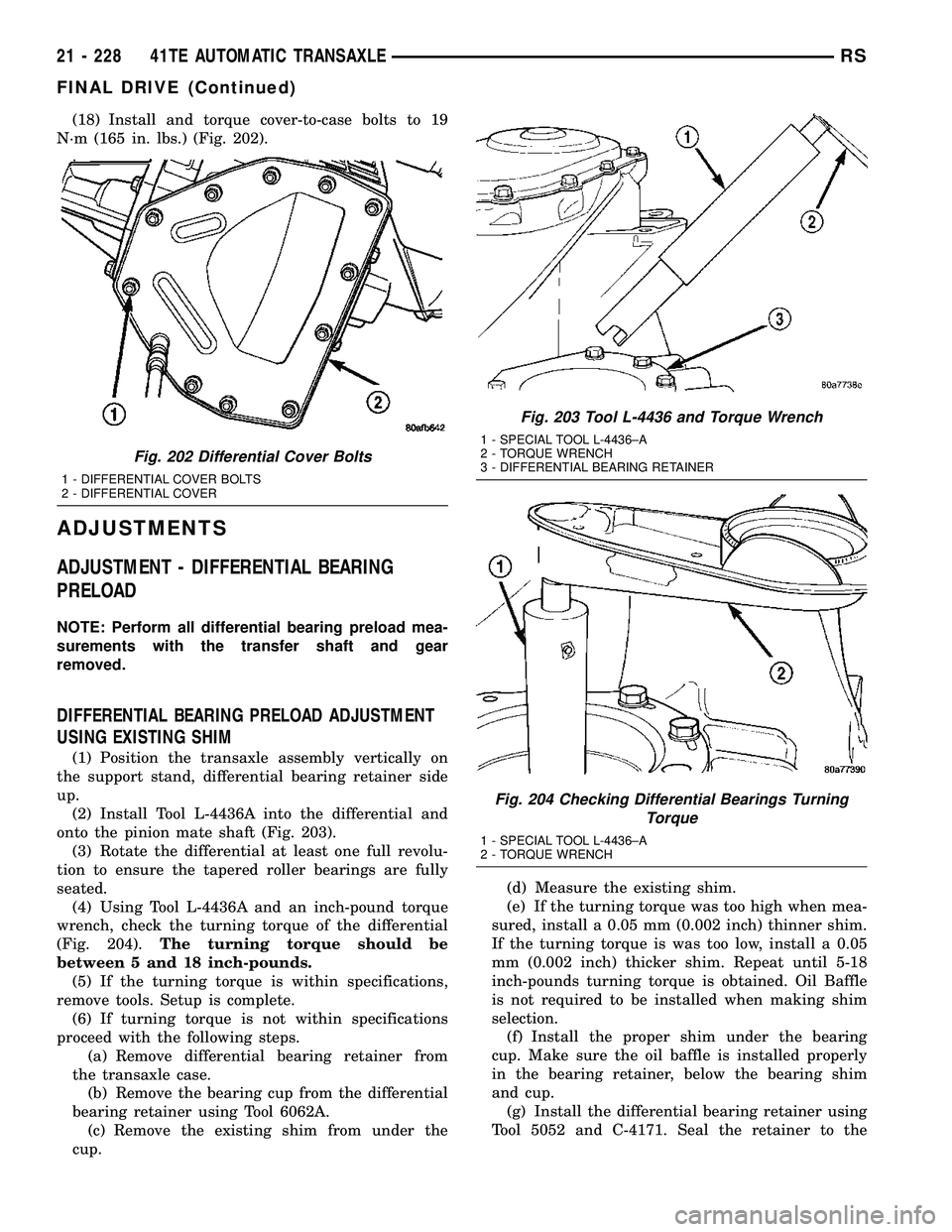

(17) Apply a bead of MopartSilicone Rubber

Adhesive Sealant to differential cover and install to

case (Fig. 201).

Fig. 198 Differential Bearing Retainer

1 - DIFFERENTIAL BEARING CUP

2 - DIFFERENTIAL BEARING RETAINER

Fig. 199 Differential Bearing Retainer

1 - DIFFERENTIAL BEARING CUP

2 - DIFFERENTIAL BEARING RETAINER

Fig. 200 Differential Retainer Bolts

1 - DIFFERENTIAL RETAINER BOLTS

Fig. 201 Install Differential Cover

1 - DIFFERENTIAL ASSEMBLY

2 - DIFFERENTIAL COVER

RS41TE AUTOMATIC TRANSAXLE21 - 227

FINAL DRIVE (Continued)

Page 1689 of 2339

(18) Install and torque cover-to-case bolts to 19

N´m (165 in. lbs.) (Fig. 202).

ADJUSTMENTS

ADJUSTMENT - DIFFERENTIAL BEARING

PRELOAD

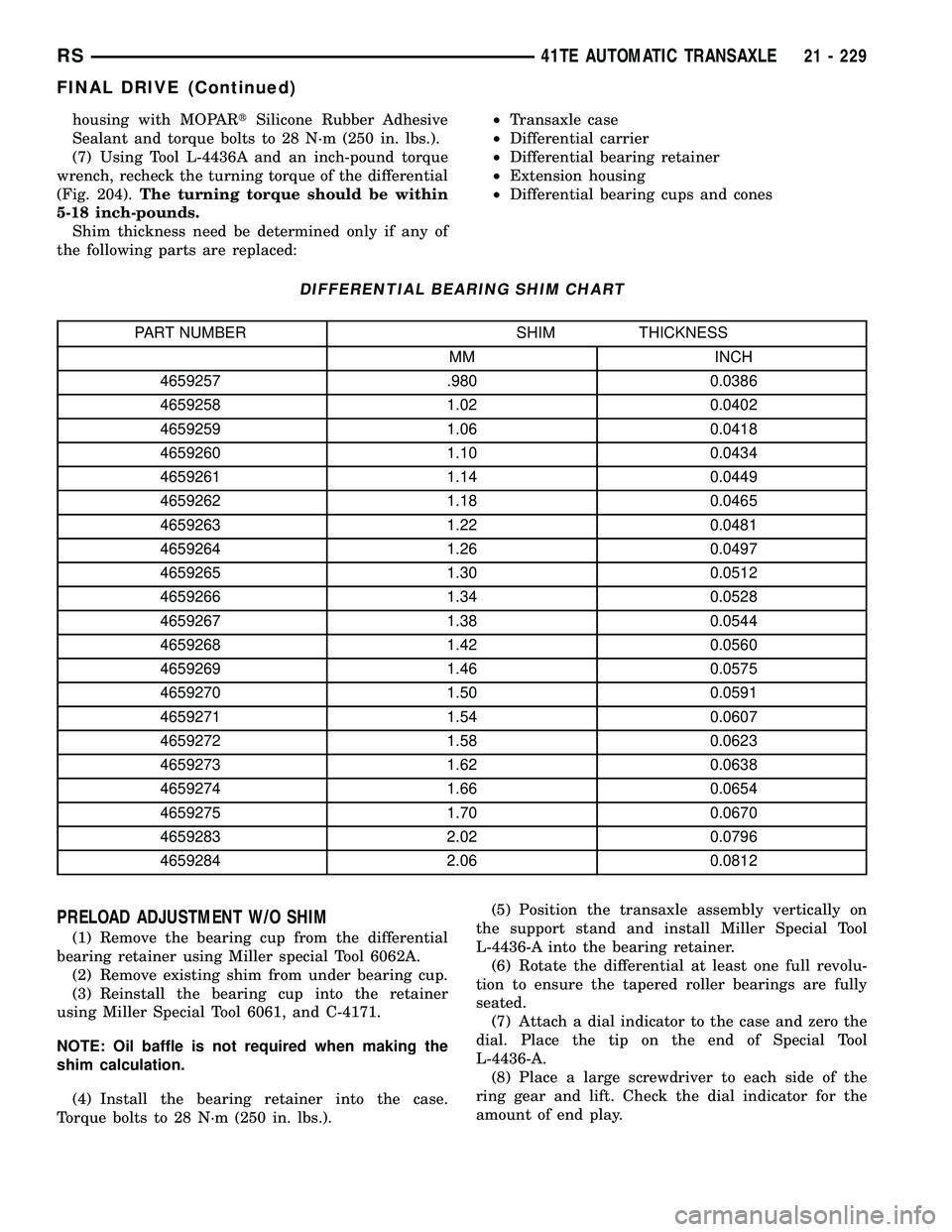

NOTE: Perform all differential bearing preload mea-

surements with the transfer shaft and gear

removed.

DIFFERENTIAL BEARING PRELOAD ADJUSTMENT

USING EXISTING SHIM

(1) Position the transaxle assembly vertically on

the support stand, differential bearing retainer side

up.

(2) Install Tool L-4436A into the differential and

onto the pinion mate shaft (Fig. 203).

(3) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated.

(4) Using Tool L-4436A and an inch-pound torque

wrench, check the turning torque of the differential

(Fig. 204).The turning torque should be

between 5 and 18 inch-pounds.

(5) If the turning torque is within specifications,

remove tools. Setup is complete.

(6) If turning torque is not within specifications

proceed with the following steps.

(a) Remove differential bearing retainer from

the transaxle case.

(b) Remove the bearing cup from the differential

bearing retainer using Tool 6062A.

(c) Remove the existing shim from under the

cup.(d) Measure the existing shim.

(e) If the turning torque was too high when mea-

sured, install a 0.05 mm (0.002 inch) thinner shim.

If the turning torque is was too low, install a 0.05

mm (0.002 inch) thicker shim. Repeat until 5-18

inch-pounds turning torque is obtained. Oil Baffle

is not required to be installed when making shim

selection.

(f) Install the proper shim under the bearing

cup. Make sure the oil baffle is installed properly

in the bearing retainer, below the bearing shim

and cup.

(g) Install the differential bearing retainer using

Tool 5052 and C-4171. Seal the retainer to the

Fig. 202 Differential Cover Bolts

1 - DIFFERENTIAL COVER BOLTS

2 - DIFFERENTIAL COVER

Fig. 203 Tool L-4436 and Torque Wrench

1 - SPECIAL TOOL L-4436±A

2 - TORQUE WRENCH

3 - DIFFERENTIAL BEARING RETAINER

Fig. 204 Checking Differential Bearings Turning

Torque

1 - SPECIAL TOOL L-4436±A

2 - TORQUE WRENCH

21 - 228 41TE AUTOMATIC TRANSAXLERS

FINAL DRIVE (Continued)

Page 1690 of 2339

housing with MOPARtSilicone Rubber Adhesive

Sealant and torque bolts to 28 N´m (250 in. lbs.).

(7) Using Tool L-4436A and an inch-pound torque

wrench, recheck the turning torque of the differential

(Fig. 204).The turning torque should be within

5-18 inch-pounds.

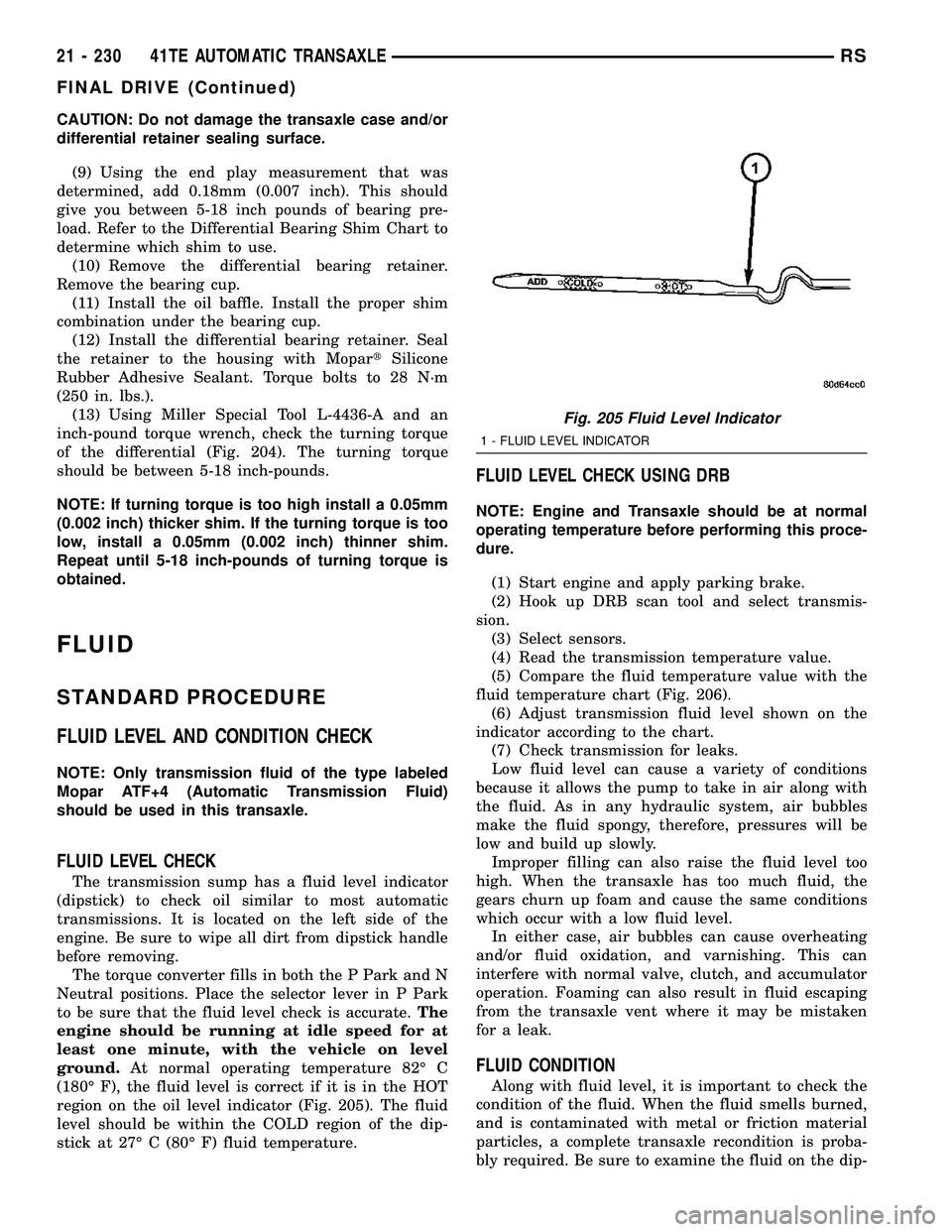

Shim thickness need be determined only if any of

the following parts are replaced:²Transaxle case

²Differential carrier

²Differential bearing retainer

²Extension housing

²Differential bearing cups and cones

DIFFERENTIAL BEARING SHIM CHART

PART NUMBER SHIM THICKNESS

MM INCH

4659257 .980 0.0386

4659258 1.02 0.0402

4659259 1.06 0.0418

4659260 1.10 0.0434

4659261 1.14 0.0449

4659262 1.18 0.0465

4659263 1.22 0.0481

4659264 1.26 0.0497

4659265 1.30 0.0512

4659266 1.34 0.0528

4659267 1.38 0.0544

4659268 1.42 0.0560

4659269 1.46 0.0575

4659270 1.50 0.0591

4659271 1.54 0.0607

4659272 1.58 0.0623

4659273 1.62 0.0638

4659274 1.66 0.0654

4659275 1.70 0.0670

4659283 2.02 0.0796

4659284 2.06 0.0812

PRELOAD ADJUSTMENT W/O SHIM

(1) Remove the bearing cup from the differential

bearing retainer using Miller special Tool 6062A.

(2) Remove existing shim from under bearing cup.

(3) Reinstall the bearing cup into the retainer

using Miller Special Tool 6061, and C-4171.

NOTE: Oil baffle is not required when making the

shim calculation.

(4) Install the bearing retainer into the case.

Torque bolts to 28 N´m (250 in. lbs.).(5) Position the transaxle assembly vertically on

the support stand and install Miller Special Tool

L-4436-A into the bearing retainer.

(6) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated.

(7) Attach a dial indicator to the case and zero the

dial. Place the tip on the end of Special Tool

L-4436-A.

(8) Place a large screwdriver to each side of the

ring gear and lift. Check the dial indicator for the

amount of end play.

RS41TE AUTOMATIC TRANSAXLE21 - 229

FINAL DRIVE (Continued)

Page 1691 of 2339

CAUTION: Do not damage the transaxle case and/or

differential retainer sealing surface.

(9) Using the end play measurement that was

determined, add 0.18mm (0.007 inch). This should

give you between 5-18 inch pounds of bearing pre-

load. Refer to the Differential Bearing Shim Chart to

determine which shim to use.

(10) Remove the differential bearing retainer.

Remove the bearing cup.

(11) Install the oil baffle. Install the proper shim

combination under the bearing cup.

(12) Install the differential bearing retainer. Seal

the retainer to the housing with MopartSilicone

Rubber Adhesive Sealant. Torque bolts to 28 N´m

(250 in. lbs.).

(13) Using Miller Special Tool L-4436-A and an

inch-pound torque wrench, check the turning torque

of the differential (Fig. 204). The turning torque

should be between 5-18 inch-pounds.

NOTE: If turning torque is too high install a 0.05mm

(0.002 inch) thicker shim. If the turning torque is too

low, install a 0.05mm (0.002 inch) thinner shim.

Repeat until 5-18 inch-pounds of turning torque is

obtained.

FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK

NOTE: Only transmission fluid of the type labeled

Mopar ATF+4 (Automatic Transmission Fluid)

should be used in this transaxle.

FLUID LEVEL CHECK

The transmission sump has a fluid level indicator

(dipstick) to check oil similar to most automatic

transmissions. It is located on the left side of the

engine. Be sure to wipe all dirt from dipstick handle

before removing.

The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate.The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground.At normal operating temperature 82É C

(180É F), the fluid level is correct if it is in the HOT

region on the oil level indicator (Fig. 205). The fluid

level should be within the COLD region of the dip-

stick at 27É C (80É F) fluid temperature.

FLUID LEVEL CHECK USING DRB

NOTE: Engine and Transaxle should be at normal

operating temperature before performing this proce-

dure.

(1) Start engine and apply parking brake.

(2) Hook up DRB scan tool and select transmis-

sion.

(3) Select sensors.

(4) Read the transmission temperature value.

(5) Compare the fluid temperature value with the

fluid temperature chart (Fig. 206).

(6) Adjust transmission fluid level shown on the

indicator according to the chart.

(7) Check transmission for leaks.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transaxle vent where it may be mistaken

for a leak.

FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle recondition is proba-

bly required. Be sure to examine the fluid on the dip-

Fig. 205 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

21 - 230 41TE AUTOMATIC TRANSAXLERS

FINAL DRIVE (Continued)

Page 1722 of 2339

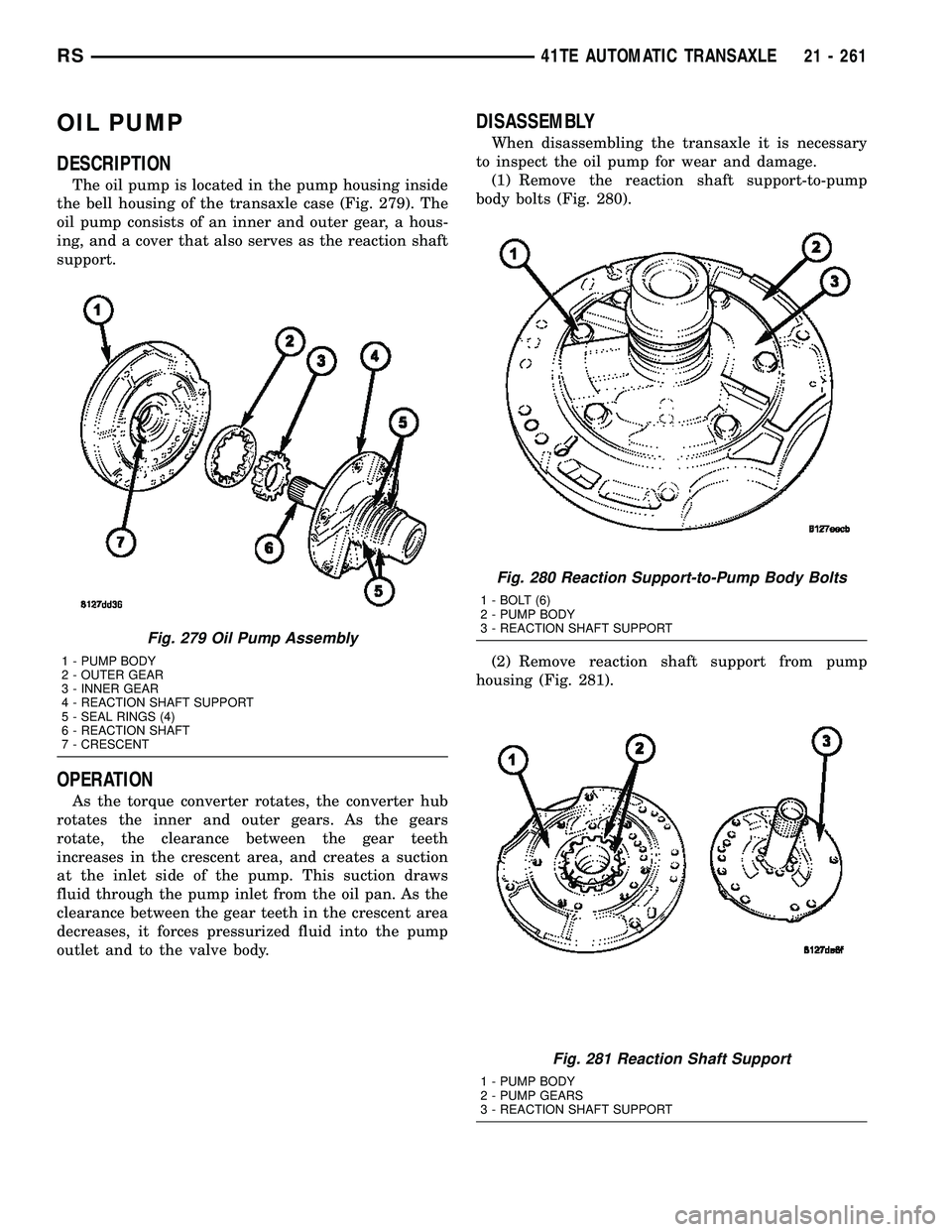

OIL PUMP

DESCRIPTION

The oil pump is located in the pump housing inside

the bell housing of the transaxle case (Fig. 279). The

oil pump consists of an inner and outer gear, a hous-

ing, and a cover that also serves as the reaction shaft

support.

OPERATION

As the torque converter rotates, the converter hub

rotates the inner and outer gears. As the gears

rotate, the clearance between the gear teeth

increases in the crescent area, and creates a suction

at the inlet side of the pump. This suction draws

fluid through the pump inlet from the oil pan. As the

clearance between the gear teeth in the crescent area

decreases, it forces pressurized fluid into the pump

outlet and to the valve body.

DISASSEMBLY

When disassembling the transaxle it is necessary

to inspect the oil pump for wear and damage.

(1) Remove the reaction shaft support-to-pump

body bolts (Fig. 280).

(2) Remove reaction shaft support from pump

housing (Fig. 281).

Fig. 279 Oil Pump Assembly

1 - PUMP BODY

2 - OUTER GEAR

3 - INNER GEAR

4 - REACTION SHAFT SUPPORT

5 - SEAL RINGS (4)

6 - REACTION SHAFT

7 - CRESCENT

Fig. 280 Reaction Support-to-Pump Body Bolts

1 - BOLT (6)

2 - PUMP BODY

3 - REACTION SHAFT SUPPORT

Fig. 281 Reaction Shaft Support

1 - PUMP BODY

2 - PUMP GEARS

3 - REACTION SHAFT SUPPORT

RS41TE AUTOMATIC TRANSAXLE21 - 261