Citroen C5 2017 (RD/TD) / 2.G Owner's Manual

Manufacturer: CITROEN, Model Year: 2017, Model line: C5, Model: Citroen C5 2017 (RD/TD) / 2.GPages: 348, PDF Size: 10.72 MB

Page 211 of 348

209

C5_en_Chap08_en-cas-de-panne_ed01-2016

Removing the pipe and cartridge

F Turn the pipe assembly 2 to the left until it contacts the unit.

F

D

isconnect the union 1 from the cartridge

by turning it a quarter turn anti-clockwise.

F

E

xtract the pipe assembly 2 , then

disconnect the union 3 from the air delivery

pipe by turning it a quarter turn anti-

clockwise. Beware of discharges of fluid.

The expiry date of the fluid is indicated

on the cartridge.

The sealant cartridge is designed for

single use; even if only partly used, it

must be replaced.

After use, do not discard the cartridge

into the environment, take it to an

authorised waste disposal site or a

CITROËN dealer.

Do not forget to obtain a new sealant

cartridge, available from CITROËN

dealers or from a qualified workshop.

F

R emove the pipe assembly 2

.

F S upport the compressor vertically.

F

U

nscrew the cartridge 4 from the bottom.

To fit the new cartridge and new pipe, carry out

these operations in reverse order.

8

In the event of a breakdown

Page 212 of 348

210

C5_en_Chap08_en-cas-de-panne_ed01-2016

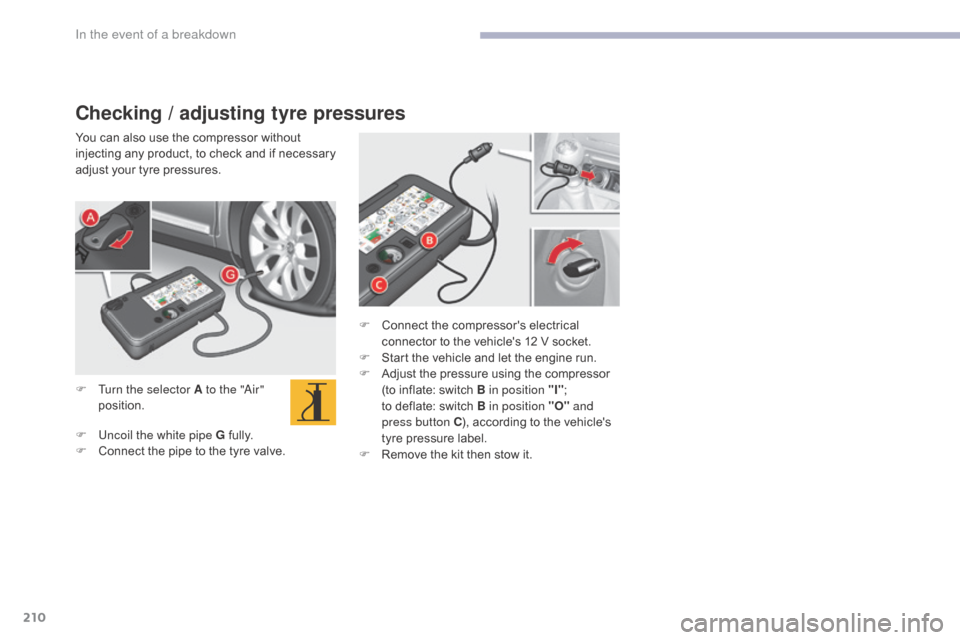

Checking / adjusting tyre pressures

You can also use the compressor without

injecting any product, to check and if necessary

adjust your tyre pressures.

F

T

urn the selector A to the "Air"

position.

F

U

ncoil the white pipe G fully.

F

C

onnect the pipe to the tyre valve. F

C

onnect the compressor's electrical

connector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(to inflate: switch B in position "I" ;

to

deflate: switch B in position "O" and

press button C ), according to the vehicle's

tyre pressure label.

F

R

emove the kit then stow it.

In the event of a breakdown

Page 213 of 348

211

C5_en_Chap08_en-cas-de-panne_ed01-2016

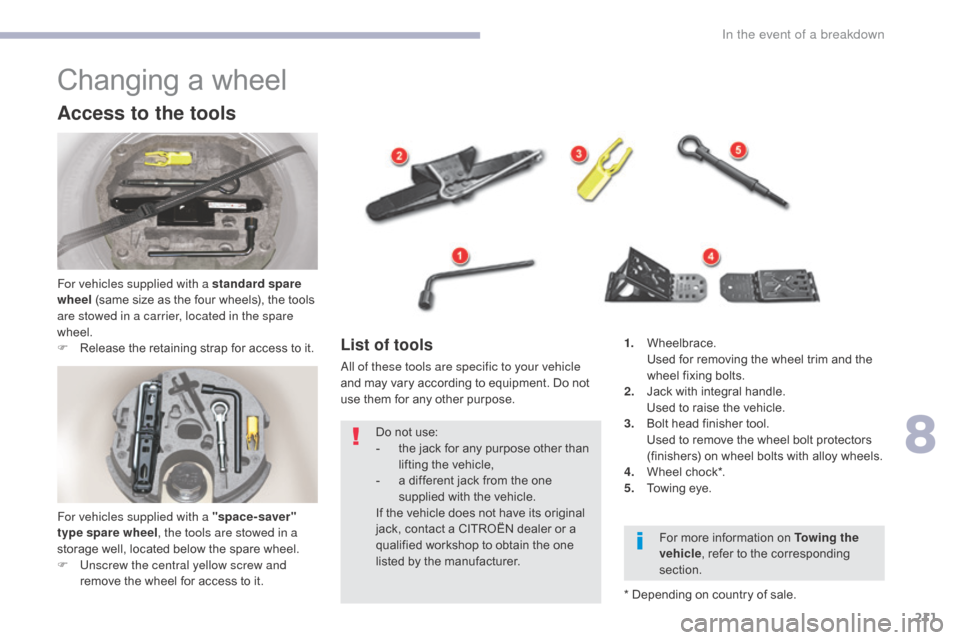

Changing a wheel

Access to the tools

For vehicles supplied with a standard spare

wheel (same size as the four wheels), the tools

are stowed in a carrier, located in the spare

wheel.

F

R

elease the retaining strap for access to it.

List of tools

All of these tools are specific to your vehicle

and may vary according to equipment. Do not

use them for any other purpose. 1.

W

heelbrace. U

sed for removing the wheel trim and the

wheel fixing bolts.

2.

J

ack with integral handle.

U

sed to raise the vehicle.

3.

B

olt head finisher tool.

U

sed to remove the wheel bolt protectors

(finishers) on wheel bolts with alloy wheels.

4.

Wh

eel chock*.

5.

T

owing eye.

Do not use:

-

t

he jack for any purpose other than

lifting the vehicle,

-

a d

ifferent jack from the one

supplied with the vehicle.

If the vehicle does not have its original

jack, contact a CITROËN dealer or a

qualified workshop to obtain the one

listed by the manufacturer. For more information on Towing the

vehicle

, refer to the corresponding

section.

* Depending on country of sale.

For vehicles supplied with a "space-saver"

type spare wheel

, the tools are stowed in a

storage well, located below the spare wheel.

F

U

nscrew the central yellow screw and

remove the wheel for access to it.

8

In the event of a breakdown

Page 214 of 348

212

C5_en_Chap08_en-cas-de-panne_ed01-2016

Access to the spare wheel

Removing the boot floor

F Saloon: raise the boot floor and fold in two.

F T ourer : raise the boot floor and hook it

using the retractable handle. Secure the

hook to the top part of the boot.

Removing the standard spare

wheel

F Detach the strap, then push the wheel for wards so as to be able to lift it.

Repositioning the standard spare

wheel

F Position the spare wheel flat in the boot, then pull it towards you.

F

N

ext place the toolbox inside the wheel,

then secure the assembly using the strap.

Removing the "space-saver"

spare wheel

F Unscrew the central nut.

F R emove the fixing parts (nut and bolt).

F

T

ake the spare wheel from the rear and lift

it towards you.

F

R

emove the wheel from the boot.

In the event of a breakdown

Page 215 of 348

213

C5_en_Chap08_en-cas-de-panne_ed01-2016

The tyre pressures are indicated on the

label located on the left-hand centre

door pillar.

Tyre pressures are given on this label

for different vehicle loading conditions.Repositioning the "space-saver"

spare wheel

F Return the spare wheel to its housing above the toolbox.

F

U

nscrew the nut on the bolt by a few turns.

F

P

lace the fixing parts (nut and bolt) in the

middle of the wheel.

F

T

ighten the central nut until it clicks to

secure the wheel.

Repositioning the boot floor

F Release the boot floor to return it to its initial position.

8

In the event of a breakdown

Page 216 of 348

214

C5_en_Chap08_en-cas-de-panne_ed01-2016

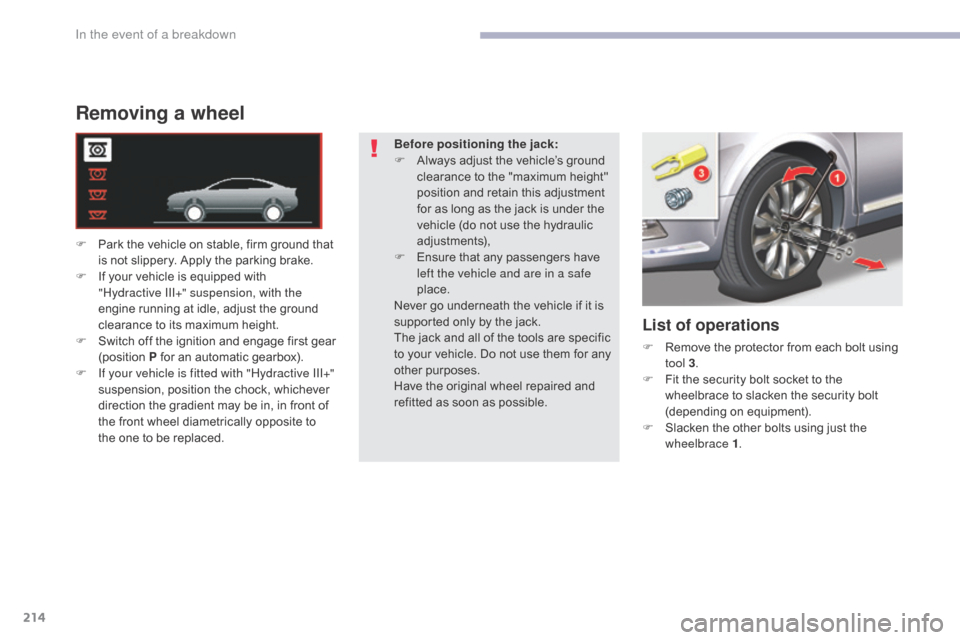

Removing a wheel

F Park the vehicle on stable, firm ground that is not slippery. Apply the parking brake.

F

I

f your vehicle is equipped with

"Hydractive

III+" suspension, with the

engine running at idle, adjust the ground

clearance to its maximum height.

F

S

witch off the ignition and engage first gear

(position P for an automatic gearbox).

F

I

f your vehicle is fitted with "Hydractive III+"

suspension, position the chock, whichever

direction the gradient may be in, in front of

the front wheel diametrically opposite to

the one to be replaced.

List of operations

F Remove the protector from each bolt using tool 3 .

F

F

it the security bolt socket to the

wheelbrace to slacken the security bolt

(depending on equipment).

F

S

lacken the other bolts using just the

wheelbrace 1 .

Before positioning the jack:

F

A

lways adjust the vehicle’s ground

clearance to the "maximum height"

position and retain this adjustment

for as long as the jack is under the

vehicle (do not use the hydraulic

adjustments),

F

E

nsure that any passengers have

left the vehicle and are in a safe

place.

Never go underneath the vehicle if it is

supported only by the jack.

The jack and all of the tools are specific

to your vehicle. Do not use them for any

other purposes.

Have the original wheel repaired and

refitted as soon as possible.

In the event of a breakdown

Page 217 of 348

215

C5_en_Chap08_en-cas-de-panne_ed01-2016

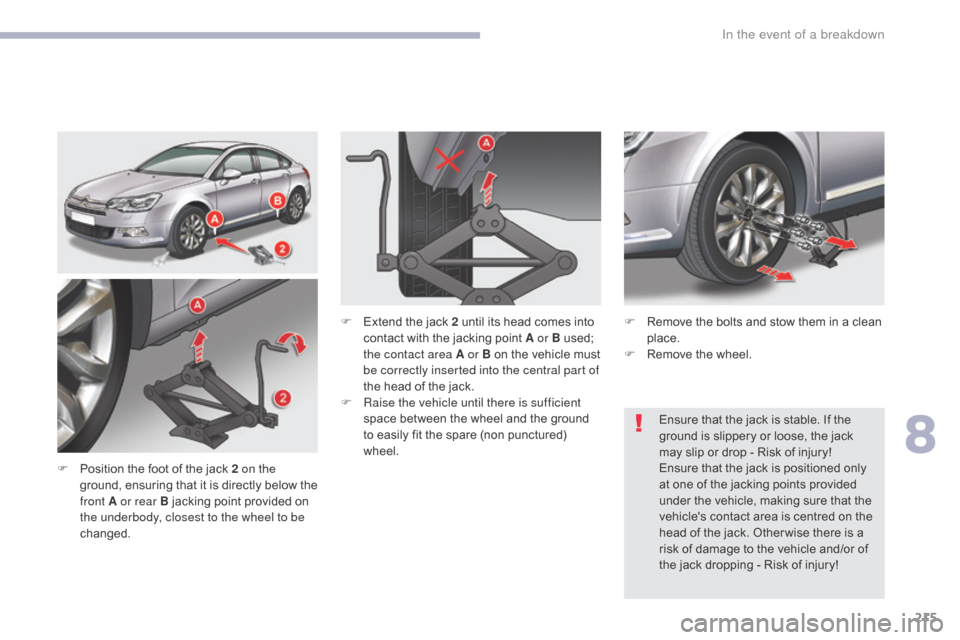

F Position the foot of the jack 2 on the ground, ensuring that it is directly below the

front A or rear B jacking point provided on

the underbody, closest to the wheel to be

changed. Ensure that the jack is stable. If the

ground is slippery or loose, the jack

may slip or drop - Risk of injury!

Ensure that the jack is positioned only

at one of the jacking points provided

under the vehicle, making sure that the

vehicle's contact area is centred on the

head of the jack. Other wise there is a

risk of damage to the vehicle and/or of

the jack dropping - Risk of injury!

F

E

xtend the jack 2 until its head comes into

contact with the jacking point A or B used;

the contact area A or B on the vehicle must

be correctly inserted into the central part of

the head of the jack.

F

Ra

ise the vehicle until there is sufficient

space between the wheel and the ground

to easily fit the spare (non punctured)

wheel. F

R

emove the bolts and stow them in a clean

place.

F

R

emove the wheel.

8

In the event of a breakdown

Page 218 of 348

216

C5_en_Chap08_en-cas-de-panne_ed01-2016

List of operations

Fitting a wheel

Wheel for temporary use

Your vehicle may be fitted with a spare wheel

which is different to those on the vehicle. When

fitting the spare wheel, it is normal to notice

that the wheel bolt washers do not come into

contact with the wheel rim. The spare wheel is

secured by the conical tapering of the wheel

bolt’s shaft.

When refitting the original wheel, ensure that

the wheel bolt contact sur faces are clean and

in good condition. F

L

ower the vehicle to the ground.

F

L

ower the jack 2 and remove it.

F

F

it the wheel on the hub.

F

F

it and tighten the bolts by hand.

F

P

re-tighten the security bolt using the

wheelbrace 1 fitted with the security bolt

socket (depending on equipment).

F

P

re-tighten the other bolts using just the

wheelbrace 1 .

In the event of a breakdown

Page 219 of 348

217

C5_en_Chap08_en-cas-de-panne_ed01-2016

If your vehicle is fitted with a spare

wheel of a different size to those on the

vehicle, you must not exceed 50 mph

(80 km/h) whilst using the spare wheel.

The wheel bolts are specific to the type

of wheel.

If the type of wheel is changed,

check with your CITROËN dealer or a

qualified workshop that the wheel bolts

are compatible with the new wheels.

Take care to note down the code

number engraved on the head of the

security bolt socket. This will enable

you to obtain a replacement security

bolt socket from your dealer.

F

T

ighten the security bolt using

wheelbrace

1 fitted with the security bolt

socket (depending on equipment).

F

T

ighten the other bolts using just the

wheelbrace 1 .

F

R

efit the protectors on the bolts (depending

on equipment).

F

S

tow the tools in the carrier box.

F

R

eturn the suspension to the normal

position.

F

C

heck that the tyre pressure is correct and

have the balancing checked.Tyre under-inflation detection

The space-saver type or steel spare

wheel does not have a sensor.

The punctured wheel must be repaired

by a CITROËN dealer or a qualified

workshop.

8

In the event of a breakdown

Page 220 of 348

218

C5_en_Chap08_en-cas-de-panne_ed01-2016

Changing a bulb

Front lamps

Model with Xenon headlamps (D1S)

1. Dual-function Xenon headlamps (dipped/main): D1S

2.

C

ornering lighting: HP19

3.

D

aytime running lamps / sidelamps:

LEDs

For the maintenance of the front lamps and

changing HP19 and D1S bulbs and LED lamps,

contact a CITROËN dealer or a qualified

workshop.

Risk of electrocution

Xenon bulbs must be replaced by

a CITROËN dealer or a qualified

workshop.

You are advised to change both D1S

bulbs at the same time, if one of them

has failed.

The headlamps have polycarbonate

lenses with a protective coating:

F

d

o not clean them using a dr y

or abrasive cloth, nor with a

detergent or solvent product,

F

u

se a sponge and soapy water or

a

pH neutral product,

F

w

hen using a high pressure washer

on persistent marks, do not keep

the lance directed towards the

lamps or their edges for too long,

so as not to damage their protective

coating and seals. Changing a bulb should only be done

after the headlamp has been switched

off for several minutes (risk of serious

burns).

F

D

o not touch the bulb directly with

your fingers, use a lint-free cloth.

It is imperative to use only anti-

ultraviolet (UV) type bulbs to avoid

damaging the headlamp.

Always replace a failed bulb with a

new bulb with the same type and

specification.

In the event of a breakdown