ECU Citroen C5 2000 (DC/DE) / 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2000, Model line: C5, Model: Citroen C5 2000 (DC/DE) / 1.GPages: 259, PDF Size: 2.29 MB

Page 156 of 259

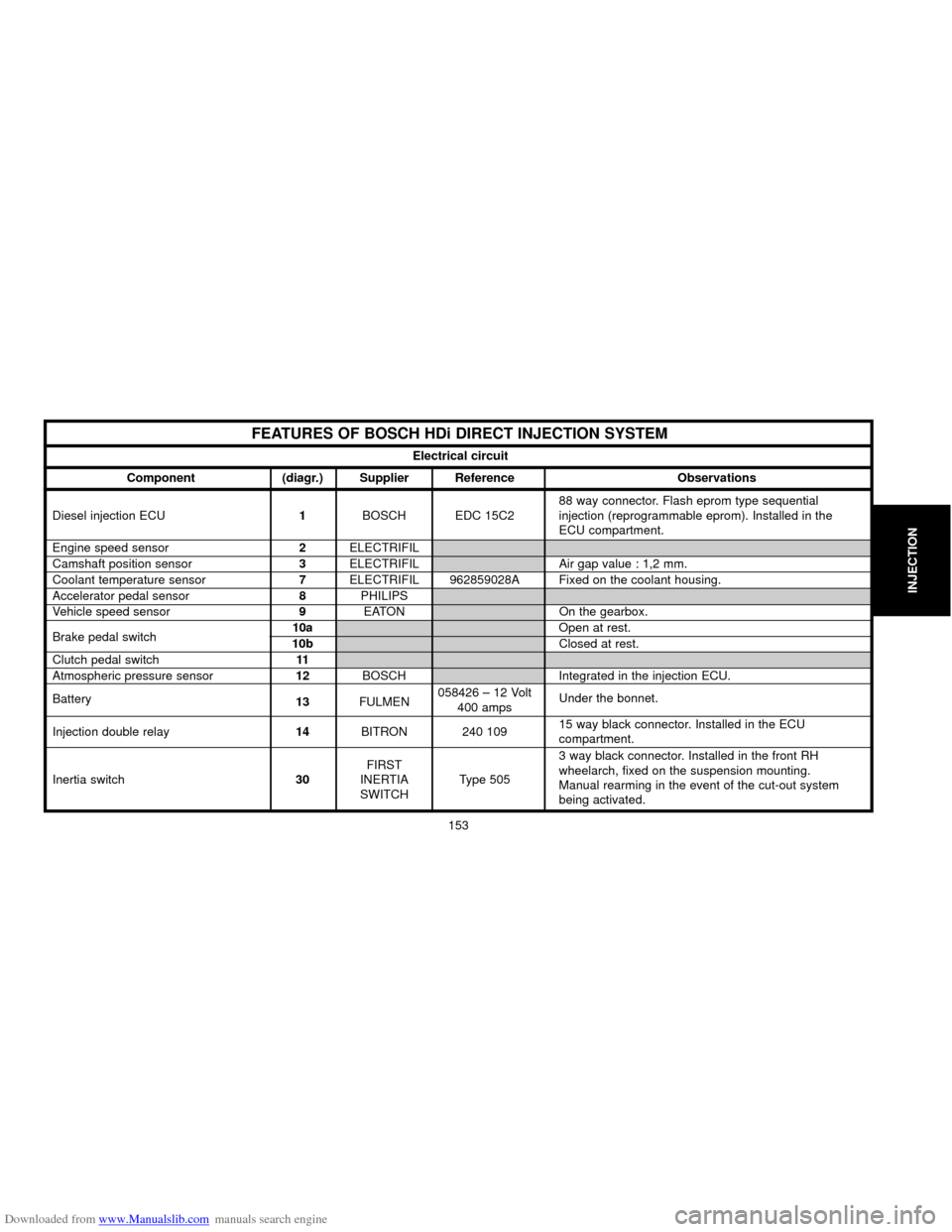

Downloaded from www.Manualslib.com manuals search engine 153

INJECTION

Component (diagr.) Supplier Reference Observations

88 way connector. Flash eprom type sequential

Diesel injection ECU1BOSCHEDC 15C2 injection (reprogrammable eprom). Installed in the

ECU compartment.

Engine speed sensor2ELECTRIFIL

Camshaft position sensor3ELECTRIFIL Air gap value : 1,2 mm.

Coolant temperature sensor7ELECTRIFIL 962859028A Fixed on the coolant housing.

Accelerator pedal sensor8PHILIPS

Vehicle speed sensor9EATON On the gearbox.

Brake pedal switch10aOpen at rest.

10bClosed at rest.

Clutch pedal switch11

Atmospheric pressure sensor12BOSCHIntegrated in the injection ECU.

Battery

13FULMEN058426 – 12 Volt

400 ampsUnder the bonnet.

Injection double relay14BITRON 240 10915 way black connector. Installed in the ECU

compartment.

FIRST3 way black connector. Installed in the front RH

Inertia switch30INERTIA Type 505wheelarch, fixed on the suspension mounting.

SWITCHManual rearming in the event of the cut-out system

being activated.

FEATURES OF BOSCH HDi DIRECT INJECTION SYSTEM

Electrical circuit

Page 157 of 259

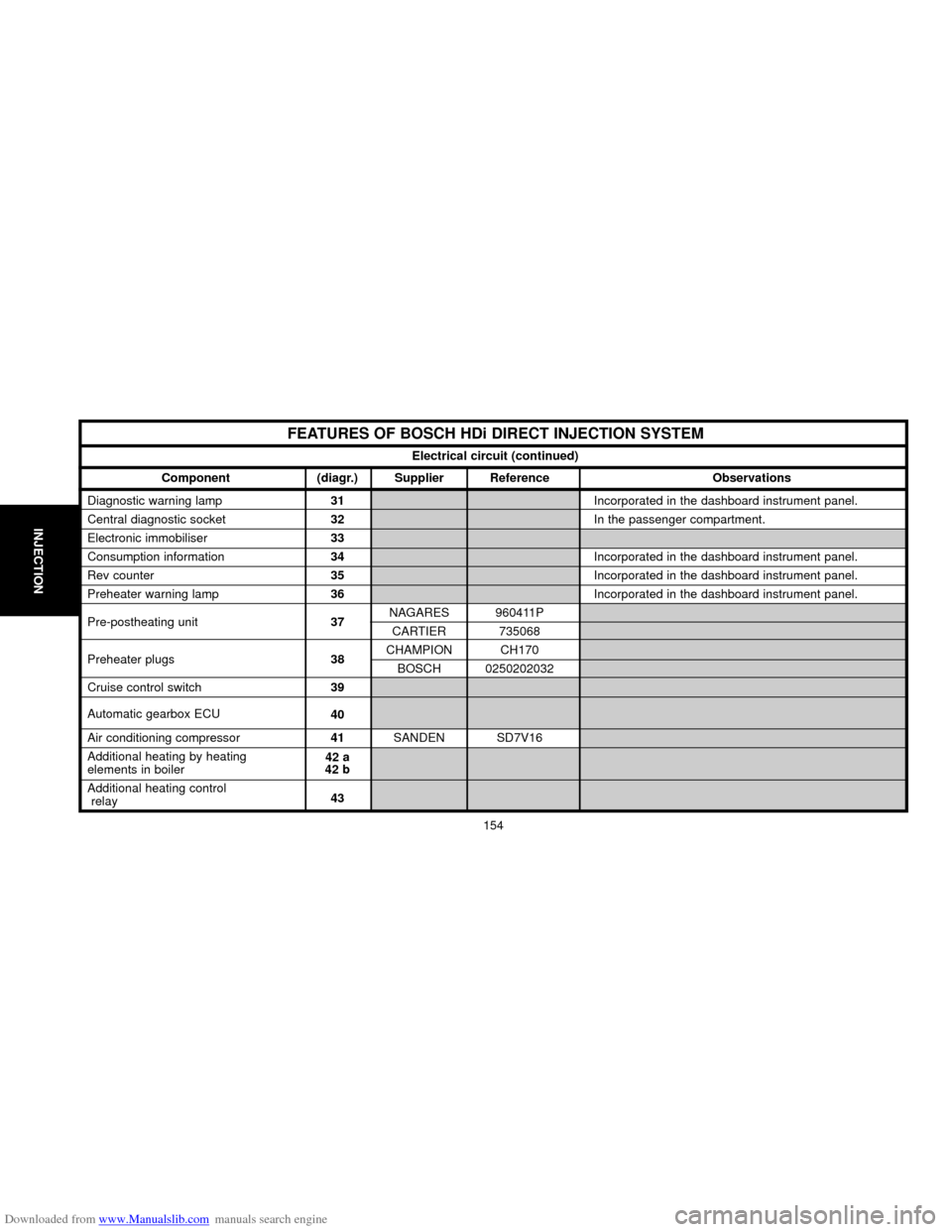

Downloaded from www.Manualslib.com manuals search engine 154

INJECTION

Component (diagr.) Supplier Reference Observations

Diagnostic warning lamp31Incorporated in the dashboard instrument panel.

Central diagnostic socket32In the passenger compartment.

Electronic immobiliser33

Consumption information 34Incorporated in the dashboard instrument panel.

Rev counter35Incorporated in the dashboard instrument panel.

Preheater warning lamp36Incorporated in the dashboard instrument panel.

Pre-postheating unit37NAGARES 960411P

CARTIER 735068

Preheater plugs38CHAMPION CH170

BOSCH0250202032

Cruise control switch39

Automatic gearbox ECU

40

Air conditioning compressor41SANDEN SD7V16

Additional heating by heating

42 a

elements in boiler42 b

Additional heating control

relay43

FEATURES OF BOSCH HDi DIRECT INJECTION SYSTEM

Electrical circuit (continued)

Page 161 of 259

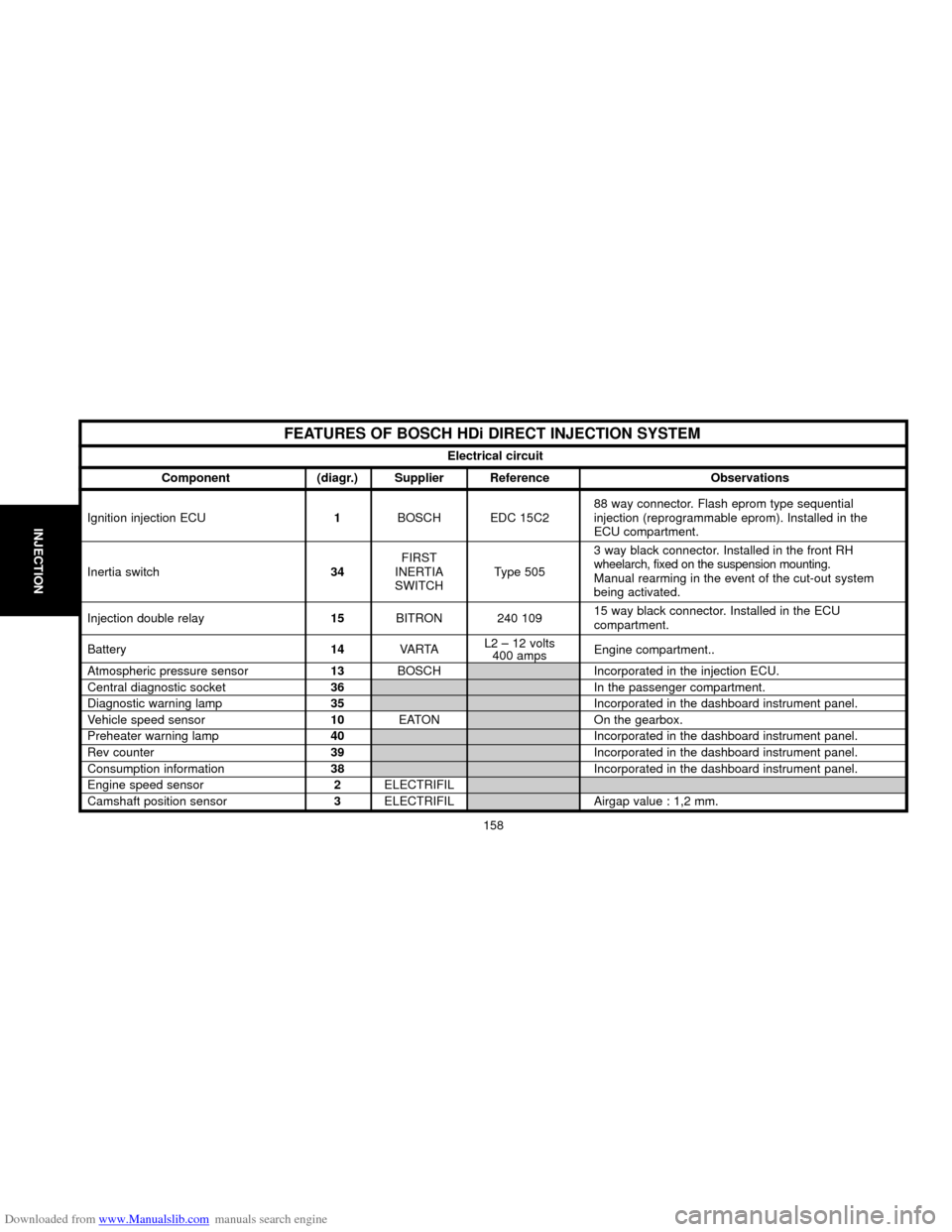

Downloaded from www.Manualslib.com manuals search engine 158

INJECTION

FEATURES OF BOSCH HDi DIRECT INJECTION SYSTEM

Component (diagr.) Supplier Reference Observations

88 way connector. Flash eprom type sequential

Ignition injection ECU1BOSCHEDC 15C2 injection (reprogrammable eprom). Installed in the

ECU compartment.

FIRST3 way black connector. Installed in the front RH

Inertia switch34INERTIA Type 505wheelarch, fixed on the suspension mounting.

SWITCHManual rearming in the event of the cut-out system

being activated.

Injection double relay15BITRON 240 10915 way black connector. Installed in the ECU

compartment.

Battery14VA R TAL2 – 12 volts

400 ampsEngine compartment..

Atmospheric pressure sensor13BOSCHIncorporated in the injection ECU.

Central diagnostic socket36In the passenger compartment.

Diagnostic warning lamp35Incorporated in the dashboard instrument panel.

Vehicle speed sensor10EATON On the gearbox.

Preheater warning lamp40Incorporated in the dashboard instrument panel.

Rev counter39Incorporated in the dashboard instrument panel.

Consumption information 38Incorporated in the dashboard instrument panel.

Engine speed sensor2ELECTRIFIL

Camshaft position sensor3ELECTRIFIL Airgap value : 1,2 mm.

Electrical circuit

Page 162 of 259

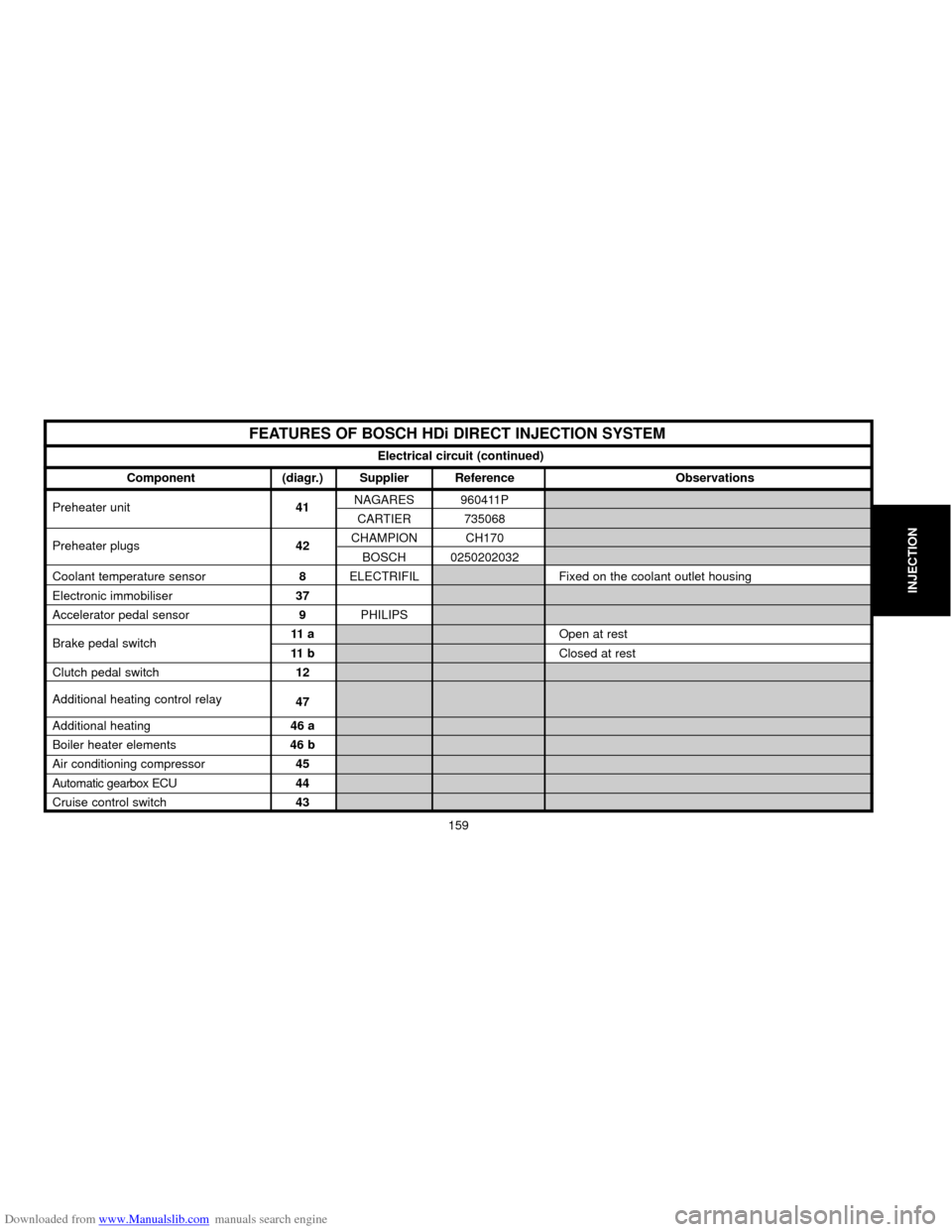

Downloaded from www.Manualslib.com manuals search engine Electrical circuit (continued)

INJECTION

FEATURES OF BOSCH HDi DIRECT INJECTION SYSTEM

159

Component (diagr.) Supplier Reference Observations

Preheater unit41NAGARES 960411P

CARTIER 735068

Preheater plugs42CHAMPION CH170

BOSCH0250202032

Coolant temperature sensor8ELECTRIFIL Fixed on the coolant outlet housing

Electronic immobiliser37

Accelerator pedal sensor9PHILIPS

Brake pedal switch 11 aOpen at rest

11 bClosed at rest

Clutch pedal switch12

Additional heating control relay

47

Additional heating46 a

Boiler heater elements46 b

Air conditioning compressor45

Automatic gearbox ECU44

Cruise control switch43

Page 166 of 259

Downloaded from www.Manualslib.com manuals search engine 163

INJECTION

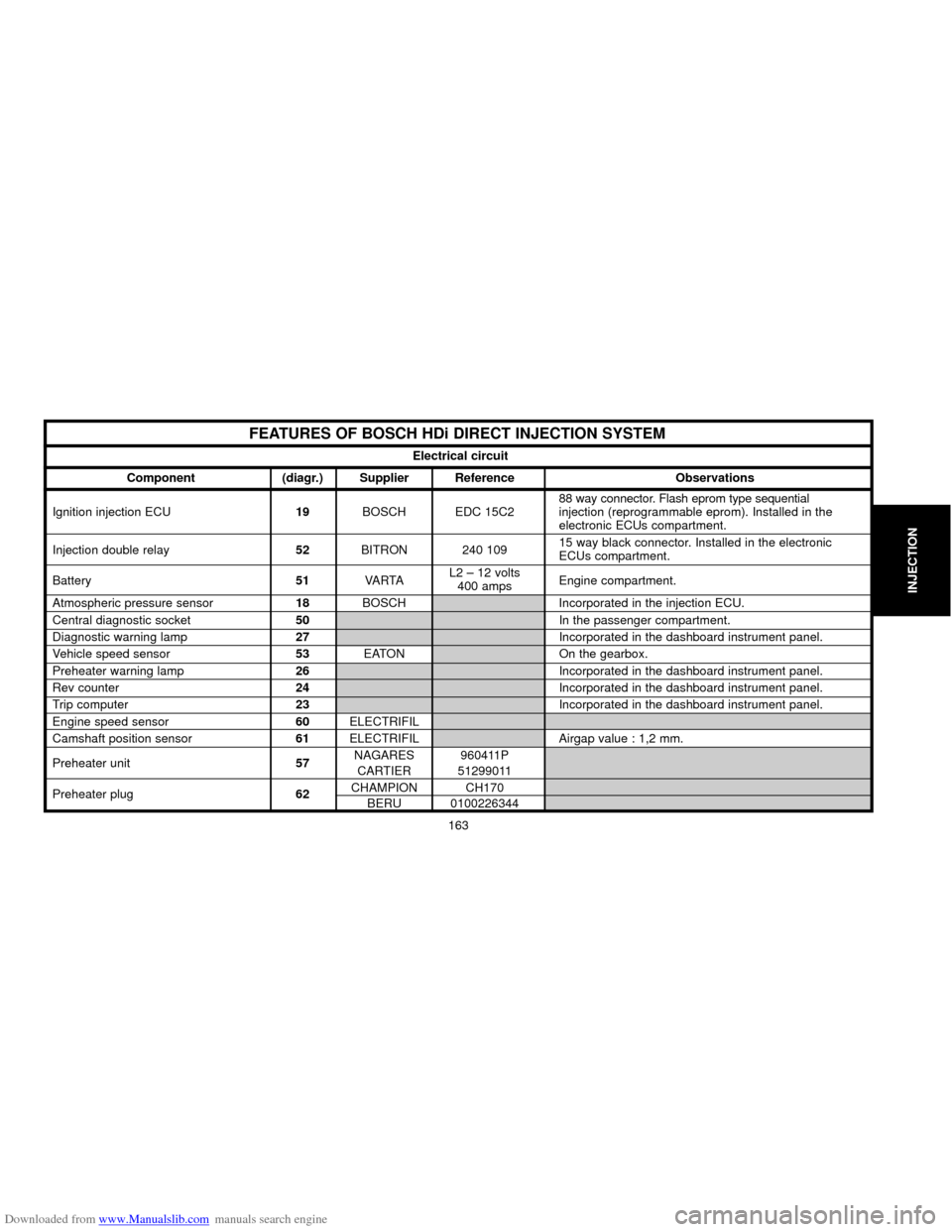

FEATURES OF BOSCH HDi DIRECT INJECTION SYSTEM

Component (diagr.) Supplier Reference Observations

88 way connector. Flash eprom type sequential

Ignition injection ECU19BOSCHEDC 15C2 injection (reprogrammable eprom). Installed in the

electronic ECUs compartment.

Injection double relay52BITRON 240 10915 way black connector. Installed in the electronic

ECUs compartment.

Battery51VA R TAL2 – 12 volts

Engine compartment.

400 amps

Atmospheric pressure sensor18BOSCHIncorporated in the injection ECU.

Central diagnostic socket50In the passenger compartment.

Diagnostic warning lamp27Incorporated in the dashboard instrument panel.

Vehicle speed sensor53EATON On the gearbox.

Preheater warning lamp26Incorporated in the dashboard instrument panel.

Rev counter24Incorporated in the dashboard instrument panel.

Trip computer23Incorporated in the dashboard instrument panel.

Engine speed sensor60ELECTRIFIL

Camshaft position sensor61ELECTRIFIL Airgap value : 1,2 mm.

Preheater unit57NAGARES 960411P

CARTIER 51299011

Preheater plug62CHAMPION CH170

BERU 0100226344

Electrical circuit

Page 167 of 259

Downloaded from www.Manualslib.com manuals search engine 164

INJECTION

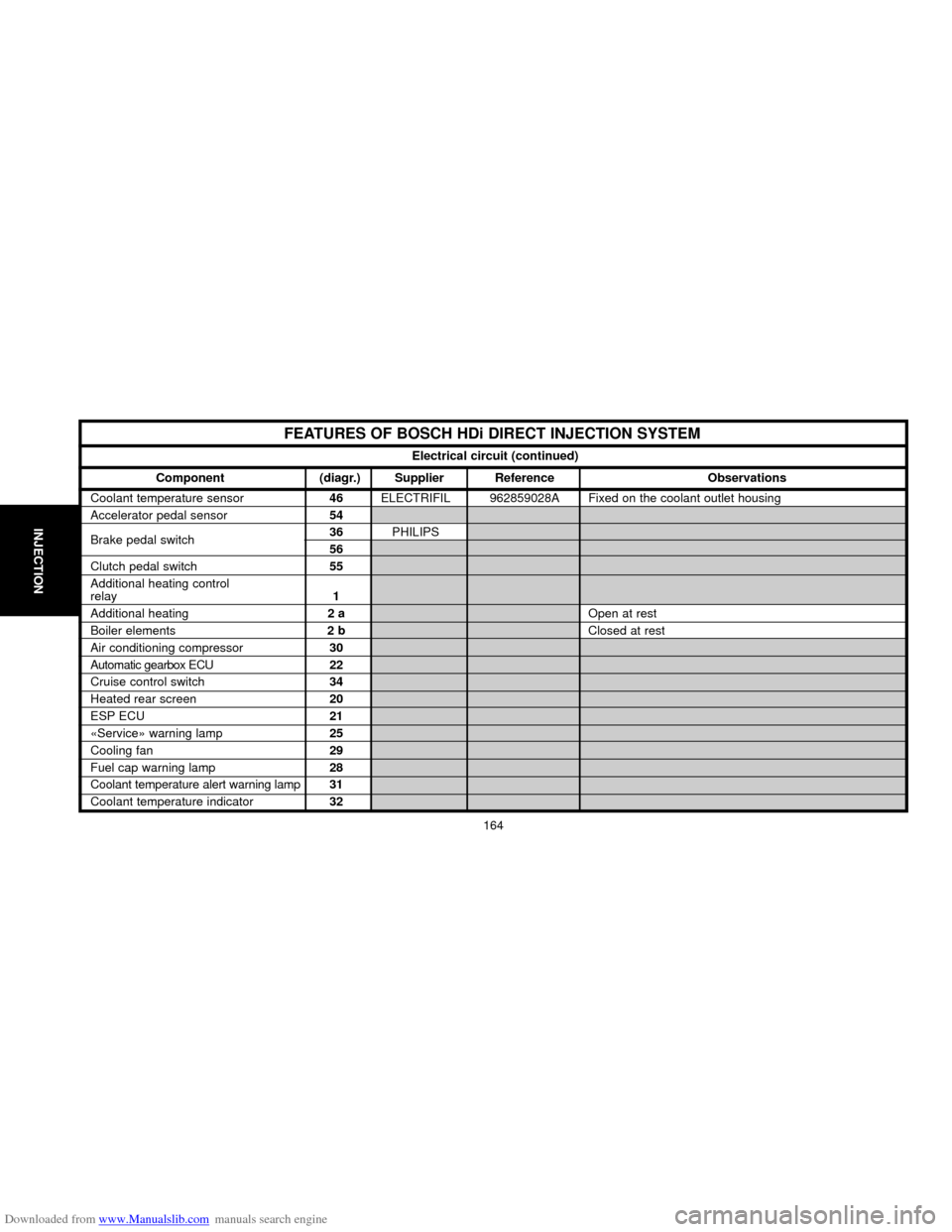

FEATURES OF BOSCH HDi DIRECT INJECTION SYSTEM

Electrical circuit (continued)

Component (diagr.) Supplier Reference Observations

Coolant temperature sensor46ELECTRIFIL 962859028A Fixed on the coolant outlet housing

Accelerator pedal sensor54

Brake pedal switch36PHILIPS

56

Clutch pedal switch55

Additional heating control

relay1

Additional heating2 aOpen at rest

Boiler elements2 bClosed at rest

Air conditioning compressor 30

Automatic gearbox ECU22

Cruise control switch34

Heated rear screen20

ESP ECU21

«Service» warning lamp25

Cooling fan29

Fuel cap warning lamp28

Coolant temperature alert warning lamp31

Coolant temperature indicator32

Page 171 of 259

Downloaded from www.Manualslib.com manuals search engine 168

INJECTION

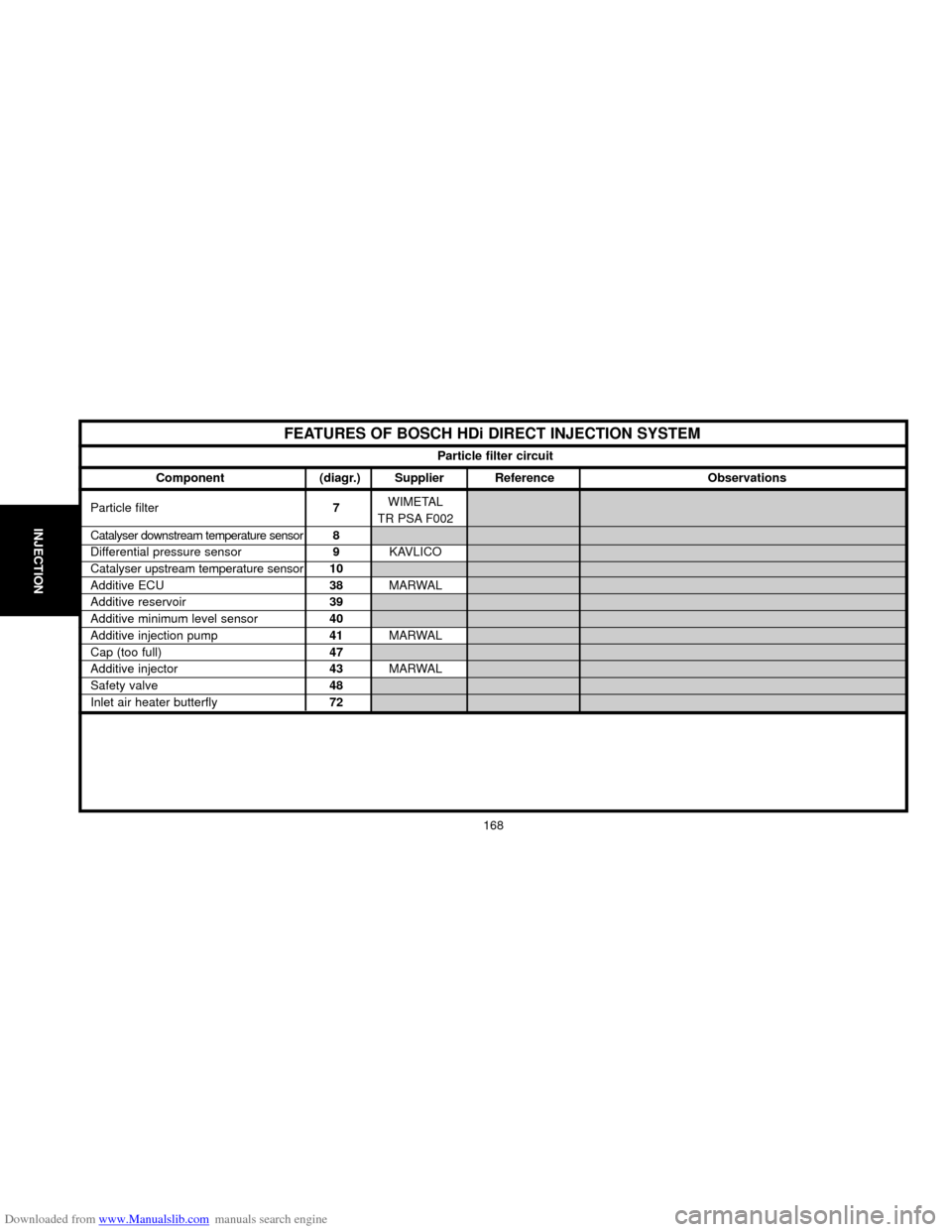

FEATURES OF BOSCH HDi DIRECT INJECTION SYSTEM

Particle filter circuit

Component (diagr.) Supplier Reference Observations

WIMETAL

Particle filter7

TR PSA F002

Catalyser downstream temperature sensor8

Differential pressure sensor9KAVLICO

Catalyser upstream temperature sensor10

Additive ECU38MARWAL

Additive reservoir39

Additive minimum level sensor40

Additive injection pump41MARWAL

Cap (too full)47

Additive injector43MARWAL

Safety valve48

Inlet air heater butterfly72

Page 200 of 259

Downloaded from www.Manualslib.com manuals search engine 197

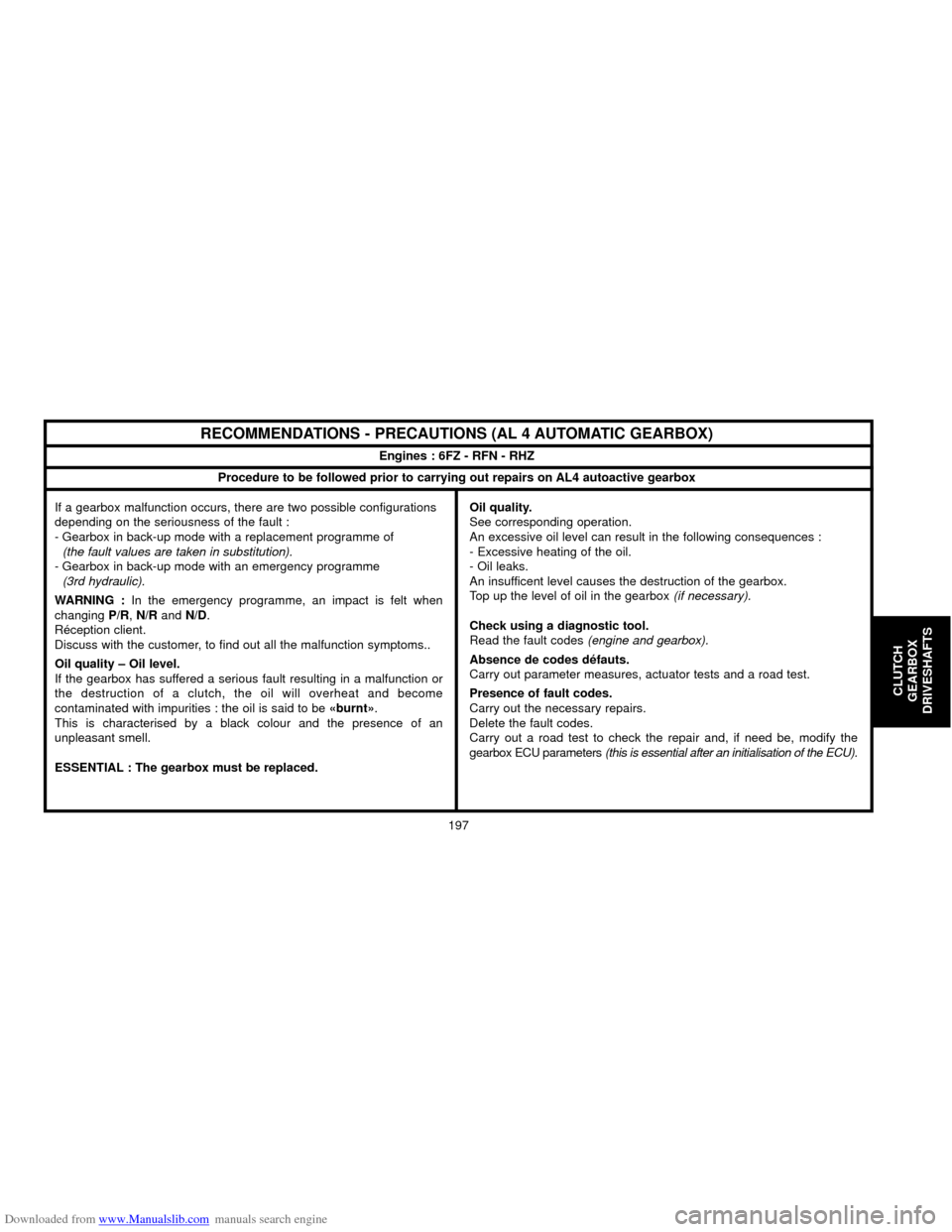

RECOMMENDATIONS - PRECAUTIONS (AL 4 AUTOMATIC GEARBOX)

Engines : 6FZ - RFN - RHZ

Procedure to be followed prior to carrying out repairs on AL4 autoactive gearbox

CLUTCH

GEARBOX

DRIVESHAFTS

If a gearbox malfunction occurs, there are two possible configurations

depending on the seriousness of the fault :

- Gearbox in back-up mode with a replacement programme of

(the fault values are taken in substitution).

- Gearbox in back-up mode with an emergency programme

(3rd hydraulic).

WARNING : In the emergency programme, an impact is felt when

changing P/R, N/RandN/D.

Réception client.

Discuss with the customer, to find out all the malfunction symptoms..

Oil quality – Oil level.

If the gearbox has suffered a serious fault resulting in a malfunction or

the destruction of a clutch, the oil will overheat and become

contaminated with impurities : the oil is said to be «burnt».

This is characterised by a black colour and the presence of an

unpleasant smell.

ESSENTIAL : The gearbox must be replaced.Oil quality.

See corresponding operation.

An excessive oil level can result in the following consequences :

- Excessive heating of the oil.

- Oil leaks.

An insufficent level causes the destruction of the gearbox.

Top up the level of oil in the gearbox (if necessary).

Check using a diagnostic tool.

Read the fault codes (engine and gearbox).

Absence de codes défauts.

Carry out parameter measures, actuator tests and a road test.

Presence of fault codes.

Carry out the necessary repairs.

Delete the fault codes.

Carry out a road test to check the repair and, if need be, modify the

gearbox ECU parameters (this is essential after an initialisation of the ECU).

Page 201 of 259

Downloaded from www.Manualslib.com manuals search engine 198

CLUTCH

GEARBOX

DRIVESHAFTS

RECOMMENDATIONS - PRECAUTIONS (AL 4 and 4 HP 20 AUTOMATIC GEARBOXES)

Engines : 6FZ - RFN - RHZ - XFX - 4HX

Procedure prior to carrying out repairs (continued)

When the ECU detects an erroneous or non-existent value

on input or output :

- It writes the fault in memory.

- For each associated context, it writes the context of the oldest fault

in memory.

- It initiates a back-up mode strategy.

There are two types of back-up modes :

- The ECU makes replacement values available (relating to comfort,

gear selection quality, loss of functions).

- Access to emergency programme (only 3rd ratio and reverse are

available)

NOTE : 4 HP 20 : A snatching may be felt when changing :P/R - N/R - N/D.Reading the fault codes.

Read the fault codes.

No fault codes present :

Carry out a measure of parameters.

Anomalies present :

- YES : Carry out the necessary repairs.

- NO : Read the fault codes – engine ECU.

- Carry out a road test.

Following an initialisation of the ECU, for a certain period of time there

may be an inconsistent gear selection quality(while ECU parameters

are adapted to the gearbox).

To achieve a consistent standard, it is necessary to carry out a road test

taking in frequent gear changes (auto-adaptive laws).

Page 202 of 259

Downloaded from www.Manualslib.com manuals search engine 199

RECOMMENDATIONS - PRECAUTIONS (AL 4 and 4 HP 20 AUTOMATIC GEARBOXES)

Engines : 6FZ - RFN - RHZ - XFX - 4HX

CLUTCH

GEARBOX

DRIVESHAFTS

ECU : Downloading, Configuration, Initialisation (Pedal).

Downloading. ( AL 4 and 4 HP 20 )

Updating the gearbox ECU by downloading :

- Follow the procedure using the diagnostic equipment.

The operation of downloading is used to update the automatic gearbox ECU or to adapt it to evolutions of the engine ECU.

After downloading, carry out the following :

- Note down the value in the oil usage counter present in the automatic gearbox ECU.

- Delete the fault codes.

- Again note down the value in the oil usage counter and compare it with the value previously read.

- Pedal initialisation (AL 4)

- Configuration (if needed) (AL 4)Following the diagnostic tool procedure.

- A reinitialisation of the autoadaptives (AL4 - 4 HP 20).

- A road test (AL 4 - 4 HP 20).

IMPERATIVE : Every update of the automatic gearbox ECU must

be accompanied by an update of the engine ECU.