torque CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1808 of 2339

REAR LATCH STRIKER

REMOVAL

(1) Open sliding door.

(2) Mark outline of striker on C-pillar door jamb

face to aid installation.

(3) Remove screws attaching striker to C-pillar

(Fig. 9).

(4) Remove striker from vehicle.

INSTALLATION

(1) Place striker in position on vehicle.

(2) Align striker to outline marks on C-pillar.

(3) Install screws attaching striker to C-pillar.

Tighten screws to 28 N´m (21 ft. lbs.) torque.

(4) Verify sliding door alignment and operation.

SLIDING DOOR

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Apply masking tape to outside surface of quar-

ter panel below the center roller channel, rearward of

the door opening.

(2) Release sliding door latch and open door.

(3) Apply masking tape to door jamb area, rear-

ward of the upper roller channel.

(4) Remove screw attaching upper stop bumper to

upper roller arm (Fig. 10).

(5) Remove upper stop from upper roller arm.(6) Remove center stop from sliding door. (Refer to

23 - BODY/DOORS - SLIDING/STOP BUMPER -

REMOVAL)

(7) Remove sliding door sill plate. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(8) Remove hold open latch striker (Refer to 23 -

BODY/DOORS - SLIDING/HOLD OPEN LATCH

STRIKER - REMOVAL).

(9) Open quarter glass.

(10) Remove center roller channel end cover (Fig.

11).

(11) Support sliding door on a suitable lifting

device with a padded upper surface. The door must

be moveable with lifting device in place.

CAUTION: Do not allow the center hinge roller to

contact the quarter glass. Glass can break.

(12) Slide door rearward until the upper sliding

door hinge roller disengages from the upper channel

(Fig. 12).

(13) Continue moving the door rearward until the

lower rollers exit the lower track.

(14) Continue moving door rearward till center

hinge roller exits the channel (Fig. 13)

(15) Remove sliding door from vehicle.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Place sliding door in position on lifting device.

(2) Engage center hinge roller into channel and

move door forward (Fig. 13).

Fig. 9 SLIDING DOOR LATCH STRIKER

1 - LATCH STRIKER

2 - SLIDING DOOR

Fig. 10 SLIDING DOOR UPPER STOP

1 - UPPER STOP PLATE

2 - SLIDING DOOR

3 - UPPER SLIDING DOOR HINGE

RSDOORS - SLIDING23-29

Page 1810 of 2339

(4) Check door for height using character lines as

a reference. Also check roof contour as a controlling

factor.

Using the procedures noted below, adjust the side

door in the order the individual steps are called out.

DOOR FLUSHNESS ADJUSTMENT

(1) Check sliding door flushness at the C-pillar

striker.

(2) If the sliding door is under or over flush,

remove striker assembly and move thread plate over

keeping one bolt in plate so it will not fall between

inner and outer panels.

(3) Adjust the C-pillar striker in or out until the

door is flush. Then, the on size hole can be elongated

in the direction required. This can be done by grind-

ing or filing the sheet metal and then painting raw

edge to prevent rusting.

(4) Check upper B-pillar flushness to A-pillar

cover.

(5) The sliding door upper hinge can only be

moved outboard by addinga1mmshim behind the

hinge mounting area once the two attachment bolts

are removed and reinstalled.

(6) Check flushness at upper C-pillar.

(7) If upper C-pillar flushness is out of specifica-

tion use a heavy rubber mallet on the door assembly

until door is in specifications.

DOOR GAP ADJUSTMENT - UP/DOWN

(1) Check height of sliding door at the B-pillar and

C-pillar to determine which area is contributing the

greatest to the incorrect gaps.

(2) Visually inspect the sliding door for fitting low

at the top of the door by checking the alignment of

the top contour of the door to the quarter panel.

(3) If the sliding door is high at the C-pillar.

(a) Open the door to mid-point of travel.

(b) Mark outline of center hinge on sliding door

to assist in making adjustments.

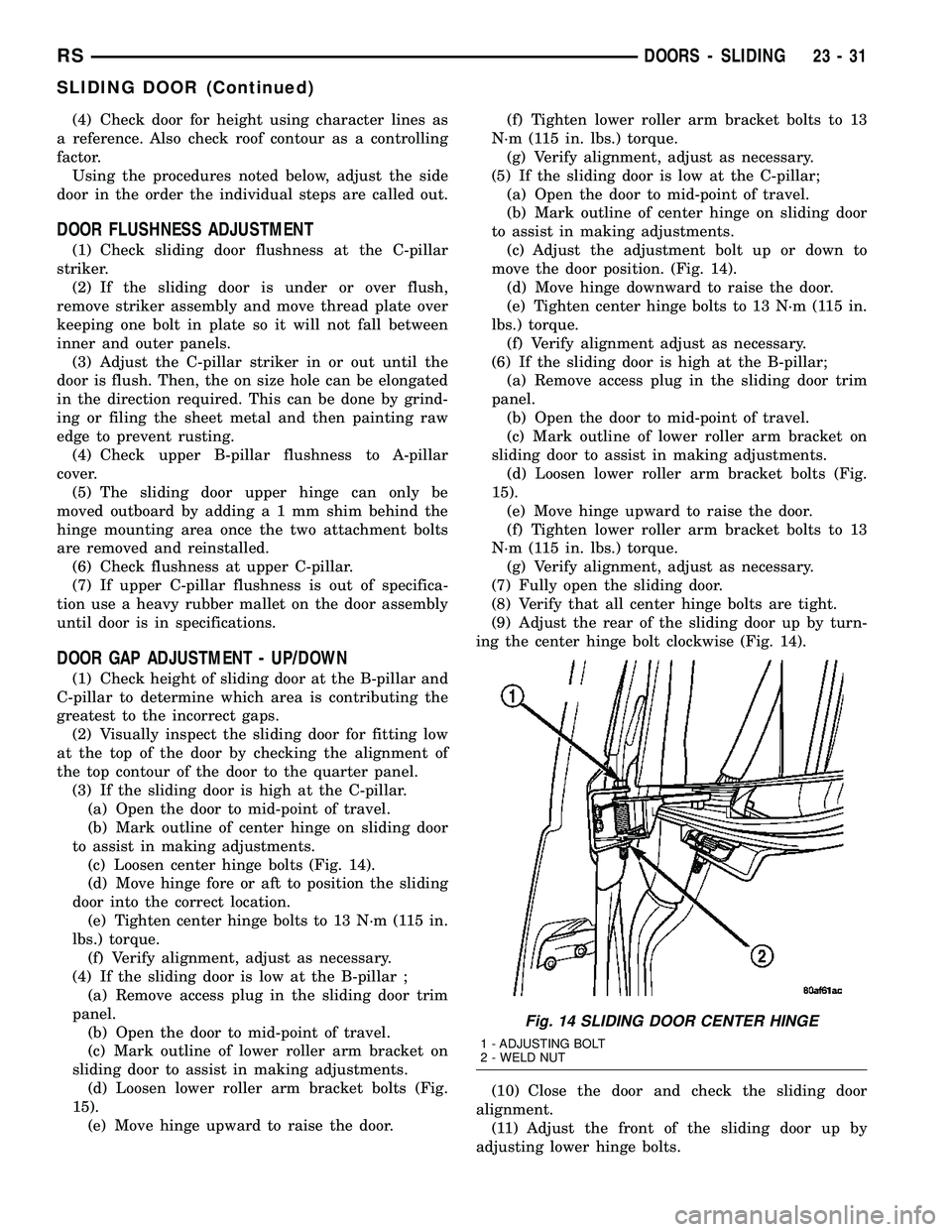

(c) Loosen center hinge bolts (Fig. 14).

(d) Move hinge fore or aft to position the sliding

door into the correct location.

(e) Tighten center hinge bolts to 13 N´m (115 in.

lbs.) torque.

(f) Verify alignment, adjust as necessary.

(4) If the sliding door is low at the B-pillar ;

(a) Remove access plug in the sliding door trim

panel.

(b) Open the door to mid-point of travel.

(c) Mark outline of lower roller arm bracket on

sliding door to assist in making adjustments.

(d) Loosen lower roller arm bracket bolts (Fig.

15).

(e) Move hinge upward to raise the door.(f) Tighten lower roller arm bracket bolts to 13

N´m (115 in. lbs.) torque.

(g) Verify alignment, adjust as necessary.

(5) If the sliding door is low at the C-pillar;

(a) Open the door to mid-point of travel.

(b) Mark outline of center hinge on sliding door

to assist in making adjustments.

(c) Adjust the adjustment bolt up or down to

move the door position. (Fig. 14).

(d) Move hinge downward to raise the door.

(e) Tighten center hinge bolts to 13 N´m (115 in.

lbs.) torque.

(f) Verify alignment adjust as necessary.

(6) If the sliding door is high at the B-pillar;

(a) Remove access plug in the sliding door trim

panel.

(b) Open the door to mid-point of travel.

(c) Mark outline of lower roller arm bracket on

sliding door to assist in making adjustments.

(d) Loosen lower roller arm bracket bolts (Fig.

15).

(e) Move hinge upward to raise the door.

(f) Tighten lower roller arm bracket bolts to 13

N´m (115 in. lbs.) torque.

(g) Verify alignment, adjust as necessary.

(7) Fully open the sliding door.

(8) Verify that all center hinge bolts are tight.

(9) Adjust the rear of the sliding door up by turn-

ing the center hinge bolt clockwise (Fig. 14).

(10) Close the door and check the sliding door

alignment.

(11) Adjust the front of the sliding door up by

adjusting lower hinge bolts.

Fig. 14 SLIDING DOOR CENTER HINGE

1 - ADJUSTING BOLT

2 - WELD NUT

RSDOORS - SLIDING23-31

SLIDING DOOR (Continued)

Page 1811 of 2339

(12) Open door half way and remove lower hinge

bolt access plug.

(13) Loosen bolts as necessary to move the front of

door up or down.

(14) Check the upper hinge for possible bind,

adjust as necessary.

(15) Close the door and check the sliding door

alignment.

(16) Fully open door and apply thread lock nut

onto the center hinge bolt. Tighten nut until till it

butts up against the welded nut on the center hinge.

Tighten nut to 13 N´m (115 in. lbs.) torque. It may be

necessary to hold the center hinge bolt to prevent it

from turning while tightening nut.

(17) Verify alignment, adjust as necessary.

DOOR GAP ADJUSTMENT - FORE/AFT

(1) Check C-pillar and B-pillar for door to aperture

gaps (5 mm + 1 mm), and door to door gap (5 mm +

1 mm).

(2) If adjust gaps require adjustment, loosen cen-

ter hinge screws as necessary to move center hinge

forward or rearward.

(3) Moving center hinge rearward increases the

gap at C-pillar and decreases gap at B-pillar. Moving

center hinge forward decreases gap at the C-pillar

and increases gap at the B-pillar

(4) Move center hinge as necessary, and tighten

screws.

(5) Close the door and check the sliding door align-

ment.

(6) Verify door alignment, adjust as necessary.

(7) Tighten center hinge screws to 13 N´m (115 in.

lbs.) torque.

DOOR SEAL COMPRESSION

(1) First check Gap & Flush (Refer to 23 - BODY/

BODY STRUCTURE/GAP AND FLUSH - SPECIFI-

CATIONS). Check seal compression near the middle

of the door even with the latch assembly. Using a

piece of paper, place it across door seal and close

door. Pull paper out of door opening. If paper tears

setting is to tight, if paper slides thought to easily

the compression is insufficient and needs to be

adjusted.

(2) Adjust seal compression at the top of the B-pil-

lar seal;

(a) Open door to mid-point of travel.

(b) Mark outline of upper roller arm on door to

assist in making adjustments.

(c) Loosen bolts attaching upper roller arm to

door (Fig. 16).

(d) Decrease the length of the upper roller arm

to increase seal compression.

(e) Increase the length of the upper roller arm to

decrease seal compression.

(f) Tighten all upper roller arm bolts to 13 N´m

(115 in. lbs.) torque.

(g) Verify door alignment, adjust as necessary.

(3) Adjust seal compression at the bottom of B-pil-

lar seal.

(a) Open door to mid-point of travel.

(b) Mark outline of lower roller arm on lower

roller arm bracket to assist in making adjustments

(Fig. 17).

(c) Loosen bolts holding lower roller arm to

lower roller arm bracket.

(d) Pivot lower roller arm toward center of vehi-

cle to decrease seal compression.

Fig. 15 SLIDING DOOR LOWER ROLLER ARM

1 - LOWER ROLLER ARM BRACKET

2 - BOLTS

3 - SLIDING DOOR

Fig. 16 Sliding Door Upper Roller Arm

1 - UPPER STOP PLATE

2 - SLIDING DOOR

3 - UPPER SLIDING DOOR HINGE

23 - 32 DOORS - SLIDINGRS

SLIDING DOOR (Continued)

Page 1812 of 2339

(e) Pivot lower roller arm outward to increase

seal compression.

(f) Tighten lower roller arm bolts to 13 N´m (115

in. lbs.) torque.

(g) Verify alignment, adjust as necessary.

NOTE: Adjusting seal compression at the B-pillar

can affect door flushness the C-pillar.

STABILIZER ADJUSTMENT - UPPER/LOWER

(1) Open sliding door.

(2) Loosen the bolts holding the male stabilizers to

the sliding door enough that the stabilizers can move

with some effort.

(3) Close and then reopen sliding door.

(4) Tighten all stabilizers bolts.

STABILIZER

REMOVAL

(1) Open sliding door.

(2) Remove screws attaching stabilizer to door end

frame (Fig. 18).

(3) Remove stabilizer from vehicle.

INSTALLATION

(1) Place stabilizer in position on vehicle.

NOTE: Loose install screws first. Fit should be

snug but free to move when closing door to align to

body half stabilizer.

(2) Install screws attaching stabilizer to door end

frame.

(3) Open door and final tighten screws.

(4) Verify sliding door operation.

STABILIZER SOCKET

REMOVAL

(1) Open sliding door.

(2) Remove screws holding stabilizer socket to

B-pillar (Fig. 19).

(3) Remove stabilizer socket from vehicle.

INSTALLATION

(1) Place stabilizer socket in position on vehicle.

NOTE: Ensure that sealing feature damaged, if reus-

ing stabilizer socket.

Fig. 17 Sliding Door Lower Roller Arm

1 - POWER LOWER ROLLER ARM

2 - MANUAL LOWER ROLLER ARM

Fig. 18 SLIDING DOOR STABILIZER

1 - SLIDING DOOR

2 - STABILIZER

Fig. 19 SLIDING DOOR STABILIZER SOCKET

1 - B-PILLAR

2 - STABILIZER SOCKET

RSDOORS - SLIDING23-33

SLIDING DOOR (Continued)

Page 1813 of 2339

(2) Install screws to hold stabilizer socket to B-pil-

lar. Tighten nuts to 5 N´m (45 in. lbs.) torque.

(3) Close sliding door and verify operation.

TRIM PANEL

REMOVAL

(1) Remove sliding door upper frame molding.

(2) If removing the left sliding door trim panel,

remove screw from inside ash receiver bezel.

(3) Remove screw from pull cup.

(4) Disengage push-in fasteners holding trim to

door panel around perimeter and upper edge of door

(Fig. 20).

(5) Remove sliding door trim panel from vehicle.

INSTALLATION

(1) Place sliding door trim panel in position on

vehicle.

(2) Align locating pins on backside of trim panel to

mating holes in the inner door panel.

(3) Engage push-in fasteners to hold trim to door

panel around perimeter and upper edge of door (Fig.

20).

(4) Install pull cup screw.

(5) If necessary, install screw from inside ash

receiver bezel on left sliding door trim panel.(6) Install sliding door upper frame molding.

INSIDE LATCH HANDLE

REMOVAL

(1) Remove sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL -

REMOVAL)

(2) Remove screws attaching bottom of inside latch

handle to sliding door (Fig. 21).

(3) Remove two screw attaching top of inside latch

handle to sliding door.

(4) Remove latch handle from sliding door.

(5) Disengage cable end from clip on release han-

dle mechanism.

(6) Disengage cable end from release handle mech-

anism.

(7) Remove push pin fastener attaching cable end

to release handle.

(8) Disengage cable casing end from release handle

(Fig. 22).

(9) Disengage cable end from latch handle.

(10) Remove handle from vehicle.

INSTALLATION

(1) Place inside latch handle in position on vehicle.

(2) Engage cable end into latch handle.

(3) Engage cable casing end into release handle.

(4) Install push pin fastener to hold cable into

release handle.

(5) Engage cable end into release handle mecha-

nism.

Fig. 20 SLIDING DOOR TRIM PANEL

1 - PUSH-IN FASTENERS

2 - SLIDING DOOR UPPER FRAME MOLDING

3 - SLIDING DOOR TRIM PANEL

4 - PUSH-IN FASTENERS

5 - PUSH-IN FASTENERS

6 - SLIDING DOOR

Fig. 21 SLIDING DOOR INSIDE HANDLE

1 - INSIDE ASSIST HANDLE

2 - INSIDE RELEASE HANDLE CABLE

3 - ATTACHING SCREWS

23 - 34 DOORS - SLIDINGRS

STABILIZER SOCKET (Continued)

Page 1819 of 2339

DECKLID/HATCH/LIFTGATE/TAILGATE

TABLE OF CONTENTS

page page

EXTERIOR HANDLE

REMOVAL.............................40

INSTALLATION.........................40

HINGE

REMOVAL.............................40

INSTALLATION.........................40

LATCH

REMOVAL.............................41

INSTALLATION.........................41

LATCH STRIKER

REMOVAL.............................41

INSTALLATION.........................42

LIFTGATE

REMOVAL.............................42

INSTALLATION.........................42

LOCK CYLINDER

REMOVAL.............................42INSTALLATION.........................42

SUPPORT CYLINDER

REMOVAL.............................42

INSTALLATION.........................43

TRIM PANEL

REMOVAL.............................43

INSTALLATION.........................43

SLAM BUMPER

REMOVAL

REMOVAL - BODY SIDE................44

REMOVAL - LIFTGATE SIDE.............44

INSTALLATION

INSTALLATION - BODY SIDE............44

INSTALLATION - LIFTGATE SIDE.........44

EXTERIOR HANDLE

REMOVAL

(1) Remove liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL)

(2) Disconnect the exterior handle electrical con-

nectors.

(3) Remove the two outer screws and the two inner

screws.

(4) Remove the exterior handle/license plate light

assembly.

INSTALLATION

(1) Route the exterior handle electrical connector

through the door and position handle.

(2) Install the two out screws and tighten to 3 N´m

(22 in. lbs.).

(3) Install the two inner bolts and tighten to 5

N´m (40 in. lbs.).

(4) Connect the electrical connector.

(5) Install the trim panel. (Refer to 23 - BODY/

DECKLID/HATCH/LIFTGATE/TAILGATE/TRIM

PANEL - INSTALLATION)

HINGE

REMOVAL

(1) Release liftgate latch and open liftgate.

(2) Support liftgate on a suitable lifting device in

the full open position.

(3) Apply several layers of duct tape on the outside

of to roof across the gap to the lift gate to hold the

liftgate in position.

(4) Remove bolts attaching liftgate hinge to roof

header.

(5) Disconnect VTSS switch from the body har-

ness.

(6) Remove bolts attaching hinge to liftgate (Fig.

1).

(7) Remove hinge from vehicle.

INSTALLATION

(1) If necessary, paint replacement hinge before

installation.

(2) Place hinge in position on vehicle.

(3) Align hinge to marks on liftgate.

(4) Install bolts attaching hinge to liftgate (Fig. 1).

Tighten bolts to 33 N´m (24 ft. lbs.) torque.

(5) Align hinge to marks on roof header.

23 - 40 DECKLID/HATCH/LIFTGATE/TAILGATERS

Page 1820 of 2339

(6) Install bolts attaching liftgate hinge to roof

header. Tighten outer two bolts to 33 N´m (24 ft. lbs.)

torque. The sheet medal screw at center 12 N´m (105

in. lbs.)

(7) Remove duct tape from roof and liftgate.

(8) Verify liftgate alignment. Refer to Liftgate

Remove and Installation for proper gap measure-

ments.

LATCH

REMOVAL

(1) Remove liftgate trim panel.

(2) Disengage outside key cylinder link from clip

on latch.

(3) Disconnect wire connector from liftgate latch

(Fig. 2).

(4) Remove screws attaching latch to liftgate.

(5) Remove latch from vehicle.

INSTALLATION

(1) Engage key cylinder link and place latch in

position on vehicle.

(2) Install screws attaching latch to liftgate.

Tighten to 11 N´m (95 in. lbs.) torque.

(3) Connect wire connector to liftgate latch.

(4) Verify liftgate fit and operation. Adjust as nec-

essary.

(5) Install liftgate trim panel.

LATCH STRIKER

REMOVAL

(1) Open liftgate.

(2) Mark outline of striker on sill to aid installa-

tion.

(3) Remove screws attaching striker to sill (Fig. 3).

(4) Remove striker from vehicle.

Fig. 1 LIFTGATE HINGE

1 - LIFTGATE

2 - HINGE

3 - REAR ROOF HEADER

Fig. 2 LIFTGATE LATCH

1 - ELECTRICAL CONNECTOR

2 - LIFTGATE LATCH

3 - SCREW

4 - LIFTGATE

5 - LIFTGATE LOCK CYLINDER

Fig. 3 LIFTGATE LATCH STRIKER

1 - LIFTGATE SILL

2 - LIFTGATE STRIKER

RSDECKLID/HATCH/LIFTGATE/TAILGATE23-41

HINGE (Continued)

Page 1821 of 2339

INSTALLATION

(1) Place striker in position on vehicle.

(2) Align striker to outline mark on sill.

(3) Install screws attaching striker to sill. Tighten

screws to 28 N´m (21 ft. lbs.) torque.

(4) Verify liftgate alignment and operation.

LIFTGATE

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Release liftgate latch and open liftgate.

(3) Remove liftgate upper frame molding.

(4) Remove screws attaching liftgate wire connec-

tor to rear header.

(5) Disconnect liftgate wire harness from body

wire harness.

(6) Disconnect rear window washer hose from

spray nozzle.

(7) Support liftgate on a suitable lifting device.

(8) Disconnect power liftgate link, if equipped.

(9) Remove screws attaching support cylinders to

liftgate.

(10) Remove bolts attaching liftgate hinge to roof

header (Fig. 4).

(11) With assistance, remove liftgate from vehicle.

INSTALLATION

(1) With assistance, place liftgate in position on

vehicle.

(2) Install bolts attaching liftgate hinge to roof

header. Tighten bolts to 33 N´m (24 ft. lbs.) torque.

(3) Install screws attaching support cylinders to

liftgate. Tighten bolts to 28 N´m (21 ft. lbs.) torque.(4) Reconnect power liftgate link, if equipped.

(5) Remove lifting device from under liftgate.

(6) Connect liftgate wire harness into body wire

harness.

(7) Install screws attaching wire connector to rear

header.

(8) Connect rear window washer hose onto spray

nozzle.

(9) Install liftgate upper frame molding.

(10) Install battery negative cable.

(11) Verify liftgate alignment. The liftgate should

have a gap to adjacent panels and fit flush across the

gaps. The gap is; (Refer to 23 - BODY/BODY STRUC-

TURE/GAP AND FLUSH - SPECIFICATIONS).

²8.0 mm 2.5 to the rear fascia,

²8.0 mm 2.0 to the roof,

²2.0 mm 0.5 mm to the aperture.

LOCK CYLINDER

REMOVAL

(1) Remove the liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL)

(2) Disconnect the electrical connector.

(3) Disconnect the latch rod.

(4) Rotate plastic lock cylinder nut one quarter

turn and remove nut and spring washer.

(5) Remove the lock cylinder from the liftgate.

INSTALLATION

(1) Install lock cylinder into liftgate.

(2) Install the plastic lock cylinder lock nut, spring

washer and rotate one quarter turn.

(3) Connect the electrical connector.

(4) Connect the latch rod.

(5) Install the trim panel. (Refer to 23 - BODY/

DECKLID/HATCH/LIFTGATE/TAILGATE/TRIM

PANEL - INSTALLATION)

(6) Verify lock cylinder operation.

SUPPORT CYLINDER

REMOVAL

(1) Release liftgate latch and open liftgate.

(2) Support liftgate on a suitable lifting device in

the full open position.

(3) Pull liftgate opening weatherstrip from D-pillar

flange next to prop assembly end pivot.

(4) Remove bolt attaching end pivot to D-pillar

(Fig. 5).

(5) Remove bolt attaching prop assembly to lift-

gate.

(6) Remove prop assembly from vehicle.

Fig. 4 LIFTGATE

1 - HINGE

2 - ROOF

3 - NET HOLE OR SLOT

23 - 42 DECKLID/HATCH/LIFTGATE/TAILGATERS

LATCH STRIKER (Continued)

Page 1822 of 2339

INSTALLATION

Ensure that the cylinder end is attached to the

D-pillar and the shaft end is attached to the liftgate.

(1) Place prop assembly in position.

(2) Install bolt attaching prop assembly to liftgate.

(3) Install bolt attaching end pivot to D-pillar.

Tighten bolts to 28 N´m (21 ft. lbs.) torque.

(4) Install liftgate opening weatherstrip to D-pillar

flange next to prop assembly end pivot.

(5) Close liftgate. Check liftgate operation.

TRIM PANEL

REMOVAL

(1) Remove the bolt attaching the lift motor link, if

equipped (Fig. 6).

(2) Remove liftgate upper frame molding (Fig. 7).

(3) Remove assist handle screws.

(4) Disengage hidden clips holding trim panel to

liftgate from around perimeter or liftgate (Fig. 7).

(5) Disconnect wire connector from lamps.

(6) Remove liftgate trim panel from vehicle.

INSTALLATION

(1) Place liftgate trim panel in position on vehicle.

(2) Engage hidden clips to hold trim panel to lift-

gate and fasteners around perimeter of liftgate (Fig.

7).(3) Connect wire connector into lamp.

(4) Install courtesy lamps into liftgate trim.

(5) Install screws to hold assist handle to liftgate.

(6) Install upper frame side moldings.

(7) Install liftgate upper frame molding.

(8) Install the bolt attaching the lifgate motor link

and tighten to 28 N´m (21 ft. lbs.)

Fig. 5 LIFTGATE PROP ASSEMBLY

1 - LIFTGATE

2 - PROP ASSEMBLY

Fig. 6 LIFTGATE MOTOR

1 - LIFTGATE MOTOR LINK BOLT

2 - LIFTGATE MOTOR

3 - LIFTGATE

Fig. 7 LIFTGATE TRIM

1 - LIFTGATE

2 - LOWER TRIM PANEL

3 - ASSIST HANDLE SCREWS

4 - UPPER TRIM

5 - UPPER TRIM CLIPS

RSDECKLID/HATCH/LIFTGATE/TAILGATE23-43

SUPPORT CYLINDER (Continued)

Page 1830 of 2339

(7) Tighten screw to 1.2 N´m (11 in. lbs.) torque.

(8) Install the wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS - INSTAL-

LATION)

(9) Check for proper spray pattern from washer

nozzles.

EXTERIOR NAME PLATES -

TAPE ATTACHED

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) Using a nonmetallic prying device, such as a

plastic or wood trim stick gently pry up at corners

and remove.

(4) Clean off all traces of adhesive or double sided

tape from the panel with a general purpose adhesive

remover.

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Align badgeing to reference points.

(3) Install and press securely to full adhesive con-

tact

(4) Clean away any reference points.

EXTERIOR NAME PLATES -

ADHESIVE ATTACHED

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) With your fingernail lift up and peel away

badgeing/tape from panel, using a heat gun as you

go.

(4) Clean off all traces of adhesive from the pan-

el(s) with a general purpose adhesive remover.

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Remove paper carrier and align badgeing/tape

to reference points or adjacent panel.

(3) Install and press securely, using a plastic

spreader to eliminate all air bubbles.

(4) Remove top protective carrier.

(5) Clean away any reference points.

FRONT FENDER

REMOVAL

(1) Remove headlamp housing. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - REMOVAL)

(2) Remove mirror bezel

(3) Remove mud guard.

(4) Remove inner splash shield.

(5) Remove fender to fascia nuts.

Fig. 6 COWL COVER

1 - COWL COVER

2 - WIPER PIVOT

3 - WASHER HOSES

4 - HOOD

Fig. 7 COWL COVER RETAINERS

1 - SCREW

2 - WINDSHIELD

3 - COWL COVER

4 - FRONT FENDER

RSEXTERIOR23-51

COWL GRILLE (Continued)