CITROEN C4 2018 Owners Manual

Manufacturer: CITROEN, Model Year: 2018, Model line: C4, Model: CITROEN C4 2018Pages: 317, PDF Size: 9.31 MB

Page 191 of 317

189

C4-cactus_en_Chap08_En-cas-de-panne_ed01-2016

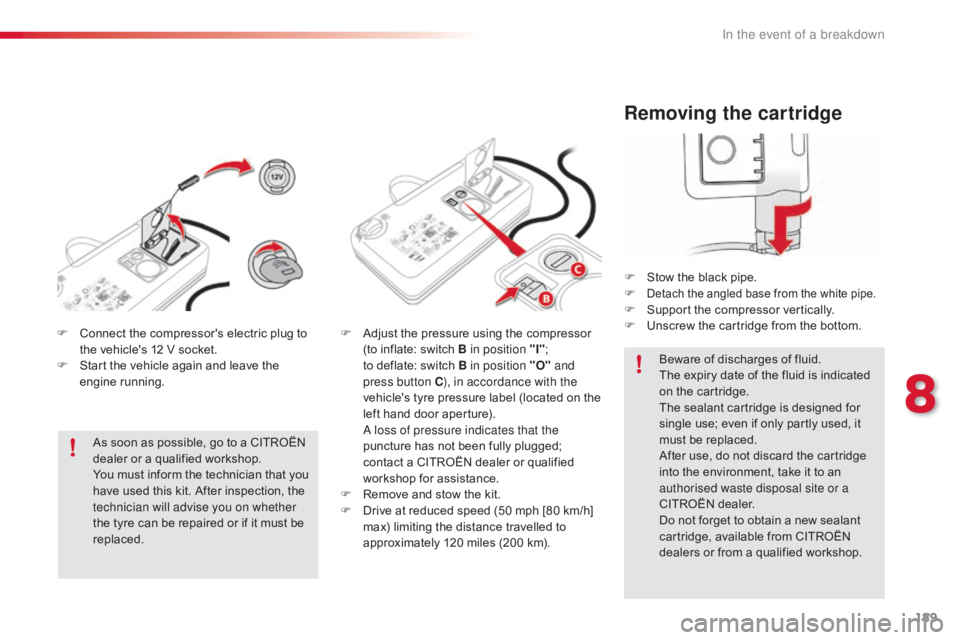

Removing the cartridge

Fô Stowô the ô black ô pipe.

F Detachô theô angledô baseô fromô theô whiteô pipe.Fô Support ô the ô compressor ô vertically.

F ô U nscrew ô the ô cartridge ô from ô the ô bottom.

Beware

ô of ô discharges ô of ô fluid.

The

ô expiry ô date ô of ô the ô fluid ô is ô indicated ô

o

n ô the ô cartridge.

The

ô sealant ô cartridge ô is ô designed ô for ô

s

ingle ô use; ô even ô if ô only ô partly ô used, ô it ô

m

ust ô be ô replaced.

After

ô use, ô do ô not ô discard ô the ô cartridge ô

i

nto ô the ô environment, ô take ô it ô to ô an ô

a

uthorised waste disposal site or a

CITROûN

ô dealer.

Do

ô not ô forget ô to ô obtain ô a ô new ô sealant ô

c

artridge, ô available ô from ô CITROûN ô

d

ealers ô or ô from ô a ô qualified ô workshop.

F

ô

C

onnect

ô

the

ô

compressor's

ô

electric

ô

plug

ô

to

ô

t

he

ô

vehicle's

ô

12

ô

V

ô

socket.

F

ô

S

tart

ô

the

ô

vehicle

ô

again

ô

and

ô

leave

ô

the

ô

e

ngine

ô r

unning.

As

ô

soon

ô

as

ô

possible,

ô

go

ô

to

ô

a

ô

CITROûN

ô

d

ealer

ô

or

ô

a

ô

qualified

ô

workshop.

You

ô

must

ô

inform

ô

the

ô

technician

ô

that

ô

you

ô

h

ave

ô

used

ô

this

ô

kit.

ô

After

ô

inspection,

ô

the

ô

t

echnician will advise you on whether

the

ô

tyre

ô

can

ô

be

ô

repaired

ô

or

ô

if

ô

it

ô

must

ô

be

ô

r

eplaced. F

ô

A

djust

ô

the

ô

pressure

ô

using

ô

the

ô

compressor

ô

(

to

ô

inflate:

ô

switch

ô

B in position "I" ;

ô

t

oô deflate:

ô

switch

ô

B

in position "O" and

press button C ), in accordance with the

vehicle's

ô

t

yre

ô

pressure

ô

label

ô

(located

ô

on

ô

the

ô

l

eft

ô

hand

ô

door

ô

aperture).

ô

A l

oss of pressure indicates that the

puncture

ô

has

ô

not

ô

been

ô

fully

ô

plugged;

ô

c

ontact

ô

a

ô

CITROûN

ô

dealer

ô

or

ô

qualified

ô

w

orkshop

ô

for

ô

assistance.

F

ô

R

emove

ô

and

ô

stow

ô

the

ô

kit.

F

ô

D

rive

ô

at

ô

reduced

ô

speed

ô

(50

ô

mph

ô

[80

ô

km/h]

ô

m

ax)

ô

limiting

ô

the

ô

distance

ô

travelled

ô

to

ô

a

pproximately

ô

120

ô

miles

ô

(200

ô

km).

8

In the event of a breakdown

Page 192 of 317

190

C4-cactus_en_Chap08_En-cas-de-panne_ed01-2016

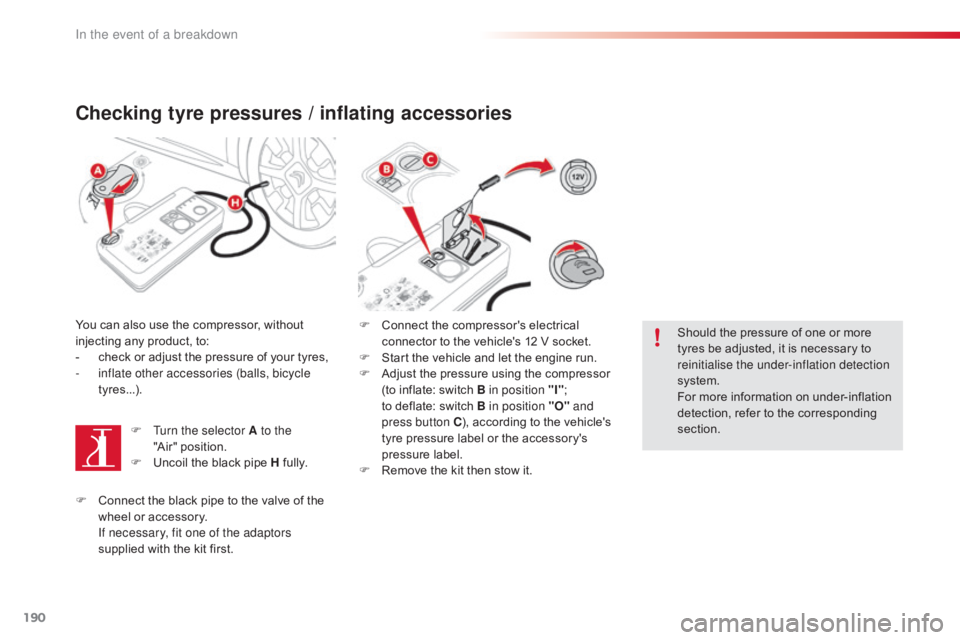

Checking tyre pressures / inflating accessories

Youô canô alsoô useô theô compressor,ô withoutô injecting ô any ô product, ô to:

-

ô

c

heck ô or ô adjust ô the ô pressure ô of ô your ô tyres,

-

i

nflate other accessories (balls, bicycle

tyres...).

F

T

urn the selector A to the

"Air"ô position.

F

ô

U

ncoil ô the ô black ô pipe ô H ô

f

ully.F

ô C onnect ô the ô compressor's ô electrical ô

c

onnector ô to ô the ô vehicle's ô 12 ô V ô socket.

F

ô

S

tart ô the ô vehicle ô and ô let ô the ô engine ô run.

F

ô

A

djust ô the ô pressure ô using ô the ô compressor ô

(

to ô inflate: ô switch ô B in position "I";

ô

t

oô deflate: ô switch ô B in position "O" and

press button C ),

ô according ô to ô the ô vehicle's ô

t

yre ô pressure ô label ô or ô the ô accessory's ô

p

ressure ô label.

F

ô

R

emove ô the ô kit ô then ô stow ô it.Should

ô the ô pressure ô of ô one ô or ô more ô

t

yres ô be ô adjusted, ô it ô is ô necessary ô to ô

r

einitialise the under-inflation detection

system.

For

ô more ô information ô on ô under-inflation ô

d

etection, ô refer ô to ô the ô corresponding ô

s

ection.

F

ô

C

onnect ô the ô black ô pipe ô to ô the ô valve ô of ô the ô

w

heel ô or ô accessory.

I

f necessary, fit one of the adaptors

supplied

ô with ô the ô kit ô first.

In the event of a breakdown

Page 193 of 317

191

C4-cactus_en_Chap08_En-cas-de-panne_ed01-2016

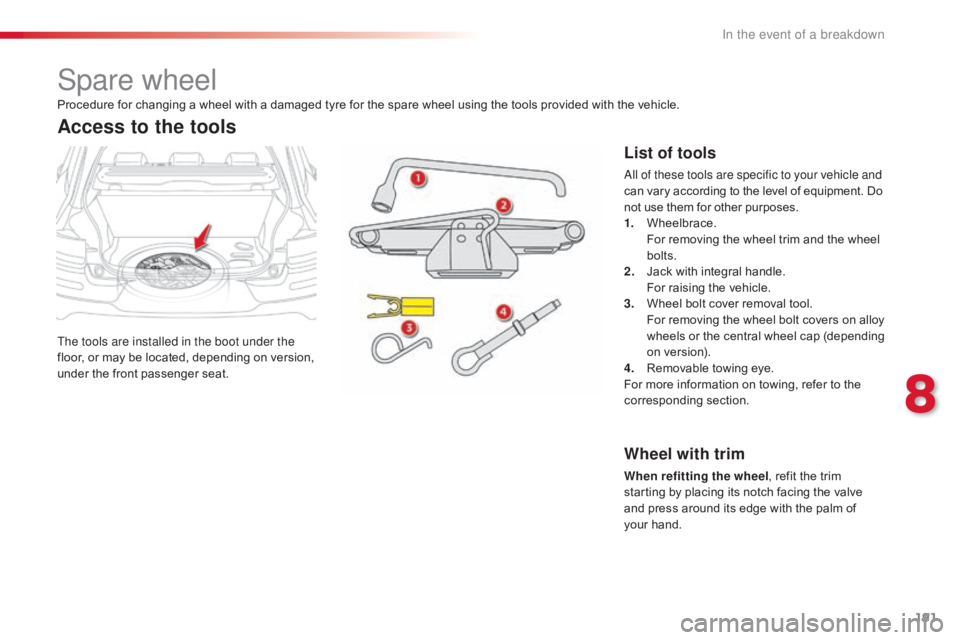

Spare wheel

The tools are installed in the boot under the

floor,ô or ô may ô be ô located, ô depending ô on ô version, ô

u

nder

ô t

he

ô f

ront

ô p

assenger

ô sea

t.

Access to the tools

List of tools

All of these tools are specific to your vehicle and

canô vary ô according ô to ô the ô level ô of ô equipment. ô Doô n

ot ô use ô them ô for ô other ô purposes.

1.

ô W

heelbrace.

ô F

or ô removing ô the ô wheel ô trim ô and ô the ô wheel ô

bol

ts.

2.

ô J

ack ô with ô integral ô handle.

ô F

or ô raising ô the ô vehicle.

3.

ô W

heel ô bolt ô cover ô removal ô tool.

ô F

or ô removing ô the ô wheel ô bolt ô covers ô on ô alloy ô

w

heels

ô o

r

ô t

he

ô c

entral

ô w

heel

ô c

ap

ô (

depending

ô o

n ô version).

4.

ô R

emovable ô towing ô eye.

For

ô more ô information ô on ô towing, ô refer ô to ô the ô

c

orresponding

ô s

ection.

Procedure

ô

for

ô

changing

ô

a

ô

wheel

ô

with

ô

a

ô

damaged

ô

tyre

ô

for

ô

the

ô

spare

ô

wheel

ô

using

ô

the

ô

tools

ô

provided

ô

with

ô

the ô vehicle.

Wheel with trim

When refitting the wheel

, ô refit ô the ô trim ô s

tarting ô by ô placing ô its ô notch ô facing ô the ô valve ô

a

nd ô press ô around ô its ô edge ô with ô the ô palm ô of ô

y

ourô hand.

8

In the event of a breakdown

Page 194 of 317

192

C4-cactus_en_Chap08_En-cas-de-panne_ed01-2016

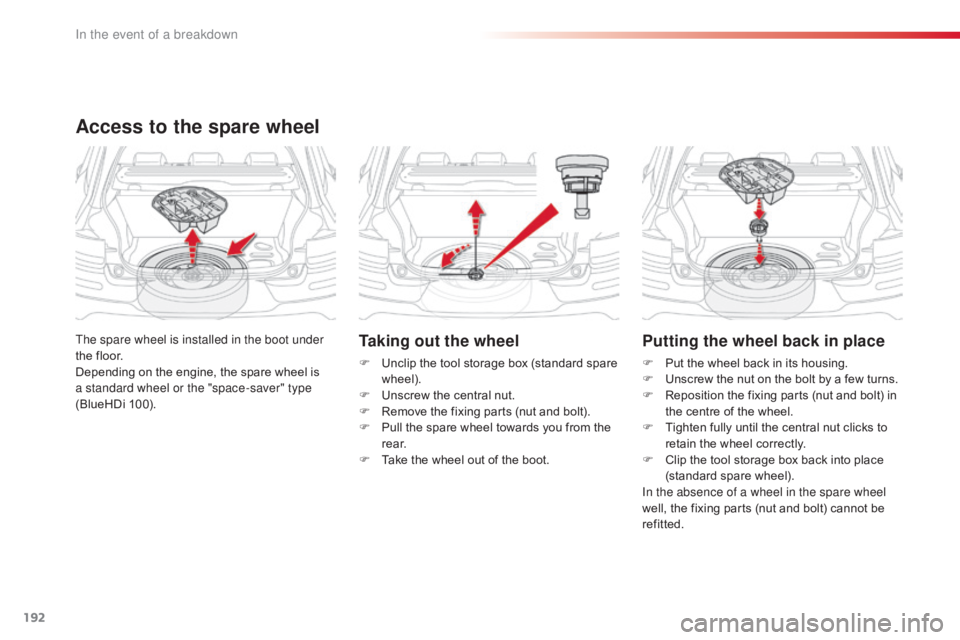

Taking out the wheel

Fô Unclipô the ô tool ô storage ô box ô (standard ô spare ô w

heel).

F

ô

U

nscrew ô the ô central ô nut.

F

ô

R

emove ô the ô fixing ô parts ô (nut ô and ô bolt).

F

ô

P

ull ô the ô spare ô wheel ô towards ô you ô from ô the ô

r

e a r.

F

ô

T

ake ô the ô wheel ô out ô of ô the ô boot.

The spare wheel is installed in the boot under

the

ô

floor.

Depending

ô

on

ô

the

ô

engine,

ô

the

ô

spare

ô

wheel

ô

is

ô

a s

tandard wheel or the "space-saver" type

(BlueHDi

ô

100).

Access to the spare wheel

Putting the wheel back in place

Fô Put ô the ô wheel ô back ô in ô its ô housing.

F ô U nscrew ô the ô nut ô on ô the ô bolt ô by ô a ô few ô turns.

F

ô

R

eposition ô the ô fixing ô parts ô (nut ô and ô bolt) ô in ô

t

he ô centre ô of ô the ô wheel.

F

ô

T

ighten ô fully ô until ô the ô central ô nut ô clicks ô to ô

r

etain ô the ô wheel ô correctly.

F

ô

C

lip ô the ô tool ô storage ô box ô back ô into ô place ô

(

standard

ô spar

e

ô w

heel).

In the absence of a wheel in the spare wheel

well,

ô the ô fixing ô parts ô (nut ô and ô bolt) ô cannot ô be ô

r

efitted.

In the event of a breakdown

Page 195 of 317

193

C4-cactus_en_Chap08_En-cas-de-panne_ed01-2016

Removing a wheel

Parking the vehicle

Immobiliseô theô vehicleô whereô itô doesô notô block ô traffic: ô the ô ground ô must ô be ô level, ô

s

table ô and ô not ô slippery.

Apply

ô the ô parking ô brake, ô switch ô off ô the ô

i

gnition ô and ô engage ô first ô gear ô to ô block ô

t

he ô wheels.

Check

ô that ô the ô parking ô brake ô warning ô

l

amps ô in ô the ô instrument ô panel ô come ô on.

The

ô occupants ô must ô get ô out ô of ô the ô

v

ehicle ô and ô wait ô where ô they ô are ô safe.

Ensure

ô that ô the ô jack ô is ô correctly ô

p

ositioned ô at ô one ô of ô the ô vehicle's ô

j

acking ô points.

Incorrect

ô use ô of ô the ô jack ô could ô cause ô

t

he ô vehicle ô to ô drop.

Never

ô go ô underneath ô a ô vehicle ô raised ô

u

sing ô a ô jack; ô use ô an ô axle ô stand.

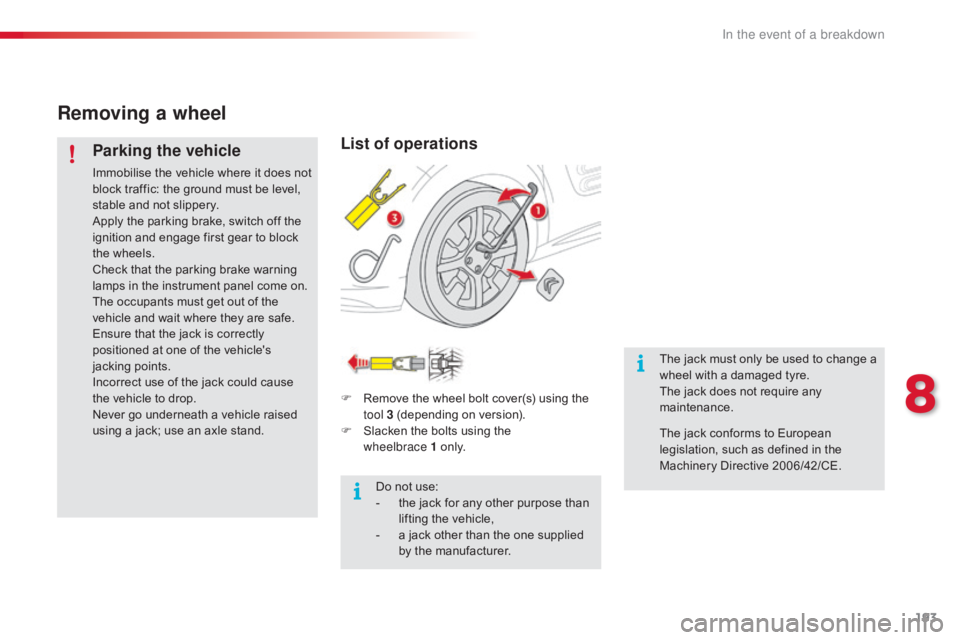

List of operations

Fô Removeô the ô wheel ô bolt ô cover(s) ô using ô the ô t

ool 3 ô (depending ô on ô version).

F

ô

S

lacken ô the ô bolts ô using ô the ô

w

heelbrace

1ô o n l y.

Do

ô not ô use:

-

ô

t

he ô jack ô for ô any ô other ô purpose ô than ô

l

ifting ô the ô vehicle,

-

ô

a

ô jack ô other ô than ô the ô one ô supplied ô

b

y ô the ô manufacturer. The

ô jack ô must ô only ô be ô used ô to ô change ô a ô

w

heel ô with ô a ô damaged ô tyre.

The ô jack ô does ô not ô require ô any ô m

aintenance.

The

ô jack ô conforms ô to ô European ô

l

egislation, ô such ô as ô defined ô in ô the ô

M

achinery ô Directive ô 2006/42/CE.

8

In the event of a breakdown

Page 196 of 317

194

C4-cactus_en_Chap08_En-cas-de-panne_ed01-2016

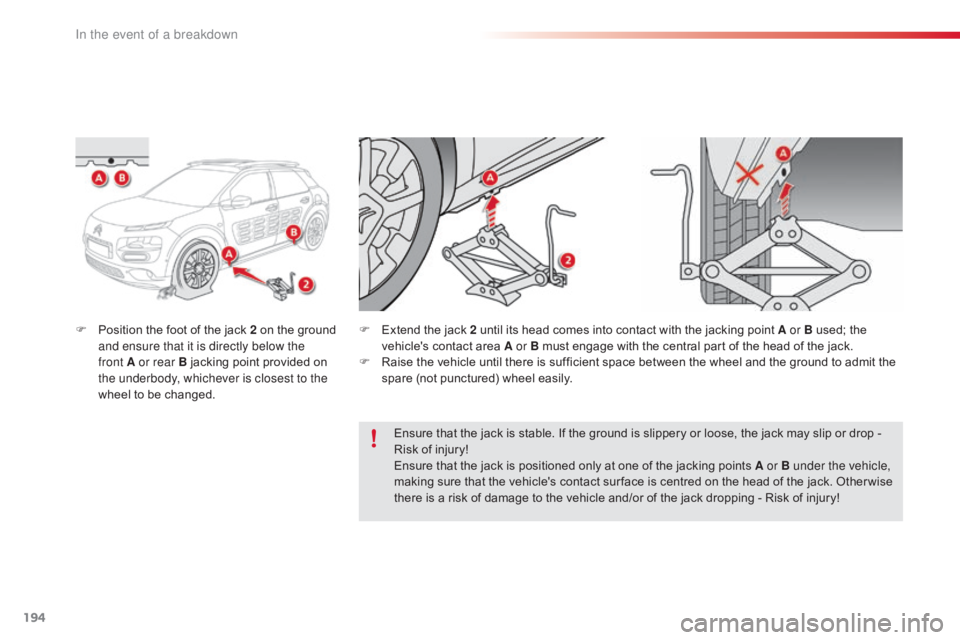

Fô Positionô the ô foot ô of ô the ô jack ô 2 ô on ô the ô ground ô a

nd ensure that it is directly below the

front

A or rear B ô jacking ô point ô provided ô on ô

t

he underbody, whichever is closest to the

wheel

ô to ô be ô changed. F

ô E xtend ô the ô jack ô 2 ô until ô its ô head ô comes ô into ô contact ô with ô the ô jacking ô point ô A or B ô used; ô the ô v

ehicle's ô contact ô area ô A or B ô must ô engage ô with ô the ô central ô part ô of ô the ô head ô of ô the ô jack.

F

ô

R

aise ô the ô vehicle ô until ô there ô is ô sufficient ô space ô between ô the ô wheel ô and ô the ô ground ô to ô admit ô the ô

s

pare ô (not ô punctured) ô wheel ô easily.

Ensure

ô that ô the ô jack ô is ô stable. ô If ô the ô ground ô is ô slippery ô or ô loose, ô the ô jack ô may ô slip ô or ô drop ô - ô

R

isk ô of ô injury!

Ensure

ô that ô the ô jack ô is ô positioned ô only ô at ô one ô of ô the ô jacking ô points ô A or B under the vehicle,

making

ô sure ô that ô the ô vehicle's ô contact ô sur face ô is ô centred ô on ô the ô head ô of ô the ô jack. ô Other wise ô

t

here ô is ô a ô risk ô of ô damage ô to ô the ô vehicle ô and/or ô of ô the ô jack ô dropping ô - ô Risk ô of ô injury!

In the event of a breakdown

Page 197 of 317

195

C4-cactus_en_Chap08_En-cas-de-panne_ed01-2016

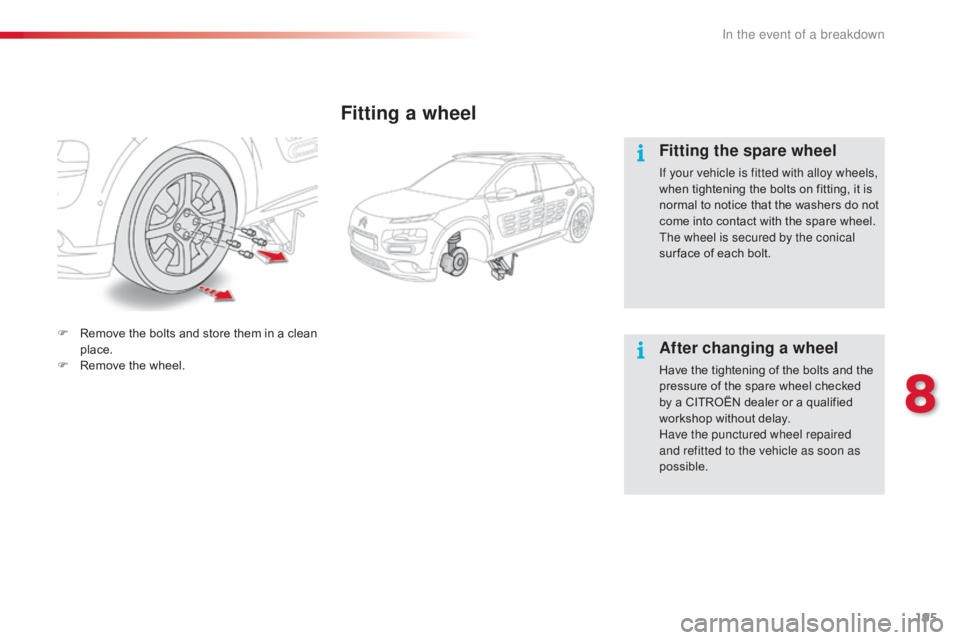

Fitting a wheel

Fitting the spare wheel

If your vehicle is fitted with alloy wheels,

whenô tightening ô the ô bolts ô on ô fitting, ô it ô is ô

n

ormal ô

t

o ô

n

otice ô

t

hat ô

t

he ô

w

ashers ô

d

o ô

n

ot ô

c

ome ô into ô contact ô with ô the ô spare ô wheel. ô

T

he wheel is secured by the conical

sur face

ô of ô each ô bolt.

After changing a wheel

Haveô theô tighteningô ofô theô boltsô andô theô pressure ô of ô the ô spare ô wheel ô checked ô

b

y ô a ô CITROûN ô dealer ô or ô a ô qualified ô

w

orkshop ô without ô delay.

Have the punctured wheel repaired

and refitted to the vehicle as soon as

possible.

F

ô

R

emove

ô

the

ô

bolts

ô

and

ô

store

ô

them

ô

in

ô

a

ô

clean

ô

p

lace.

F

ô R

emove

ô

the

ô

wheel.

8

In the event of a breakdown

Page 198 of 317

196

C4-cactus_en_Chap08_En-cas-de-panne_ed01-2016

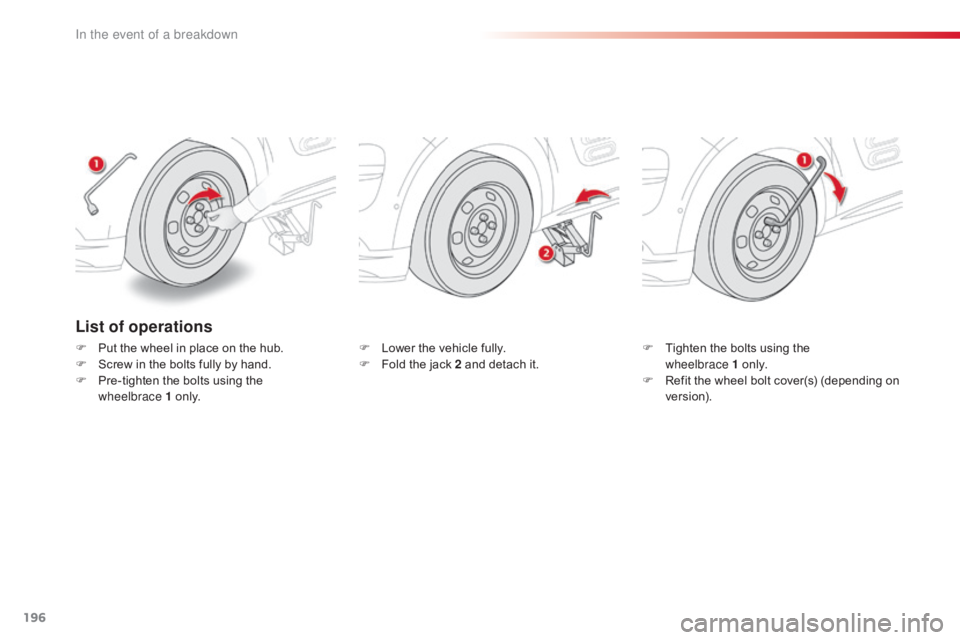

List of operations

Fô Putô the ô wheel ô in ô place ô on ô the ô hub.

F ô S crew ô in ô the ô bolts ô fully ô by ô hand.

F

ô

P

re-tighten ô the ô bolts ô using ô the ô

w

heelbrace

1 ô

o

n l y. F

ô L ower ô the ô vehicle ô fully.

F ô F old ô the ô jack ô 2 ô and ô detach ô it.F

ô T ighten ô the ô bolts ô using ô the ô w

heelbrace 1ô o n l y.

F

ô

R

efit ô the ô wheel ô bolt ô cover(s) ô (depending ô on ô

v

e r s i o n).

In the event of a breakdown

Page 199 of 317

197

C4-cactus_en_Chap08_En-cas-de-panne_ed01-2016

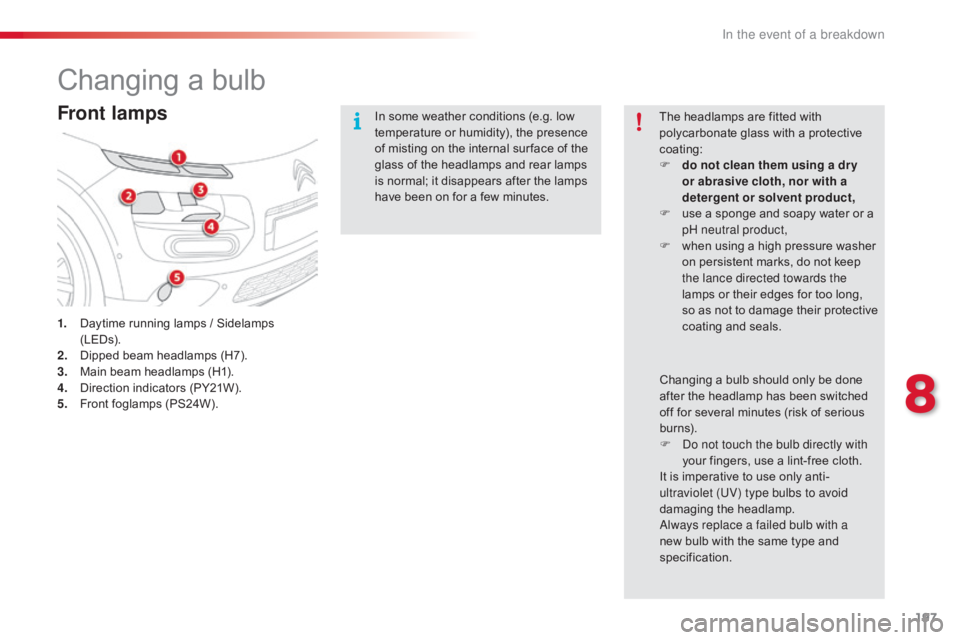

Changingô aô bulb

Front lamps

1.ô Daytimeô running ô lamps ô / ô Sidelamps ô (LE

Ds).

2.

ô D

ipped ô beam ô headlamps ô (H7).

3.

ô M

ain ô beam ô headlamps ô (H1).

4.

ô D

irection ô indicators ô (PY21W).

5.

ô F

ront ô foglamps ô (PS24W). In

ô some ô weather ô conditions ô (e.g. ô low ô

t

emperature ô or ô humidity), ô the ô presence ô

o

f ô misting ô on ô the ô internal ô sur face ô of ô the ô

g

lass ô of ô the ô headlamps ô and ô rear ô lamps ô

i

s ô normal; ô it ô disappears ô after ô the ô lamps ô

h

ave ô been ô on ô for ô a ô few ô minutes.

The ô headlamps ô are ô fitted ô with ô

p

olycarbonate ô glass ô with ô a ô protective ô

c

oating:

F

d

o not clean them using a dr y

or abrasive cloth, nor with a

detergent or solvent product,

F ô

u

se ô a ô sponge ô and ô soapy ô water ô or ô a ô

p

H neutral product,

F ô

w

hen ô using ô a ô high ô pressure ô washer ô

o

n ô persistent ô marks, ô do ô not ô keep ô

t

he lance directed towards the

lamps ô or ô their ô edges ô for ô too ô long, ô s

o ô as ô not ô to ô damage ô their ô protective ô c

oatingô a ndô sea ls.

Changing

ô a ô bulb ô should ô only ô be ô done ô

a

fter ô the ô headlamp ô has ô been ô switched ô

o

ff ô for ô several ô minutes ô (risk ô of ô serious ô

b

urns).

F

D

o not touch the bulb directly with

your

ô fingers, ô use ô a ô lint-free ô cloth.

It

ô is ô imperative ô to ô use ô only ô anti-

ultraviolet (UV) type bulbs to avoid

damaging

ô t

he

ô h

eadlamp.

Always replace a failed bulb with a

new

ô bulb ô with ô the ô same ô type ô and ô

s

pecification.

8

In the event of a breakdown

Page 200 of 317

198

C4-cactus_en_Chap08_En-cas-de-panne_ed01-2016

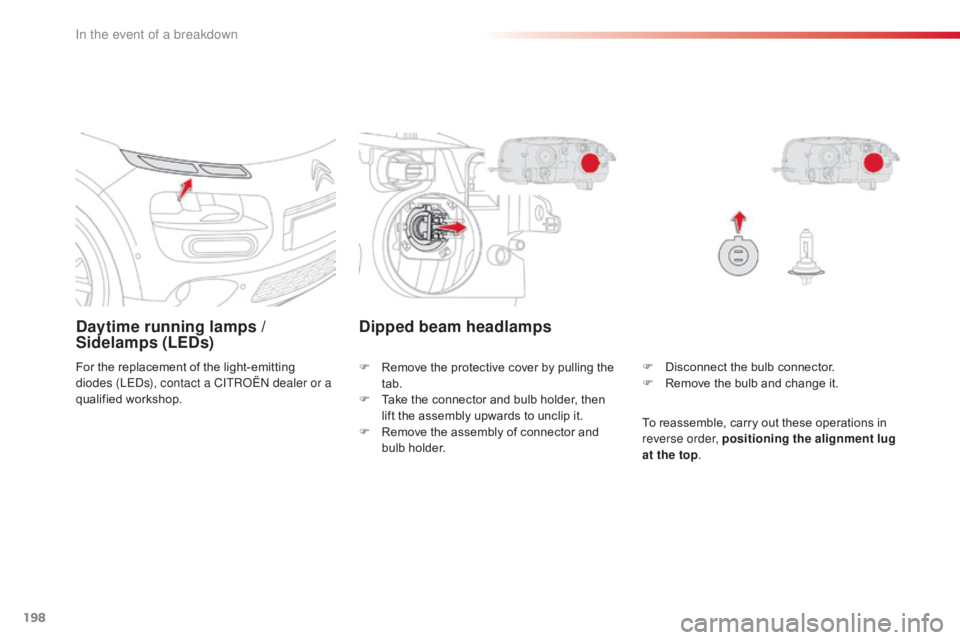

Daytime running lamps /

S idelamps (LEDs)

Forô theô replacementô ofô theô light-emittingô d

iodes (LEDs), contact a CITROûN dealer or a

qualified

ô w

orkshop. F

ô D isconnect ô the ô bulb ô connector.

F

ô

R

emove ô the ô bulb ô and ô change ô it.

Dipped beam headlamps

Fô Removeô the ô protective ô cover ô by ô pulling ô the ô t

ab.

F

ô

T

ake ô the ô connector ô and ô bulb ô holder, ô then ô

l

ift ô the ô assembly ô upwards ô to ô unclip ô it.

F

ô

R

emove ô the ô assembly ô of ô connector ô and ô

b

ulb ô holder. To

ô reassemble, ô carry ô out ô these ô operations ô in ô

r

everse order, positioning the alignment lug

at the top .

In the event of a breakdown