ESP CITROEN RELAY 2020 Handbook (in English)

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2020, Model line: RELAY, Model: CITROEN RELAY 2020Pages: 196, PDF Size: 34.07 MB

Page 100 of 196

98

Practical information

A clogged passenger compartment filter can adversely affect air conditioning

system performance and generate

undesirable odours.

Oil filter

Change the oil filter each time the engine

oil is changed.

Particle filter (Diesel)

In addition to the catalytic converter, this filter

actively contributes to the preservation of

air quality by trapping the unburnt pollutant

particles. Black exhaust fumes are therefore not

emitted.

Operation

This filter, inserted into the exhaust system,

accumulates the carbonaceous particles. The

engine management computer automatically

and periodically manages the removal of

carbonaceous particles (regeneration).

The regeneration procedure is triggered

according to the amount of accumulated

particles and the conditions of use of the vehicle.

During this phase, you may notice certain

phenomena - accelerated idling, triggering of

the cooling fan, increased smoke and increased

temperature at the exhaust - which have no

impact on the operation of the vehicle and the

environment.

Screenwash and headlamp

washer fluid

To check the level or top up this fluid on

vehicles fitted with headlamp washers,

immobilise the vehicle and switch off the engine.

Reservoir capacity: approximately 5.5 litres.

To access the filler cap, pull the telescopic filler

neck and unclip the cap.

Fluid specification

The fluid must be topped up with a ready-to-use

mixture.

In winter (temperatures below zero), a liquid

containing an agent to prevent freezing must

be used which is appropriate for the prevailing

conditions, in order to protect the elements of the

system (pump, tank, ducts, jets, etc.).

Filling with pure water is prohibited under

all circumstances (risk of freezing,

limestone deposits, etc.).

AdBlue (BlueHDi)

An alert is triggered when the reserve level is

reached.

For more information on Indicators and in

particular the AdBlue range indicators, refer to

the corresponding section.

To avoid the vehicle being immobilised in

accordance with regulations, you must top up the

AdBlue tank.

For more information on AdBlue

® (BlueHDi),

and in particular on the supply of AdBlue, refer to

the corresponding section.

Checks

Unless otherwise indicated, check these

components in accordance with the

manufacturer's service schedule and according

to your engine.

Otherwise, have them checked by a CITROËN

dealer or a qualified workshop.

Only use products recommended by

CITROËN or products of equivalent

quality and specification.

In order to optimise the operation of

components as important as those in the

braking system, CITROËN selects and offers

very specific products.

12 V battery

The battery does not require any maintenance.

However, check regularly that the terminals

are correctly tightened (versions without quick

release terminals) and that the connections are

clean.

For more information on the precautions

to take before any work on the 12 V

battery, refer to the corresponding section.

Versions equipped with Stop & Start are

fitted with a 12 V lead-acid battery of

specific technology and specification.

Its replacement should be carried out only by

a CITROËN dealer or a qualified workshop.

Air filter

Depending on the environment and the

use of the vehicle (e.g. dusty atmosphere,

city driving), change it twice as often, if

necessary .

Passenger compartment

filter

Depending on the environment and the

use of the vehicle (e.g. dusty atmosphere,

city driving), change it twice as often, if

necessary .

Page 102 of 196

100

Practical information

reading and have an adverse effect on road

holding.

Fitting different tyres on the front and rear axles

can cause the ESC to mistime.

AdBlue® (BlueHDi

engines)

To respect the environment and ensure

compliance with the Euro 6 standard, without

adversely affecting the performance or fuel

consumption of its Diesel engines, CITROËN

has taken the decision to equip its vehicles

with a system that associates SCR (Selective

Catalytic Reduction) with a Diesel Particle Filter

(DPF) for the treatment of exhaust gases.

SCR system

Using a liquid called AdBlue® that contains

urea, a catalytic converter turns up to 85% of

the nitrogen oxides (NOx) into nitrogen and

Brake disc wear

For information on checking brake disc

wear, contact a CITROËN dealer or a

qualified workshop.

Manual parking brake

If you notice excessive brake lever travel

or decreased effectiveness, the parking

brake must be adjusted, even between two

services.

This system must be checked by a CITROËN

dealer or a qualified workshop.

Diesel fuel filter

The Diesel fuel filter is located under the bonnet,

close to the brake fluid reservoir.

If this warning lamp comes on, the filter

must be purged to remove water.

You can also purge the fuel filter regularly, every

time the engine oil is changed.

Bleeding the water in the filter

► Couple a clear hose to the bleed screw

1head.

► Place the other end of the clear hose in a

container.

► Loosen bleed screw 2.

► Switch on the ignition.

► Wait for the scavenge pump to stop.

► Switch off the ignition.

► Tighten bleed screw 2.

► Remove, then drain the clear hose and the

container.

► Start the engine.

► Check that there are no leaks.

HDi engines make use of advanced

technology. Any intervention requires a

special qualification guaranteed by the

CITROËN dealer network or a qualified

workshop .

Wheels and tyres

The inflation pressure of all tyres, including the spare wheel, must be

checked on "cold” tyres.

The pressures indicated on the tyre pressure

label are valid for "cold" tyres. If you have driven

for more than 10 minutes or more than 6 miles

(10 kilometres) at over 31 mph (50 km/h), add

0.3 bar (30 kPa) to the values indicated on the

label.

Under-inflation increases fuel

consumption. Non-compliant tyre

pressure causes premature wear on tyres and

has an adverse effect on the vehicle's road

holding - risk of an accident!

Driving with worn or damaged tyres reduces the

braking and road holding performance of the

vehicle. It is recommended to regularly check the

condition of the tyres (tread and sidewalls) and

wheel rims as well as the presence of the valves.

When the wear indicators no longer appear set

back from the tread, the depth of the grooves is

less than 1.6 mm; it is imperative to replace the

tyres.

Using different size wheels and tyres from those

specified can affect the lifetime of tyres, wheel

rotation, ground clearance, the speedometer

Page 103 of 196

101

Practical information

7reading and have an adverse effect on road

holding.

Fitting different tyres on the front and rear axles

can cause the ESC to mistime.

AdBlue® (BlueHDi

engines)

To respect the environment and ensure

compliance with the Euro 6 standard, without

adversely affecting the performance or fuel

consumption of its Diesel engines, CITROËN

has taken the decision to equip its vehicles

with a system that associates SCR (Selective

Catalytic Reduction) with a Diesel Particle Filter

(DPF) for the treatment of exhaust gases.

SCR system

Using a liquid called AdBlue® that contains

urea, a catalytic converter turns up to 85% of

the nitrogen oxides (NOx) into nitrogen and

water, which are harmless to health and the

environment.

The AdBlue

® is contained in a special tank

holding about 19 litres.

It has an external filler neck, located in the fuel

filler flap under the filler neck of the fuel tank,

closed by a blue cap.

Its capacity allows a driving range of

approximately 3,700 miles (6,000 km) ( which

may vary considerably depending on the

driving style and the type of vehicle).

An alert system is triggered when the remaining

range reaches 1,500 miles (2,400 km), i.e. once

the reserve level has been reached.

Once the AdBlue® tank is empty, a

system required by legislation prevents

starting of the engine.

If the SCR system is defective, the level of

emissions from your vehicle will no longer

meet the Euro 6 standard: your vehicle

becomes polluting.

In the event of a confirmed fault with the SCR

system, you must go to a CITROËN dealer

or a qualified workshop as soon as possible:

after travelling a distance of 250 miles (400

km), a system will be triggered automatically

to prevent engine starting.

Freezing of the AdBlue®

AdBlue® freezes at temperatures below

around -11°C.

The SCR system includes a heater for the

AdBlue® tank, allowing you to continue driving

in very cold conditions.

Supply of AdBlue®

It is recommended that the AdBlue® be topped

up as soon as the first alert is issued indicating

that the reserve level has been reached.

For the correct operation of the SCR

system:

– Use only AdBlue

® fluid that meets the ISO

22241 standard.

– Never transfer AdBlue

® to another container

as it would lose its purity.

– Never dilute AdBlue

® with water.

It is possible to obtain AdBlue

® from a CITROËN

dealer or a qualified workshop.

You can also visit a service station equipped with AdBlue® pumps specially

designed for passenger vehicles.

Recommendations on storage

AdBlue® freezes at about -11°C and deteriorates

above +25°C. Containers should be stored in a

cool area and protected from direct sunlight.

Under these conditions, the fluid can be kept for

at least a year.

If the fluid has frozen, it can be used once it has

completely thawed out at room temperature.

Page 110 of 196

108

In the event of a breakdown

Never go underneath a vehicle raised

using a jack (use an axle stand).

Do not use:

– The jack for any other purpose than lifting

the vehicle.

– A jack other than the one supplied by the

manufacturer.

The jack must only be used to change a wheel with a damaged or punctured tyre.

The jack does not require any maintenance.

The jack meets European standards, as

defined in the Machinery Directive 2006/42/

CE.

Certain parts of the jack such as the

screw thread or the joints could cause

injury: avoid touching them.

Carefully remove all traces of lubrication

grease.

At the front

► Position the jack C at location 1 provided on

the underbody, near the front wheel.

At the rear

The jack must be located about 60 cm

from the edge of the rear wheel.

► Position the jack C at location 2 in the hole

provided for this purpose.

Special feature with a side footboard

If the vehicle is so equipped, make sure to place

the jack at 45° so that it does not interfere with

the footboard.

4 - Replacing the wheel to

be repaired

► Remove the wheel trim (depending on

version) by levering with screwdriver E.

► Unlock the bolts using wheelbrace D and

wheel bar B.

For more information on Positioning the

jack, refer to the corresponding section.

► Make sure that the jack is stable and

correctly positioned on the underbody.

► Using wheelbrace D and wheel bar B, extend

the jack sufficiently to release the wheel.

To clear the wheel easily, a space of about 2 to 3 cm is needed between the

ground and the tyre.

If the wheel is badly punctured/crushed,

increase the space but do not operate the

jack to its maximum lifting position.

Page 111 of 196

109

In the event of a breakdown

84 - Replacing the wheel to

be repaired

► Remove the wheel trim (depending on

version) by levering with screwdriver E.

► Unlock the bolts using wheelbrace D and

wheel bar B.

For more information on Positioning the

jack, refer to the corresponding section.

► Make sure that the jack is stable and

correctly positioned on the underbody.

► Using wheelbrace D and wheel bar B, extend

the jack sufficiently to release the wheel.

To clear the wheel easily, a space of about 2 to 3 cm is needed between the

ground and the tyre.

If the wheel is badly punctured/crushed,

increase the space but do not operate the

jack to its maximum lifting position.

► Unscrew the bolts completely and remove the

wheel to be repaired.

► Make sure that the spare wheel contact

surfaces, the bolts and bolt housings are clean

and free of impurities that could cause loosening

of the fixing bolts.

Do not grease the bolts before screwing

them on: they could unscrew themselves

spontaneously.

► Fit the spare wheel by aligning the 2

holes M with the 2 corresponding shafts N.

► Start screwing the bolts by hand.

Screw the bolts in this order.

Page 112 of 196

11 0

In the event of a breakdown

► Lightly tighten using wheelbrace D and wheel

bar B.

► Lower the vehicle using wheelbrace D and

wheel bar B, and then remove the jack.

► Tighten the bolts again using wheelbrace D

and wheel bar B.

Have the tightening of the bolts and the

pressure of the spare wheel checked by

the Manufacturer's dealer network or a

qualified workshop without delay.

Have the punctured wheel repaired and

refitted on the vehicle as soon as possible.

If your vehicle has tyre under-inflation

detection, check the tyre pressures and

reinitialise the system.

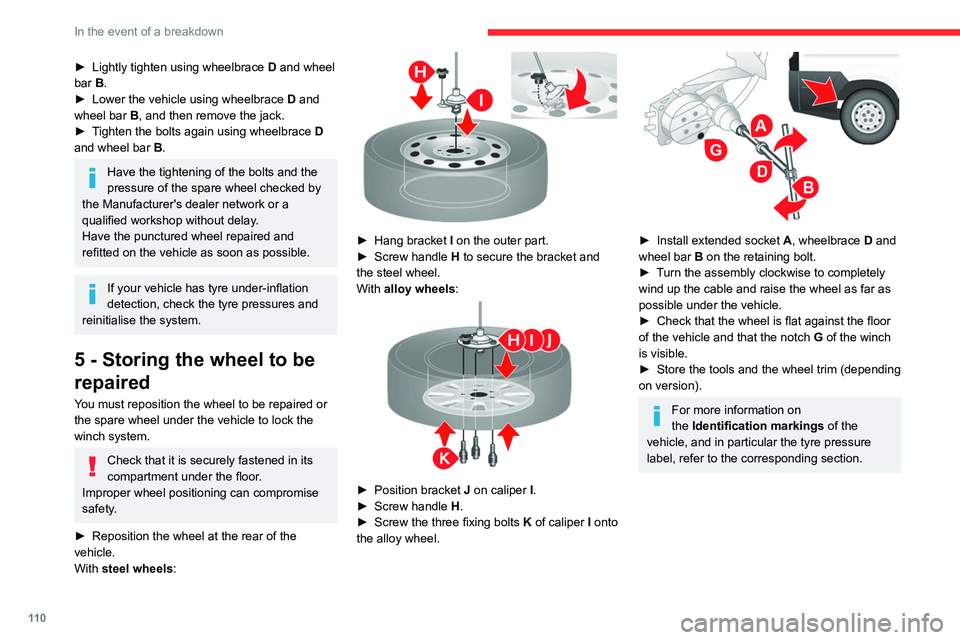

5 - Storing the wheel to be

repaired

You must reposition the wheel to be repaired or

the spare wheel under the vehicle to lock the

winch system.

Check that it is securely fastened in its

compartment under the floor.

Improper wheel positioning can compromise

safety.

► Reposition the wheel at the rear of the

vehicle.

With steel wheels:

► Hang bracket I on the outer part.

► Screw handle H to secure the bracket and

the steel wheel.

With alloy wheels:

► Position bracket J on caliper I.

► Screw handle H.

► Screw the three fixing bolts K of caliper I onto

the alloy wheel.

► Install extended socket A, wheelbrace D and

wheel bar B on the retaining bolt.

► Turn the assembly clockwise to completely

wind up the cable and raise the wheel as far as

possible under the vehicle.

► Check that the wheel is flat against the floor

of the vehicle and that the notch G of the winch

is visible.

► Store the tools and the wheel trim (depending

on version).

For more information on

the Identification markings of the

vehicle, and in particular the tyre pressure

label, refer to the corresponding section.

Changing a bulb

The headlamps have polycarbonate lenses with a protective coating:

► do not clean them using a dry or

abrasive cloth, nor with a detergent or

solvent product,

► use a sponge and soapy water or a pH

neutral product,

► when using a high pressure washer on

persistent marks, do not keep the lance

directed towards the lamps or their edges for

too long, so as not to damage their protective

coating and seals.

Changing a bulb must only be done with

the ignition off and after the lamp has

been switched off for several minutes - Risk

of serious burns!

► Do not touch the bulb directly with your

fingers, use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a failed bulb with a new bulb

with the same type and specification.

In some weather conditions (e.g. low

temperature or humidity), the presence

of misting on the internal surface of the glass

of the headlamps and rear lamps is normal; it

Page 116 of 196

11 4

In the event of a breakdown

Front/Rear

► Press the points indicated by the arrows, then

remove the courtesy lamp.

► Open the protective flap.

► Remove the bulb by separating the two

contacts.

► Check that the new bulbs are securely held

between the two contacts.

► Close the protective flap.

► Fix the courtesy lamp in its housing and

make sure it is locked.

Rear lamps

1. Brake lamps

Type B, P21W - 21W

2. Brake lamps / Sidelamps

Type B, P21/5W - 21W et 5W

3. Direction indicators

Type B, PY21W - 21W

4. Reversing lamps

Type A, W16W - 16W

5. Foglamp

Type A, W16W - 16W

For more information on the Types of

bulbs , refer to the corresponding

section.

► Remove the faulty bulb, then open the rear

doors.

► Remove the corresponding access flap by

removing its seven fixing screws (van)

or

► Remove the corresponding access flap by

pulling its handle to unclip it (combi).

► Disconnect the electrical connector by

pressing on its central tab.

► Remove the two fixing nuts from the lens unit.

► From the outside, pull the lens unit.

► Remove the six fixing screws from the bulb

holder.

► Open the three retaining tabs and pull the

bulb holder out of its housing.

► Change the bulb.

► Carry out the operations in reverse order to

reposition each bulb.

Number plate lamps

Type C, C5W - 5W

Page 118 of 196

11 6

In the event of a breakdown

Changing a fuse

The three fuseboxes are located on the

dashboard on the left-hand side, in the pillar

on the right-hand side and in the engine

compartment.

The designations provided are only for the fuses

that can be replaced by the user. For any other

work, visit a CITROËN dealer or a qualified

workshop.

Professional repairers: for full information

on the fuses and relays, consult the

wiring information and diagrams available

from a CITROËN dealer.

Removing and fitting a fuse

Good

Failed

Before changing a fuse, the cause of the fault

must be found and rectified. The numbers of the

fuses are indicated on the fuse box.

Always replace a faulty fuse with a fuse of

the same rating.

CITROËN accepts no responsibility for

the cost incurred in repairing your vehicle

or for rectifying malfunctions resulting from

the installation of accessories not supplied or

not recommended by CITROËN and not

installed in accordance with its

recommendations, in particular when the

combined power consumption of all of the

additional equipment connected exceeds 10

milliamperes.

Left-hand side dashboard

fuses

► Remove the screws and tilt the casing to

access the fuses.

Fuses A (amperes)Allocation

12 7.5Right-hand dipped beam headlamp

13 7.5Left-hand dipped beam headlamp

Page 126 of 196

124

Technical data

Engine technical data and

towed loads

Engines

The engine characteristics are given in the

vehicle's registration document, as well as in

sales brochures.

The maximum power corresponds to the value type-approved on a test bed, under

conditions defined in European legislation

(Directive 1999/99/EC).

For more information, contact a CITROËN dealer

or a qualified workshop.

Weights and towed loads

The weights and towed loads relating to

the vehicle are indicated on the registration

document, as well as in sales brochures.

These values are also indicated on the

manufacturer's plate or label.

For more information, contact a CITROËN dealer

or a qualified workshop.

The GTW (Gross Train Weight) values and the

towable loads listed are valid for a maximum

altitude of 1,000 metres. The towable load must

be reduced by steps of 10% for each additional

1,000 metres.

The maximum authorised nose weight

corresponds to the weight permitted on the

towball.

When exterior temperatures are high, the

vehicle performance may be limited in

order to protect the engine. When the exterior

temperature is higher than 37°C, reduce the

towed weight.

Towing even with a lightly loaded vehicle can adversely affect its road holding.

Braking distances are increased when towing

a trailer.

When using a vehicle to tow, never exceed

a speed of 62 mph (100 km/h) (observe the

local legislation in force).

Diesel engines

Euro 6.2 Diesel engines

Engines 2.2 BlueHDi 120 S&S2.2 BlueHDi 140 S&S2.2 BlueHDi 165 S&S

Gearbox Manual 6-speed (BVM6)

Cubic capacity (cc) 2,1972,1972,197

Max. power - EC standard (kW) 88103121

Fuel DieselDieselDiesel

Euro 6.1 Diesel engines

Engines 2.0 BlueHDi 110

2.0 BlueHDi 110 S&S 2.0 BlueHDi 130

2.0 BlueHDi 130 S&S 2.0 BlueHDi 160

2.0 BlueHDi 160 S&S

Gearbox Manual 6-speed (BVM6)

Cubic capacity (cc) 1,9971,9971,997

Engines 2.0 BlueHDi 110

2.0 BlueHDi 110 S&S 2.0 BlueHDi 130

2.0 BlueHDi 130 S&S 2.0 BlueHDi 160

2.0 BlueHDi 160 S&S

Max. power - EC standard (kW) 8196120

Fuel DieselDieselDiesel

Euro 4/Euro 5 Diesel engines

(Depending on country of sale)

Engines 2.2 HDi 1102.2 HDi 130

2.2 e-HDi 130 2.2 HDi 150

2.2 e-HDi 150 3 HDi 180

Gearbox Manual 6-speed (BVM6)

Cubic capacity (cc) 2,1982,1982,1982,999

Max. power - EC standard (kW) 819611 0130

Fuel DieselDieselDieselDiesel

Weights and towed loads

These tables present the approved weight values (in kg) according to the dimensions and designations of the vehicle.

Minibus

Dimensions DesignationsGVWUnbraked trailerMaximum authorised

nose weight

L3 H2 4404,005XX

L4 H2 4424,250XX

For Combi versions, the maximum weight of the Braked trailer (within the GTW limit), on a 10% or 12% gradient, is: 2,500 kg.

Page 135 of 196

133

Technical data

9Identification markings

A. Manufacturer's plate

This plate is located on the crossbar of the front

bumper, under the bonnet. 1 -

European whole vehicle type approval

number

2 - Vehicle identification number (VIN)

3 - Gross vehicle weight (GVW)

4 - Gross train weight (GTW)

5.1 - Maximum weight on the front axle

5.2 - Maximum weight on the rear axle

B. Serial number on the

bodywork

C. Tyres

This label (may differ from image shown), affixed

to the driver's side door pillar, indicates:

– the tyre sizes,

– the tyre pressures when laden.

The tyre pressures must be checked when

the tyres are cold, at least monthly.

D. Paint code

This reference number is located on the front

crossmember, under the bonnet.

E. Serial number on the

bodywork

This number is located under the plastic cover, at

the sill on the right-hand side.

Glossary of labels

This section contains all of the text written on the

labels present in the vehicle.

For the Identification markings , refer to

the corresponding section.