Rear control CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1 of 2339

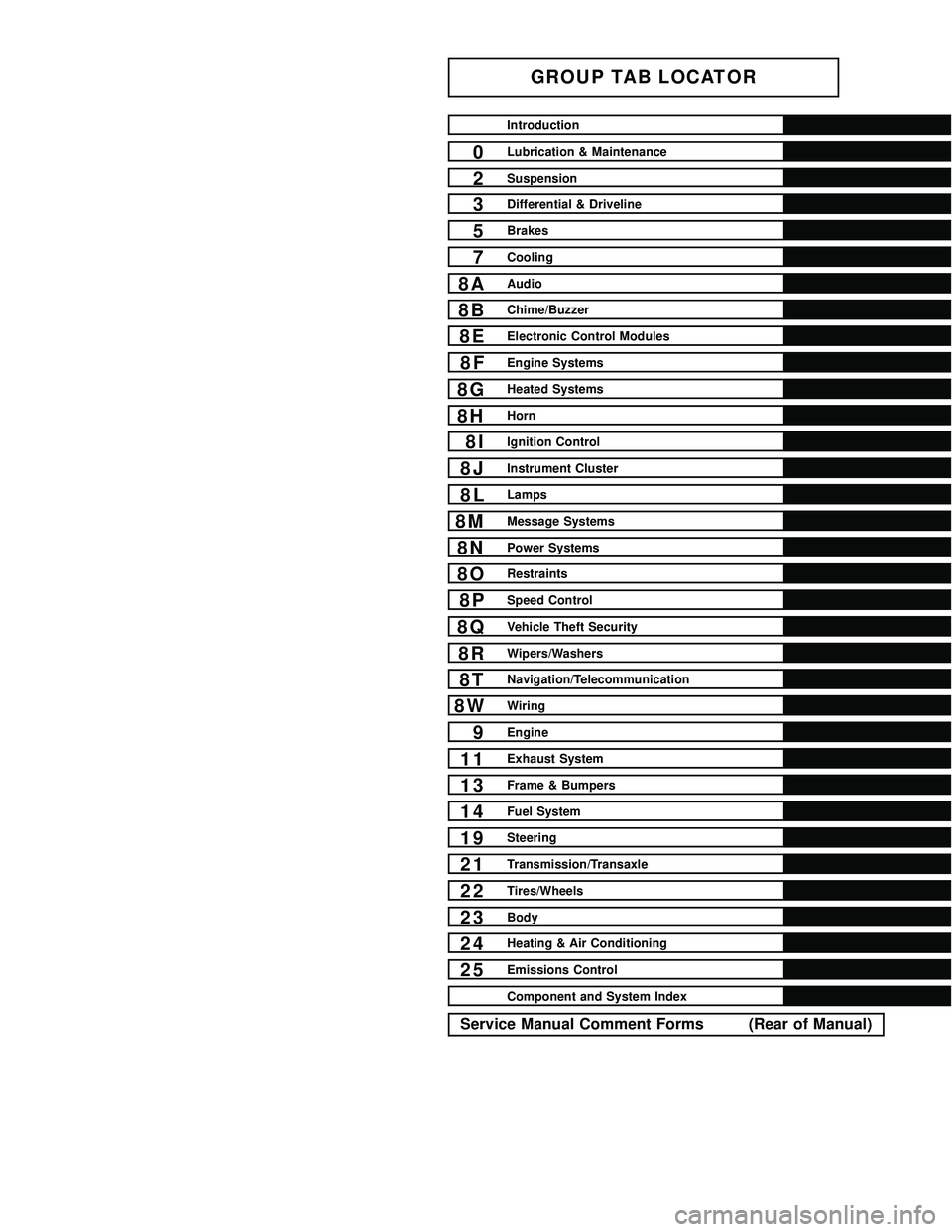

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

7Cooling

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8TNavigation/Telecommunication

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission/Transaxle

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 6 of 2339

FASTENER USAGE

DESCRIPTION

FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Fasteners and torque specifications references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

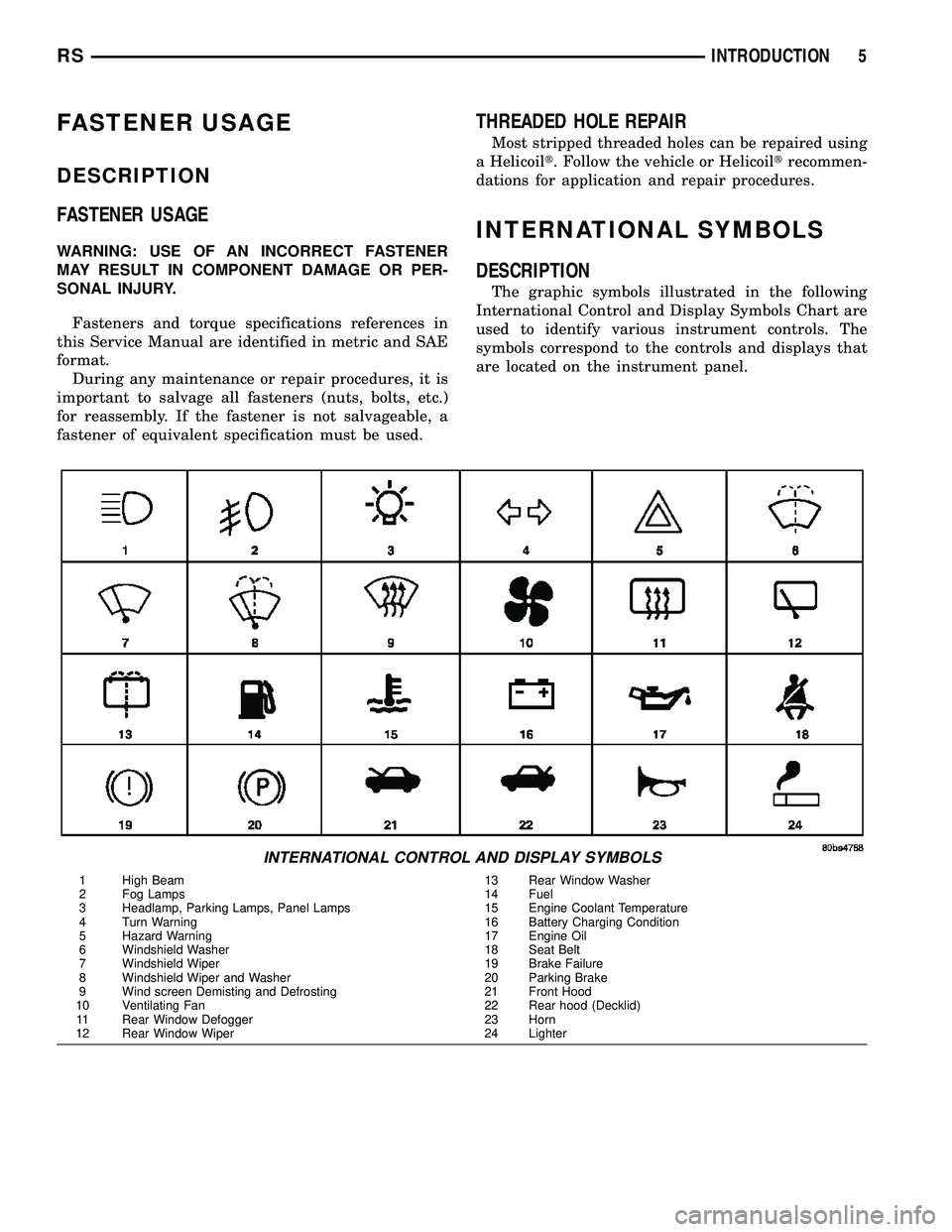

INTERNATIONAL SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Wind screen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RSINTRODUCTION5

Page 12 of 2339

VEHICLE CERTIFICATION

LABEL

DESCRIPTION

A vehicle certification label is attached to the rear

shutface of the driver's door (Fig. 3). This label indi-

cates date of manufacture (month and year), Gross

Vehicle Weight Rating (GVWR), Gross Axle Weight

Rating (GAWR) front, Gross Axle Weight Rating

(GAWR) rear and the Vehicle Identification Number

(VIN). The Month, Day and Hour of manufacture is

also included.

All communications or inquiries regarding the

vehicle should include the Month-Day-Hour and

Vehicle Identification Number.

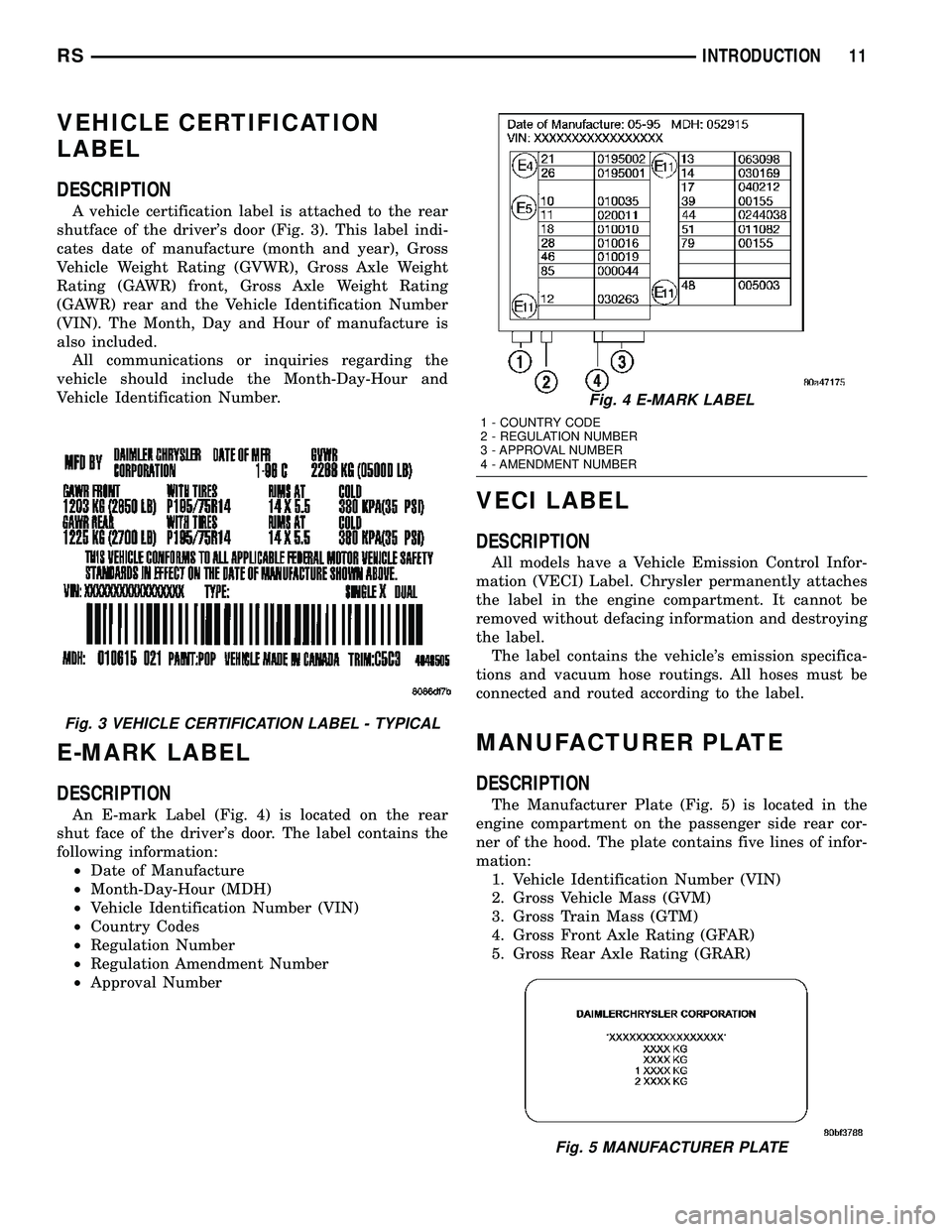

E-MARK LABEL

DESCRIPTION

An E-mark Label (Fig. 4) is located on the rear

shut face of the driver's door. The label contains the

following information:

²Date of Manufacture

²Month-Day-Hour (MDH)

²Vehicle Identification Number (VIN)

²Country Codes

²Regulation Number

²Regulation Amendment Number

²Approval Number

VECI LABEL

DESCRIPTION

All models have a Vehicle Emission Control Infor-

mation (VECI) Label. Chrysler permanently attaches

the label in the engine compartment. It cannot be

removed without defacing information and destroying

the label.

The label contains the vehicle's emission specifica-

tions and vacuum hose routings. All hoses must be

connected and routed according to the label.

MANUFACTURER PLATE

DESCRIPTION

The Manufacturer Plate (Fig. 5) is located in the

engine compartment on the passenger side rear cor-

ner of the hood. The plate contains five lines of infor-

mation:

1. Vehicle Identification Number (VIN)

2. Gross Vehicle Mass (GVM)

3. Gross Train Mass (GTM)

4. Gross Front Axle Rating (GFAR)

5. Gross Rear Axle Rating (GRAR)

Fig. 3 VEHICLE CERTIFICATION LABEL - TYPICAL

Fig. 4 E-MARK LABEL

1 - COUNTRY CODE

2 - REGULATION NUMBER

3 - APPROVAL NUMBER

4 - AMENDMENT NUMBER

Fig. 5 MANUFACTURER PLATE

RSINTRODUCTION11

Page 42 of 2339

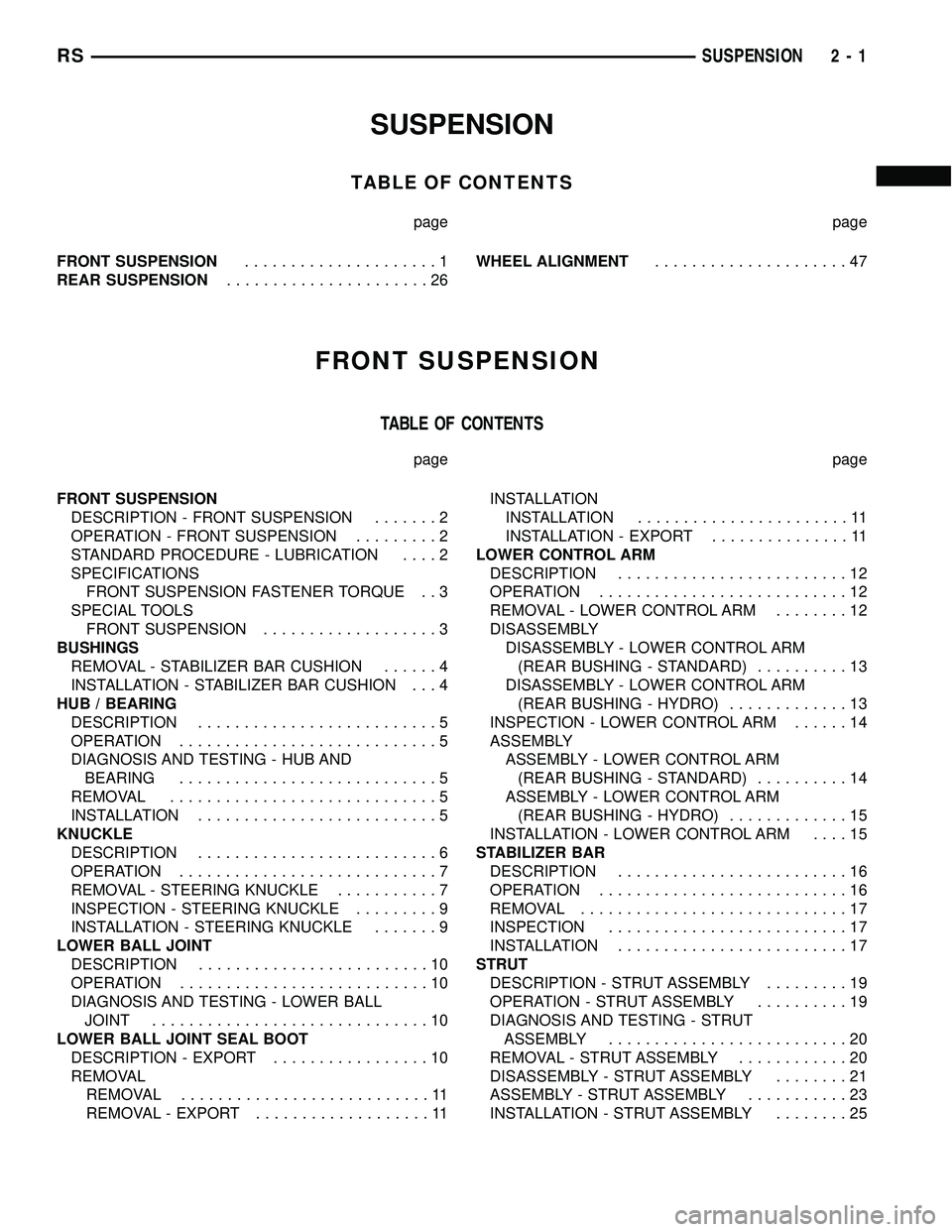

SUSPENSION

TABLE OF CONTENTS

page page

FRONT SUSPENSION.....................1

REAR SUSPENSION......................26WHEEL ALIGNMENT.....................47

FRONT SUSPENSION

TABLE OF CONTENTS

page page

FRONT SUSPENSION

DESCRIPTION - FRONT SUSPENSION.......2

OPERATION - FRONT SUSPENSION.........2

STANDARD PROCEDURE - LUBRICATION....2

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUE . . 3

SPECIAL TOOLS

FRONT SUSPENSION...................3

BUSHINGS

REMOVAL - STABILIZER BAR CUSHION......4

INSTALLATION - STABILIZER BAR CUSHION . . . 4

HUB / BEARING

DESCRIPTION..........................5

OPERATION............................5

DIAGNOSIS AND TESTING - HUB AND

BEARING............................5

REMOVAL.............................5

INSTALLATION..........................5

KNUCKLE

DESCRIPTION..........................6

OPERATION............................7

REMOVAL - STEERING KNUCKLE...........7

INSPECTION - STEERING KNUCKLE.........9

INSTALLATION - STEERING KNUCKLE.......9

LOWER BALL JOINT

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - LOWER BALL

JOINT..............................10

LOWER BALL JOINT SEAL BOOT

DESCRIPTION - EXPORT.................10

REMOVAL

REMOVAL...........................11

REMOVAL - EXPORT...................11INSTALLATION

INSTALLATION.......................11

INSTALLATION - EXPORT...............11

LOWER CONTROL ARM

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL - LOWER CONTROL ARM........12

DISASSEMBLY

DISASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - STANDARD)..........13

DISASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - HYDRO).............13

INSPECTION - LOWER CONTROL ARM......14

ASSEMBLY

ASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - STANDARD)..........14

ASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - HYDRO).............15

INSTALLATION - LOWER CONTROL ARM....15

STABILIZER BAR

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................17

INSPECTION..........................17

INSTALLATION.........................17

STRUT

DESCRIPTION - STRUT ASSEMBLY.........19

OPERATION - STRUT ASSEMBLY..........19

DIAGNOSIS AND TESTING - STRUT

ASSEMBLY..........................20

REMOVAL - STRUT ASSEMBLY............20

DISASSEMBLY - STRUT ASSEMBLY........21

ASSEMBLY - STRUT ASSEMBLY...........23

INSTALLATION - STRUT ASSEMBLY........25

RSSUSPENSION2-1

Page 47 of 2339

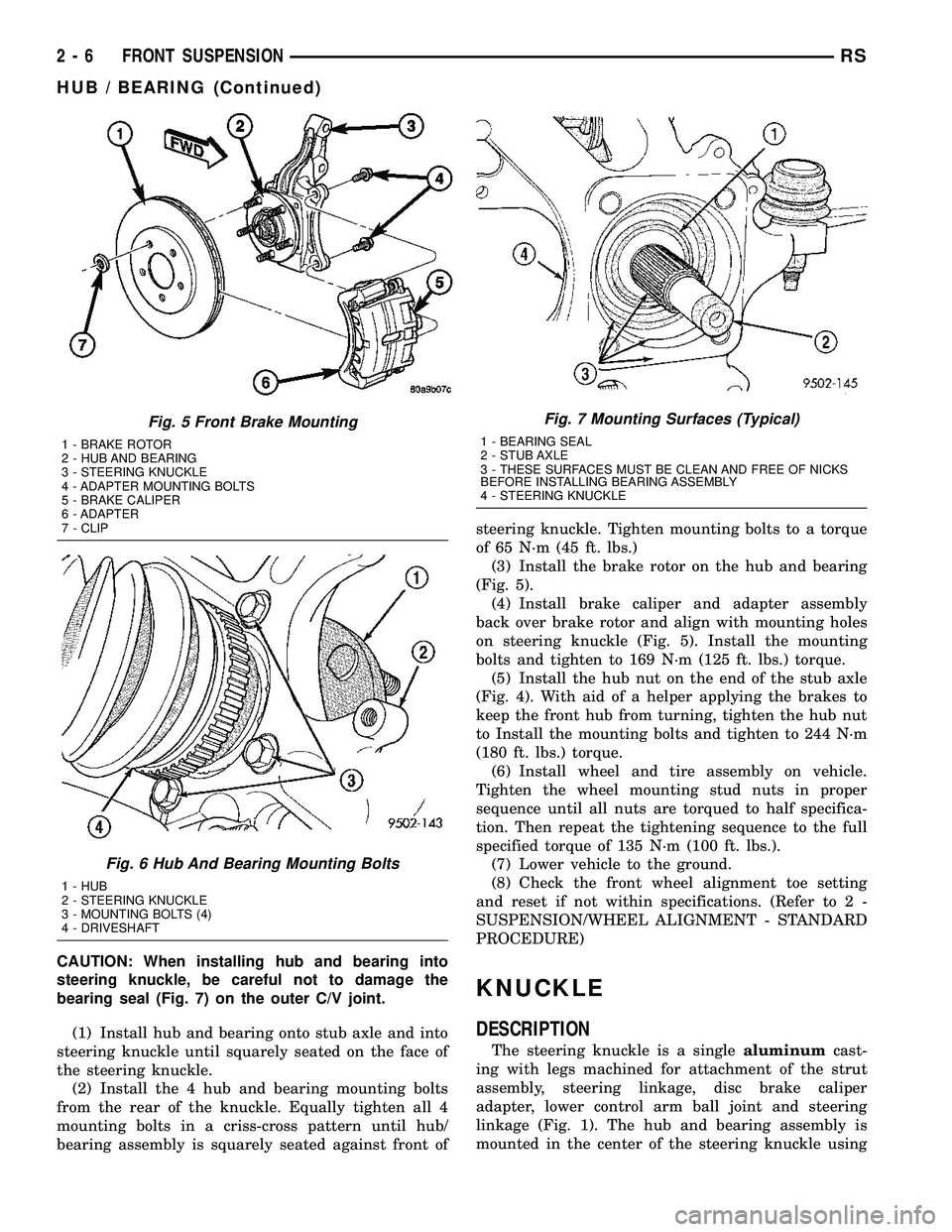

CAUTION: When installing hub and bearing into

steering knuckle, be careful not to damage the

bearing seal (Fig. 7) on the outer C/V joint.

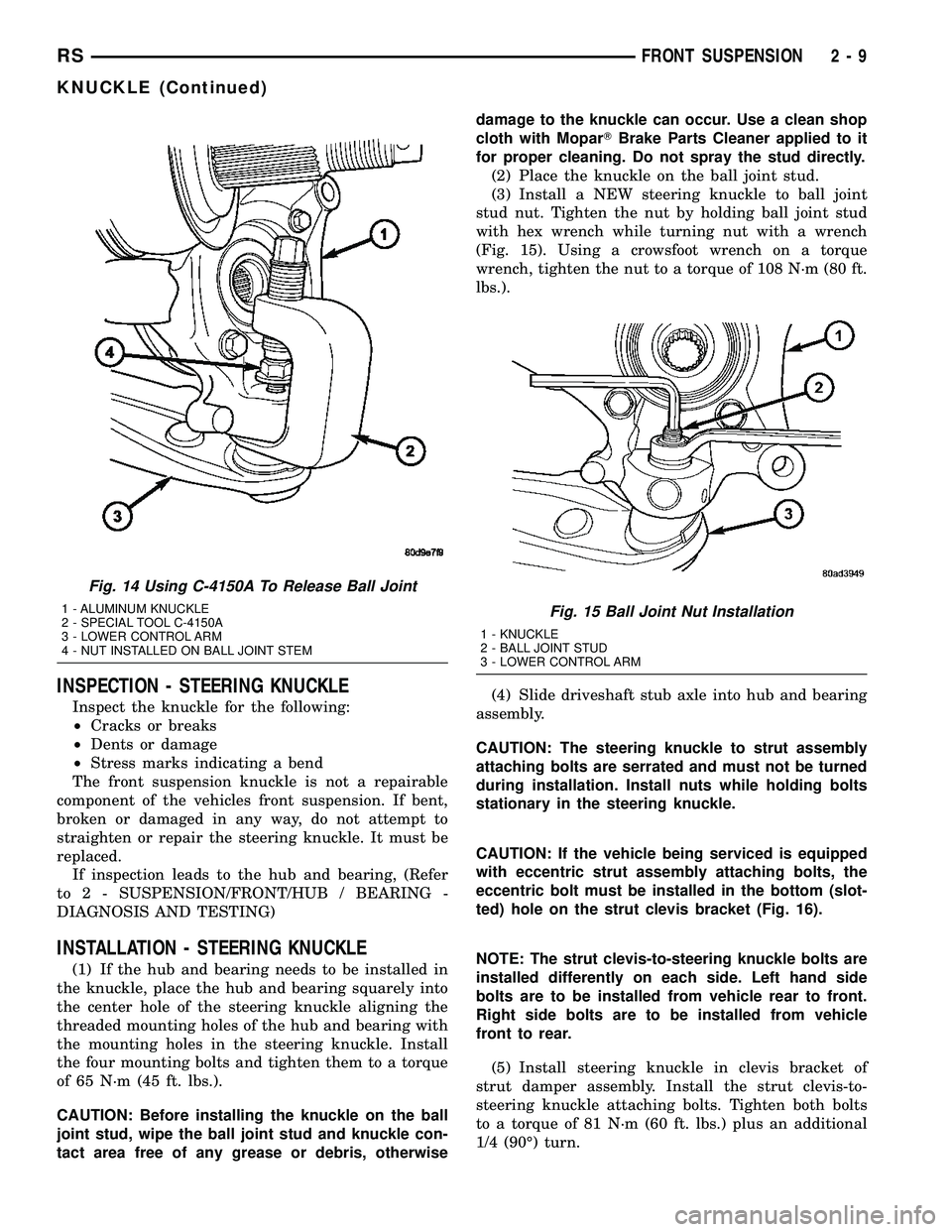

(1) Install hub and bearing onto stub axle and into

steering knuckle until squarely seated on the face of

the steering knuckle.

(2) Install the 4 hub and bearing mounting bolts

from the rear of the knuckle. Equally tighten all 4

mounting bolts in a criss-cross pattern until hub/

bearing assembly is squarely seated against front ofsteering knuckle. Tighten mounting bolts to a torque

of 65 N´m (45 ft. lbs.)

(3) Install the brake rotor on the hub and bearing

(Fig. 5).

(4) Install brake caliper and adapter assembly

back over brake rotor and align with mounting holes

on steering knuckle (Fig. 5). Install the mounting

bolts and tighten to 169 N´m (125 ft. lbs.) torque.

(5) Install the hub nut on the end of the stub axle

(Fig. 4). With aid of a helper applying the brakes to

keep the front hub from turning, tighten the hub nut

to Install the mounting bolts and tighten to 244 N´m

(180 ft. lbs.) torque.

(6) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(7) Lower vehicle to the ground.

(8) Check the front wheel alignment toe setting

and reset if not within specifications. (Refer to 2 -

SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE)

KNUCKLE

DESCRIPTION

The steering knuckle is a singlealuminumcast-

ing with legs machined for attachment of the strut

assembly, steering linkage, disc brake caliper

adapter, lower control arm ball joint and steering

linkage (Fig. 1). The hub and bearing assembly is

mounted in the center of the steering knuckle using

Fig. 5 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

Fig. 6 Hub And Bearing Mounting Bolts

1 - HUB

2 - STEERING KNUCKLE

3 - MOUNTING BOLTS (4)

4 - DRIVESHAFT

Fig. 7 Mounting Surfaces (Typical)

1 - BEARING SEAL

2 - STUB AXLE

3 - THESE SURFACES MUST BE CLEAN AND FREE OF NICKS

BEFORE INSTALLING BEARING ASSEMBLY

4 - STEERING KNUCKLE

2 - 6 FRONT SUSPENSIONRS

HUB / BEARING (Continued)

Page 50 of 2339

INSPECTION - STEERING KNUCKLE

Inspect the knuckle for the following:

²Cracks or breaks

²Dents or damage

²Stress marks indicating a bend

The front suspension knuckle is not a repairable

component of the vehicles front suspension. If bent,

broken or damaged in any way, do not attempt to

straighten or repair the steering knuckle. It must be

replaced.

If inspection leads to the hub and bearing, (Refer

to 2 - SUSPENSION/FRONT/HUB / BEARING -

DIAGNOSIS AND TESTING)

INSTALLATION - STEERING KNUCKLE

(1) If the hub and bearing needs to be installed in

the knuckle, place the hub and bearing squarely into

the center hole of the steering knuckle aligning the

threaded mounting holes of the hub and bearing with

the mounting holes in the steering knuckle. Install

the four mounting bolts and tighten them to a torque

of 65 N´m (45 ft. lbs.).

CAUTION: Before installing the knuckle on the ball

joint stud, wipe the ball joint stud and knuckle con-

tact area free of any grease or debris, otherwisedamage to the knuckle can occur. Use a clean shop

cloth with MoparTBrake Parts Cleaner applied to it

for proper cleaning. Do not spray the stud directly.

(2) Place the knuckle on the ball joint stud.

(3) Install a NEW steering knuckle to ball joint

stud nut. Tighten the nut by holding ball joint stud

with hex wrench while turning nut with a wrench

(Fig. 15). Using a crowsfoot wrench on a torque

wrench, tighten the nut to a torque of 108 N´m (80 ft.

lbs.).

(4) Slide driveshaft stub axle into hub and bearing

assembly.

CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during installation. Install nuts while holding bolts

stationary in the steering knuckle.

CAUTION: If the vehicle being serviced is equipped

with eccentric strut assembly attaching bolts, the

eccentric bolt must be installed in the bottom (slot-

ted) hole on the strut clevis bracket (Fig. 16).

NOTE: The strut clevis-to-steering knuckle bolts are

installed differently on each side. Left hand side

bolts are to be installed from vehicle rear to front.

Right side bolts are to be installed from vehicle

front to rear.

(5) Install steering knuckle in clevis bracket of

strut damper assembly. Install the strut clevis-to-

steering knuckle attaching bolts. Tighten both bolts

to a torque of 81 N´m (60 ft. lbs.) plus an additional

1/4 (90É) turn.

Fig. 14 Using C-4150A To Release Ball Joint

1 - ALUMINUM KNUCKLE

2 - SPECIAL TOOL C-4150A

3 - LOWER CONTROL ARM

4 - NUT INSTALLED ON BALL JOINT STEMFig. 15 Ball Joint Nut Installation

1 - KNUCKLE

2 - BALL JOINT STUD

3 - LOWER CONTROL ARM

RSFRONT SUSPENSION2-9

KNUCKLE (Continued)

Page 53 of 2339

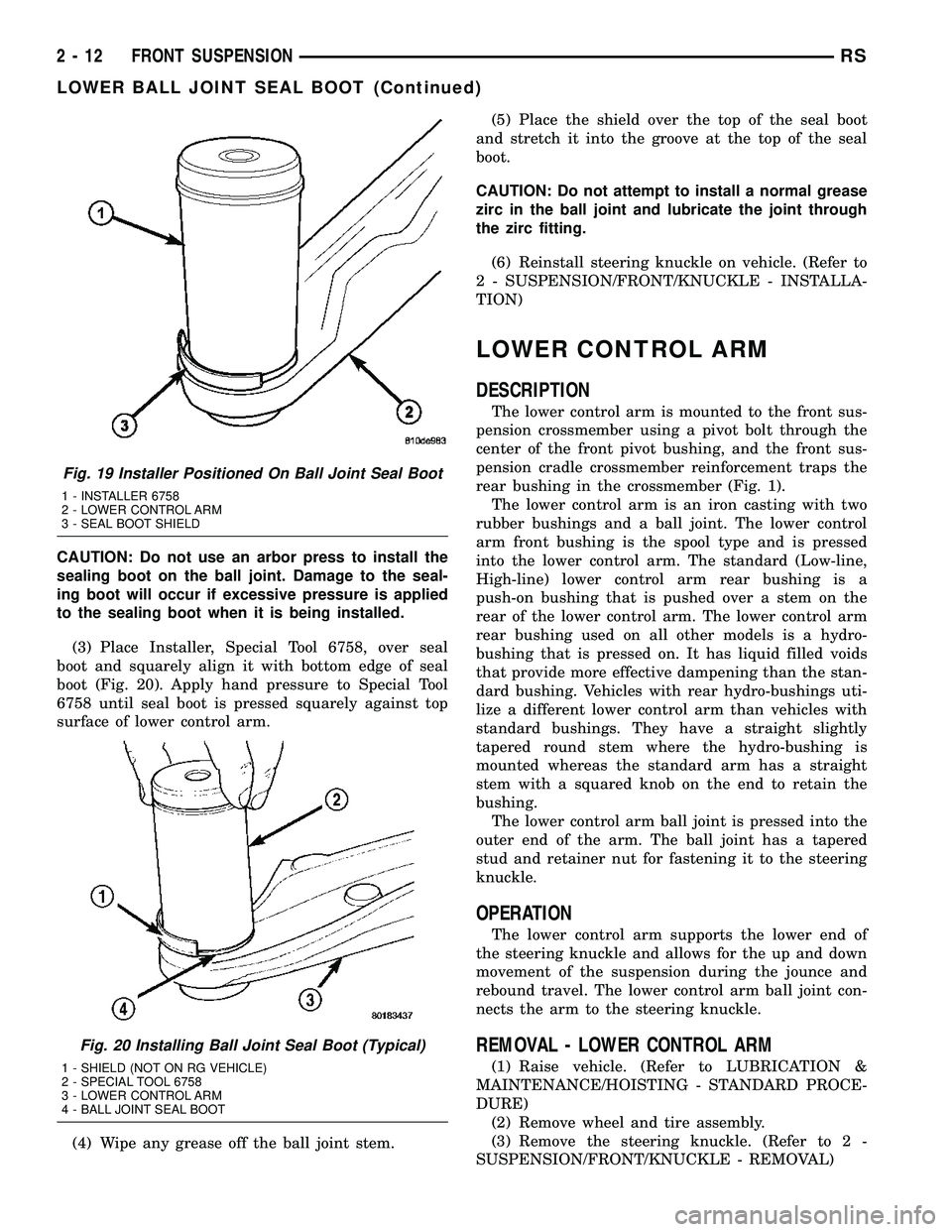

CAUTION: Do not use an arbor press to install the

sealing boot on the ball joint. Damage to the seal-

ing boot will occur if excessive pressure is applied

to the sealing boot when it is being installed.

(3) Place Installer, Special Tool 6758, over seal

boot and squarely align it with bottom edge of seal

boot (Fig. 20). Apply hand pressure to Special Tool

6758 until seal boot is pressed squarely against top

surface of lower control arm.

(4) Wipe any grease off the ball joint stem.(5) Place the shield over the top of the seal boot

and stretch it into the groove at the top of the seal

boot.

CAUTION: Do not attempt to install a normal grease

zirc in the ball joint and lubricate the joint through

the zirc fitting.

(6) Reinstall steering knuckle on vehicle. (Refer to

2 - SUSPENSION/FRONT/KNUCKLE - INSTALLA-

TION)

LOWER CONTROL ARM

DESCRIPTION

The lower control arm is mounted to the front sus-

pension crossmember using a pivot bolt through the

center of the front pivot bushing, and the front sus-

pension cradle crossmember reinforcement traps the

rear bushing in the crossmember (Fig. 1).

The lower control arm is an iron casting with two

rubber bushings and a ball joint. The lower control

arm front bushing is the spool type and is pressed

into the lower control arm. The standard (Low-line,

High-line) lower control arm rear bushing is a

push-on bushing that is pushed over a stem on the

rear of the lower control arm. The lower control arm

rear bushing used on all other models is a hydro-

bushing that is pressed on. It has liquid filled voids

that provide more effective dampening than the stan-

dard bushing. Vehicles with rear hydro-bushings uti-

lize a different lower control arm than vehicles with

standard bushings. They have a straight slightly

tapered round stem where the hydro-bushing is

mounted whereas the standard arm has a straight

stem with a squared knob on the end to retain the

bushing.

The lower control arm ball joint is pressed into the

outer end of the arm. The ball joint has a tapered

stud and retainer nut for fastening it to the steering

knuckle.

OPERATION

The lower control arm supports the lower end of

the steering knuckle and allows for the up and down

movement of the suspension during the jounce and

rebound travel. The lower control arm ball joint con-

nects the arm to the steering knuckle.

REMOVAL - LOWER CONTROL ARM

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove wheel and tire assembly.

(3) Remove the steering knuckle. (Refer to 2 -

SUSPENSION/FRONT/KNUCKLE - REMOVAL)

Fig. 19 Installer Positioned On Ball Joint Seal Boot

1 - INSTALLER 6758

2 - LOWER CONTROL ARM

3 - SEAL BOOT SHIELD

Fig. 20 Installing Ball Joint Seal Boot (Typical)

1 - SHIELD (NOT ON RG VEHICLE)

2 - SPECIAL TOOL 6758

3 - LOWER CONTROL ARM

4 - BALL JOINT SEAL BOOT

2 - 12 FRONT SUSPENSIONRS

LOWER BALL JOINT SEAL BOOT (Continued)

Page 54 of 2339

(4) Remove the bolts fastening the power steering

cooler to the front suspension cradle crossmember

reinforcement (Fig. 21).

(5) Remove the lower control arm rear bushing

retainer bolts located on each side of each lower con-

trol arm rear bushing.

NOTE: The bolts fastening the cradle crossmember

reinforcement are of three different thread sizes.

Note the location of the various sizes.

(6) Remove the bolts attaching the cradle cross-

member reinforcement to the front suspension cradle

crossmember (Fig. 22). Remove the 2 bolts fastening

the reinforcement and rear of cradle crossmember to

the body of the vehicle. Remove the reinforcement.

(7) Remove the pivot bolt attaching the front bush-

ing of the lower control arm to the front suspension

cradle crossmember.

(8) Remove the lower control arm.

DISASSEMBLY

DISASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - STANDARD)

(1) Remove the lower control arm from the front

suspension cradle. (Refer to 2 - SUSPENSION/

FRONT/LOWER CONTROL ARM - REMOVAL)

(2) Mount the lower control arm in a visewithout

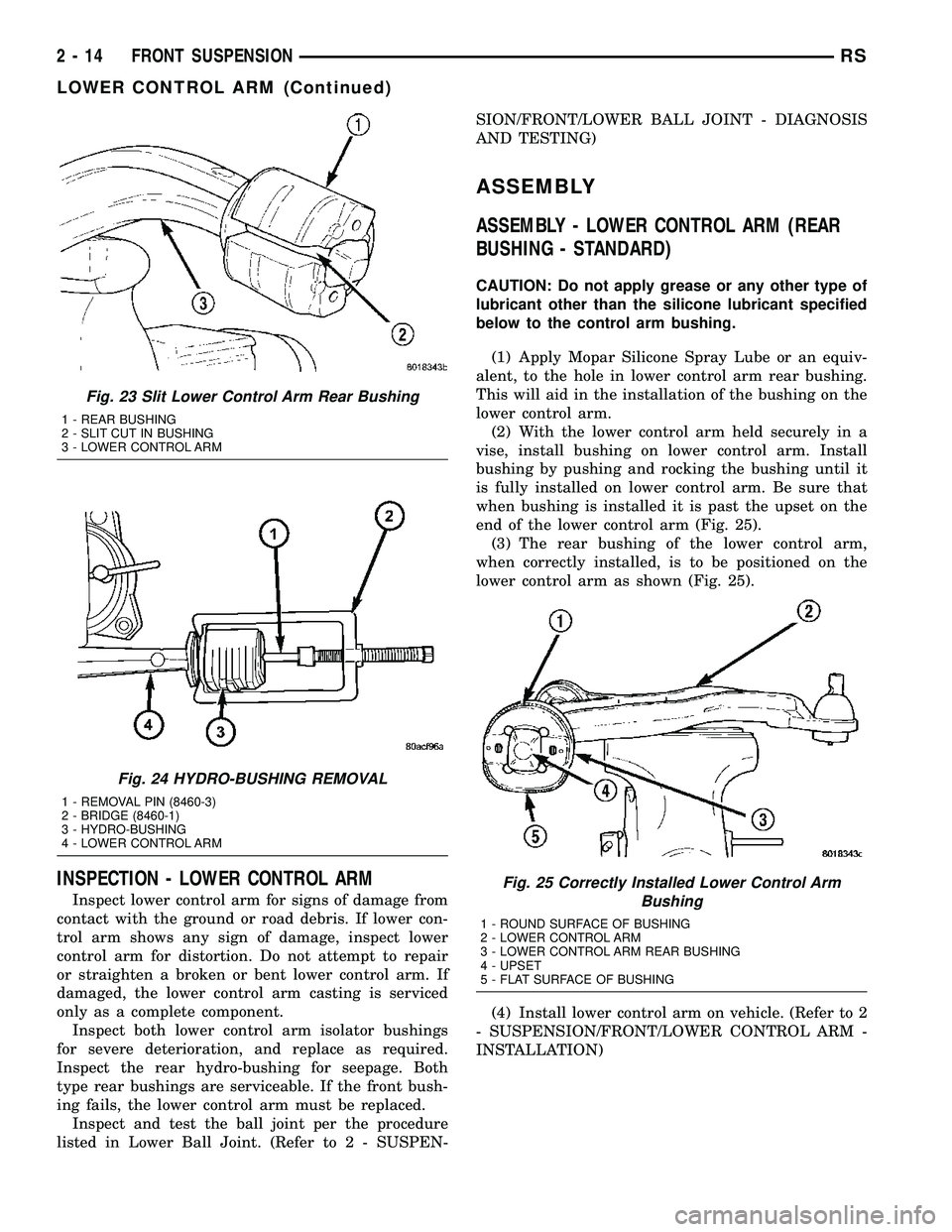

using excessive clamping force.(3) Using a sharp knife (such as a razor), slit the

bushing lengthwise (Fig. 23) to allow its removal

from the lower control arm (Fig. 23).

(4) Remove the bushing from the lower control

arm.

DISASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - HYDRO)

(1) Remove the lower control arm from the front

suspension cradle. (Refer to 2 - SUSPENSION/

FRONT/LOWER CONTROL ARM - REMOVAL)

(2) Mount the lower control arm in a visewithout

using excessive clamping force.

(3) Install Remover, Special Tool 8460, on hydro-

bushing as shown (Fig. 24). Removal Pin, Special

Tool 8460±3, must extend though hole in center of

bushing rear.

(4) Tighten forcing screw of Bridge (Special Tool

8460±1), removing bushing from lower control arm.

Fig. 21 Power Steering Cooler

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLER

Fig. 22 Cradle Crossmember Reinforcement

Attachment

1 - STEERING GEAR

2 - RIGHT LOWER CONTROL ARM

3 - LEFT LOWER CONTROL ARM

4 - CRADLE CROSSMEMBER REINFORCEMENT

5 - REAR CRADLE CROSSMEMBER ISOLATOR BUSHING

6 - STABILIZER BAR

7 - CRADLE CROSSMEMBER

RSFRONT SUSPENSION2-13

LOWER CONTROL ARM (Continued)

Page 55 of 2339

INSPECTION - LOWER CONTROL ARM

Inspect lower control arm for signs of damage from

contact with the ground or road debris. If lower con-

trol arm shows any sign of damage, inspect lower

control arm for distortion. Do not attempt to repair

or straighten a broken or bent lower control arm. If

damaged, the lower control arm casting is serviced

only as a complete component.

Inspect both lower control arm isolator bushings

for severe deterioration, and replace as required.

Inspect the rear hydro-bushing for seepage. Both

type rear bushings are serviceable. If the front bush-

ing fails, the lower control arm must be replaced.

Inspect and test the ball joint per the procedure

listed in Lower Ball Joint. (Refer to 2 - SUSPEN-SION/FRONT/LOWER BALL JOINT - DIAGNOSIS

AND TESTING)

ASSEMBLY

ASSEMBLY - LOWER CONTROL ARM (REAR

BUSHING - STANDARD)

CAUTION: Do not apply grease or any other type of

lubricant other than the silicone lubricant specified

below to the control arm bushing.

(1) Apply Mopar Silicone Spray Lube or an equiv-

alent, to the hole in lower control arm rear bushing.

This will aid in the installation of the bushing on the

lower control arm.

(2) With the lower control arm held securely in a

vise, install bushing on lower control arm. Install

bushing by pushing and rocking the bushing until it

is fully installed on lower control arm. Be sure that

when bushing is installed it is past the upset on the

end of the lower control arm (Fig. 25).

(3) The rear bushing of the lower control arm,

when correctly installed, is to be positioned on the

lower control arm as shown (Fig. 25).

(4) Install lower control arm on vehicle. (Refer to 2

- SUSPENSION/FRONT/LOWER CONTROL ARM -

INSTALLATION)

Fig. 23 Slit Lower Control Arm Rear Bushing

1 - REAR BUSHING

2 - SLIT CUT IN BUSHING

3 - LOWER CONTROL ARM

Fig. 24 HYDRO-BUSHING REMOVAL

1 - REMOVAL PIN (8460-3)

2 - BRIDGE (8460-1)

3 - HYDRO-BUSHING

4 - LOWER CONTROL ARM

Fig. 25 Correctly Installed Lower Control Arm

Bushing

1 - ROUND SURFACE OF BUSHING

2 - LOWER CONTROL ARM

3 - LOWER CONTROL ARM REAR BUSHING

4 - UPSET

5 - FLAT SURFACE OF BUSHING

2 - 14 FRONT SUSPENSIONRS

LOWER CONTROL ARM (Continued)

Page 56 of 2339

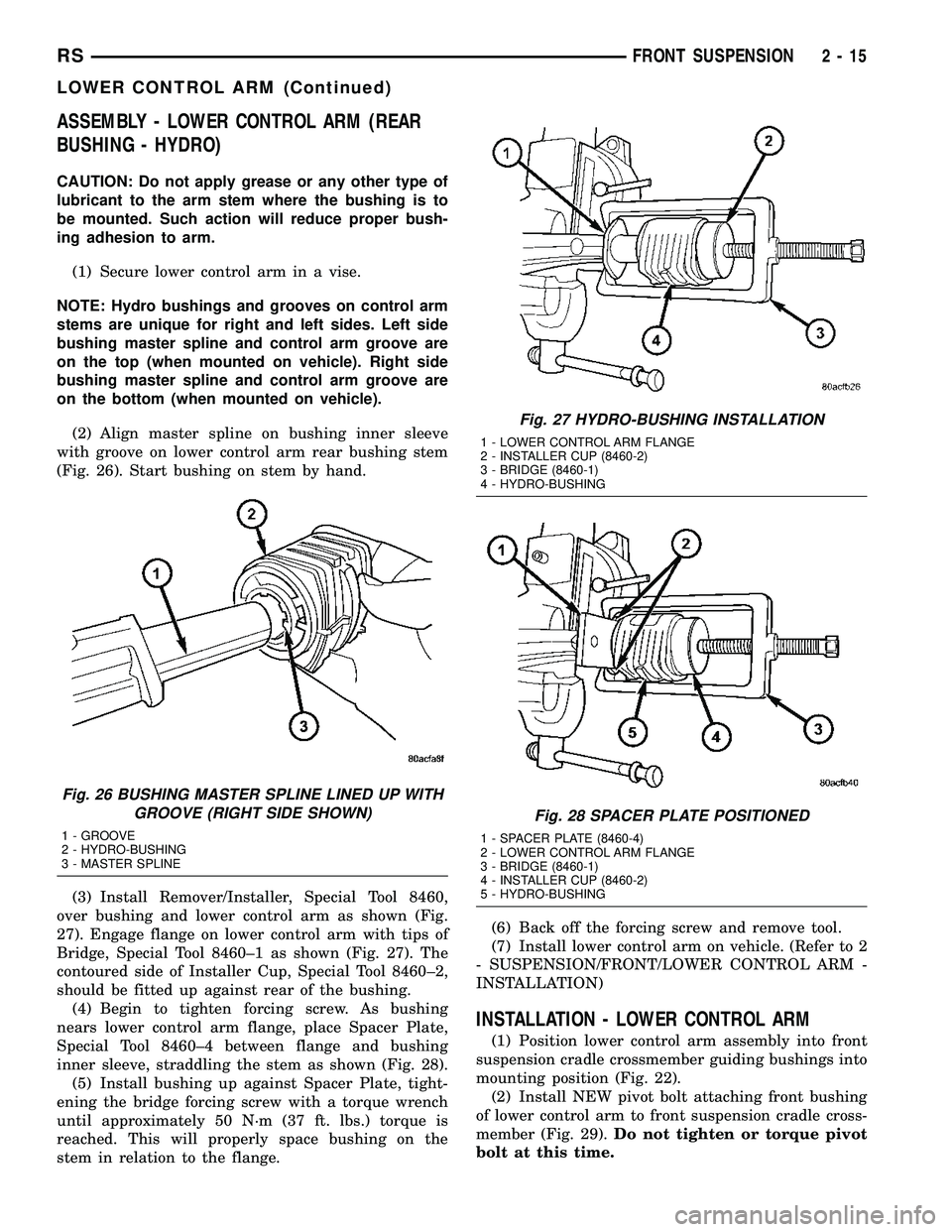

ASSEMBLY - LOWER CONTROL ARM (REAR

BUSHING - HYDRO)

CAUTION: Do not apply grease or any other type of

lubricant to the arm stem where the bushing is to

be mounted. Such action will reduce proper bush-

ing adhesion to arm.

(1) Secure lower control arm in a vise.

NOTE: Hydro bushings and grooves on control arm

stems are unique for right and left sides. Left side

bushing master spline and control arm groove are

on the top (when mounted on vehicle). Right side

bushing master spline and control arm groove are

on the bottom (when mounted on vehicle).

(2) Align master spline on bushing inner sleeve

with groove on lower control arm rear bushing stem

(Fig. 26). Start bushing on stem by hand.

(3) Install Remover/Installer, Special Tool 8460,

over bushing and lower control arm as shown (Fig.

27). Engage flange on lower control arm with tips of

Bridge, Special Tool 8460±1 as shown (Fig. 27). The

contoured side of Installer Cup, Special Tool 8460±2,

should be fitted up against rear of the bushing.

(4) Begin to tighten forcing screw. As bushing

nears lower control arm flange, place Spacer Plate,

Special Tool 8460±4 between flange and bushing

inner sleeve, straddling the stem as shown (Fig. 28).

(5) Install bushing up against Spacer Plate, tight-

ening the bridge forcing screw with a torque wrench

until approximately 50 N´m (37 ft. lbs.) torque is

reached. This will properly space bushing on the

stem in relation to the flange.(6) Back off the forcing screw and remove tool.

(7) Install lower control arm on vehicle. (Refer to 2

- SUSPENSION/FRONT/LOWER CONTROL ARM -

INSTALLATION)

INSTALLATION - LOWER CONTROL ARM

(1) Position lower control arm assembly into front

suspension cradle crossmember guiding bushings into

mounting position (Fig. 22).

(2) Install NEW pivot bolt attaching front bushing

of lower control arm to front suspension cradle cross-

member (Fig. 29).Do not tighten or torque pivot

bolt at this time.

Fig. 26 BUSHING MASTER SPLINE LINED UP WITH

GROOVE (RIGHT SIDE SHOWN)

1 - GROOVE

2 - HYDRO-BUSHING

3 - MASTER SPLINE

Fig. 27 HYDRO-BUSHING INSTALLATION

1 - LOWER CONTROL ARM FLANGE

2 - INSTALLER CUP (8460-2)

3 - BRIDGE (8460-1)

4 - HYDRO-BUSHING

Fig. 28 SPACER PLATE POSITIONED

1 - SPACER PLATE (8460-4)

2 - LOWER CONTROL ARM FLANGE

3 - BRIDGE (8460-1)

4 - INSTALLER CUP (8460-2)

5 - HYDRO-BUSHING

RSFRONT SUSPENSION2-15

LOWER CONTROL ARM (Continued)