check engine Citroen CX 1981 1.G Repair Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1981, Model line: CX, Model: Citroen CX 1981 1.GPages: 394

Page 241 of 394

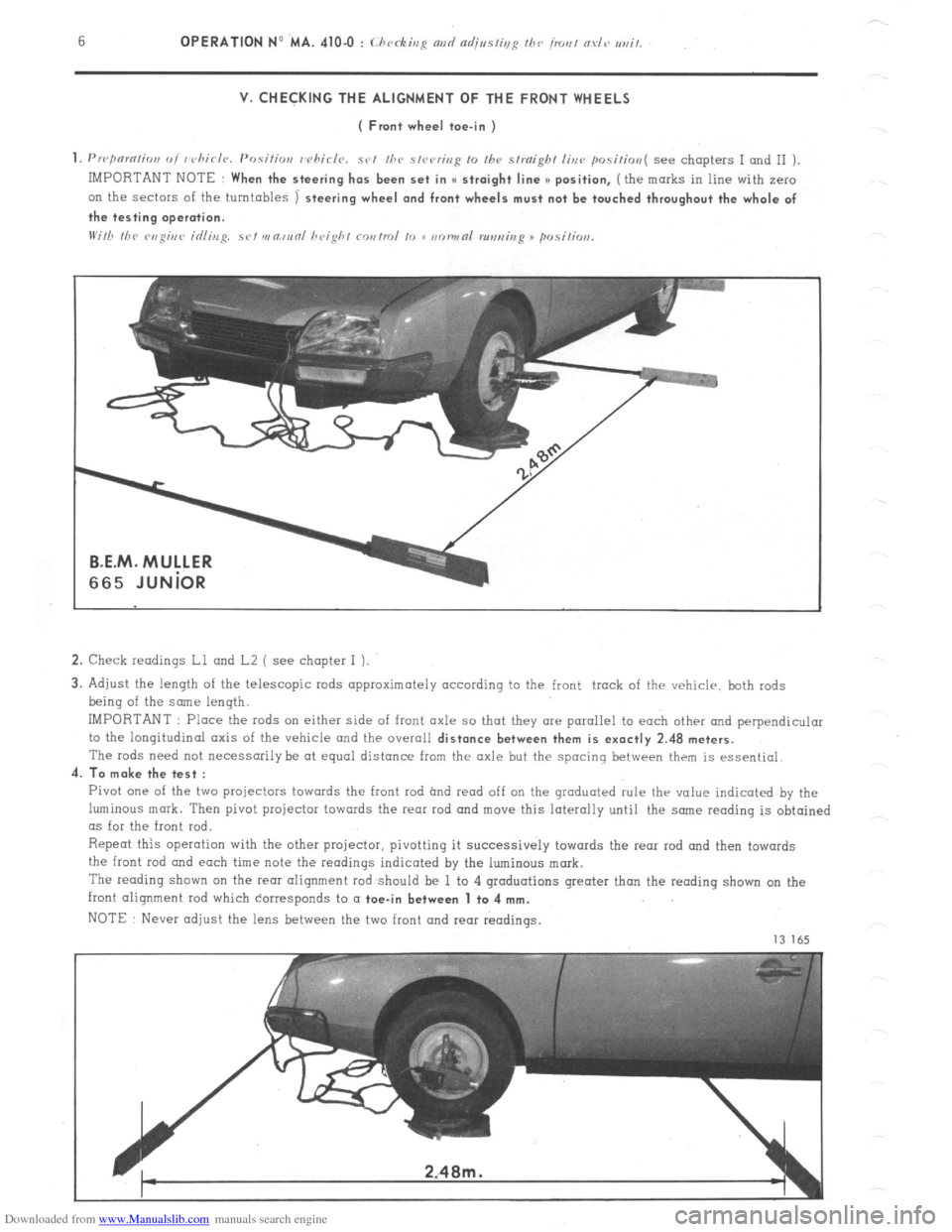

Downloaded from www.Manualslib.com manuals search engine V. CHECKING THE ALIGNMENT OF THE FRONT WHEELS

( Front wheel toe-in )

1. Prrpnmtion oi whirlr~. Positior,

whirls. set /he s,rering 10 Ihv straight line positim~( see chapters I and II )

IMPORTANT NOTE

When the steering has been set in I( straight line >) position, (the marks in line with zero

on the sectors of the turntables

1 steering wheel and front wheels must not be touched throughout the whole of

the testing operation.

2. Check readings Ll and L2 ( see chapter I ).

3. Adjust the length of the telescopic rods approximately according to the front track of the vehicle, both rods

being of the some length.

IMPORTANT : Place the rods on either side of front axle so that they are parallel to each other and perpendicular

to the longitudinal axis of the vehicle and the overall

distance between them is exactly 2.48 meters.

The rods need not necessarily be at equal distance from the axle but the spacing between them is essential.

4.

To make the test :

Pivot one of the two projectors towards the front rod hnd read off on the graduated rule thr value indicated by the

luminous mark. Then pivot projector towards the rear rod and move this laterally until the snne reading is obtained

as for the front rod.

Repeat this operation with the other projector, pivotting it successively towards the rear rod and then towards

the front

rod and each time note the readings indicated by the luminous mark.

The reading shown on the rem alignment rod should be 1 to 4 graduations greater than the reading shown on the

front alignment rod which corresponds to a

toe-in between 1 to 4 mm.

NOTE Never adjust the lens between the two front and rear readings.

13 165

Page 242 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 410-O : I hvr-6iq n,,d od;n.s/isg /hc /~,a, nrle uei/ Op. MA. 410-O 7

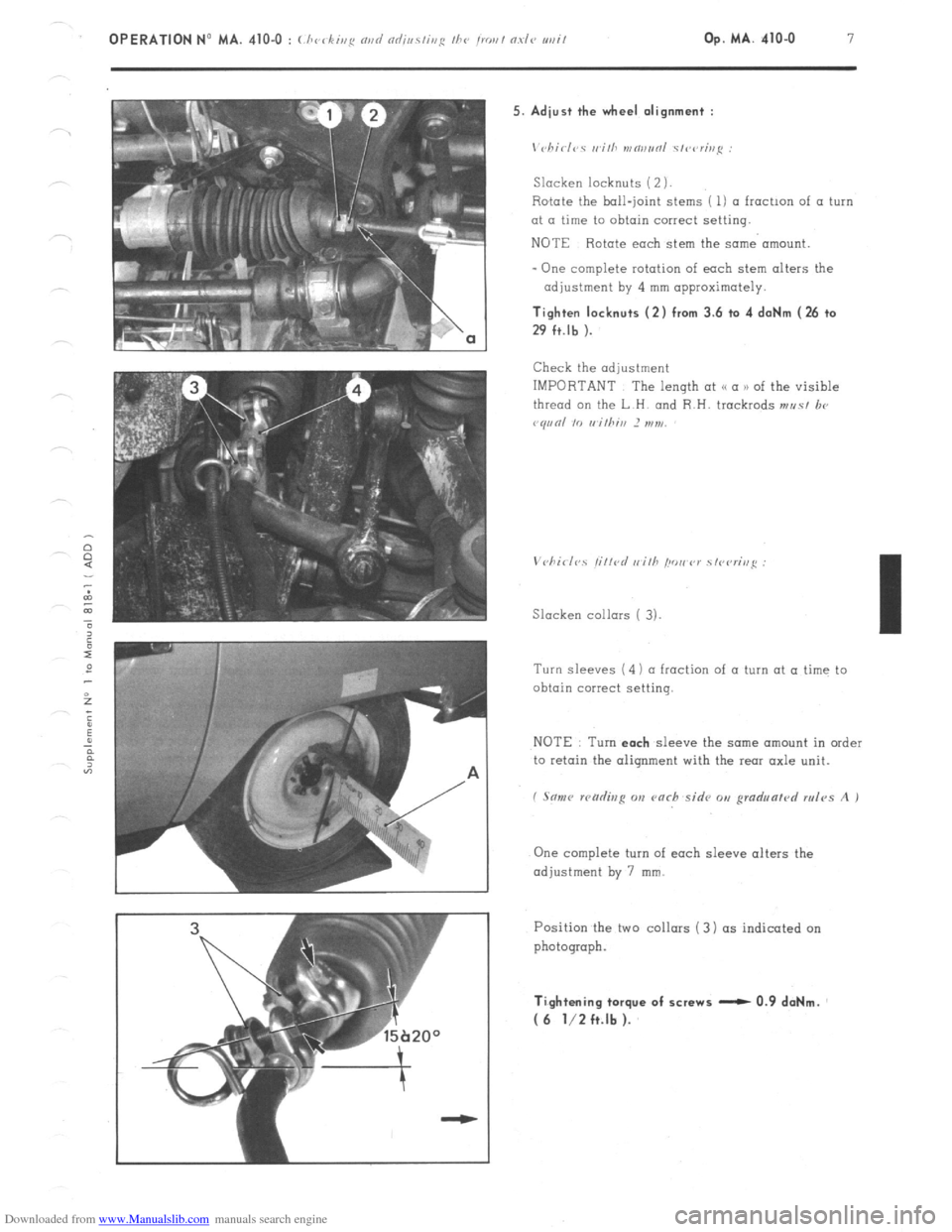

’ 15b20° 5. Adiust the wheel alignment :

\‘chirl‘,s II ilh mw,r,ol s/wrh,i: :

Slacken locknuts (2 ).

Rotate the ball-joint stems ( 1) a froctmn of a turn

at a time to obtain correct setting.

NOTE Rotate each stem the same’ amount.

- One complete rotation of each stem alters the

adjustment by 4 mm approximately. Tighten locknuts (2) from 3.6 to 4 daNm (26 to

29 ft.lb ).

Check the adjustment

IMPORTANT The length at (< a n of the visible

thread on the L.H. and R.H. trackrods ,,,r,s/ lx,

vq,,nl IO rrithin 2 ,,,7,,,

Slacken collars ( 3).

Turn sleeves (4) ~1 fraction of a turn at a time to

obtain correct setting.

NOTE Turn each

sleeve the same amount in order

to retain the oiiqnment with the rear axle unit.

I Son<, wcidisp on varh sidv o,, gmd,,lrrn/r,d rules A I

One complete turn of each sleeve alters the

adjustment by 7 mm.

Position the two collars ( 3) (IS indicated on

photograph. Ti.ghtening torque of screws - 0.9 daNm.

( 6 l/2 ft.lb ).

Page 243 of 394

Downloaded from www.Manualslib.com manuals search engine a OPERATION N’ MA. 410-O : (./~rrkiq N,,I/

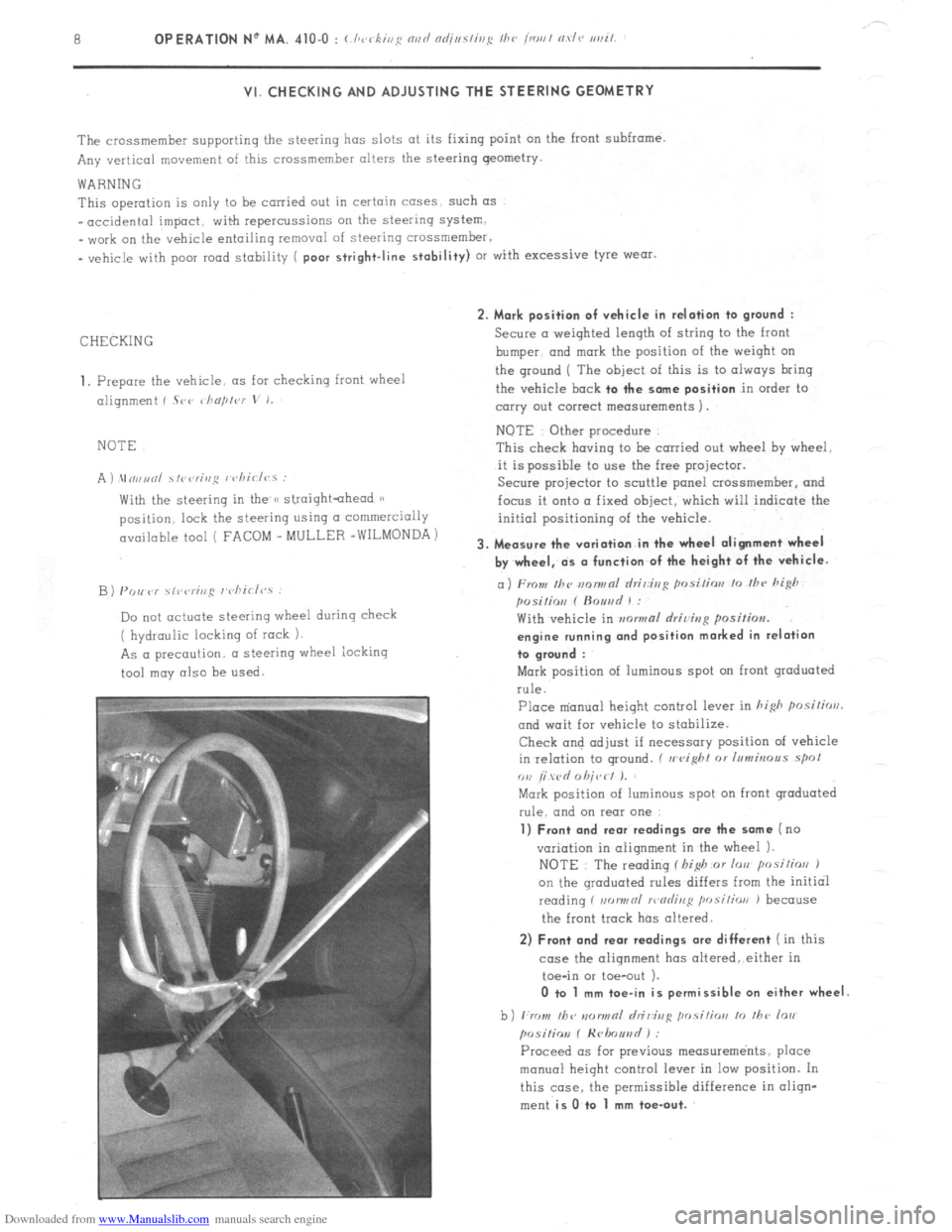

VI. CHECKING AND ADJUSTING THE STEERING GEOMETRY

The crossmember supporting the steering has slots at its fixing point on the front subframe.

Any vertical movement of this crossmember alters the steering geometry.

WARNING

This operation is only to

be carried out in certain ccxses such as

-accidental impact, with repercussions on the steering system.

-work on the vehicle entoiling removal of steering crossmember.

- vehicle with poor

road stability ( p oar stright-line stability) 01 with excessive tyre weor.

CHECKING

1, Prepare the vehicle. as for checking front wheel

alignment ( Srr ~ho/,lvr

V I.

NOTE

A ) \In,,unl ~fi~<,r;,,~ I chiclvs :

With the steering in the /< straightahead 1)

position. lock the steering using CI commercially

available tool ( FACOM _ MULLER -WILMONDA)

B) PO,, P)’ \,r,rr;ng r’cliirl<,.s :

Do not actuate steering wheel during check

( hydraulic locking of rock 1.

As a precaution. a steering wheel iocking

tool may also be

used. 2. Mark position of vehicle in relation to

ground :

Secure a weighted length of string to the front

bumper. and

mark the position of the weiqht on

the ground ( The

object of this is to always bring

the vehicle

bock to the some position in order to

carry out correct measurements 1.

NOTE Other procedure

This check having to be carried out wheel hy wheel.

it is possible to use the free projector.

Secure projector to scuttle panel crossmemher, and

focus it onto a fixed object, which will indicate the

initial positioning of the vehicle.

3. Measure the variation in the wheel alignment wheel

by wheel, ds o function of the height of the vehicle.

a) From Ihc m~nwnl rlri,:ir,g posi/ior, lo /hc hi@

posilio,, f ftouad 1 :

With vehicle in mwmal rlriving position.

engine running ond position marked in relation

to groond :

Mark position of luminous spot on front graduated

rule.

Place m’anual height control lever in hi&

posilirrrl.

and wait for vehicle to stabilize.

Check and adjust if necessary position of vehicle

in relation to ground. ( II

eight 01 Inmbrous spol

ou /i wd 0 hit,< I J.

Mark position of luminous spot on front graduated

rule. and on rear one

1) Front and rear readings ore the some (no

variation in alignment in the wheel 1.

NOTE : The reading f I,i$ or lorr posilios J

on the qroduated rules differs from the initial

reading f non,,nl >r,nrlinl:

position J because

the front track has altered.

2) Front and rear readings ore different ( in this

case the alignment has oltered,.either in

toe-in or toe-out ).

0 to 1 mm toe-in is permissible on either wheel

b) ,:rr ,,I, /bv IIDIINRI hi&g ,,osi,;orr lo ,I,<, lo,,

posiliov f Hrlmuad ) :

Proceed OS for previous measurements, place

manual height control lever in low position. In

this case. the permissible difference in oliqn-

ment

is O.to 1 mm toe-out.

Page 244 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 4104 : (./ , k’ 1

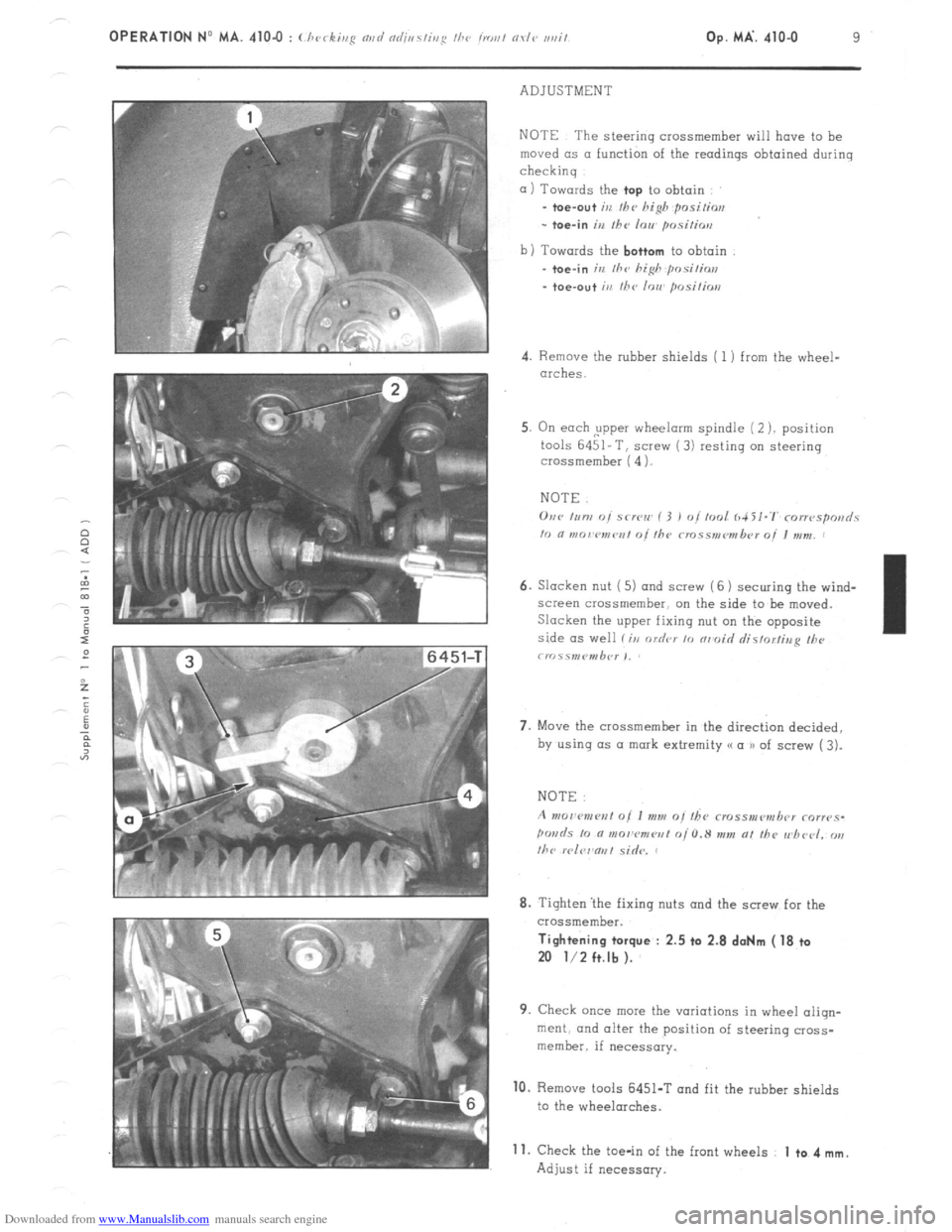

ADJUSTMENT

NOTE The steering crossmember will have to be

moved (IS a function of the readings obtained during

checkinq

01) Towards the top to

obtain

_ toe-out ir, Ihe hish positim

- toe-in irr the 10~ psitios

b) Towards the bottom

to obtain

.

toe-in in Ihr hi& posilins

- toe-out iu fhc IOU posilios

4. Remove the rubber shields ( 1 ) from the wheel-

arches.

5. On each ,upper wheelorm spindle (2 ). position

tools 6451-T, screw (3) resting on steering

crossmember ( 4 1.

NOTE.

6. Slacken nut ( 5) and screw (6 1 securing the wind-

screen crossmember. on the side to be moved.

Slacken the upper fixing nut on the opposite

side as well li,r order 10 nrmoid rlistorfina II><,

crr~.ss,nP”,b<~r ,,

7. Move the crossmember in the direct& decided,

by using (1s a mark extremity (( a u of screw ( 3).

8. Tighten ‘the fixing nuts and the screw for the

crossmember. Tightening torque : 2.5 ta 2.8 doNm ( 18 ta

20 l/2 ft.lb ).

9. Check once mew the variations in wheel aliqn-

merit. and alter the position of steering cross-

member. if necessary. 10.

Remove tools 6451-T and fit the rubber shields

to the wheelarches.

Adjust if necessary. 11.

Check the toe-in of the front wheels 1 to 4 mm.

Page 250 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 420.0 1

CHECKING THE REAR AXLE USING OPTICAL EQUIPMENT

NOTE For detailed instructions on the use of optical equipment see front axle checking operation (Op. MA. 410-O)

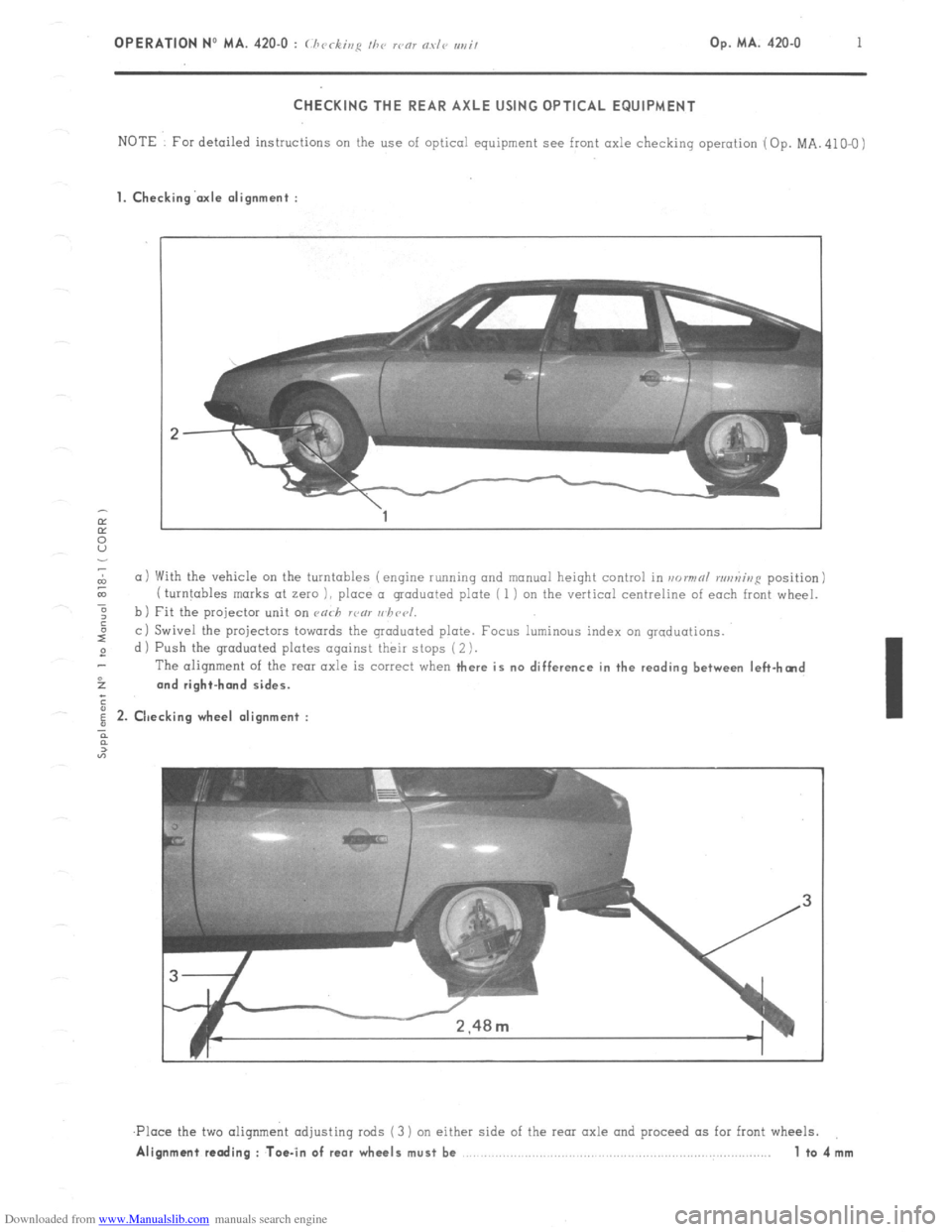

1. Checking’axle alignment :

L

(11 With the vehicle on the turntables (engine running and manual height control in normnl runniup position)

& ( turntables marks at zero 1, place a graduated plate ( 1 i on the vertical centreline of each front wheel.

-6

: b) Fit the projector unit on ca<-h rcnl uhccl.

I”

c i Swivel the projectors towards the graduated plate. Focus luminous index on graduations.

2 d ) Push the graduated plates against their stops ( 2 ).

The alignment of the

rear axle is correct when there is no difference in the reading between left-hcnd

52 and right-hand sides.

;

i 2. Checking wheel alignment :

n

2

“7

,Ploce the two aliqnmeht adjusting rods (3 ) on either side of the rear axle and proceed as for front wheels.

Alignment reading : Toe-in of rear wheels must be 1 to4mm

Page 251 of 394

Downloaded from www.Manualslib.com manuals search engine 2 OPERATION No MA. 420.0 : (:h ’ k’ j I/ cc ,,I:, >

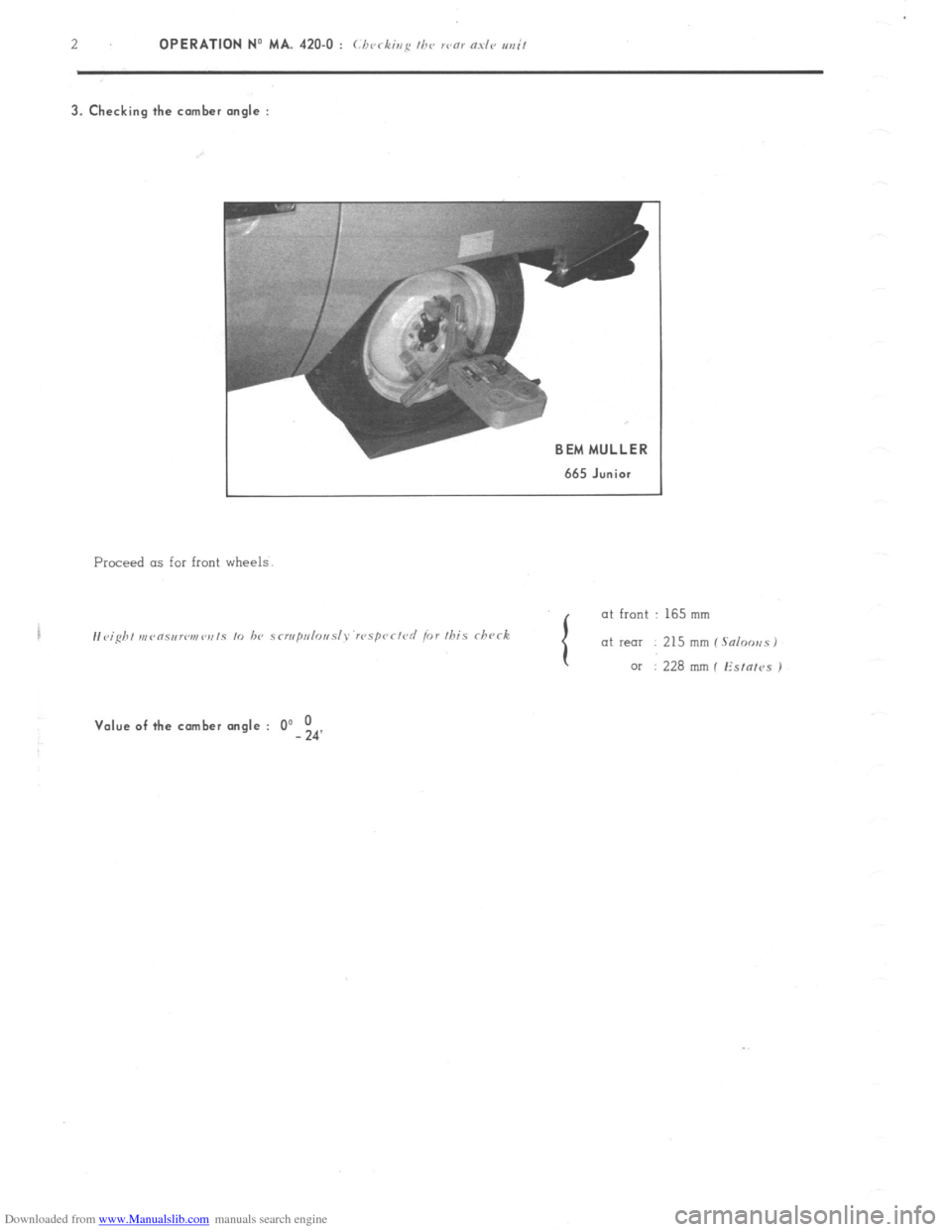

BEM MULLER

665 Junior

Proceed as for front wheels

at front : 165 mm

He;@/ ,),~ns,,r‘,,,,~,,,,s lo be srn,p,,lmosly ‘rcs,wrlcd Ior /his rhrck

at rem : 215 mm ~Saloo,rsJ

a : 228

mm f Estatus J V&e of the camber angle : On

-024’

Page 257 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 430-O : Checking md ndjusting the suspcusion and its control. 06. MA. 430-O i

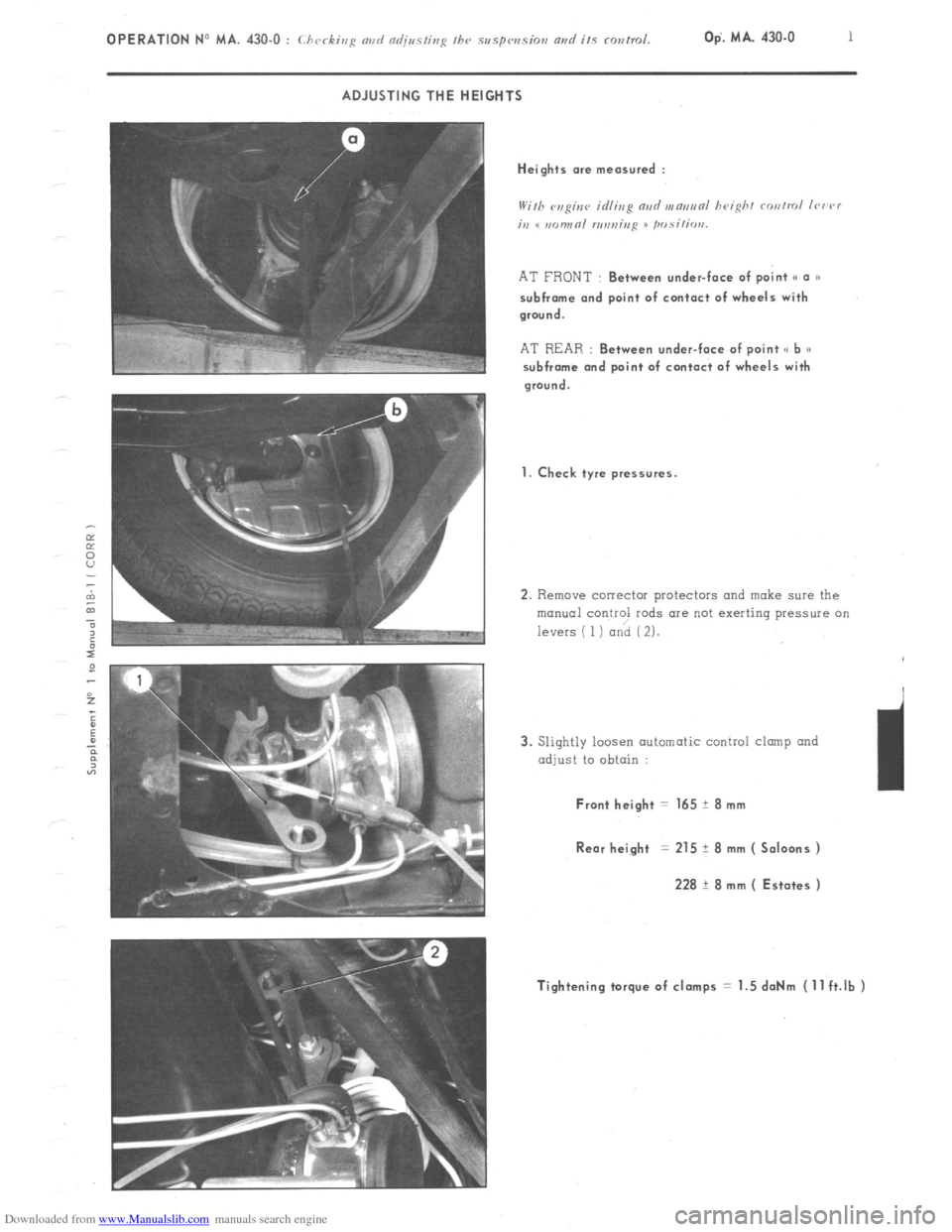

ADJUSTING THE HEIGHTS

AT FRONT : Between under-face of point (c o ))

subfrome ond point of contoct of wheels with

ground.

AT REAR : Between under-face of point <( b a)

subfrome ond point of contact of wheels with

ground.

1. Check tyre pressures.

2. Remove corrector protectors and make sure the

manual control rods are not exerting pressure on

levers ( 1) and ( 2).

3. Slightly loosen automatic control clump and

adjust to obtain :

3

Front height = 165 ? 8 mm

Rear height = 215 ? 8 mm ( Saloons )

228 t 8 mm ( Estates )

Tightening torque of clomps = 1.5 doNm (11 ft.lb )

Page 258 of 394

Downloaded from www.Manualslib.com manuals search engine 2 OPERATION No MA. 430-O : ~hwki~zg nrtd nrijustittg the suspwrsiott ntd its cotttrol

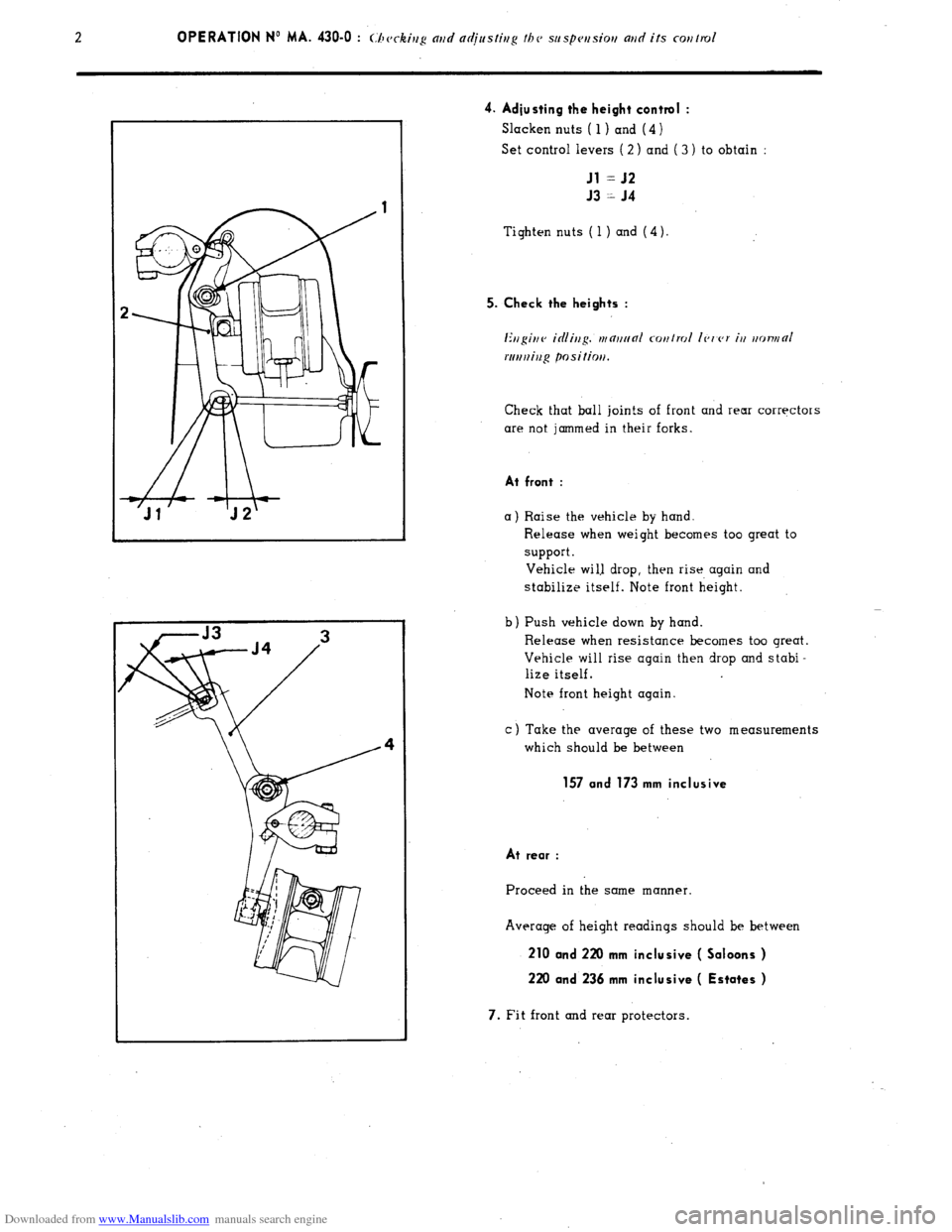

4. Adjusting the height control :

Slacken nuts ( 1) and (4 )

Set control levers ( 2 ) and ( 3 ) to obtain :

Jl = J2

J3 = J4

Tighten nuts ( 1 ) and (4).

5. Check the heights :

Ertgittv icilittg. tttnttt~nl cotttrol Ic,t’c,r itt ttotvttO/

rtrrtttiug positiott.

Check that ball join!s of front and rear corrqctors

are not jammed in their forks.

At front :

a) Raise the vehicle by hand.

b Release when weight becomes too great to

support.

Vehicle wi1.l drop, then rise again and

stabilize itself. Note front height.

Push vehicle down by hand

Release when resistance becomes too great.

Vehicle will rise again then drop and stabi-

lize itself.

Note front height again.

c) Take the average of these two measurements

which should be between

157 and 173 mm inclusive

At rear :

Proceed in the same manner.

Average of height readings should be between

210 and 220 mm inclusive ( Saloons )

220 and 236 mm inclusive ( Estates )

7. Fit front and rear protectors.

Page 280 of 394

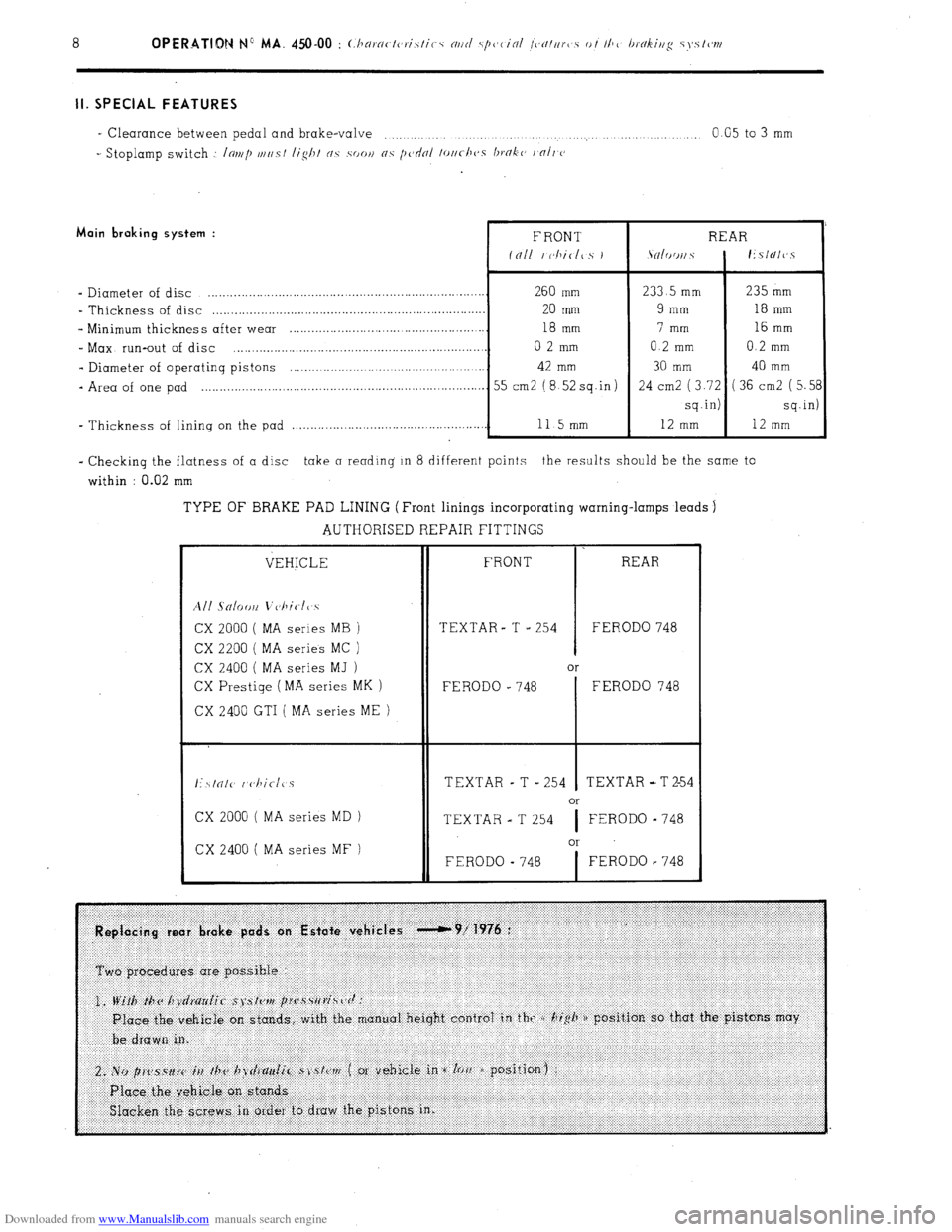

Downloaded from www.Manualslib.com manuals search engine II. SPECIAL FEATURES

- Clearance between pedal and brake-valve

” ..: 0.05 to 3 mm

_ Stoplamp switch ,: Inal/) VII/S/ lislli c/c .soo,~ 05 [I(‘~~II /~//c-/~c,s IJTO~(~ /,fl// (J Main braking system :

- Diameter of disc .......................................................................... 260 mm

- Thickness of disc .........................................................................

20 mm

s Minimum thickness after wear .................................................... 18 mm

_ Max run-out of disc ...................................................................

0 2 mm

- Diameter of operatinq pistons ....................................................

42 mm

- Area of one pad ............................................................................

55 cm2 (8 52sq.in)

- Thickness of lining on the pad .,,_.,..,_.__.._.._,....,.......................... 115mm

233 5 mm 235 mm

9 mm 18 mm

7 mm 16 mm

0.2 mm 0 2 mm

30 mm 40 mm

24 cm2 (3.72 (36cm2 (5.5

sq.in) sq.in

12 mm

12 mm

- Checking the flatness of a disc take a reading in 8 different points the results should be the same to

within : 0.02 mm

TYPE OF BRAKE PAD LINING (Front linings incorporating warning-lamps leads

j

AUTHORISED REPAIR FITTINGS

VEHICLE

All Snlow L’c~l,ir-ll 5

CX 2000

( MA series MB )

CX 2200 ( MA series MC )

CX 2400 ( MA series MJ )

CX Prestiqe (MA series MK )

CX 2400 GTI ( MA series ME )

CX 2000 ( MA series MD )

CX 2400 ( MA series MF )

8

1

FRONT REAR

TEXTAR- T .= 254 FERODO 748

or

FERODO e 748

I FERODO 748

TEXTAR - T - 254 1 TEXTAR -T2-54

or

TEXTAR - T 254

I FERODO - 748

or

FERODO - 748

I FERODO r 748

Page 282 of 394

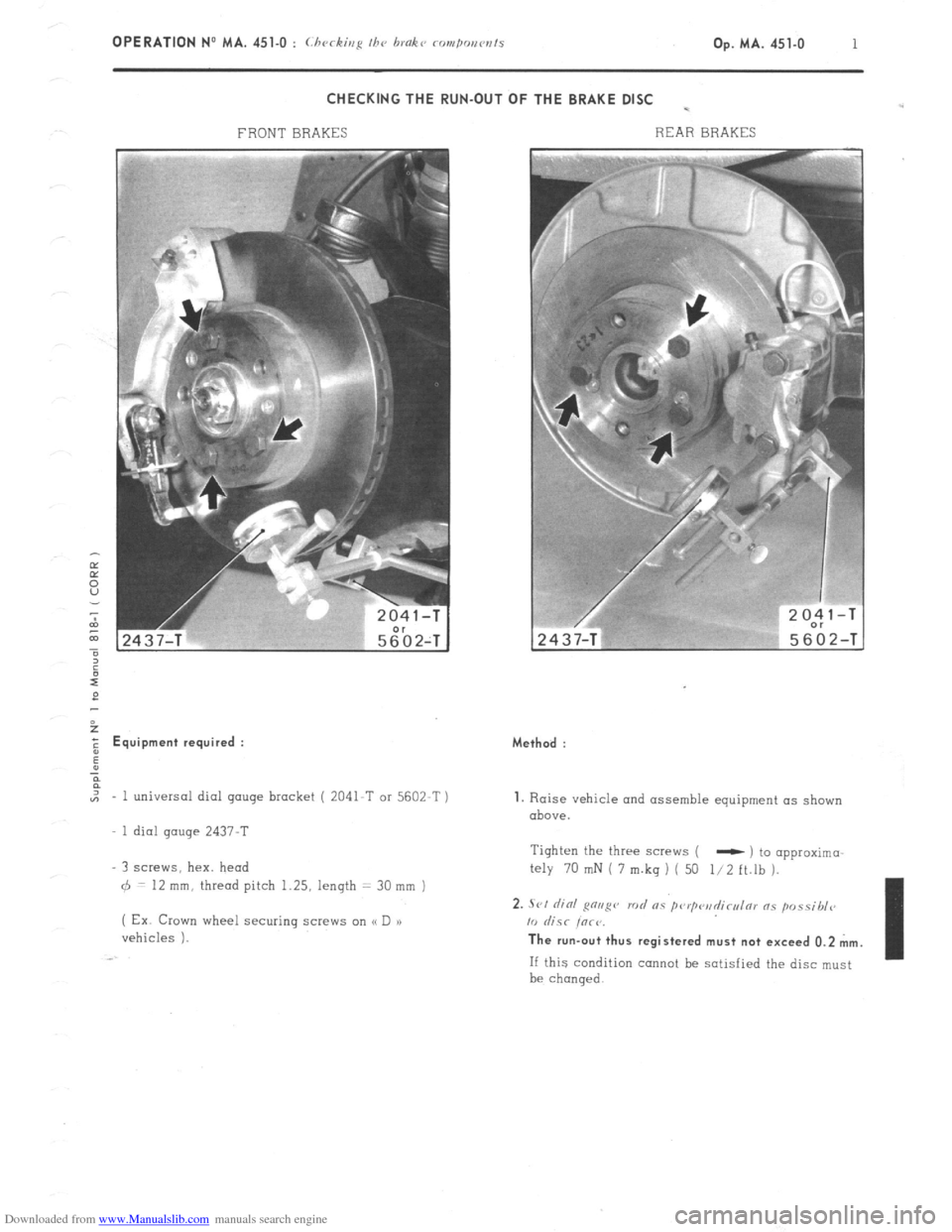

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 451-O : Uwckirrg the hrflkv rov,~o,rrnts Op. MA. 451.0 1

CHECKING THE RUN-OUT OF THE BRAKE DISC -

FRONT BRAKES REAR BRAKES 2

E Equipment required :

,,, - 1 universal dial gauge bracket ( 2041-T or 5602-T )

1 dial gauge 2437-T

3 screws, hex. head

6 = 12 mm, thread pitch 1.25, length = 30 mm )

( Ex Crown wheel securing screw on (< D a)

vehicles ). Method :

1. Raise vehicle and assemble equipment as shown

above.

Tighten the three screws (

- ) to opproximo

My 70 mN i 7 m.kq ) ( 50 l/2 ft.lh ).

2. .Sl,l did g”“g” rod RS pwp<‘il~cl,l171 ns p”ssibl<~

10 &SC iorr. The run-out thus registered must not exceed 0.2 mm.

If this condition cannot be satisfied the disc must

be chanqed.