engine coolant CHRYSLER VOYAGER 2005 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1318 of 2339

OIL COOLER & LINES

DESCRIPTION

An engine oil cooler is used on 3.3/3.8L engines

(Heavy Duty Cooling Only) (Fig. 99). The cooler is a

coolant-to-oil type and mounted between the oil filter

and engine block.

OPERATION

Engine oil travels from the oil filter and into the

oil cooler. Engine oil then exits the cooler into the

main gallery. Engine coolant flows into the cooler

from the heater return tube and exits into the water

pump inlet.

REMOVAL

(1) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE - COOLING SYSTEM

DRAINING).

(2) Disconnect oil cooler inlet and outlet hoses

(Fig. 98).

(3) Remove oil filter.

(4) Remove oil cooler attachment fitting (Fig. 99).

(5) Remove oil cooler.

INSTALLATION

(1) Lubricate seal and position oil cooler to connec-

tor fitting on oil filter adapter (Fig. 99).

NOTE: Position the flat side of oil cooler parallel to

oil pan rail.

(2) Install oil cooler attachment fitting and tighten

to 27 N´m (20 ft. lbs.) (Fig. 99).(3) Install oil filter.

(4) Connect oil cooler inlet and outlet hoses (Fig.

98).

(5) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE - COOLING SYSTEM

FILLING).

OIL FILTER

REMOVAL

CAUTION: When servicing the oil filter avoid

deforming the filter can by installing the remove/in-

stall tool band strap against the can-to-base lock

seam. The lock seam joining the can to the base is

reinforced by the base plate.

(1) Using suitable oil filter wrench, turn filter

counterclockwise to remove from oil filter adapter

(Fig. 100). Properly discard used oil filter.

INSTALLATION

(1) Wipe oil filter adapter base clean and inspect

gasket contact surface.

(2) Lubricate gasket of new filter with clean

engine oil.

(3) Install new filter until gasket contacts base

(Fig. 100). Tighten filter 1 turn or 20 N´m (15 ft.

lbs.). Use filter wrench if necessary.

(4) Start engine and check for leaks.

Fig. 98 Engine Oil Cooler Hoses

1 - OIL COOLER INLET TUBE

2 - INLET HOSE

3 - OIL COOLER OUTLET TUBE

4 - OUTLET HOSE

5 - WATER PUMP INLET TUBE

Fig. 99 Engine Oil Cooler - 3.3/3.8L (Heavy Duty

Cooling)

1 - OIL FILTER ADAPTER

2 - CONNECTOR

3 - ENGINE OIL COOLER

4 - OIL COOLER ATTACHMENT FITTING

5 - OIL FILTER

RSENGINE 3.3/3.8L9 - 141

Page 1324 of 2339

(2) Install timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION) and oil pan (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

INTAKE MANIFOLD

DESCRIPTION

The intake system is made up of an upper and

lower intake manifold. The upper intake manifold is

made of a composite for both the 3.3L engine and for

the 3.8L engine (Fig. 118). The lower intake manifold

is common between the two engines (Fig. 122). It also

provides coolant crossover between cylinder heads

and houses the coolant thermostat (Fig. 122).

The intake manifold utilizes a compact design with

very low restriction and outstanding flow balance.

This design allows the engine to perform with a wide

torque curve while increasing higher rpm horse-

power.

If, for some reason, the molded-in vacuum ports

break, the composite manifold can be salvaged. The

vacuum ports are designed to break at the shoulder,

if overloaded. Additional material in the shoulder

area provides sufficient stock to repair. For more

information and procedure, (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - STANDARD

PROCEDURE). Also, if the special screws that attach

the MAP sensor, power steering reservoir, throttle

cable bracket, and the EGR tube become stripped, an

oversized screw is available to repair the stripped-out

condition. For more information and procedure,

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - STANDARD PROCEDURE)

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

INTAKE MANIFOLD - UPPER

STANDARD PROCEDURE

STANDARD PROCEDURE - MANIFOLD

STRIPPED THREAD REPAIR

The composite upper intake manifold thread

bosses, if stripped out, can be repaired by utilizing a

repair screw available through Mopartparts. Repair

screws are available for the following manifold

attached components:

²MAP sensor

²Power steering reservoir

²EGR tube

²Throttle cable bracket

The repair screws require a unique tightening

torque specification from the original screw. Refer to

the following chart for specification.

DESCRIPTION TORQUE*

STRIP-OUT REPAIR SCREWS ONLY

MAP Sensor Repair

Screw4 N´m (35 in. lbs.)

Power Steering Reservoir

Repair Screw9 N´m (80 in. lbs.)

EGR Tube Attaching

Repair Screw9 N´m (80 in. lbs.)

Throttle Cable Bracket

Repair Screw9 N´m (80 in. lbs.)

*Install Slowly Using Hand Tools Only

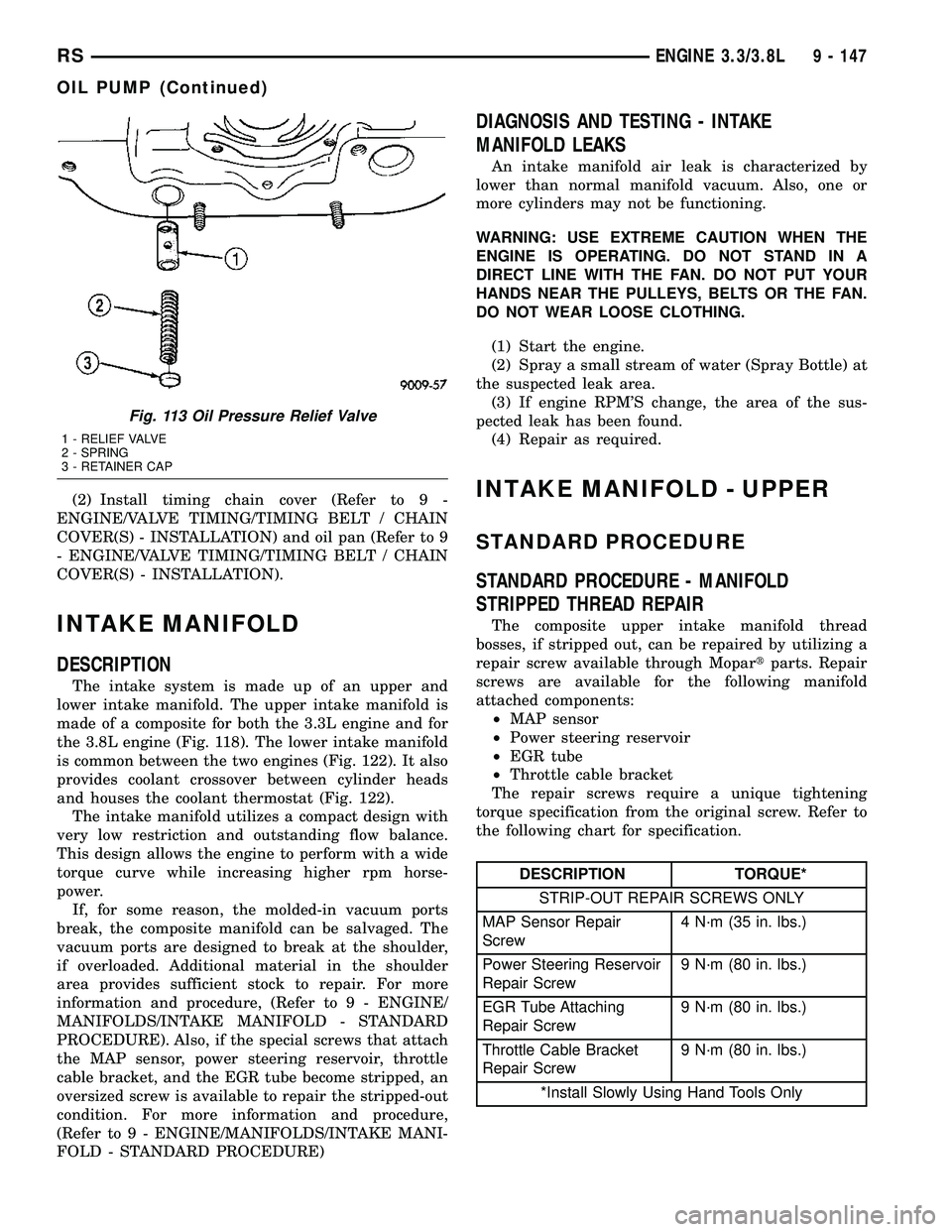

Fig. 113 Oil Pressure Relief Valve

1 - RELIEF VALVE

2 - SPRING

3 - RETAINER CAP

RSENGINE 3.3/3.8L9 - 147

OIL PUMP (Continued)

Page 1328 of 2339

WARNING: INTAKE MANIFOLD GASKET IS MADE

OF VERY THIN METAL AND MAY CAUSE PER-

SONAL INJURY, HANDLE WITH CARE.

(12) Remove intake manifold seal retainers screws

(Fig. 122). Remove intake manifold gasket.

(13) Inspect and clean manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSPECTION) (Refer to 9 - ENGINE/MANIFOLDS/

INTAKE MANIFOLD - CLEANING)

CLEANING

(1) Discard gasket(s).

(2) Clean all sealing surfaces.

INSPECTION

Check for:

²Damage and cracks of each section.

²Clogged water passages in end cross-overs (if

equipped).²Check for cylinder head mounting surface distor-

tion using a straightedge and thickness gauge. (Refer

to 9 - ENGINE/CYLINDER HEAD - INSPECTION)

INSTALLATION - LOWER INTAKE MANIFOLD

(1) Place a bead (approximately 1/4 in. diameter)

of MopartEngine RTV GEN II onto each of thefour

manifold to cylinder head gasket corners (Fig. 123).

(2) Carefully install the new intake manifold gas-

ket (Fig. 122). Tighten end seal retainer screws to 12

N´m (105 in. lbs.).

(3) Install lower intake manifold (Fig. 122). Install

the bolts and torque to 1 N´m (10 in. lbs.). Then

torque bolts to 22 N´m (200 in. lbs.) in sequence

shown in (Fig. 124). Then torque again to 22 N´m

(200 in. lbs.). After intake manifold is in place,

inspect to make sure seals are in place.

(4) Install the fuel injectors and rail assembly.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL RAIL - INSTALLATION)

(5) Connect fuel injector electrical harness.

(6) Connect the engine coolant temperature sensor

(Fig. 121).

(7) Connect the heater supply (Fig. 121) and radi-

ator upper hoses to manifold.

(8) Connect the fuel line. (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

Fig. 120 FUEL RAIL AND IGNITION COIL &

BRACKET

1 - FUEL RAIL

2 - BOLT - FUEL RAIL

3 - NUT - IGNITION COIL

4 - BOLT - IGNITION COIL

5 - IGNITION COIL

6 - BRACKET - IGNITION COIL

7 - STUD - IGNITION COIL

8 - SEPARATOR - SPARK PLUG CABLE

9 - BRACKET - SPARK PLUG CABLE SEPARATOR

10 - BOLT - SEPARATOR BRACKET

11 - BRACKET - SPARK PLUG CABLE SEPARATOR

Fig. 121 ECT SENSOR & HEATER SUPPLY

1 - ENGINE COOLANT TEMPERATURE SENSOR

2 - CONNECTOR - ENGINE COOLANT SENSOR

3 - FITTING - HEATER SUPPLY

RSENGINE 3.3/3.8L9 - 151

INTAKE MANIFOLD - LOWER (Continued)

Page 1387 of 2339

FUEL INJECTION

OPERATION

OPERATION - INJECTION SYSTEM

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

The PCM can adapt its programming to meet

changing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are theprimaryinputs that determine

injector pulse width.

OPERATION - MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCM

programming. Inputs from the upstream and down-

stream heated oxygen sensors are not monitored dur-

ing OPEN LOOP modes, except for heated oxygensensor diagnostics (they are checked for shorted con-

ditions at all times).

During CLOSED LOOP modes the PCM monitors

the inputs from the upstream and downstream

heated oxygen sensors. The upstream heated oxygen

sensor input tells the PCM if the calculated injector

pulse width resulted in the ideal air-fuel ratio of 14.7

to one. By monitoring the exhaust oxygen content

through the upstream heated oxygen sensor, the

PCM can fine tune injector pulse width. Fine tuning

injector pulse width allows the PCM to achieve opti-

mum fuel economy combined with low emissions.

For the PCM to enter CLOSED LOOP operation,

the following must occur:

(1) Engine coolant temperature must be over 35ÉF.

²If the coolant is over 35ÉF the PCM will wait 38

seconds.

²If the coolant is over 50ÉF the PCM will wait 15

seconds.

²If the coolant is over 167ÉF the PCM will wait 3

seconds.

(2) For other temperatures the PCM will interpo-

late the correct waiting time.

(3) O2 sensor must read either greater than 0.745

volts or less than 0.29 volt.

(4) The multi-port fuel injection systems has the

following modes of operation:

²Ignition switch ON (Zero RPM)

²Engine start-up

²Engine warm-up

²Cruise

²Idle

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

(5) The engine start-up (crank), engine warm-up,

deceleration with fuel shutoff and wide open throttle

modes are OPEN LOOP modes. Under most operat-

ing conditions, the acceleration, deceleration (with

A/C on), idle and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injec-

tion system, the following actions occur:

²The PCM monitors the engine coolant tempera-

ture sensor and throttle position sensor input. The

PCM determines basic fuel injector pulse width from

this input.

²The PCM determines atmospheric air pressure

from the MAP sensor input to modify injector pulse

width.

When the key is in the ON position and the engine

is not running (zero rpm), the Auto Shutdown (ASD)

and fuel pump relays de-energize after approximately

14 - 22 FUEL INJECTIONRS

Page 1388 of 2339

1 second. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injectors and heated

oxygen sensors.

ENGINE START-UP MODE

This is an OPEN LOOP mode. If the vehicle is in

park or neutral (automatic transaxles) or the clutch

pedal is depressed (manual transaxles) the ignition

switch energizes the starter relay when the engine is

not running. The following actions occur when the

starter motor is engaged.

²If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the Auto Shutdown (ASD) relay and fuel pump relay.

If the PCM does not receive both signals within

approximately one second, it will not energize the

ASD relay and fuel pump relay. The ASD and fuel

pump relays supply battery voltage to the fuel pump,

fuel injectors, ignition coil, (EGR solenoid and PCV

heater if equipped) and heated oxygen sensors.

²The PCM energizes the injectors (on the 69É

degree falling edge) for a calculated pulse width until

it determines crankshaft position from the camshaft

position sensor and crankshaft position sensor sig-

nals. The PCM determines crankshaft position within

1 engine revolution.

²After determining crankshaft position, the PCM

begins energizing the injectors in sequence. It adjusts

injector pulse width and controls injector synchroni-

zation by turning the individual ground paths to the

injectors On and Off.

²When the engine idles within 64 RPM of its

target RPM, the PCM compares current MAP sensor

value with the atmospheric pressure value received

during the Ignition Switch On (zero RPM) mode.

Once the ASD and fuel pump relays have been

energized, the PCM determines injector pulse width

based on the following:

²MAP

²Engine RPM

²Battery voltage

²Engine coolant temperature

²Inlet/Intake air temperature (IAT)

²Throttle position

²The number of engine revolutions since cranking

was initiated

During Start-up the PCM maintains ignition tim-

ing at 9É BTDC.

ENGINE WARM-UP MODE

This is an OPEN LOOP mode. The following inputs

are received by the PCM:

²Manifold Absolute Pressure (MAP)

²Crankshaft position (engine speed)

²Engine coolant temperature

²Inlet/Intake air temperature (IAT)²Camshaft position

²Knock sensor

²Throttle position

²A/C switch status

²Battery voltage

²Vehicle speed

²Speed control

²O2 sensors

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts ignition timing and engine idle

speed. Engine idle speed is adjusted through the idle

air control motor.

CRUISE OR IDLE MODE

When the engine is at operating temperature this

is a CLOSED LOOP mode. During cruising or idle

the following inputs are received by the PCM:

²Manifold absolute pressure

²Crankshaft position (engine speed)

²Inlet/Intake air temperature

²Engine coolant temperature

²Camshaft position

²Knock sensor

²Throttle position

²Exhaust gas oxygen content (O2 sensors)

²A/C switch status

²Battery voltage

²Vehicle speed

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts engine idle speed and ignition

timing. The PCM adjusts the air/fuel ratio according

to the oxygen content in the exhaust gas (measured

by the upstream and downstream heated oxygen sen-

sor).

The PCM monitors for engine misfire. During

active misfire and depending on the severity, the

PCM either continuously illuminates or flashes the

malfunction indicator lamp (Check Engine light on

instrument panel). Also, the PCM stores an engine

misfire DTC in memory, if 2nd trip with fault.

The PCM performs several diagnostic routines.

They include:

²Oxygen sensor monitor

²Downstream heated oxygen sensor diagnostics

during open loop operation (except for shorted)

²Fuel system monitor

²EGR monitor (if equipped)

²Purge system monitor

²Catalyst efficiency monitor

²All inputs monitored for proper voltage range,

rationality.

RSFUEL INJECTION14-23

FUEL INJECTION (Continued)

Page 1389 of 2339

²All monitored components (refer to the Emission

section for On-Board Diagnostics).

The PCM compares the upstream and downstream

heated oxygen sensor inputs to measure catalytic

convertor efficiency. If the catalyst efficiency drops

below the minimum acceptable percentage, the PCM

stores a diagnostic trouble code in memory, after 2

trips.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C status

²Battery voltage

²Battery temperature or Calculated Battery Tem-

perature

²Engine coolant temperature

²Engine run time

²Inlet/Intake air temperature

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

²Wide Open Throttle-open loop

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C status

²Battery voltage

²Inlet/Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Throttle position sensor

²IAC motor (solenoid) control changes in response

to MAP sensor feedback

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration (Open Loop). In response, the

PCM may momentarily turn off the injectors. This

helps improve fuel economy, emissions and engine

braking.

WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are used by

the PCM:

²Inlet/Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor

²Manifold absolute pressure

²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system and disables

EGR (if equipped).

The PCM adjusts injector pulse width to supply a

predetermined amount of additional fuel, based on

MAP and RPM.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to the Emission sec-

tion for On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

FUEL CORRECTION or ADAPTIVE MEMORIES

DESCRIPTION

In Open Loop, the PCM changes pulse width with-

out feedback from the O2 Sensors. Once the engine

warms up to approximately 30 to 35É F, the PCM

goes into closed loopShort Term Correctionand

utilizes feedback from the O2 Sensors. Closed loop

Long Term Adaptive Memoryis maintained above

170É to 190É F unless the PCM senses wide open

throttle. At that time the PCM returns to Open Loop

operation.

OPERATION

Short Term

The first fuel correction program that begins func-

tioning is the short term fuel correction. This system

corrects fuel delivery in direct proportion to the read-

ings from the Upstream O2 Sensor.

The PCM monitors the air/fuel ratio by using the

input voltage from the O2 Sensor. When the voltage

reaches its preset high or low limit, the PCM begins

to add or remove fuel until the sensor reaches its

switch point. The short term corrections then begin.

The PCM makes a series of quick changes in the

injector pulse-width until the O2 Sensor reaches its

14 - 24 FUEL INJECTIONRS

FUEL INJECTION (Continued)

Page 1398 of 2339

IDLE AIR CONTROL MOTOR

DESCRIPTION

The idle air control valve is mounted on the throt-

tle body. The PCM operates the idle air control valve

(Fig. 15) or (Fig. 16).

OPERATION

The PCM adjusts engine idle speed through the

idle air control valve to compensate for engine load,

coolant temperature or barometric pressure changes.The throttle body has an air bypass passage that

provides air for the engine during closed throttle idle.

The idle air control valve regulates air flow through

the bypass passage.

The PCM controls engine idle speed by adjusting

the position of the idle air control valve. The adjust-

ments are based on inputs the PCM receives. The

inputs are from the throttle position sensor, crank-

shaft position sensor, coolant temperature sensor,

MAP sensor, vehicle speed sensor and various switch

operations (brake, park/neutral, air conditioning).

When engine rpm is above idle speed, the IAC is

used for the following functions:

²Off-idle dashpot

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

Target Idle

Target idle is determined by the following inputs:

²Gear position

²ECT Sensor

²Battery voltage

²Ambient/Battery Temperature Sensor

²VSS

²TPS

²MAP Sensor

REMOVAL

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. If assembly of component is diffi-

cult, a light coat of engine oil may be applied to the

O-RINGS ONLY to aid assembly. Use care when

removing hoses to prevent damage to hose or hose

nipple.

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from idle air con-

trol valve (Fig. 17).

(3) Remove idle air control valve mounting screw.

(4) Remove valve from throttle body. Ensure the

O-rings is removed with the valve.

INSTALLATION

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. If assembly of component is diffi-

cult,a light coat of engine oil may be applied to

the O-RINGS ONLY (Fig. 18)to aid assembly. Use

care when removing hoses to prevent damage to hose

or hose nipple.

(1) Carefully place idle air control motor into

throttle body.

Fig. 15 TPS/IAC 2.4L

1 - Idle Air Control Valve

2 - Throttle Position Sensor

Fig. 16 TPS/IAC 3.3/3.8L

1 - Idle Air Control Valve

2 - Throttle Position Sensor

RSFUEL INJECTION14-33

Page 1590 of 2339

TORQUE CONVERTER CLUTCH (TCC)

In a standard torque converter, the impeller and

turbine are rotating at about the same speed and the

stator is freewheeling, providing no torque multipli-

cation. By applying the turbine's piston to the front

cover's friction material, a total converter engage-

ment can be obtained. The result of this engagement

is a direct 1:1 mechanical link between the engine

and the transmission.

The engagement and disengagement of the TCC

are automatic and controlled by the Powertrain Con-

trol Module (PCM). The engagement cannot be acti-

vated in the lower gears because it eliminates the

torque multiplication effect of the torque converter

necessary for acceleration. Inputs that determine

clutch engagement are: coolant temperature, vehicle

speed and throttle position. The torque converter

clutch is engaged by the clutch solenoid on the valve

body. The clutch will engage at approximately 56

km/h (35 mph) with light throttle, after the shift to

third gear.

REMOVAL

(1) Remove transmission and torque converter

from vehicle. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE - REMOVAL)

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate converter hub and oil pump seal lip

with transmission fluid.(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 305). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE - INSTALLATION)

(9) Fill the transmission with the recommended

fluid. (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 41TE/FLUID - STANDARD PROCE-

DURE)

Fig. 305 Checking Torque Converter Seating

1 - SCALE

2 - STRAIGHTEDGE

RS40TE AUTOMATIC TRANSAXLE21 - 129

TORQUE CONVERTER (Continued)

Page 1592 of 2339

OPERATION

The Transmission Range Sensor (TRS) (Fig. 307)

communicates shift lever position (SLP) to the PCM/

TCM as a combination of open and closed switches.

Each shift lever position has an assigned combina-

tion of switch states (open/closed) that the PCM/TCM

receives from four sense circuits. The PCM/TCM

interprets this information and determines the

appropriate transaxle gear position and shift sched-

ule.

Since there are four switches, there are 16 possible

combinations of open and closed switches (codes).

Seven of these codes are related to gear position and

three are recognized as ªbetween gearº codes. This

results in six codes which should never occur. These

are called ªinvalidº codes. An invalid code will result

in a DTC, and the PCM/TCM will then determine the

shift lever position based on pressure switch data.

This allows reasonably normal transmission opera-

tion with a TRS failure.

TRS SWITCH STATES

SLP T42 T41 T3 T1

PCL CL CL OP

RCL OP OP OP

NCL CL OP CL

ODOP OP OP CL

3OP OP CL OP

LCL OP CL CL

TRANSMISSION TEMPERATURE SENSOR

The TRS has an integrated thermistor (Fig. 308)

that the PCM/TCM uses to monitor the transmis-

sion's sump temperature. Since fluid temperature

can affect transmission shift quality and convertor

lock up, the PCM/TCM requires this information to

determine which shift schedule to operate in. The

PCM also monitors this temperature data so it can

energize the vehicle cooling fan(s) when a transmis-

sion ªoverheatº condition exists. If the thermistor cir-

cuit fails, the PCM/TCM will revert to calculated oil

temperature usage.

CALCULATED TEMPERATURE

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-dicted fluid temperature which is calculated from a

combination of inputs:

²Battery (ambient) temperature

²Engine coolant temperature

²In-gear run time since start-up

REMOVAL

(1) Remove valve body assembly from transaxle.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 41TE/VALVE BODY - REMOVAL)

(2) Remove transmission range sensor retaining

screw and remove sensor from valve body (Fig. 309).

(3) Remove TRS from manual shaft.

INSTALLATION

(1) Install transmission range sensor (TRS) to the

valve body and torque retaining screw (Fig. 309) to 5

N´m (45 in. lbs.).

(2) Install valve body to transaxle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

41TE/VALVE BODY - INSTALLATION)

Fig. 309 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

RS40TE AUTOMATIC TRANSAXLE21 - 131

TRANSMISSION RANGE SENSOR (Continued)

Page 1741 of 2339

ment can be obtained. The result of this engagement

is a direct 1:1 mechanical link between the engine

and the transmission.

The engagement and disengagement of the TCC

are automatic and controlled by the Powertrain Con-

trol Module (PCM). The engagement cannot be acti-

vated in the lower gears because it eliminates the

torque multiplication effect of the torque converter

necessary for acceleration. Inputs that determine

clutch engagement are: coolant temperature, vehicle

speed and throttle position. The torque converter

clutch is engaged by the clutch solenoid on the valve

body. The clutch will engage at approximately 56

km/h (35 mph) with light throttle, after the shift to

third gear.

REMOVAL

(1) Remove transmission and torque converter

from vehicle. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE - REMOVAL)

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate converter hub and oil pump seal lip

with transmission fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

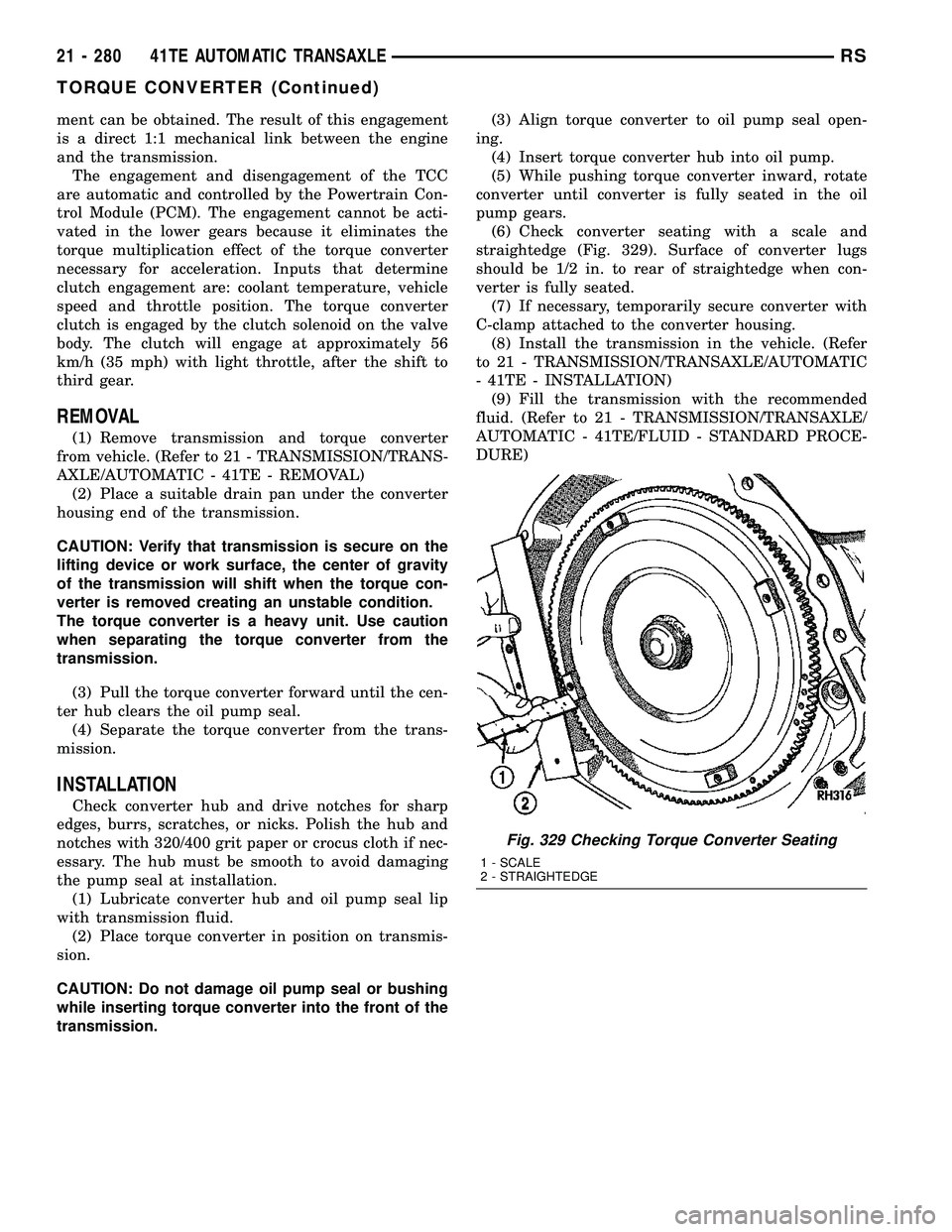

(6) Check converter seating with a scale and

straightedge (Fig. 329). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE - INSTALLATION)

(9) Fill the transmission with the recommended

fluid. (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 41TE/FLUID - STANDARD PROCE-

DURE)

Fig. 329 Checking Torque Converter Seating

1 - SCALE

2 - STRAIGHTEDGE

21 - 280 41TE AUTOMATIC TRANSAXLERS

TORQUE CONVERTER (Continued)