Rear control CHRYSLER VOYAGER 2005 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 205 of 2339

(1) Lubricate the sensor O-ring with Mopar Wheel

Bearing Grease before installation into the Hub And

Bearing.If not lubricated, an improper seal may

result due to rolling of the O-ring.

(2) If metal sensor retaining clip is not in the neu-

tral installed position on hub and bearing cap, install

from the bottom, if necessary, and push clip upward

until it snaps into position.

(3) Install wheel speed sensor head into rear of

hub and bearing aligning index tab with the notch in

the top of the mounting hole. Push the sensor in

until it snaps into place on the metal retaining clip.

(4)

Install secondary (yellow) retaining clip over wheel

speed sensor head and engage the tabs on each side.

(5) Route sensor cable under leaf spring along rear

of axle. Install speed sensor cable into routing clips

on rear brake flex hose (Fig. 3).

(6) Install cable into metal routing clip and attach

it to the rear axle with mounting bolt (Fig. 3).

Tighten mounting bolt to 16 N´m (140 in. lbs.).

(7) Connect wheel speed sensor cable to vehicle

wiring harness (Fig. 2).Be sure speed sensor

cable connector is fully seated and locked into

vehicle wiring harness connector.

(8)

Install speed sensor cable grommet into hole in

floor pan making sure grommet is fully seated into hole.

(9) Lower vehicle.

(10) Road test vehicle to ensure proper operation

of the base and ABS braking systems.

TONE WHEEL

INSPECTION - TONE WHEEL

NOTE: Rear tone wheels for front-wheel-drive vehi-

cles are sealed within the hub and bearing assem-

bly and cannot be inspected or replaced.

Replacement of the hub and bearing is necessary.

Tone wheels can cause erratic wheel speed sensor

signals. Inspect tone wheels for the following possible

causes.

²missing, chipped, or broken teeth

²contact with the wheel speed sensor

²wheel speed sensor to tone wheel alignment

²wheel speed sensor to tone wheel clearance

²excessive tone wheel runout

²tone wheel loose on its mounting surface

If a front tone wheel is found to need replacement,

the drive shaft must be replaced. No attempt should

be made to replace just the tone wheel. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/HALF SHAFT -

REMOVAL)

If a rear tone wheel is found to need replacement

on an all-wheel-drive model, the drive shaft must be

replaced. No attempt should be made to replace justthe tone wheel. (Refer to 3 - DIFFERENTIAL &

DRIVELINE/HALF SHAFT - REMOVAL)

If wheel speed sensor to tone wheel contact is evi-

dent, determine the cause and correct it before

replacing the wheel speed sensor or tone wheel.

Check the gap between the speed sensor head and

the tone wheel to ensure it is within specifications.

(Refer to 5 - BRAKES - ABS/ELECTRICAL - SPEC-

IFICATIONS)

Excessive wheel speed sensor runout can cause

erratic wheel speed sensor signals. Refer to SPECI-

FICATIONS in this section of the service manual for

the maximum allowed tone wheel runout (Refer to 5 -

BRAKES - ABS/ELECTRICAL - SPECIFICATIONS).

If tone wheel runout is excessive, determine if it is

caused by a defect in the driveshaft assembly or hub

and bearing. Replace as necessary.

Tone wheels are pressed onto their mounting sur-

faces and should not rotate independently from the

mounting surface. Replacement of the front drive-

shaft, rear driveshaft (AWD only) or rear hub and

bearing is necessary.

TRACTION CONTROL SWITCH

DIAGNOSIS AND TESTING - TRACTION

CONTROL SWITCH

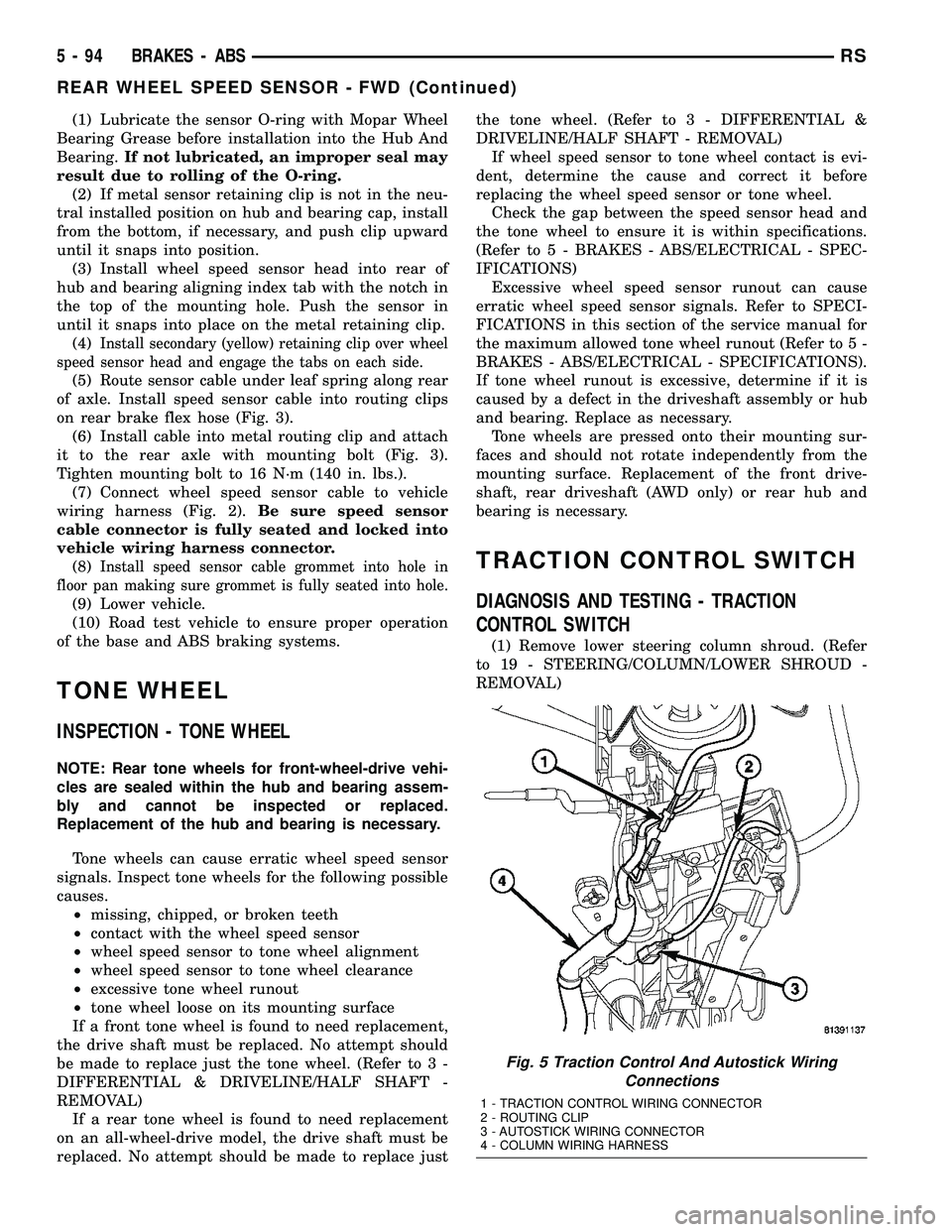

(1) Remove lower steering column shroud. (Refer

to 19 - STEERING/COLUMN/LOWER SHROUD -

REMOVAL)

Fig. 5 Traction Control And Autostick Wiring

Connections

1 - TRACTION CONTROL WIRING CONNECTOR

2 - ROUTING CLIP

3 - AUTOSTICK WIRING CONNECTOR

4 - COLUMN WIRING HARNESS

5 - 94 BRAKES - ABSRS

REAR WHEEL SPEED SENSOR - FWD (Continued)

Page 212 of 2339

For more information, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ICU (INTEGRATED CON-

TROL UNIT) - DESCRIPTION)

OPERATION

For information on the operation of the HCU as a

whole, refer to Hydraulic Circuits And Valve Opera-

tion which can be found elsewhere in this section.

For information on the operation of the components

within the HCU, refer to the following three topics.

VALVES AND SOLENOIDS

The valve block contains four inlet valves and four

outlet valves. The inlet valves are spring-loaded in

the open position and the outlet valves are spring-

loaded in the closed position during normal braking.

The fluid is allowed to flow from the master cylinder

to the wheel brakes.

During an ABS stop, these valves cycle to maintain

the proper slip ratio for each wheel. The inlet valve

closes preventing further pressure increase and the

outlet valve opens to provide a path from the wheel

brake to the HCU accumulators and pump/motor.

This releases (decays) pressure from the wheel brake,

thus releasing the wheel from excessive slippage.

Once the wheel is no longer slipping, the outlet valve

is closed and the inlet valve is opened to reapply

(build) pressure.

On vehicles with traction control, there is an extra

set of valves and solenoids. The ASR valves, mounted

in the HCU valve block, are normally in the open

position and close only when the traction control is

applied.

These isolator valves are used to isolate the rear

(non-driving) wheels of the vehicle from the hydraulic

pressure that the HCU pump/motor is sending to the

front (driving) wheels when traction control is being

applied. The rear brakes need to be isolated from the

master cylinder when traction control is being

applied so the rear wheels do not drag. For more

information, refer to Traction Control System in this

section.

BRAKE FLUID ACCUMULATORS

There are two fluid accumulators in the HCU±one

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Each hydraulic circuit uses

a 5 cc accumulator.

The fluid accumulators temporarily store brake

fluid that is removed from the wheel brakes during

an ABS cycle. This stored fluid is used by the pump/

motor to provide build pressure for the brake hydrau-

lic system. When the antilock stop is complete, the

accumulators are drained by the pump/motor.

On ABS-only vehicles, there is a mini-accumulator

on the secondary hydraulic circuit that protects the

master cylinder seals during an ABS stop, and there

is a noise dampening chamber on the primary circuit.

On ABS with traction control vehicles, there are

two noise dampening chambers in the HCU.

PUMP/MOTOR

There are two pump assemblies in the HCUÐone

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Both pumps are driven by a

common electric motor. This DC-type motor is inte-

gral to the HCU and is controlled by the CAB.

The pump/motor provides the extra amount of

brake fluid needed during antilock braking. Brake

fluid is released to the accumulators when the outlet

valve is opened during an antilock stop. The pump

mechanism consists of two opposing pistons operated

by an eccentric camshaft. In operation, one piston

draws fluid from the accumulators, and the opposing

piston pumps fluid to the master cylinder circuits.

When the antilock stop is complete, the pump/motor

drains the accumulators.

The CAB may turn on the pump/motor when an

antilock stop is detected. The pump/motor continues

to run during the antilock stop and is turned off after

the stop is complete. Under some conditions, the

pump/motor runs to drain the accumulators during

the next drive-off.

The pump/motor is not a serviceable item; if it

requires replacement, the HCU must be replaced.

RSBRAKES - ABS5 - 101

HCU (HYDRAULIC CONTROL UNIT) (Continued)

Page 215 of 2339

CHANICAL/ICU (INTEGRATED CONTROL UNIT) -

DISASSEMBLY).

REMOVAL - RHD

NOTE: Before proceeding, (Refer to 5 - BRAKES -

WARNING)(Refer to 5 - BRAKES - CAUTION)

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

draining out of the master cylinder when the

brake tubes are removed from the HCU.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove the routing clip attaching the ICU wir-

ing harness to the ICU mounting bracket (Fig. 17).

CAUTION: Do not apply a 12 volt power source to

any terminals of the HCU connector when discon-

nected.

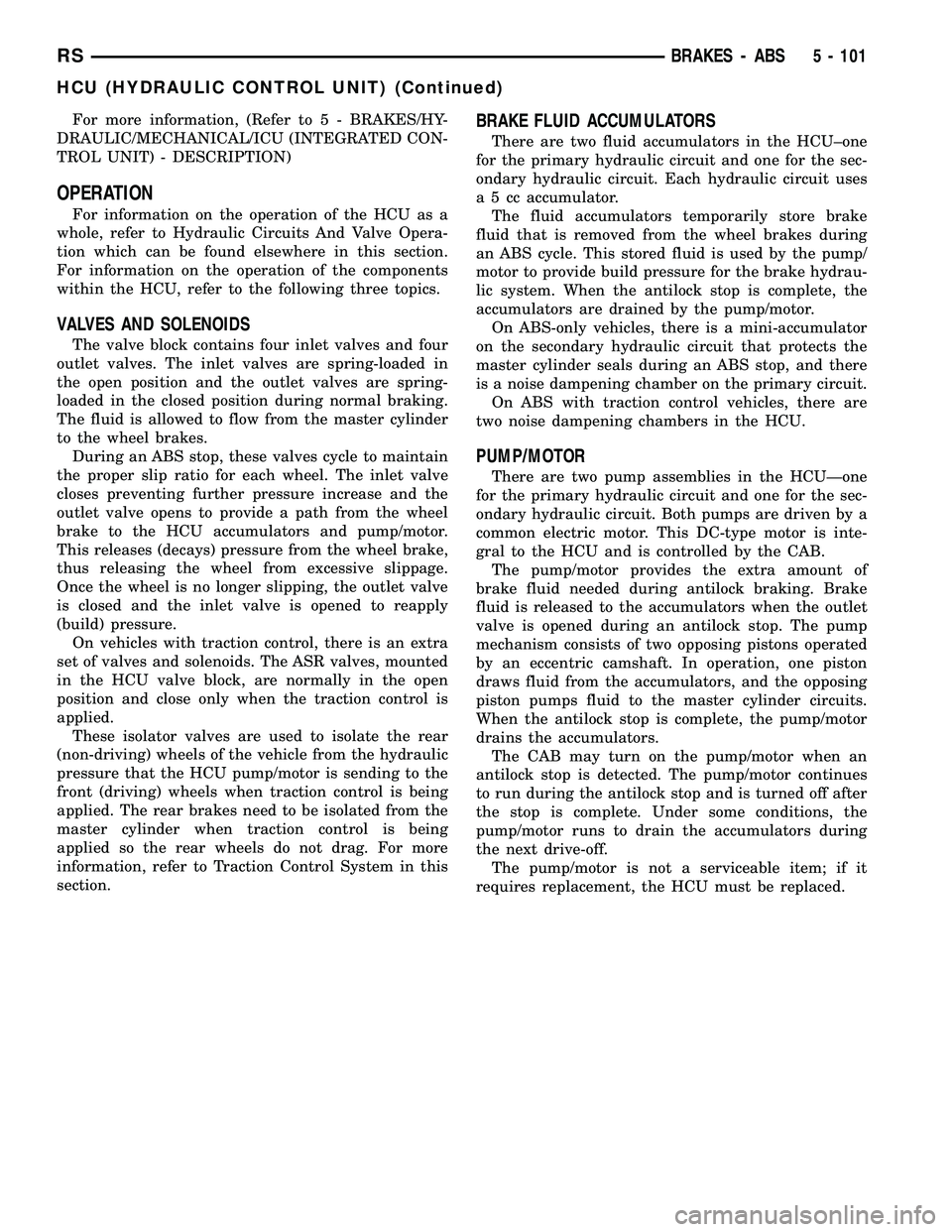

(5) Remove the 24-way connector (Fig. 17) from

the CAB. The 24-way connector is removed from the

CAB using the following procedure. Grasp the lock

on the 24-way connector (Fig. 17) and pull it as far

out as possible (Fig. 18). This will raise and unlock

the 24-way connector from the socket on the CAB.

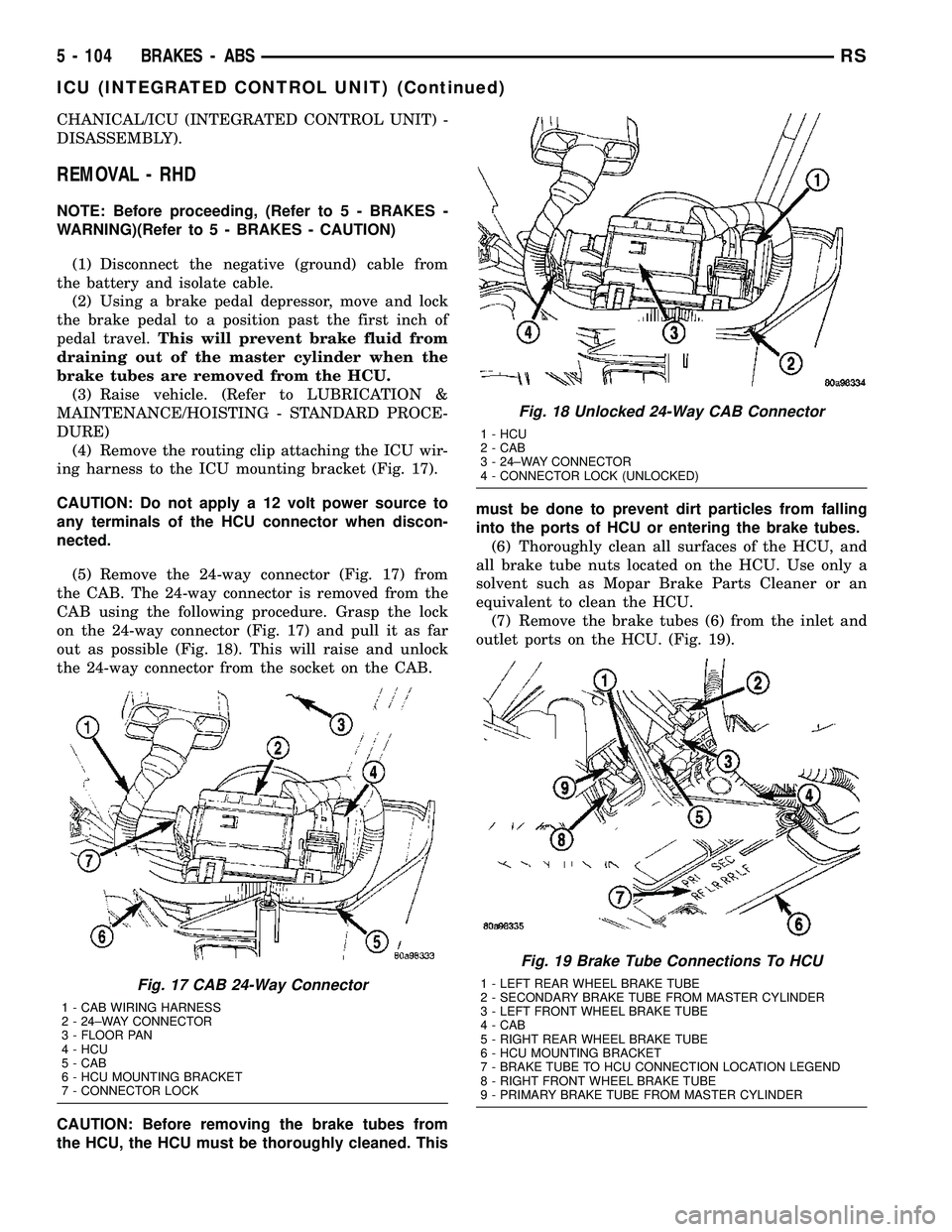

CAUTION: Before removing the brake tubes from

the HCU, the HCU must be thoroughly cleaned. Thismust be done to prevent dirt particles from falling

into the ports of HCU or entering the brake tubes.

(6) Thoroughly clean all surfaces of the HCU, and

all brake tube nuts located on the HCU. Use only a

solvent such as Mopar Brake Parts Cleaner or an

equivalent to clean the HCU.

(7) Remove the brake tubes (6) from the inlet and

outlet ports on the HCU. (Fig. 19).

Fig. 17 CAB 24-Way Connector

1 - CAB WIRING HARNESS

2 - 24±WAY CONNECTOR

3 - FLOOR PAN

4 - HCU

5 - CAB

6 - HCU MOUNTING BRACKET

7 - CONNECTOR LOCK

Fig. 18 Unlocked 24-Way CAB Connector

1 - HCU

2 - CAB

3 - 24±WAY CONNECTOR

4 - CONNECTOR LOCK (UNLOCKED)

Fig. 19 Brake Tube Connections To HCU

1 - LEFT REAR WHEEL BRAKE TUBE

2 - SECONDARY BRAKE TUBE FROM MASTER CYLINDER

3 - LEFT FRONT WHEEL BRAKE TUBE

4 - CAB

5 - RIGHT REAR WHEEL BRAKE TUBE

6 - HCU MOUNTING BRACKET

7 - BRAKE TUBE TO HCU CONNECTION LOCATION LEGEND

8 - RIGHT FRONT WHEEL BRAKE TUBE

9 - PRIMARY BRAKE TUBE FROM MASTER CYLINDER

5 - 104 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 263 of 2339

CONDITION POSSIBLE CAUSE CORRECTION

4. RADIO

INOPERATIVE.4. USING A SCAN TOOL, CHECK FOR TROUBLE CODES IN

THE AUDIO SYSTEM.

HEADPHONES

WILL NOT HOLD

A CHANNEL OR

HAVE STATIC1. WEAK BATTERIES IN

THE HEADPHONES.1. REPLACE BATTERIES.

2. CLOSENESS TO

RADIO TRANSMITTER

SUCH AS A RADIO

TOWER, AIRPORT

TRANSMITTER OR

SOME MOBILE

RADIOS.2. MOVE TO AN AREA AWAY FROM THESE CONDITIONS.

REMOTE

CONTROL

INOPERATIVE1. WEAK BATTERIES IN

THE REMOTE

CONTROL.1. REPLACE BATTERIES.

2. OPERATION

CONSTRAINT OF

SYSTEM2. MAKE SURE THAT REAR AUDIO IS IN A DIFFERENT MODE

THAN FRONT SPEAKERS. REMOTE CONTROL WILL NOT

WORK WHEN BOTH ARE IN THE SAME MODE.

8A - 4 AUDIO/VIDEORS

AUDIO/VIDEO (Continued)

Page 272 of 2339

(6) Install glove box (Refer to 23 - BODY/INSTRU-

MENT PANEL/GLOVE BOX - INSTALLATION).

(7) Connect the battery negative cable.

QUARTER GLASS INTEGRAL

ANTENNA - EXPORT

DESCRIPTION

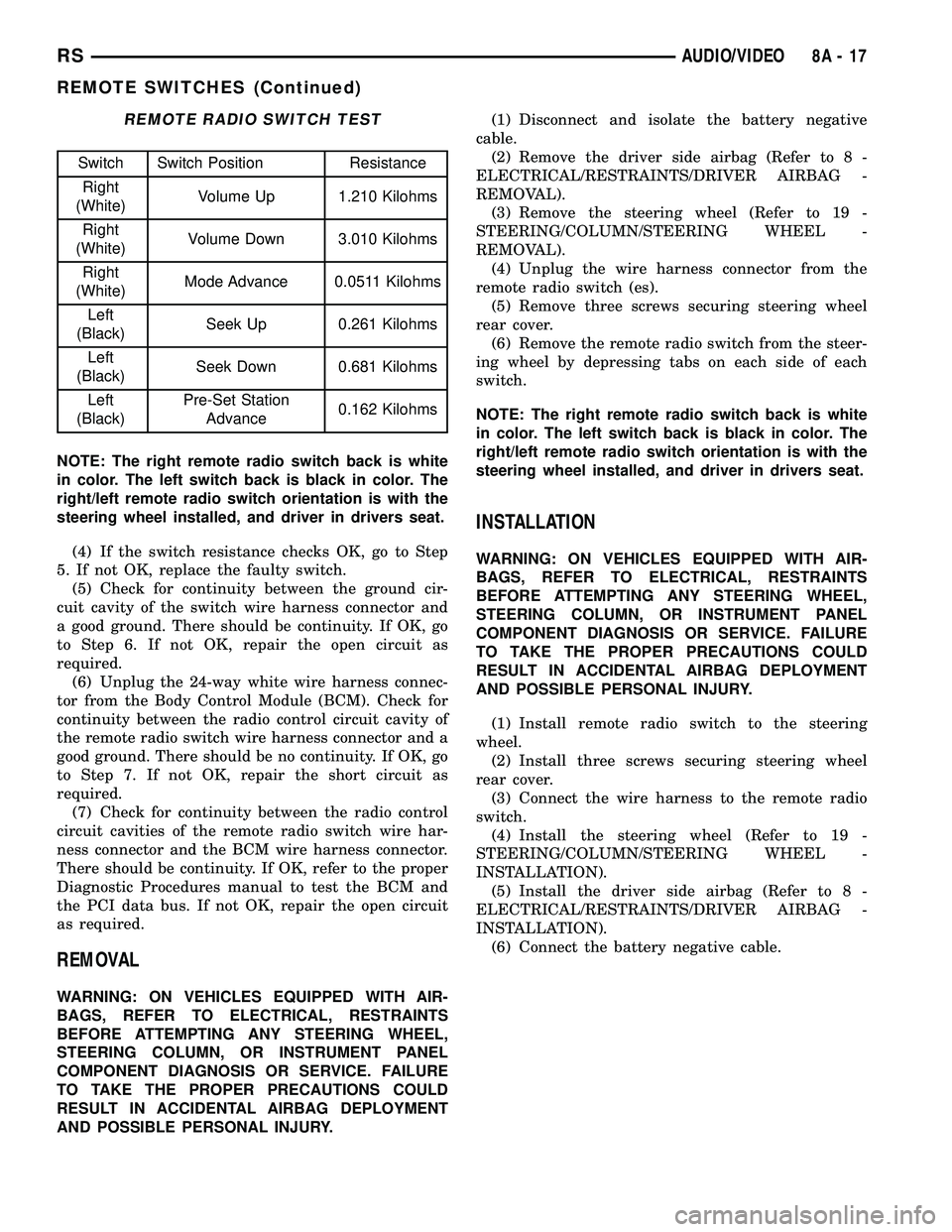

The quarter glass integral antenna element is

bonded to the right rear quarter glass and is replaced

with the glass assembly only (Fig. 12).

OPERATION

The integral antenna receives radio frequencies

and sends them to the antenna module for amplifica-

tion.

DIAGNOSIS AND TESTING

QUARTER GLASS INTEGRAL ANTENNA -

EXPORT

The antenna grid pattern is divided into two sepa-

rate patterns. Each terminal connects to a separate

grid pattern, one for AM and the other for FM.

For circuit descriptions and diagrams, refer to the

appropriate wiring information.

(1) Disconnect the antenna module connector from

the antenna terminals on the glass.

(2) Using an ohmmeter, place a lead on one of the

terminals and check each end of the grid pattern con-

nected to this terminal for continuity. If continuity is

not present, move one lead through the grid in pro-

gression starting at the terminal with the other lead

on the terminal until continuity is lost. Repeat pro-

cedure for the other terminal. A break in the antenna

grid can be repaired using a Mopar Rear Window

Defogger Repair Kit (Part Number 4267922) or

equivalent. (Refer to 8 - ELECTRICAL/HEATED

GLASS/WINDSHIELD GRID - STANDARD PROCE-

DURE).

RADIO

DESCRIPTION

Available radio receivers for this vehicle include:

²AM/FM/cassette/CD (RAZ or RBP sales code)

²AM/FM/cassette/CD with rear audio (RBU sales

code)

²AM/FM/cassette (RBB sales code)

²AM/FM/6±disc CD radio (RBQ sales code)

²AM/FM/CD/Navigation (RB3 sales code)

²AM/FM/CD with CD changer control (RBK sales

code) export only

²AM/FM/cassette/CD (RBY,RAD, or RBT sales

code) export only

All radio receivers can communicate on the Pro-

grammable Communications Interface (PCI) data bus

network.

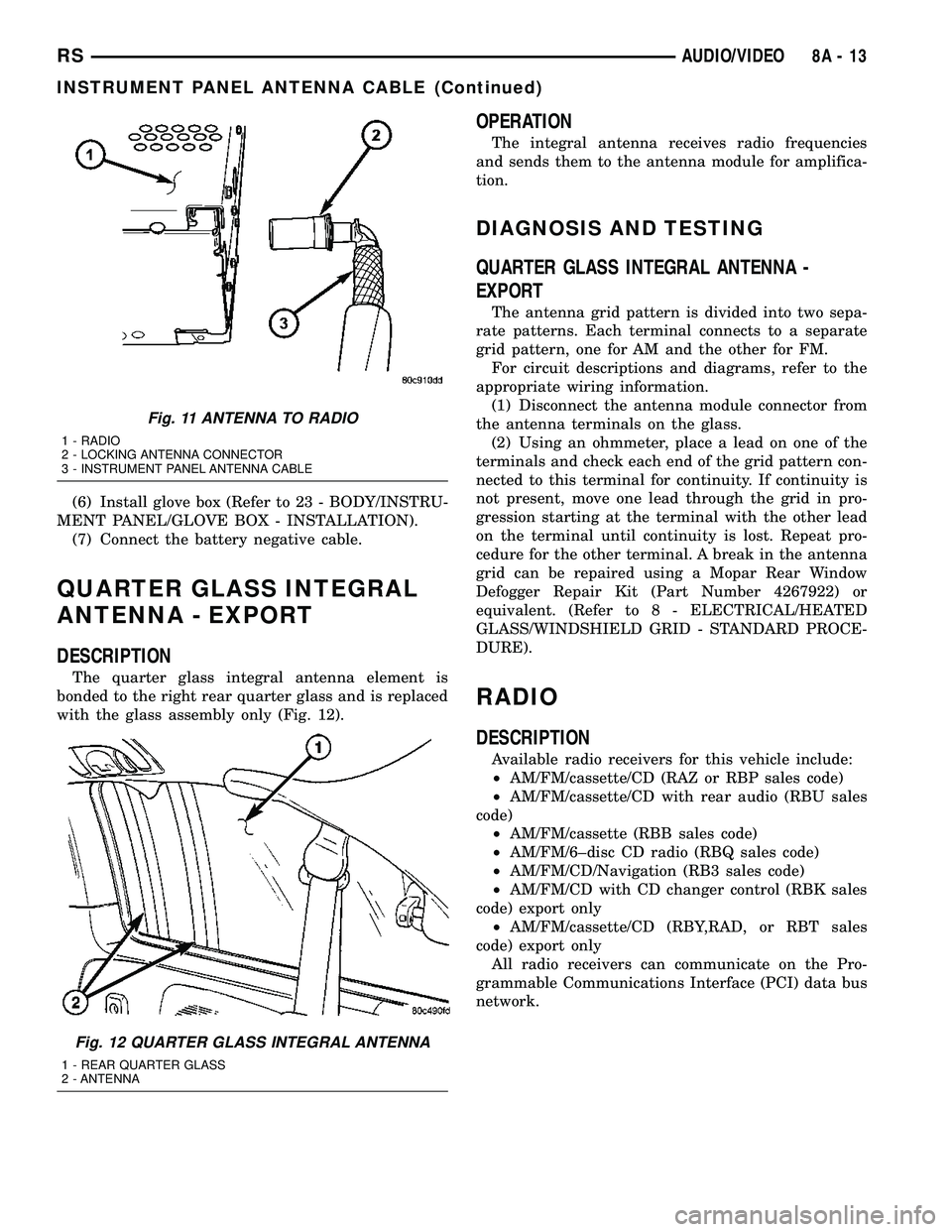

Fig. 11 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

Fig. 12 QUARTER GLASS INTEGRAL ANTENNA

1 - REAR QUARTER GLASS

2 - ANTENNA

RSAUDIO/VIDEO8A-13

INSTRUMENT PANEL ANTENNA CABLE (Continued)

Page 276 of 2339

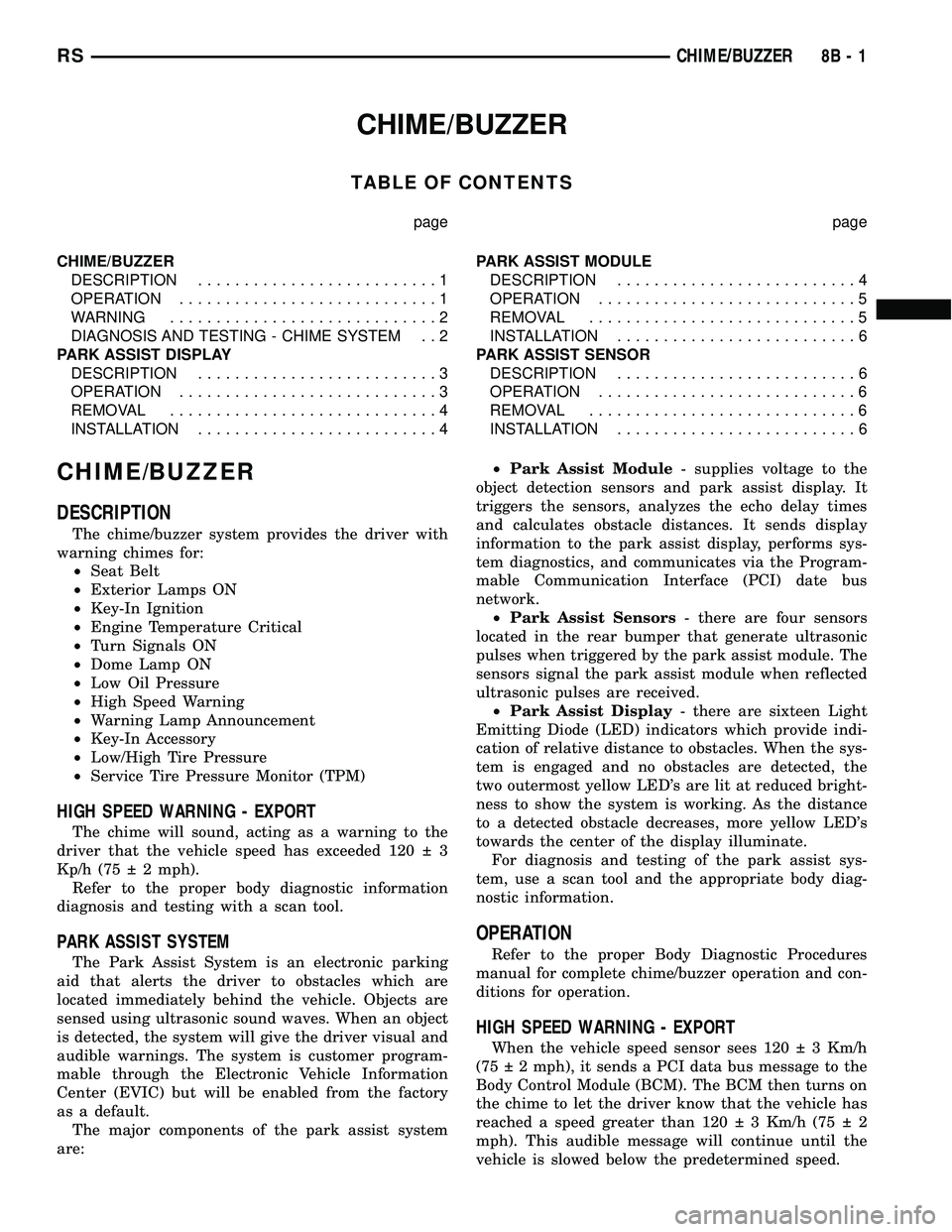

REMOTE RADIO SWITCH TEST

Switch Switch Position Resistance

Right

(White)Volume Up 1.210 Kilohms

Right

(White)Volume Down 3.010 Kilohms

Right

(White)Mode Advance 0.0511 Kilohms

Left

(Black)Seek Up 0.261 Kilohms

Left

(Black)Seek Down 0.681 Kilohms

Left

(Black)Pre-Set Station

Advance0.162 Kilohms

NOTE: The right remote radio switch back is white

in color. The left switch back is black in color. The

right/left remote radio switch orientation is with the

steering wheel installed, and driver in drivers seat.

(4) If the switch resistance checks OK, go to Step

5. If not OK, replace the faulty switch.

(5) Check for continuity between the ground cir-

cuit cavity of the switch wire harness connector and

a good ground. There should be continuity. If OK, go

to Step 6. If not OK, repair the open circuit as

required.

(6) Unplug the 24-way white wire harness connec-

tor from the Body Control Module (BCM). Check for

continuity between the radio control circuit cavity of

the remote radio switch wire harness connector and a

good ground. There should be no continuity. If OK, go

to Step 7. If not OK, repair the short circuit as

required.

(7) Check for continuity between the radio control

circuit cavities of the remote radio switch wire har-

ness connector and the BCM wire harness connector.

There should be continuity. If OK, refer to the proper

Diagnostic Procedures manual to test the BCM and

the PCI data bus. If not OK, repair the open circuit

as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side airbag (Refer to 8 -

ELECTRICAL/RESTRAINTS/DRIVER AIRBAG -

REMOVAL).

(3) Remove the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

REMOVAL).

(4) Unplug the wire harness connector from the

remote radio switch (es).

(5) Remove three screws securing steering wheel

rear cover.

(6) Remove the remote radio switch from the steer-

ing wheel by depressing tabs on each side of each

switch.

NOTE: The right remote radio switch back is white

in color. The left switch back is black in color. The

right/left remote radio switch orientation is with the

steering wheel installed, and driver in drivers seat.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Install remote radio switch to the steering

wheel.

(2) Install three screws securing steering wheel

rear cover.

(3) Connect the wire harness to the remote radio

switch.

(4) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(5) Install the driver side airbag (Refer to 8 -

ELECTRICAL/RESTRAINTS/DRIVER AIRBAG -

INSTALLATION).

(6) Connect the battery negative cable.

RSAUDIO/VIDEO8A-17

REMOTE SWITCHES (Continued)

Page 277 of 2339

SPEAKER

DIAGNOSIS AND TESTING

SPEAKER

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

(1) If all speakers are inoperative, check the radio

fuses in the Junction Block (JB). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Check the amplifier fuse (if equipped) in the

junction block. If OK, go to Step 3. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(3) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 4.

(4) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negative

cable. If vehicle isnotequipped with a amplifier,

remove the radio receiver. If vehicle is equipped with

an amplifier. disconnect wire harness connector at

output side of amplifier. Go to Step 4.

(5) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.(6) Disconnect wire harness connector at the inop-

erative speaker. Check for continuity between the

speaker feed (+) circuit cavities of the radio receiver

wire harness connector or if equipped, the amplifier

wire harness connector and the speaker wire harness

connector. Repeat the check between the speaker

return (-) circuit cavities of the radio receiver wire

harness connector and the speaker wire harness con-

nector. In each case, there should be continuity. If

OK, replace the faulty speaker. If not OK, repair the

open speaker feed (+) and/or return (-) circuits(s) as

required.

REMOVAL

D-PILLAR SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove rear header trim (right side speaker).

(3) Remove jack cover (left side speaker).

(4) Remove liftgate scuff plate.

(5) Remove upper seat belt bolt. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT OUT-

BOARD FRONT - REMOVAL).

(6) Partially remove quarter trim panel to access

the D-pillar speaker.

(7) Slide the speaker from the retainer (Fig. 17).

(8) Disconnect the wire harness connector from the

speaker.

Fig. 17 D-PILLAR SPEAKER

1 - SPEAKER

2 - RETAINER

3 - TRIM PANEL

8A - 18 AUDIO/VIDEORS

Page 280 of 2339

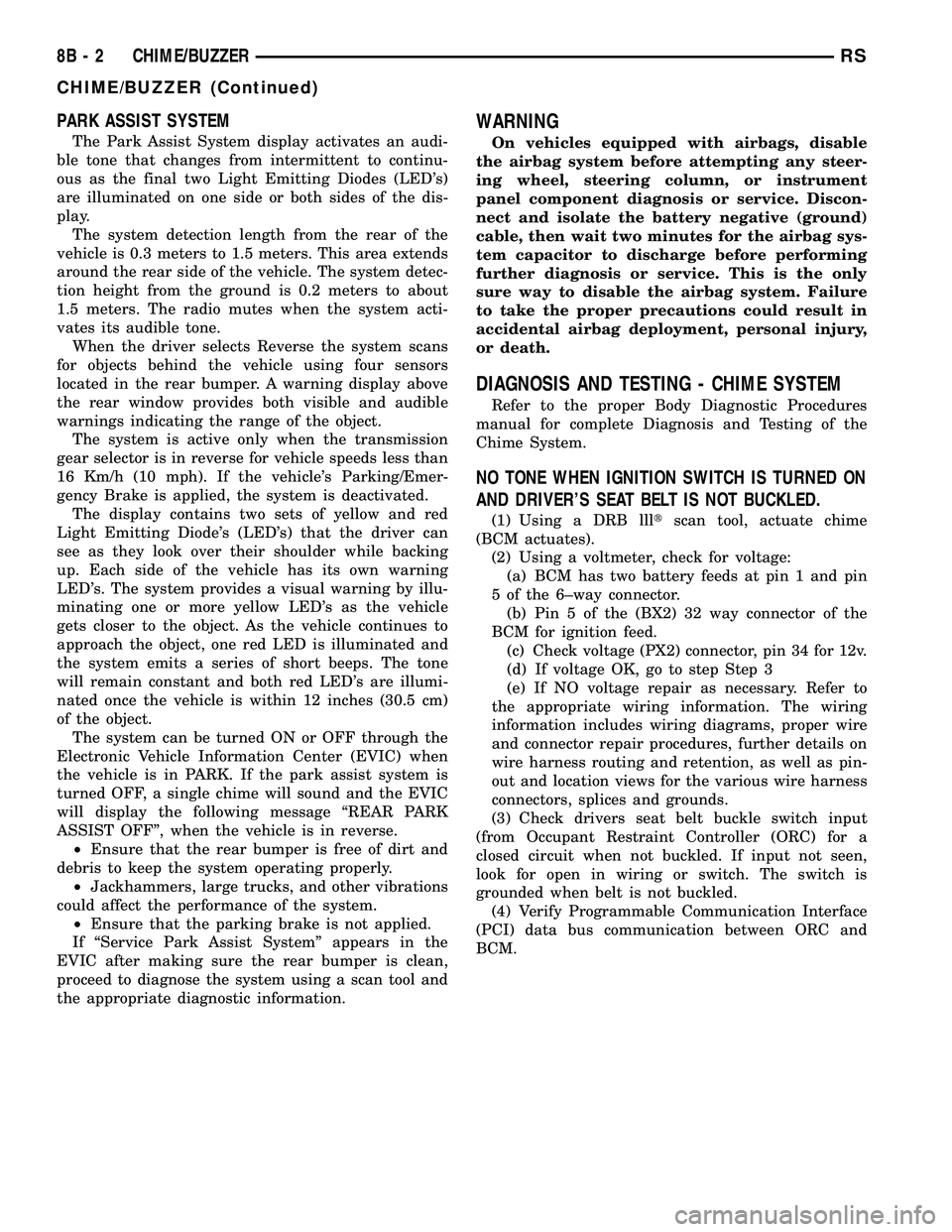

CHIME/BUZZER

TABLE OF CONTENTS

page page

CHIME/BUZZER

DESCRIPTION..........................1

OPERATION............................1

WARNING.............................2

DIAGNOSIS AND TESTING - CHIME SYSTEM . . 2

PARK ASSIST DISPLAY

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................4

INSTALLATION..........................4PARK ASSIST MODULE

DESCRIPTION..........................4

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................6

PARK ASSIST SENSOR

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

CHIME/BUZZER

DESCRIPTION

The chime/buzzer system provides the driver with

warning chimes for:

²Seat Belt

²Exterior Lamps ON

²Key-In Ignition

²Engine Temperature Critical

²Turn Signals ON

²Dome Lamp ON

²Low Oil Pressure

²High Speed Warning

²Warning Lamp Announcement

²Key-In Accessory

²Low/High Tire Pressure

²Service Tire Pressure Monitor (TPM)

HIGH SPEED WARNING - EXPORT

The chime will sound, acting as a warning to the

driver that the vehicle speed has exceeded 120 3

Kp/h (75 2 mph).

Refer to the proper body diagnostic information

diagnosis and testing with a scan tool.

PARK ASSIST SYSTEM

The Park Assist System is an electronic parking

aid that alerts the driver to obstacles which are

located immediately behind the vehicle. Objects are

sensed using ultrasonic sound waves. When an object

is detected, the system will give the driver visual and

audible warnings. The system is customer program-

mable through the Electronic Vehicle Information

Center (EVIC) but will be enabled from the factory

as a default.

The major components of the park assist system

are:²Park Assist Module- supplies voltage to the

object detection sensors and park assist display. It

triggers the sensors, analyzes the echo delay times

and calculates obstacle distances. It sends display

information to the park assist display, performs sys-

tem diagnostics, and communicates via the Program-

mable Communication Interface (PCI) date bus

network.

²Park Assist Sensors- there are four sensors

located in the rear bumper that generate ultrasonic

pulses when triggered by the park assist module. The

sensors signal the park assist module when reflected

ultrasonic pulses are received.

²Park Assist Display- there are sixteen Light

Emitting Diode (LED) indicators which provide indi-

cation of relative distance to obstacles. When the sys-

tem is engaged and no obstacles are detected, the

two outermost yellow LED's are lit at reduced bright-

ness to show the system is working. As the distance

to a detected obstacle decreases, more yellow LED's

towards the center of the display illuminate.

For diagnosis and testing of the park assist sys-

tem, use a scan tool and the appropriate body diag-

nostic information.

OPERATION

Refer to the proper Body Diagnostic Procedures

manual for complete chime/buzzer operation and con-

ditions for operation.

HIGH SPEED WARNING - EXPORT

When the vehicle speed sensor sees 120 3 Km/h

(75 2 mph), it sends a PCI data bus message to the

Body Control Module (BCM). The BCM then turns on

the chime to let the driver know that the vehicle has

reached a speed greater than 120 3 Km/h (75 2

mph). This audible message will continue until the

vehicle is slowed below the predetermined speed.

RSCHIME/BUZZER8B-1

Page 281 of 2339

PARK ASSIST SYSTEM

The Park Assist System display activates an audi-

ble tone that changes from intermittent to continu-

ous as the final two Light Emitting Diodes (LED's)

are illuminated on one side or both sides of the dis-

play.

The system detection length from the rear of the

vehicle is 0.3 meters to 1.5 meters. This area extends

around the rear side of the vehicle. The system detec-

tion height from the ground is 0.2 meters to about

1.5 meters. The radio mutes when the system acti-

vates its audible tone.

When the driver selects Reverse the system scans

for objects behind the vehicle using four sensors

located in the rear bumper. A warning display above

the rear window provides both visible and audible

warnings indicating the range of the object.

The system is active only when the transmission

gear selector is in reverse for vehicle speeds less than

16 Km/h (10 mph). If the vehicle's Parking/Emer-

gency Brake is applied, the system is deactivated.

The display contains two sets of yellow and red

Light Emitting Diode's (LED's) that the driver can

see as they look over their shoulder while backing

up. Each side of the vehicle has its own warning

LED's. The system provides a visual warning by illu-

minating one or more yellow LED's as the vehicle

gets closer to the object. As the vehicle continues to

approach the object, one red LED is illuminated and

the system emits a series of short beeps. The tone

will remain constant and both red LED's are illumi-

nated once the vehicle is within 12 inches (30.5 cm)

of the object.

The system can be turned ON or OFF through the

Electronic Vehicle Information Center (EVIC) when

the vehicle is in PARK. If the park assist system is

turned OFF, a single chime will sound and the EVIC

will display the following message ªREAR PARK

ASSIST OFFº, when the vehicle is in reverse.

²Ensure that the rear bumper is free of dirt and

debris to keep the system operating properly.

²Jackhammers, large trucks, and other vibrations

could affect the performance of the system.

²Ensure that the parking brake is not applied.

If ªService Park Assist Systemº appears in the

EVIC after making sure the rear bumper is clean,

proceed to diagnose the system using a scan tool and

the appropriate diagnostic information.

WARNING

On vehicles equipped with airbags, disable

the airbag system before attempting any steer-

ing wheel, steering column, or instrument

panel component diagnosis or service. Discon-

nect and isolate the battery negative (ground)

cable, then wait two minutes for the airbag sys-

tem capacitor to discharge before performing

further diagnosis or service. This is the only

sure way to disable the airbag system. Failure

to take the proper precautions could result in

accidental airbag deployment, personal injury,

or death.

DIAGNOSIS AND TESTING - CHIME SYSTEM

Refer to the proper Body Diagnostic Procedures

manual for complete Diagnosis and Testing of the

Chime System.

NO TONE WHEN IGNITION SWITCH IS TURNED ON

AND DRIVER'S SEAT BELT IS NOT BUCKLED.

(1) Using a DRB llltscan tool, actuate chime

(BCM actuates).

(2) Using a voltmeter, check for voltage:

(a) BCM has two battery feeds at pin 1 and pin

5 of the 6±way connector.

(b) Pin 5 of the (BX2) 32 way connector of the

BCM for ignition feed.

(c) Check voltage (PX2) connector, pin 34 for 12v.

(d) If voltage OK, go to step Step 3

(e) If NO voltage repair as necessary. Refer to

the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices and grounds.

(3) Check drivers seat belt buckle switch input

(from Occupant Restraint Controller (ORC) for a

closed circuit when not buckled. If input not seen,

look for open in wiring or switch. The switch is

grounded when belt is not buckled.

(4) Verify Programmable Communication Interface

(PCI) data bus communication between ORC and

BCM.

8B - 2 CHIME/BUZZERRS

CHIME/BUZZER (Continued)

Page 288 of 2339

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus.

OPERATION

The Body Control Module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the BCM is interfaced to the

vehicle's serial bus communications network, referred

to as the Programmable Communications Interface

(PCI) bus.

This network consists of the;

²Powertrain Control Module (PCM)

²Transmission Control Module (TCM)

²Mechanical Instrument Cluster (MIC)

²Occupant Restraint Controller (ORC)

²Compass/Mini-Trip Computer (CMTC)

²Electronic Vehicle Information Center (EVIC)

²Controller Antilock Brake (CAB)

²HVAC Control Module

²Sliding Door Control Modules (driver and pas-

senger side doors)

²Power Liftgate Module (PLG)

²Audio system equipped with RAZ, RBU, RBK,

and RBB radios.

²Sentry Key Remote Entry Module (SKREEM).

²Side Impact Airbag Control Module (SIACM)²Memory Seat Module (MSM)

²Sentry Key Immobilizer Module (SKIM)

The BCM is operational when battery power is

supplied to the module.

The BCM provides the following features:

²Power Door Locks

²Automatic Door Locks

²Battery Protection - The BCM will automatically

turn off all exterior lamps after 3 minutes, and all

interior lamps after 15 minutes after the ignition is

turned off, if they are not turned off by the driver.

²Chime Control

²Compass/Mini-Trip support.

²Interior Lighting (Courtesy/Reading Lamps)

²BCM Diagnostic Reporting

²Electronic Liftgate Release (with Power Door

Locks)

²Exterior Lighting

²Headlamp Time Delay (with/without Automatic

Headlamps)

²Illuminated Entry

²Fade to Off Interior Lamps - This feature dims

the interior lighting (courtesy lamps) gradually if the

BCM does not receive any new inputs that would

cause the interior lamps to remain on.

²Pulse Width Modulated Instrument Panel Dim-

ming

²Door Lock Inhibit - This feature disables the

door lock functions if the key is in the ignition and

either front door is ajar. Pressing the Remote Keyless

Entry (RKE) lock/unlock button under these condi-

tions result in normal lock/unlock activation.

The BCM has the ability to LEARN additional fea-

tures in the vehicle, provided the appropriate switch

input and PCI data bus messages are received. Refer

to the LEARNED FEATURES table.

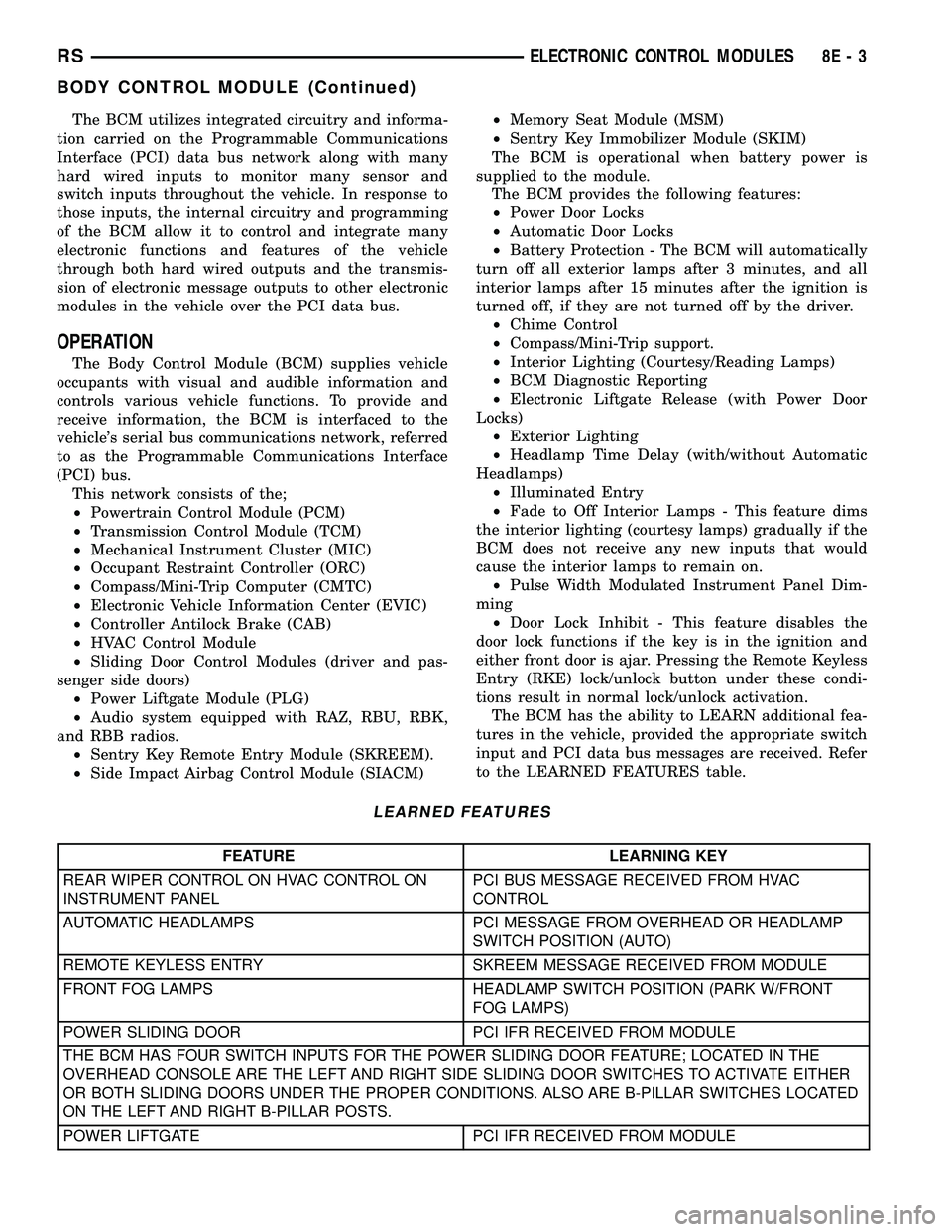

LEARNED FEATURES

FEATURE LEARNING KEY

REAR WIPER CONTROL ON HVAC CONTROL ON

INSTRUMENT PANELPCI BUS MESSAGE RECEIVED FROM HVAC

CONTROL

AUTOMATIC HEADLAMPS PCI MESSAGE FROM OVERHEAD OR HEADLAMP

SWITCH POSITION (AUTO)

REMOTE KEYLESS ENTRY SKREEM MESSAGE RECEIVED FROM MODULE

FRONT FOG LAMPS HEADLAMP SWITCH POSITION (PARK W/FRONT

FOG LAMPS)

POWER SLIDING DOOR PCI IFR RECEIVED FROM MODULE

THE BCM HAS FOUR SWITCH INPUTS FOR THE POWER SLIDING DOOR FEATURE; LOCATED IN THE

OVERHEAD CONSOLE ARE THE LEFT AND RIGHT SIDE SLIDING DOOR SWITCHES TO ACTIVATE EITHER

OR BOTH SLIDING DOORS UNDER THE PROPER CONDITIONS. ALSO ARE B-PILLAR SWITCHES LOCATED

ON THE LEFT AND RIGHT B-PILLAR POSTS.

POWER LIFTGATE PCI IFR RECEIVED FROM MODULE

RSELECTRONIC CONTROL MODULES8E-3

BODY CONTROL MODULE (Continued)