tow Citroen GRAND C4 PICASSO RHD 2016 2.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2016, Model line: GRAND C4 PICASSO RHD, Model: Citroen GRAND C4 PICASSO RHD 2016 2.GPages: 523, PDF Size: 13.63 MB

Page 271 of 523

269

Bonnet

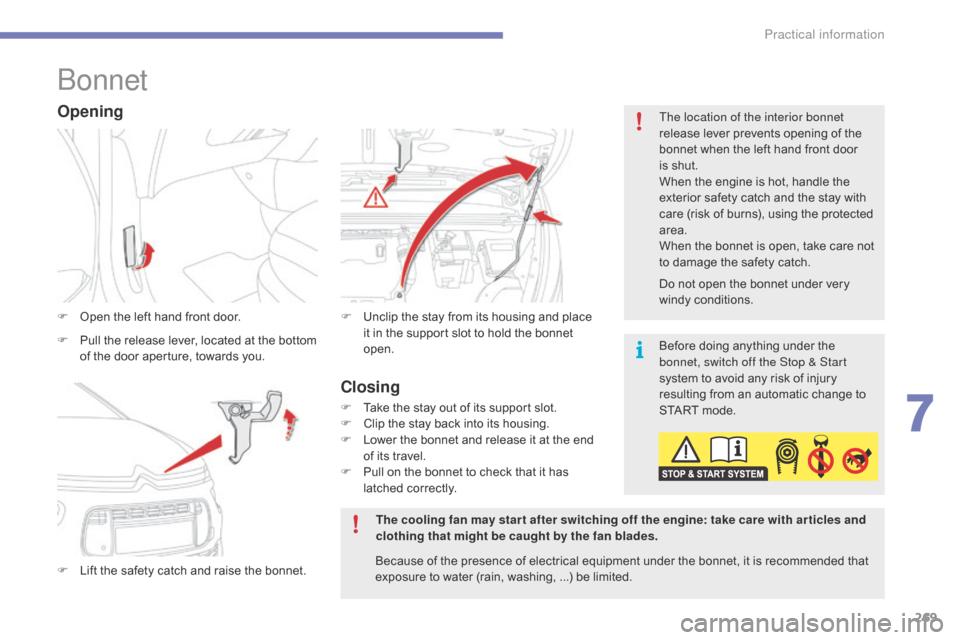

F Open the left hand front door.

F

L

ift the safety catch and raise the bonnet.F

U nclip the stay from its housing and place i

t in the support slot to hold the bonnet

ope

n.

Opening

F Pull the release lever, located at the bottom o

f the door aperture, towards you. Before

doing anything under the

b

onnet, switch off the Stop & Start

system

to avoid any risk of injury

r

esulting from an automatic change to

S

TART mode.

The cooling fan may star t after switching off the engine: take care with ar ticles and

clothing that might be caught by the fan blades. Do

not open the bonnet under very

wi

ndy

c

onditions.

The location of the interior bonnet

release lever prevents opening of the

b

onnet when the left hand front door

i

s shut.

When the engine is hot, handle the

e

xterior safety catch and the stay with

c

are (risk of burns), using the protected

a

rea.

When the bonnet is open, take care not

t

o damage the safety catch.

Because of the presence of electrical equipment under the bonnet, it is recommended that

e

xposure to water (rain, washing, ...) be limited.

Closing

F Take the stay out of its support slot.

F C lip the stay back into its housing.

F

L

ower the bonnet and release it at the end

o

f its travel.

F

P

ull on the bonnet to check that it has

l

atched correctly.

7

Practical information

Page 278 of 523

276

Brake wear depends on the style of driving, particularly in the case o

f vehicles used in town, over short

d

istances. It may be necessary to have

t

he condition of the brakes checked,

e

ven between vehicle services.

Brake pads

For information on checking brake disc wear, contact a CITROËN dealer

o

r a qualified workshop.

Brake disc wear

Only use products recommended by CITROËN or products of equivalent

q

uality

an

d

sp

ecification.

In

order to optimise the operation of

u

nits as important as those in the

b

raking system, CITROËN selects and

o

ffers very specific products.

After

washing the vehicle, dampness,

o

r in wintry conditions, ice can form

o

n the brake discs and pads: braking

e

fficiency may be reduced. Make light

b

rake applications to dry and defrost

t

he brakes.

Electric parking brake

For more information, refer to the "E lectric

parking brake - Operating faults "

section.

This

system does not require any

r

outine servicing. However, in the

e

vent of a problem, have the system

c

hecked by a CITROËN dealer or a

q

ualified

w

orkshop.

Manual gearbox

The gearbox does not require any m

aintenance (no oil change).

Refer

to the manufacturer's service

s

chedule for the checking interval for

t

his

c

omponent.

Automatic gearbox

The gearbox does not require any maintenance (no oil change).

Refer

to the manufacturer's service

s

chedule for details of the level

c

hecking interval for this component.

To

avoid damaging the electrical units,

n

ever use a high pressure jet wash in

t

he engine compartment.

Unless

there is a leak in the circuit, a drop in

t

he brake fluid level indicates that the brake

p

ads are worn.

Practical information

Page 283 of 523

281

Warning triangle

This safety device should be used in addition to the hazard warning lamps.

Its

presence in the vehicle is mandatory in

s

ome countries.

A

location for stowing the warning triangle is

p

rovided in the tailgate interior trim.

Placing the triangle in the road

F Place the triangle behind the vehicle, as r

equired by the legislation in force in your

c

o unt r y.Before

leaving your vehicle to set up

a

nd install the triangle, switch on the

h

azard warning lamps and put on your

h

igh visibility vest.

Refer to the instructions provided by the

s

upplier on folding and unfolding the

t

riangle.

8

In the event of a breakdown

Page 284 of 523

282

This kit is installed i n t he s torage b ox, u nder t he b

oot floor.

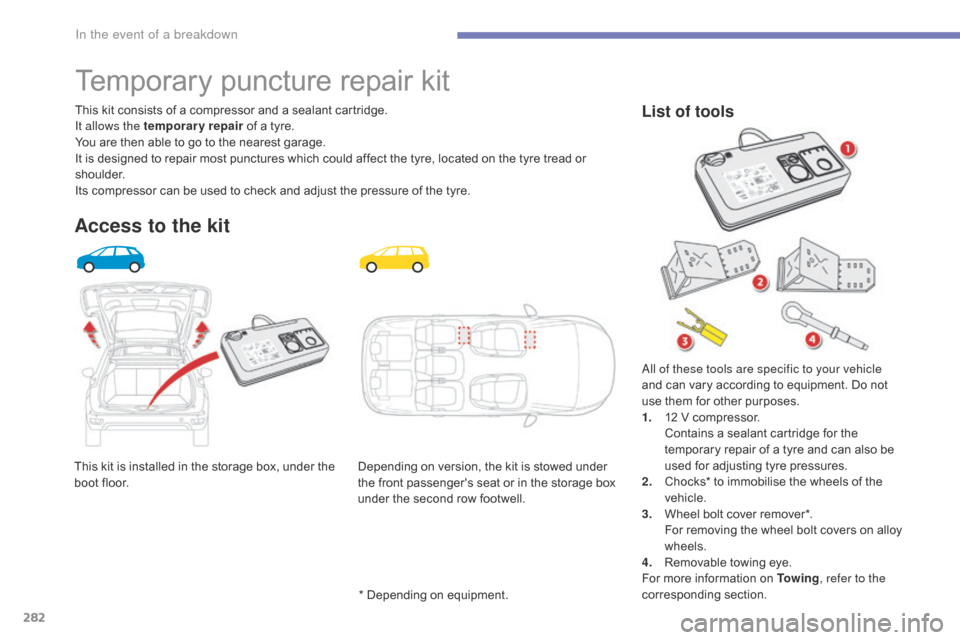

This

kit consists of a compressor and a sealant cartridge.

It allows the temporary repair

of a tyre.

You are then able to go to the nearest garage.

It is designed to repair most punctures which could affect the tyre, located on the tyre tread or

s

houlder.

Its compressor can be used to check and adjust the pressure of the tyre.

Temporary pu

ncture r epair k it

Access to the kit

Depending on version, the kit is stowed under t

he front passenger's seat or in the storage box

u

nder the second row footwell.

List of tools

* Depending on equipment. A ll of these tools are specific to your vehicle

and can vary according to equipment. Do not

u

se them for other purposes.

1.

1

2 V compressor.

C

ontains a sealant cartridge for the

t

emporary repair of a tyre and can also be

u

sed for adjusting tyre pressures.

2.

C

hocks* to immobilise the wheels of the

v

ehicle.

3.

W

heel bolt cover remover*.

F

or removing the wheel bolt covers on alloy

w

heels.

4.

R

emovable towing eye.

For more information on To w i n g

, refer to the

corresponding s ection.

In the event of a breakdown

Page 288 of 523

286

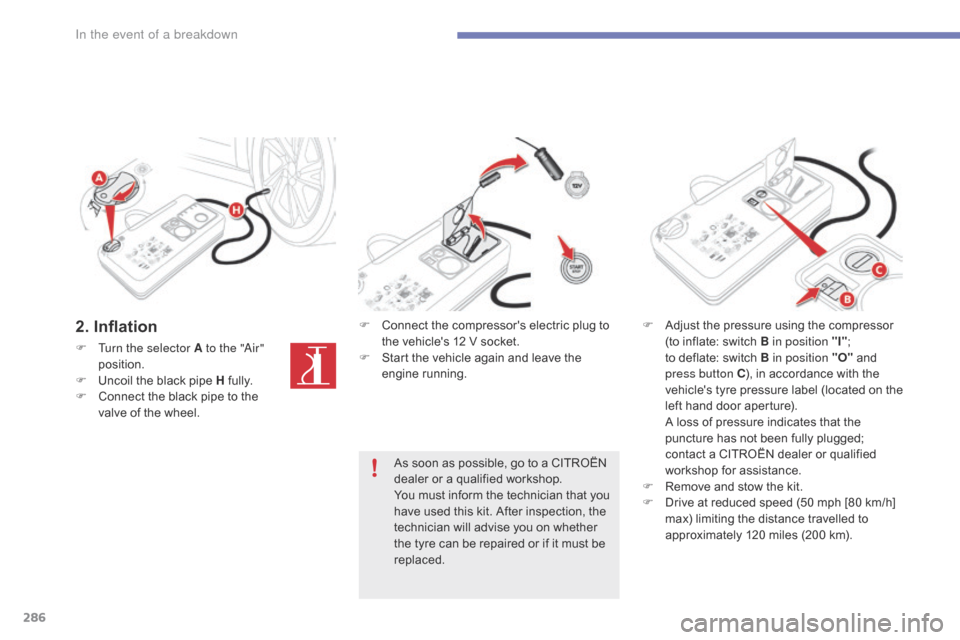

2. Inflation

F Turn the selector A to the "Air" position.

F

U

ncoil the black pipe H

f

ully.

F

C

onnect the black pipe to the

v

alve of the wheel. F

C

onnect the compressor's electric plug to t

he vehicle's 12 V socket.

F S tart the vehicle again and leave the

e

ngine

r

unning.

As

soon as possible, go to a CITROËN

d

ealer or a qualified workshop.

You

must inform the technician that you

h

ave used this kit. After inspection, the

t

echnician will advise you on whether

t

he tyre can be repaired or if it must be

r

eplaced.F

A

djust the pressure using the compressor (

to inflate: switch B in position "I"

; t

o deflate: switch B in position "O" and

p

ress button C),

in accordance with the

v

ehicle's

t

yre pressure label (located on the

l

eft hand door aperture).

A

loss of pressure indicates that the

p

uncture has not been fully plugged;

c

ontact a CITROËN dealer or qualified

w

orkshop for assistance.

F

R

emove and stow the kit.

F

D

rive at reduced speed (50 mph [80 km/h]

m

ax) limiting the distance travelled to

a

pproximately 120 miles (200 km).

In the event of a breakdown

Page 289 of 523

287

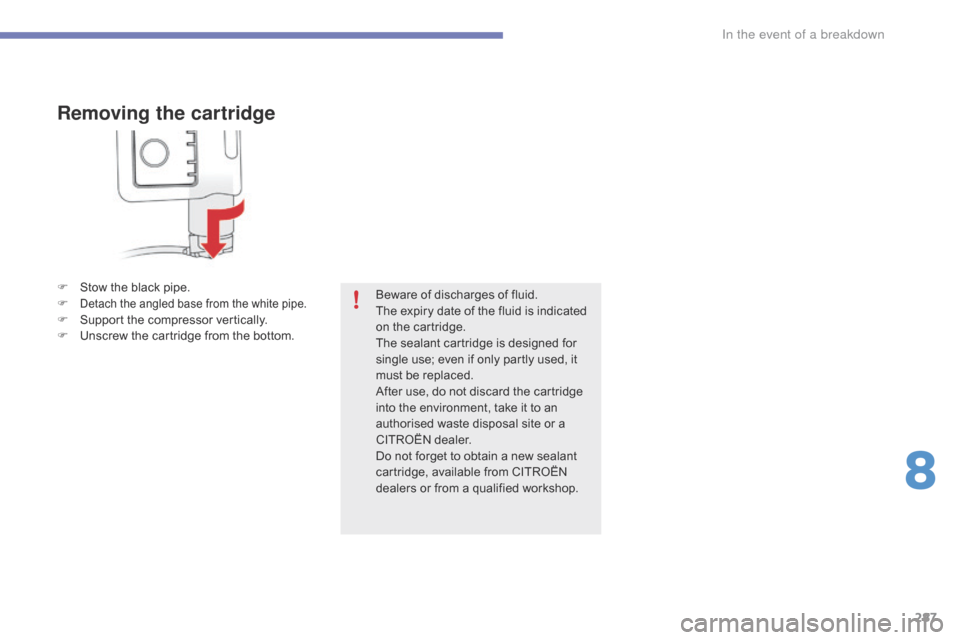

Removing the cartridge

F Stow the black pipe.

F Detach the angled base from the white pipe.F Support the compressor vertically.

F U nscrew the cartridge from the bottom.Beware

of discharges of fluid.

The expiry date of the fluid is indicated o

n the cartridge.

The

sealant cartridge is designed for

s

ingle use; even if only partly used, it

m

ust be replaced.

After

use, do not discard the cartridge

i

nto the environment, take it to an

a

uthorised waste disposal site or a

C

ITROËN dealer.

Do

not forget to obtain a new sealant

c

artridge, available from CITROËN

d

ealers or from a qualified workshop.

8

In the event of a breakdown

Page 290 of 523

288

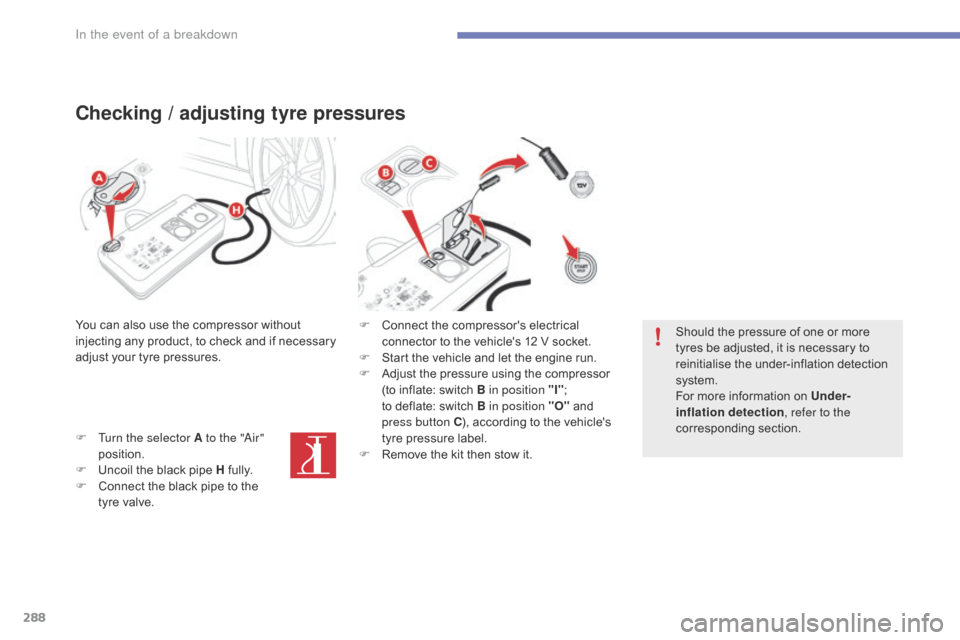

Checking / adjusting tyre pressures

You can also use the compressor without injecting any product, to check and if necessary

a

djust your tyre pressures.

F

T

urn the selector A to the "Air"

position.

F

U

ncoil the black pipe H

f

ully.

F

C

onnect the black pipe to the

t

yre valve. F

C onnect the compressor's electrical

c

onnector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(

to inflate: switch B in position "I";

t

o deflate: switch B in position "O"

and

p

ress button C),

according to the vehicle's

t

yre pressure label.

F

R

emove the kit then stow it.Should

the pressure of one or more

t

yres be adjusted, it is necessary to

r

einitialise the under-inflation detection

s

ystem.

For

more information on Under-

inflation detection , refer to the

corresponding

s

ection.

In the event of a breakdown

Page 292 of 523

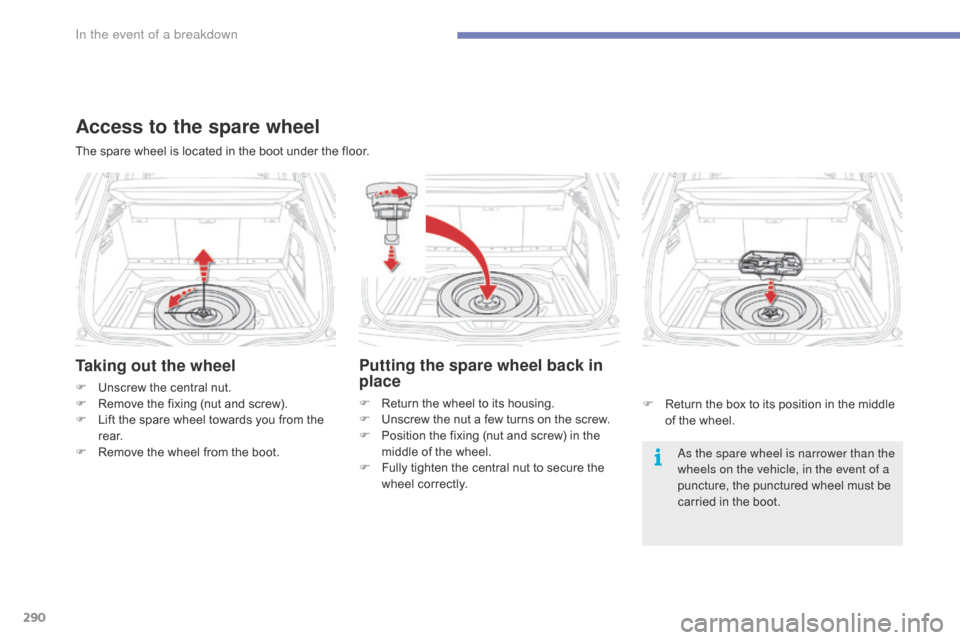

290

Taking out the wheel

F Unscrew the central nut.

F R emove the fixing (nut and screw).

F

L

ift the spare wheel towards you from the

r

e a r.

F

R

emove the wheel from the boot. As the spare wheel is narrower than the

wheels on the vehicle, in the event of a

puncture,

the punctured wheel must be

c

arried in the boot.

The

spare wheel is located in the boot under the floor.

Access to the spare wheel

Putting the spare wheel back in

place

F Return

the wheel to its housing.

F U nscrew the nut a few turns on the screw.

F

P

osition the fixing (nut and screw) in the

m

iddle of the wheel.

F

F

ully tighten the central nut to secure the

w

heel correctly. F

R eturn the box to its position in the middle

o

f the wheel.

In the event of a breakdown

Page 293 of 523

291

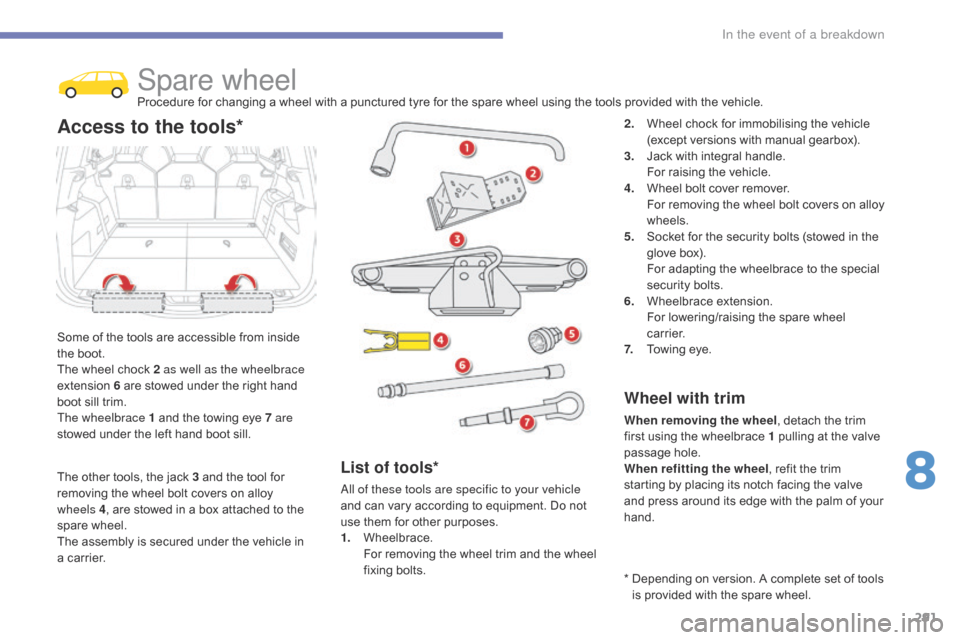

Spare wheelProcedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.

S

ome

of

the

tools are accessible from inside

t

he

boot.

The

wheel

chock 2 as well as the wheelbrace

extension

6

are stowed under the right hand

b

oot

sill

trim.

The wheelbrace 1

and the towing eye 7 are

stowed

under

the left hand boot sill.

Access to the tools*2. Wheel chock for immobilising the vehicle (

except versions with manual gearbox).

3.

J

ack with integral handle.

F

or raising the vehicle.

4.

W

heel bolt cover remover.

F

or removing the wheel bolt covers on alloy

w

heels.

5.

S

ocket for the security bolts (stowed in the

g

love box).

F

or adapting the wheelbrace to the special

s

ecurity bolts.

6.

W

heelbrace

e

xtension.

F

or lowering/raising the spare wheel

c

a r r i e r.

7.

T

owing eye.

Wheel with trim

When removing the wheel , detach the trim f

irst using the wheelbrace 1 pulling at the valve

p

assage hole.

When refitting the wheel ,

refit the trim

s

tarting by placing its notch facing the valve

a

nd press around its edge with the palm of your

han

d.

List of tools*

All of these tools are specific to your vehicle

and can vary according to equipment. Do not

u

se them for other purposes.

1.

W

heelbrace.

F

or removing the wheel trim and the wheel

f

ixing

bol

ts. *

D

epending on version. A complete set of tools

i

s provided with the spare wheel.

The

other

tools,

the

jack

3

and

the

tool

for

r

emoving

the

wheel

bolt

covers

on

alloy

w

heels

4 ,

are

stowed

in

a

box

attached

to

the

spar

e

w

heel.

The

assembly

is

secured

under

the

vehicle

in

a

carrier.

8

In the event of a breakdown

Page 295 of 523

293

A punctured wheel from the vehicle cannot be fitted under the vehicle. It

m

ust

b

e

c

arried

i

n

t

he

b

oot.

U

se

a

c

over

t

o protect the boot.

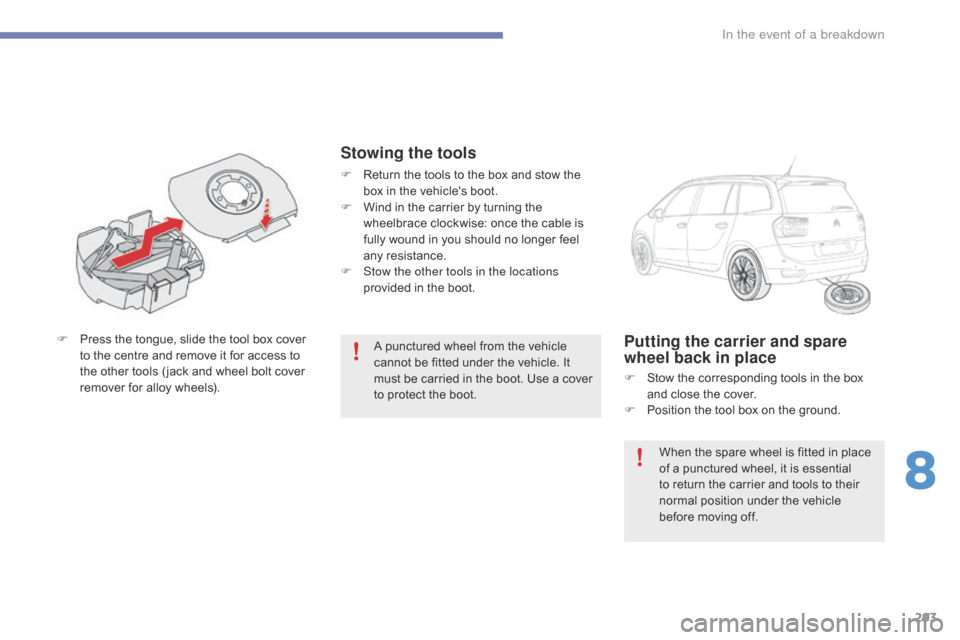

F

P

ress

the

tongue,

slide

the

tool

box

cover

t

o

the

centre

and

remove

it

for

access

to

t

he

other

tools

( jack

and

wheel

bolt

cover

r

emover

for

alloy

wheels).Putting the carrier and spare

wheel back in place

F Stow the corresponding tools in the box a

nd close the cover.

F

P

osition the tool box on the ground.

Stowing the tools

F Return the tools to the box and stow the b

ox in the vehicle's boot.

F

W

ind in the carrier by turning the

w

heelbrace clockwise: once the cable is

f

ully wound in you should no longer feel

an

y

r

esistance.

F

S

tow the other tools in the locations

provided

in the boot.

When

the spare wheel is fitted in place

o

f a punctured wheel, it is essential

t

o return the carrier and tools to their

n

ormal position under the vehicle

b

efore moving off.

8

In the event of a breakdown