CITROEN C-ELYSÉE 2015 Owners Manual

Manufacturer: CITROEN, Model Year: 2015, Model line: C-ELYSÉE, Model: CITROEN C-ELYSÉE 2015Pages: 285, PDF Size: 13.42 MB

Page 121 of 285

119

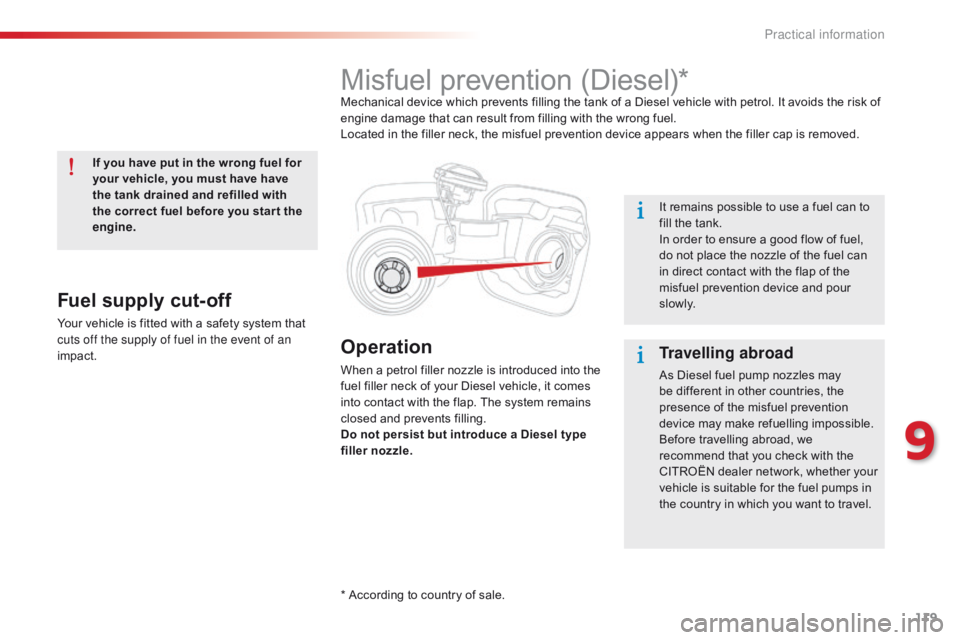

Operation

When a petrol filler nozzle is introduced into the

fuel filler neck of your Diesel vehicle, it comes

into contact with the flap. The system remains

closed and prevents filling.

Do not persist but introduce a Diesel type

filler nozzle.

Misfuel prevention (Diesel)*Mechanical device which prevents filling the tank of a Diesel vehicle with petrol. It avoids the risk of

engine damage that can result from filling with the wrong fuel.

Located in the filler neck, the misfuel prevention device appears when the filler cap is removed.

* According to country of sale.It remains possible to use a fuel can to

fill the tank.

In order to ensure a good flow of fuel,

do not place the nozzle of the fuel can

in direct contact with the flap of the

misfuel prevention device and pour

s l ow l y.

Travelling abroad

As Diesel fuel pump nozzles may

be different in other countries, the

presence of the misfuel prevention

device may make refuelling impossible.

Before travelling abroad, we

recommend that you check with the

CITROËN dealer network, whether your

vehicle is suitable for the fuel pumps in

the country in which you want to travel.

If you have put in the wrong fuel for

your vehicle, you must have have

the tank drained and refilled with

the correct fuel before you star t the

engine.

Fuel supply cut-off

Your vehicle is fitted with a safety system that

cuts off the supply of fuel in the event of an

impact.

9

Practical information

Page 122 of 285

120

Fuel used for petrol

engines

The petrol engines are compatible with

E10 bio-petrol (containing 10 % ethanol),

conforming to European standards EN 228 and

EN 15376.

E85 type fuels (containing up to 85 % ethanol)

are reserved exclusively for vehicles marketed

for the use of this type of fuel (BioFlex

vehicles). The quality of the ethanol must

comply with European standard EN 15293.

Fuel used for Diesel

engines

The Diesel engines are compatible with

biofuels which conform to current and future

European standards (Diesel fuel which

complies with standard EN 590 mixed with

a biofuel which complies with standard

EN

14214) available at the pumps (containing

up to 7 % Fatty Acid Methyl Ester).

B30 biofuel can be used in certain Diesel

engines. However, this use, even occasional,

requires strict application of the special

servicing conditions. Contact a CITROËN

dealer or a qualified workshop.

The use of any other type of (bio)fuel

(vegetable or animal oils, pure or diluted,

domestic fuel...) is strictly prohibited (risk of

damage to the engine and fuel system).

Practical information

Page 123 of 285

121

On vehicle fitted with HDi engines, the fuel

system must be primed if you run out of fuel;

refer to the engine compartment view on the

"Diesel engine" section.

If the tank on your vehicle is fitted with

a misfuel prevention device, refer to the

corresponding section.

Running out of fuel (Diesel)

If the engine does not start first time,

don't keep trying. Start the procedure

again from the beginning.F

F

ill the fuel tank with at least five litres of

diesel.

F

O

pen the bonnet.

F

S

queeze and release the priming pump

repeatedly until resistance is felt (there

may be resistance at the first press).

F

O

perate the starter until the engine starts

(if the engine does not start at the first

attempt, wait around 15 seconds before

trying again).

F I f the engine does not start after a few

attempts, operate the priming pump again

then start the engine.

F

C

lose the bonnet.

HDi 92 engine

9

Practical information

Page 124 of 285

122

This kit is installed in the storage box, under the

boot floor. Complete system consisting of a compressor

and a sealant cartridge which permits

temporary repair of a tyre so that you can

drive to the nearest garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

Temporary puncture repair kit

Access to the kitList of tools

all of these tools are specific to your vehicle

and can vary according to equipment. Do not

use them for other purposes.

1.

1

2 V compressor.

C

ontains a sealant cartridge for the

temporary repair of a tyre and can also be

used for adjusting tyre pressures.

2.

R

emovable towing eye.

For more information on the removable towing

eye, refer to the "Towing the vehicle" section. The vehicle's electric system allows the

connection of a compressor for long

enough to inflate a tyre after a puncture

repair or for inflating a small inflatable

accessory.

Practical information

Page 125 of 285

123

A. "Sealant" or "Air" position selector.

B. on "

I" / off "O" switch.

C.

D

eflation button.

D.

P

ressure gauge (in bar and p.s.i.).

E.

C

ompartment housing:

-

a c

able with adaptor for 12 V socket,

-

v

arious inflation adaptors for

accessories, such as balls, bicycle

tyres...

Description of the kit

F. Sealant cartridge.

G. W hite pipe with cap for repair.

H.

B

lack pipe for inflation.

I.

S

peed limit sticker. The speed limit sticker I must be affixed

to the vehicle's steering wheel to remind

you that a wheel is in temporary use.

Do not exceed a speed of 50 mph

(80 km/h) when driving with a tyre

repaired using this type of kit.

9

Practical information

Page 126 of 285

124

Repair procedure

F Switch off the ignition.F U ncoil the white pipe G fully.

F U nscrew the cap from the white pipe.

F

C

onnect the white pipe to the valve of the

tyre to be repaired. F

C onnect the compressor's electric plug to

the vehicle's 12 V socket.

F

S

tart the vehicle and leave the engine

running.

Take care, this product is harmful (e.g.

ethylene-glycol, colophony...) if swallowed

and causes irritation to the eyes.

Keep this product out of the reach of

children.

Avoid removing any foreign bodies

which have penetrated into the tyre.

1. Sealing

F Turn the selector A to the "sealant"

position.

F

C

heck that the switch B is in

position "O" .

Practical information

Page 127 of 285

125

Do not start the compressor before

connecting the white pipe to the tyre

valve: the sealant product would be

expelled through the pipe.

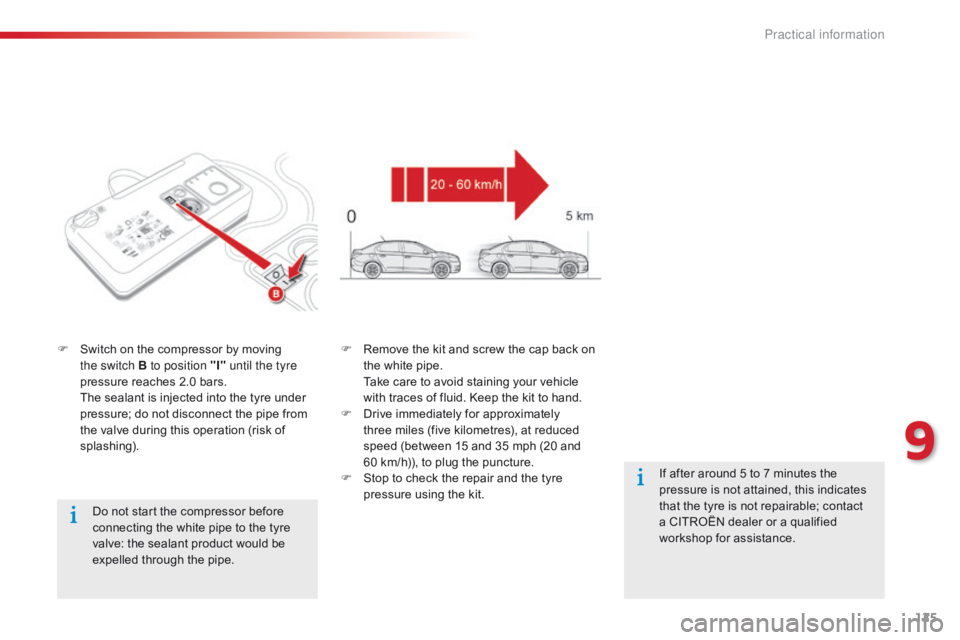

F

S

witch on the compressor by moving

the switch B to position "I" until the tyre

pressure reaches 2.0 bars.

T

he sealant is injected into the tyre under

pressure; do not disconnect the pipe from

the valve during this operation (risk of

splashing). F

R

emove the kit and screw the cap back on

the white pipe.

T

ake care to avoid staining your vehicle

with traces of fluid. Keep the kit to hand.

F

D

rive immediately for approximately

three miles (five kilometres), at reduced

speed (between 15 and 35 mph (20 and

60 km/h)), to plug the puncture.

F

S

top to check the repair and the tyre

pressure using the kit. If after around 5 to 7 minutes the

pressure is not attained, this indicates

that the tyre is not repairable; contact

a CITROËN dealer or a qualified

workshop for assistance.

9

Practical information

Page 128 of 285

126

2. Inflation

F Connect the compressor's electric plug to the vehicle's 12 V socket.

F

S

tart the vehicle again and leave the

engine running. F

A djust the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B

in position "O" and press

button C ), in accordance with the vehicle's

tyre pressure label (located on the left

hand door aperture).

A l

oss of pressure indicates that the

puncture has not been fully plugged;

contact a CITROËN dealer or qualified

workshop for assistance.

F

R

emove and stow the kit.

F

D

rive at reduced speed (50 mph

[80

km/h] max) limiting the distance

travelled to approximately 120 miles

(200

km).

As soon as possible, go to a CITROËN

dealer or a qualified workshop.

You must inform the technician that you

have used this kit. After inspection, the

technician will advise you on whether

the tyre can be repaired or if it must be

replaced.

F

T

urn the selector A to the "air"

position.

F

U

ncoil the black pipe H fully.

F

C

onnect the black pipe to the

valve of the wheel.

Practical information

Page 129 of 285

127

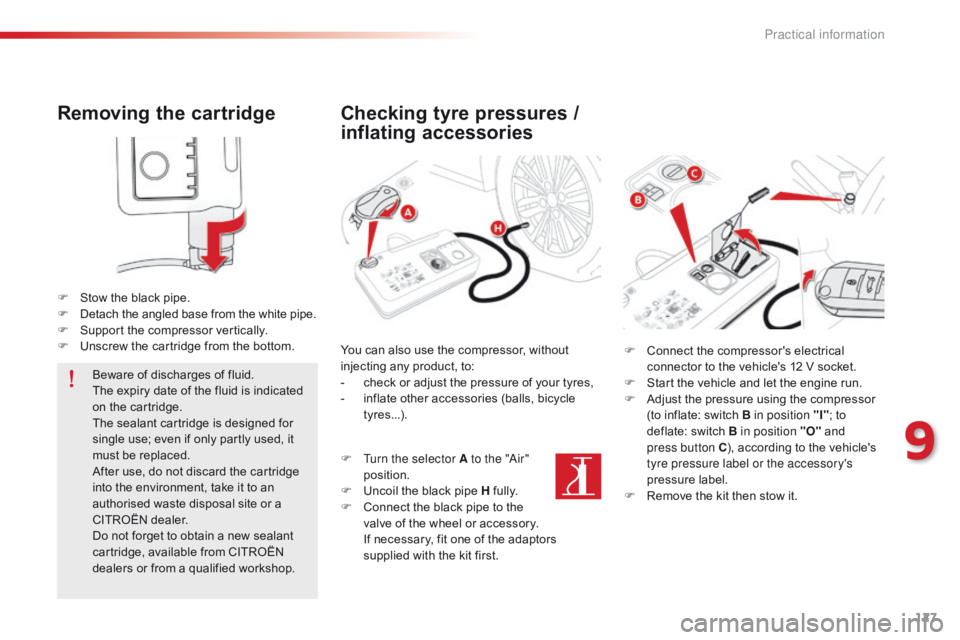

Removing the cartridge

F Stow the black pipe.

F D etach the angled base from the white pipe.

F

S

upport the compressor vertically.

F

U

nscrew the cartridge from the bottom.Beware of discharges of fluid.

The expiry date of the fluid is indicated

on the cartridge.

The sealant cartridge is designed for

single use; even if only partly used, it

must be replaced.

After use, do not discard the cartridge

into the environment, take it to an

authorised waste disposal site or a

CITROËN dealer.

Do not forget to obtain a new sealant

cartridge, available from CITROËN

dealers or from a qualified workshop.

Checking tyre pressures /

inflating accessories

You can also use the compressor, without

injecting any product, to:

-

c

heck or adjust the pressure of your tyres,

-

i

nflate other accessories (balls, bicycle

tyres...).

F

T

urn the selector A to the "

ai

r"

position.

F

U

ncoil the black pipe H fully.

F

C

onnect the black pipe to the

valve of the wheel or accessory.

I

f necessary, fit one of the adaptors

supplied with the kit first. F

C onnect the compressor's electrical

connector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B in position "O" and

press

button C), according to the vehicle's

tyre pressure label or the accessory's

pressure label.

F

R

emove the kit then stow it.

9

Practical information

Page 130 of 285

128

Changing a wheel

The tools are installed in the boot under the

f l o o r.

To gain access to them:

F

o

pen the boot,

F

l

ift the floor and remove it,

F

r

emove the storage box containing the

tools.

Access to the tools

List of tools

Procedure for changing a faulty wheel for the spare wheel using the tools provided with the vehicle.

al

l of these tools are specific to your

vehicle and can vary according to the level

of equipment. Do not use them for other

purposes.

1.

W

heelbrace.

F

or removing the wheel trim and removing

the wheel bolts.

2.

J

ack with integral handle.

F

or raising the vehicle.

3.

"

Bolt cover" tool.

F

or removing the bolt protectors (covers)

on alloy wheels.

4.

T

owing eye.

S

ee "Recovering the vehicle".

Practical information