check engine Citroen CX 1981 1.G Repair Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1981, Model line: CX, Model: Citroen CX 1981 1.GPages: 394

Page 229 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 390-O : Checkin

P the hydraulic componm~s on the ucbicle Op. MA. 390-O 3

f Mama sleeting wbi&s I

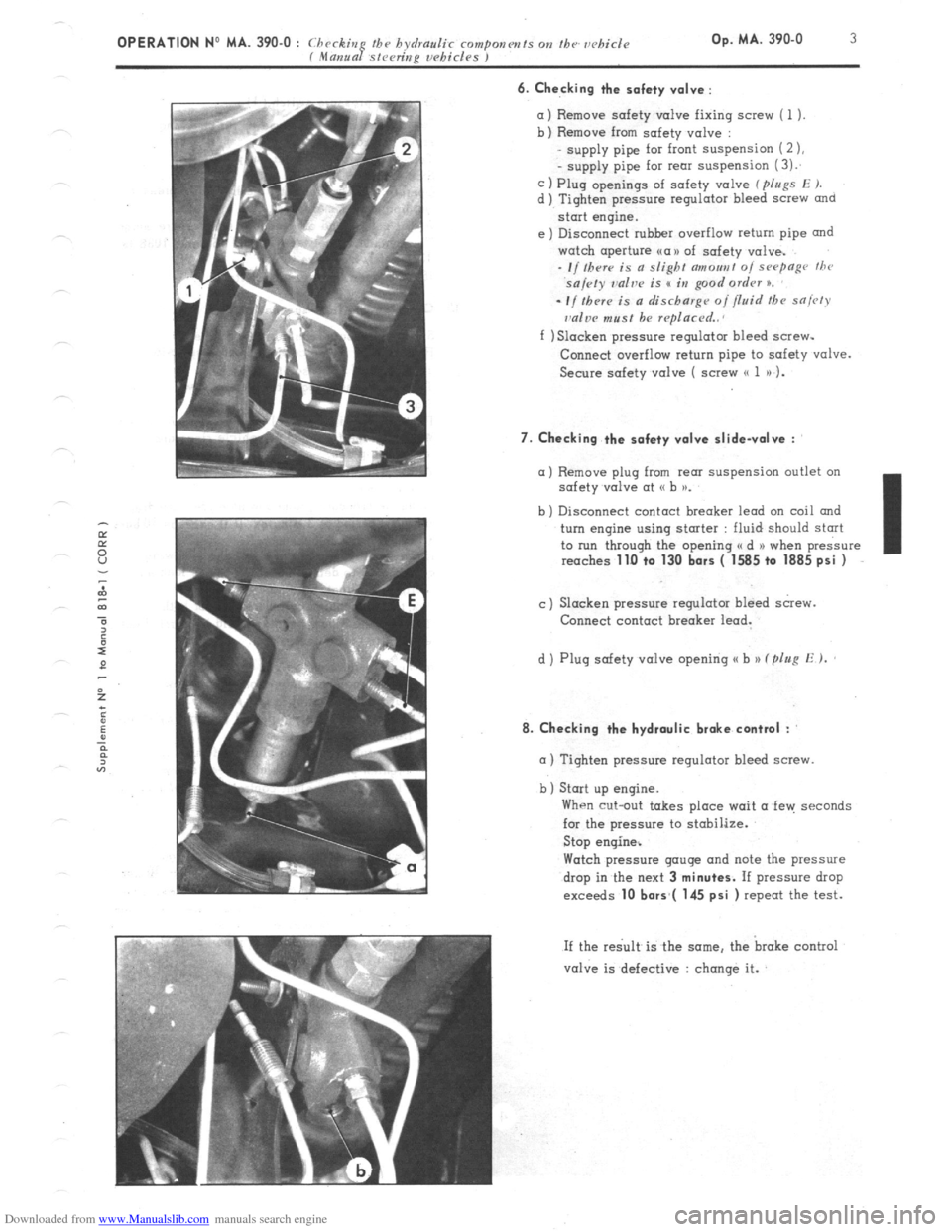

6. Checking the safety valve :

=I

bl

Cl

dl

Remove safety v&e fixing screw ( 1 ).

Remove from safety valve :

supply pipe for front suspension (2 ),

- supply pipe for rem suspension (3):

Plug openings of safety valve ( pIugs E J.

Tighten pressure regulator bleed screw

and

start engine.

Disconnect rubher overflow return pipe and

watch aperture ~a>> of safety valve.

- I/ Iherr is a slight c7moa,,t 0, sHymge thr

sa/cty ~dve is s in good ordrv n.

el

-If thrr~ is a discharge of fluid the sniw

dw must be rqlacrd..

f ) Slacken pressure regulator bleed screw-

Conned overflow return pipe to safety valve.

Secure safety valve ( screw (( 1 a) 1.

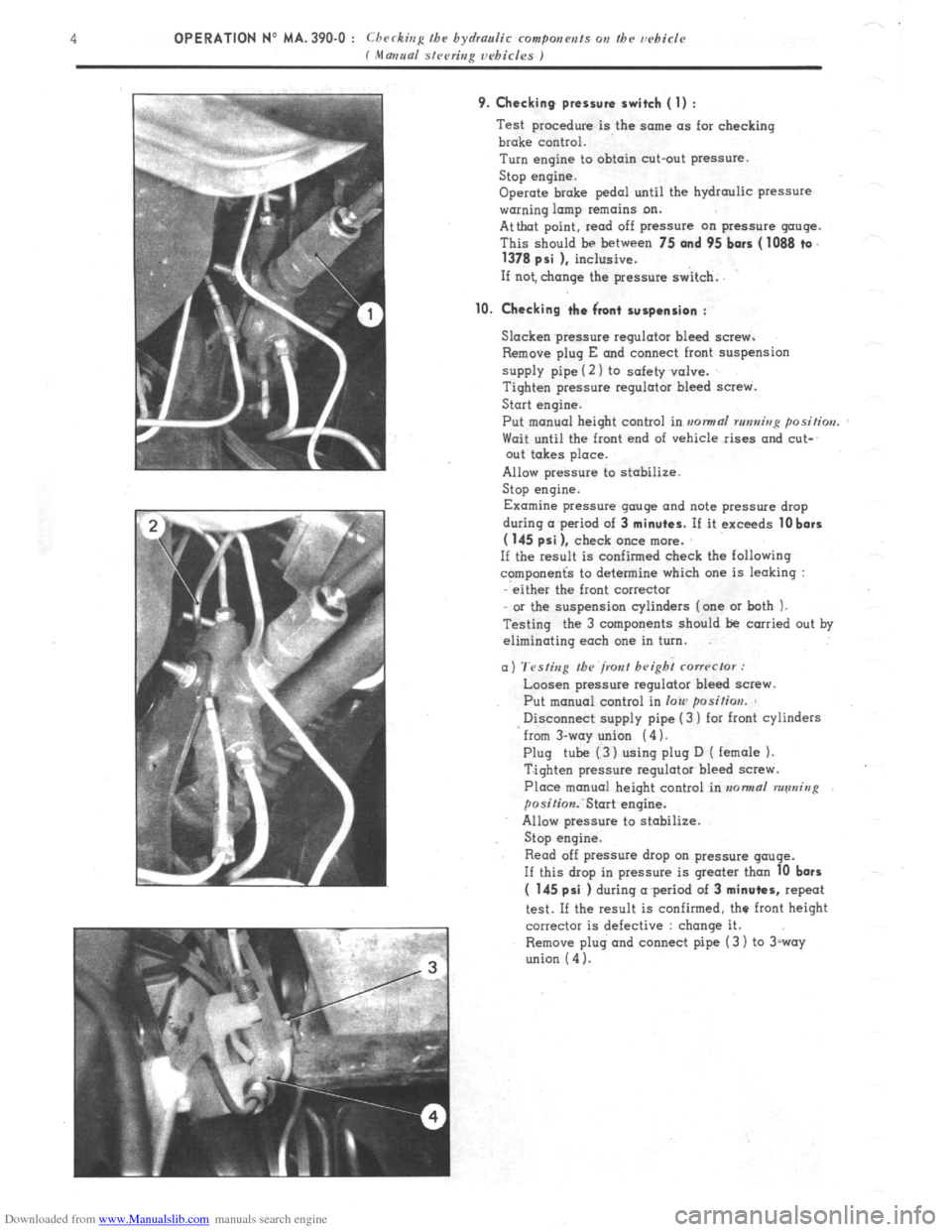

7. Checking the safety valve slidevolve :

a) Remove plug from rem suspension outlet on

safety v&e at G b >a.

b ) Disconnect contact breaker lead on coil and

turn engine using stmter : fluid should start

to run through the opening a d N when pressure

reaches

1lLl +o 130 bars ( 1585 to 1885 psi )

c) Slacken pressure regulator bleed screw.

Connect contact breaker lead.

d ) Plug safety valve opening u b )) (plug E ).

8. Checking the hydraulic brake contml :

m ) Tighten pressure regulator bleed screw.

b) Start up engine.

When cut-out takes place wait a fen: seconds

for the pressure to stobilize.

Stop engine%

Watch pressure gauge and note the pressure

drop in the next 3

minutes. If pressure drop

exceeds 10 bors*( 145 psi ) repeat the test.

If the re< is the same. the broke control

valve is defective : change it.

Page 230 of 394

Downloaded from www.Manualslib.com manuals search engine 9. Checking pressure switch (1) : Test procedure is the sctme as for checking

broke control.

Turn engine to obtain cut-out pressure.

Stop engine.

Operate brake pedal until the hydraulic pressure

warning lamp remains on.

Attbat point, read off pressure on pressure gauge.

This should be between 75

and 95 bars ( 1088 ta.

1378 psi 1, inclusive.

If not, change the pressure switch.

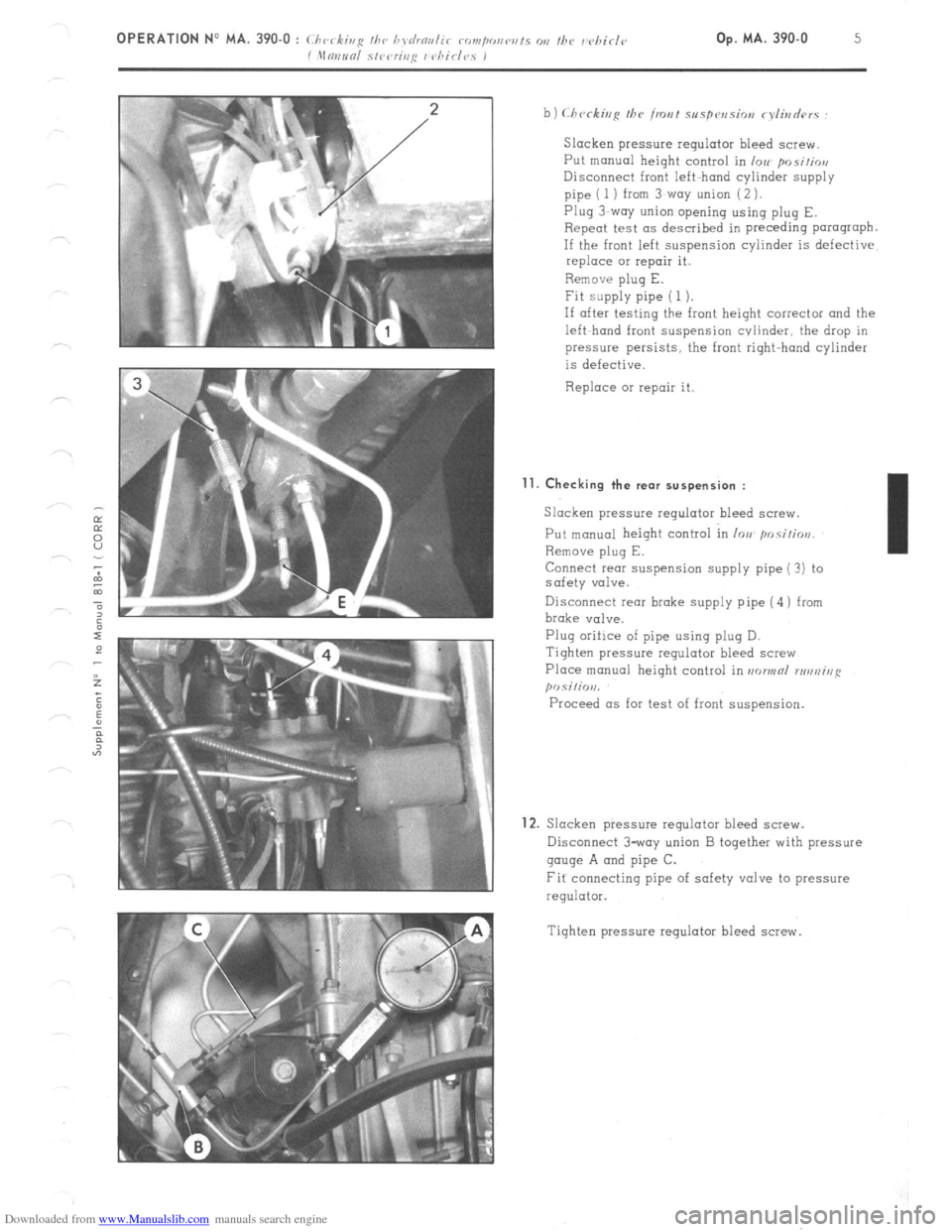

10. Checking the Front suspension : Slacken.pressure regulator bleed screw.

Remove plug E and connect front suspension

supply pipe (2 ) to safety valve.

Tighten pressure regulator bleed screw.

Start engine.

Put manual height control in

rronnaf rtmni>rp positim. Wait until the front end of vehicle rises and cut-

out takes place.

Allow pressure to stabilize.

Stop engine.

Examine pressure gauge and note pressure drop

during wperiod of 3

minutes. If it exceeds 10 bars

( 145 psi 1, check once more.

If the result is confirmed check the following

c?mponenG to determine which one is leaking :

either the front corrector

or the suspension cylinders (one or both ).

Testing the 3 components should be carried out by

eliminating each one in turn.

(I) Testing the front height cmwclor : Loosen pressure regulator bleed saew.

Put manual control in

loin position. Disconnect supply pipe (3 ) for front cylinders

from 3-way union (4 ).

Plug tube (3 ) using plug D ( female 1.

Tighten pressure regulator bleed scwe.

Place manual height control in normal running

posiGon:Start engine.

Allow pressure to stabilize.

Stop engine.

Read off pressure drop on pressure qtruqe.

If this drop in pressure is greater than

10 bars (

145 psi ) during a period of 3 minutes, repeat

test. If the result is confirmed, the front height

corrector is defective : change it.

Remove plug and connect pipe (3 ) to 3roy

union

(4 ).

Page 231 of 394

Downloaded from www.Manualslib.com manuals search engine Slacken pressure regulator bleed screw.

Put manual height control in /VII. position

Disconnect front left-hand cylinder supply

pipe ( 1 ) from 3~woy union (2 ).

Plug 3-way union opening using plug E.

Repeat test as described in preceding parograpb.

If the front left suspension cylinder is defective

replace 01 repair it.

Remove plug E.

Fit supply pipe ( 1 ).

If after testing the front height corrector and the

left-hand front suspension cvlinder, the drop in

pressure persists, the front right-hand cylinder

is defective.

Replace or repair it. Il.

Checking the rear suspension :

Slacken pressure regulator bleed screw.

Put manual height control in IOU pnsi!ios,

Remove plug E.

Connect rear suspension supply pipe (?) to

safety valve.

Disconnect rear brake supply pipe (4) from

brake valve.

Plug oriilce of pipe using plug D.

Tighten pressure regulator bleed screw

Place manual height control in aorwnl rrruniug

posilio,,.

Proceed as for test of front suspension.

12. Slacken pressure regulator bleed screw.

Disconnect 3-way union B together with pressure

gauge A and pipe C.

Fit connecting pipe of safety valve to pressure

regulator.

Tighten pressure regulator bleed screw.

Page 232 of 394

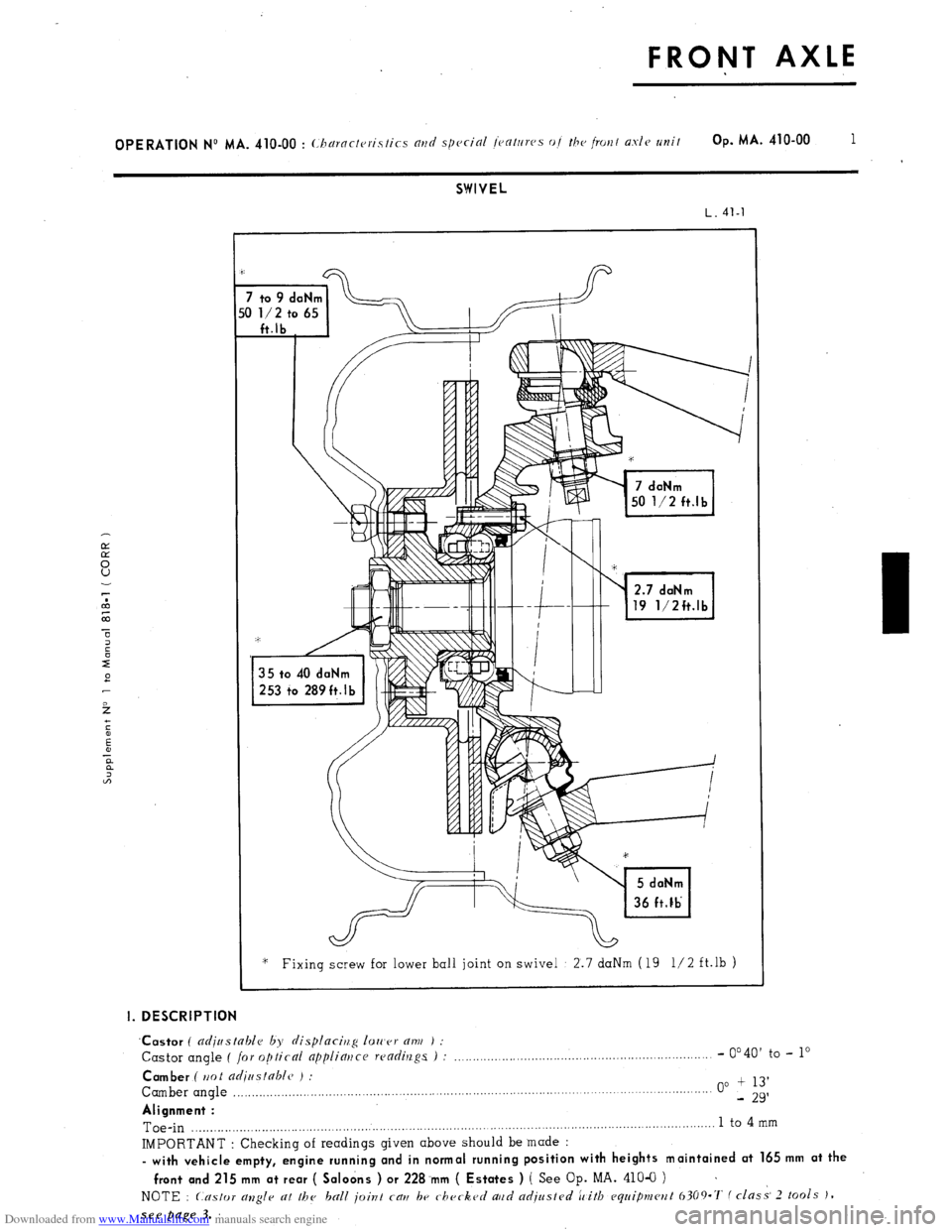

Downloaded from www.Manualslib.com manuals search engine FRONT AXLE

OPERATION No MA. 410-00 : Charnctvristics arid S(ICJCI’O~ /‘rattrres o,i the front as/e unit Op. MA. 410-00 1

t

SWIVEL

L. 41-l

2.7 daNm

19 1/2ft.lb

‘* Fixing screw for lower ball joint on swivel 2.7 daNm (19 l/2 ft.lb )

I. DESCRIPTION

‘Castor

( adjustable by displacirlg 1011’er am ) :

Castor angle ( for optical appliatjce readings ) : _.,,....._..._,......,,,,,,.......,.,........,,,.,......,,............ - 0’40’

to - lo

Camber ( ttot adiastable ) :

Camber angle ,,.,,,.,,,..._,,,__.....,...,,.........,,.,.......................................................................... . . . . . 00 + 13’

- 29’

Alignment :

Toe-in ,.........._.__...,.,..,.,,.,,,,,.........,,,,.,......................,....................................................................... 1 to 4

mm

IMPORTANT : Checking of readings given above should be made :

- with vehicle empty, engine running and in normal running position with heights maintained at 165 mm at the

front and 215 mm at rear ( Saloons ) or 228.mm ( Estates ) ( See

Op. MA. 410-O ) ~

NOTE : Castor allgle at the ball joint cau be checked aud adjusted ic’itb equipmcwt 6309.7‘ f class- 2 tools J,

see page 3.

Page 234 of 394

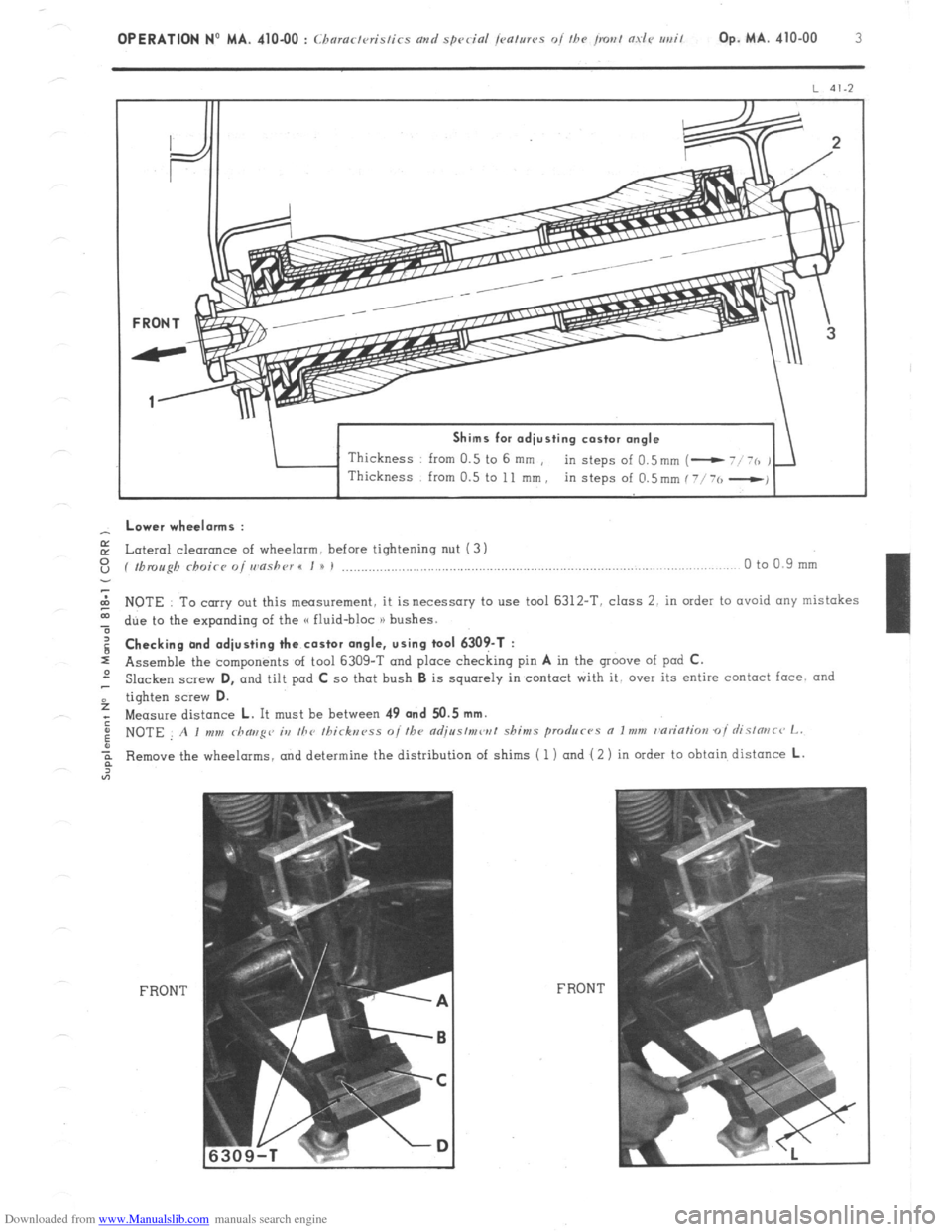

Downloaded from www.Manualslib.com manuals search engine Shims for adjusting castor angle

Thickness from 0.5 to 6 mm ,

in steps of 0.5mm (- - Lower wheelorms :

E Lateral cleoronce of wheelarm. before tightening nut (3 1

z ( fbmugh rhoicr o/ wnshr~r I I u I ,..................,.,............................,..,..,.,........................,....,...... 0 to 0.9 mm

2 NOTE To carry out this measurement, it is necessary to use tool 6312-T. class 2. in order to ovoid any mistakes

t due to the expanding of the G fluid-bloc n bushes. g Checking and adjusting the castor angle, using tool 6309-T :

s Assemble the components of tool 6309-T and place checking pin A in the groove of pod C.

2 Slacken screw D,

and tilt pad C so that bush B is squarely in contact with it, over its entire contact face. and

f tighten screw D.

; Measure distance L. It must be between 49 and 50.5 mm.

: NOTE A I mm rhaug~~ ia the Ihirknrss o//he adjr~s/mw/ shims produc-~s a Imm r~ariatim oi rlislmc~ L.

Remove the wheelarms, and determine the distribution of shims ( 1) and ( 2 ) in order to obtain distance L.

FRONT FRON T

Page 236 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 410-O : ( /,c

1

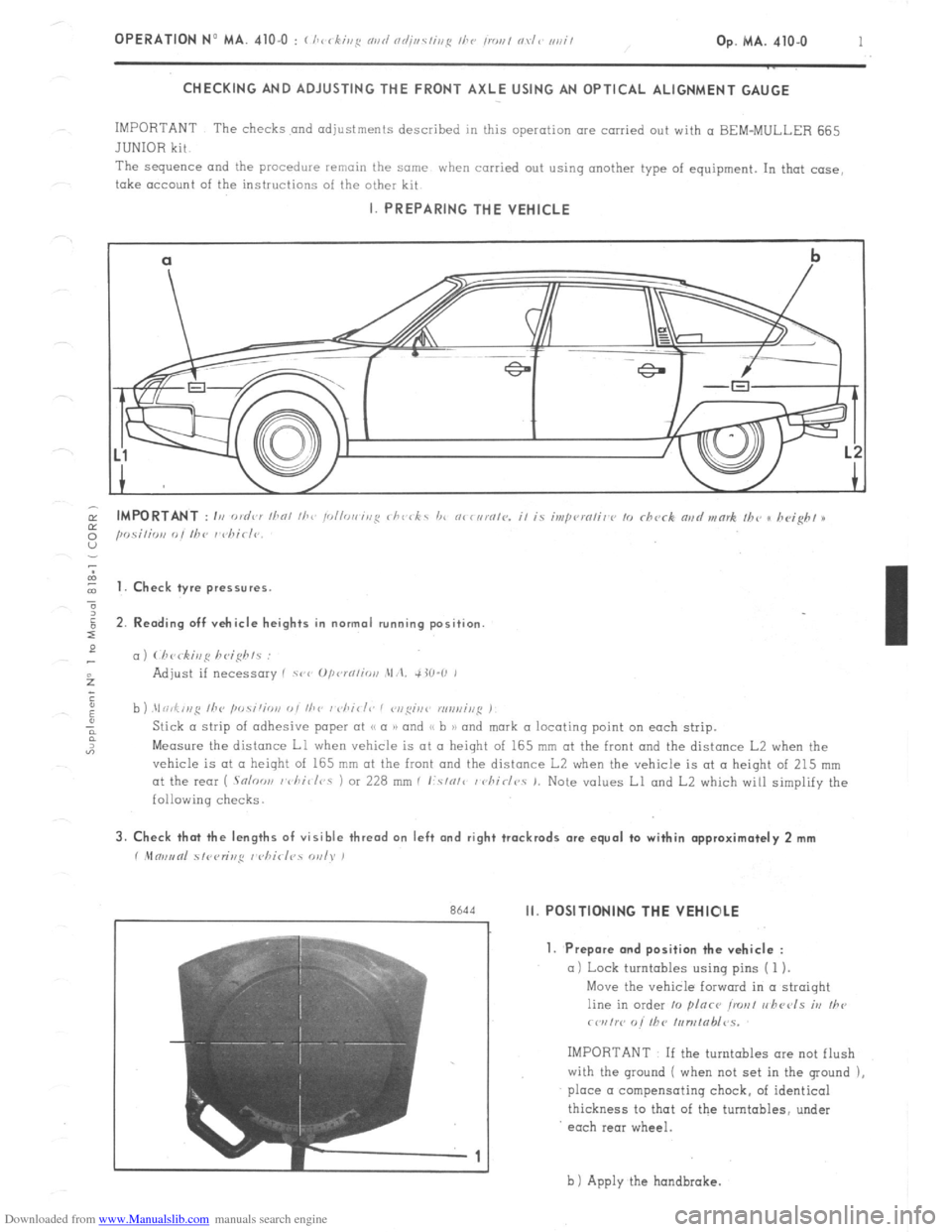

CHECKING AND ADJUSTING THE FRONT AXLE USING AN OPTICAL ALIGNMENT GAUGE

IMPORTANT The checks and adjustments described in this operation are carried out with a BEM-MULLER 665

JUNIOR kit

The sequence and

the procedure remain the same when carried out using another type of equipment. In that case,

take account of the instructions of the other kit I. PREPARING THE VEHICLE

cl

b

-.

I t 1. Check tyre pressures.

2. Rending off vehicle heights in normal running position

c,)

b ) .\I ri,f,,,g /he ,w.s;‘;o,,

Measure the distance Ll when vehicle is at II height of 165 mm at the front and the distance L2 when the

vehicle is at CL height of 165 mm at the front and the distance L2 when the vehicle is at a height of 215 mm

at the rear ( .Snloo,, I vhi~/r,s 1 or 228 mm I I:.s/o/c / chirlr,. 1. Note values Ll and L2 which will simplify the

following checks. 3. Check that the lengths of visible thread on left and right trackrods are equal to within approximately 2 mm

r .Mm,,tnl 51<,<,r;r,,q I <,hirl?s WI). )

r

Rh‘td Ii. POSITIONING THE VEHIOLE

7

-1 1. Prepare and position the vehicle :

a) Lock turntables using pins ( 1 ).

Move the vehicle forward in a straight

line in order 10 plnce ironl r,hccls iv

Ihe

rwrtw o/’ fhC /,,n,tab/~s.

IMPORTANT If the turntables ore not flush

with the ground ( when not set in the ground ),

place a compensating chock, of identical

thickness to that of the turntables, under

each rear wheel.

b 1 Apply the hondbrake.

Page 237 of 394

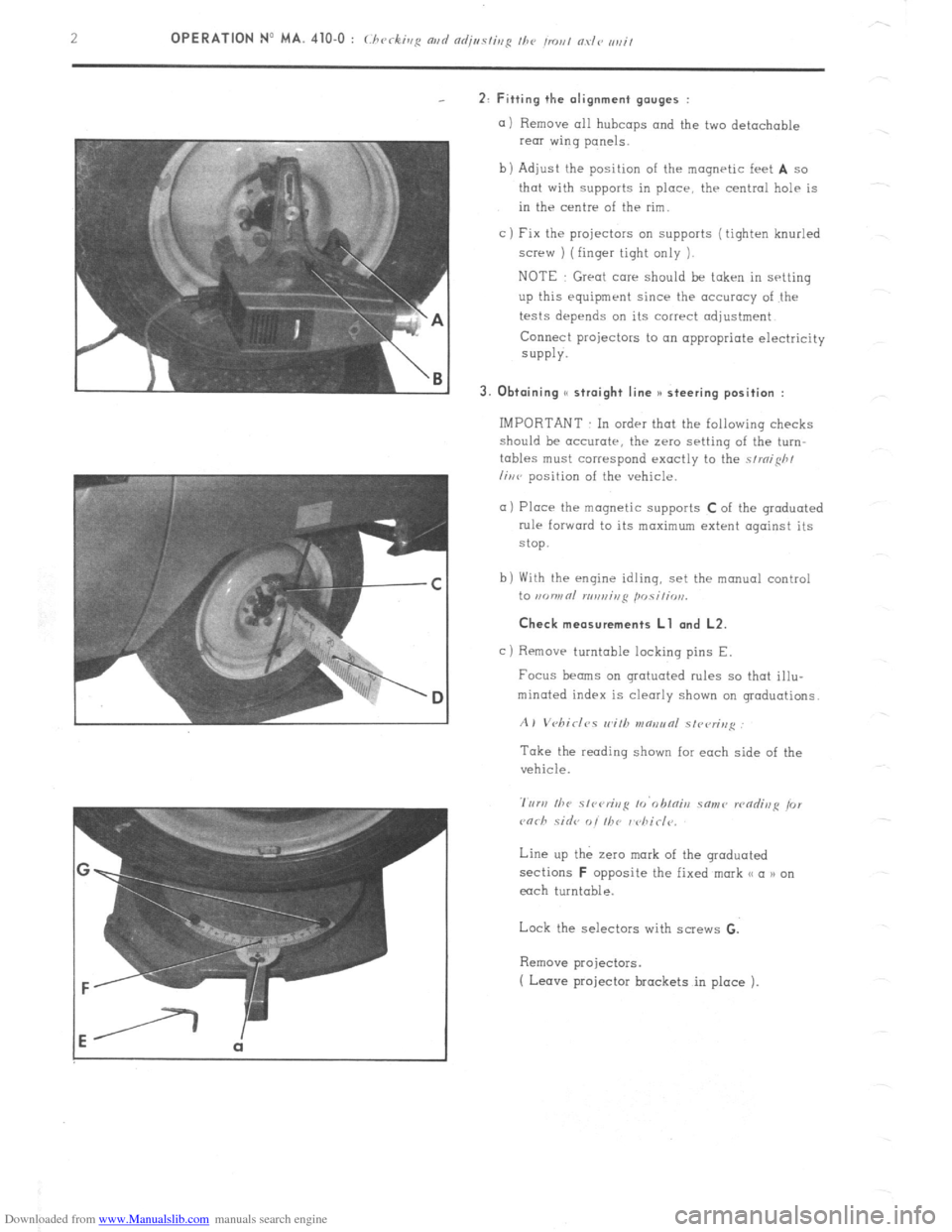

Downloaded from www.Manualslib.com manuals search engine 2: Fitting the alignment gauges :

a) Remove all hubcaps and the two detachable

rear wing panels.

b) Adjust the position of the magnetic feet

A so

that with supports in place, thr central help is

in the centre of the rim.

c ) Fix the projectors on supports ( tighten knurled

screw ) (finger tight only 1.

NOTE Great care should be taken in setting

up this equipment since the accuracy of the

tests depends on its correct adjustment

Connect projectors to on appropriate electricity

SUPPlY.

3. Obtaining S( straight line )I steering position :

IMPORTANT In order that the following checks

should be accurate, the zero setting of the turn-

tables must correspond exactly to the strnifih/

liwv position of the vehicle.

a) Place the magnetic supports C of the graduated

rule forward to its maximum extent against its

stop.

b) With the engine idling, set the manual control

to ,KJWRl n,n,,ir,ji posili, ,,,.

Check measurements Ll and L2.

c)

Removr turntable locking pins E.

Focus beams on grotuoted rules so that illu-

minated index is clearly shown on graduations.

A) Vebirlc,s wilh v~aeunl slvvrin,~

Take the reading shown for each side of the

vehicle.

Line up the zero mark of the graduated

sections

F opposite the fixed mark << a n on

each turntable.

Lock the selectors with screws G.

Remove projectors.

( Leave projector brackets in place ).

Page 238 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 410.0 3

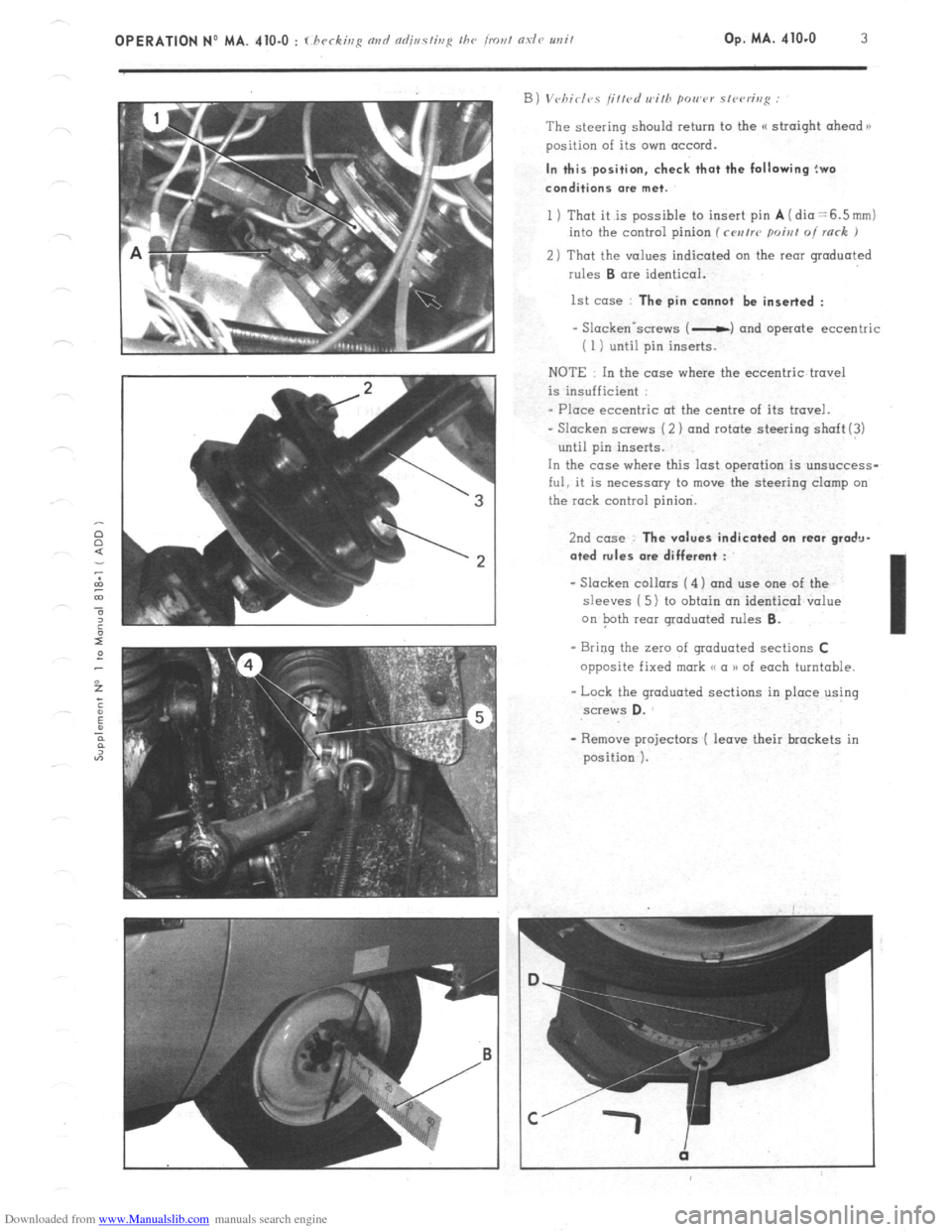

The steering should return to the (( straight ahead n

position of its own accord. In this position, check that the following !wo

conditions me met.

1 ) That it is possible to insert pin A (dia =6.5mm)

into the control pinion (rwrrr poiat oi rack J

2) That the values indicated on the rear graduated

rules B ore identical.

1st case : The pin cannot be inserted :

- Slackenvscrews ( -c) and operate eccentric

i 1 i until pin inserts.

NOTE In the case where the eccentric travel

is insufficient :

- Place eccentric ot the centre of its travel.

- Slacken screws (2 ) and rotate steering shaft(!)

until pin inserts.

In the case where this last operation is unsuccess-

ful, it is necessary to move the steering clamp on

the rock control pinion.

2nd case : The values indicated on rear gradu-

ated rules ore different :

- Slacken collars ( 4) and use one of the

sleeves ( 5 1 to obtain an identical value

on Path rear graduated rules 6.

- Bring the Z~IO of graduated sections C

opposite fixed mark <( a )I of each turntable.

- Lock the graduated sections in place using screws D.

Page 239 of 394

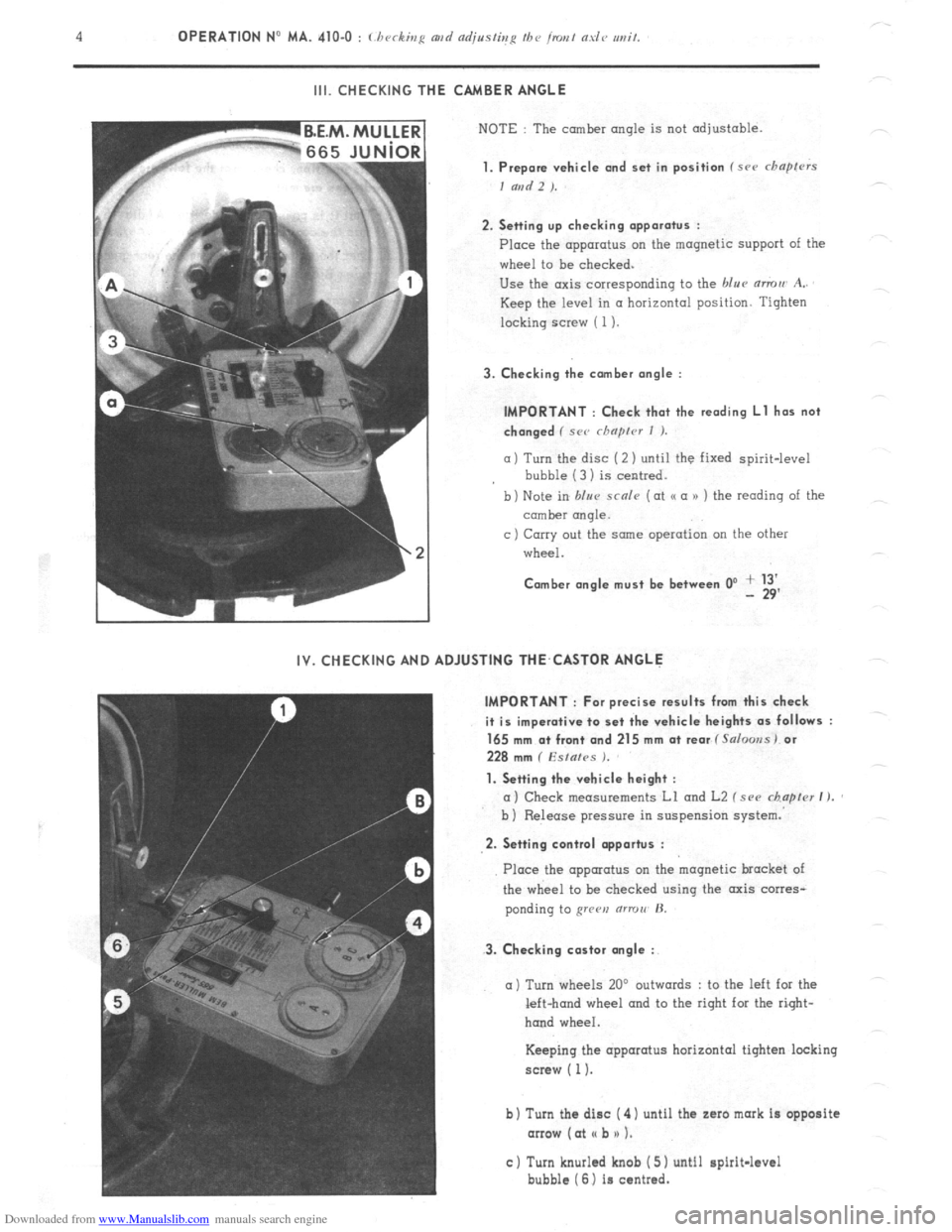

Downloaded from www.Manualslib.com manuals search engine III. CHECKING THE CAMBER ANGLE

NOTE : The camber angle is not adjustable.

1. Prepare vehicle and set in position f src chapfrrs

I and 2 ).

2. Setting up checking apparatus :

Place the apparatus on the magnetic support of the

wheel to be checked.

Use the axis corresponding to the blue mmu A..

Keep the level in a horizontal position. Tighten

locking screw ( 1).

3. Checking the comber angle :

IMPORTANT : Check that the reading Ll has not

changed ( SC<’ rhnprcr I ).

a) Turn the disc (2 ) until the fixed spirit-level

bubble (3 1 is centred.

b) Note in blur scnle (at o a n ) the reading of the

comber rmqle.

c ) Carry out the same operation on the other

wheel.

Comber angle must be between 0’ + 13’ - 29’

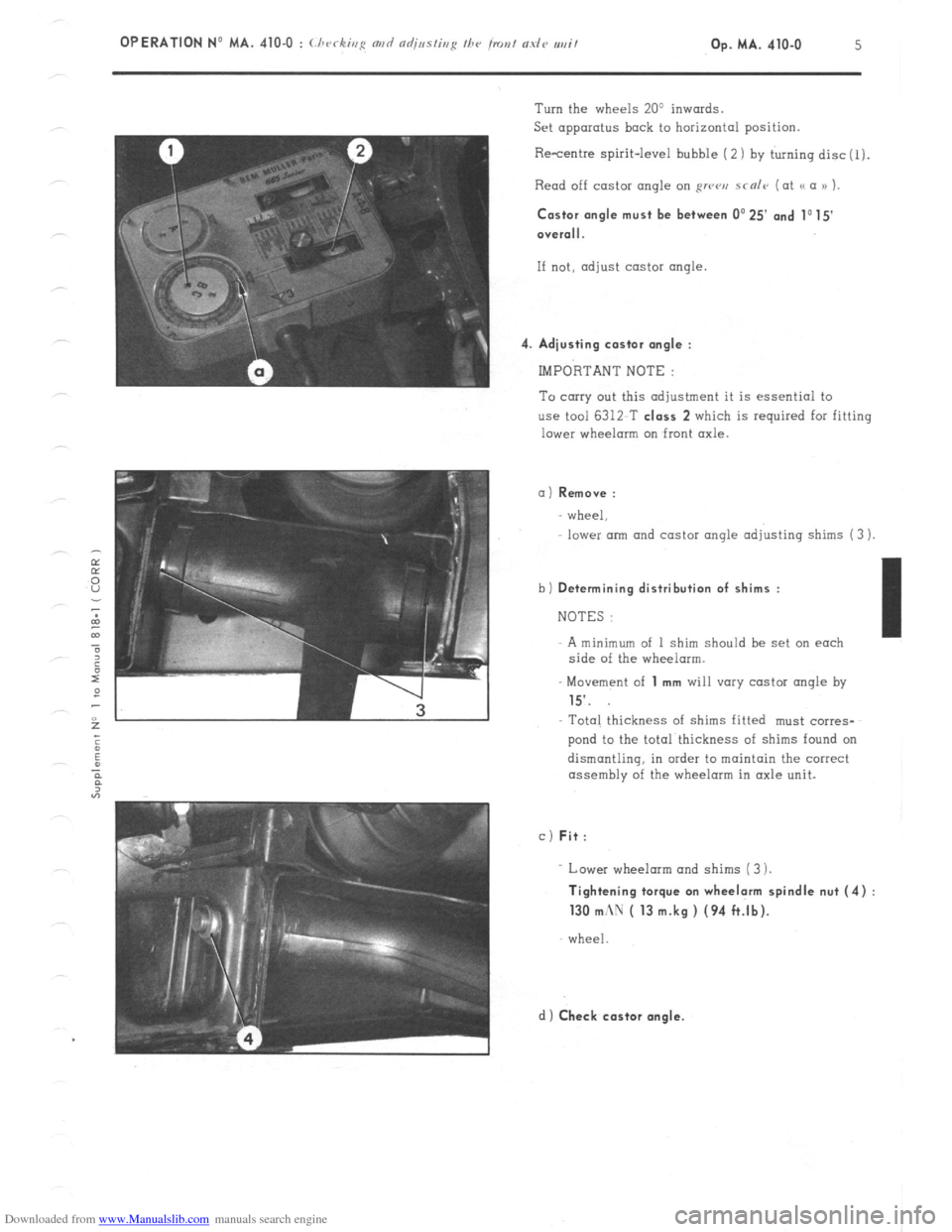

IV. CHECKING AND ADJUSTING THE,CASTOR ANGLE

IMPORTANT : For precise results from this check

it is imperative to set the vehicle heights as follows :

165 mm a+ front and 215 mm at rear f Salooss) or

228 mm ( Esfafes ).

1. Setting the vehicle height :

a) Check measurements Ll and L2 f see chapter I ).

b ) Release pressure in suspension system.

2. Setting control opportus :

3. Checking castor angle :

Place the apparatus on the magnetic bracket of

the wheel to be checked using the axis corres-

ponding to grren (ITTOII’ H.

a) Turn wheels 20’ outwards : to the left for the

left-hand wheel and to the right for the right-

hand wheel.

Keeping the apparatus horizontal tighten locking

screw ( 1).

b) Turn the disc ( 4) until the zaro mark is opposite

arrow (at I( b n 1.

c) Turn knurled knob ( 5) until spirit-level

bubble (6) is centred.

Page 240 of 394

Downloaded from www.Manualslib.com manuals search engine 4 Turn the wheels 20’ inwards.

Set apparatus back to horizontal position.

Resentre spirit-level bubble ( 2) by turning disc(l).

Read off castor angle on RWCJ,J scnlr (at a a )) ).

Castor angle must be

between 0’25’ and 1015

O”erall.

If not, adjust castor angle

Adiusting castor angle :

IMPORTANT NOTE :

To carry out this adjustment it is essential to

use tool 6312 T class 2 which is required for fitting

lower wheelorm on front axle.

a) Remove :

wheel,

lower arm and castor angle adjusting shims (3 )

b)

Determining distribution of shims :

NOTES :

A minimum of 1 shim should be set on each

side of the wheelarm.

- Movement of

1 mm will vary castor angle by

15’.

Total thickness of shims fitted must corres-

pond to the total thickness of shims found on

dismantling, in order to maintain the correct

assembly of the wheelarm in axle unit.

c) Fit:

Lower wheelarm and shims (3 ).

Tightening torque on wheelarm spindle nut (4)

130 mc\U ( 13 m.kg ) (94 ft.lb).

wheel

d) Check castor angle.