Servo CHRYSLER VOYAGER 2005 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1327 of 2339

(5) Connect the MAP sensor electrical connector.

(6) Connect the brake booster and LDP vacuum

hose to intake manifold (Fig. 117).CAUTION: The special screws used for attaching

the EGR tube and power steering reservoir to the

manifold must be installed slowly using hand tools

only. This requirement is to prevent the melting of

material that causes stripped threads. If threads

become stripped, an oversize repair screw is avail-

able. For more information and procedure (Refer to

9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - STAN-

DARD PROCEDURE - MANIFOLD STRIPPED

THREAD REPAIR).

(7) Install the power steering reservoir (Fig. 116).

Tighten screws to manifold to 5.6 N´m (50 in. lbs.).

(8) Connect throttle and speed control cables to

throttle body (Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/THROTTLE CONTROL CABLE -

INSTALLATION)

(9) Attach make up air hose clip into the hole in

the throttle cable bracket.

(10) Connect the wiring connectors to the throttle

position sensor (TPS) and Automatic Idle Speed (AIS)

motor.

(11) Install air cleaner and air inlet hose assembly.

(12) Connect the inlet air temperature (IAT) sen-

sor electrical connector.

(13) Connect battery negative cable.

INTAKE MANIFOLD - LOWER

REMOVAL - LOWER INTAKE MANIFOLD

(1) Perform fuel system pressure release procedure

(before attempting any repairs).(Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE)

(2) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(3) Remove the upper intake manifold. (Refer to 9

- ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL)

(4) Remove the fuel line. (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL LINES - STANDARD

PROCEDURE) (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE)

(5) Remove ignition coil and bracket (Fig. 120).

(6) Disconnect heater supply hose and engine cool-

ant temperature sensor (Fig. 121).

(7) Disconnect the fuel injector wire harness.

(8) Remove the fuel injectors and rail assembly

(Fig. 120).

(9) Remove radiator upper hose.

(10) Remove the intake manifold bolts.

(11) Remove lower intake manifold (Fig. 122).

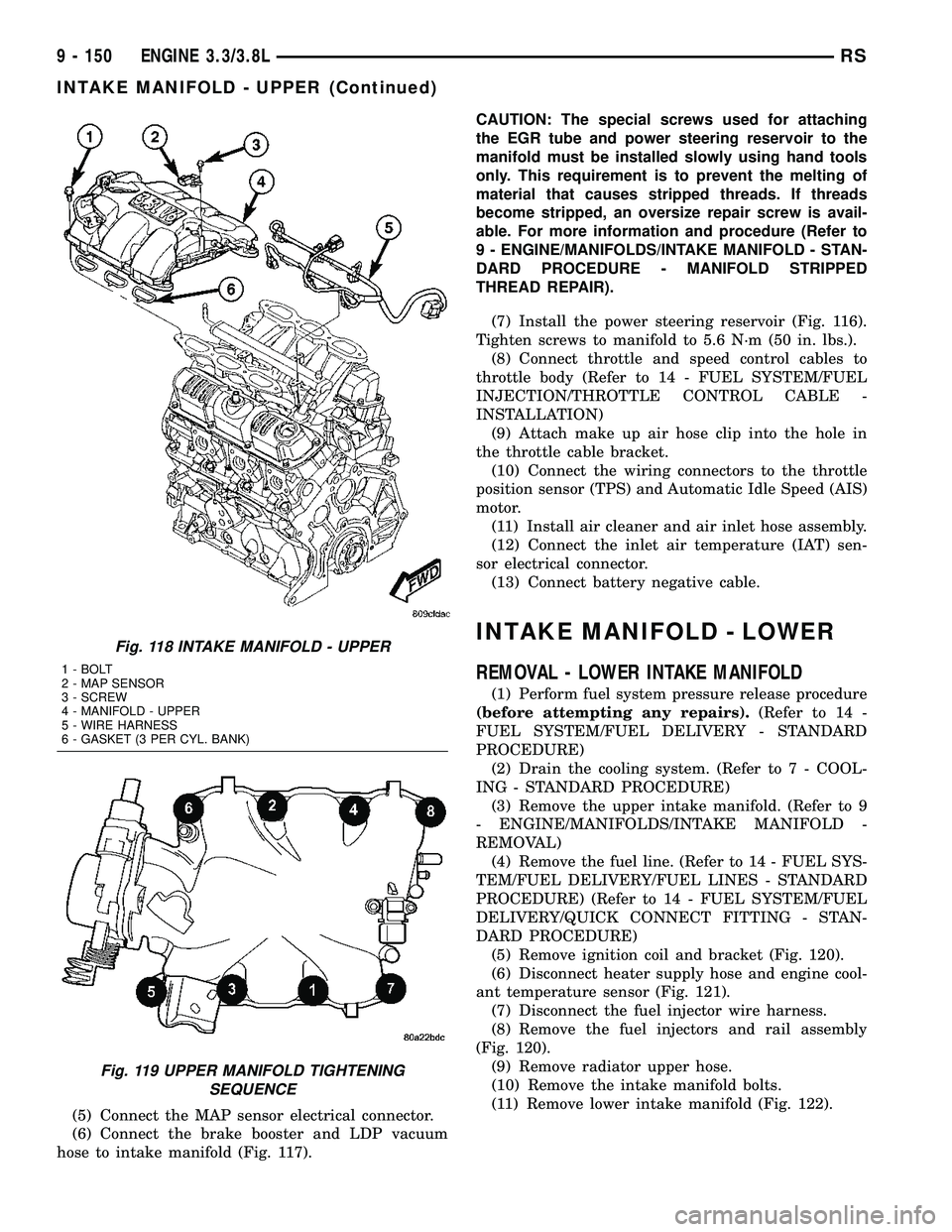

Fig. 118 INTAKE MANIFOLD - UPPER

1 - BOLT

2 - MAP SENSOR

3 - SCREW

4 - MANIFOLD - UPPER

5 - WIRE HARNESS

6 - GASKET (3 PER CYL. BANK)

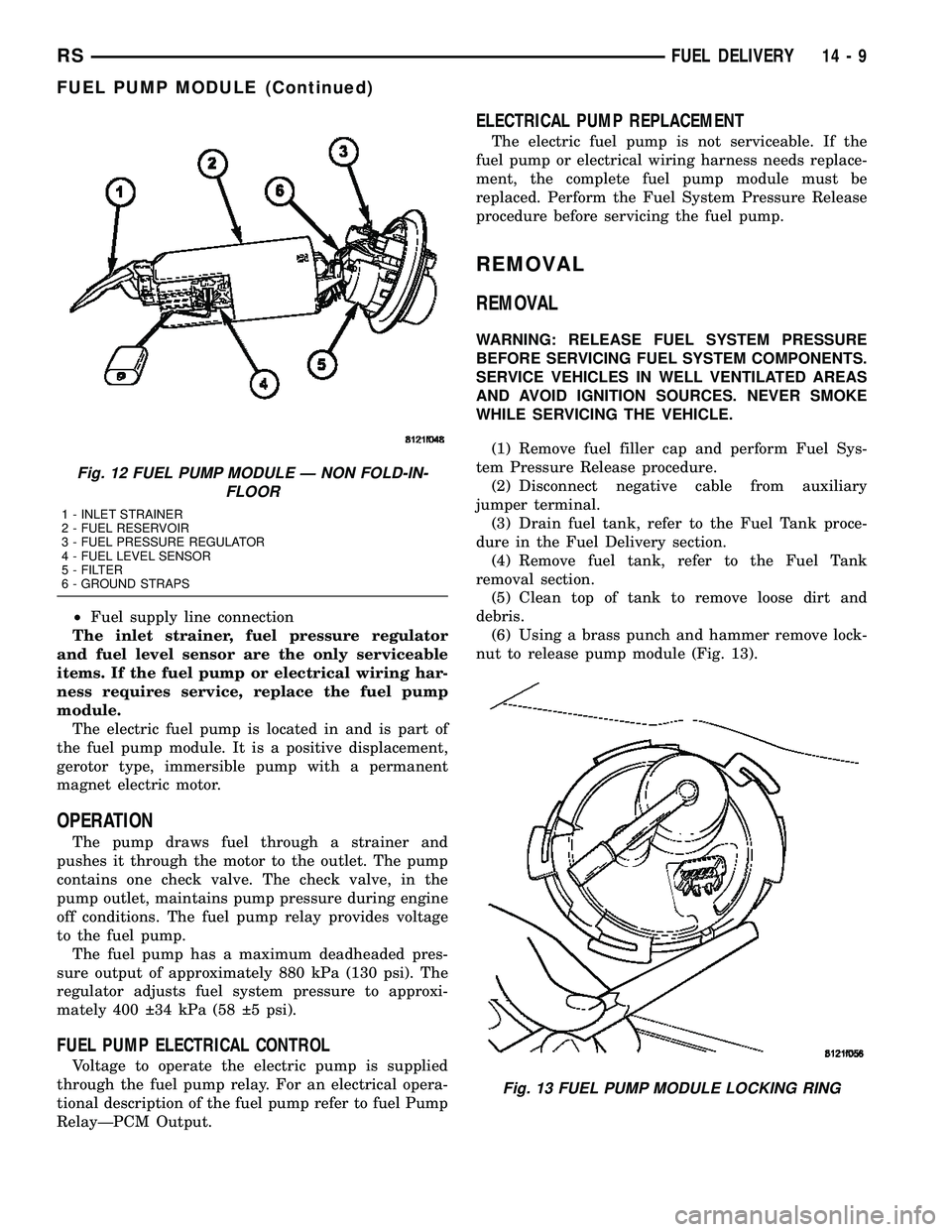

Fig. 119 UPPER MANIFOLD TIGHTENING

SEQUENCE

9 - 150 ENGINE 3.3/3.8LRS

INTAKE MANIFOLD - UPPER (Continued)

Page 1373 of 2339

(1) Lightly lubricate the O-rings with clean engine

oil and place them into opening in pump module (Fig.

9).

(2) Push regulator into opening in pump module.

(3) Retaining tabs snap into housing.

FUEL PUMP

DESCRIPTION

The electric fuel pump is located in and is part of

the fuel pump module. It is a positive displacement,

gerotor type, immersible pump with a permanent

magnet electric motor. The fuel pump module is sus-

pended in fuel in the fuel tank.

OPERATION

The pump draws fuel through a strainer and

pushes it through the motor to the outlet. The pump

contains a check valve. The valve, in the pump out-

let, maintains pump pressure during engine off con-

ditions, for a short while. It is normal for fuel

pressure to drop to zero after cooldown. The fuel

pump relay provides voltage to the fuel pump. The

fuel pump has a maximum deadheaded pressure out-

put of approximately 880 kPa (130 psi). The regula-

tor adjusts fuel system pressure to approximately

400 kpa 34 kpa (58 psi 5 psi).

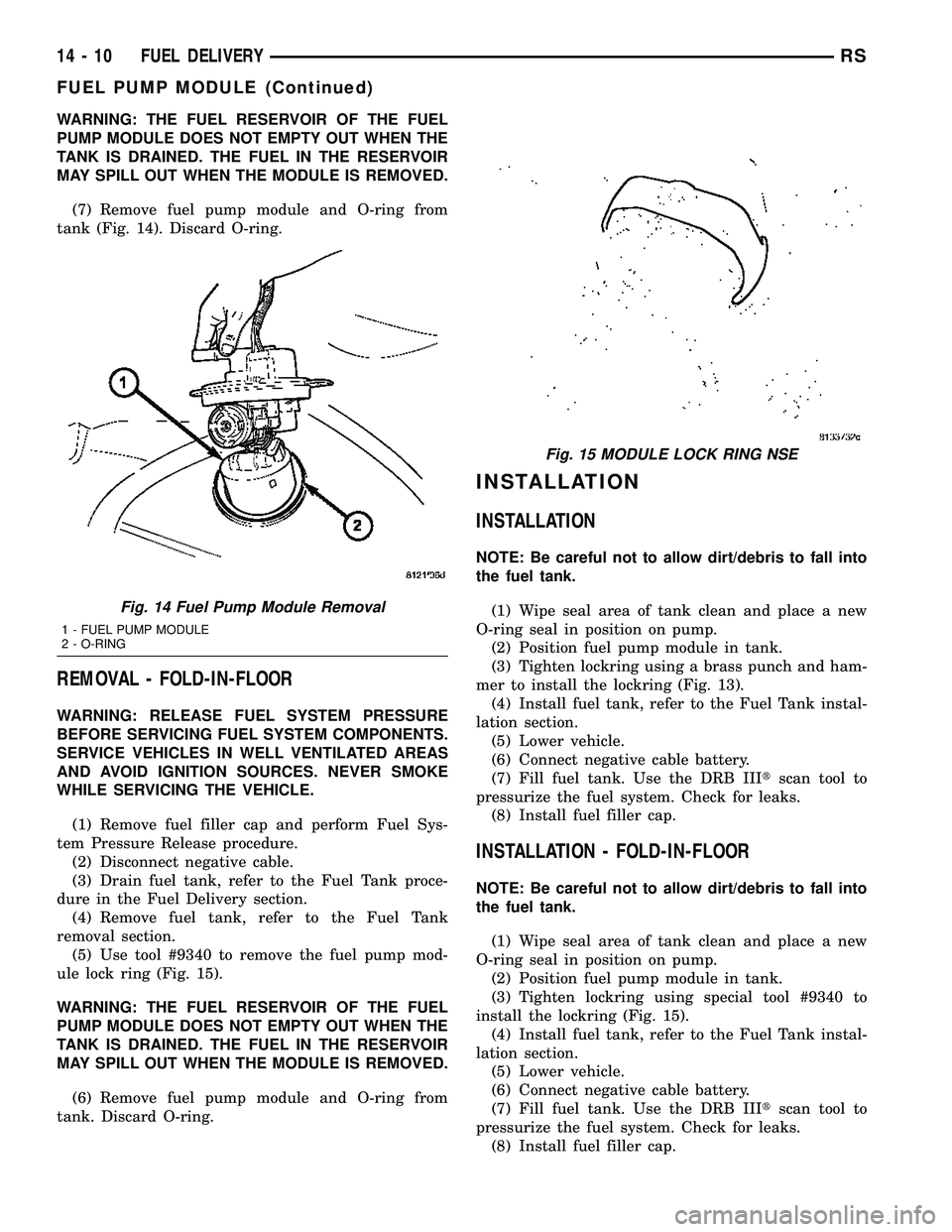

FUEL PUMP MODULE

DESCRIPTION

The fuel pump module is installed in the top of the

fuel tank (Fig. 10), (Fig. 11), and (Fig. 12).The fuel pump module contains the following:

²Electric fuel pump

²Fuel pump reservoir

²Inlet strainer

²Fuel pressure regulator

²Fuel gauge sending unit

Fig. 9 Fuel Pressure Regulator O-rings

1 - UPPER O-RING

2 - LOWER 0-RING

Fig. 10 LEVEL SENSOR - FOLD-IN-FLOOR

2 - FUEL PUMP MODULE

3 - PRESSURE REGULATOR

4 - FUEL LEVEL SENDER

Fig. 11 REGULATOR AND WIRING - FOLD-IN-FLOOR

2 - FUEL RESERVOIR

3 - PRESSURE REGULATOR

6 - GROUND STRAPS

14 - 8 FUEL DELIVERYRS

FUEL PRESSURE REGULATOR (Continued)

Page 1374 of 2339

²Fuel supply line connection

The inlet strainer, fuel pressure regulator

and fuel level sensor are the only serviceable

items. If the fuel pump or electrical wiring har-

ness requires service, replace the fuel pump

module.

The electric fuel pump is located in and is part of

the fuel pump module. It is a positive displacement,

gerotor type, immersible pump with a permanent

magnet electric motor.

OPERATION

The pump draws fuel through a strainer and

pushes it through the motor to the outlet. The pump

contains one check valve. The check valve, in the

pump outlet, maintains pump pressure during engine

off conditions. The fuel pump relay provides voltage

to the fuel pump.

The fuel pump has a maximum deadheaded pres-

sure output of approximately 880 kPa (130 psi). The

regulator adjusts fuel system pressure to approxi-

mately 400 34 kPa (58 5 psi).

FUEL PUMP ELECTRICAL CONTROL

Voltage to operate the electric pump is supplied

through the fuel pump relay. For an electrical opera-

tional description of the fuel pump refer to fuel Pump

RelayÐPCM Output.

ELECTRICAL PUMP REPLACEMENT

The electric fuel pump is not serviceable. If the

fuel pump or electrical wiring harness needs replace-

ment, the complete fuel pump module must be

replaced. Perform the Fuel System Pressure Release

procedure before servicing the fuel pump.

REMOVAL

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Remove fuel filler cap and perform Fuel Sys-

tem Pressure Release procedure.

(2) Disconnect negative cable from auxiliary

jumper terminal.

(3) Drain fuel tank, refer to the Fuel Tank proce-

dure in the Fuel Delivery section.

(4) Remove fuel tank, refer to the Fuel Tank

removal section.

(5) Clean top of tank to remove loose dirt and

debris.

(6) Using a brass punch and hammer remove lock-

nut to release pump module (Fig. 13).

Fig. 12 FUEL PUMP MODULE Ð NON FOLD-IN-

FLOOR

1 - INLET STRAINER

2 - FUEL RESERVOIR

3 - FUEL PRESSURE REGULATOR

4 - FUEL LEVEL SENSOR

5 - FILTER

6 - GROUND STRAPS

Fig. 13 FUEL PUMP MODULE LOCKING RING

RSFUEL DELIVERY14-9

FUEL PUMP MODULE (Continued)

Page 1375 of 2339

WARNING: THE FUEL RESERVOIR OF THE FUEL

PUMP MODULE DOES NOT EMPTY OUT WHEN THE

TANK IS DRAINED. THE FUEL IN THE RESERVOIR

MAY SPILL OUT WHEN THE MODULE IS REMOVED.

(7) Remove fuel pump module and O-ring from

tank (Fig. 14). Discard O-ring.

REMOVAL - FOLD-IN-FLOOR

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Remove fuel filler cap and perform Fuel Sys-

tem Pressure Release procedure.

(2) Disconnect negative cable.

(3) Drain fuel tank, refer to the Fuel Tank proce-

dure in the Fuel Delivery section.

(4) Remove fuel tank, refer to the Fuel Tank

removal section.

(5) Use tool #9340 to remove the fuel pump mod-

ule lock ring (Fig. 15).

WARNING: THE FUEL RESERVOIR OF THE FUEL

PUMP MODULE DOES NOT EMPTY OUT WHEN THE

TANK IS DRAINED. THE FUEL IN THE RESERVOIR

MAY SPILL OUT WHEN THE MODULE IS REMOVED.

(6) Remove fuel pump module and O-ring from

tank. Discard O-ring.

INSTALLATION

INSTALLATION

NOTE: Be careful not to allow dirt/debris to fall into

the fuel tank.

(1) Wipe seal area of tank clean and place a new

O-ring seal in position on pump.

(2) Position fuel pump module in tank.

(3) Tighten lockring using a brass punch and ham-

mer to install the lockring (Fig. 13).

(4) Install fuel tank, refer to the Fuel Tank instal-

lation section.

(5) Lower vehicle.

(6) Connect negative cable battery.

(7) Fill fuel tank. Use the DRB IIItscan tool to

pressurize the fuel system. Check for leaks.

(8) Install fuel filler cap.

INSTALLATION - FOLD-IN-FLOOR

NOTE: Be careful not to allow dirt/debris to fall into

the fuel tank.

(1) Wipe seal area of tank clean and place a new

O-ring seal in position on pump.

(2) Position fuel pump module in tank.

(3) Tighten lockring using special tool #9340 to

install the lockring (Fig. 15).

(4) Install fuel tank, refer to the Fuel Tank instal-

lation section.

(5) Lower vehicle.

(6) Connect negative cable battery.

(7) Fill fuel tank. Use the DRB IIItscan tool to

pressurize the fuel system. Check for leaks.

(8) Install fuel filler cap.

Fig. 14 Fuel Pump Module Removal

1 - FUEL PUMP MODULE

2 - O-RING

Fig. 15 MODULE LOCK RING NSE

14 - 10 FUEL DELIVERYRS

FUEL PUMP MODULE (Continued)

Page 1382 of 2339

(8)For RGDisconnect the vent at the top of the

filler tube.

(9) Remove the ground strap.

(10) Remove filler tube at tank.

INSTALLATION

(1) Install filler tube to tank (Fig. 32).

(2) Install filler tube shield (Fig. 34).

(3) Install the ground strap.

(4)For RGConnect the vent at the top of the filler

tube.

(5) Install the 3 screws at the filler door.(6)For RGInstall the canister from filler tube

(Fig. 33).

(7) Install the splash shield.

(8) Install the left rear tire.

(9) lower vehicle.

(10) Connect the negative battery cable.

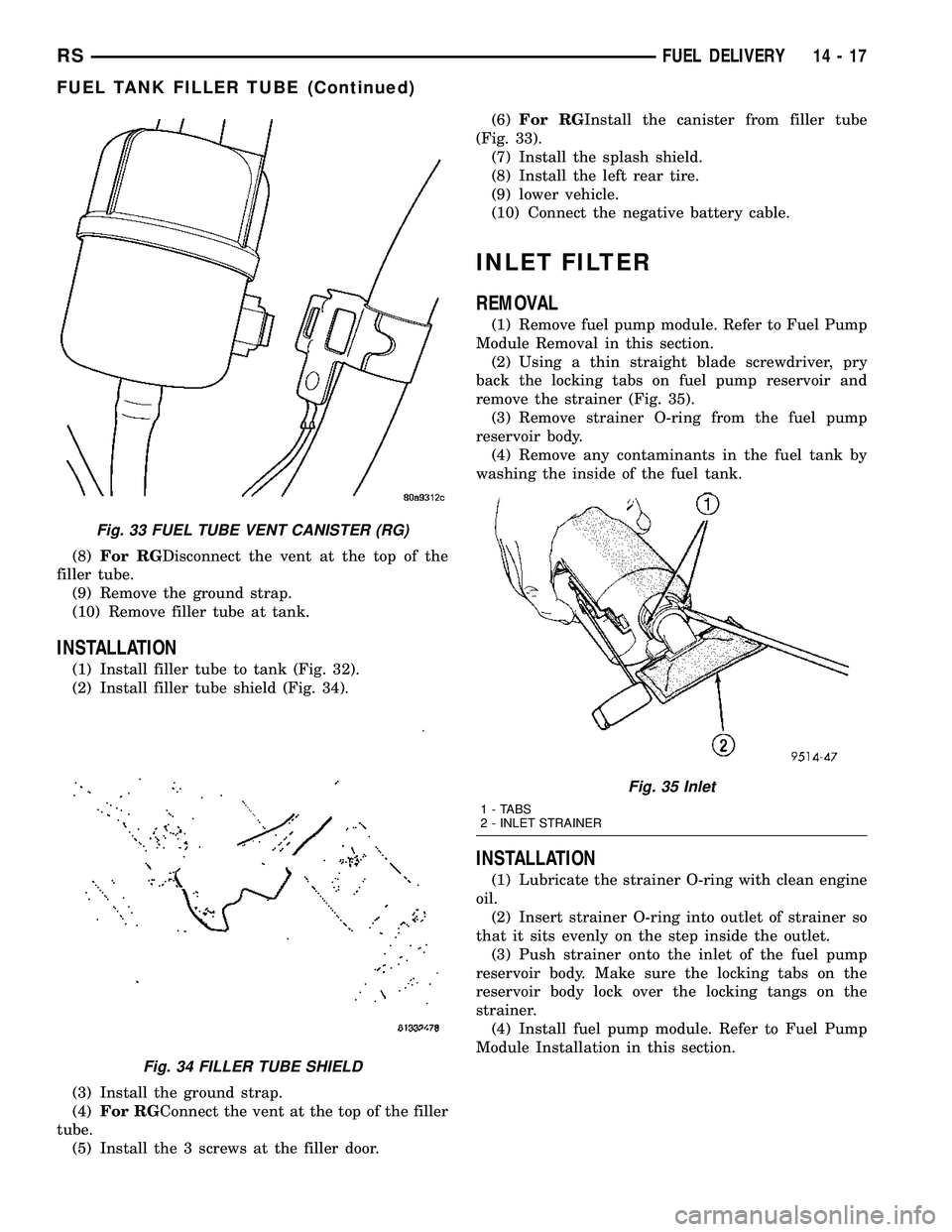

INLET FILTER

REMOVAL

(1) Remove fuel pump module. Refer to Fuel Pump

Module Removal in this section.

(2) Using a thin straight blade screwdriver, pry

back the locking tabs on fuel pump reservoir and

remove the strainer (Fig. 35).

(3) Remove strainer O-ring from the fuel pump

reservoir body.

(4) Remove any contaminants in the fuel tank by

washing the inside of the fuel tank.

INSTALLATION

(1) Lubricate the strainer O-ring with clean engine

oil.

(2) Insert strainer O-ring into outlet of strainer so

that it sits evenly on the step inside the outlet.

(3) Push strainer onto the inlet of the fuel pump

reservoir body. Make sure the locking tabs on the

reservoir body lock over the locking tangs on the

strainer.

(4) Install fuel pump module. Refer to Fuel Pump

Module Installation in this section.

Fig. 33 FUEL TUBE VENT CANISTER (RG)

Fig. 34 FILLER TUBE SHIELD

Fig. 35 Inlet

1 - TABS

2 - INLET STRAINER

RSFUEL DELIVERY14-17

FUEL TANK FILLER TUBE (Continued)

Page 1391 of 2339

The following components access or send informa-

tion on the PCI Bus.

²Instrument Panel

²Body Control Module

²Air Bag System Diagnostic Module

²Full ATC Display Head (if equipped)

²ABS Module

²Transmission Control Module

²Powertrain Control Module

²Travel Module

²SKIMSYSTEM DIAGNOSIS

OPERATION

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.

For DTC information see On-Board Diagnostics

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/POWERTRAIN CONTROL MOD-

ULE - DESCRIPTION) .

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

MAP SENSOR PLASTIC

MANIFOLD1.7 15

MAP SENSOR

ALUMINUM MANIFOLD3.3 30

POWER STEERING

RESERVOIR PLASTIC

MANIFOLD5.7 50

POWER STEERING

RESERVOIR ALUMINUM

MANIFOLD11.9 105

THROTTLE CABLE

BRACKET PLASTIC

MANIFOLD5.7 50

THROTTLE CABLE

BRACKET ALUMINUM

MANIFOLD11.9 105

EGR TUBE PLASTIC

MANIFOLD5.7 50

EGR TUBE ALUMINUM

MANIFOLD11.9 105

THROTTLE BODY BOLTS

2.4L28 20.65 250 50

THROTTLE BODY BOLTS

3.3/3.8L11.8 8.7 105 20

O2 Sensors 27 20

The composite manifolds uses special Plastic screws. The factory installed Plastic screws can be removed and

installed up to 5 times. Do not exceed the specified torque. These screws must be installed slowly (less than 600

rpms) to avoid melting the parent material. There are service repair screws avialable for repair. They require a

higher torque than the original screws..

14 - 26 FUEL INJECTIONRS

FUEL INJECTION (Continued)

Page 1403 of 2339

REMOVAL - UPSTREAM 1/1 - 3.3/3.8L

(1) Remove battery, refer to the Battery section for

more information.

(2) Remove the battery tray, refer to the Battery

section for more information.

(3) Disconnect the speed control vacuum harness

from servo.

(4) Disconnect the electrical connector from servo.

(5) Remove the speed control servo and bracket

and reposition.

(6) Use a socket such as the Snap-OntYA8875 or

equivalent to remove the sensor (Fig. 25).

(7) When the sensor is removed, the threads must

be cleaned with an 18 mm X 1.5 + 6E tap. If using

the original sensor, coat the threads with Loctite

771±64 anti-seize compound or equivalent.

REMOVAL - DOWNSTREAM 1/2 - 2.4/3.3/3.8L

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

(3) Disconnect the electrical connector (Fig. 26).

(4) Use a socket such as the Snap-OntYA8875 or

equivalent to remove the sensor (Fig. 27).

(5) When the sensor is removed, the threads must

be cleaned with an 18 mm X 1.5 + 6E tap. If using

the original sensor, coat the threads with Loctite

771±64 anti-seize compound or equivalent.

INSTALLATION

INSTALLATION - UPSTREAM 1/1 - 2.4L

The engines uses two heated oxygen sensors.

(1) After removing the sensor, the exhaust mani-

fold threads must be cleaned with an 18 mm X 1.5 +

6E tap. If reusing the original sensor, coat the sensor

threads with an anti-seize compound such as Loctite

771- 64 or equivalent. New sensors have compound

on the threads and do not require an additional coat-

ing.

Fig. 25 O2 SENSOR 1/1

Fig. 26 Downstream Oxygen Sensor (1/2)

1 - OXYGEN SENSOR CONNECTOR

2 - CATALYTIC CONVERTER

3 - DOWNSTREAM OXYGEN SENSOR

4 - ENGINE HARNESS CONNECTOR

Fig. 27 DOWNSTREAM 2/1 O2 SENSOR

14 - 38 FUEL INJECTIONRS

O2 SENSOR (Continued)

Page 1404 of 2339

(2) Install sensor and tighten to 27 N´m (20 ft.

lbs.) (Fig. 23).

(3) Connect the electrical connector for the O2 sen-

sor and install onto bracket.

(4) Lower vehicle.

(5) Connect the negative battery cable.

INSTALLATION - UPSTREAM 1/1 - 3.3/3.8L

The engines uses two heated oxygen sensors.

(1) After removing the sensor, the exhaust mani-

fold threads must be cleaned with an 18 mm X 1.5 +

6E tap. If reusing the original sensor, coat the sensor

threads with an anti-seize compound such as Loctite

771- 64 or equivalent. New sensors have compound

on the threads and do not require an additional coat-

ing.

(2) Install sensor and tighten to 27 N´m (20 ft.

lbs.).

(3) Connect the electrical connector for the O2 sen-

sor and install onto bracket.

(4) Connect the electrical connector for the speed

control servo.

(5) Install the speed control servo and bracket

refer to the Speed Control Servo for more informa-

tion.

(6) Connect the speed control vacuum harness to

servo.

(7) Install the battery tray, refer to the Battery

section for more information.

(8) Install battery, refer to the Battery section for

more information.

INSTALLATION DOWNSTREAM 2/1 -

2.4/3.3/3.8L

The O2S is located on the side of the catalytic con-

verter.

Threads of new oxygen sensors are factory coated

with anti-seize compound to aid in removal.DO

NOT add any additional anti-seize compound to

the threads of a new oxygen sensor.

(1) Install sensor and tighten to 27 N´m (20 ft.

lbs.).

(2) Connect the electrical connector.

(3) Lower vehicle.

(4) Install the negative battery cable.

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold

(Fig. 28) or (Fig. 29). Fuel does not enter the intake

manifold through the throttle body. Fuel is sprayed

into the manifold by the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake

manifold through the throttle body. The throttle body

contains an air control passage controlled by an Idle

Air Control (IAC) motor. The air control passage is

used to supply air for idle conditions. A throttle valve

(plate) is used to supply air for above idle conditions.

Certain sensors are attached to the throttle body.

The accelerator pedal cable, speed control cable are

connected to the throttle body cam.

Fig. 28 IAC VALVE 2.4L

1 - Idle Air Control Valve

2 - Throttle Position Sensor

Fig. 29 IAC VALVE LOCATION 3.3/3.8L

1 - Idle Air Control Valve

2 - Throttle Position Sensor

RSFUEL INJECTION14-39

O2 SENSOR (Continued)

Page 1408 of 2339

STEERING

TABLE OF CONTENTS

page page

STEERING

DESCRIPTION - POWER STEERING SYSTEM . . 1

OPERATION - POWER STEERING SYSTEM . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER

STEERING SYSTEM FLOW AND

PRESSURE TEST......................1

DIAGNOSIS AND TESTING - STEERING

SYSTEM DIAGNOSIS CHARTS............3SPECIFICATIONS

POWER STEERING FASTENER TORQUE . . . 9

SPECIAL TOOLS

POWER STEERING....................9

COLUMN..............................10

GEAR.................................26

PUMP.................................36

STEERING

DESCRIPTION - POWER STEERING SYSTEM

This vehicle comes with power steering as stan-

dard equipment. The power steering system consists

of these major components:

²POWER STEERING PUMP

²POWER STEERING GEAR

²POWER STEERING FLUID

²POWER STEERING FLUID COOLER (If

Equipped)

²POWER STEERING FLUID RESERVOIR

²POWER STEERING FLUID SUPPLY HOSE

²POWER STEERING FLUID PRESSURE HOSE

²POWER STEERING FLUID RETURN HOSE

For information on the first two components, refer

to their respective sections within this service man-

ual group. Information on all other components can

be found in POWER STEERING PUMP.

OPERATION - POWER STEERING SYSTEM

Turning of the steering wheel is converted into lin-

ear (side-to-side) travel through the meshing of the

helical pinion teeth with the rack teeth within the

steering gear. The lateral travel pushes and pulls the

tie rods to change the direction of the vehicle's front

wheels.

Power assist steering is provided by a belt driven

rotary type pump. It directs fluid through power

steering fluid hoses to the power steering gear where

it is used to assist the driver's turning effort.

Manual steering control of the vehicle can be main-

tained if power steering assist is lost. However,

under this condition, steering effort is significantly

increased.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER STEERING

SYSTEM FLOW AND PRESSURE TEST

ALL ENGINES

The following procedure is to be used to test the

operation of the power steering system on this vehi-

cle. This test will provide the flow rate of the power

steering pump along with the maximum relief pres-

sure. This test is to be performed to determine if the

power steering pump or power steering gear is not

functioning properly. The following flow and pressure

test is performed using the Power Steering Analyzer

Kit, Special Tool 6815 (Fig. 1), hoses, Special Tools

6905 and 6959, and fittings from adapter kit, Special

Tool 6893.

Fig. 1 Power Steering Analyzer With Hoses Installed

1 - OUTLET

2 - SPECIAL TOOL 6815

3 - INLET

RSSTEERING19-1

Page 1411 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

4. Loose lower control arm mounting

bolts at front suspension

crossmember.4. Tighten control arm mounting bolts to

the specified torques.

5. Lower control arm pivot bushing

worn.5. Replace lower control arm pivot

bushing.

6. Loose strut assembly mounting

fasteners at tower or knuckle.6. Tighten strut assembly fasteners to

the specified torque.

7. Power steering fluid hose touching

the body of the vehicle.7. Adjust hose to proper position by

loosening, repositioning, and tightening

attachments to specified torque. Do not

bend tubing.

8. Damaged front suspension

crossmember.8. Replace front suspension

crossmember.

9. Stabilizer bar link ball joints worn. 9. Replace stabilizer bar link.

10. Lug nuts loose. 10. Tighten lug nuts to specifications.

11. Excessive Wheel bearing

free-play.11. Verify correct halfshaft hub nut

torque. Replace hub and bearing if

torque is okay.

12. Internal power steering gear

noise.12. Replace power steering gear.

POPPING NOISE 1. Worn outer tie rod. 1. Check ball joint for free-play;

Replace outer tie rod.

2. Loose inner tie rod. 2. Replace power steering gear.

CHIRP OR SQUEAL

(POWER STEERING

PUMP)1. Loose power steering pump drive

belt.1. Check and adjust power steering

pump drive belt to specifications or

replace automatic tensioner where

applicable. Replace belt if worn or

glazed.

2. Malfuctioning belt auto-tensioner 2. Replace belt auto-tensioner.

WHINE, GROWL, MOAN

OR GROAN (POWER

STEERING PUMP)***1. Low fluid level. 1. Fill power steering fluid reservoir to

proper level and check for leaks (make

sure all air is bled from the system

fluid).

2. Power steering hose touching

vehicle body or frame.2. Adjust hose to proper position by

loosening, repositioning, and tightening

fitting to specified torque. Do not bend

tubing. Replace hose if damaged.

3. Extremely low ambient

temperature.3. Some noise can be expected, but will

go away as vehicle warms. Replace

pump if noise is excessive.

4. Extreme wear of power steering

pump internal components.4. Replace power steering pump and

flush system as necessary.

19 - 4 STEERINGRS

STEERING (Continued)