engine coolant CHRYSLER VOYAGER 2005 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1743 of 2339

OPERATION

The Transmission Range Sensor (TRS) (Fig. 331)

communicates shift lever position (SLP) to the PCM/

TCM as a combination of open and closed switches.

Each shift lever position has an assigned combina-

tion of switch states (open/closed) that the PCM/TCM

receives from four sense circuits. The PCM/TCM

interprets this information and determines the

appropriate transaxle gear position and shift sched-

ule.

Since there are four switches, there are 16 possible

combinations of open and closed switches (codes).

Seven of these codes are related to gear position and

three are recognized as ªbetween gearº codes. This

results in six codes which should never occur. These

are called ªinvalidº codes. An invalid code will result

in a DTC, and the PCM/TCM will then determine the

shift lever position based on pressure switch data.

This allows reasonably normal transmission opera-

tion with a TRS failure.

TRS SWITCH STATES

SLP T42 T41 T3 T1

PCL CL CL OP

RCL OP OP OP

NCL CL OP CL

ODOP OP OP CL

3OP OP CL OP

LCL OP CL CL

TRANSMISSION TEMPERATURE SENSOR

The TRS has an integrated thermistor (Fig. 332)

that the PCM/TCM uses to monitor the transmis-

sion's sump temperature. Since fluid temperature

can affect transmission shift quality and convertor

lock up, the PCM/TCM requires this information to

determine which shift schedule to operate in. The

PCM also monitors this temperature data so it can

energize the vehicle cooling fan(s) when a transmis-

sion ªoverheatº condition exists. If the thermistor cir-

cuit fails, the PCM/TCM will revert to calculated oil

temperature usage.

CALCULATED TEMPERATURE

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-dicted fluid temperature which is calculated from a

combination of inputs:

²Battery (ambient) temperature

²Engine coolant temperature

²In-gear run time since start-up

REMOVAL

(1) Remove valve body assembly from transaxle.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 41TE/VALVE BODY - REMOVAL)

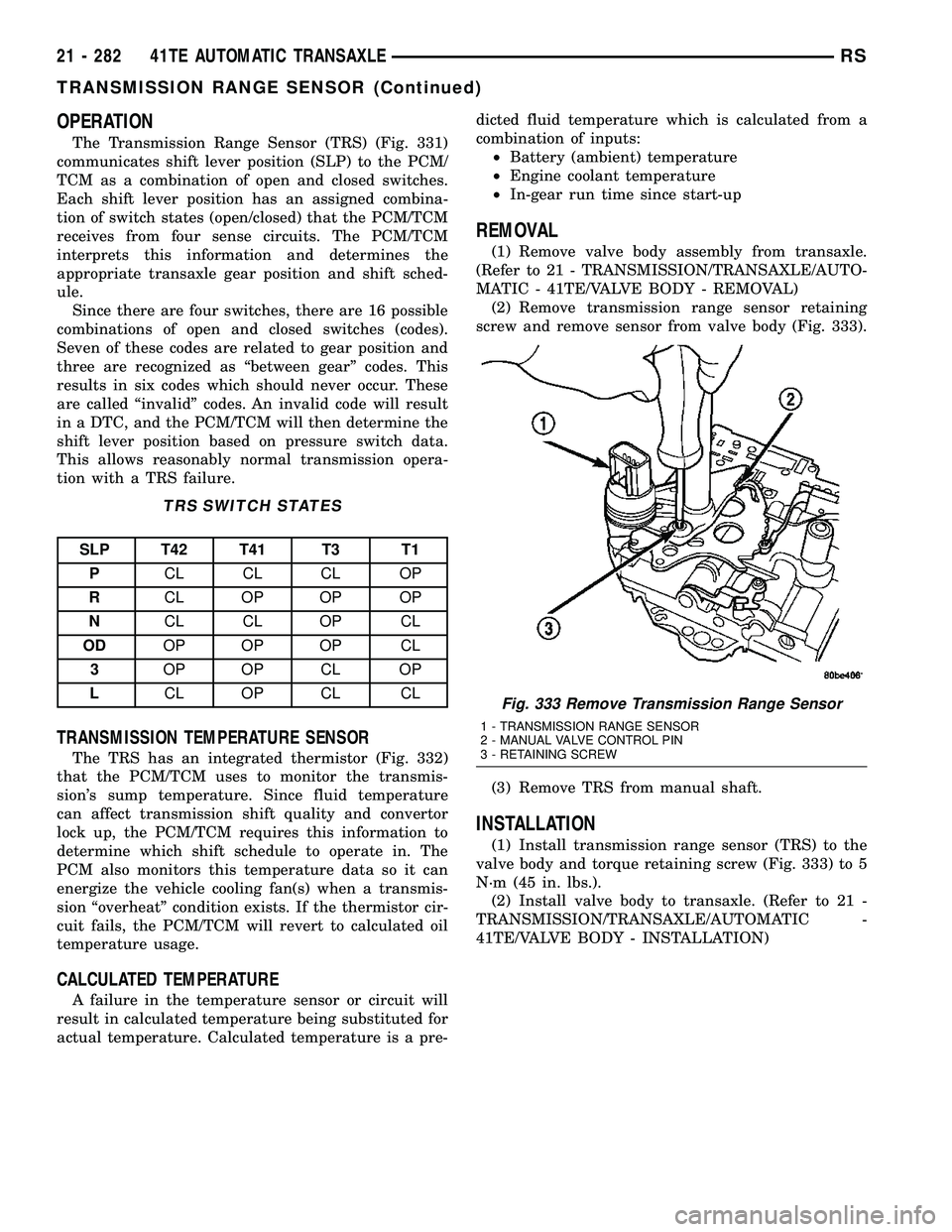

(2) Remove transmission range sensor retaining

screw and remove sensor from valve body (Fig. 333).

(3) Remove TRS from manual shaft.

INSTALLATION

(1) Install transmission range sensor (TRS) to the

valve body and torque retaining screw (Fig. 333) to 5

N´m (45 in. lbs.).

(2) Install valve body to transaxle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

41TE/VALVE BODY - INSTALLATION)

Fig. 333 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

21 - 282 41TE AUTOMATIC TRANSAXLERS

TRANSMISSION RANGE SENSOR (Continued)

Page 1835 of 2339

UPPER RADIATOR

CROSSMEMBER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove radiator sight shield.

(3) Remove engine air inlet resonator.

(4) Unclip hood cable from upper radiator cross-

member.

(5) Remove bolts attaching hood latch to cross-

member and position latch out of the way.

(6) Remove hood prop rod.

(7) Remove screw attaching coolant recovery bottle

to crossmember.

(8) Remove bolts attaching radiator isolators to

crossmember.

(9) Remove bolts attaching ends of crossmember to

radiator closure panel (Fig. 16).

(10) Lift crossmember upward and away from

radiator closure panel.

(11) Remove crossmember from vehicle.

INSTALLATION

(1) Place radiator closure panel crossmember in

position on vehicle.

Fig. 15 GRILLE

1 - SCREW(S)

2 - SPRING CLIP(S)3 - PUSH PIN FASTENER(S)

4 - RETAINER(S)

Fig. 16 RADIATOR CLOSURE PANEL

CROSSMEMBER

1 - RADIATOR CLOSURE PANEL CROSSMEMBER

2 - FRONT FASCIA

23 - 56 EXTERIORRS

GRILLE (Continued)

Page 1836 of 2339

(2) Insert ends of crossmember between layered

metal sections of radiator closure panel at each side

of radiator.

(3) Align with paint breaks around bolt heads.

(4) Install bolts attaching ends of crossmember to

radiator closure panel (Fig. 16). Tighten bolts to 19

N´m (14 ft. lbs.) torque.

(5) Install bolts attaching radiator isolators to

crossmember.

(6) Install screw attaching coolant recovery bottle

to crossmember.

(7) Install bolt attaching air cleaner housing to

crossmember.

(8) Install engine air inlet resonator.

(9) Install hood prop rod.

(10) Align hood latch by placing latch over net

pierce tabs. If alignment is required, flatten tabs.

(11) Install bolts attaching hood latch to cross-

member and clip cable. Tighten bolts to 13.5 N´m (10

ft. lbs.) torque.

(12) Install radiator sight shield.

(13) Verify hood latch operation and hood align-

ment.

FRONT WHEELHOUSE

SPLASH SHIELD

REMOVAL

(1) Hoist and support vehicle on safety stands.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE).

(2) Remove front wheel.

(3) Remove push pin fasteners attaching splash

shield to frame rail forward of suspension.

(4) Remove push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(5) Remove screws attaching wheelhouse splash

shield to front fender and front bumper fascia.

(6) Remove splash shield from vehicle (Fig. 17).

INSTALLATION

(1) Place splash shield in position on vehicle (Fig.

17).

(2) Install push pin fasteners attaching splash

shield to frame rail forward of suspension.

(3) Install push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(4) Install screws attaching wheelhouse splash

shield to front fender.

(5) Install front wheel.

(6) Lower vehicle.

LUGGAGE RACK RISER

REMOVAL

(1) Remove two fasteners from the front riser.

Gently pull up on the luggage rack side rail and

detach the riser snap to remove riser from the rail

(Fig. 18).

(2) Repeat for the opposite side, if necessary.

(3) Remove front riser(s) from vehicle (Fig. 19).

Fig. 17 FRONT WHEELHOUSE SPLASH SHIELD

1 - FRONT FENDER WHEELHOUSE SPLASH SHIELD

2 - PUSH PIN FASTENERS

3 - ACCESSORY DRIVE SPLASH SHIELD

4 - SCREWS

Fig. 18 LUGGAGE RACK RISER COVER

1 - FRONT RISER COVER

2 - LOCK TABS

3 - LUGGAGE RACK SIDE RAIL

4 - FRONT RISER

RSEXTERIOR23-57

UPPER RADIATOR CROSSMEMBER (Continued)

Page 2152 of 2339

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

ENGINE COOLING SYSTEM

REQUIREMENTS.......................1

HEATER AND AIR CONDITIONER..........1

MANUAL SINGLE ZONE.................2

MANUAL DUAL ZONE...................2

MANUAL THREE ZONE..................2

AUTOMATIC TEMPERATURE CONTROL....3

OPERATION

HEATER AND AIR CONDITIONER..........4

MANUAL SINGLE ZONE.................4

MANUAL DUAL ZONE...................5

MANUAL THREE ZONE..................5AUTOMATIC TEMPERATURE CONTROL....5

DIAGNOSIS AND TESTING

A/C COOL DOWN TEST.................6

A/C PERFORMANCE TEST...............7

HEATER PERFORMANCE TEST..........10

SPECIFICATIONS

A/C SYSTEM.........................11

CONTROLS - FRONT.....................13

CONTROLS - REAR......................33

DISTRIBUTION - FRONT...................42

DISTRIBUTION - REAR....................56

PLUMBING - FRONT.....................64

PLUMBING - REAR......................98

CABIN HEATER........................113

HEATING & AIR

CONDITIONING

DESCRIPTION

ENGINE COOLING SYSTEM REQUIREMENTS

To maintain the performance level of the heating,

ventilation and air conditioning (HVAC) system, the

engine cooling system must be properly maintained.

The use of a bug screen is not recommended. Any

obstructions in front of the radiator or condenser will

reduce the performance of the air conditioning and

engine cooling systems.

The engine cooling system includes the radiator,

thermostat, radiator hoses and the engine coolant

pump. Refer to Cooling for more information before

opening or attempting any service to the engine cool-

ing system.

HEATER AND AIR CONDITIONER

A manually controlled single zone type heating-air

conditioning system, manually controlled dual zone

type heating-air conditioning system, manually con-

trolled three zone type heating-air conditioning sys-

tem or an automatic controlled three zone type

heating-air conditioning system is available on this

model.

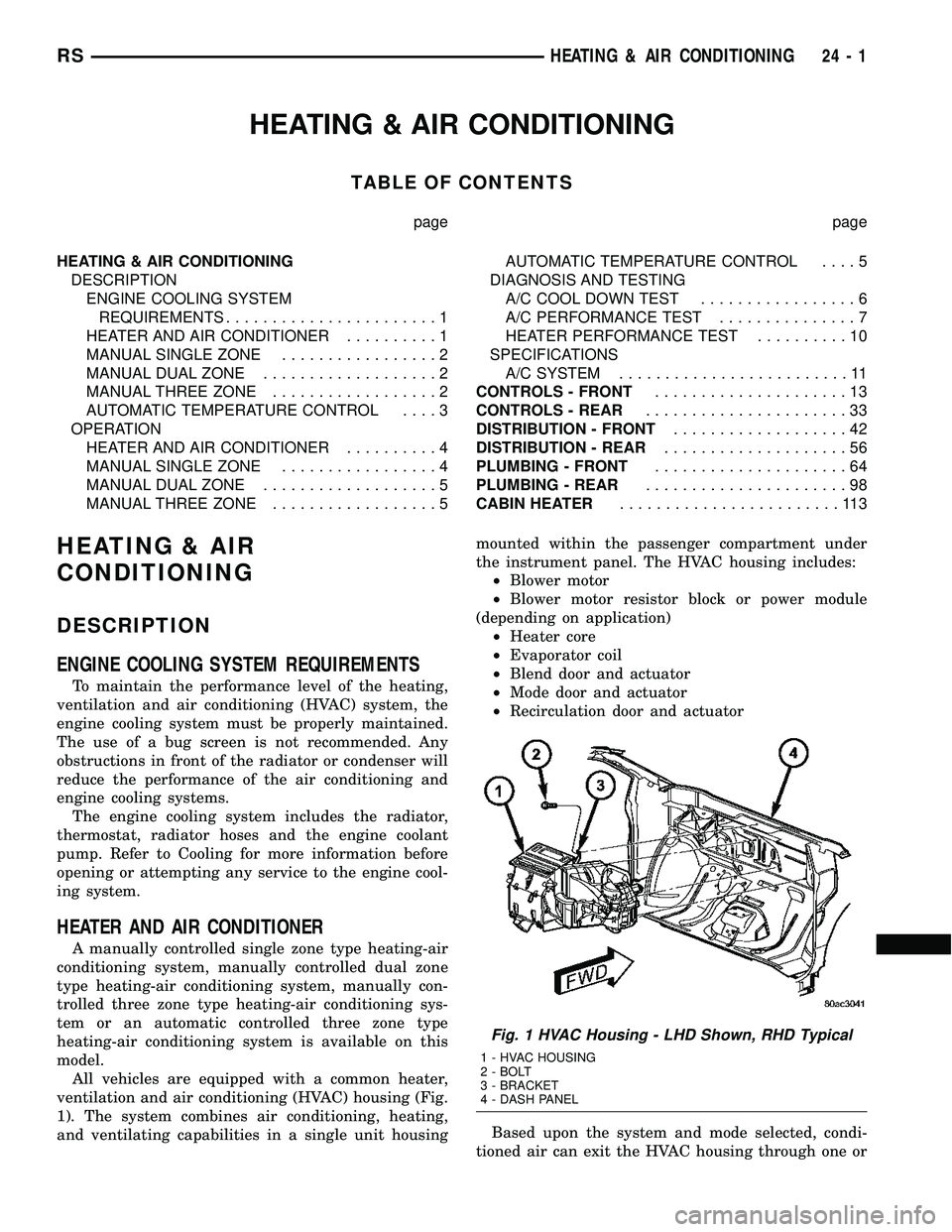

All vehicles are equipped with a common heater,

ventilation and air conditioning (HVAC) housing (Fig.

1). The system combines air conditioning, heating,

and ventilating capabilities in a single unit housingmounted within the passenger compartment under

the instrument panel. The HVAC housing includes:

²Blower motor

²Blower motor resistor block or power module

(depending on application)

²Heater core

²Evaporator coil

²Blend door and actuator

²Mode door and actuator

²Recirculation door and actuator

Based upon the system and mode selected, condi-

tioned air can exit the HVAC housing through one or

Fig. 1 HVAC Housing - LHD Shown, RHD Typical

1 - HVAC HOUSING

2 - BOLT

3 - BRACKET

4 - DASH PANEL

RSHEATING & AIR CONDITIONING24-1

Page 2154 of 2339

²a rotary adjustment knob for temperature.

²a rotary adjustment for fan speed control.

AUTOMATIC TEMPERATURE CONTROL

Two different automatic temperature control (ATC)

heating-A/C systems are available for this model

depending on the market.

The Dual-Zone ATC system allows the driver and

front occupants to each select individual comfort tem-

peratures.

The Three-Zone ATC system allows both the driver

and front occupants and the rear intermediate occu-

pants to select individual comfort temperatures.

NOTE: Individual comfort temperatures are the per-

ceived temperature level at the individual seating

areas, NOT the actual passenger compartment air

temperature.

The ATC system includes a particulate air filter.

The filter element is the same size as the A/C evap-

orator to ensure ample capacity. A door at the base of

the HVAC housing below the glove box provides easy

access to the filter element.

The ATC computer utilizes integrated circuitry and

information carried on the programmable communi-

cations interface (PCI) data bus network to monitor

many sensors and switch inputs throughout the vehi-

cle. In response to those inputs, the internal circuitry

and programming of the ATC computer allow it to

control electronic functions and features of the ATC

system. The inputs to the ATC computer are:

²Vehicle Speed/Engine RPM± The ATC com-

puter monitors engine rpm, vehicle speed and mani-

fold absolute pressure information from the

powertrain control module (PCM).

²Coolant Temperature± ATC computer moni-

tors coolant temperature received from the PCM and

converts it to degrees Fahrenheit.

²Ambient Temperature± ATC computer moni-

tors ambient temperature from the compass mini trip

computer (CMTC) and converts it to degrees Fahren-

heit.

²Engine Miscellaneous Sensor Status±ATC

computer monitors A/C disable information from the

PCM.

²Refrigerant Pressure± ATC computer moni-

tors barometric pressure, intake air temperature,

high side pressure and methanol content as broad-

cast by the PCM.

²Door Ajar Status± The ATC computer moni-

tors driver front door, passenger front door, left rear

door, right rear door and liftgate ajar information, as

identified by the body control module (BCM), to

determine if all in-car temperatures should be main-

tained.²Dimming± The ATC computer monitors dim-

ming status from the BCM to determine the required

level of brightness and will dim accordingly.

²Vehicle Odometer± The ATC computer moni-

tors the vehicle odometer information from the BCM

to prevent flashing the vacuum-flourescent (VF) dig-

ital display icons if the manual motor calibration or

manual cool down tests have failed. Flashing of the

display icons will cease when the vehicle odometer is

greater than 3 miles.

²English/Metric± The ATC computer monitors

the English/Metric information broadcast by the

CMTC. The set temp displays for both the front and

rear control heads will be set accordingly.

²Vehicle Identification Number± The ATC

computer monitors the last eight characters of the

VIN broadcast by the PCM and compares it to the

information stored in EEPROM. If it is different, the

new number will be stored over the old one and a

motor calibration shall be initiated.

²A/C System Information± The ATC computer

will send a message for evaporator temperature too

low, fan blower relay status, evaporator sensor fail-

ure, rear window defogger relay and A/C select.

FRONT CONTROL PANEL

The front A/C-heater control and integral computer

is mounted in the instrument panel and contains:

²a power button which allows the system to be

completely turned off. The display is blank when the

system is off.

²a rocker switch that selects a cool-down rate.

LO-AUTO or HI-AUTO are displayed when the sys-

tem is in automatic operation.

²three rocker switches that select comfort temper-

atures from 15É to 30É C (59É to 85É F), which are

shown in the VF digital display. If the set temp is 15É

C (59É F) and the down button is pressed, the set

temp value will become 13É C (55É F) but the display

will show LO. If the set temp is 29É C (85É F) and the

up button is pressed, the set temp value will become

32É C (90É F) but the display will show HIGH. Tem-

peratures can be displayed in either metric or Fahr-

enheit, which is controlled from the overhead console.

²an air conditioning button that allows the com-

pressor to be turned off. A Snowflake symbol is illu-

minated when air conditioning is on, whether under

manual or automatic control.

²an air recirculation button. A Recirculation sym-

bol appears in the display when the button is

pressed, or when the system exceeds 80 percent recir-

culated air under automatic control due to high air

conditioning demand.

²a rear window defogger on/off switch. A graphic

symbol shows when the defroster is on.

RSHEATING & AIR CONDITIONING24-3

HEATING & AIR CONDITIONING (Continued)

Page 2155 of 2339

²a rotary knob for front fan speed selection can

override the automatic controls. LEDs surrounding

the knob show the current setting.

²a rotary knob for control of the rear system

(Three-Zone ATC system only).

²a rotary knob for mode control can override the

automatic controls. LEDs surrounding the knob show

the current setting.

²computer logic which remembers the settings of

the controls when the ignition is turned off and

retains those settings after a restart. If the system is

off when the ignition is turned off it will be off when

the engine is restarted, etc.

²computer logic which provides variable air recir-

culation under high temperature and humidity condi-

tions. Because recirculation is generally accompanied

by increased fan noise, the proportion of recirculated

to outside air gradually approaches full recirculation

over a broad temperature range.

²computer logic which enables additional heat for

diesel equipped vehicles by using a supplemental

engine coolant heater.

REAR CONTROL PANEL

The Three-Zone ATC sytem utilizes a rear control

panel centrally mounted on the headliner which

includes a VF digital display, a rocker control for

temperature and rotary controls for adjustment of

mode and fan speed of the rear heating-A/C system

by intermediate seat passengers.

OPERATION

HEATER AND AIR CONDITIONER

The heating and air conditioning systems pulls

outside (ambient) air through the cowl opening at the

base of the windshield and into the plenum chamber

above the heating, ventilation and air conditioning

(HVAC) housing, then through the evaporator coil.

Air flow can be directed either through or around the

heater core by adjusting the blend door with the tem-

perature control knob on the A/C-heater control

located on instrument panel. The air flow can then

be directed out from the panel, floor and defrost out-

lets in various combinations using the mode control

knob located on the A/C-heater control. Air flow

velocity can be adjusted with the blower speed selec-

tor located on the A/C-heater control.

NOTE: It is important to keep the air intake opening

clear of debris. Leaf particles and other debris that

is small enough to pass through the cowl opening

screen can accumulate within the HVAC housing.

The closed, warm, damp and dark environment cre-

ated within the housing is ideal for the growth of

certain molds, mildews and other fungi. Any accu-mulation of decaying plant matter provides an addi-

tional food source for fungal spores, which enter

the housing with the fresh intake-air. Excess debris,

as well as objectionable odors created by decaying

plant matter and growing fungi can be discharged

into the passenger compartment during heater-A/C

operation if the air intake opening is not kept clear

of debris.

The heater and air conditioning system is a blend-

air type system. In a blend-air system, a blend door

controls the amount of conditioned air that is allowed

to flow through, or around, the heater core. The tem-

perature control knob determines the discharge air

temperature by actuating an electric motor, which

operates the blend door. This allows an almost imme-

diate control of the output air temperature of the sys-

tem.

On all models, the outside air intake can be shut

off by pressing the Recirculation button on the A/C-

heater control. This will operate a electric actuated

recirculation air door that closes off the outside fresh

air intake and recirculates the air that is already

inside the vehicle.

The air conditioning compressor can be engaged in

any mode by pressing the snowflake, A/C on/off but-

ton. It can also be engaged by placing the mode con-

trol in the mix to defrost positions. This will remove

heat and humidity from the air before it is directed

through or around the heater core. The mode control

knob on the A/C-heater control is used to also direct

the conditioned air to the selected system outlets.

The mode control switch uses an electric motor to

control the mode doors.MANUAL SINGLE ZONE

²The temperature control knob enables continu-

ously variable proportioning of the conditioned air.

²The mode control knob enables continuously

variable proportioning of air flow between modes and

has detents adjacent to each icon.

²The blower control provides four separate speeds

and an Off position.

²When the heater-A/C system is off, the HVAC

computer closes the recirculation door to prevent out-

side air from entering the passenger compartment.

²Interior air may be recirculated to speed up

heating or cooling in all modes except defrost and

mix by pressing the Recirculate button on the A/C-

heater control.

²To reduce humidity for rapid defogging, the A/C

compressor runs automatically in modes from ªmixº

to full defrost when outside temperatures are above

freezing.

²Air conditioning is available in any mode by

pressing the snowflake, A/C on/off button.

24 - 4 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

Page 2157 of 2339

defogger function will be active for 10 minutes and

can be turned off by a switch press. The defogger will

function while the control is in the ON mode.

²FAN/MODE± The Fan and Mode knobs have

17 manual selectable positions. Manually changing

either of the rotary knobs for mode or fan speed set-

tings makes control of that blower motor manual. If

only one is changed manually, the other remains

under automatic control. Pressing the HI-AUTO/LO-

AUTO rocker switch restores full automatic control.

²BLOWER DELAY TIMER± The word DELAY

is displayed at start-up to signify that the system is

waiting so that cold air will not be blowing. This tells

the operator that it is unnecessary to turn the sys-

tem off, raise the temperature setting or turn the fan

speed setting down to prevent cold air from blowing.

A countdown in minutes and seconds until the engine

is warm enough to begin delivering heat to the pas-

sengers alternates with the DELAY message at 25

second intervals. This countdown is based on actual

measurement of the rate of engine coolant tempera-

ture change. During the delay time, mix mode is

selected and the fan operates at a low speed to keep

the windshield fog free.

²REAR CONTROL (Three-Zone only)± When

the Rear System control knob is moved to the OFF

position, there will be a delay of approximately 1 sec-

ond before the system actually turns off. This delay

is to prevent an undesired blower dropout if the knob

is moved through OFF to the other selections.

REAR CONTROL PANEL ± THREE ZONE ATC

SYSTEM

Primary control of the rear compartment heating-

A/C system for the Three-Zone ATC system is in the

instrument panel center stack. This control allows

the driver to turn the rear heating-A/C system off, or

allows the intermediate seat occupants control of the

rear system by switching to the REAR position, or

provides fully automatic control based on the temper-

ature setting shown on the front control display.

²REAR CONTROL± Selecting automatic control

of the rear unit at the instrument panel, illuminates

a Locked Padlock in the rear control panel display.

Selecting REAR activates the rear control panel and

the Padlock then appears unlocked.

²FAN KNOB± The rear fan control has Off and

AUTO positions and a range of manual speed set-

tings that override the AUTO setting.

²MODE KNOB± The mode control allows inter-

mediate seat occupants to manually override the

automatic mode and select any balance of air flow

between overhead and floor outlets from full over-

head to full floor.

²SET TEMP± The rear set temp control will

operate identical to the front controls. If the frontcontrol rear set temp button is pressed simulta-

neously with the rear control head, then the front

control head press events shall have priority, i.e. if

the front user presses Rear Set Temp down and the

rear user presses Set Temp up, then the rear set

temp will decrease.

DIAGNOSIS AND TESTING

A/C COOL DOWN TEST

The heater-A/C control module can perform an A/C

cool down test, which is a test performed during the

manufacturing process to confirm that the air condi-

tioning system is performing satisfactorily. This test

can also provide a quick confirmation of air condi-

tioning system performance to the service technician.

If the test is completed satisfactorily, no further ser-

vice is required. If the test is failed, proceed to the

A/C Performance Test to confirm the A/C system is

operating properly, or use a DRBIIItscan tool to

diagnose the A/C system control and distribution sys-

tems. Refer to the appropriate diagnostic informa-

tion.

MANUAL TEMPERATURE CONTROL

The front blower speed and rear blower speed (if

equipped with rear HVAC) must be set to High and

the evaporator temperature sensor must be greater

than 13É C (55É F) or the test will fail immediately.

The test is activated by depressing the A/C and Rear

Wipe/Wash buttons simultaneously and holding them

depressed for no less than five seconds. The Rear

Wipe/Wash and A/C LEDs will blink on and off until

the test is complete. If the LEDs stop blinking before

two minutes, then the cool down test has been com-

pleted successfully. If the two minutes expire without

the expansion valve temperature reaching -6É C (20É

F) less than the outside air temperature, then the

cool down test has been failed and further A/C sys-

tem diagnosis is required. If the test is failed, the

LEDs will continue to blink until the vehicle has

been driven for greater than 13 km (8 miles).

AUTOMATIC TEMPERATURE CONTROL

The ambient air temperature in the room where

the vehicle will be tested must be a minimum of 21É

C (70ÉF) for this test. The test is activated by

depressing the A/C and PWR buttons simultaneously

and holding them depressed for no less than four sec-

onds. The snowflake icon and the DELAY text in the

ATC display will blink on and off alternately until

the test is complete. If the snowflake icon and the

DELAY text stop blinking before two minutes, then

the cool down test has been completed successfully. If

the two minutes expire without the evaporator tem-

perature reaching -6É C (20É F) less than the evapo-

24 - 6 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

Page 2161 of 2339

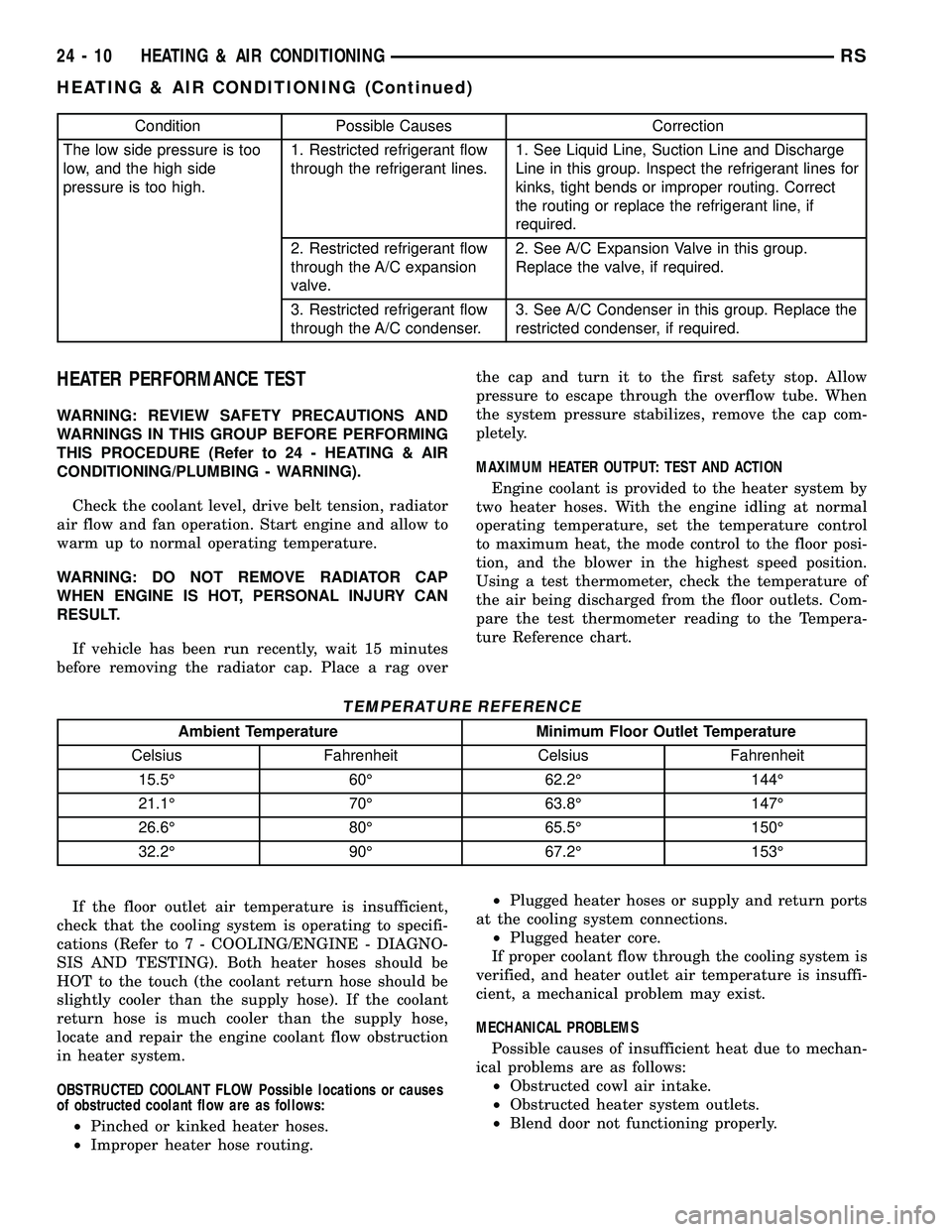

Condition Possible Causes Correction

The low side pressure is too

low, and the high side

pressure is too high.1. Restricted refrigerant flow

through the refrigerant lines.1. See Liquid Line, Suction Line and Discharge

Line in this group. Inspect the refrigerant lines for

kinks, tight bends or improper routing. Correct

the routing or replace the refrigerant line, if

required.

2. Restricted refrigerant flow

through the A/C expansion

valve.2. See A/C Expansion Valve in this group.

Replace the valve, if required.

3. Restricted refrigerant flow

through the A/C condenser.3. See A/C Condenser in this group. Replace the

restricted condenser, if required.

HEATER PERFORMANCE TEST

WARNING: REVIEW SAFETY PRECAUTIONS AND

WARNINGS IN THIS GROUP BEFORE PERFORMING

THIS PROCEDURE (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING).

Check the coolant level, drive belt tension, radiator

air flow and fan operation. Start engine and allow to

warm up to normal operating temperature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing the radiator cap. Place a rag overthe cap and turn it to the first safety stop. Allow

pressure to escape through the overflow tube. When

the system pressure stabilizes, remove the cap com-

pletely.

MAXIMUM HEATER OUTPUT: TEST AND ACTION

Engine coolant is provided to the heater system by

two heater hoses. With the engine idling at normal

operating temperature, set the temperature control

to maximum heat, the mode control to the floor posi-

tion, and the blower in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged from the floor outlets. Com-

pare the test thermometer reading to the Tempera-

ture Reference chart.

TEMPERATURE REFERENCE

Ambient Temperature Minimum Floor Outlet Temperature

Celsius Fahrenheit Celsius Fahrenheit

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

If the floor outlet air temperature is insufficient,

check that the cooling system is operating to specifi-

cations (Refer to 7 - COOLING/ENGINE - DIAGNO-

SIS AND TESTING). Both heater hoses should be

HOT to the touch (the coolant return hose should be

slightly cooler than the supply hose). If the coolant

return hose is much cooler than the supply hose,

locate and repair the engine coolant flow obstruction

in heater system.

OBSTRUCTED COOLANT FLOW Possible locations or causes

of obstructed coolant flow are as follows:

²Pinched or kinked heater hoses.

²Improper heater hose routing.²Plugged heater hoses or supply and return ports

at the cooling system connections.

²Plugged heater core.

If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is insuffi-

cient, a mechanical problem may exist.

MECHANICAL PROBLEMS

Possible causes of insufficient heat due to mechan-

ical problems are as follows:

²Obstructed cowl air intake.

²Obstructed heater system outlets.

²Blend door not functioning properly.

24 - 10 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

Page 2162 of 2339

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob on the

A/C-heater control panel, the following could require

service:

²Blend door binding.

²Faulty blend door actuator.

²Faulty A/C-heater control.

²Faulty related wiring harness or connectors.²Improper engine coolant temperature.

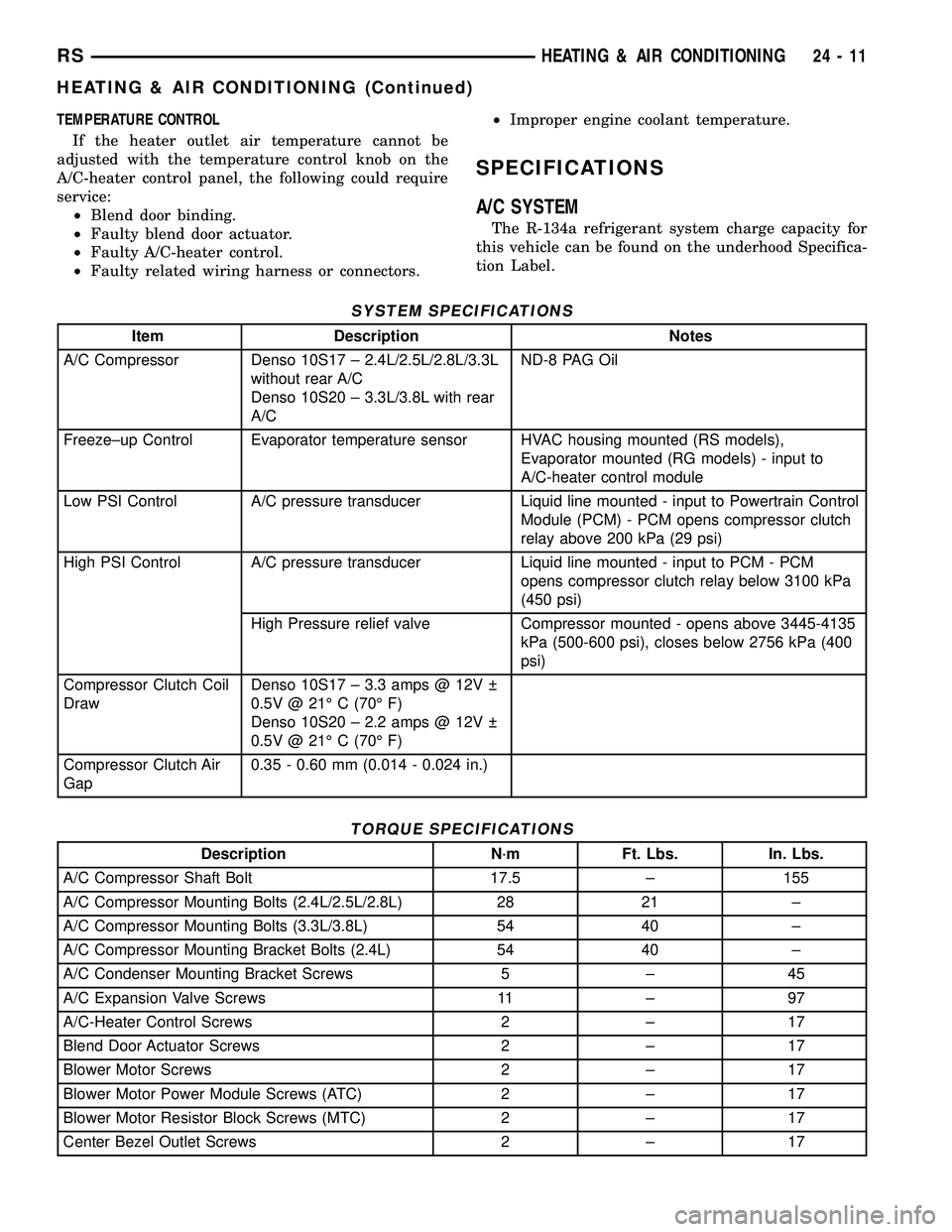

SPECIFICATIONS

A/C SYSTEM

The R-134a refrigerant system charge capacity for

this vehicle can be found on the underhood Specifica-

tion Label.

SYSTEM SPECIFICATIONS

Item Description Notes

A/C Compressor Denso 10S17 ± 2.4L/2.5L/2.8L/3.3L

without rear A/C

Denso 10S20 ± 3.3L/3.8L with rear

A/CND-8 PAG Oil

Freeze±up Control Evaporator temperature sensor HVAC housing mounted (RS models),

Evaporator mounted (RG models) - input to

A/C-heater control module

Low PSI Control A/C pressure transducer Liquid line mounted - input to Powertrain Control

Module (PCM) - PCM opens compressor clutch

relay above 200 kPa (29 psi)

High PSI Control A/C pressure transducer Liquid line mounted - input to PCM - PCM

opens compressor clutch relay below 3100 kPa

(450 psi)

High Pressure relief valve Compressor mounted - opens above 3445-4135

kPa (500-600 psi), closes below 2756 kPa (400

psi)

Compressor Clutch Coil

DrawDenso 10S17 ± 3.3 amps @ 12V

0.5V @ 21É C (70É F)

Denso 10S20 ± 2.2 amps @ 12V

0.5V @ 21É C (70É F)

Compressor Clutch Air

Gap0.35 - 0.60 mm (0.014 - 0.024 in.)

TORQUE SPECIFICATIONS

Description N´m Ft. Lbs. In. Lbs.

A/C Compressor Shaft Bolt 17.5 ± 155

A/C Compressor Mounting Bolts (2.4L/2.5L/2.8L) 28 21 ±

A/C Compressor Mounting Bolts (3.3L/3.8L) 54 40 ±

A/C Compressor Mounting Bracket Bolts (2.4L) 54 40 ±

A/C Condenser Mounting Bracket Screws 5 ± 45

A/C Expansion Valve Screws 11 ± 97

A/C-Heater Control Screws 2 ± 17

Blend Door Actuator Screws 2 ± 17

Blower Motor Screws 2 ± 17

Blower Motor Power Module Screws (ATC) 2 ± 17

Blower Motor Resistor Block Screws (MTC) 2 ± 17

Center Bezel Outlet Screws 2 ± 17

RSHEATING & AIR CONDITIONING24-11

HEATING & AIR CONDITIONING (Continued)

Page 2212 of 2339

(13) Remove the two screws that secure the top of

the quarter trim panel attaching bracket to the quar-

ter inner panel.(14) Remove the two screws that secure the bottom

of the quarter trim panel attaching bracket to the

rear HVAC housing.

(15) Remove the rear floor heat duct from the

right quarter inner panel (Refer to 24 - HEATING &

AIR CONDITIONING/DISTRIBUTION/REAR

FLOOR HEAT DUCT - REMOVAL).

(16) Take the proper precautions to protect the

carpeting below the rear heater core from spilled

engine coolant and have absorbent toweling readily

available to clean up any spills.

(17) Disconnect the heater hoses at the rear heater

core (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - REAR/HEATER HOSE -

REMOVAL).

(18) Install plugs in, or tape over the opened

heater core fittings and both heater hoses.

(19) Use absorbent toweling to mop up any engine

coolant spills from the preceding operation.

(20) Remove the screw that secures the back of the

rear HVAC housing to the right D-pillar (Fig. 8).

(21) Remove the screw that secures the front of

the rear HVAC housing to the right quarter inner

panel.

(22) Lift the rear HVAC housing up far enough for

the lower mounting studs and the evaporator exten-

sion lines to clear the mounting holes in the rear

floor panel.

(23) Remove the rear HVAC housing from the

vehicle.

(24) Use absorbent toweling to mop up any engine

coolant spills from the preceding operation.

Fig. 5 Underbody A/C Line Rear Connections ± with

New Seating Element (NSE)

1 - UNDERBODY LIQUID LINE

2 - NUT

3 - SEALING PLATE

4 - UNDERBODY SUCTION LINE

5 - EXTENSION LINE TAPPING PLATE

Fig. 6 Underbody A/C Line Rear Connections ±

without New Seating Element (NSE)

1 - UNDERBODY LIQUID LINE

2 - BOLT

3 - EXTENSION LINE TAPPING PLATE

4 - UNDERBODY SUCTION LINE

5 - SEALING PLATE

Fig. 7 Rear HVAC Housing Mounting Studs ±

Typical

1 - REAR HVAC HOUSING MOUNTING STUDS

RSDISTRIBUTION - REAR24-61

HVAC HOUSING (Continued)