CHRYSLER VOYAGER 2005 Service Manual

Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 481 of 2339

(7) Pull back the sealing patches and remove the

lower track retaining nuts (Fig. 24).

(8) Carefully remove the lower sliding door track

from the vehicle.

INSTALLATION

(1) Carefully position the lower sliding door track

in the vehicle.

(2) Install the lower track retaining nuts and

install the sealing patches, (Fig. 25). Torque the nuts

to 8 N´m (70 in. lbs).

(3) Install the lower hinge assembly on the door,

(Refer to 23 - BODY/DOORS - SLIDING/LOWER

ROLLER ARM - INSTALLATION).NOTE: Take care to locate the lower hinge assem-

bly on the door in its original position (ie. match

screw washer with rings left on hinge). Adjust door

fit if required, (Refer to 23 - BODY/DOORS - SLID-

ING/SLIDING DOOR - ADJUSTMENTS).

(4) Remove the floor jack.

(5) Install the hold-open striker, (Refer to 23 -

BODY/DOORS - SLIDING/HOLD OPEN LATCH

STRIKER - INSTALLATION).

(6) Install the side door sill plate, (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION).

(7) Connect the battery negative cable.

Fig. 24 Lower Track Retaining Nuts

1 - Lower Track Retaining Nuts

2 - Lower Door Track

Fig. 25 Lower Track Retaining Nuts

1 - Lower Track Retaining Nuts

2 - Lower Door Track

8N - 58 POWER SLIDING DOOR SYSTEMRS

LOWER DRIVE UNIT TRACK & RACK (Continued)

Page 482 of 2339

WIRING HARNESS

DESCRIPTION

The wire harness supplies power (12v), ground and

various electrical signals to the power sliding door for

various power door functions. A plastic chain or wir-

ing track covers the wire harness assembly (Fig. 26)

and is used to protect the wire harness from abrasion

and/or tangling. This wiring track is replaced with

the wire harness assembly. The wire harness assem-

bly is a replaceable component.

OPERATION

The wire harness and plastic wiring track provide

a safe and reliable means of supplying power, ground

and other various electrical connections to the power

sliding door. During sliding door movement the wir-

ing track folds and unfolds like the links in a chain.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the appropriate door trim panel from

the power sliding door, (Refer to 23 - BODY/DOORS -

SLIDING/TRIM PANEL - REMOVAL).

(3) Remove the lower drive unit cover retaining

screws and remove the cover (Fig. 27).(4) Disconnect the power sliding door electrical

connector, located just behind the lower drive unit

assembly.

(5) Disengage retaining pushpin and pull wire har-

ness away from its power sliding door mounting loca-

tion.

(6) Using a suitable flat bladed tool, unsnap the

wire harness retaining clip from the lower drive unit.

(7) Slide the wire harness off the forward lower

drive unit stud.

(8) Using a pushpin removal tool (special tool #

C-4755), unsnap wire harness retaining pushpins

from the rocker panel.

(9) Remove sliding door lower sill plate, (Refer to

23 - BODY/INTERIOR/SLIDING DOOR SILL PLATE

- REMOVAL).

(10) Pull back the rearward edge of the B-pillar

trim to access the wire harness connector and discon-

nect connector.

(11) Remove the wire harness assembly from the

vehicle.INSTALLATION

(1) Position the wire harness assembly in the vehi-

cle.

(2) Connect the wire harness connector located at

the rearward edge of the B-pillar.

Fig. 26 WIRE HARNESS POSITION AND

ORIENTATION

1 - LOWER DOOR TRACK AND RACK ASSEMBLY

2 - WIRE HARNESS

3 - RACK ACCESS HOLE SEALING PATCHES

4 - LOWER DRIVE UNIT COVER

Fig. 27 LOWER HINGE/DRIVE ASSEMBLY

1 - LOWER DRIVE UNIT COVER

2 - LOWER DRIVE UNIT COVER RETAINING SCREWS

3 - SLIDING DOOR

4 - LOWER HINGE ARM BRACKET

RSPOWER SLIDING DOOR SYSTEM8N-59

Page 483 of 2339

(3) Install the sliding door lower sill plate, (Refer

to 23 - BODY/INTERIOR/SLIDING DOOR SILL

PLATE - INSTALLATION).

(4) Snap the wire harness retaining pushpins in

the rocker panel.

(5) Slide the wire harness on the lower drive unit

stud.

(6) Install the wire harness retaining clip on the

lower drive unit stud.

(7) Connect the power sliding door electrical con-

nector, located just behind the lower drive unit.

(8) Install the lower drive unit cover and retaining

screws (Fig. 28).

(9) Install the appropriate sliding door trim panel,

(Refer to 23 - BODY/DOORS - SLIDING/TRIM

PANEL - INSTALLATION).

(10) Connect the battery negative cable.

Fig. 28 LOWER HINGE/DRIVE ASSEMBLY

1 - LOWER DRIVE UNIT COVER

2 - LOWER DRIVE UNIT COVER RETAINING SCREWS

3 - SLIDING DOOR

4 - LOWER HINGE ARM BRACKET

8N - 60 POWER SLIDING DOOR SYSTEMRS

WIRING HARNESS (Continued)

Page 484 of 2339

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................61

OPERATION...........................61

DIAGNOSIS AND TESTING

POWER WINDOWS....................61

VENT WINDOW MOTOR

DIAGNOSIS AND TESTING

VENT WINDOW MOTOR................62

REMOVAL.............................62INSTALLATION.........................62

WINDOW MOTOR

REMOVAL.............................62

WINDOW SWITCH

DIAGNOSIS AND TESTING

WINDOW SWITCH....................63

REMOVAL.............................64

INSTALLATION.........................64

POWER WINDOWS

DESCRIPTION

The Power Window System is activated through

switches mounted on the driver and passenger door

panels.

OPERATION

Front door window lift motors use permanent type

magnets. The B+ and ground applied at the motor

terminal pins will cause the motor to rotate in one

direction. Reversing current through the motor ter-

minals will cause the motor to rotate in the opposite

direction.

The power window motors ground through the

master switch in the driver door by a black wire

attached to the left cowl panel. Refer to the appropri-

ate wiring information.

The power rear vent windows, if equipped, are

operated by switches mounted in the driver door

switch bezel. A separate switch is used for each win-

dow. Permanent magnet type motors connected to a

crank system are used to open and close the rear

vent windows. A battery positive and negative con-

nection to either of the two motor terminals will

cause the motor to rotate in one direction. Reversing

current through these same two connections will

cause the motor to rotate in the opposite direction.

DIAGNOSIS AND TESTING

POWER WINDOWS

POWER WINDOW MOTOR TEST

If the power window motor is receiving proper cur-

rent and ground and does not operate, proceed withmotor test. Refer to the appropriate wiring informa-

tion.

(1) Remove front door trim panel and sound pad as

necessary to gain access to power window motor wire

connector, (Refer to 23 - BODY/DOOR - FRONT/

TRIM PANEL - REMOVAL).

(2) Disconnect power window motor wire connector

from door harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window up or

down. If window is all the way up or down the motor

will grunt and the inner door panel will flex when

actuated in that one direction.

(6) Reverse jumper probes at the motor connector

terminals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely up or down, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that reg-

ulator is not binding.

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

(1) Remove the power window switch and bezel

assembly from the driver door. (Refer to 8 - ELEC-

TRICAL/POWER WINDOWS/POWER WINDOW

SWITCH - REMOVAL).

(2) Disconnect wire connector from back of power

window switch.

RSPOWER WINDOWS8N-61

Page 485 of 2339

(3) Switch ignition ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 13 in door harness connector at the window

switch. Touch the test light probe to Pin 9 and then

to Pin 11.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If the lamp does not illuminate, first check the

25 amp circuit breaker attached to the electrical dis-

tribution wiring bracket. If the circuit breaker is OK,

then check the 40 amp fuse (#28) in the Integrated

Power Module (IPM). If both components are OK,

then check for a broken wire.

VENT WINDOW MOTOR

DIAGNOSIS AND TESTING

VENT WINDOW MOTOR

If the power vent window motor is receiving proper

current and ground and does not operate proceed

with motor test. Refer to the appropriate wiring

information.

(1) Remove D-pillar trim panel necessary to gain

access to power vent window motor wire connector,

(Refer to 23 - BODY/INTERIOR/LEFT D-PILLAR

TRIM PANEL - REMOVAL) or (Refer to 23 - BODY/

INTERIOR/RIGHT D-PILLAR TRIM PANEL -

REMOVAL).

(2) Disconnect power vent window motor wire con-

nector from body harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window open or

closed. If window is all the way open or closed the

motor will grunt and the crank system will flex when

actuated in that one direction.

Reverse jumper probes at the motor connector ter-

minals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely open or closed, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that

crank system is not binding.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.(2) Remove D-pillar trim panel. (Refer to 23 -

BODY/INTERIOR/LEFT D-PILLAR TRIM PANEL -

REMOVAL) or (Refer to 23 - BODY/INTERIOR/

RIGHT D-PILLAR TRIM PANEL - REMOVAL).

(3) Disconnect wire connector from power vent

motor.

(4) Using a flat bladed tool, carefully lift the circu-

lar actuator link tab. Remove link from window ball

socket.

(5) Remove bolts holding power vent motor to

D-pillar (Fig. 1).

(6) Remove power vent motor.

INSTALLATION

(1) Obtain new vent window motor.

(2) Snap the actuator link socket onto the quarter

window ball socket. Using a soft rubber mallet, push

the circular link tab flush with link surface.

(3) Install bolts holding power vent motor to D-pil-

lar.

(4) Reconnect wire connector to power vent motor.

(5) Reconnect the battery negative cable.

(6) Cycle quarter window open/close to verify func-

tion.

(7) Install D-pillar trim panel.

WINDOW MOTOR

REMOVAL

The window motor is incorporated into the window

regulator assembly. If the window motor requires

replacement, the window regulator must be replaced.

(Refer to 23 - BODY/DOOR - FRONT/WINDOW

REGULATOR - REMOVAL).

Fig. 1 VENT WINDOW MOTOR

1 - VENT WINDOW MOTOR

2 - WIRE HARNESS CONNECTOR

3 - BOLT

4 - VENT WINDOW

8N - 62 POWER WINDOWSRS

POWER WINDOWS (Continued)

Page 486 of 2339

WINDOW SWITCH

DIAGNOSIS AND TESTING

WINDOW SWITCH

(1) Remove the desired switch to be tested from

the door trim panel. Driver's side (master) or passen-

ger side. (Refer to 8 - ELECTRICAL/POWER WIN-

DOWS/POWER WINDOW SWITCH - REMOVAL).

(2) Using an ohmmeter, Test driver door switch for

continuity as described in (Fig. 2).

POWER WINDOW MASTER SWITCH TEST

SWITCH POSITION CONTINUITY BETWEEN

OFF 13 and 1

13 and 2

13 and 3

13 and 4

13 and 5

13 and 6

13 and 7

13 and 8

UP DRIVER 11 and 8

*DOWN DRIVER 11 and 6

*X DOWN DRIVER 11and 6

UP PASSENGER 9 and 4

DOWN PASSENGER 9 and 2

LEFT VENT OPEN 11 and 7

LEFT VENT CLOSE 9 and 3

RIGHT VENT OPEN 9 and 1

RIGHT VENT CLOSE 11 and 5

* MUST TEST WITH B+ ON PIN 9 AND

GROUND ON PIN 13 FOR CONTINUITY

BETWEEN PINS 11 AND 6

(3) If the result are not OK, replace the driver side

window lift switch.

(4) Test passenger door switch for continuity as

described in (Fig. 3).

PASSENGER WINDOW SWITCH TEST

SWITCH POSITION CONTINUITY BETWEEN

OFF 3 AND 8

OFF 2 AND 5

UP 1 AND 8

DOWN 1 AND 5

(5) If the results are not OK, replace the switch.

The power window master switch has a Auto-Down

feature. The switch is equipped with two detent posi-

tions when actuating the power window OPEN. The

first detent position allows the window to roll down

and stop when the switch is released. The second

detent position actuates an integral express roll

down relay that rolls the window down after the

switch is released. When the express down circuit

senses stall current (window has reached end of

down travel), the switch will turn current off to the

motor. The AUTO feature can be cancelled by actuat-

ing the switch UP or DOWN while window is in

motion. If the electronic circuit in the switch fails to

detect a stall current, the auto down circuit will time

out within 9 to 13 seconds.

Fig. 2 Power Window Master Switch Connector

Fig. 3 Passenger Door Power Window Switch

RSPOWER WINDOWS8N-63

Page 487 of 2339

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a trim stick, start at the bottom of the

switch and bezel assembly and pry up to remove the

switch and bezel assembly from the door trim panel

(Fig. 4).

(3) Unlatch the locking tab on the harness side

connector of the switch.

(4) Disconnect wire harness connectors from

switch.

INSTALLATION

(1) Reconnect wire harness connector to switch.

(2) Insert switch into door trim panel and press

into place.

(3) Reconnect battery negative cable.

Fig. 4 POWER WINDOW SWITCH

1 - DOOR TRIM PANEL

2 - POWER WINDOW SWITCH AND BEZEL ASSEMBLY

8N - 64 POWER WINDOWSRS

WINDOW SWITCH (Continued)

Page 488 of 2339

RESTRAINTS

TABLE OF CONTENTS

page page

RESTRAINTS

DESCRIPTION..........................2

OPERATION............................4

WARNING

WARNINGS...........................5

DIAGNOSIS AND TESTING - AIRBAG SYSTEM . 6

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

AIRBAGS.............................6

STANDARD PROCEDURE - SERVICE

AFTER AN AIRBAG DEPLOYMENT.........7

BELT TENSION SENSOR

DESCRIPTION..........................8

OPERATION............................9

CHILD RESTRAINT ANCHOR

DESCRIPTION..........................9

OPERATION...........................10

CLOCKSPRING

DESCRIPTION.........................10

OPERATION...........................11

STANDARD PROCEDURE - CLOCKSPRING

CENTERING.........................11

REMOVAL.............................12

INSTALLATION.........................12

CURTAIN AIRBAG

DESCRIPTION.........................12

OPERATION...........................13

REMOVAL.............................14

INSTALLATION.........................16

DRIVER AIRBAG

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................17

INSTALLATION.........................18

IMPACT SENSOR

DESCRIPTION.........................18

REMOVAL.............................19

INSTALLATION.........................21

KNEE BLOCKER AIRBAG

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................23

INSTALLATION.........................23

OCCUPANT CLASSIFICATION MODULE

DESCRIPTION.........................25

OPERATION...........................25

REMOVAL.............................26

INSTALLATION.........................26OCCUPANT RESTRAINT CONTROLLER

DESCRIPTION.........................27

OPERATION...........................28

REMOVAL.............................29

INSTALLATION.........................29

PASSENGER AIRBAG

DESCRIPTION.........................30

OPERATION...........................30

REMOVAL.............................30

INSTALLATION.........................32

PASSENGER AIRBAG DISABLED INDICATOR

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................34

INSTALLATION.........................34

SEAT BELT BUCKLE - FRONT INBOARD

REMOVAL.............................35

INSTALLATION.........................35

SEAT BELT BUCKLE - FIRST ROW INBOARD -

QUAD BUCKET

REMOVAL.............................35

INSTALLATION.........................36

SEAT BELT BUCKLE - FIRST ROW - BENCH

REMOVAL.............................36

INSTALLATION.........................37

SEAT BELT BUCKLE - SECOND ROW

INBOARD - 50/50 BENCH

REMOVAL.............................37

INSTALLATION.........................38

SEAT BELT HEIGHT ADJUSTER-BOR

C-PILLAR

REMOVAL.............................38

INSTALLATION.........................38

SEAT BELT HEIGHT ADJUSTER KNOB

REMOVAL.............................38

INSTALLATION.........................38

SEAT BELT & RETRACTOR - OUTBOARD -

FRONT

REMOVAL.............................38

INSTALLATION.........................39

SEAT BELT & RETRACTOR - FIRST ROW -

OUTBOARD

REMOVAL.............................39

INSTALLATION.........................40

SEAT BELT BUCKLE - SECOND ROW - THREE

PASSENGER BENCH

REMOVAL.............................40

INSTALLATION.........................40

RSRESTRAINTS8O-1

Page 489 of 2339

SEAT BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD

REMOVAL.............................40

INSTALLATION.........................40

SEAT BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD WITH REAR HVAC - LWB

REMOVAL.............................41

INSTALLATION.........................41

SEAT BELT & RETRACTOR - SECOND ROW -

LEFT OUTBOARD

REMOVAL.............................42INSTALLATION.........................42

SEAT BELT TENSIONER

DESCRIPTION.........................43

OPERATION...........................43

SEAT WEIGHT BLADDER & PRESSURE

SENSOR

DESCRIPTION.........................43

OPERATION...........................44

RESTRAINTS

DESCRIPTION

This vehicle is equipped with a Frontal Impact Air-

bag System, which utilizes the driver/passenger air-

bags, two front impact sensors, and seat belt

tensioners located in the front seat belt buckles. This

system is designed to protect occupants in the event

of a front impact collision. These airbags are all ser-

viceable parts. The tensioners are integral to the

front seat belt buckles. If these pyrotechnics are

deployed or defective, they must be replaced.

Vehicles equipped with the Side Impact Airbag

System utilize a curtain airbag, three side impact

sensors, and the Occupant Restraint Controller

(ORC) to determine if the airbag should be deployed.

Following a side impact event where the side airbag

was deployed, the headliner as well as the curtain

airbag must be replaced.

The occupant restraints include both active and

passive types. Active restraints are those which

require the vehicle occupants to take some action to

employ, such as fastening a seat belt; while passive

restraints require no action by the vehicle occupants

to be employed.

ACTIVE RESTRAINTS

The active restraints include:

²Front Seat Belts- Both front seating positions

are equipped with three-point seat belt systems

employing a lower B-pillar mounted inertia latch-

type retractor, height-adjustable upper B-pillar

mounted turning loops, a fixed lower seat belt anchor

secured to the lower B-pillar, and a traveling end-re-

lease buckle secured to the inboard side of the seat

cushion frame. The driver side front seat belt buckle

includes an integral Hall-effect seat belt switch that

detects whether the driver side front seat belt has

been fastened.²Rear Seat Belts- Both outboard rear second

and third seating positions are equipped with three-

point seat belt systems. The outboard seating posi-

tion belts employ a lower C or D-pillar mounted

inertia latch-type retractor, a fixed position upper C

or D-pillar mounted turning loop, and a fixed lower

seat belt anchor secured to the inboard side of the

seat cushion frame.

²Child Restraint Anchors- Also equipped in

this vehicle are two, fixed-position, child seat upper

tether anchors located on the lower seat cushion, in

the rear of the lower seat cushion. There is one

anchor integral to the back of the third row seat back

panel, one on each seat back panel. Two lower second

row anchors are also provided for each rear outboard

seating position. The lower anchors are integral to

the seat cushion frame and are accessed from the

front of the second row seat where the seat back

meets the seat cushion.

PASSIVE RESTRAINTS

The passive restraints available for this model

include the following:

²Dual Front Airbags- Multistage driver. front

passenger, and driver knee blocker airbags are avail-

able for this model. This airbag system is a passive,

inflatable, Supplemental Restraint System (SRS) and

vehicles with this equipment can be readily identified

by the ªSRS - AIRBAGº logo molded into the driver

airbag trim cover in the center of the steering wheel

and also into the passenger airbag door on the

instrument panel above the glove box. Vehicles with

the airbag system can also be identified by the airbag

indicator, which will illuminate in the instrument

cluster for about seven seconds as a bulb test each

time the ignition switch is turned to the ON position.

A pyrotechnic-type seat belt tensioner is integral to

the driver and passenger front seat belt buckle of all

models equipped with dual front airbags.

8O - 2 RESTRAINTSRS

Page 490 of 2339

²Occupant Classification System- These

vehicles also include an Occupant Classification Sys-

tem (OCS) with components that are located on or in

the passenger front seat cushion. These components

include an Occupant Classification Module (OCM)

and a seat weight bladder and pressure sensor

assembly. In addition, this system includes a belt

tension sensor integral to the lower anchor of the

passenger side front seat belt. Vehicles equipped with

the OCS can be readily identified by a Passenger Air-

bag Disabled (PAD) indicator (Fig. 1) located in the

center stack on the instrument panel above HVAC

control head and radio.

²Curtain Airbags- Curtain airbags are avail-

able for this model when it is also equipped with

dual front airbags. This airbag system is a passive,

inflatable, Supplemental Restraint System (SRS) and

vehicles with this equipment can be readily identified

by a molded identification trim button with the ªSRS

- AIRBAGº logo (Fig. 2) located on the headliner

above each B-pillar.

This vehicle is equipped with a Frontal Impact Air-

bag System, which utilizes the driver/passenger air-

bags, driver knee blocker airbag, and seat belt

tensioners. This system is designed to protect occu-

pants in the event of a front impact collision. These

airbags and seat belt tensioners are all serviceable

parts. If these pyrotechnics are deployed or defective,

they must be replaced, as well as the OccupantRestraint Controller (ORC) must be diagnosed follow-

ing procedures outlined in the diagnostic information.

The Driver and Passenger Airbag System was

designed to reduce the likelihood of injury or death

in frontal collisions. Each separate system is supple-

mental (Fig. 2) orPassiveto the primary restraint

device, which are the seat belts.

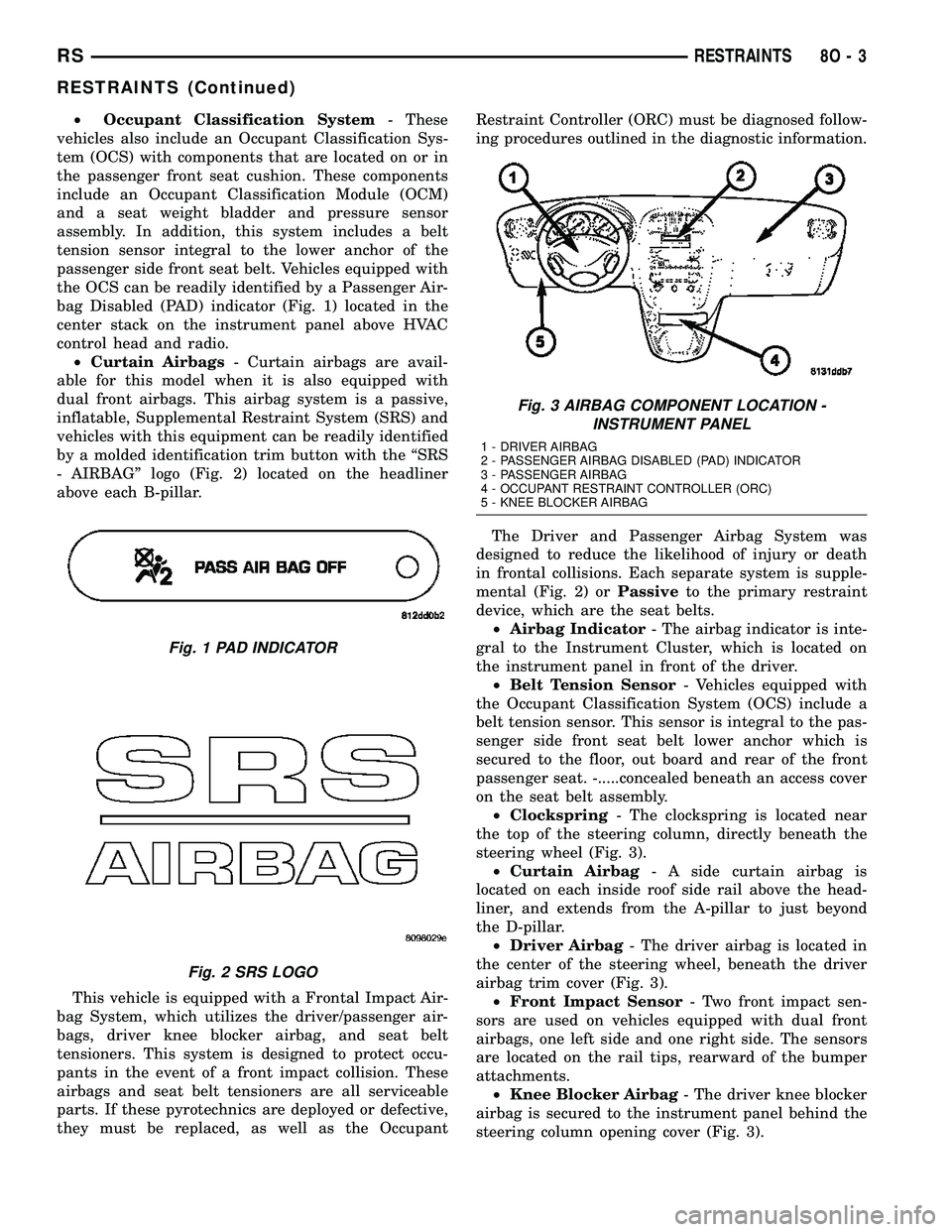

²Airbag Indicator- The airbag indicator is inte-

gral to the Instrument Cluster, which is located on

the instrument panel in front of the driver.

²Belt Tension Sensor- Vehicles equipped with

the Occupant Classification System (OCS) include a

belt tension sensor. This sensor is integral to the pas-

senger side front seat belt lower anchor which is

secured to the floor, out board and rear of the front

passenger seat. -.....concealed beneath an access cover

on the seat belt assembly.

²Clockspring- The clockspring is located near

the top of the steering column, directly beneath the

steering wheel (Fig. 3).

²Curtain Airbag- A side curtain airbag is

located on each inside roof side rail above the head-

liner, and extends from the A-pillar to just beyond

the D-pillar.

²Driver Airbag- The driver airbag is located in

the center of the steering wheel, beneath the driver

airbag trim cover (Fig. 3).

²Front Impact Sensor- Two front impact sen-

sors are used on vehicles equipped with dual front

airbags, one left side and one right side. The sensors

are located on the rail tips, rearward of the bumper

attachments.

²Knee Blocker Airbag- The driver knee blocker

airbag is secured to the instrument panel behind the

steering column opening cover (Fig. 3).

Fig. 1 PAD INDICATOR

Fig. 2 SRS LOGO

Fig. 3 AIRBAG COMPONENT LOCATION -

INSTRUMENT PANEL

1 - DRIVER AIRBAG

2 - PASSENGER AIRBAG DISABLED (PAD) INDICATOR

3 - PASSENGER AIRBAG

4 - OCCUPANT RESTRAINT CONTROLLER (ORC)

5 - KNEE BLOCKER AIRBAG

RSRESTRAINTS8O-3

RESTRAINTS (Continued)