rear lamp CHRYSLER VOYAGER 2005 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 202 of 2339

(1) Make sure all hydraulic fluid lines are installed

and properly torqued.

(2) Connect the DRBIIItscan tool to the diagnos-

tics connector. The diagnostic connector is located

under the lower steering column cover to the left of

the steering column.

(3) Using the DRB, check to make sure the CAB

does not have any fault codes stored. If it does, clear

them using the DRB.

WARNING: WHEN BLEEDING THE BRAKE SYSTEM

WEAR SAFETY GLASSES. A CLEAR BLEED TUBE

MUST BE ATTACHED TO THE BLEEDER SCREWS

AND SUBMERGED IN A CLEAR CONTAINER FILLED

PART WAY WITH CLEAN BRAKE FLUID. DIRECT

THE FLOW OF BRAKE FLUID AWAY FROM YOUR-

SELF AND THE PAINTED SURFACES OF THE VEHI-

CLE. BRAKE FLUID AT HIGH PRESSURE MAY

COME OUT OF THE BLEEDER SCREWS WHEN

OPENED.

(4) Bleed the base brake system using the stan-

dard pressure or manual bleeding procedure. (Refer

to 5 - BRAKES - BASE - STANDARD PROCEDURE)

(5) Using the DRB, select ANTILOCK BRAKES,

followed by MISCELLANEOUS, then BLEED

BRAKES. Follow the instructions displayed. When

the scan tool displays TEST COMPLETED, discon-

nect the scan tool and proceed.

(6) Bleed the base brake system a second time.

Check brake fluid level in the reservoir periodically

to prevent emptying, causing air to enter the hydrau-

lic system.

(7) Fill the master cylinder reservoir to the full

level.

(8) Test drive the vehicle to be sure the brakes are

operating correctly and that the brake pedal does not

feel spongy.

SPECIFICATIONS

ABS FASTENER TORQUE

Refer to BRAKE FASTENER TORQUE. (Refer to 5

- BRAKES - BASE - SPECIFICATIONS)

TONE WHEEL RUNOUT

DESCRIPTION SPECIFICATION

Front Tone Wheel

Maximum Runout0.15 mm (0.006 in.)

Rear Tone Wheel

Maximum Runout0.15 mm (0.006 in.)

WHEEL SPEED SENSOR AIR GAP

DESCRIPTION SPECIFICATION

Front Sensor0.35 ± 1.20 mm

0.014 ± 0.047 in.

Rear Sensor0.40 ± 1.20 mm

0.016 ± 0.047 in.

FRONT WHEEL SPEED

SENSOR

REMOVAL

(1)Raise vehicle. (Refer to LUBRICATION & MAIN-

TENANCE/HOISTING - STANDARD PROCEDURE)

(2) Remove the tire and wheel assembly.

(3) Remove the sensor cable routing clamp screws.

CAUTION: When disconnecting the wheel speed

sensor from vehicle wiring harness, be careful not

to damage pins on connector

(4) Remove speed sensor cable grommets from

intermediate bracket on strut.

(5) Disconnect speed sensor cable from vehicle wir-

ing harness behind fender well shield.

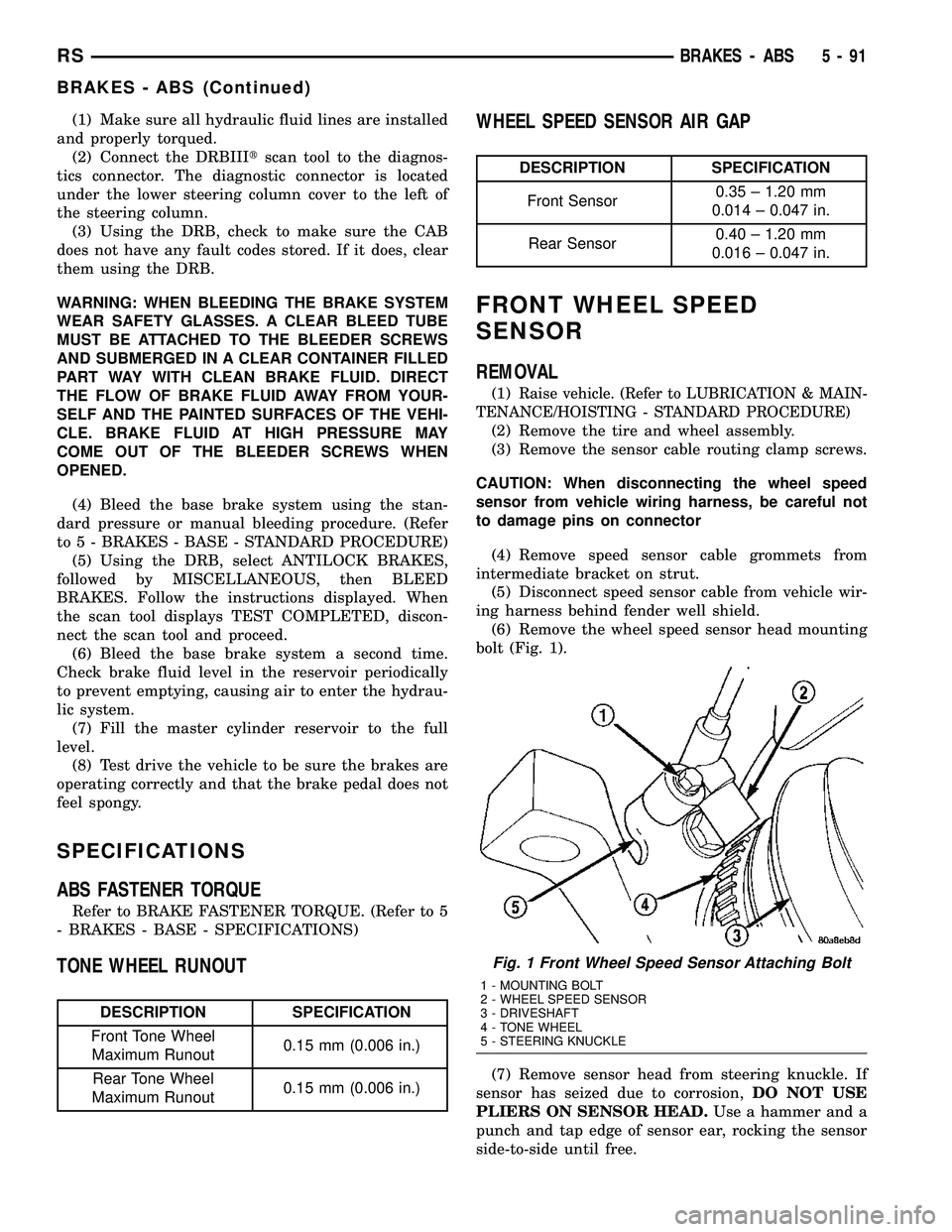

(6) Remove the wheel speed sensor head mounting

bolt (Fig. 1).

(7) Remove sensor head from steering knuckle. If

sensor has seized due to corrosion,DO NOT USE

PLIERS ON SENSOR HEAD.Use a hammer and a

punch and tap edge of sensor ear, rocking the sensor

side-to-side until free.

Fig. 1 Front Wheel Speed Sensor Attaching Bolt

1 - MOUNTING BOLT

2 - WHEEL SPEED SENSOR

3 - DRIVESHAFT

4 - TONE WHEEL

5 - STEERING KNUCKLE

RSBRAKES - ABS5-91

BRAKES - ABS (Continued)

Page 203 of 2339

(8) Remove front wheel speed sensor from vehicle.

INSTALLATION

CAUTION: Proper installation of wheel speed sen-

sor cables is critical to continued system operation.

Be sure that cables are installed in retainers. Fail-

ure to install cables in retainers as shown in this

section may result in contact with moving parts and

over extension of cables, resulting in an open cir-

cuit.

(1) Connect the front wheel speed sensor cable to

the vehicle wiring harness connector. Be sure speed

sensor cable connector is fully seated and locked into

vehicle wiring harness connector.

(2) Install the bolts attaching the routing clamps

to the body of the vehicle. Tighten the bolts to a

torque of 14 N´m (125 in. lbs.).

(3) Insert speed sensor cable grommets into inter-

mediate bracket on strut.

(4) Install the wheel speed sensor head mounting

bolt (Fig. 1). Tighten the bolt to a torque of 13 N´m

(115 in. lbs.)

(5) Install the wheel and tire assembly on vehicle.

(6) Lower vehicle.

(7) Road test vehicle to ensure proper operation of

the base and ABS brake systems.

REAR WHEEL SPEED SENSOR

-AWD

REMOVAL

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

CAUTION: When disconnecting speed sensor cable

from vehicle wiring harness be careful not to dam-

age pins on the electrical connectors. Also, inspect

connectors for any signs of previous damage.

(2) Remove grommet from floor pan of vehicle and

disconnect speed sensor cable connector from vehicle

wiring harness.

CAUTION: When removing rear wheel speed sensor

cable from routing clips, be sure not to damage the

routing clips. Routing clips that are molded onto

the brake hose will require replacement of the brake

hose if damaged during removal or installation of

the speed sensor cable.

(3) Carefully remove speed sensor cable from

press-in routing clips along brake hose and tubing.(4) Remove bolt securing wheel speed sensor cable

metal clip to rear of axle. Remove metal clip from

cable if necessary.

CAUTION: If speed sensor head has seized due to

corrosion, do not use pliers on speed sensor head

in an attempt to remove it. Use a hammer and a

punch and tap mounting flange edge side-to-side,

rocking the sensor until free.

(5) Remove wheel speed sensor head attaching

bolt.

(6) Remove wheel speed sensor head from the axle,

and remove sensor from vehicle.

INSTALLATION

CAUTION: Proper installation of wheel speed sen-

sor cables is critical to continued system operation.

Be sure that cables are installed in retainers. Fail-

ure to install cables in retainers as indicated may

result in contact with moving parts or over-exten-

sion of cables, resulting in an open circuit.

(1) Install wheel speed sensor head in axle flange.

CAUTION: Prior to installing the speed sensor head

attaching bolt, the plastic anti-rotation pin must be

fully seated into the bearing flange.

(2) Install wheel speed sensor head attaching bolt.

Tighten bolt to a torque 10 N´m (90 in. lbs.).

(3) Check the air gap between the face of the

wheel speed sensor and the top surface of the tone

wheel. (Refer to 5 - BRAKES - SPECIFICATIONS)

CAUTION: When installing wheel speed sensor

cable in the routing clips on rear brake flex hose,

be sure not to damage the routing clips. Routing

clips are molded onto the hose and will require

replacement of the brake hose if damaged.

(4) Install speed sensor cable under leaf spring

onto brake hose and tubing utilizing routing clips to

secure it in place.

(5) Install metal routing clip on speed sensor cable

and mount it to rear of axle with mounting bolt.

Tighten mounting bolt to 16 N´m (140 in. lbs.).

(6) Connect wheel speed sensor cable to vehicle

wiring harness.Be sure speed sensor cable con-

nector is fully seated and locked into vehicle

wiring harness connector.

(7) Install speed sensor cable grommet into the

floor pan, being sure the grommet is fully seated into

the access hole.

(8) Lower vehicle.

(9) Road test vehicle to ensure proper operation of

the base and ABS braking systems.

5 - 92 BRAKES - ABSRS

FRONT WHEEL SPEED SENSOR (Continued)

Page 221 of 2339

OPERATION

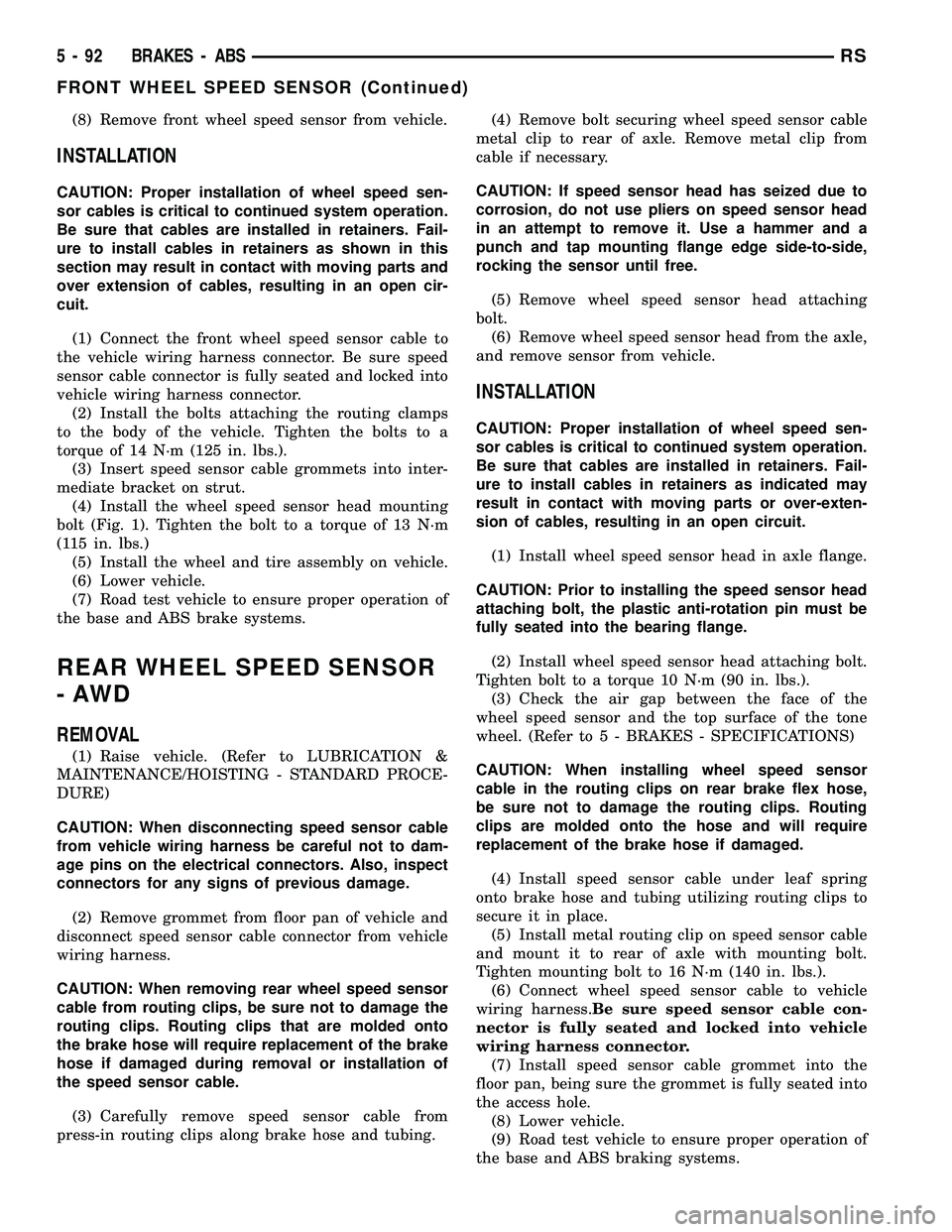

OPERATION - COOLING SYSTEM

The engine cooling systems primary purpose is to

maintain engine temperature in a range that will

provide satisfactory engine performance and emission

levels under all expected driving conditions. It also

provides hot water (coolant) for heater performance

and cooling for automatic transmission oil. It does

this by transferring heat from engine metal to cool-

ant, moving this heated coolant to the radiator, and

then transferring this heat to the ambient air.

²When engine is cold: thermostat is closed, cool-

ing system has no flow through the radiator. The

coolant bypass flows through the engine only.

²When engine is warm: thermostat is open, cool-

ing system has bypass flow and coolant flow through

radiator.

Coolant flow circuits for the 2.4L and 3.3/3.8L

engines are shown in (Fig. 2).

OPERATION - HOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, use Special Tool 6094 or equivalent, con-

stant tension clamp pliers (Fig. 3) to compress the

hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING SYSTEM

LEAK TEST

WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

Fig. 2 Cooling System Flow

1 - HEATER - REAR (3.3/3.8L OPTIONAL EQUIPMENT) 6 - WATER PUMP

2 - HEATER - FRONT 7 - RADIATOR

3 - ENGINE 8 - COOLANT RECOVERY/RESERVE CONTAINER

4 - THERMOSTAT 9 - COOLANT FLOW - PRESSURE CAP VACUUM

5 - ENGINE OIL COOLER (3.3/3.8L OPTIONAL EQUIPMENT) 10 - COOLANT FLOW - PRESSURE CAP RELIEF

7 - 2 COOLINGRS

COOLING (Continued)

Page 280 of 2339

CHIME/BUZZER

TABLE OF CONTENTS

page page

CHIME/BUZZER

DESCRIPTION..........................1

OPERATION............................1

WARNING.............................2

DIAGNOSIS AND TESTING - CHIME SYSTEM . . 2

PARK ASSIST DISPLAY

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................4

INSTALLATION..........................4PARK ASSIST MODULE

DESCRIPTION..........................4

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................6

PARK ASSIST SENSOR

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

CHIME/BUZZER

DESCRIPTION

The chime/buzzer system provides the driver with

warning chimes for:

²Seat Belt

²Exterior Lamps ON

²Key-In Ignition

²Engine Temperature Critical

²Turn Signals ON

²Dome Lamp ON

²Low Oil Pressure

²High Speed Warning

²Warning Lamp Announcement

²Key-In Accessory

²Low/High Tire Pressure

²Service Tire Pressure Monitor (TPM)

HIGH SPEED WARNING - EXPORT

The chime will sound, acting as a warning to the

driver that the vehicle speed has exceeded 120 3

Kp/h (75 2 mph).

Refer to the proper body diagnostic information

diagnosis and testing with a scan tool.

PARK ASSIST SYSTEM

The Park Assist System is an electronic parking

aid that alerts the driver to obstacles which are

located immediately behind the vehicle. Objects are

sensed using ultrasonic sound waves. When an object

is detected, the system will give the driver visual and

audible warnings. The system is customer program-

mable through the Electronic Vehicle Information

Center (EVIC) but will be enabled from the factory

as a default.

The major components of the park assist system

are:²Park Assist Module- supplies voltage to the

object detection sensors and park assist display. It

triggers the sensors, analyzes the echo delay times

and calculates obstacle distances. It sends display

information to the park assist display, performs sys-

tem diagnostics, and communicates via the Program-

mable Communication Interface (PCI) date bus

network.

²Park Assist Sensors- there are four sensors

located in the rear bumper that generate ultrasonic

pulses when triggered by the park assist module. The

sensors signal the park assist module when reflected

ultrasonic pulses are received.

²Park Assist Display- there are sixteen Light

Emitting Diode (LED) indicators which provide indi-

cation of relative distance to obstacles. When the sys-

tem is engaged and no obstacles are detected, the

two outermost yellow LED's are lit at reduced bright-

ness to show the system is working. As the distance

to a detected obstacle decreases, more yellow LED's

towards the center of the display illuminate.

For diagnosis and testing of the park assist sys-

tem, use a scan tool and the appropriate body diag-

nostic information.

OPERATION

Refer to the proper Body Diagnostic Procedures

manual for complete chime/buzzer operation and con-

ditions for operation.

HIGH SPEED WARNING - EXPORT

When the vehicle speed sensor sees 120 3 Km/h

(75 2 mph), it sends a PCI data bus message to the

Body Control Module (BCM). The BCM then turns on

the chime to let the driver know that the vehicle has

reached a speed greater than 120 3 Km/h (75 2

mph). This audible message will continue until the

vehicle is slowed below the predetermined speed.

RSCHIME/BUZZER8B-1

Page 282 of 2339

NO FASTEN SEAT BELT LAMP WHEN IGNITION

SWITCH IS TURNED ON.

(1) Check for burned out lamp.

(2) Using a voltmeter check for voltage at the clus-

ter connector:

(a) Pin 2 of the mechanical instrument cluster

for battery feed.

(b) Pin 11 of the mechanical instrument cluster

for ignition voltage.

(3) Repair as necessary.

FASTEN SEAT BELT LAMP OR TONE CONTINUES

FOR MORE THAN 10 SECONDS AFTER SEAT

BELTS ARE FASTENED AND DRIVER'S DOOR IS

CLOSED.

Refer to the proper Body Diagnostic Procedures

manual.

NO TONE WHEN PARK OR HEADLAMPS ARE ON

AND DRIVER'S DOOR IS OPEN.

Make sure ignition is in lock position with the key

removed.

(1) Check the BCM DTC's and BCM sensors to

verify the door is open. Repair as necessary.

(2) Actuate Chime (BCM actuates).

(3) Inspect BCM connectors and wires for proper

connection.

(4) Measure with a voltmeter the voltage (12v) on

BCM connector (PX2) pin 34 with harness connected.

(5) Check BCM sensors to verify headlamp switch

position.

PARK ASSIST DISPLAY

DESCRIPTION

The Park Assist Display is located in the rear of

vehicle, over the rear window in the headliner (Fig.

1). It is a molded plastic unit housing Light Emitting

Diodes (LED's) and a chime module. Located in the

rear of the vehicle for easy visual reference when the

driver is backing up.

The display is used to alert the driver of any obsta-

cles detected in the rear of the vehicle. The chime or

audible signal also comes from the display unit.

OPERATION

When the ignition is put in the RUN position, all

the Light Emitting Diodes (LED's) will illuminate for

approximately one second. This will be interrupted if

the system senses an obstacle.

The ready status will be sensed by the outermost

two yellow LED's being illuminated at 50% intensity.

As the obstacle is sensed, the yellow LED's will start

illuminating inward until the object in approximately

one foot away and then the inner red LED will light.

The display is sensitive to which side of the rear of

the vehicle that the object is detected. If on the left

rear, the left segments will light and the same for the

right side of the vehicle.

Fig. 1 PARK ASSIST DISPLAY

RSCHIME/BUZZER8B-3

CHIME/BUZZER (Continued)

Page 288 of 2339

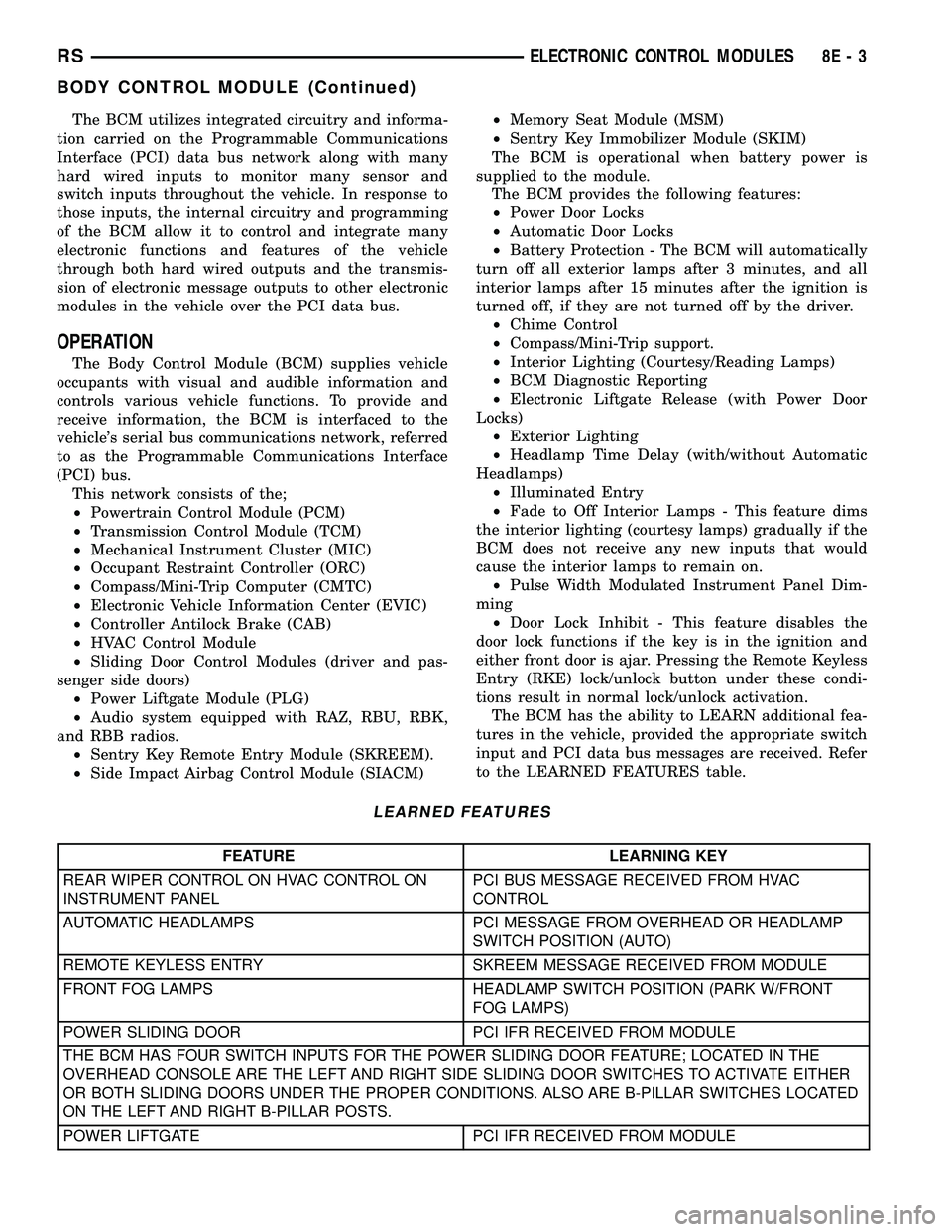

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus.

OPERATION

The Body Control Module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the BCM is interfaced to the

vehicle's serial bus communications network, referred

to as the Programmable Communications Interface

(PCI) bus.

This network consists of the;

²Powertrain Control Module (PCM)

²Transmission Control Module (TCM)

²Mechanical Instrument Cluster (MIC)

²Occupant Restraint Controller (ORC)

²Compass/Mini-Trip Computer (CMTC)

²Electronic Vehicle Information Center (EVIC)

²Controller Antilock Brake (CAB)

²HVAC Control Module

²Sliding Door Control Modules (driver and pas-

senger side doors)

²Power Liftgate Module (PLG)

²Audio system equipped with RAZ, RBU, RBK,

and RBB radios.

²Sentry Key Remote Entry Module (SKREEM).

²Side Impact Airbag Control Module (SIACM)²Memory Seat Module (MSM)

²Sentry Key Immobilizer Module (SKIM)

The BCM is operational when battery power is

supplied to the module.

The BCM provides the following features:

²Power Door Locks

²Automatic Door Locks

²Battery Protection - The BCM will automatically

turn off all exterior lamps after 3 minutes, and all

interior lamps after 15 minutes after the ignition is

turned off, if they are not turned off by the driver.

²Chime Control

²Compass/Mini-Trip support.

²Interior Lighting (Courtesy/Reading Lamps)

²BCM Diagnostic Reporting

²Electronic Liftgate Release (with Power Door

Locks)

²Exterior Lighting

²Headlamp Time Delay (with/without Automatic

Headlamps)

²Illuminated Entry

²Fade to Off Interior Lamps - This feature dims

the interior lighting (courtesy lamps) gradually if the

BCM does not receive any new inputs that would

cause the interior lamps to remain on.

²Pulse Width Modulated Instrument Panel Dim-

ming

²Door Lock Inhibit - This feature disables the

door lock functions if the key is in the ignition and

either front door is ajar. Pressing the Remote Keyless

Entry (RKE) lock/unlock button under these condi-

tions result in normal lock/unlock activation.

The BCM has the ability to LEARN additional fea-

tures in the vehicle, provided the appropriate switch

input and PCI data bus messages are received. Refer

to the LEARNED FEATURES table.

LEARNED FEATURES

FEATURE LEARNING KEY

REAR WIPER CONTROL ON HVAC CONTROL ON

INSTRUMENT PANELPCI BUS MESSAGE RECEIVED FROM HVAC

CONTROL

AUTOMATIC HEADLAMPS PCI MESSAGE FROM OVERHEAD OR HEADLAMP

SWITCH POSITION (AUTO)

REMOTE KEYLESS ENTRY SKREEM MESSAGE RECEIVED FROM MODULE

FRONT FOG LAMPS HEADLAMP SWITCH POSITION (PARK W/FRONT

FOG LAMPS)

POWER SLIDING DOOR PCI IFR RECEIVED FROM MODULE

THE BCM HAS FOUR SWITCH INPUTS FOR THE POWER SLIDING DOOR FEATURE; LOCATED IN THE

OVERHEAD CONSOLE ARE THE LEFT AND RIGHT SIDE SLIDING DOOR SWITCHES TO ACTIVATE EITHER

OR BOTH SLIDING DOORS UNDER THE PROPER CONDITIONS. ALSO ARE B-PILLAR SWITCHES LOCATED

ON THE LEFT AND RIGHT B-PILLAR POSTS.

POWER LIFTGATE PCI IFR RECEIVED FROM MODULE

RSELECTRONIC CONTROL MODULES8E-3

BODY CONTROL MODULE (Continued)

Page 292 of 2339

FRONT CONTROL MODULE

DESCRIPTION

The Front Control Module (FCM) is a micro con-

troller based module located in the engine compart-

ment. The FCM mates to the Power Distribution

Center (PDC) to form the Integrated Power Module

(IPM). The IPM connects directly to the battery and

provides the primary means of circuit protection and

power distribution for all vehicle electrical systems.

The FCM controls power to some of these vehicle sys-

tems electrical and electromechanical loads based on

inputs received from hard wired switch inputs and

data received on the Programmable Communications

Interface (PCI) data bus.

For information on the IPM, (Refer to 8 - ELEC-

TRICAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - DESCRIPTION)

OPERATION

As messages are sent over the Programmable Com-

munications Interface (PCI) data bus, the Front Con-

trol Module (FCM) reads these messages and controls

power to some of the vehicles electrical systems by

completing the circuit to ground (low side driver) or

completing the circuit to 12 volt power (high side

driver).

The following functions arecontrolledby the

Front Control Module:

²Accessory Relay Actuation

²Brake Transmission Shift Interlock Functions

(BTSI - gas engine only)

²Diesel Cabin Heater (Diesel Engine Vehicles)

²Electronic Back Light (EBL) Rear Defogger

²Front and Rear Blower Motor Relay Actuation

²Front Fog Lamp Relay Actuation

²Washer Motor (front and rear)

²Front Windshield Wiper ªHIº & ªLOº Relay

Actuation

²Front Windshield Wiper ªONº Relay Actuation

²Headlamp Power with Voltage Regulation

²Horn Relay Actuation

²Headlamp Washer Relay Actuation (IF

EQUIPPED - EXPORT ONLY)

²Name Brand Speaker (NBS) Relay Actuation

²Park Lamp Relay Actuation

The following inputs areReceived/Monitoredby

the Front Control Module:

²Ambient Temperature Sensing

²Back-Up switch

²Brake Fluid Level

²B+ Connection Detection

²Engine Crank Signal (Diesel Engine Vehicles)

²Horn Input

²Ignition Switch Start Only

²Ignition Switch Run and Start Only²Stop Lamp Sense

²Washer Fluid Level

²Windshield Wiper Park

DIAGNOSIS AND TESTING

FRONT CONTROL MODULE

The Front Control Module (FCM) is a printed cir-

cuit board based module with a on-board micro-pro-

cessor. The FCM interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus. In order to

obtain conclusive testing the PCI data bus and all of

the electronic modules that provide inputs to, or

receive outputs from the FCM must be checked. All

PCI communication faults must be resolved prior to

further diagnosing any front control module related

issues.

The FCM was designed to be diagnosed with an

appropriate diagnostic scan tool, such as the DRB

IIIt. The most reliable, efficient, and accurate means

to diagnose the front control module requires the use

of a DRB IIItscan tool and the proper Body Diag-

nostic Procedures manual.

Before any testing of the FCM is attempted, the

battery should be fully charged and all wire harness

and ground connections inspected around the affected

areas on the vehicle.

REMOVAL

(1) Disconnect and isolate the negative and posi-

tive battery cables from the battery.

(2) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(3) Using a long flat-bladed screwdriver, gently

twist the Integrated Power Module (IPM) retaining

clip outboard to free the IPM from its mounting

bracket (Fig. 5). Rotate IPM upward to access the

Front Control Module (FCM) retaining screws.

(4) Remove the front control module retaining

screws.

(5) Pull the FCM straight from the IPM assembly

to disconnect the electrical connector (Fig. 6) and

remove the FCM from the vehicle.

INSTALLATION

NOTE: Front Control Module must be programmed

to the correct radio EQ curve using the DRB IIIT.

This will ensure that the audio system is operating

correctly.

(1) Install the Front Control Module (FCM) in the

Integrated Power Module (IPM) assembly by pushing

the 49-way electrical connector straight in.

RSELECTRONIC CONTROL MODULES8E-7

Page 347 of 2339

OPERATION

When the rear window defogger button is

depressed to the On position, current is directed to

the rear defogger grid lines and the heated power

mirrors (if equipped). The heated grid lines heat the

glass to help clear the rear window and side mirror

surfaces of fog or frost.

The electric backlight (EBL) system is controlled

by a momentary switch located in the A/C-heater

control on the instrument panel. A yellow indicator in

the switch will illuminate to indicate when the sys-

tem is turned on. The integrated power module (IPM)

contains the EBL system control circuitry.

NOTE: The rear window defogger turns off automat-

ically after approximately 10 minutes of initial oper-

ation. Each following activation cycle of the

defogger system will last approximately five min-

utes.

The EBL system will be automatically turned off

after a programmed time interval of about ten min-

utes. After the initial time interval has expired, if the

defogger switch is turned on again during the same

ignition cycle, the defogger system will automatically

turn off after about five minutes.

The EBL system will automatically shut off if the

ignition switch is turned to the Off position, or it can

be turned off manually by depressing the defogger

switch a second time.

DIAGNOSIS AND TESTING

ELECTRIC BACKLIGHT (EBL) SYSTEM

NOTE: Illumination of the defogger switch indicator

lamp means that there is electrical current available

at the output of the rear window defogger logic cir-

cuitry, but does not confirm that the electrical cur-

rent is reaching the rear glass heating grid lines.

NOTE: For circuit descriptions and diagrams of the

rear window defogger system, refer to 8W - WIRING

DIAGRAM INFORMATION.

Operation of the electrical backlight (EBL) system

can be confirmed by the following:(1) Turn the ignition switch to the On position. Set

the defogger switch in the On position. The rear win-

dow defogger operation can be checked by feeling the

rear window glass. A distinct difference in tempera-

ture between the grid lines and the adjacent clear

glass can be detected within three to four minutes of

operation.

(2) If a temperature difference is not detected, use

a 12-volt DC voltmeter and contact the rear glass

heating grid terminal B with the negative lead, and

terminal A with the positive lead (Fig. 2). The volt-

meter should read battery voltage. If the voltmeter

does not read battery voltage, check the following:

²Confirm that the ignition switch is in the On

position.

²Make sure that the rear glass heating grid feed

wire and ground wire are connected to the terminals.

Confirm that the ground wire has continuity to

ground.

²Check that fuse 13 (40 amp) in the integrated

power module (IPM) is OK. The fuse must be tight in

it's receptacle and all electrical connections must be

secure.

(3) When the above steps have been completed and

the rear glass heating grid is still inoperative, one or

more of the following is faulty. It may be necessary to

connect a DRBIIItscan tool to perform further diag-

nostics. Refer to Body Diagnostic Procedures.

²Rear window defogger switch in the A/C-heater

control.

²J1850 bus communication between the A/C-

heater control and the front control module (FCM).

²Rear window defogger (EBL) relay in the IPM.

²Rear window defogger (EBL) relay control circu-

ity in the IPM.

²Check for a loose wire connector or a wire

pushed out of a connector.

²Rear window grid lines (all grid lines would

have to be broken, or the power feed or ground wire

not connected, for the entire heating grid to be inop-

erative).

(4) If the system operation has been verified but

defogger switch LED indicator does not illuminate,

replace the A/C-heater control.

8G - 2 HEATED GLASSRS

HEATED GLASS (Continued)

Page 349 of 2339

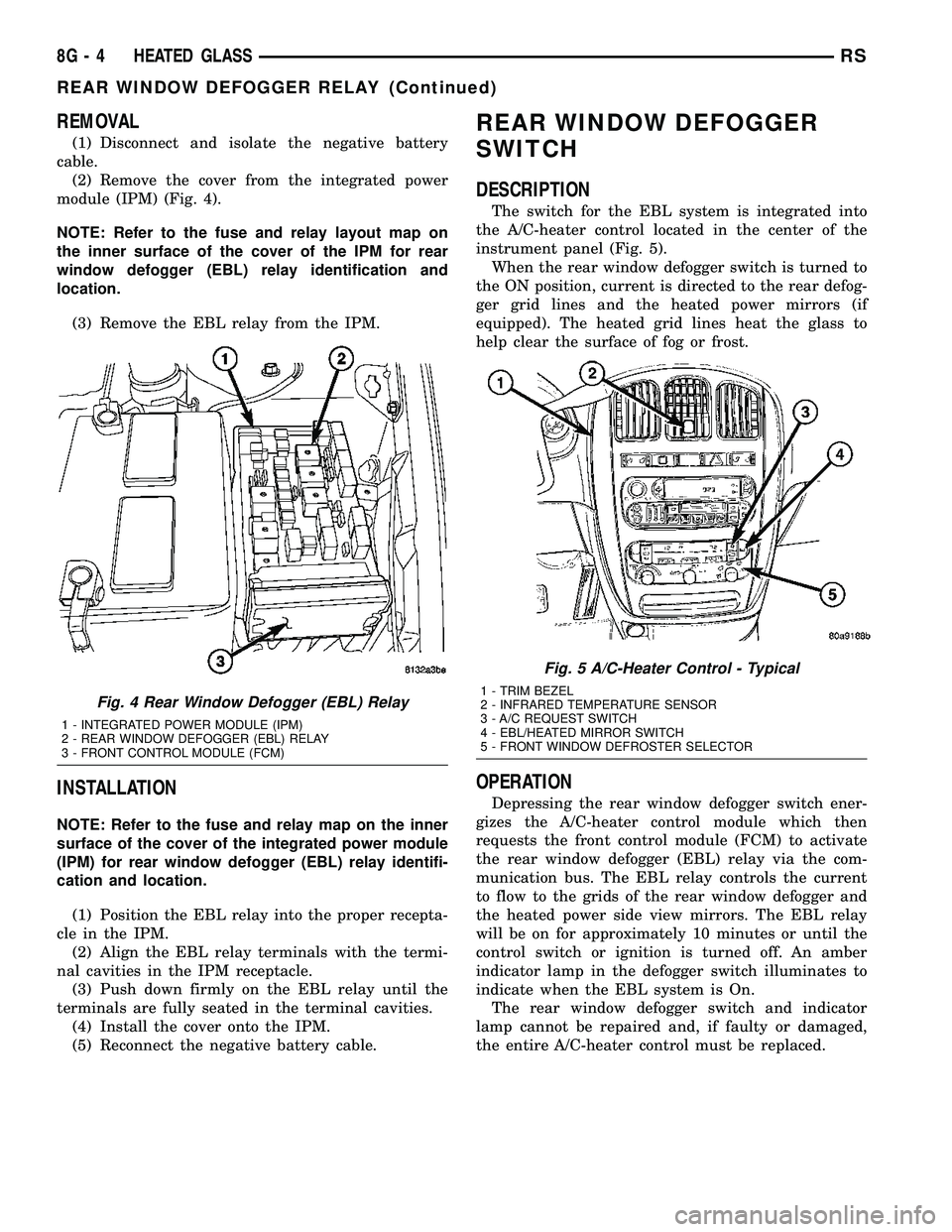

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the integrated power

module (IPM) (Fig. 4).

NOTE: Refer to the fuse and relay layout map on

the inner surface of the cover of the IPM for rear

window defogger (EBL) relay identification and

location.

(3) Remove the EBL relay from the IPM.

INSTALLATION

NOTE: Refer to the fuse and relay map on the inner

surface of the cover of the integrated power module

(IPM) for rear window defogger (EBL) relay identifi-

cation and location.

(1) Position the EBL relay into the proper recepta-

cle in the IPM.

(2) Align the EBL relay terminals with the termi-

nal cavities in the IPM receptacle.

(3) Push down firmly on the EBL relay until the

terminals are fully seated in the terminal cavities.

(4) Install the cover onto the IPM.

(5) Reconnect the negative battery cable.

REAR WINDOW DEFOGGER

SWITCH

DESCRIPTION

The switch for the EBL system is integrated into

the A/C-heater control located in the center of the

instrument panel (Fig. 5).

When the rear window defogger switch is turned to

the ON position, current is directed to the rear defog-

ger grid lines and the heated power mirrors (if

equipped). The heated grid lines heat the glass to

help clear the surface of fog or frost.

OPERATION

Depressing the rear window defogger switch ener-

gizes the A/C-heater control module which then

requests the front control module (FCM) to activate

the rear window defogger (EBL) relay via the com-

munication bus. The EBL relay controls the current

to flow to the grids of the rear window defogger and

the heated power side view mirrors. The EBL relay

will be on for approximately 10 minutes or until the

control switch or ignition is turned off. An amber

indicator lamp in the defogger switch illuminates to

indicate when the EBL system is On.

The rear window defogger switch and indicator

lamp cannot be repaired and, if faulty or damaged,

the entire A/C-heater control must be replaced.

Fig. 4 Rear Window Defogger (EBL) Relay

1 - INTEGRATED POWER MODULE (IPM)

2 - REAR WINDOW DEFOGGER (EBL) RELAY

3 - FRONT CONTROL MODULE (FCM)

Fig. 5 A/C-Heater Control - Typical

1 - TRIM BEZEL

2 - INFRARED TEMPERATURE SENSOR

3 - A/C REQUEST SWITCH

4 - EBL/HEATED MIRROR SWITCH

5 - FRONT WINDOW DEFROSTER SELECTOR

8G - 4 HEATED GLASSRS

REAR WINDOW DEFOGGER RELAY (Continued)

Page 350 of 2339

REAR WINDOW DEFOGGER

GRID

STANDARD PROCEDURE

GRID REPAIR PROCEDURE

WARNING: Materials contained in the Repair Kit

(Part Number 04549275) may cause skin or eye irri-

tation. The kit contains epoxy resin and amine type

hardener, which are harmful if swallowed. Avoid

contact with the skin and eyes. For skin contact,

wash the affected areas with soap and water. For

contact with the eyes, flush with plenty of water. Do

not take internally. If taken internally, induce vomit-

ing and call a physician immediately. Use with ade-

quate ventilation. Do not use near fire or flame.

Contains flammable solvents. Keep out of the reach

of children. Failure to follow the warnings could

result in possible personal injury or death.

Repair of the rear glass heating grid lines, bus

bars or terminals can be accomplished using the

MopartRear Window Defogger Repair Kit (Part

Number 04549275) or equivalent.

(1) Mask the repair area with masking tape so

that the conductive epoxy can be applied neatly (Fig.

6). Extend the epoxy application onto the grid line or

the bus bar on each side of the break.

(2) Follow the instructions in the repair kit for

preparing the damaged area.

(3) Remove the package separator clamp and mix

the two conductive epoxy components thoroughly

within the packaging. Fold the package in half and

cut the center corner to dispense the epoxy.

(4) For grid line repairs, mask the area to be

repaired with masking tape or use a template.

(5) Apply the epoxy through the slit in the mask-

ing tape or template. Overlap both ends of the break

by at least 19 millimeters (0.75 inch).

(6) For a terminal replacement, mask the adjacent

areas so the epoxy can be extended onto the adjacent

grid line as well as the bus bar. Apply a thin layer of

epoxy to the area where the terminal was fastened

and onto the adjacent grid line.(7) Apply a thin layer of conductive epoxy to the

terminal and place it in the proper location on the

bus bar. To prevent the terminal from moving while

the epoxy is curing, it must be wedged or clamped.

(8) Carefully remove the masking tape or tem-

plate.

CAUTION: Do not allow the glass surface to exceed

204É C (400É F) when using a heat gun, or the glass

may fracture.

(9) Allow the epoxy to cure 24 hours at room tem-

perature, or carefully use a heat gun for fifteen min-

utes. When using a heat gun, hold it approximately

25.4 centimeters (10 inches) from the repair and do

not allow the glass surface to exceed 204É C (400É F).

NOTE: Do not attach the wire harness connectors

to the terminals until the curing process is com-

plete.

(10) After the conductive epoxy is properly cured,

remove the wedge or clamp from the terminal.

(11) Connect the wire harness leads to the grid

terminals and verify EBL operation.

Fig. 6 Grid Line Repair

1 - BREAK

2 - GRID LINE

3 - MASKING TAPE

RSHEATED GLASS8G-5